Page 1

Liquid level controller

EKC 347

Manual

Page 2

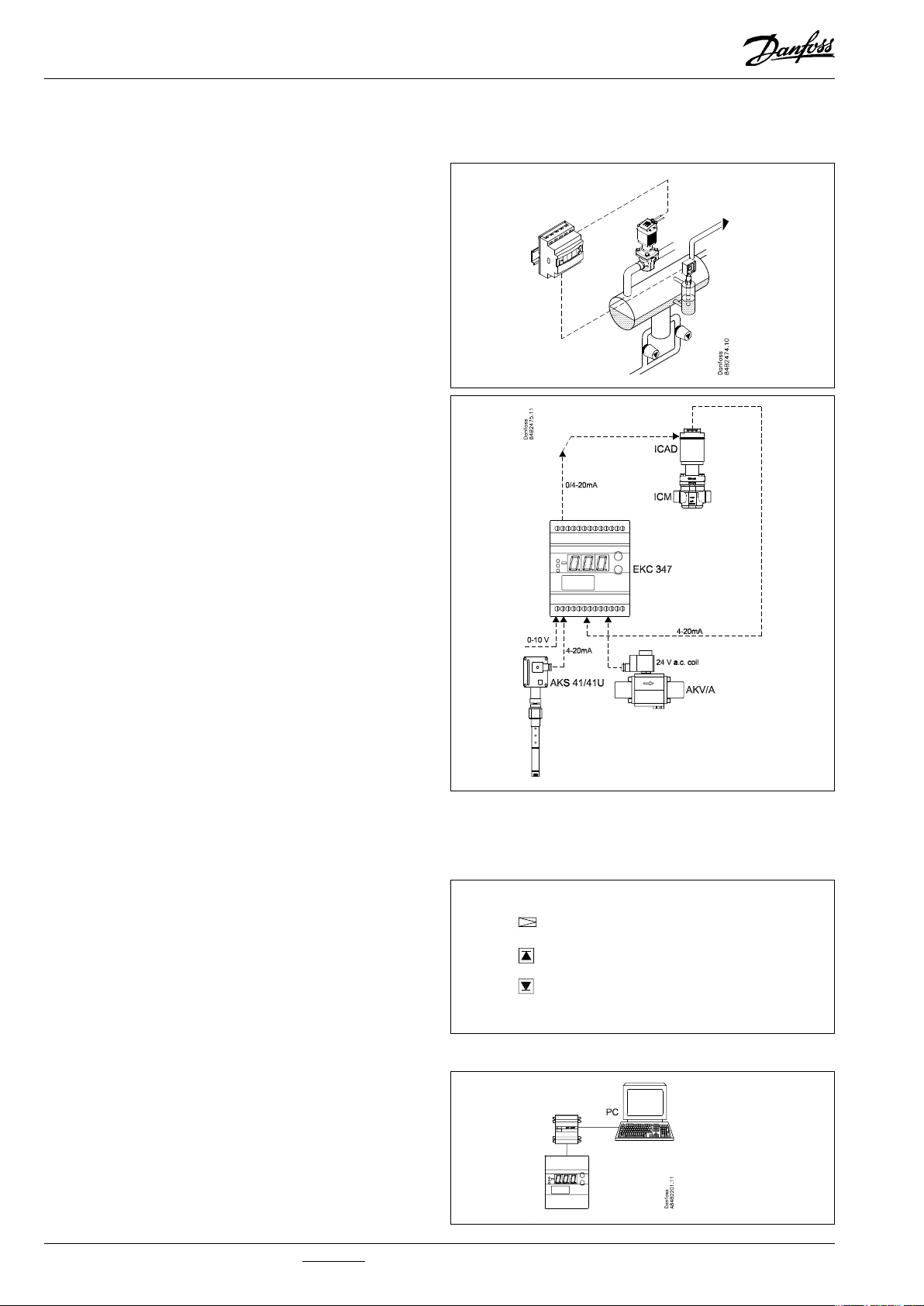

Introduction

Application

The controller is used for regulation of the refrigerant level in:

• Pump reservoirs

• Separators

• Intermediate coolers

• Economisers

• Condensers

• Receivers

System

A signal transmitter will constantly measure the refrigerant liquid

level in the reservoir - the controller will receive the signal and

subsequently control the valve, in order to control the refrigerant

liquid level according to liquid level setpoint.

Signaltransmitter

With the capacitive rod it is possible to set the refrigerant level

within a wide range.

