Page 1

User Guide

Controller for cascade systems

with CO

2

EKC 313

ADAP-KOOL® Refrigeration control systems

Page 2

Introduction

Danfoss

Application

The controller can be used in systems with cascade regulating and

CO2 as refrigerant on the low temperature circuit.

It regulates the cooling of the heat exchanger to optimise superheat.

Advantages

• Dedicated cascade controller

System

The controller must receive a signal from two pressure transmitters and two temperature sensors. The pressure transmitters must

have a type AKS 32R or AKS 2050 ratiometric output signal, as

determined by the actual pressure conditions. The signal from the

pressure transmitters can be a voltage signal of either 0-10 V or

1-5 V.

Type AKS 11 temperature sensors can be used, but type AKS 21

must be used if the temperature exceeds 100°C.

Functions

Output signal

The controller has a voltage output on 0-10 V.

The signal can be used for:

• Indicating the valve's opening degree when using an ETS valve

• Controlling the valve when using an ICAD/ICMTS valve

Valves opening degree

The valve's opening degree can be limited.

Relay

The relay in the controller can be used for:

• Alarm relay

• Control of solenoid valve in liquid line

Start/stop

A switch can be connected for starting and stopping the regulation.

PC-operation

The controller can be provided with data communication so that it

can be connected to other products in the range of ADAP-KOOL®

refrigeration controls. In this way operation, monitoring and data

collection can be performed from one PC – either on the spot or in

a service company.

84B2959.10

Contents

Introduction ....................................................................................................... 2

Example ............................................................................................................... 3

Function overview ........................................................................................... 4

Operation ............................................................................................................ 8

2 User Guide RS8FZ402 © Danfoss 2015-07 EKC 313

Menu survey ....................................................................................................... 8

Connections ..................................................................................................... 10

Data ..................................................................................................................... 11

Ordering ............................................................................................................11

