Page 1

User Guide

Controller to regulate

CO2 gas pressure

EKC 326A

ADAP-KOOL® Refrigeration control systems

Page 2

Introduction

Application

The controller can be used in systems with transcritical and subcritical cooling control systems where CO2 is used as a refrigerant.

The controller regulates the pressure in the gas cooler (condenser) so that the system achieves the optimal COP.

The controller covers the following:

• Transcritical CO2 refrigeration systems (booster, cascade, high

pressure)

• Transcritical CO2 heat pump systems

• Transcritical CO2 refrigeration systems with heat recovery

• Transcritical CO2 chiller systems

• Extra capacity in warm periods. An improvement in the system’s

cooling performance can be achieved by displacement of the

set point (“extra compressor")

Advantages

• Maximum COP

The controller guarantees the system’s maximum performance

by maintaining the optimal pressure in the gas cooler when

regulation takes place in the transcritical range.

• The controller will always optimise to a subcritical state.

• Regulating the receiver pressure based on the receiver pressure

reading

• Heat recovery with adjustable reference pressure, 0-10 V

• Optimum heat pump operation

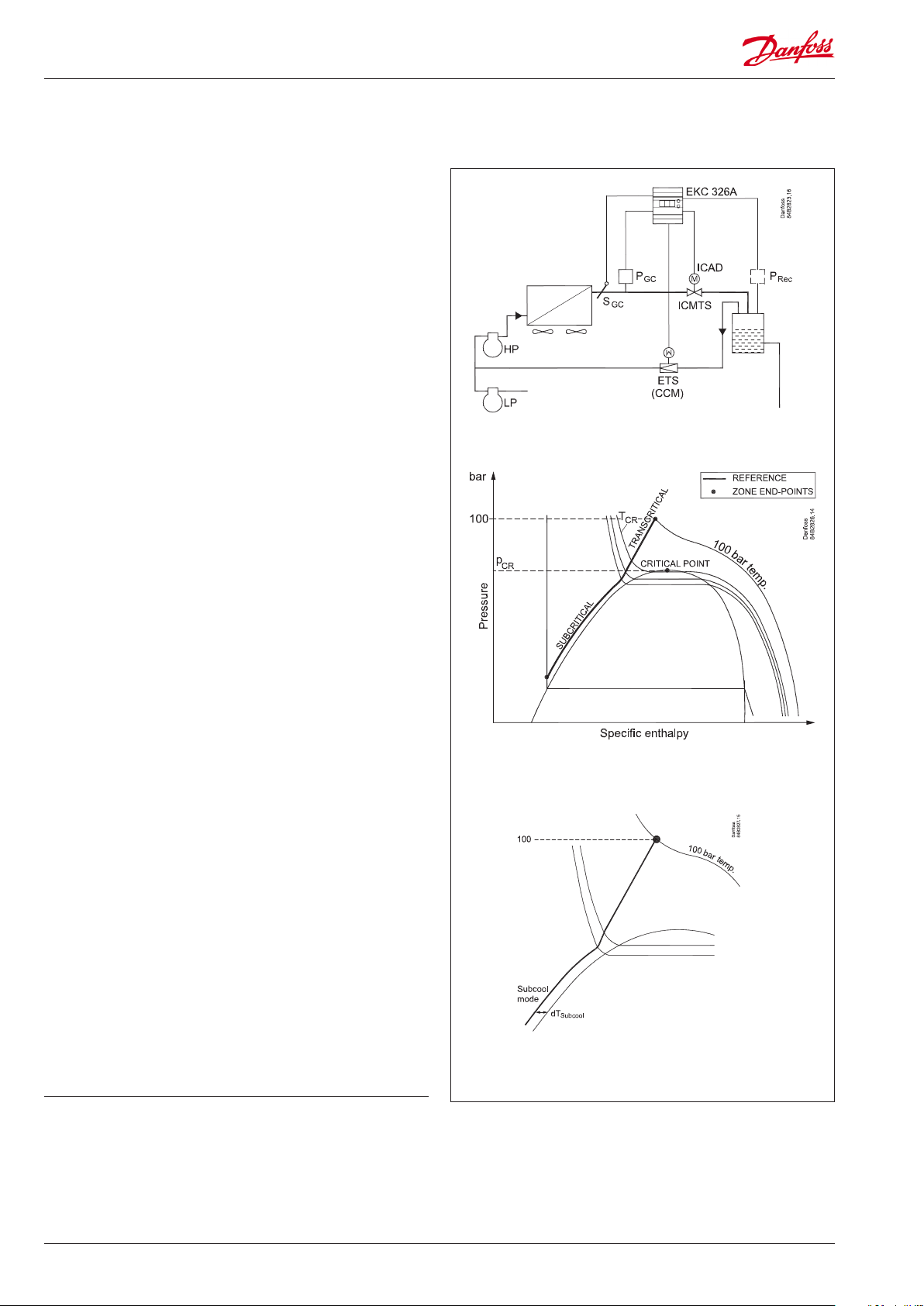

System

The pressure in the gas cooler is controlled by the valve. Regulation must have inputs from both a pressure transmitter PGC and

a temperature sensor SGC. Both must be tted in the outlet immediately after the gas cooler.

The valve is an ICMTS valve, which has been specially developed

for the pressure conditions that exist in a transcritical CO2 system.

The motor section of the valve is an ICAD actuator and is controlled by a 0-10 V signal from the controller.

If it is necessary to maintain a constant receiver pressure, a valve

(ETS, CCM or CCMT) and pressure transmitter (Prec) can be installed. The gas from the receiver bypasses to the inlet side of the

high pressure compressor.

Functions

Maximum COP control

The controller maintains optimum pressure in the transcritical

range based on a pressure and temperature reading.

The reference line is dened with a point at 100 bar. The desired

temperature can be set here.

Subcooling

d T subcooling can be used in the subcritical range.

