Page 1

Capacity controller

EKC 331T

Manual

Page 2

Introduction

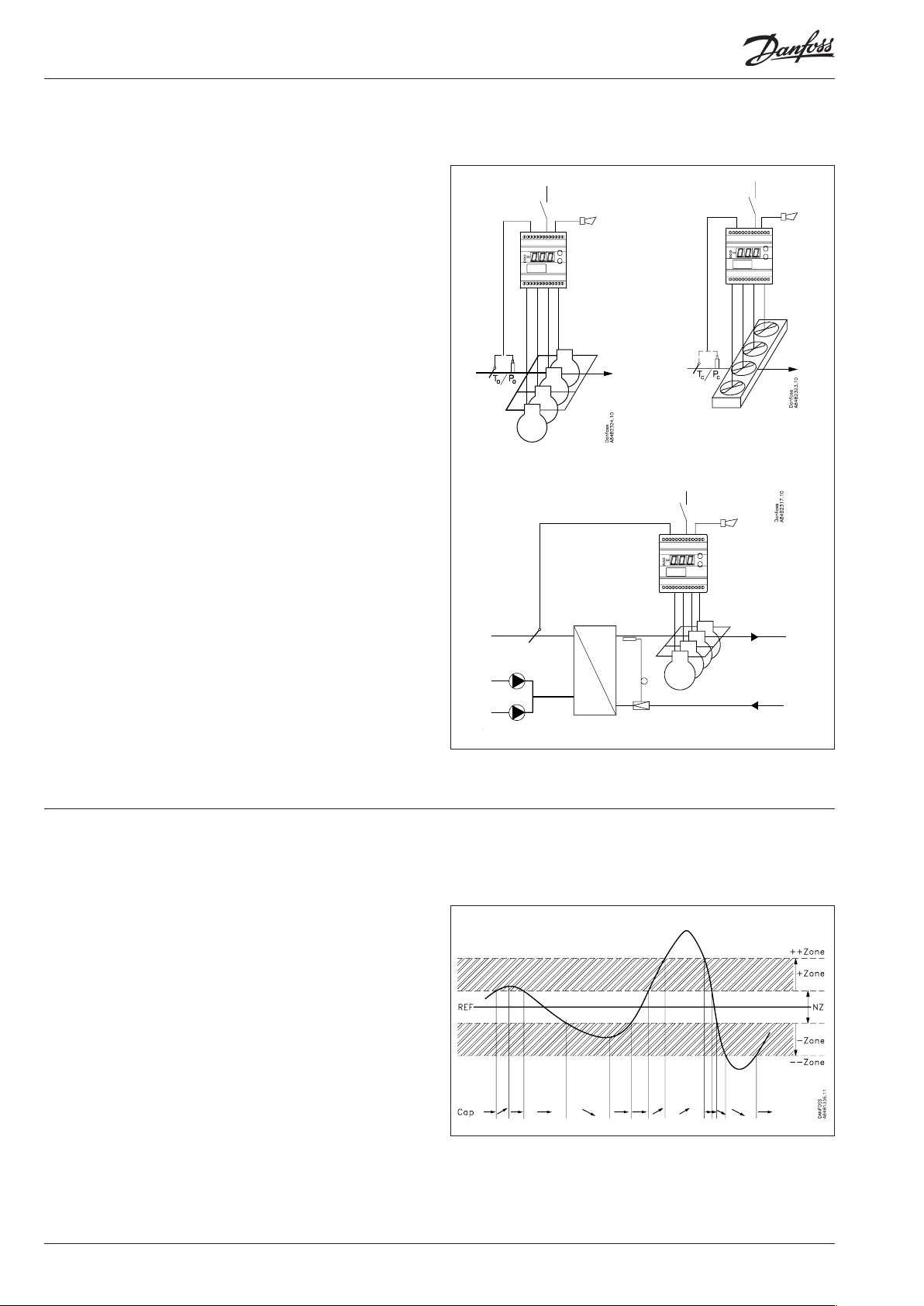

Application

The controller is used for capacity regulation of compressors or

condensers in small refrigerating systems.

Regulation can be carried out with up to four identical capacity

steps.

Advantages

• Patented neutral zone regulation

• Sequential or cyclic operation

Functions

• Regulation

Regulation with up to four relay outputs can be carried out.

Regulation takes place with a set reference which is compared

to a signal from a pressure transmitter or a temperature sensor.

• Relay module

It is possible to use the controller as relay module, so that the

relays are cut in or out by means of an external voltage signal.

