Page 1

User Guide

Media temperature controller

EKC 361

The controller and valve can be used where

there are stringent requirements to accurate

temperature control in connection with refrigeration.

E.g.:

• Cold room for fruits and food products

• Refrigerating systems

• Work premises in the food industry

• Process cooling of liquids

Features • The temperature is kept within an accuracy of

±0.25°C or better after a transient

phenomenon.

• The evaporator's temperature is kept as high

as possible, so that the air humidity is kept

high and waste is limited.

• A transient phenomenon can be controlled

with the adaptive function. Select either:

- Fast build-up where underswings are

allowed

- Not quite so fast build-up where under

swings are less pronounced

- Build-up without underswings

• PID regulation

• p0 limitation

© Danfoss | DCS (ADAP-KOOL®) |2015-11

DKRCI.PS.RP0.B2.02 | 1

Page 2

User Guide | Media temperature controller, EKC 361

Introduction

Functions

• Modulating temperature control

• Digital ON/OFF input for start/stop of regulation ICS/PM or

forced closing of ICM

• Alarm if the set alarm limits are exceeded

• Relay output for fan

• Relay output for solenoid valves

• Analog input signal that can displace the temperature reference

• Analog Output signal corresponding to selecting temperature

as running display value. Please observe : Not possible if ICM is

selected as valve

ICS or PM

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

Start/

stop

DKRCI.PS.RP0.B2.02 | 2

Page 3

User Guide | Media temperature controller, EKC 361

Application examples

ICS/PM

ISC/PM with CVQ is a pilot-operated and pressure-dependent

valve for controlling media temperature.

The ICS or PM must be equipped with a CVQ pilot valve in order

to position ICS or PM. The CVQ valve is operated by the EKC 361

controller.

Please notice that a power failure will cause the CVQ pilot valve to

fully open ICS/PM. If it is required that ICS/PM must close at power

failure, the pilot valve type EVM-NC can be installed.

If the Digital Input is ON, it releases the ICS/PM for controlling

temperature. If the Digital Input is OFF, if stops controlling PM/ICS,

but EKC 361 will maintain a CVQ minimum temperature. (Parameter n02)

Please see separate literature for ICS/PM

ICS : DKRCI.PD.HS0.APM : DKRCI.PD.HL0.A-

ICM

ICM is a direct activating and pressure independent valve for controlling media temperature.

When ICM is selected, the ICM is positioned directly via the analog

output 0/4-20mA output from the EKC 361.

If the Digital Input is ON, it releases the ICM for controlling temperature. If the Digital Input is OFF, the ICM is forced to close.

The opening degree OD 0-100 % can be limited by parameter n32

and n33.

Please see separate literature for ICM

ICM : DKRCI.PD.HT0.A-

General for ICS/PM and ICM

The EKC 361 can also operate a solenoid valve in the liquid line

(Digital output on terminal 9 and 10). It will follow the status of

Digital Input, however if a low temperature alarm is detected (A2

alarm) the solenoid valve in the liquid line will be closed.

The EKC 361 can also operate a fan (Digital output on terminal 8

and 10). It will follow the status of Digital Input.

The Parameter (r12) must be ON in order to ensure general operation. If Parameter (r12) is OFF, EKC 361 will operate corresponding

to if Digital Input is OFF

As media temperature sensor is S

can also be used to control liquid.

is used. Please observe that S

air

air

As option an auxiliary temperature sensor Saux can be installed

but only for monitoring.

S

can both be shown as running display value selected by

air/Saux

parameter o17. The selected sensor (S

out on the Analog Output as 0/4-20 mA.

air

or S

) will be sent

aux

Temperature scaling with parameter o27 and o28. Please observe

by ICM the Analog Output is not available for sending temperature

signals (S

It is normally recommended, on a aircooler, to install S

evaporator air outlet side.

air

or S

).

aux

, at the

air

Extra options

• PC operation

The controller can be provided with data communication, so

that it may be hooked up with other products in the ADAPKOOL® range of refrigeration controls. Operation, moni toring

and data collection can then be performed from a PC - either in

situ or at a service company.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 3