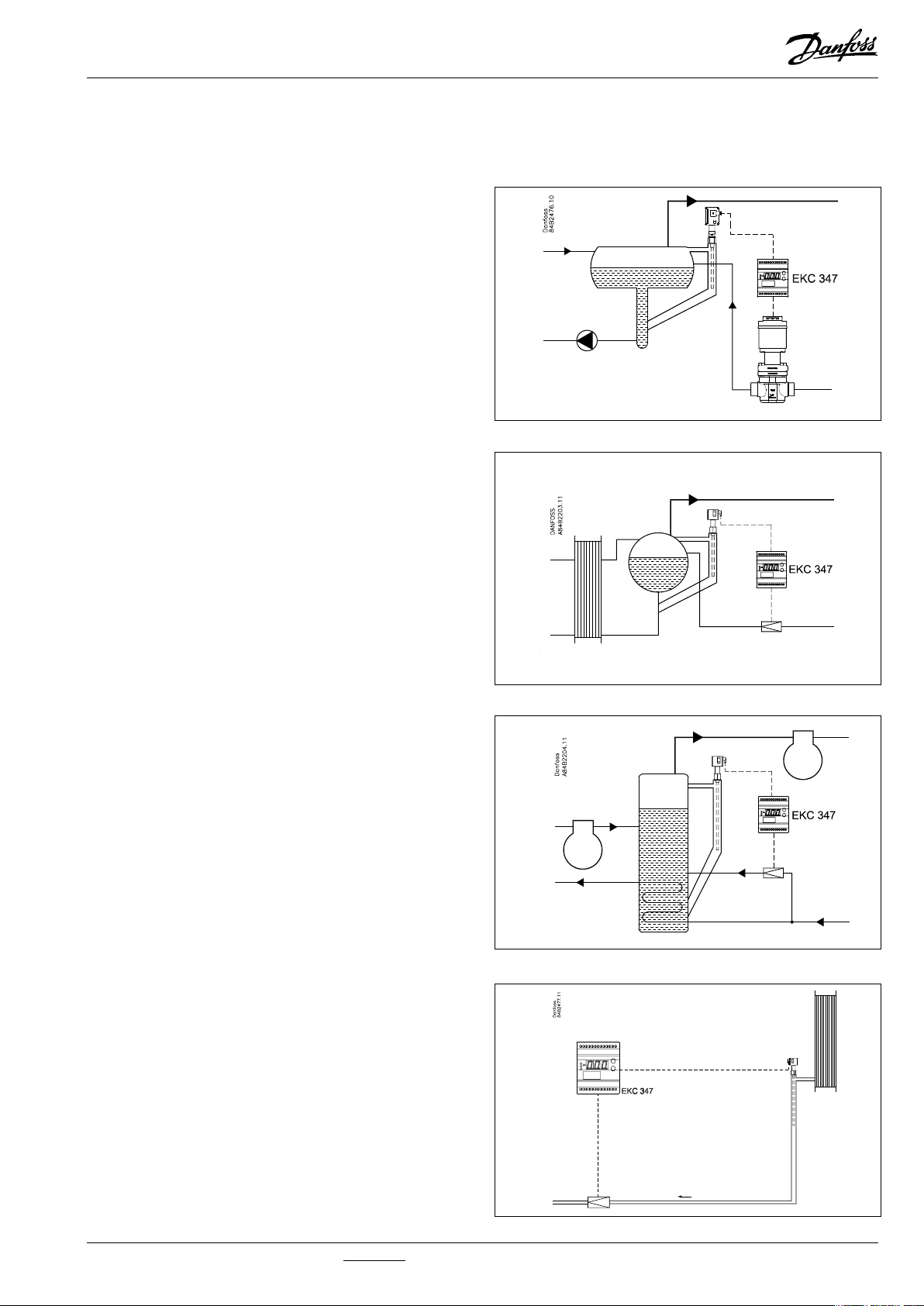

EKC 347

The controller receive a signal and are then able to contol

low or high side applications. A analog input signal (voltage/

current) can displace the setpoint and then remote change of

setpoint is thus possible.

EKC 347 does support 2 types of Danfoss expansion valves. (see

below)

One analog input is available as feed back from ICM in order to

indicate Opening degreee of the ICM.

Expansions valve

Two types of Danfoss expansion valves can be used

ICM - ICM are direct operated motorized valves driven by

digital stepper motor type ICAD

AKV/A - AKVA or AKV are pulse-width modulating expansion

valves.

Functions

• Liquid level control

• Alarm if the set alarm limits are exceeded

• Relay outputs for upper and lower level limits and for alarm level

• Analog input signal which can displace the reference

• PI control

• Low or High side control

• When AKV/A is selected, a MASTER/SLAVE system can run up to 3

AKV/A with distributed Opening Degree

• Manual control of output

• Limitation of Opening degree possible

• ON/OFF operation with hysteresis

Extra options

• PC operation

The controller can be provided with data communication, so

that it may be hooked up with other products in the ADAPKOOL® range of refrigeration controls. Operation, moni toring

and data collection can then be performed from a PC - either in

situ or at a service company.