• Alarm function

A relay becomes activated when the set alarm limits are exceeded.

• Digital input

The digital input can be used for:

- night operation where the suction pressure is raised

- heat recovery where the condensing pressure is raised

- external start/stop of the regulation.

- Monitoring of safety circuit

• Reverse function

The regulation can be reversed so that the relays are activated

in case of falling temperature, rather than by the rising temperature.

• Possibility of data communication

Display

A signal from a pressure transmitter will always be converted and

shown as a temperature value.

Settings are made as for temperature values.

Function

Capacity regulation

The cut-in capacity is controlled by signals from the connected

pressure transmitter (temperature sensor) and the set reference.

Outside the reference a neutral zone is set where the capacity will

neither be cut in nor out.

Outside the neutral zone (in the hatched areas named +zone and

-zone) the capacity will be cut in or out if the regulation registers

a change of pressure (the temperature) “away” from the neutral

zone. Cutin and cutout will take place with the set time delays.

If the pressure (the temperature) however “approaches” the

neutral zone, the controller will make no changes of the cut-in

capacity.

If regulation takes place outside the hatched area (named ++zone

and --zone), changes of the cut-in capacity will occur somewhat

faster than if it were in the hatched area.

Cutin of steps can be dened for either sequential or cyclic operation.

2 Manual RS8CU502 © Danfoss 08-2012 EKC 331T

Page 3

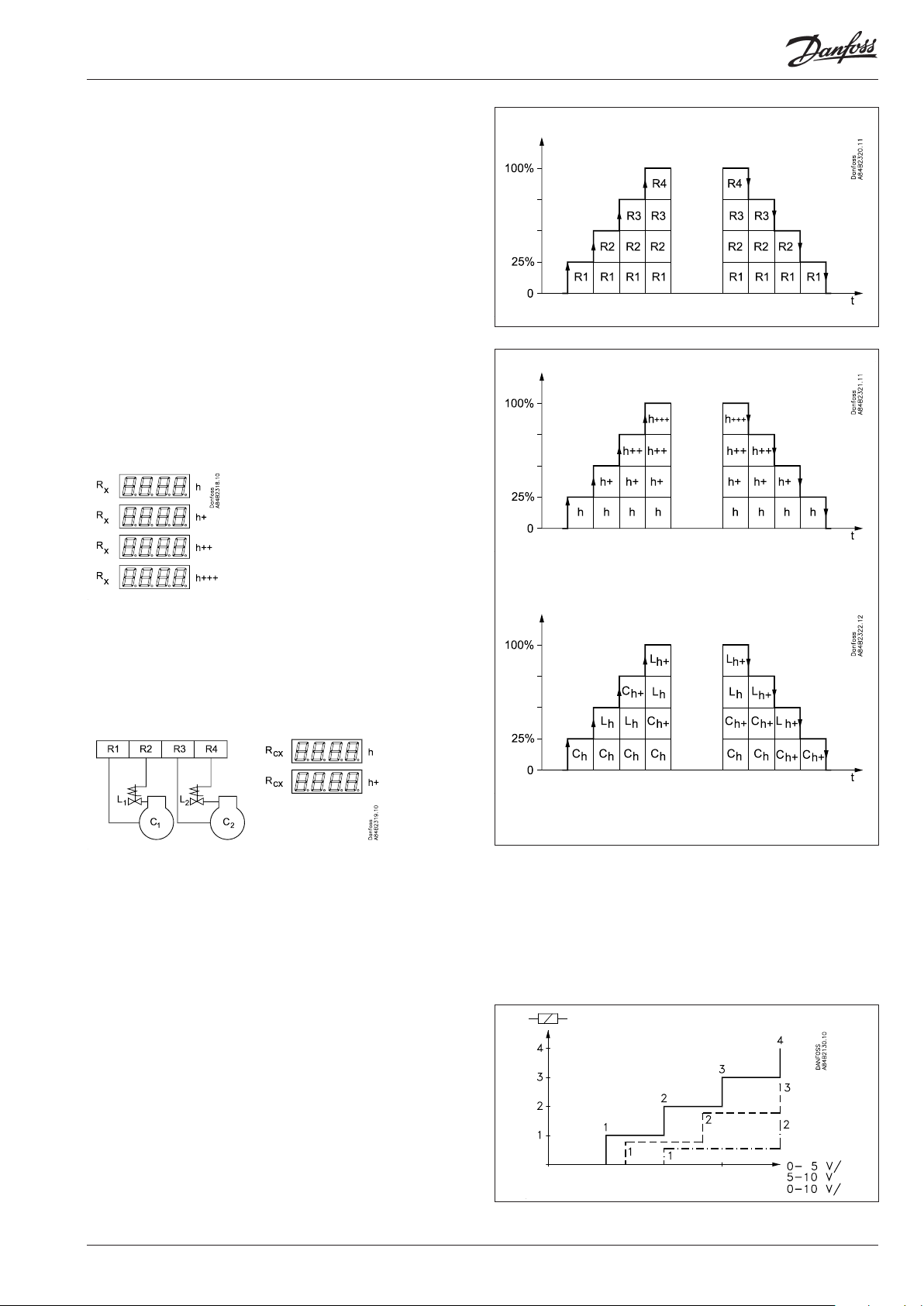

Sequential

The relays are here cut in in sequence – rst relay number 1, then

2, etc.

Cutout takes place in the opposite sequence, i.e. the last cut-in

relay will be cut out rst.

Cyclic

The relays are coupled here so that the operating time of the

individual relays will become equalised.

At each cutin the regulation scans the individual relays’ timer,

cutting in the relay with least time on it.

At each cutout a similar thing happens. Here the relay is cut out

that has most hours on the timer.

Rx = random relay

h = number of hours

If capacity regulation is carried out on two compressors with one

unloader each, the following function can be used:

Relays 1 and 3 are connected to the compressor motor.

Relays 2 and 4 are connected to the unloaders.

Relays 1 and 3 will operate in such a way that the operating time

for the two relays will become equalised.

Relay module

The controller can also be used as a relay module where the relays

in the module are operated by the received voltage signal. The

signal must be connected to terminal 15-16.

Depending on the denition of the signal and the number of

relays used, the relays will be ”distributed” over the signal.

A hysteresis at the individual coupling points will ensure that the

relay will not cut in or out when not required.

C = compressor, L = Unloader

EKC 331T Manual RS8CU502 © Danfoss 08-2012 3