Contents

Introduction ....................................................................................................... 2

Examples ............................................................................................................. 4

Survey of functions .......................................................................................... 6

Operation .......................................................................................................... 10

2 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

Menu survey .....................................................................................................10

Connections ..................................................................................................... 11

Data ..................................................................................................................... 13

Ordering ............................................................................................................13

Appendix ........................................................................................................... 14

Page 3

Receiver control

The receiver pressure can be controlled so that it is kept at a set

reference point. This control requires the installation of an ETS

valve a (CCM valve) and a pressure transmitter.

If only monitoring and not control is required, the valve should

not be installed. Install the pressure transmitter only.

Ensuring that the receiver pressure is not too low

A limit value can be set, and if the pressure falls below this value,

the ICMTS valve will be opened. The valve will then open gradually

through the associated P band. Open to the value "n32" ( Vhp OD

Max).

Protecting against high receiver pressure

A limit value can be set, and if the pressure rises beyond this value,

the ICMTS valve will be closed. The valve will then close gradually

through the associated P band.

Extra refrigeration capacity (“extra compressor”)

This function improves the system’s refrigeration capacity by

increasing the reference pressure in the gas cooler with a oset

value.

It is activated via a switch function.

Heat recovery or heat pump

This function will increase the gas pressure to a set value. This

value will be equivalent to a specic temperature.

The value can either be xed or can vary in accordance with an

input signal of 0-10 V as follows:

A signal of 1.5 V or above can activate the function and increase

the reference to Pgc HR Min.

If a variable reference is required, then a signal between 2-10 V

can be connected. The signal will increase the reference further.

This function works both in subcritical and transcritical ranges.

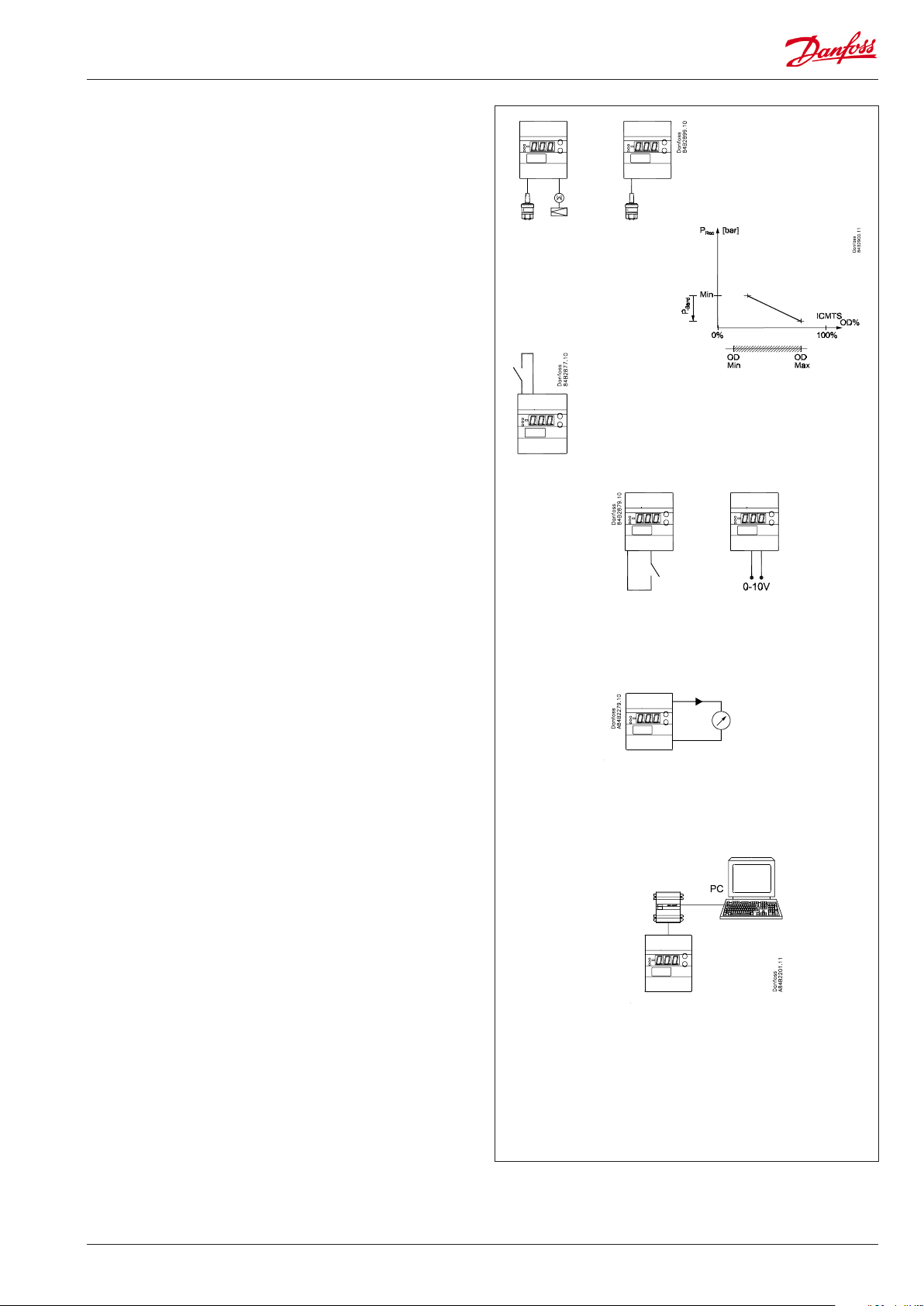

Output signal

The controller has a voltage output on 0-10 V. The signal is used to

control the ICMTS valve via the ICAD actuator.

Valves opening degree

The opening degree of both ICMTS and ETS valves (CCM valve)

can be narrowed if necessary.

PC-operation

The controller can be provided with data communication so that it

can be connected to other products in the range of ADAP-KOOL®

refrigeration controls. In this way operation, monitoring and data

collection can be performed from one PC – either on the spot or in

a service company.