Page 4

User Guide | Media temperature controller, EKC 361

Function

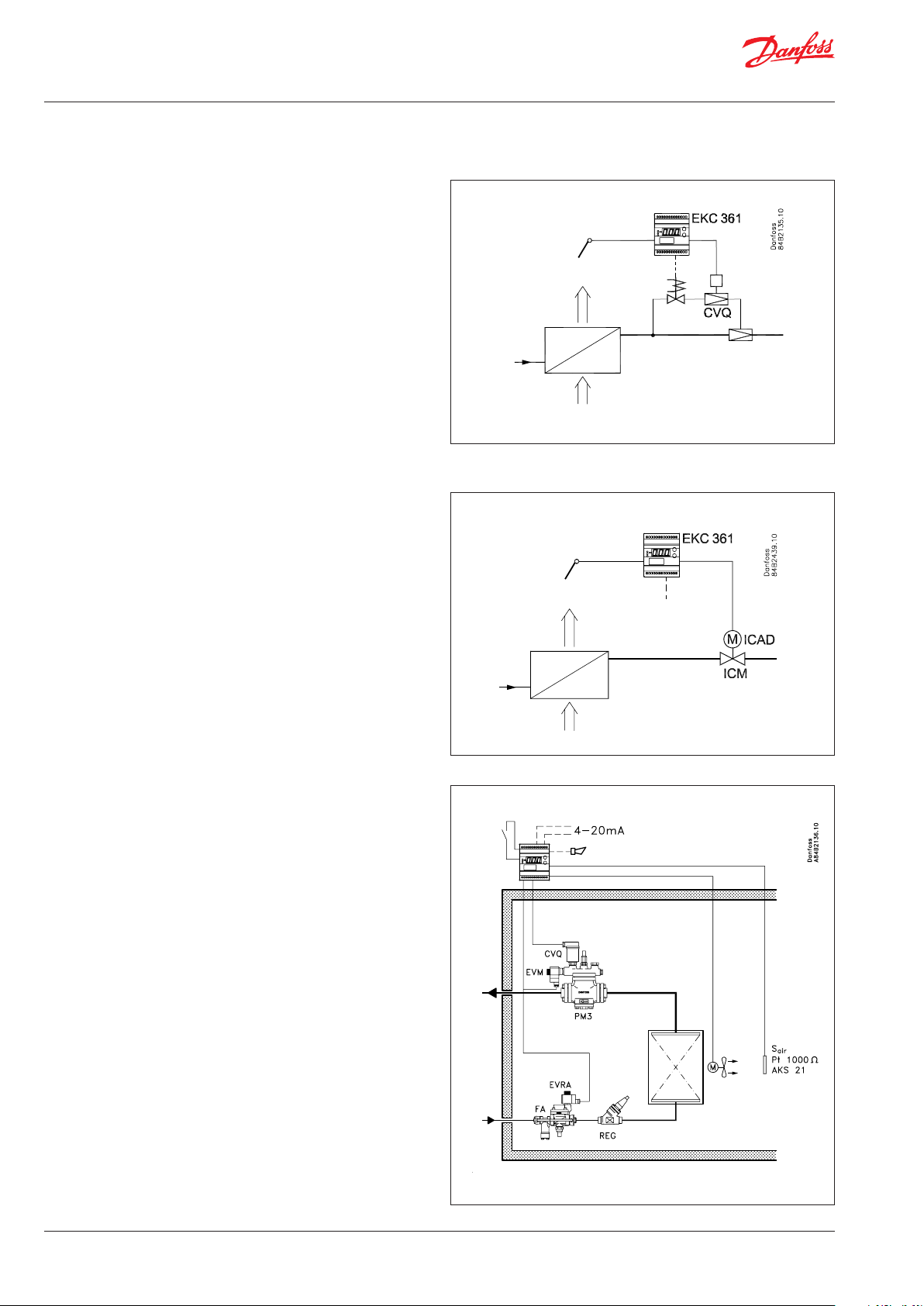

Very accurate temperature control

With this system where controller, pilot valve and main valve have

been adapted for optimum use in the refrigerating plant, the refrigerated products may be stored with temperature uctuations

of less than ±0.25°C.

High air humidity

As the evaporating temperature is constantly adapted to the

refrigeration needs and will always be as high as possible with a

very small temperature uctuation, the relative air humidity in the

room will be kept at a maximum.

Drying-out of the products will in this way be reduced to a mini-

mum.

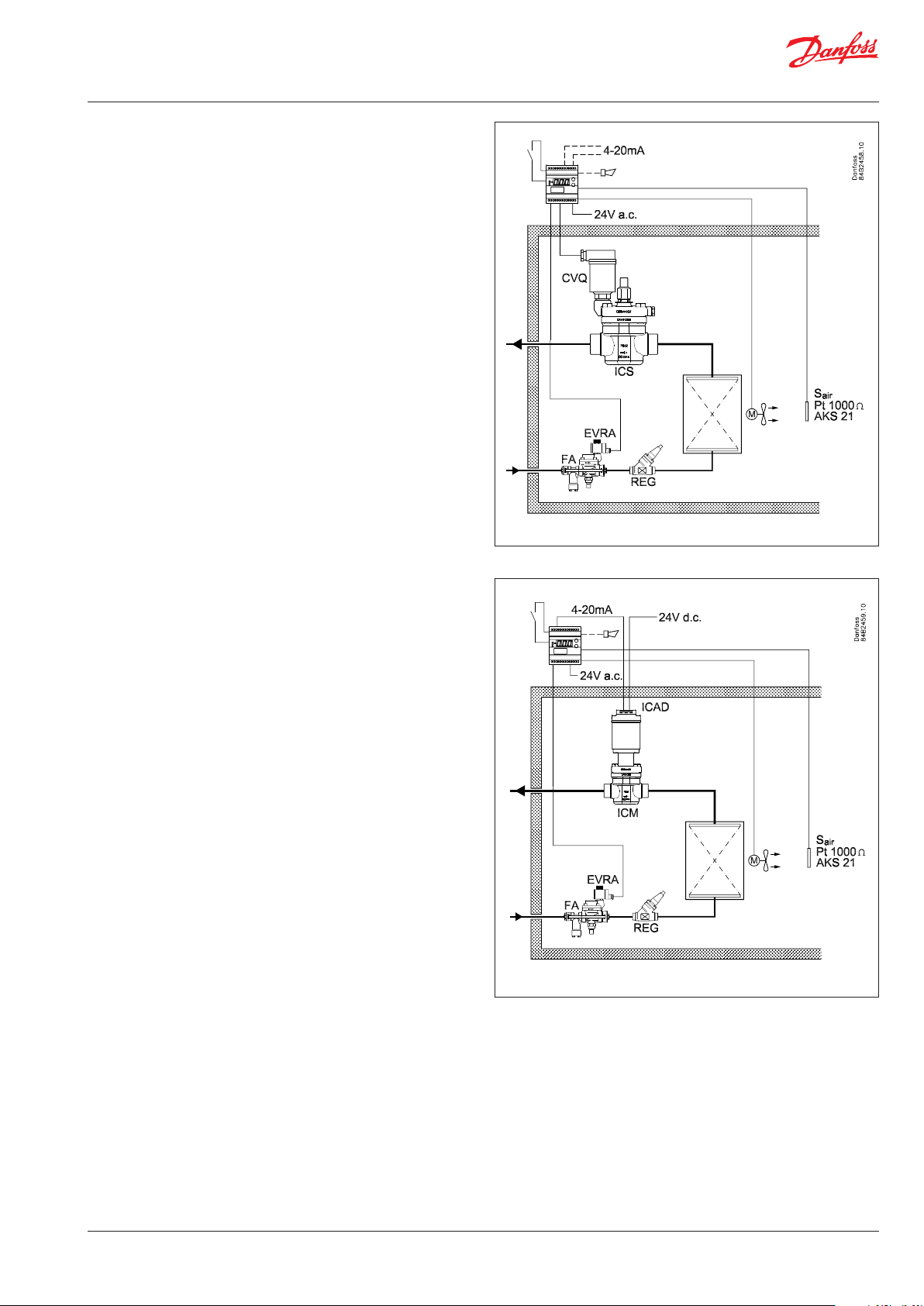

Temperature is quickly attained

With the built-in PID control and the possibility of choosing between three transient phenomena, the controller can be adapted

to a kind of temperature performance that is optimum for this

particular refrigerating plant. See parameter (n07).