LED's on front panel

All

Opening signal to valve

Indication of upper level limit

Indication of lower level limit

Indication of alarm level

EKC 347

2 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

Page 3

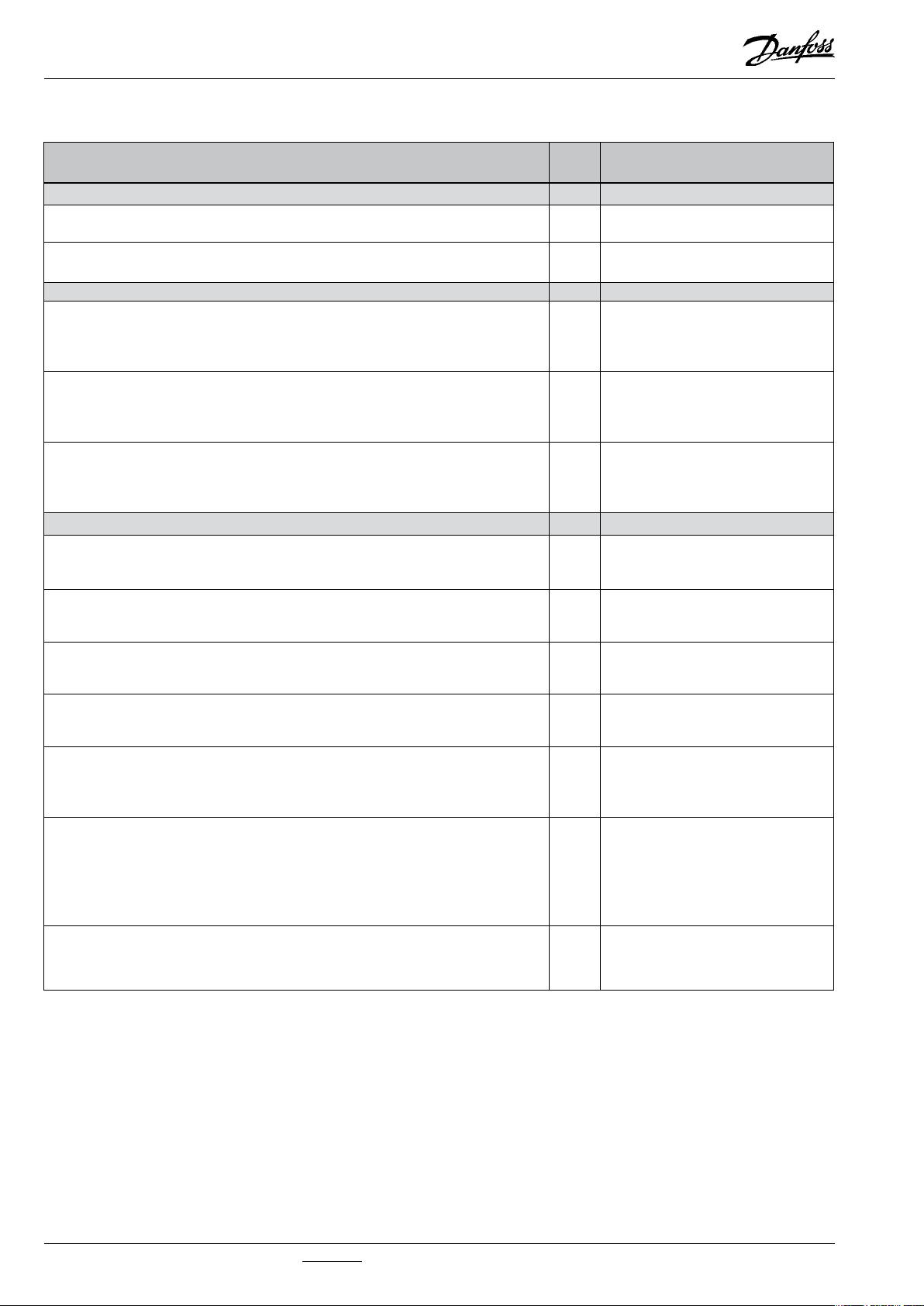

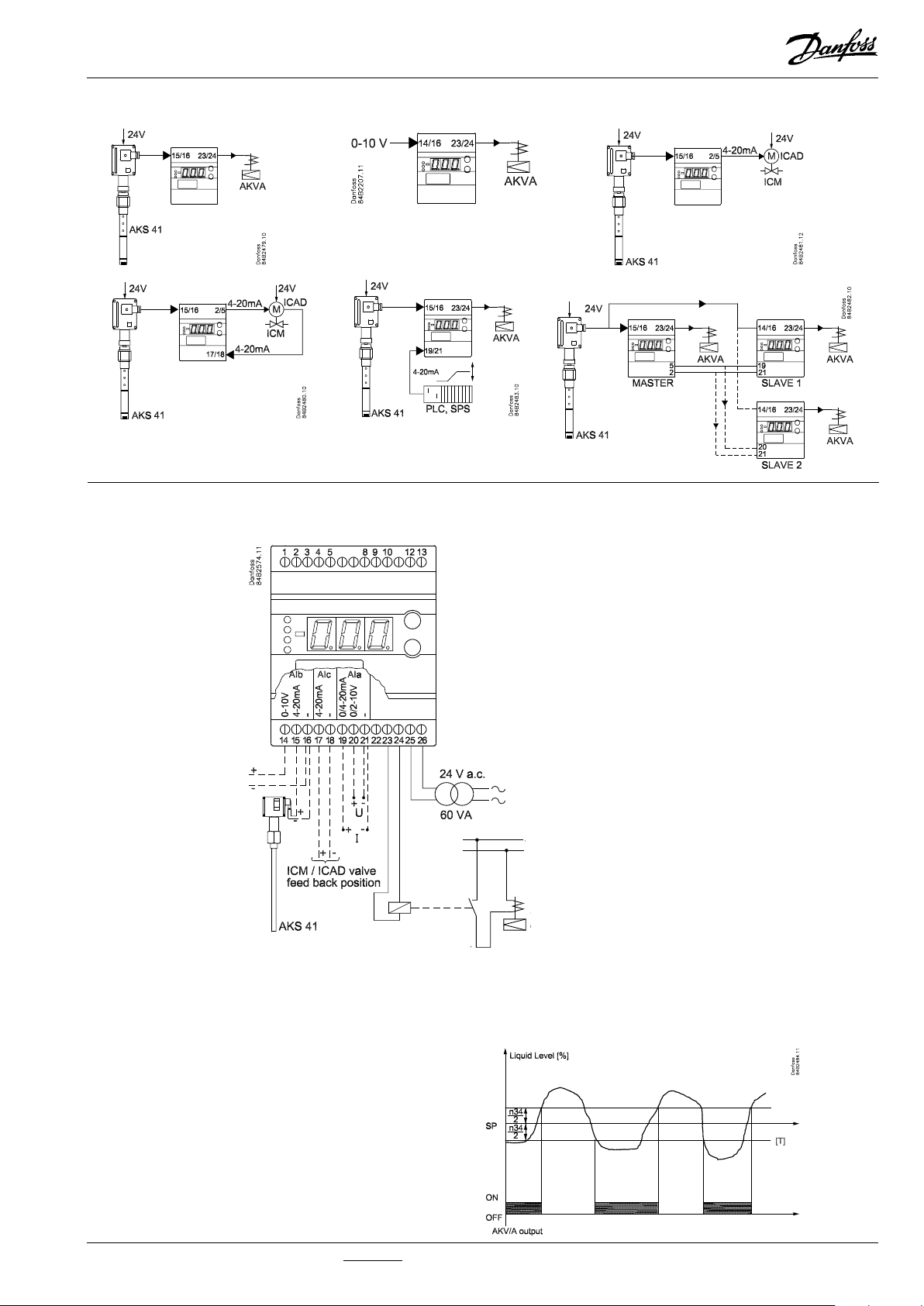

Application examples

Pump reservoir

Modulating control of injection makes for a more stable liquid

level and suction pressure.