Temperature reading

The temperature by the gas cooler must be measured using a Pt

1000 ohm sensor type AKS 21.

The sensor must be mounted immediately next to the gas

cooler outlet to produce a correct signal.

Pressure reading (bar)

The pressure by the gas cooler must be measured using a pressure

transmitter type AKS 2050.

The pressure transmitter must be mounted immediately next

to the gas cooler outlet to produce a correct signal.

Emergency cooling

The valve's average opening degree for the last six hours is

regularly saved. This opening degree is used if there is a need for

emergency cooling.

EKC 326A Manual RS8FM602 © Danfoss 02-2016 3

Page 4

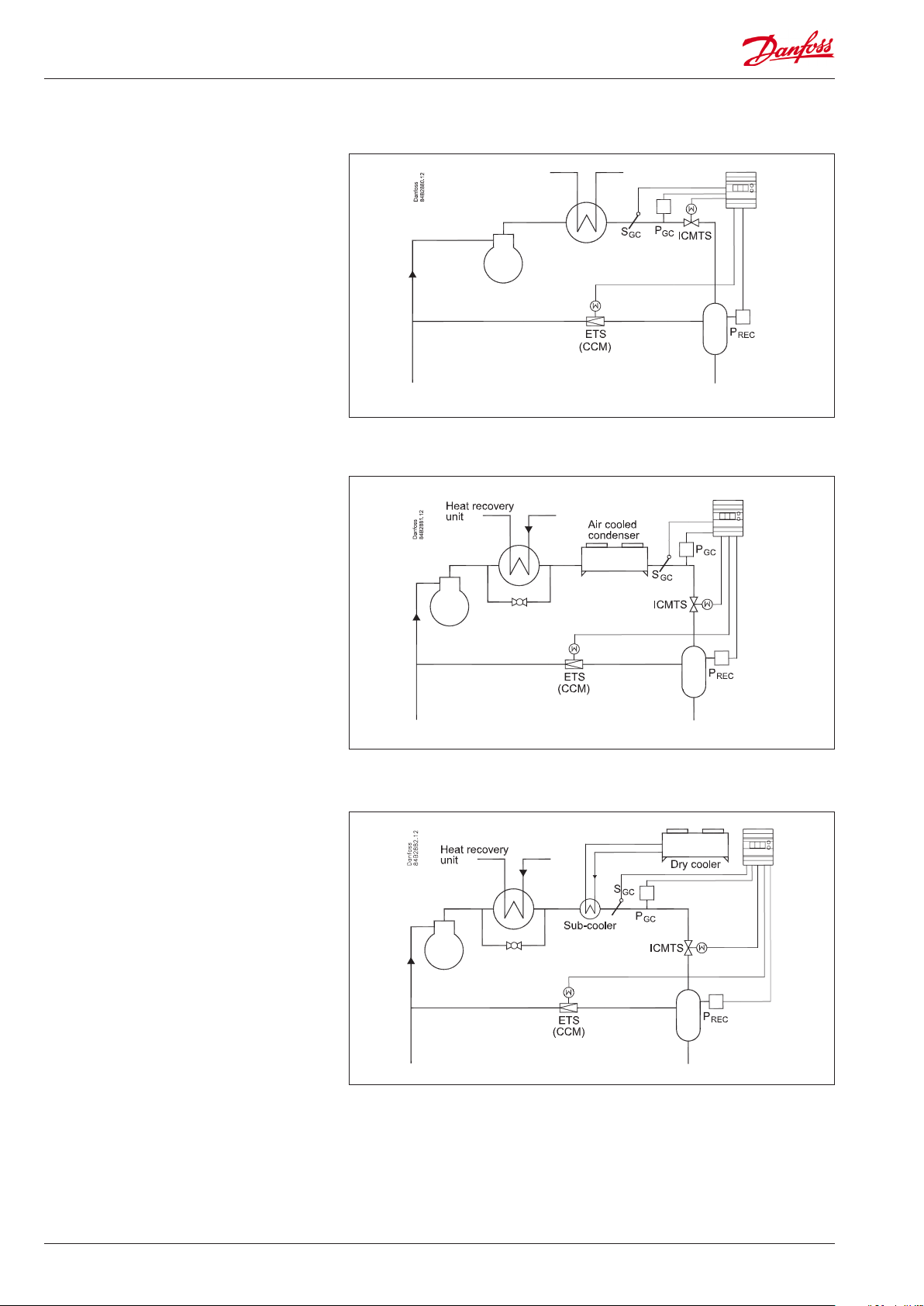

Examples

Simple heat recovery system

Partial heat recovery system

Heat recovery system

(or heat pump system)