• Fastest possible cooling

• Cooling with less underswing

• Cooling where underswing is unwanted.

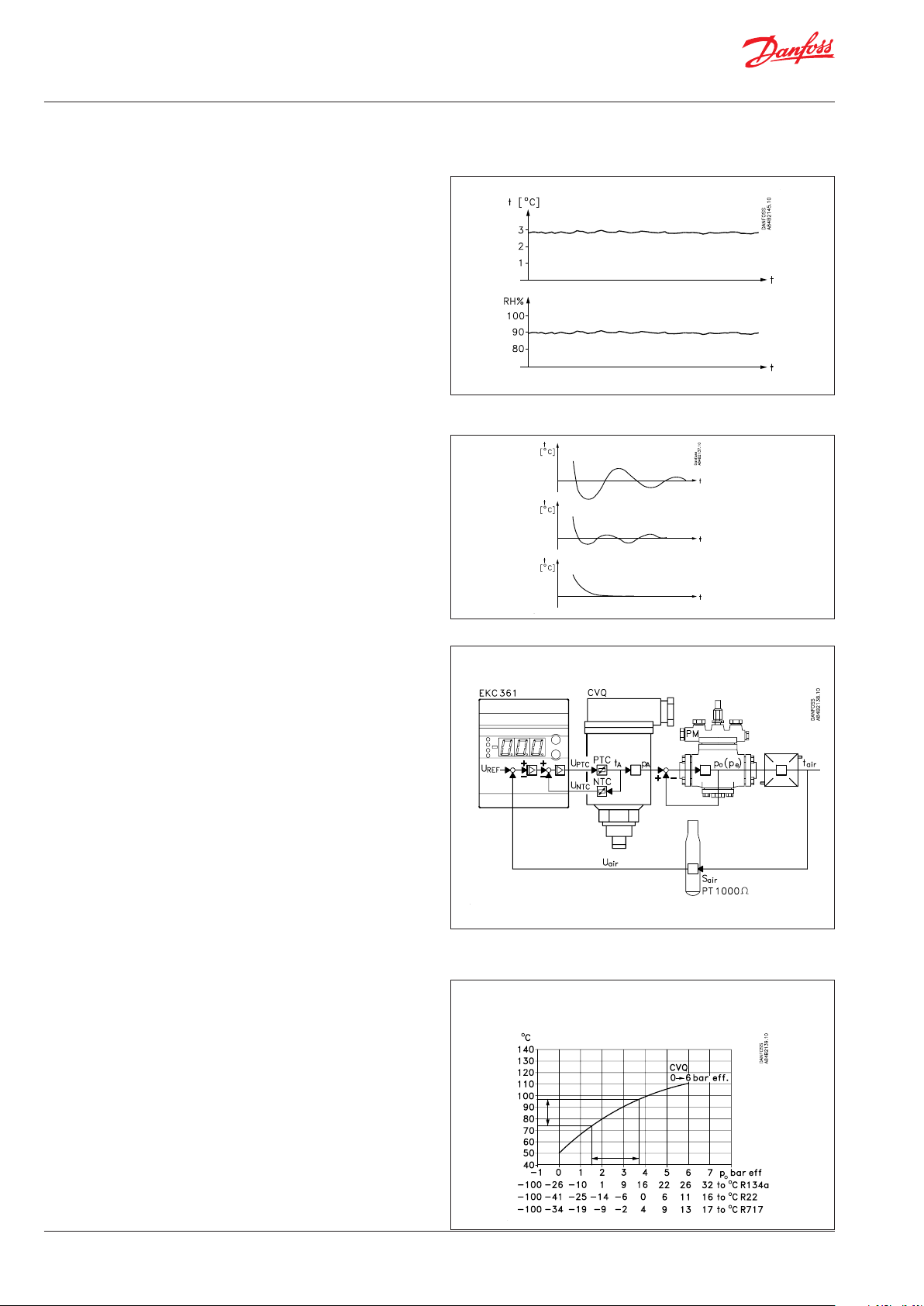

Regulation ICS/PM with CVQ

The controller receives signals from room sensor S

sensor must be placed at the air outlet from the evaporator to

. This room

air

obtain the best possible regulation. The controller sees to it that

the required room temperature is maintained.

Built-in between the controller and the actuator is a so-called

inner control loop which constantly checks the temperature (pressure) in the actuator’s pressure vessel. In this way a very stable

control system is obtained.

If there is a deviation between the required and the registered

temperature the controller will immediately send more or fewer

pulses to the actuator to counteract the error. A change of the

number of pulses will act on the temperature and hence the

pressure in the pressure vessel. As the charging pressure and the

evaporating pressure p0 follow each other, a changed charging

pressure will produce the eect that the valve’s opening degree is

also changed. The ICS/PM with CVQ system maintains the pressure

in the evaporator whatever pressure changes there may be on the

suction side (on the ICS/PM valve’s outlet).

Evaporating pressure limitation (p0 limitation)

The inner control loop mentioned above also causes the evaporating pressure to stay within a xed limit. In this way the system is

safeguarded against a too low supply air temperature.

It oers the following advantages:

- High-temperature systems can be connected to low-tempera ture

compressor units

- Protection against icing on evaporator

- Frost protection of liquid coolers

The allowed temperature in the actuator determines the evapora ting pressure

Actuator temperature

Regulation with ICM

When using ICM as selected valve the system will still control ICM

in order to maintain S

This system does not include any inner control loop.

according to entered setpoint.

air

It is a direct operating and pressure independent valve for controlling media temperature. (S

).

air

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 4

Page 5

User Guide | Media temperature controller, EKC 361

Survey of functions

Function Para-

meter

Normal display

Parameter by operation via data communication

Normally S

S

aux

(017=Air) will be shown as running display value. If lower button is activated

air

will be displayed for 5 sec, and then return to S

air

If (017=Au) Saux will be shown as running display value. If lower button is activated

Sair will be displayed for 5 sec, and then return to Saux

If ICM has been selected (n03=6)

If (017=Air) S

(u24) will be displayed for 5 sec, and then return to S

If (017=Au) OD (u24) will be shown as running display value. If lower button is activated S

be displayed for 5 sec, and then return to OD (u24)

(017=Air) will be shown as running display value. If lower button is activated OD

air

.

air

air

will

Reference

Setpoint

Regulation is performed based on the set value provided that there is no external contribution

(o10).