Page 3

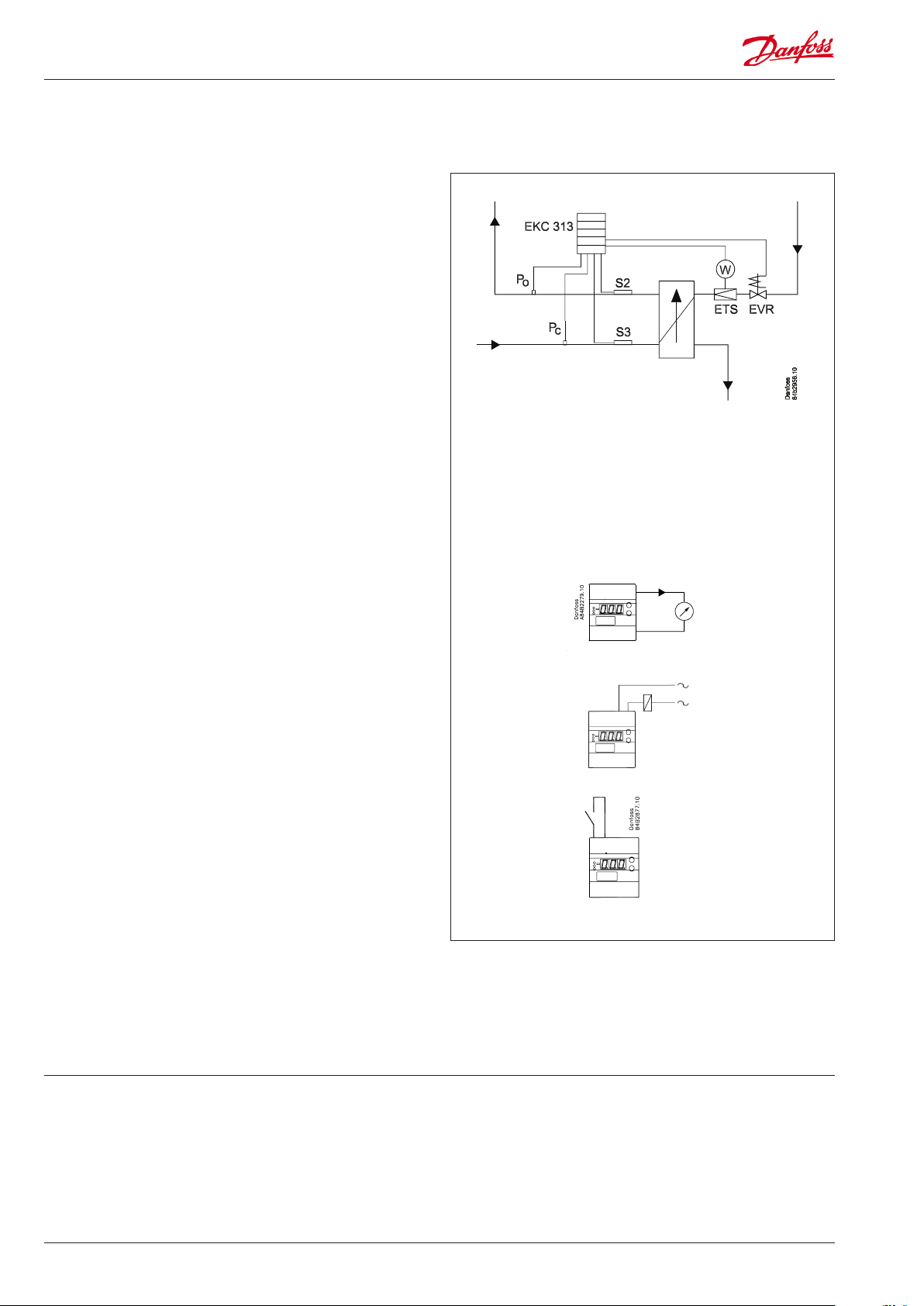

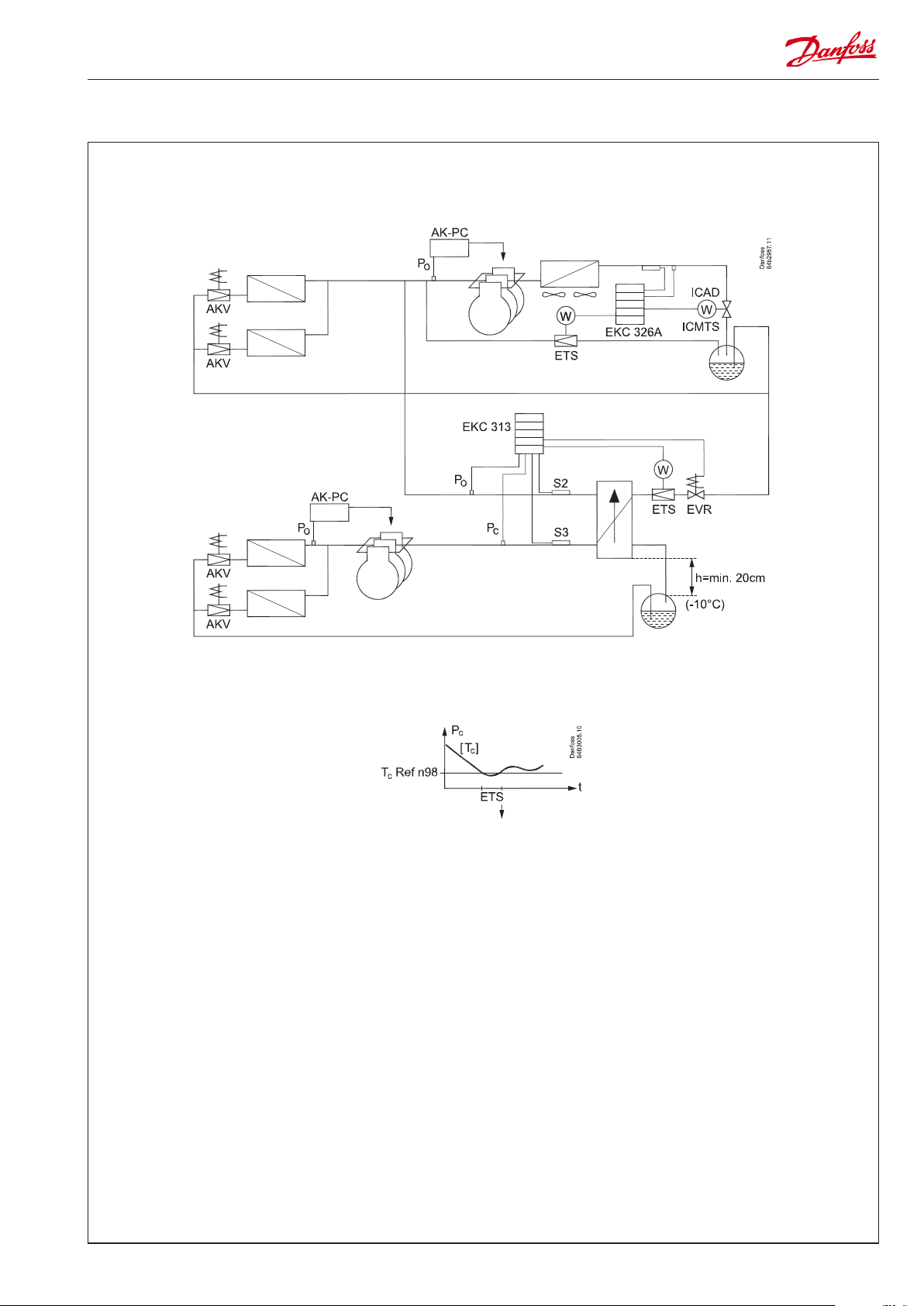

Example

Optimised superheat regulation with limit if the condensing pressure is low.

Optimised superheat regulation is used when the condensing

pressure is above the set value.

If the condensing pressure falls below the set value, the optimised superheat regulation ceases and the ETS valve closes

gradually until the pressure rises above the value.

EKC 313 User Guide RS8FZ402 © Danfoss 2015-07 3

Page 4

Function overview

Function Para-

meter

Normal display

Displays either the valve's actual opening degree or the actual superheat value.

(Desired value can be set in o17)

Briey pushing the bottom button will display one of the two readings.

Briey pushing both buttons will display the superheat reference (u22).

Control parameters Injection control

Start/stop of regulation

This setting can be used to start and stop regulation.

I: Integration time Tn

If the Tn value is increased the regulation becomes slower

Lower limit value for the condensing pressure.

If the pressure falls, the valve will start closing.

Max. opening degree

The valve's opening degree can be limited here.

The setting is expressed as a % of the total opening degree. The voltage signal of 0-10

V on the output will be limited correspondingly.

Amplication factor for the superheat

This setting determines the valve’s opening degree as a function of the change in

evaporating pressure. An increase of the evaporating pressure will result in a reduced

opening degree. When there is a drop-out on the low-pressure thermostat during

start-up the value must be raised a bit. If there is pendling during start-up the value