4 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

Page 5

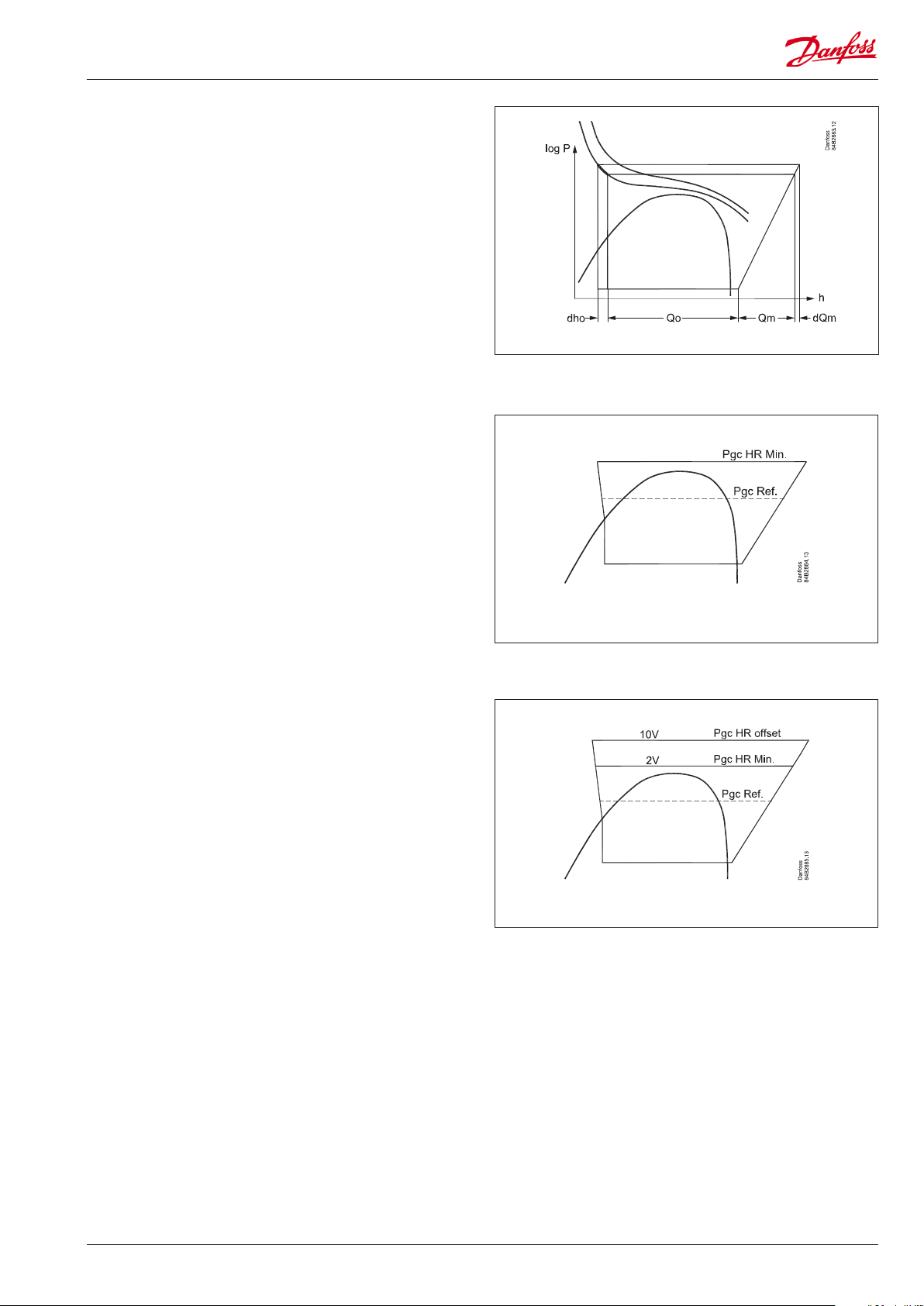

Extra refrigeration capacity (“extra compressor”)

This function improves the system’s refrigeration capacity by

increasing the reference pressure (Pgc Ref) in the gas cooler. The

cooling performance increases to Q0+dh0.

The function also increases the load on the compressor motor as

pressure increases. Power consumption increases to Qm+dQm.

Increasing pressure reference with heat recovery

The function will increase the gas pressure reference to the Pgc HR

Min. value when it receives a signal.

The function is activated by an on/o signal at the voltage input.

Increasing pressure reference with heat recovery, variable

reference

The function will increase the gas pressure reference to the value

where it receives a signal.

The function is activated by a voltage signal between 0-10 V.

• Between 0-2 V it is regulated normally

• At 2 V the reference changes to the setting “Pc HR Min”

• At 10 V the reference will increase further using the setting

“Pgc HR oset”

• Between 2-10 V the reference is variable.

EKC 326A Manual RS8FM602 © Danfoss 02-2016 5

Page 6

Survey of functions

Function Para-

meter

Normal display

The normal display shows the pressure in the gas cooler. The pressure is measured

using Pgc. The measurement can also be seen in menu U06.

The control reference can be viewed by pressing both buttons.

If a pressure transmitter is mounted to display the receiver pressure, the measurement can be brought up on the display by pressing the lower button. The measurement can also be seen in menu U07.

Gas pressure control Gas cooler control

Dening the reference line

Set the end point for the reference line in the transcritical range. Set the desired temperature value at 100 bar.

The reference

The reference is pre-programmed to follow the optimal COP from the pressure/enthalpy chart. See the illustration on page 2.

The current reference can be read o in menu U03.

Start/stop of regulation

This setting can be used to start and stop regulation.

Stopping regulation will always cause the valve will close at the value set in "n87" and

"n93".

The function in o02 requires that it has been dened.

Max. opening degree

The ICMTS-valve’s opening degree can be limited here.

Limitation takes place by limiting the voltage signal that is sent to the valve actuator.

The setting is expressed as a % of the total opening degree. The voltage signal of 0-10

V on the output will be limited correspondingly.

Minimum opening degree

The closing degree of the ICMTS valve can be limited here.

Limitation takes place by increasing the lower part of the voltage signal that is sent to

the valve actuator.

The setting is expressed as a percentage of the total opening degree. The output voltage signal of 0-10 V will be limited correspondingly.

The gas cooler’s max. pressure

This is where you dene the maximum pressure permitted in the gas cooler. If the

pressure reaches this value, the valve is open as set in "n32 OD max".

P-band to force open the valve from normal regulation

P-band under “n69, Pgc Max lim”, where the valve is forced open so that the valve is

fully open if the pressure reaches “n69, Pgc Max lim”.

The pressure is not critical, so opening of the valve will take place under controlled

conditions.

The gas cooler’s min. pressure

This is where you dene the minimum pressure permitted in the gas cooler.

Parameter by operation via

data communication

U06

Pgc bar

U07

Prec bar

n99 T100

U03 Pgc Ref

r12 Main Switch

n32 Vhp OD Max

n87 Vhp OD Min

n69 Pgc Max

n70 Pgc P-band

n81 Pgc Min

Subcooling is required to be regulated according to temperature

Set the desired subcooling in K.

P: Amplication factor Kp

If the Kp value is reduced the regulation becomes slower.