(Push both buttons simultaneously to set the setpoint).

Temperature unit

Here you select whether the controller is to indicate the temperature values in °C or in °F. If indication in °F is selected, other temperature settings will also change over to Fahrenheit, either as

absolute values or as delta values.

External contribution to the setpoint

This setting determines how large a contribution (in °C/°F) is to be added to the set setpoint

when the input signal is max. (20 mA).

Correction of signal from S

(Compensation possibility through long sensor cable).

Correction of signal from S

(Compensation possibility through long sensor cable).

air

aux

Start/stop of refrigeration

With this setting refrigeration can be started and stopped. Start/stop of refrigeration can also be

accomplished with the external switch function. See also appendix 1.

Alarm

The controller can give alarm in dierent situations. When there is an alarm all the light-emitting

diodes (LED) will ash on the controller front panel, and the alarm relay will cut in.

Alarm for upper deviation

The alarm for too high S

active when the S

+ r06) can be seen in u02).

temperature is set here. The value is set in Kelvin. The alarm becomes

air

temperature exceeds the actual reference plus A01. (The actual reference (SP

air

Alarm for lower deviation

The alarm for too low S

active when the S

ture alarm is detected (A2 alarm) the solenoid valve in the liquid line (Digital output on terminal

temperature is set here. The value is set in Kelvin. The alarm becomes

air

temperature drops below the actual reference minus A02. If a low tempera-

air

9 and 10) will be closed

Alarm delay

If one of the two limit values is exceeded, a timer function will commence. The alarm will not

become active until the set time delay has been passed. The time delay is set in minutes.

Control parameters

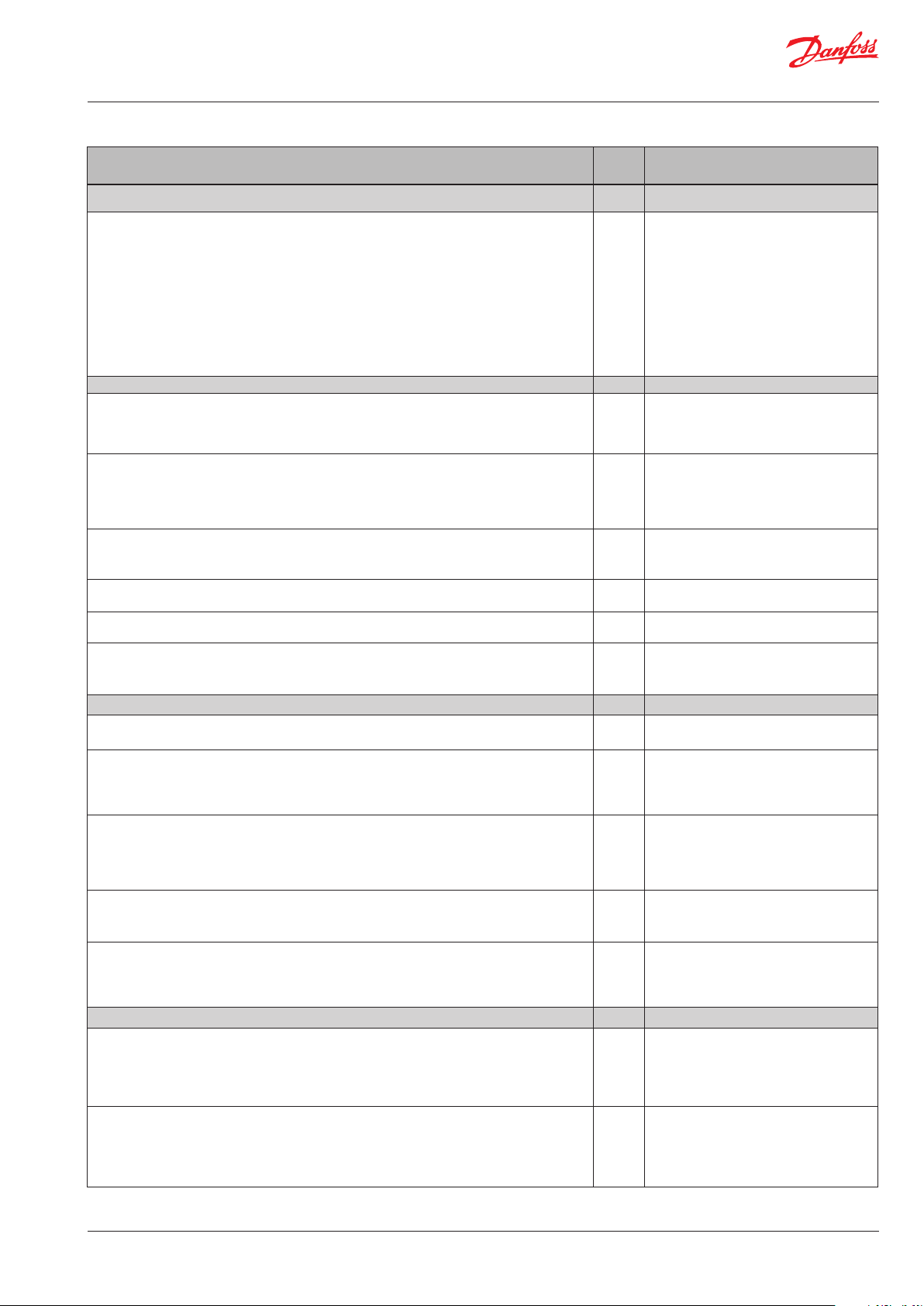

Actuator’s max. temperature

Set the temperature (°C) the actuator is to have at the limit of the regulating range. The setting

ensures that the actuator will not become superheated and work itself away from the regulating

range. Due to tolerances in the actuator the value must be set 10K higher than indicated in the

curves on page 11.