Page 4

Suvey of functions

Function Para-

meter

Normal display

Normally the signal from the pressure transmitter/temperature sensor is shown

If the controller is used as relay module, Uin will appear on the display.

Pressure regulation Reference Settings

Regulation setpoint

Regulation is based on the set value.

A change of the set value can be limited/xed by means of the settings in r02 and r03.

(Push both buttons simultaneously to set the menu.)

Neutral zone

There is a neutral zone around the reference. See also page 2.

Start/stop of refrigeration

With this setting the refrigeration can be started and stopped. Start/stop of refrigeration may also be performed with an external contact function connected to the input

named "DI".

Reference

The set reference may be displaced with a xed value when a signal is received at the

DI input. Regulation will then be based on the set point plus the value set here.

(Cf. also Denition of DI input).

Night setback

OFF: No change of the reference

ON: (1) Oset value in "r13" forms part of the reference

The total reference can be seen when you push the lower of the two buttons - Reference

Reference limitation

With these settings the setpoint can only be set between the two values.

(This also apply if regulation with displacements of the reference).

Max. permissible reference value. r25 Max. reference

Parameter by operation via

data communication

Pressure / Temp°C

- Set point°C

r01 Neutral zone

r12 Main switch

r13 Ref. oset

r27 NightSetback

Min. permissible reference value. r26 Min. reference

Correction of temperature measurement

An oset adjustment of the registered temperature can be made. The function is used

if correction for a too long sensor cable has to be made.

Unit

Here you can select whether the display is to indicate SI units or US units (°C and bar

or °F and psig)

Setting = "C-b" will give °C and bar

Setting = "F-P" will give °F and psig.

All settings made in ° C or ° F. Excluding o20 and o21, which is set in the bar / PSIG.

Capacity Capacity Settings

Running time

To prevent frequent start/stop, values have to be set for how the relays are to cut in

and out.

Min. ON time for relays. c01 Min.ON time

Min. time period between cutin of same relay. c07 Recycle time

Coupling (compressor and condensor)

Cutin and cutout can take place in three ways:

1. Sequential: First relay 1 cuts in, then relay 2, etc. Cutout takes place in the opposite

sequence. (”First in, last out”).

2. Cyclic: An automatic operating time equalisation is arranged here, so that all steps

will have the same operating time. (The relay with the fewest number of operating

hours cuts in or out before the others) (Or put dierently: ”First in, last out”).

3. Compressor(s) with unloader: The cyclic operation is performed on relays 1 and 3.

The unloaders are mounted on relays 2 and 4 (relays 1 and 2 belong to the rst compressor, relays 3 and 4 to the other). The above mentioned ”Min. On-time” and "Min.

recycle time" are not used for unloaders.