I: Integration time Tn

If the Tn value is increased the regulation becomes slower

Increasing refrigeration capacity

This function increases the gas pressure reference. Control moves from optimum

COP control to maximum refrigeration control. (The pressure increases, temperature

remains unchanged and the total heat content increases.)

Set the pressure increase value.

The function is activated by closing the switch function on terminals 1 and 2. (see

o02)

6 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

n79 dT Subcool

n04 Kp Gascool

n05 Tn Gascool

n88 Pgc Cap Oset

Page 7

Minimum pressure reference during heat recovery

The function can only be used if heat recovery or heat pumps are also used in the system.

The function will increase the gas pressure to the set value when it receives a signal.

The function is activated by a voltage signal at the input to terminal 20. A voltage

over 1.5 V will activate the function. (Please install a support relay if there is any risk of

error signals, e.g. with long wires.)

If the function is only required for displacement, r68 should be set to 0.

(The gas pressure can be further increased using the r68 function.)

Displacement of the control reference during heat recovery

This function increases the reference to a value above the n89 setting, but no higher

than the set value.

Displacement occurs when an input voltage of above 2 V is received for terminal 20.

The new reference is: Setting in n89 + displacement.

The value of the displacement is determined by the voltage signal and the setting for

r68.

10 V gives maximum displacement, i.e. the set value. 2 V or below will give nothing.

Displacement is linear between 2 and 10 V.

Ramp for reference modication

This can be used to set the speed at which the reference must drop again following

heat recovery (number bar/min). The function is only active after heat recovery is

complete.

Receiver control Receiver pressure control

Receiver control

Whether control of the receiver pressure should take place is dened here.

On: ETS (CCM) control. Alarm active

O: No ETC (CCM) control. No alarm. Pressure control is active

Receiver reference

The reference for receiver control is set here.

n89 Pgc HR Min

r68 Pgc HR oset

r65 Pgc Ref Ramp

n90 Prec. Ctrl

n91 Prec Ref

Maximum opening degree

The ETS (CCM) valve’s opening degree can be limited here. The setting is expressed as

a percentage of the total opening degree.

Minimum opening degree

The closing degree of ETS (CCM) valves can be limited here. The setting is expressed

as a percentage of the total opening degree.

Min. pressure in the receiver

The function monitors the pressure in the receiver and will start to force open the

ICMTS-valve if the pressure falls below the preset value. The value must be at least 1

bar below the reference. The function is deactivated if n72 is set to 0.

P-band to force open the ICMTS-valve if the receiver pressure is too low

P-band under “n71, Prec Min” when the valve is forced open.

If the pressure falls to n71 minus n72, the ICMTS valve will open to the value in n32,

Vhp OD Max. An alarm is then transmitted.

The pressure is not critical, so opening of the valve will take place under controlled

conditions.

P: Amplication factor Kp

If the Kp value is reduced the regulation becomes slower.

I: Integration time Tn

If the Tn value is increased the regulation becomes slower

Actuator type

If receiver control takes place, the type of valve should be set:

0: ETS 12½, ETS 25, CCM 10, CCM 20

1: ETS 50, CCM 30

2: ETS 100, CCM 40

3: ETS 250

4: ETS 400

5: Other type. "n37" and "n38" should also be set when the setting = 5

("n37" and "n38" are automatically set for settings 0 to 4)

6: CCMT 2, 4, 8

ETS (CCM) setting

Number of steps open from 0-100%

Automatically set when "n03" is set to 0, 1, 2, 3, 4 or 6

ETS (CCM) setting

Speed of spindle travel (no. of steps per second)

Automatically set when "n03" is set to 0, 1, 2, 3, 4 or 6

n92 Vgbp OD Max

n93 Vgbp OD Min

n71 Prec Min

n72 Prec Min Pband

n60 Kp Receiver

n61 Tn Receiver

n03 Valve type

n37 Max. steps

n38 Steps / sec

EKC 326A Manual RS8FM602 © Danfoss 02-2016 7

Page 8

Max. pressure in the receiver

The function monitors the pressure in the receiver and will initiate the closing of the

ICMTS valve if the pressure exceeds the preset value. The value must be at least one

bar over the reference. The function is not activated when 'n59' is set to 0.

(If n70 is active and attempts to open the valve, n58 will not be active.)

P-band to force closing the ICMTS-valve if the receiver pressure is too high

P-band over “n58, Prec Max” when the valve is forced closed.

If the pressure becomes 'n58' plus 'n59', the ICMTS valve will be closed.

The closing of the valve will take place under controlled conditions.

Miscellaneous

Digital input signal - DI (terminal 1 and 2)

The controller has a digital input which can be used for one of the following functions:

0: The input is not used

1: External main switch (se also r12)

2: Increasing the pressure in the gas cooler (additional cooling capacity). (closed DI =

additional capacity)

Address

If the controller is built into a network with data communication, it must have an

address, and the master gateway (system unit) of the data communication must then

know this address.

These settings can only be made when a data communication module has been

mounted in the controller and the installation of the data communication cable has

been completed.

This installation is mentioned in a separate document “RC8AC”

The address is set between 0 and 119 (999) o03 -

The address is sent to the gateway when the menu is set in pos. ON

(The setting will automatically change back to O after a few seconds.)

n58 Prec Max

n59 PrecMaxPband

o02 DI Cong

o04 -

Following installation of a data communication module, the controller can

be operated on a par with the other

controllers in ADAP-KOOL® refrigeration controls.

Frequency

Set the net frequency.

Pressure transmitter denition for Pgc. Pressure transmitter lower limit o20 MinTransPgc

Pressure transmitter denition for Pgc. Pressure transmitter upper limit o21 MaxTransPgc

Pressure transmitter denition for Prec. Pressure transmitter lower limit o47 MinTransPrec

Pressure transmitter denition for Prec. Pressure transmitter upper limit o48 MaxTransPrec

Alarm settings Alarm settings

Pgc Min alarm limit

An alarm is issued if the value is exceeded

Permitted variation in relation to Pgc reference

An alarm is issued if the Pgc pressure falls below or exceeds the permitted variation,

but only once the delay time has expired. This is an 'A94 PgcRef alarm'.