Actuator’s min. temperature

Set the temperature (°C) the actuator will have at the limit of the regulating range. The setting

ensures that the actuator will not become too cold and work itself away from the regulating

range. Due to tolerances in the actuator the value must be set 10K lower than indicated in the

curves on page 11.

Air temp.

- SP Temp.

r05 Temp unit

°C=0,

°F=1

(In AKM only °C is displayed whatever the

setting)

r06 Ext. Ref.o set (°C/°F)

r09 Adjust S

r10 Adjust S

(°C/°F)

Air

(°C/°F)

Aux

r12 Main Switch

A01 Upper deviation

A02 Lower deviation

A03 Temp alarm delay

With data communication the importance

of the individual alarms can be dened.

Setting is carried out in the “Alarm destinations” menu. See also page 10.

n01 Q-max. temp.

n02 Q-min. temp.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 5

Page 6

User Guide | Media temperature controller, EKC 361

Actuator type

Here you dene the actuator mounted in the system:

1: CVQ -1-5 bar

2: CVQ 0-6 bar

3: CVQ 1.7-8 bar

4: CVMQ

5: KVQ

6: ICM

P: Amplication factor Kp

If the Kp value is reduced the regulation becomes slower.

I: Integration time Tn

The I-setting can be cancelled by setting the value to max. (600s). If it is set to 600s, parameter

n07 must be set to “0”. (If the Tn value is increased the regulation becomes slower).

D: Dierentiation time Td

The D-setting can be cancelled by setting the value to min. (0).

Transient phenomenon

If the refrigeration requires a very fast transient phenomenon or must not have an underswing or

temperature shift, this function can be used. (see page 4)

0: Ordinary regulating technique

1: Fast building-up where a minor underswing is allowed

2: Not quite so fast building-up, but without underswing

OD - Opening degree Max. Limitation - ICM only

When ICM has been selected (n03=6) the Maximum OD can be entered. ICM will never go above

this value. (If n32=n33, ICM is forced to this value)

OD - Opening degree Min. Limitation - ICM only

When ICM has been selected (n03=6) the Minimum OD can be entered. ICM will never go below

this value. (If n32=n33, ICM is forced to this value)

Miscellaneous

Output signal

The controller can transmit a current signal via the analog output (terminal 2 and 5). Range of

current signal can be selected below:

If (017=Air) Sair will send out to the analog output.

If (017=Au) Saux will send out to the analog output

S

min. value (0 or 4 mA) will correspond to the setting in "o27"

air/Saux

S

max. value (20 mA) will correspond to the setting in "o28"

air/Saux

If ICM has been selected (n03=6)

OD (u24) to control ICM, is send out to the analog output

(o27) and (o28) is not active

Range for current signal:

0: No output signal

1: 4-20 mA

2: 0-20 mA

Input signal

If you wish to connect a signal that is to displace the controller’s control reference, the signal

must be dened in this menu.

0: No signal

1: 4-20 mA

2: 0-20 mA

(4 or 0 mA will not give a displacement. 20 mA will displace the reference by the value set in

menu r06).

Data communication

If the controller is built into a network with data communication, it must have an address, and

the master gateway of the data communication must then know this address.

These settings can only be made when a data communication module has been mounted in the

controller and the installation of the data communication cable has been completed.

This installation is mentioned in a separate document “RC8AC”.

The address is set between 1 and 60

The address is sent to the gateway when the menu is set in pos. ON

(The setting will automatically change back to O after a few seconds.)

Language

This setting is only required if data communication is connected to the controller.

Settings: 0=English, 1=German, 2=French, 3=Danish, 4=Spanish and 6=Swedish

When the controller is operated via data communication, the texts in the right-hand column will

be shown in the selected language.

When you change the setting to an other language you must activate o04 before "the new

language" can be visible from the AKM program.

Frequency

Set the net frequency.

Valve type

n03

Kp factor

n04

Tn sec.

n05

Td sec.

n06

Q-ctrl. mode

n07

ICM OD Max.

n32

ICM OD Min.

n33

AO type

o09

AI type

o10

Following installation of a data communication module, the controller can be operated

on a par with the other controllers in ADAPKOOL® refrigeration controls.

-

o03

-

o04

Language

o11

50 / 60 Hz

o12

(50=0, 60=1)

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 6

Page 7

User Guide | Media temperature controller, EKC 361

Selection of running display value

If S

(017=Air) will be shown as running display value. If lower button is activated S

air

be displayed for 5 sec, and then return to S

S

will send out to the analog output. See also (o09),(o27),(o28)

air

If (017=Au) S

be displayed for 5 sec, and then return to S

S

will send out to the analog output. See also (o09),(o27),(o28)

aux

will be shown as running display value. If lower button is activated S

aux

air

aux

will

aux

will

air

o17

Display Aux/Air

Aux =0

Air = 1

If ICM has been selected (n03=6)

If (017=Air) S

OD (u24) will be displayed for 5 sec, and then return to S

(017=Air) will be shown as running display value. If lower button is activated

air

air

If (017=Au) OD (u24) will be shown as running display value. If lower button is activated

S

will be displayed for 5 sec, and then return to OD (u24)

air

(Setting for the function o09)

o27 Temp. at AO min.

Set the temperature value where the output signal must be minimum

(0 or 4 mA)

(Setting for the function o09)

o28 Temp. at AO max.

Set the temperature value where the output signal must be maximum (20 mA). (With a temperature range of 50°C (dierential between the settings in o27 and o28) the dissolution will be

better than 0.1 °C. With 100°C the dissolution wil be better than 0.2°C.)

Service

A number of controller values can be printed for use in a service situation

Read the temperature at the S

Read the control reference

sensor (calibrated value) u01 Air temp.

air

u02 Air reference

(Setpoint + any contribution from external signal)

Read temperature at the S

(This showing can also be uploaded from the normal display, if you push the lowermost button

sensor (calibrated value)

aux

u03 Aux. temp.

for almost a second)

Read valve’s actuator temperature u04 Actuator temp.