In connection with cutout, the two unloaders are cut out before the compressors are

cut out.

r04 Adjust sensor

r05 (In AKM only °C and bar is used, what-

ever the setting)

c08 Step mode

Unloaders’ cutin and cutout mode

(Only in connection with cutin/cutout mode 3. See above).

The relays for the two unloaders can be set to switch on when more capacity is required (setting = no), or they can switch o when more capacity is called for (setting

= nc).

4 Manual RS8CU502 © Danfoss 08-2012 EKC 331T

c09 Unloader

(switch on = 0)

(switch o = 1)

Page 5

Setting for neutral zone regulation

Regulation band under the neutral zone c10 + Zone K

Time delay between step cut-ins in the regulation band over the neutral zone c11 + Zone m

Time delay between step cut-ins in the regulation band over the "+Zone band". c12 + + Zone s

Regulation band over the neutral zone c13 - Zone K

Time delay between step cut-outs in the regulation band under the neutral zone c14 - Zone m

Time delay between step cut-outs in the regulation band under the "-Zone band" c15 - - Zone s

Manual control of compressor capacity

This sets the capacity that is to be cut in when switching to manual control.

Manual control

Manual control of the compressor capacity is enabled here.

When set to ON, the capacity that is set in “c31” is cut in.

Alarm Alarm settings

The controller can give alarm in dierent situations. When there is an alarm all the

light-emitting diodes (LED) will ash on the controller front panel, and the alarm relay

will cut in.

Upper deviation

Here you set when the alarm at high temperature/pressure is to enter into eect. The

value is set as an absolute value.

See also emergency procedure page 7.

Lower deviation

Here you set when the alarm at low temperature/pressure is to enter into eect. The

value is set as an absolute value.

See also emergency procedure page 7.

Alarm delay

If one of the two limit values is exceeded, a timer function will commence. The alarm

will not become active until the set time delay has been passed. The time delay is set

in minutes.

Give the top button a brief push to zeroset the alarm and to have the message shown

on the display.

Miscellaneous Miscellaneous

External signal

Here you set the signal to be connected to the controller.

0: No signal/regulation stopped (display will then show OFF)

1: 4-20 mA from pressure transmitter for compressor regulation

2: 4-20 mA from pressure transmitter for condenser regulation

3: Pressure transmitter type AKS 32R for compressor regulation

4: Pressure transmitter type AKS 32R for condenser regulation

5: 0-10 V from other regulation

6: 0-5 V from other regulation

7: 5-10 V from other regulation

8: Pt1000 ohm temperature sensor for compressor regulation

9: Pt1000 ohm temperature sensor for condenser regulation

10: PTC1000 ohm temperature sensor for compressor regulation

11: PTC1000 ohm temperature sensor for condenser regulation

Number of relays

Depending on the application, up to four relays may be used. This number must be

set in the controller. (The relays are always used in numerical sequence).

Pressure transmitter’s working range

Depending on the pressure, a pressure transmitter with a given working range is

used. This working range must be set in the controller (e.g.: -1 to 12 bar

The values must be set in bar if display in °C has been selected. And in psig, if °F has

been selected.

Min. value o20 Min. Trs. pres

Max. value o21 Max Trs. pres

c31 ManualCap %

c32 ManualCap

- Capacity %

Read cut-in compressor capacity

A10 Max. Al. limit

A11 Min. Al. limit

A03 Alarm delay

Reset alarm

The function zerosets all alarms when

set in pos. ON.

With data communication the importance of the individual alarms can be

dened. Setting is carried out in the

“Alarm destinations” menu.

o10 Application mode

o19 Number of steps

If the two values are to be set from the

AKM programme, they must be set in

bar.

EKC 331T Manual RS8CU502 © Danfoss 08-2012 5

Page 6

Use of DI input

The digital input can be connected to a contact function, and the contact can now be

used for one of the following functions:

Setting / function:

0: DI input not used

1: Regulation reference displaced when contact is cut in

2: Regulation is started and stopped when the contact is cut in and out, respectively.

3: Monitoring of the compressor’s safety circuit. When the contact on the DI input

cuts out, all relay outputs will immediately be cut out. At the same time the alarm will

sound.

Operating hours

The operating hours for the four relays can be read in the following menus. The read

value is multiplied by 1000 to obtain the number of hours. On reaching 999 hours the

display stops and must now be reset to, say, 0. There will be no alarm or error message

for counter overow.