Permitted variation in relation to the Prec reference

An alarm is issued if Prec pressure exceeds or falls below the permitted variation, but

only once the delay time has expired. This is an 'A95 PrecRef alarm'.

Delay time for 'A94 PgcRef alarm' A68 PgcAlDelay

Delay time for 'A95 PrecRef alarm' A69 PrecAlDelay

Service

A number of controller values can be printed for use in a service situation

Read input voltage at Ai-input u07 AI Volt

Read status of input DI (start/stop input)

Opening degree for ETS (CCM) valve u24 Vgbp OD %

Calculated reference for regulation (desired pressure in the gas cooler) U03 Pgc Ref

The output signal to the high pressure valve ICMTS converted into opening degree U04 Vhp OD %

The temperature in the gas cooler. Measured using temperature sensor Sgc. U05 Sgc temp.

The pressure in the gas cooler. Measured using pressure transmitter Pgc. U06 Pgc bar

The pressure in the receiver. Measured using pressure transmitter Prec, but only if it is

mounted.

o12 50 / 60 Hz

(50=0, 60=1)

A65 PgcMin AlLim

A66 PgcAl Limit

A67 PrecAl Limit

u10 DI

U07 Prec bar

8 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

Page 9

Operating status

The controller’s operating status can be called forth by a brief (1s) activation of the

upper button. If a status code exists it will be shown. (Status codes have lower priority

than alarm codes. This means that status codes cannot be seen if there is an active

alarm code.

The individual status codes have the following meanings:

S10 (o): Regulation stopped by the internal start/ stop. 10

S20: Emergency cooling is activated because of defect sensor 20

S42: Heat recovery or heat pump control is active 42

S43: Higher capacity through displacement of the pressure reference 43

Alarms

E1: Fault in controller Controller fault

E15: Cut-out Sgc sensor Sgc o.c.

E16: Short circuited Sgc sensor Sgc S.C.

E20: Fault on the signal from Pgc Sgc input err

E39: Fault on the signal from Prec Prec input err

A43: Step motor error. Output or phase Step motor err

A45: Regulation stopped. Main switch r12 = o Standby mode

A82: The Pgc gas pressure measured is higher than the maximum limit for n69 PgcMax alarm

A83: The Pgc gas pressure measured is lower than the minimum limit for A65 PgcMin alarm

A84: The receiver pressure measured is lower than "n71" minus "n72" PrecMin alarm

A94: Pgc gas pressure measured is outside the permitted reference PgcRef alarm

A95: Prec receiver pressure measured outside the permitted reference PrecRef alarm

EKC State

(0 = regulation)

EKC 326A Manual RS8FM602 © Danfoss 02-2016 9

Page 10

Operation Menu survey

Display

The values will be shown with three digits.

Temperature are to be shown in °C and pressure in bar.

Light-emitting diodes (LED) on front panel

The four LED’s will ash, if there is an error in the regulation.

In this situation you can upload the error code on the display and

cancel the alarm by giving the uppermost button a brief push.

The controller can give the following messages:

E1

E15 Cut-out Sgc sensor

Error message

E16 Short circuited Sgc sensor

E20 Fault on the signal from Pgc

E39 Fault on the signal from Prec

A43

A45 Regulation stopped. Main switch r12 = o

A82

A83

Alarm message

A84

A94 Pgc alarm limit "A66" is exceeded

A95 Prec alarm limit "A67" is exceeded

Fault in controller

Step motor error. Output or phase

The Pgc gas pressure measured is higher than the

maximum limit for n69

The Pgc gas pressure measured is lower than Pgc

min (A65)

The receiver pressure measured is lower than "n71"

minus "n72"

The buttons

When you want to change a setting, the two buttons will give you

a higher or lower value depending on the button you are pushing. But before you change the value, you must have access to the

menu. You obtain this by pushing the upper button for a couple

of seconds - you will then enter the column with parameter codes.

Find the parameter code you want to change and push the two

buttons simultaneously. When you have changed the value, save

the new value by once more pushing the two buttons simultaneously.

Gives access to the menu

Gives access to changes

Saves a change

(or cutout an alarm)

Examples of operations

Set a menus

1. Push the upper button until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push both buttons simultaneously until the parameter value is

shown

4. Push one of the buttons and select the new value

5. Push both buttons again to conclude the setting

Function

Normal display

Shows the current pressure after the gas cooler

Pushing both buttons briey will display the

reference

Pushing the bottom button briey will display

Prec.

Start / stop

Start / stop of regulation r12 OFF (0) On (1) On (1)

Ramp for reference after heat recovery r65 0.1 20 1

Displacement of the Pgc minimum reference

(n89) during heat recovery. (Displacement value

at 10 V)

Alarm Settings

Alarm limit for Pgc Min. A65 0 bar 200 bar 40

Permitted Pgc reference variation

0 = no alarm function (recommended)

Permitted Prec reference variation

0 = no alarm function (recommended)

Delay time for 'A94' Pgc reference alarm A68 5 min. 360 min 15

Delay time for 'A95' Prec reference alarm A69 5 min. 360 min 15

Regulating parameters

Actuator type for receiver control

0=ETS12,5/25 / CCM10/20,

1=ETS50 / CCM30, 2=ETS100 / CCM40,

3=ETS250, 4=ETS400,

5=User dened (set: n37 and n38)

6=CCMT2/4/8

P: Amplication factor Kp n04 0.5 20 2.0

I: Integration time Tn n05 10 s 600 s 75

Max. opening degree. of the valve n32 0 100 100

Number of steps from 0-100% opening degree

(x10) **

Number of steps per second n38 0 300 250

Max. permitted receiver pressure, Prec n58 10 bar 200 bar 60

P-belt beyond PrecMax for valve to close n59 0 bar 60 bar 0

P: Amplication factor Kp for receiver n60 0.5 20 5

I: Integration time Tn for receiver n61 10 600 75

The gas cooler’s max. pressure

This is where you set the maximum pressure permitted in the gas cooler. If the pressure reaches

this value, the valve is fully open.