Read reference for valve’s actuator temperature u05 Actuator Ref.

Read value of external current signal u06 AI mA

Read value of transmitted current signal u08 AO mA

Read status of input DI (start/stop input) u10 DI

ICM opening degree.

u24 OD%

Only active if (n03)=6

-- DO1 Alarm

Read status of alarm relay

-- DO2 Cooling

Read status of relay for solenoid valve

-- DO3 Fan

Read status of relay for fan

Operating status

Operating status of the controller can be called forth in the display. Push briey (1s) the upper

button. If there is a status code, it will be shown on the display. (Status codes have lower priority

EKC State

(0 = regulation)

than alarm codes. In other words, you cannot see a status code, if there is an active alarm).

The individual status codes have the following meanings:

S10: Refrigeration stopped by the internal or external start/ stop 10

S12: Refrigeration stopped due to low S

air

12

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 7

Page 8

User Guide | Media temperature controller, EKC 361

Operation

Display

The values will be shown with three digits, and with a setting you

can determine whether the temperature is to be shown in °C or in

°F.

Light-emitting diodes (LED) on front panel

There are LED’s on the front panel which will light up when the

corresponding relay is activated.

The three lowest LED’s will ash, if there is an error in the regulation.

In this situation you can upload the error code on the display and

cancel the alarm by giving the uppermost button a brief push.

The controller can give the following messages:

E1

E7 Cut-out S

Error message

E8 Short circuited S

E11 Valve’s actuator temperature outside its range

E12 Analog input signal is outside the range

A1

Alarm message

A2 Low-temperature alarm

The buttons

When you want to change a setting, the two buttons will give you

a higher or lower value depending on the button you are pushing. But before you change the value, you must have access to the

menu. You obtain this by pushing the upper button for a couple

of seconds - you will then enter the column with parameter codes.

Find the parameter code you want to change and push the two

buttons simultaneously. When you have changed the value, save

the new value by once more pushing the two buttons simultaneously.

Gives access to the menu

Gives access to changes

Saves a change

Examples of operations

Set set-point

1. Push the two buttons simultaneously

2. Push one of the buttons and select the new value

3. Push both buttons again to conclude the setting

Set one of the other menus

1. Push the upper button until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push both buttons simultaneously until the parameter value is

shown

4. Push one of the buttons and select the new value

5. Push both buttons again to conclude the setting

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

Errors in the controller

air

air

High-temperature alarm

(or cutout an alarm)

Menu survey

Function

Normal display

Shows the temperature at the selected sensor

At ICM valve OD also can be selected

Reference

Set the required room temperature - -70°C 160°C 10°C

Temperature unit r05 °C °F °C

Input signal’s temperature inuence r06 -50°C 50°C 0.0

Correction of the signal from S

Correction of the signal from S

Start/stop of refrigeration r12 OFF/0 On/1 On/1

Alarm

Upper deviation (above the temperature setting) A01 0 50 K 5.0

Lower deviation (below the temperature setting) A02 0 50 K 5.0

Alarm’s time delay A03 0

Regulating parameters

Actuator max. temperature n01 41°C 140°C 140

Actuator min. temperature n02 40°C 139°C 40

Actuator type (1=CVQ-1 to 5 bar, 2=CVQ 0 to 6

bar, 3=CVQ 1.7 to 8 bar, 4= CVMQ, 5=KVQ, 6= ICM)

P: Amplication factor Kp n04 0,5 50 3

I: Integration time Tn (600 = o) n05 60 s 600 s 240

D: Dierentiation time Td (0 = o) n06 0 s 60 s 10

Transient phenomenon

0: Ordinary control

1: Underswing minimised

2: No underswing

OD - Opening degree - max. limit - ICM only n32 0% 100% 100

OD - Opening degree min limit - ICM only n33 0% 100% 0

Miscellaneous

Controller's address (0-120) o03* 0 990 0

ON/OFF switch (service-pin message) o04* - -

Dene output signal of analog output:

0: no signal, 1: 4 - 20 mA, 2: 0 - 20 mA

Dene input signal of analog input

0: no signal, 1: 4 - 20 mA, 2: 0 - 20 mA

Language (0=english, 1=German, 2=French,

3=Danish, 4=Spanish and 6=Swedish.)When you

change the setting to an other language you must

activate o04 before "the new language" can be

visible from the AKM program.

Set supply voltage frequency o12

Select of running display value o17 Au/0 Air/1 Air/1

(Setting for the function o09)

Set the temperature value where the output signal

must be minimum (0 or 4 mA)

(Setting for the function o09)

Set the temperature value where the output signal

must be maximum (20 mA)

Service

Read temperature at the S

Read regulation reference u02

Read temperature at the S

Read valve's actuator temperature u04

Read reference of the valve's actuator temperature u05

Read value of external current signal u06

Read value of transmitted current signal u08

Read status of input DI u10

ICM opening degree. (only at ICM) u24

*) This setting will only be possible if a data communication module has been

installed in the controller.

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep both buttons depressed at the same time as you recon nect the supply voltage

air

aux

sensor u01

air

sensor u03

aux

Para-

Min. Max.

meter

-

r09 -10,0°C 10,0°C 0.0

r10 -10,0°C 10,0°C 0.0

n03 1 6 2

n07 0 2 2

o09 0 2 0

o10 0 2 0

011* 0 6 0

50

Hz/0

o27 -70°C 160°C -35

o28 -70°C 160°C 15

SW =1.5x

180

min

60

Hz/1

mA

mA

on/o

Fac.

setting

°C

30

0

°C

°C

°C

°C

°C

%

DKRCI.PS.RP0.B2.02 | 8

Page 9

User Guide | Media temperature controller, EKC 361

Data

Supply voltage

Power consumption

Input signal

Sensor input 2 pcs. Pt 1000 ohm

Output signal Current signal

Relay output 2 pcs. SPST

Alarm relay 1 pcs. SPST

Actuator

Data communication

Ambient

temperature

Enclosure IP 20

Weight 300 g

Mounting DIN rail

Display LED, 3 digits

Terminals max. 2.5 mm2 multicore

Approvals

24 V a.c. +/-15% 50/60 Hz, 80 VA

(the supply voltage is galvanically separated

from the input and output signals)