Value for relay number 1 o23 DO 1 run hour

Value for relay number 2 o24 DO 2 run hour

Value for relay number 3 o25 DO 3 run hour

Value for relay number 4 o26 DO 4 run hour

Refrigerant setting

Before refrigeration is started, the refrigeration must be dened. You may choose

between the following refrigerants:

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23. 9=R500.

10=R503. 11=R114. 12=R142b. 13=User dened. 14=R32. 15=R227. 16=R401A.

17=R507. 18=R402A. 19=R404A. 20=R407C. 21=R407A. 22=R407B. 23=R410A.

24=R170. 25=R290. 26=R600. 27=R600a. 28=R744. 29=R1270. 30=R417A.

31=R422A. 32=R413A. 33=R422D. 34=R427A. 35=R438A. 36=XP10. 37=R407F.

Warning: Wrong selection of refrigerant may cause damage to the compressor.

Manual control

From this menu the relays can be cut in and out manually. OFF gives no override, but

a number between 1 and 4 will cut in a corresponding relay. The other relays will be

o.

Frequency

Set the net frequency.

Address

If the controller is built into a network with data communication, it must have an

address, and the master gateway of the data communication must then know this

address.

These settings can only be made when a data communication module has been

mounted in the controller and the installation of the data communication cable has

been completed.

This installation is mentioned in a separate document “RC.8A.C”.

The address is set between 1 and 60 o03

The address is sent to the gateway when the menu is set in pos. ON o04

Access code

If the settings in the controller are to be protected by a numerical code, you can set a

numerical value between 0 and 100. If not, you can cancel the function with setting

OFF.

Cooling or heating

Cooling: Relays are cut in when the temperature is above the reference.

Heating: Relays are cut in when the temperature is below the reference.

o22 Di control

(In the AKM display the hour number

has not been multiplied)

o30 Refrigerant

o18

o12 50/60 Hz

(50=0, 60=1)

Following installation of a data communication module, the controller can

be operated on a par with the other

controllers in ADAP-KOOL® refrigeration controls.

o05

o07 Refg./Heat

6 Manual RS8CU502 © Danfoss 08-2012 EKC 331T

Page 7

Operating status

The controller goes through some regulating situations where it is just waiting for

the next point of the regulation. To make these “why is nothing happening” situations

visible, you can see an operating status on the display. Push briey (1s) the upper

button. If there is a status code, it will be shown on the display. The individual status

codes have the following meanings

S2: When the relay is operated, it must be activated for min. x minutes (cf. C01) 2

EKC state Ctrl. state

(0 = regulation)

S5: Renewed cutin of the same relay must not take place more often than every x minutes (cf.

5

C07)

S8: The next relay must not cut in until x minutes have elapsed (cf. C11-C12) 8

S9: The next relay must not cut out until x minutes have elapsed (cf. C14-C15) 9

S10: Regulation stopped with the internal og external start/stop 10

S20: Emergency control 20

S25: Manual regulation of outputs 25

PS: Password required. Set password PS

Alarm messages

Alarms

A1: High temperature alarm (cf. A10) High temp. alarm

A2: Low temperature alarm (cf. A11) Low temp. alarm

A11: No refrigerant has been selected (cf. o30) RFG not selected

A12: Regulation stopped due to interrupted signal on the DI input DI Alarm

A45: Regulation stopped with setting or with external switch A45 Stand by

E1: Error in the controller Controller fault

E2: Control signal outside the range (short-circuited/interrupted) Out of range

Service

u07: Voltage signal on the analogue input

u10: Status on DI- input

u15: Status on relay output DO1

u25: Signal on pressure transmitter input (bar / PSIG)

u58: Status on relay output DO2

u59: Status on relay output DO3

u60: Status on relay output DO4

u62: Status on relay output "alarm"

Warning ! Direct start of compressors *

To prevent compressor breakdown parameter c01 and c07 should be set according to suppliers requirements or in general :

Hermetic Compressors c07 min. 5 minutes

Semihermetic Compressors c07 min. 8 minutes and c01 min. 2 to 5 minutes ( Motor from 5 to 15 KW )

* ) Direct activating of solenoid valves does not require settings dierent from factory (0)

Emergency procedure

If the controller registers irregularities in the registered signals, it will start an emergency procedure:

For compressor regulation:

- If the signal from the temperature sensor/pressure transmitter becomes smaller than expected, the controller will continue operating

with the average capacity that has been cut in during the past 60 minutes. This cut-in capacity will gradually decline as time passes.