must be reduced a little.

The value should only be changed by specially trained sta.

Kp value for amplication factor for PID regulation n95 Kp Max

Parameter by operation via

data communication

u24 /

Valve OD %

u21

SH

r12 Main Switch

n05 Tn sec.

n98 Tc Ref

n32 OD% Max

n20 Kp T0

Kp value near reference value

Just around the reference this value will be used in stead of the "n95 value"

The value should only be changed by specially trained sta.

Signal safety during start-up

The control function uses the value as start value for the valve’s opening degree at

each thermostat cutin. By adaptive control the controller continuously calculates a

new value.

The value should only be changed by specially trained sta.

Start-up time for safety signal

If the controller does not obtain a reliable signal within this period of time the controller will in other ways try to establish a stable signal. (A too high value may result in

a ooded evaporator).

The value should only be changed by specially trained sta.

MOP

If no MOP function is required, select pos. O. (A value of max. (60) will correspond to

O)

Min. value for the superheat reference n10 SH Min

Max. value for the superheat reference n09 SH Max

D: Dierentiation time Td n06 Td sec

n19 Kp Min

n17 Start OD%

n15 StartUp time

n11 MOP (bar)

4 User Guide RS8FZ402 © Danfoss 2015-07 EKC 313

Page 5

Conguration Control cong

Refrigerant setting on evaporator side

Before refrigeration can be started, the refrigerant must be dened. You can select the

following refrigerants:

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23. 9=R500.