Controller

Actuator

Current signal 4-20 mA or 0-20 mA

Digital input from external contact function

Input

Output

Possible to connect a data communication

module

During operation

During transport

EU Low Voltage Directive and EMC demands re

CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 607302-9

EMC-tested acc. to EN50081-1 and EN 50082-2

5 VA

75 VA

4-20 mA or 0-20 mA

Max. load: 200 ohm

AC-1: 4 A (ohmic)

AC-15: 3 A (inductive)

Temperature signal from

sensor in the actuator

Pulsating 24 V a.c. to

actuator

-10 - 55°C

-40 - 70°C

Capacitive load

The relays cannot be used for the direct connection of capacitive loads such

as LEDs and on/o control of EC motors.

All loads with a switch mode power supply must be connected with a suitable contactor or similar.

Ordering

Type Function Code No.

EKC 361 Evaporating pressure controller 084B7060

EKA 174

Temperature sensor Pt 1000 ohm: ..........Kindly refer to catalogue RK0YG...

Valves: .............................................................DKRCI.PD.HT0.A

Data communication module

(accessories), (RS 485 module)

with galvanic separation

084B7124

Connections

Necessary connections

Terminals:

25-26 Supply voltage 24 V a.c.

17-18 Signal from actuator (from NTC)

23-24 Supply to actuator (to PTC)

20-21 Pt 1000 sensor at evaporator outlet

1-2 Switch function for start/stop of regulation. If a switch is

not connected, terminals 1 and 2 must be short circuited.

Application dependent connections

Terminal:

12-13 Alarm relay

There is connection between 12 and 13 in alarm situa tions

and when the controller is dead

8-10 Relay switch for start/stop of fan

9-10 Relay switch for start/stop of solenoid valves

18-19 Current signal from other regulation (Ext.Ref.)

21-22 Pt 1000 sensor for monitoring

2-5 Current output for Sair/Saux temperature or ICAD actuator

for ICM valve

3-4 Data communication

Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communication cable be done correctly. Cf. separate literature No.

RC8AC..

Data communication

CVQ/

CVMQ/

KVQ

Wire length: See appendix 2

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 9

Page 10

User Guide | Media temperature controller, EKC 361

Data communication

This page contains a description of a few of the possibilities you

will have when the controller is provided with data communication.

Examples

If you want to know more about operation of controllers via PC,

you may order additional literature.

Each controller is provided

with a plug-in module.

The controllers are then connected to a two-core cable.

The cable can be connected

to a gateway type AKA 245.

Example of menu display

• Measurements are shown at

one side and settings at the

other.

• You will also be able to see

the parameter names of the

functions on page 5-7.

This gateway will now control

the communication to and

from the controllers.

It will collect temperature values and it will receive alarms.

When there is an alarm the

alarm relay will be activated for

two minutes

• With a simple change-over

the values can also be

shown in a trend diagram.

• If you wish to check earlier

temperature measurements,

you can see them in the log

collection.

The gateway can now be connected to a modem.

When an alarm occurs from

one of the controllers, the

gateway will - via the modem

- make a phone call to the

service company.

Alarms

If the controller is extended

with data communication, it

will be possible to dene the

importance of the transmitted

alarms.

The importance is dened with

the setting: 1, 2, 3 or 0. When

the alarm then arises at some

time, it will result in one of the

following activities:

1 = Alarm

The alarm message is sent o

with alarm status 1. This means

that the gateway that is the

master in the system will have

its alarm relay output activated

for two minutes. Later, when

the alarm ceases, the alarm

text will be retransmitted, but

now with status value 0.

At the service company a

modem, gateway and PC with

system software type AKM

have been installed.

All the controllers’ functions

can now be operated from the

various menu displays.

The programme will for example upload all the collected

tempera ture values once a day.

2 = Message

The alarm text is transmitted

with status value 2. Later, when

the “message” lapses, the alarm

text is retransmitted, but now

with status value 0.

3 = Alarm

As “1”, but the master gateway’s

relay output is not activated.

0 = Suppressed information

The alarm text is stopped at

the controller. It is transmitted

nowhere.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 10

Page 11

User Guide | Media temperature controller, EKC 361

Appendix 1

Interaction between internal and external start/stop functions

and active functions.

Internal Start/stop O O On On

External Start/stop O On O On

Refrigeration O On

Actuator Stand-by Regulating

Actuator temperature "n02" "n02" to "n01"

Fan relay O On

Expansion valve relay O On

Temperature monitoring No Yes

Sensor monitoring Yes Ye s

Appendix 3

Appendix 2

Cable length for the CVQ actuator

The actuator must be supplied with 24 V a.c. ± 10%.

To avoid excessive voltage loss in the cable to the actuator, use a

thicker cable for large distances.

Wire cross section

Cable length

Connection between the evaporating temperature and the

CVMQ

actuator’s temperature (the values are approximate).

n01: The highest regulated room temperature will have a be longing to value which

in turn indicates the value of the n01 setting. Due to tolerances in the actuator, the setting value must be 10 K higher than shown in the curve.

n02: The lowest occurring suction pressure will have a belonging to value which in

turn indicates the value of the n02 setting. Due to tolerances in the actuator,

the setting value must be 10 K lower than shown in the curve.

CVQ KVQ

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 11

Page 12

User Guide | Media temperature controller, EKC 361

Start of controller

When the electric wires have been connected to the controller,

the following points have to be attended to before the regulation

starts:

1. Switch o the external ON/OFF switch that starts and stops the

regulation.

2. Follow the menu survey on page 7, and set the various para-

meters to the required values.

3. Switch on the external ON/OFF switch, and regulation will start.

If the temperature uctuates

When the refrigerating system has been made to work steadily,

the controller’s factory-set control parameters should in most

cases provide a stable and relatively fast regulating system.