Separator on flooded evaporator

Modulating control and the valve’s large capacity range ensure a

stable level - even under conditions of quickly changing loads.

Intermediate cooler

The level transmitter’s wide measuring range enables it to monitor

the liquid at all levels of the reservoir - and hence to use the signal

for safety functions in connection with the max. permissible level

Receiver / condenser

The control system’s short reaction time makes it very suited for

high-pressure oat systems with small refrigerant charges.

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 3

Page 4

Survey of functions

Function Para-

meter

Normal display Level control

The liquid level is indicated in %

The % value is calculated on the basis of the input signal and the denition in ”o31”.

The valve’s actual opening degree can be displayed by giving the lower button a brief

push (1s). Cf. also o17.

Reference

Set point

Regulation is based on the set value provided that there is no external contribution

(o10).

(Push both buttons simultaneously to set the setpoint).

External contribution to the reference

This setting determines how large a contribution is to be added to the set reference

when the input signal is max (20 mA or 10 V. Cf. also o10).

The value is set in %-points.

Start/stop of regulation

With this setting the level regulation can be started and stopped. Start/stop of level

regulation can also be performed with the external contact function. Regulation is

stopped if just one of them is OFF.

Alarm Level Alarms

The controller can give alarm in dierent situations.

When there is an alarm the three lowest LED’s at the front of the controller will ash,

and the alarm relay is cut in

Limit for upper level

Here you set the limit value for the upper level indication. The value is set in %. The

relay for the upper level will become activated when the level exceeds the set value.

Limit for lower level

Here you set the limit value for the lower level indication. The value is set in %. The relay for the lower level will become activated when the level drops below the set level.

Time delay for upper level limit

When the limit value is exceeded a timer function will start. The relay will not become

activated until the set time delay has been passed. The time delay is set in seconds.

Delay for lower limit level

When the limit value is exceeded a timer function will start.The relay will not become

activated until the set time delay has been passed.

The time delay is set in seconds.

Limit for alarm level

An alarm level can be set which when passed will activate the alarm relay- The value is

set in %. Cf. also the denition in A18.

If the limit alarm (A3) is not required, it can be avoided by means of the following set-

ting in A16:

100 : If the rising level denition has been chosen. (A18=0 or 2)

0: If the falling level denition has been chosen. (A18=1 or 3)

Time delay for alarm level

When the alarm level is exceeded a timer function will start. The relay will not become

activated until the set time delay has been passed.

The time delay is set in seconds.

Parameter by operation via

data communication

- Liquid level

- OD %

- SP Liquid Level

r06 r06 Ext. Ref.oset

r12 r12 Main Switch

A01 A01 Upper Dev.

A02 A02 Lower Dev.

A03 A03 Upper Delay

A15 A15 Lower Delay

A16 A16 Limit Alarm

A17 A17 Limit Delay

4 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

Page 5

Configuration of limit alarm (A3) level and lower limit alarm(A2) for pump cut-

A18 A18 Lim. LowMode

out.

To dene whether the limit alarm (A3) is linked to rising (A18=0) or falling level

(A18=1).

It is also possible to congurate the Relay for lower level limit when lower limit alarm

(A2) is detected. Dedicated to switch o pumps at low level alarm.

0: Rising level. When liquid level is higher than A16, and time in A17 has expired, A3

alarm is generated.

1: Falling level . When liquid level is lower than A16, and time in A17 has expired, A3

alarm is generated.

2: Same function as if A18=0, but in addition (to that:

- When liquid level is higher than A02. No A2 alarm and Relay for lower level limit,

gives ON signal (cut in) on terminal 8 and 10.

- When liquid level is lower than A02 and time in A15 has expired. A2 alarm is generated and Relay for lower level limit, gives OFF signal (cut out) on terminal 8 and 10.

3: Same function as if A18=1, but in addition (to that:

- When liquid level is higher than A02. No A2 alarm and Relay for lower level limit,

gives ON signal (cut in) on terminal 8 and 10.

- When liquid level is lower than A02 and time in A15 has expired. A2 alarm is generated and Relay for lower level limit, gives OFF signal (cut out) on terminal 8 and 10.

Function Alarm relay when A1, A2 or A3 alarms are detected.

0: Alarm relay to be activated when A1 or A2 or A3 are detected.

1: Alarm relay only to be activated when A3 is detected.

A19 A19 Alarm type

(With setting = 0 the alarm is also

transmitted via the data communication)

Alarm relay

The alarm relay will become activated if one of the set limits is exceeded or if the

controller loses the input signal from the level-measuring unit.

With data communication the importance of the individual alarms can be

dened. Setting is carried out in the

“Alarm destinations” menu. See also

page 11.

Control parameters Injection Settings

Definition of regulating principle

n35 n35 Low/High Pr.

Here you set whether the controller is to open or close the valve when the liquid level

is rising.

Low (0): Regulation on the low-pressure side. The valve closes when liquid level is

rising.

High (1): Regulation on the high-pressure side. The valve opens when liquid level is

rising.

Period time

n13 n13 AKV per.time

An AKV/A valve is operated with pulses of a given length. The length depends on the

opening degree required. If a large opening degree is required, the pulse will last for

an entire period time. A period time will thus comprise both open and closed valve.

P - band

n04 n04 P-band

If the value is reduced the regulating range will be reduced. (The P-band will be near

the reference).

I: Integration time Tn

n05 n05 Tn sec.

The I-link can be made passive by setting the value at max. (600s)

(If the Tn value is increased the regulation becomes slower).