P-band under n69, so the valve is fully open if

the pressure is n69.

Min. pressure in the receiver

This function is only used if the pressure transmitter Prec is mounted.

P-band to force open the valve if the receiver

pressure is too low

Subcooling is required to be regulated according to temperature

Set the desired subcooling in K.

The gas cooler’s min. pressure n81 7 200 bar 45

Min. permissible opening degree for ICMTS n87 0 100% 0

Extra capacity when the contact is closed.

(The Pgc reference is increased with this value)

Minimum permitted Pgc reference during heat

recovery (AI > 2 V). The value can be increased

further using the r68 function.

Do you require receiver pressure control: O=no,

On=yes

Prec. reference for receiver pressure control n91 7 bar 200 bar 35

Receiver pressure control. Maximum opening

degree for ETS

Receiver pressure control. Smallest opening

degree for ETS

Dene the reference curve point at 100 bar. n99 35°C 55°C 39

SW =2.0x

Para-

Min. Max.

meter

- bar

r68 0 bar 100 bar 0

A66 0 bar 50 bar 0

A67 0 bar 50 bar 0

n03 0 6 0

n37 0 500 262

n69 7 200 90

n70 0 60 5

n71 7 60 30

n72 0 60 3

n79 1 K 30 K 1

n88 0 bar 200 bar 0

n89 7 bar 200 bar 7

n90 O On On

n92 0% 100% 100

n93 0% 100% 0

Factory

setting

**) The display on the controller can show 3 digits only, but the setting value has 4 digits. Only the

3 most important will be shown. It means fx. 250 will give a setting of 2500.

10 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

Page 11

Miscellaneous

Digital input signal - DI

0: The input is not used

1: External main switch

2: additional cooling capacity

Controller’s address o03* 0 240 -

ON/OFF switch (service-pin message) o04* - - -

Set supply voltage frequency o12

Pressure transmitter range Pgc - min. o20 -1 bar 5 bar -1

Pressure transmitter range Pgc - max. o21 6 bar 199 bar 159

Pressure transmitter range Prec - min. o47 -1 bar 5 bar -1

Pressure transmitter range Prec - max. o48 6 bar 199 bar 59

*) This setting will only be possible if a data communication module has been installed in the

controller.

o02 0 2 0

50Hz

60 Hz

(0)

(1)

0

Service

Signal on AI the input u07 V

Read status of input DI u10 on/o

Read ETS/CCM valves opening degree u24 %

Calculated reference for regulation (desired pressure in the gas cooler)

The output signal to the ICMTS valve converted

into opening degree

The temperature in the gas cooler. Measured

using temperature sensor Sgc.

The pressure in the gas cooler. Measured using

pressure transmitter Pgc.

The pressure in the receiver. Measured using

pressure transmitter Prec, but only if it is

mounted.

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep both buttons depressed at the same time as you recon nect the supply voltage

U03 bar

U04 %

U05 °C

U06 bar

U07 bar

Connections

Cable connection

060G1034

14 = black

15 = brown

16 = blue

Necessary connections

Terminals:

25-26 Supply voltage 24 V a.c.

18-19 Pt 1000 sensor at gas cooler outlet (Sgc)

14,15,16 Pressure transmitter AKS 2050, -1 to 159 bar

To register the correct pressure it must be mounted as

close as possible to the gas cooler.

5-6 Voltage output to control the ICMTS valve.

Important

PGC and Sgc must be mount

ed near the gas cooler outlet

to produce a correct signal.

-

0 V = valve closed

10 V = valve open

High pressure valve

Vhp

8 VA

Gas bypass valve

See also next page

Vgbp

AKS 11: Max. 100°C

AKS 21: Max. 180°C

Application dependent connections

Terminals:

1-2 DI-input to either:

External main switch (see o02 and r12)

OR

Contact function for increasing capacity (optimised COP

operation stopped). (see o02)

Open connection = optimised COP operation

Closed connection = extra capacity.

12-13 Alarm relay

There is connection between 12 and 13 in alarm situa tions

14,16,17 Optional. A pressure transmitter can be connected so

that the pressure in the receiver can be monitored. The

pressure transmitter must be an AKS 2050, -1 to 59 bar.

21-24 If receiver pressure is to be controlled, a CCM or ETS valve

should be connected.

18-20 Heat recovery. A voltage signal between 2 and 10 V will

increase the gas pressure reference.

3-4 Data communication

Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communication cable be done correctly. Cf. separate literature No.

RC8AC...

EKC 326A Manual RS8FM602 © Danfoss 02-2016 11

Page 12

ETS (CCM) connection

If the distance between EKC 326A and the ETS (CCM/CCMT) valve

exceeds 5 m a lter must be mounted to obtain the correct valve

function. The lter must be placed close to EKC 326A.

L < 5 m

5 m < L < 50 m

Connection

Dimensions

DIN-rail mounting

Ordering

Type Description Ordering

AKA 211 Filter

4 x 10 mH

084B2238

12 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

Page 13

Data

Supply voltage

Power consumption Controller 8 VA

Input signal

Alarm relay 1 pcs. SPST

Actuator

Data communication

Environments

Enclosure IP 20

Weight 300 g

Mounting DIN rail

Display LED, 3 digits

Terminals max. 2.5 mm2 multicore

Approvals

24 V a.c. +/-15% 50/60 Hz

(the supply voltage is galvanically separated

from the input and output signals)

Pressure transmitter Ratiometric, AKS 2050

Pressure transmitter Ratiometric, AKS 2050

Digital input from external contact function

Voltage signal

Sensor input 1 pcs. Pt 1000 ohm

ICAD mounted on

ICMTS

ETS / CCM or

CCMT 2-8

Possible to connect a data communication module type EKA 174

-10 to +55°C, during operations

-40 to +70°C, during transport

20 - 80% Rh, not condensed

No shock inuence / vibrations

EMC acc. EN 61000-6-3 and EN 61000-4-(2-6, 8, 11)

LVD acc. EN 60730-1 and EN 60730-2-9

0-10 V

Ri = 100 k ohm

Signal range = 2-10 V

250 V a.c.

AC-1: 4 A (ohmic)

AC-15: 3 A (inductive)

Voltage signal

0-10 mA

Step motor

I-max. = 100 mA

Ordering

Type Function Code no.