- If the signal becomes smaller than the set value of A11, the capacity will instantly be cut out.

For condenser regulation:

- If the signal from the temperature sensor/pressure transmitter becomes smaller than expected, or if the condensing pressure becomes

bigger than the set value of A10, the entire capacity will in stantly be cut in.

EKC 331T Manual RS8CU502 © Danfoss 08-2012 7

Page 8

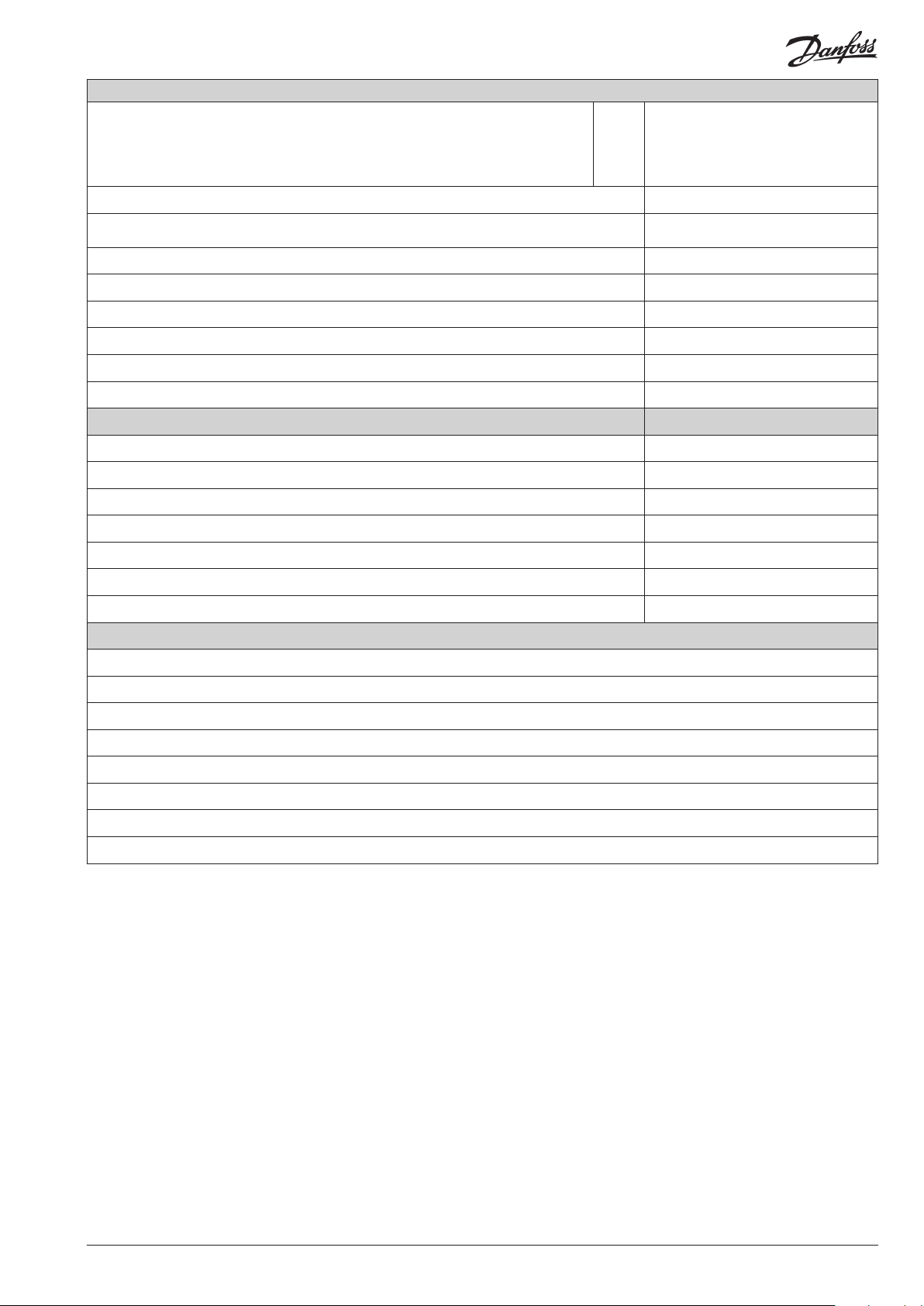

Operation Menu survey

Display

The values will be shown with three digits, and with a setting you

can determine whether the temperature are to be shown in °C or

in °F.

Light-emitting diodes (LED) on front panel

There are four LED’s on the front panel which will light up when

the relays are operated.