Neutralzone

n34 n34 Neutralzone

The function is only active if the selected expansion valve is of type ICM

Min. opening degree

n33 n33 OD Min.

Here you can make a setting if you require a limitation of the valve’s working range.

Max. opening degree

n32 n32 OD Max.

Here you can make a setting if you require a limitation of the valve’s working range.

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 5

Page 6

Miscellaneous Miscellaneous

Valve and output signal

o09

o09 AO type

The controller can control three types of expansion valves - ICM or AKV/A.

With AKV/A up to three EKC 347 controllers can be linked up to a MASTER/SLAVE

function (this function is only used if there is a need for several parallel AKV/A expan-

sion valves). The application is selected with one of the following settings:

1: ICM. AO: 4-20 mA

2: ICM. AO: 0-20 mA

3: AKV/A, AO: 4-20 mA

4: AKV/A, AO: 0-20 mA

or, if the master/slave function is used::

5: AKV/A, MASTER

6: AKV/A, SLAVE 1/1. AO:4-20 mA

7: AKV/A, SLAVE 1/1. AO:0-20 mA

8: AKV/A, SLAVE 1/2. AO:4-20 mA

9: AKV/A, SLAVE 1/2. AO:0-20 mA

10: AKV/A, SLAVE 2/2. AO:4-20 mA

11: AKV/A, SLAVE 2/2. AO:0-20 mA

12: AKV/A, SLAVE 1/1. AO:4-20 mA - AO always updated

13: AKV/A, SLAVE 1/1. AO:0-20 mA- AO always updated

14: AKV/A, SLAVE 1/2. AO:4-20 mA- AO always updated

15: AKV/A, SLAVE 1/2. AO:0-20 mA- AO always updated

16: AKV/A, SLAVE 2/2. AO:4-20 mA- AO always updated

17: AKV/A, SLAVE 2/2. AO:0-20 mA- AO always updated

With settings 1 and 2 the AO [mA] signal is dedicated for the motor valve ICM.

With settings 3, 4, AO [mA] will be send out a signal for process indications.

With settings 6, 7, 8, 9, 10 or 11, AO [mA] on EKC 347 SLAVE, will be send out a signal

for process indications.

With settings 12, 13, 14, 15, 16 or 17, AO will also be updated (active) when DI is OFF

Reference displacement

o10 o10 AI type

If you wish to connect a signal that is to displace the controller’s control reference, the

signal must be dened in this menu.

The signal is connected to terminals 19-21 or 20-21

0: No signal

1: 4 - 20 mA

2: 0 - 20 mA

3: 2 - 10 V

4: 0 - 10 V

(The min. value will give no displacement. The max. value will displace the reference

with the value set in menu r06).

Input signal from the level-measuring unit

o31 o31 Levelsign.

The input signal for terminals 14-16 or 15-16 must be dened:

0: No signal

1: Current signal of 4-20 mA

2: Voltage signal. The voltage range must be set in the next two menus. (If the connections are a master/slave system and the signal to the master is 4 to 20 mA, the

setting in the slave modules must also be selected to 1 – this must be done, even if

the signal is connected to the voltage input).

Voltage signal’s lower value

o32 o32 Lev. V. Low

(only if the setting in 031 = 2).

Voltage signal’s upper value

o33 o33 Lev. V. High

(only if the setting in o31 = 2)

Position signal

o34 o34 Valve feedb.

If a ICM valve is selected it is possible to have ICM valve position as a [mA] feed back

signal

0: Not used

1: ICM mA feedback signal from connected ICAD.

2: Not used

Frequency

Set the net frequency.

o12 o12 50 / 60 Hz

(50=0, 60=1)

Address

If the controller is built into a network with data communication, it must have an

address, and the master gateway of the data communication must then know this

address.

These settings can only be made when a data communication module has been

mounted in the controller and the installation of the data communication cable has

Following installation of a data communication module, the controller can

be operated on a par with the other

controllers in ADAP-KOOL® refrigera-

tion controls.

been completed.

This installation is mentioned in a separate document “RC8AC”..

The address is set between 1 and 60 o03 -

The address is sent to the gateway when the menu is set in pos. ON

o04 (The setting will automatically change back to O after a few seconds.)

6 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

Page 7

Language

This setting is only required when data communication is connected to the controller.

Settings: 0=English, 1=German, 2=French, 3=Danish, 4=Spanish, 5=Italian, and 6=

Swedish

When the controller is operated via data communication, the texts in the right-hand

column will be shown in the selected language.

When you change the setting to an other language you must activate o04 before "the

new language" can be visible from the AKM program.

Selection of parameter for displays and AO

The selection depends on the setting made in menu ”o34”. The selected value to

display is also send to AO, except when ICM or AKV/A as MASTER, has been selected

as valve type (o09=1 or 2 or 5)

If o34 has been set at 0, the subsequent setting of o17 will mean:

0: The liquid level will be shown in the ”normal display”

1: The valve’s opening degree OD will be shown in the ”normal display”

If o34 has been set at 1, the subsequent setting of o17 will mean:

0: The liquid level will be shown in the ”normal display”

1: The ICM valve position feed back signal [%] will be shown in the ”normal display”

The normal display has now been selected. If the other is requested, activate the controllers lowest button This will give a display showing of liquid level/opening degree

- or vice versa. After ve seconds the display will revert to the original mode.

Manual control of outputs

In connection wit service the individual relay outputs and the AKV/A output can be

put in pos. ON. But not until regulation has been stopped.