EKC 326A Gas pressure controller 084B7252

Data communication module

EKA 174

Temperature sensor Pt 1000 ohm: .............. Kindly refer to catalogue RK0YG

Pressure transmitter type AKS 2050 ........... Kindly refer to tech.broch RD5GJ

(accessories),

(Lon-RS 485 module) with

galvanic separation

084B7124

EKC 326A Manual RS8FM602 © Danfoss 02-2016 13

Page 14

Appendix

Guideline for setting automatic safety control

The following ratio between pressure and temperature can be used

to set the automatic safety control.

Safety functions

There are two safety functions for the receiver. They are only available for gas-cooled regulation.

A P-belt must be installed to be able to regulate the function, but

both are standard set to zero, which makes the function inactive.

Receiver pressure's max. limit

Set a max. receiver pressure. If the controller register receiver

pressure beyond the set value, the ICMTS valve will be closed.

The opening degree will be linear through the p-band so that the

ICMTS valve will be closed by pressing 'set max. receiver pressure'

plus 'set-p-band'.

If the valve's opening degree is set to a limited value and cannot

be fully closed, the set opening degree value will be at the pressure 'set max. receiver pressure' plus 'set p-band'.

As such, gas can still be sent through the valve.

Receiver pressure's min. limit:

A minimum receiver pressure limit can be set. If the controller

register receiver pressure below the set value, the ICMTS valve will

be opened. The opening degree will be linear through the p-band,

and the maximum permitted opening degree of the ICMTS will be

present by pressing 'set min. receiver pressure' minus 'set-p-band'.

If the setting of the valve's opening degree is limited and it cannot

be fully opened, the set opening degree value will be at the pressure 'set min. receiver pressure' minus 'set p-band'.

Regulation limitations of the receiver pressure

Note

The PI regulation of the receiver pressure must have space to

regulate without restrictions.

This means that there should be sucient space for the PI regulation to move around the reference, i.e. at least 2-3 bars – both over

and below the reference.

The value is very dependent on the tuning of the PI regulation

and the system dynamics.

An example may be a 40-bar plant in which the receiver's reference pressure is set to 35 bars. Here the system can interfere

with normal regulation because the high pressure limit is very

stringent.

14 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

Page 15

Functions for regulation reference

EKC 326A Manual RS8FM602 © Danfoss 02-2016 15

Page 16

Valve function in alarm situations

Error Alarm message ICMTS action (Vhp) ETS action (Vgbp)

EKC supply interrupted none EKC AO remains 0 V – ICMT closes if ICMTS has

EKC Standby – Main

Switch OFF

Sgc interrupted E15 – Sgc o.c. ICMTS regulates with “Emergency cooling” No change – ETS control attempts to maintain

Sgc short circuited E16 – Sgc s.c. ICMTS regulates with “Emergency cooling” No change – ETS control attempts to maintain

Pgc transmitter error E20 – Pgc input err ICMTS regulates with “Emergency cooling” No change – ETS control attempts to maintain

Prec transmitter error E39 – Prec input err No change – ICMTS control continues ETS regulates with “Emergency cooling”

StepMotor error A43 – Step motor err No change – ICMTS control continues ETS closes to 'Vgbp OD Min' setting

Pgc Max limit exceeded A82 – PgcMax alarm No change – ICMTS control attempts to lower

Pgc Min limit exceeded A83 – PgcMin alarm No change – ICMTS control attempts to raise Pgc No change – ETS control attempts to maintain

Prec Min limit exceeded A84 – PrecMin alarm No change – ICMTS control attempts to maintain

PgcRef Alarm A94 – PgcRef alarm No change – ICMTS control attempts to maintain

PrecRef Alarm A95 – PrecRef alarm No change – ICMTS control attempts to maintain

EKC HW error E1 – Controller fault No change – ICMTS control continues No change – ETS control continues

A45 – Standby mode ICMTS closes ETS closes to 'Vgbp OD Min' setting

battery back-up

Pgc

Pgc

Pgc

Pgc

No change in opening degree

Prec

Prec

Prec

No change – ETS control attempts to maintain

Prec

Prec

No change – ETS control attempts to raise Prec

No change – ETS control attempts to raise Prec

No Change – ETS control attempts to raise Prec

"Emergency cooling"

The valve's average opening degree for the last six hours is

regularly saved. This opening degree is used if there is a need for

emergency cooling.

List of literature

Instructions RI8NG (extract from this manual).

Here you can see how controllers are mounted and

programmed.

Installation guide for extended operation RC8AC

Here you can see how a data communication

connection to ADAP-KOOL® Refrigeration control

systems can be established.

Installation considerations

Accidental damage, poor installation, or site conditions, can give

rise to malfunctions of the control system, and ultimately lead to a

plant breakdown.

Every possible safeguard is incorporated into our products to

prevent this. However, a wrong installation, for example, could still

present problems. Electronic controls are no substitute for normal,

good engineering practice.

Danfoss will not be responsible for any goods, or plant components, damaged as a result of the above defects. It is the installer's

responsibility to check the installation thoroughly, and to t the

necessary safety devices.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

16 Manual RS8FM602 © Danfoss 02-2016 EKC 326A

ADAP-KOOL®

Loading...

Loading...