10=R503. 11=R114. 12=R142b. 13=User dened. 14=R32. 15=R227. 16=R401A.

17=R507. 18=R402A. 19=R404A. 20=R407C. 21=R407A. 22=R407B. 23=R410A.

24=R170. 25=R290. 26=R600. 27=R600a. 28=R744. 29=R1270, 30= R417A.

31=R422A. 32=R413A. 33=R422D. 34=R427A. 35=R438A.

(Warning: Wrong selection of refrigerant may cause damage to the compressor).

Refrigerant setting on the condenser side

Factory-set to R744, but can be changed. A modication can only be made via AKM.

Actuator type

0: ETS 12½ and ETS 25 / CCM 10 and CCM 20

1: ETS 50 / CCM30

2: ETS 100 / CCM40

3: ETS 250

4: ETS 400

5: Other type. "n37" and "n38" should also be set when the setting = 5

("n37" and "n38" are automatically set for settings 0 to 4)

6: 0-10 V output must control an ICAD actuator

7: 0-10 V output must control a solid state relay, which, in turn, controls an AKV valve

(the signal will be an on/o signal [0 or 10 V])

NB! ETS 6 can not be used

ETS Setting

Number of steps from 0% to 100% open

Must only be set when "n03" is set to 5. Automatically set when "n03" is set to 0, 1, 2,

3 or 4

ETS setting

Spindle stroke speed (number of steps per second)

Must only be set when "n03" is set to 5. Automatically set when "n03" is set to 0, 1, 2,

3 or 4

Miscellaneous Miscellaneous

o30 P0 Rfg type

- Pc Rfg type

n03 Valve type

n37 Max. steps

n38 Steps / sec

Address

If the controller is built into a network with data communication, it must have an

address, and the master gateway of the data communication must then know this

address.

These settings can only be made when a data communication module has been

mounted in the controller and the installation of the data communication cable has

been completed.

This installation is mentioned in a separate document “RC8AC”

The address is set between 0 and 119 (999) o03 -

The address is sent to the gateway when the menu is set in pos. ON

(The setting will automatically change back to O after a few seconds.)

Pressure transmitter selection

1: Ratiometric with AKS 32R / AKS 2050

2: Voltage signal with 0-10 V

3: Voltage signal with 1-5 V

Pressure transmitter denition for Pc.

Pressure transmitter lower limit

Pressure transmitter denition for Pc.

Pressure transmitter upper limit

Pressure transmitter denition for P0.

Pressure transmitter lower limit

Pressure transmitter denition for P0.

Pressure transmitter upper limit

Frequency

Set the net frequency.

Denition of relay

The relay can be dened for the following applications:

0: Alarm relay

1: Control of EVR-valve in liquid line.

o04 -

o10 Trans. type

o20 MinTransPc

o21 MaxTransPc

o47 MinTransP0

o48 MaxTransP0

o12 50 / 60 Hz

o36 Alarm/Valve

Following installation of a data communication module, the controller can

be operated on a par with the other

controllers in ADAP-KOOL® refrigeration controls.

(50=0, 60=1)

EKC 313 User Guide RS8FZ402 © Danfoss 2015-07 5

Page 6

Display view

Normal display on the controller can be set to read one of the following readings:

1: Valve’s opening degree

2: Superheat

Only access via data communication For Danfoss only

o17 Display mode

Factor for calculating the superheat reference

SHref = (S3-P0) x SHfactor / 100

Filter constant (delay) for calculating the superheat reference n97 Ref Filter

Other refrigerant

If the refrigerant type cannot be selected directly via settings 1 through 33, it can

then be dened by the user. Select setting 13 and then set the refrigerant's three

constants via AKM.