OFF: No override

1: Relay for upper level is ON

2: Relay for lower level is ON

3: AKV/A output is ON

4: Alarm relay is activated (terminals 12 and 13 will be connected)

Service Service

A number of controller values can be printed for use in a service situation

Read liquid level u01 u01 Liquid level

Read the control reference

(Set reference + any contribution from external signal)

Read valve’s opening degree u24 u24 OD %

Read value of the external current signal (reference displacement) which is received

on terminals 19-21

Read value of the external voltage signal (reference displacement) which is received

on terminals 20-21

Read value of the current signal (level signal) received on terminals 15-16 u30 u30 Levelsign. mA

Read value of the voltage signal (level signal) received on terminals 14-16 u31 u31 Levelsign. V

Read value of the current signal (position signal from the valve) received on terminals

17-18

Read position signal from the valve. The value is converted into % of the total open-

ing degree

Read value of the delivered current signal (terminals 2-5) u08 u08 AO mA

Read status of input DI (start/stop input) u10 u10 DI

Operating status

Operating status of the controller can be called forth in the display.

Push briey (1s) the upper button. If there is a status code, it will be shown on the display. (Status codes have lower priority than alarm codes. In other words, you cannot

see a status code, if there is an active alarm).

The individual status codes have the following meanings:

S10: Level regulation stopped by the internal or external start/ stop 10

S12: Liquid level had exceeded A01 limit or Liquid level is lower than A02 limit 12

o11 o11 Language

o17 o17 Display / AO

o18 -

u02 u02 Liq. Lev Ref

u06 u06 Ext. Ref. mA

u07 u07 Ext. Ref. V

u32 u32 Valve fb mA

u33 u33 Valve fb %

-- DO1 Limit alarm

Read status of alarm relay

ON is operating status with alarm

-- DO2 Upper alarm

Read status of the relay for the upper

level limit

-- DO3 Lower alarm

Read status of the relay for the lower

level limit

EKC State

(0 = regulation)

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 7

Page 8

Operation Menu survey

Display

The values will be shown with three digits, and after an opera-

tion the controller will return to its standard mode and show the

measured liquid level.

Light-emitting diodes (LED) on front panel

There are LED’s on the front panel which will light up when the

corresponding relay is activated.

The upper LED will indicate the valve’s opening degree. A short

pulse indicates a slow liquid ow and a long pulse a fast liquid

flow.

The three lowest LED’s will ash, if there is an error in the regulation.

In this situation you can upload the error code on the display and

cancel the alarm by giving the uppermost button a brief push.

The buttons

When you want to change a setting, the two buttons will give you

a higher or lower value depending on the button you are pushing. But before you change the value, you must have access to the

menu. You obtain this by pushing the upper button for a couple

of seconds - you will then enter the column with parameter codes.

Find the parameter code you want to change and push the two

buttons simultaneously. When you have changed the value, save

the new value by once more pushing the two buttons simultaneously.

Gives access to the menu

Gives access to changes

Saves a change

(or cutout an alarm)

Examples of operations

Set reference

1. Push the two buttons simultaneously

2. Push one of the buttons and select the new value

3. Push both buttons again to conclude the setting

Set one of the other menus

1. Push the upper button until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push both buttons simultaneously until the parameter value is

shown

4. Push one of the buttons and select the new value

5. Push both buttons again to conclude the setting

Literature survey:

Manual for EKC 347 ..............................................................RS8AX---

Instruction for EKC 347 .......................................................RI8BY---

Installation guide, "Data communication link

for ADAP-KOOL® " .................................................................RC8AC---

Function

Normal display

Read the measured liquid level - % 50.0

If you wish to see the actual opening degree, give the

lower button a brief push

If you wish to set the required setpoint you obtain access by pushing both buttons simultaneously

Level control

External contribution to the reference. Cf. also o10.

Value is set in %-points.

Start / stop of level control r12 OFF/0 ON/1 1

Alarm

Upper level limit A01 0 % 100% 85

Lower level limit A02 0% 100% 15

Time delay for upper level limit A03 0 s 999 s 50

Time delay for lower level limit A15 0 s 999 s 10

Level alarm limit A16 0 % 100 % 20

Delay for level alarm A17 0 s 999 s 0

The level alarm is linked to:

0: Rising level (higher level than A16)

1: Falling level (lower level than A16)

2: Same function as if A18=0. When A2 alarm is generated and Relay for lower level limit, gives OFF signal

(cut out).

3: Same function as if A18=1 When A2 alarm is generated and Relay for lower level limit, gives OFF signal

(cut out).

Function for Alarm relay when A1, A2 or A3 alarms are

detected.

0: Alarm relay to be activated when A1 or A2 or A3 are

detected.

1: Alarm relay only to be activated when A3 is detected.

Regulating parameters

P - band n04 0%/O 200% 30

I: Integration time Tn n05 60

Period time (only if AKV/A valve is used) n13 3 s 10 s 6

Max. opening degree n32 0% 100% 100

Min. opening degree n33 0% 100% 0

Neutral zone (only for ICM valve) n34 2% 25% 2

Denition of regulating principle

Low: On the low-pressure side (valve closes when

liquid level is rising)

High: On the high-pressure side (valve opens when

liquid level is rising)

Miscellaneous

Controller's address o03* 0 60 0

ON/OFF switch (service-pin message) o04* OFF ON

Dene valve and output signal:

1: ICM. AO: 4-20 mA

2: ICM. AO: 0-20 mA

3: AKV/A, AO: 4-20 mA

4: AKV/A, AO: 0-20 mA

Or if a master/slave function is used:

5: AKV/A, MASTER

6: AKV/A, SLAVE 1/1. AO:4-20 mA

7: AKV/A, SLAVE 1/1. AO:0-20 mA

8: AKV/A, SLAVE 1/2. AO:4-20 mA

9: AKV/A, SLAVE 1/2. AO:0-20 mA

10: AKV/A, SLAVE 2/2. AO:4-20 mA

11: AKV/A, SLAVE 2/2. AO:0-20 mA

12: AKV/A, SLAVE 1/1. AO:4-20 mA - AO always updated

13: AKV/A, SLAVE 1/1. AO:0-20 mA- AO always updated

14: AKV/A, SLAVE 1/2. AO:4-20 mA- AO always updated

15: AKV/A, SLAVE 1/2. AO:0-20 mA- AO always updated

16: AKV/A, SLAVE 2/2. AO:4-20 mA- AO always updated

17: AKV/A, SLAVE 2/2. AO:0-20 mA- AO always updated

SW = 1.1x

Param-

Min. Max.

eter

- % 0

- 0% 100% 100

r06 -100 100 0.0

A18 0 3 0

A19 0 1 0

n35 Low/0 Hig/1 0

o09 1 17 1

600/

O

Fac.

setting

400

8 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

Page 9

Continued from previous page

Dene the input signal on terminals 19, 20, 21 (external

reference displacement)

0: OFF

1: 4-20 mA

2: 0-20 mA

3: 2-10 V

4: 0-10 V

Language

0=English, 1=German, 2=Frensh, 3=Danish, 4=Spanish,

5=Italian, 6=Swedish. When you change the setting

you must also activate o04.

Set supply voltage frequency o12

Selection of parameter for display and AO (except from

when o09=1,2 or 5)

If o34 = 0:

0: Liquid level is show

1: Valve’s opening degree OD will be shown

If o34 = 1:

0: Liquid level is show

1: The ICM valve position feed back signal [%] will be

shown

Manual control of outputs:

OFF: No manual control

1: Upper level relay put in pos. ON

2: Lower level relay put in pos. ON

3: AKV/A output put in pos. ON

4: Alarm relay activated (cut out)

Dene input signal (level signal) on terminals 14, 15, 16

0: OFF

1: 4-20 mA

2: 0-10 V (also set the voltage values in the next two

menus)

Read functional description if the connection used is a

master/slave function.

Dene input signal’s lower value for terminal 14, if

required

Dene input signal’s upper value for terminal 14, if

required

Dene input signal on terminals 17-18

0: Not used

1: ICM mA feedback signal from ICAD connected

2: Not used

Service

Read liquid level u01 %

Read liquid level reference u02 %

Read external contribution to the reference u06 mA

Read external contribution to the reference u07 V

Read current signal on the analog output u08 mA

Read status of input DI u10

Read valve’s opening degree u24 %

Read level signal u30 mA

Read level signal u31 V

Read signal from ICM/ICAD u32 mA

Read signal from ICM/ICAD converted into % u33 %

*) This setting will only be possible if a data communication module has been

installed in the controller.

o10 0 4 0

o11* 0 6 0

0/50 Hz1/60

o17 0 1 0

o18 OFF 4 0

o31 0 2 1

o32 0.0 V 4.9 V 4.0

o33 5.0 V 10 V 6.0

o34 0 2 0

0

Hz

Error messages

The controller can give the following messages:

E1

E12

Error message

E21 Level signal outside the range 1)

E22 Signal from ICM/ICAD outside the range

A1

Alarm message

A2 Lower level limit reached

A3 Alarm level limit reached

1)

If E21 is detected. EKC 347 will force the valve to close or open the valve depending

af n35

If Low pressure has been selected. (n35=0)

The valve is forced to fully closed, however if Min. Opening Degree (n33) is higher

than 0 the valve will open to the value of n33

If High pressure has been selected. (n35=1)

The valve is forced to fully open, however if Max. Opening Degree (n32) is lower than

100 the valve will open to the value of n32

Errors in the controller

The external reference contribution is outside

the range

Upper level limit reached

Ordering

Type Function Code No.

EKC 347 Liquid level controller 084B7067

EKA 174

Level transmitter/controller: .............Kindly refer to catalogue RK0YG

AKV / AKVA Valves: ................................Kindly refer to catalogue RK0YG

ICM and ICAD................ ..........................Kindly refer to DKRCI.PD.HT0.A

Data communication module

(accessories), (RS 485 module)

with galvanic separation

084B7124

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep both buttons depressed at the same time as you recon nect the supply voltage