If the system on the other hand oscillates, you must register the

periods of oscillation and compare them with the set integration

time Tn, and then make a couple of adjustments in the indicated

parameters.

4. If the system has been tted with a thermostatic expansion

valve, it must be set to minimum stable superheating. (If a

specic T0 is required for the adjustment of the ex pansion valve,

the two setting values for the actuator temperature (n01 and

n02) can be set to the belonging value while the adjustment

of the expansion valve is carried out. Remember to reset the

values).

5. Follow the actual room temperature on the display. (On

terminals 2 and 5 a current signal can be transmitted which

represents the room temperature. Connect a data collection

unit, if applicable, so that the temperature performance can be

followed).

If the time of oscillation is longer than the integration time:

(Tp > Tn , (Tn is, say, 4 minutes))

1. Increase Tn to 1.2 times T

2. Wait until the system is in balance again

p

3. If there is still oscillation, reduce Kp by, say, 20%

4. Wait until the system is in balance

5. If it continues to oscillate, repeat 3 and 4

If the time of oscillation is shorter than the integration time:

(Tp < Tn , (Tn is, say, 4 minutes))

1. Reduce Kp by, say, 20% of the scale reading

2. Wait until the system is in balance

3. If it continues to oscillate, repeat 1 and 2

Trouble shooting - ICS/PM with CVQ

In addition to the error messages transmitted by the controller,

the table below may help identifying errors and defects.

Symptom Defect Conrmation of defect

Media temperature too low.

Actuator feels cold.

Media temperature too low.

Actuator fells warm.

Media temperature too high.

Actuator feels cold.

Media temperature too high.

Actuator feels warm.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

Short-circuited NTC resistor in

actuator.

Defective PTC resistor (heating

element) in actuator.

Undersized cable to CVQ. Measure voltage across terminals 77 and 78 (min. 18 V a.c.).

Undersized 24 V transformer. Measure voltage across transformer output terminals (24 V a.c. +10/ -15%) under all

Loss of charge in actuator. Replace actuator.

Fault in refrigerant plant. Examine plant for ther defects.

Cut out NTC resistor in actuator. If more than 200 kohm is measured across terminals 17 and 18 (disassemble the

If less than 100 ohm is measured across terminals 17 and 18 (disassemble the lead),

the NTC or the leads are short-circuited. Check the leads.

If more than 30 ohm or 0 ohm is measured across terminal 23 and 24 (disassemble

the lead), either the PTC or the leads are defective.

Check the leads.

Measure resistance in power cables to CVQ (max. 2 ohm)

working conditions.

If voltage drops under some working conditions the transformer is undersized.

lead), either the NTC or leads are disconnected.

Check the leads.

DKRCI.PS.RP0.B2.02 | 12

Page 13

User Guide | Media temperature controller, EKC 361

Fine adjustments

When the system has been operating for a while, it may be

required for some systems to optimise some of the adjustments.

Below we have a look at settings having an inuence on the speed

and accuracy of the regulation.

Adjustment of the actuator’s min. and max. temperatures

At the rst setting these values were set to 10 K outside of the

expected temperature in order to eliminate the tolerances in the

actuator. By adjusting the two values to the values where the

valve is exactly in mesh, the valve will all the time remain active in

its regulation.

If the actuator is replaced at a later date, this procedure must be

repeated for the new actuator.

Min.

By adjusting the actuator’s min. temperature you obtain a limit

for how low a pressure can occur in the evaporator (the point is

where the valve starts a limitation of the refrigerant ow).

The system must be put in an operating situation where max.

capacity is called for (large refrigeration need).

The min. temperature must now be changed upwards step by

step, at the same time as the evaporating pressure is read on the

system’s manometer.

When a change of the evaporating pressure is registered, this is

the point where the valve is exactly in mesh. (If frost protec tion is

required for the system, the value can be raised to the belonging

value).

Max.

By adjusting the actuator’s max. temperature you obtain a limit for

how high a pressure can occur in the evaporator (the refrigerant

ow is blocked completely).

The system is put in an operating situation where there is no call

for refrigeration capacity (no refrigerant ow).

The max. temperature is now changed downwards step by step, at

the same time as the evaporating pressure is read on the system’s

manometer.

When a change of the evaporating pressure is registered, this

is the point where the valve opens. Adjust the setting a little

upwards, so that the valve will again close completely for the

refrigerant ow. (If the actual application has a requirement regarding max. evaporating pressure, a lower setting may of course

be selected, so that the pressure is limited).

Method for xing Kp, Tn and Td

Described below is a method (Ziegler-Nichols) for xing Kp, Tn

and Td.

1. The system is made to regulate the temperature at the required

reference with a typical load. It is important that the valve regulates, and that it is not fully open.

2. Parameter u05 is read. The actuator’s min. and max. setting is

adjusted, so that the average of the min. and max. values is

equal to the read u05.

3. The controller is set, so that it will regulate as a P-controller. (Td is

set to 0, Tn in pos. OFF (600), and Q-Ctrl.mode is set at 0).

4. The stability of the system is examined by stopping the system

for, say, one minute (using the start/stop setting or the switch).

Now check how the building-up of the temperature proceeds.

If the building-up peters out, raise Kp a little and repeat the

start/stop operation. Continue with this until you obtain a building-up which does not peter out.

5. Kp is in this case the critical amplication (Kp

ing-up time for the continued oscillation is the critical buildingup time (T

6. Based on these values, the regulating parameters can now be

critical

).

) and the build-

critical

calculated and subsequently set:

• If PID regulation is required:

Kp < 0.6x Kp

Tn > 0.5x T

Td < 0.12x T

• If PI regulation is required:

Kp < 0.45x Kp

Tn > 0.85x T

7. Reset the values for the controller’s min. and max. tem peratures

critical

critical

critical

critical

critical

and Q-Ctrl.mode.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 13

Page 14

User Guide | Media temperature controller, EKC 361

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 14

Page 15

User Guide | Media temperature controller, EKC 361

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 15

Page 16

User Guide | Media temperature controller, EKC 361

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.B2.02 | 16

Loading...

Loading...