All LED’s will ash if there is an error in the regulation. In this situation you can upload the error code on the display and cancel the

alarm by pushing the top button briey.

The controller can give the following messages:

E1

Error message

E2

A1

A2 Low pressure alarm

A11 No refrigerant selected

Alarm message

A12

A45 Regulation is stopped

PS Password is required

Errors in the controller

Regulation out of range or control signal is

defect.

High pressure alarm

Regulation stopped due to interrupted signal

on the DI input

The buttons

When you want to change a setting, the two buttons will give you

a higher or lower value depending on the button you are pushing. But before you change the value, you must have access to the

menu. You obtain this by pushing the upper button for a couple

of seconds - you will then enter the column with parameter codes.

Find the parameter code you want to change and push the two

buttons simultaneously. When you have changed the value, save

the new value by once more pushing the two buttons simultaneously.

Gives access to the menu

Gives access to changes

Saves a change

(or cutout an alarm)

Examples of operations

Set the regulation’s set point

1. Push the two buttons simultaneously

2. Push one of the buttons and select the new value

3. Push both buttons again to conclude the setting

Set one of the other menus

1. Push the upper button until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push both buttons simultaneously until the parameter value is

shown

4. Push one of the buttons and select the new value

5. Push both buttons again to conclude the setting

Function

Normal display

Shows the signal from the temperature sensor /

pressure transmitter

Reference

Set the regulation’s set point

Neutral zone

Correction of signal from the sensor

Select SI or US display:

0=SI (bar/°C). 1=US (Psig/°F)

Start / stop of regulation (0=o) r12 0 1 0

Reference displacement by signal at DI input

Reference limitation. Max. value r25 -50°C 170°C 50°C

Reference limitation. Min. value r26 -60°C 50°C -60°C

Displacement of reference (On=activ "r13") r27 O

Capacity

Min. ON time for relays

Min. time period between cutins of same relay

Denition of regulation mode

1: Sequential (step mode / FILO)

2: Cyclic (step mode / FIFO)

3: Compressor with unloader

If the regulation mode 3 has been selected, the

relays for the unloaders can be dened to:

no: Cut in when more capacity is required

nc: Cut out when more capacity is required

Regulation parameter for + Zone

Regulation parameter for + Zone min.

Regulation parameter for ++ Zone seconds

Regulation parameter for - Zone

Regulation parameter for - Zone min.

Regulation parameter for - - Zone seconds

Cutin capacity at manual control. See also "c32" c31 0%

Manual control of capacity (when On the value in

"c31" will be used*)

Alarm

Alarm time delay

Upper alarm limit (absolute value)

Lower alarm limit (absolute value)

Miscellaneous

Controllers address

On/o switch (service-pin message)

Access code

Inverse function (HE: heating at relays = on) o07 rE HE rE

Dene input signal and application:

0: no signal / regulation stopped

1: 4-20 mA pressure transmitter - compressor reg.

2: 4-20 mA pressure transmitter - condenser reg.

3: AKS 32R pressure transmitter - compressor reg.

4: AKS 32R pressure transmitter - condenser reg.

5: 0 - 10 V relay module

6: 0 - 5 V relay module

7: 5 - 10 V relay module

8: Pt 1000 ohm sensor - compressor reg.

9: Pt 1000 ohm sensor - condenser reg.

10: PTC 1000 ohm sensor - compressor reg.

11: PTC 1000 ohm sensor - condenser reg.

Set supply voltage frequency

Manual operation with “x” relays

Parame-

Min. Max.

ter

-

- -60 °C 170 °C 3

r01 0,1 K 20 K 4.0

r04 -20 K 20 K 0.0

r05 c-b F-P c-b

r13 -50 K 50 K

c01 0 min. 30 min 2

c07 0 min. 60 min. 4

c08 1 3 1

c09 no nc no

c10 0,1 K 20 K 3

c11 0,1 min. 60 min. 2

c12 1 s 180 s 30

c13 0,1 K 20 K 3

c14 0,1 min. 60 min. 1

c15 1 s 180 s

c32 O

A03 1 min. 90 min. 30

A10 -60 °C 170 °C 50

A11 -60 °C 120 °C

o03* 1 240 0

o04* - - -

o05 o(-1) 100 -

o10 0 11 0

o12 50 Hz 60 Hz 50

o18 0 4 0

Factory

setting

°C -

0

On O

30

100% 0%

On O

-60

Continued

SW: 2.0x

8 Manual RS8CU502 © Danfoss 08-2012 EKC 331T

Page 9

Dene number of relay outputs

Pressure transmitter’s working range - min. value

Pressure transmitter’s working range - max. value

Dene DI input:

0: not used

1: Contact displaces reference

2: Contact starts and stops regulation

3: Interrupted contact will cut out the capacity,

and alarm will be given.