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 9

Page 10

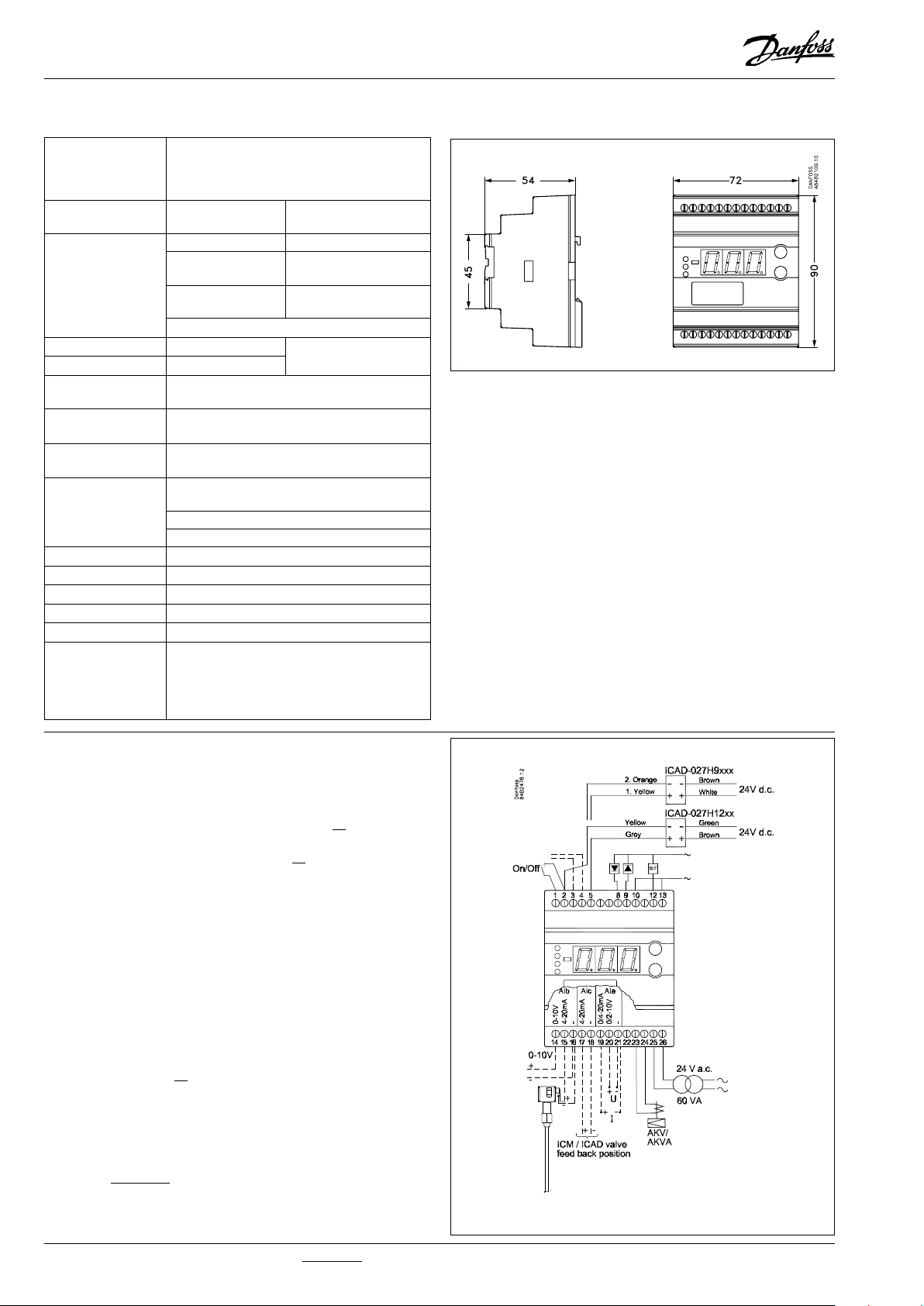

Data

24 V a.c. +/-15% 50/60 Hz, 60 VA

Supply voltage

Power consumption

Input signal

* Ri =

0(4)-20mA:100 ohm

0(2)-10 V: 100 kohm

Relay output 2 pcs. SPST

Alarm relay 1 pcs. SPST

Current output

Valve connection

Data communication

Environments

Enclosure IP 20

Weight 300 g

Mounting DIN rail

Display LED, 3-digits

Terminals max. 2.5 mm

Approvals

(the supply voltage is galvanically separated from

the input and output signals. Input/output are

not individual galvanic isolated)

Controller

20 W coil for AKV

Level signal * 4-20 mA or 0-10 V

Reference displacement *

ICM valve feedback

signal *

Contact function start/stop of regulation

0-20 mA or 4-20 mA

Max. load: 500 ohm

ICM - via current output

AKV/A- via 24 a.c. Pulse-Width Modulating output

Possible to connect a data communication

module

-10 - 55°C, during operation

-40 - 70°C, during transport

20 - 80% Rh, not condensed

No shock inuence / vibrations

EU Low Voltage Directive and EMC demands re

CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 60730-2-9

EMC-tested acc. to EN61000-6-3 and EN 61000-

6-2

2

multicore

5 VA

55 VA

4-20 mA, 0-20 mA,

2-10 V or 0-10 V

From ICAD 0/4-20 mA

AC-1: 4 A (ohmic)

AC-15: 3 A (inductive)

Connections

Necessary connections

Terminals:

25-26 Supply voltage 24 V a.c.

15-16 Signal from level transmitter type AKS 41 or

14-16 Signal from transmitter 0-10 V

23-24 Expansion valve type AKV or AKVA or

2-5 Expansion valve type: ICM with ICAD

1-2 Switch function for start/stop of regulation. If a switch is

not connected, terminals 1 and 2 must be shortcircuited.

Application dependent connections

Terminal:

12-13 Alarm relay. See A19 and A18

8-10 Relay for lower level limit. See A18 for setting of ON (cut

in) or OFF (cut out) function

9-10 Relay for upper level limit. There is connection between

9 and 10 when the set value is passed

17-18 ICM valve feedback signal from ICAD 0/4-20 mA

19-21 Current signal or

20-21 Voltage signal from other regulation (for external refer-

ence displacement)

3-4 Data communication

Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communi-

cation cable be done correctly. Cf. separate literature No.

RC8AC...

Data communication

AKS 41/41U

AKV/AKVA Coil always 24 V a.c Max. 20 W.

Can also be a relay with coil 24 V a.c.

Fx

EKC 347 5 VA

20 W coil for AKV 55 VA

10 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

Page 11

Connections examples

EKC 347 – ON/OFF Application. Open/Close solenoid valve with coil 110 V

0-10V

Auxiliary relay,

with coil : 24 V a.c

ON/OFF application

Beside of modulating PI control EKC 347 does also support ON/

OFF operation with hysteresis.

To ensure this operation:

P.Band must be (n04)=0%//OFF

Hysteresis is given by (n34)

Setpoint as normal procedure. (pushing the upper/lower buttons

simultaneously)

Low or High side system. (n35)

Voltage : 110 V a.c

Solenoid with coil :

110 V a.c

Low pressure system

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 11

Page 12

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

12 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

DE-BD

Page 13

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 13

Page 14

14 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 EKC 347

Page 15

EKC 347 Manual RS8AX702 DKRCC.ES.R1.A1.02/ 520H4020 © Danfoss 01-2011 15

Loading...

Loading...