Operating hours of relay 1 (value times 1000)

Operating hours of relay 2 (value times 1000)

Operating hours of relay 3 (value times 1000)

Operating hours of relay 4 (value times 1000)

Setting of refrigerant

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717.

6=R13. 7=R13b1. 8=R23. 9=R500. 10=R503.

11=R114. 12=R142b. 13=User dened. 14=R32.

15=R227. 16=R401A. 17=R507. 18=R402A.

19=R404A. 20=R407C. 21=R407A. 22=R407B.

23=R410A. 24=R170. 25=R290. 26=R600.

27=R600a. 28=R744. 29=R1270. 30=R417A.

31=R422A. 32=R413A. 33=R422D. 34=R427A.

35=R438A. 36=XP10. 37=R407F.

*) This setting will only be possible if a data communication moduel has been

installed in the controller.

o19 1 4 4

o20 -1 bar 5 bar -1

o21 6 bar 199 bar

o22 0 3 0

o23 0 h 99,9 h 0

o24 0 h 99,9 h 0

o25 0 h 99,9 h 0

o26 0 h 99,9 h 0

o30 0 37 0

Service

12

Voltage on the analogue input u07

Status on DI- input u10

Status on relay output DO1 u15

Signal on pressure transmitter input (bar / PSIG) u25

Status on relay output DO2 u58

Status on relay output DO3 u59

Status on relay output DO4 u60

Status on relay output "alarm" u62

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep both buttons depressed at the same time as you recon nect the supply voltage

Data

Supply voltage 230 V a.c. +/-15% 50/60 Hz, 5 VA

Pressure transmitter*) with 4-20 mA or

temperature sensor Pt 1000 ohm or

Input signal

Relay output 4 pcs. SPST

Alarmrelay 1 pcs. SPST

Data communication

Environments

Enclosure IP 20

Weight 300 g

Mounting DIN rail

Display LED, 3 digits

Terminals max. 2.5 mm2 multicore

Approvals

*) Pressure transmitter

As pressure transmitter can be used AKS 3000 or AKS 33

(AKS 33 has a higher accuracy than AKS 3000).

It is also possible to use an AKS 32R.

Please refer to catalogue RK0YG...

temperature sensor PTC 1000 ohm or

voltage signal (0 - 5 V, 0 - 10 V or 5 - 10 V)

Digital input to external contact function

AC-1: 4 A (ohmic)

AC-15: 3 A (inductive)

AC-1: 4 A (ohmic)

AC-15: 1 A (inductive)

Possible to connect a data communication

module

-10 - 55°C, during operation

-40 - 70°C, during transport

20 - 80% Rh, not condensed

No shock inuence / vibrations

EU Low voltage Directive and EMC demands re

CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 607302-9

EMC-tested acc. to EN 61000-6-3 and EN 610004-(2-6,8,11)

Ordering

Type Function Code No.

EKC 331T Capacity controller 084B7105

EKA 175

Data communication module

(accessories), (RS 485 module)

084B8579

EKC 331T Manual RS8CU502 © Danfoss 08-2012 9

Page 10

Connections

Necessary connections

Terminals:

25-26 Supply voltage 230 V a.c.

3- 10 Relay connections no. 1, 2, 3 and 4

12-13 Alarm relay

There is connection between 12 and 13 in alarm situa tions

and when the controller is dead

Control signal (see also o10)

Either terminals:

14-16 Voltage signal from AKS 32R

or

17-18 Current signal from AKS 3000 or AKS 33

or

15-16 Sensor signal from AKS 21, AKS 12 or EKS 111

or

15-16 Voltage signal from an other regulation.

External contact function, if applicable

19-20 Contact function for displacement of reference or start/

stop of the regulation or for monitoring of safety circuit.

Data communication, if applicable

21-22 Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communication cable be done correctly. Cf. separate literature No.

RC8AC...

Black

Brown

Blue

Data communication

10 Manual RS8CU502 © Danfoss 08-2012 EKC 331T

Page 11

EKC 331T Manual RS8CU502 © Danfoss 08-2012 11

Page 12

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

12 Manual RS8CU502 © Danfoss 08-2012 EKC 331T

ADAP-KOOL®

Loading...

Loading...