Service Service

A number of controller values can be printed for use in a service situation

Read status of input DI (start/stop input) u10 DI status

Read the temperature at the S3 sensor u12 S3 Temp

Read the temperature at the S2 sensor u20 S2 Temp

Read the control’s actual superheat u21 SH

Read the control’s actual superheat reference u22 SH Ref

Read the ETS valve’s opening degree u24 Valve OD %

Reading the calculated closing value for superheating. U19 SH Close

Reading the condensation pressure calculated for temperature U20 Cond Temp Tc

Reading the condensation pressure (pressure at Pc) U21 Cond Press Pc

n96 SH factor

P0Rfg.Fac A1

P0Rfg.Fac A2

P0Rfg.Fac A3

PcRfg.Fac A1

PcRfg.Fac A2

PcRfg.Fac A3

Reading the evaporating pressure (pressure at P0) U25 Evap Press P0

Reading the evaporating pressure calculated for temperature U26 Evap Temp T0

Manual control of outputs

For service purposes the valve outputs can be forced

However only when regulation has been stopped.

0: No override

1: Override: If the relay is dened for solenoid valve use in o36, the solenoid valve will

open. The opening degree of the ETS or ICMTS valve can then be set via o45.

Manual control of the ETS valve

When ”o18” is activated (=1) the valve’s opening degree can be determined from this

menu.

Operating status

The controller’s operating status can be called forth by a brief (1s) activation of the

upper button. If a status code exists it will be shown. (Status codes have lower priority

than alarm codes. This means that status codes cannot be seen if there is an active

alarm code.

The individual status codes have the following meanings:

S10 (o): Regulation stopped by the internal start/ stop.

S24: Regulation is in start-up mode 24

S44: Delay time, or the time it takes for system stability to be reached. Appears if one

of the regulating sensors fails.

o18 Manual Ctrl

o45 Man Valve OD%

EKC State

(0 = regulation)

10

44

6 User Guide RS8FZ402 © Danfoss 2015-07 EKC 313

Page 7

Alarms

The controller can give the following alarms. The alarm priority for all alarms is factory-set to 1,

"High priority". The priority level can be modied, but only by altering the data communication

settings.

E1: Fault in controller Controller fault

E15: Cut-out S2 sensor S2 o.c.

E16: Short circuited S2 sensor S2 s.c.

E17: Cut-out S3 sensor S3 o.c.

E18: Short circuited S3 sensor S3 s.c.

E20: Fault on signal from Pc Pc input err

E39: Fault on signal from P0 P0 input err

A11: No refrigerant has been selected. o30 must be set No Rfg. Sel.

A43: Step motor fault. Output or phase Step motor err

A45: Regulation stopped. Main switch r12 = o Standby mode

Alarm destinations

EKC 313 User Guide RS8FZ402 © Danfoss 2015-07 7

Page 8

Operation

Display

The values will be shown with three digits.

Temperature are shown in °C and pressure in bar.

Light-emitting diodes (LED) on front panel

All 4 light-emitting diodes will ash when there is an error in the

regulation.

In this situation you can upload the error code on the display and

cancel the alarm by giving the uppermost button a brief push.

The controller can give the following messages:

E1

E15

E16 Short circuited S2 sensor

Error message

E17 Cut-out S3 sensor

E18

E20 Fault on signal from Pc

E39 Fault on signal from P0

A11

Alarm message

A43 Step motor fault. Output or phase

A45 Regulation stopped. Main switch r12 = o

The buttons

When you want to change a setting, the two buttons will give you

a higher or lower value depending on the button you are pushing. But before you change the value, you must have access to the

menu. You obtain this by pushing the upper button for a couple

of seconds - you will then enter the column with parameter codes.

Find the parameter code you want to change and push the two

buttons simultaneously. When you have changed the value, save

the new value by once more pushing the two buttons simultaneously.

Gives access to the menu

Gives access to changes

Saves a change

Examples of operations

Set of a menu

1. Push the upper button until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push both buttons simultaneously until the parameter value is

shown

4. Push one of the buttons and select the new value

5. Push both buttons again to conclude the setting

*) This setting will only be possible if a data communication module has been installed in the

controller.

**) The display on the controller can show 3 digits only, but the setting value has 4 digits. Only the

3 most important will be shown. It means fx. 250 will give a setting of 2500.

Fault in controller

Cut-out S2 sensor

Short circuited S3 sensor

No refrigerant has been selected

(or cutout an alarm)

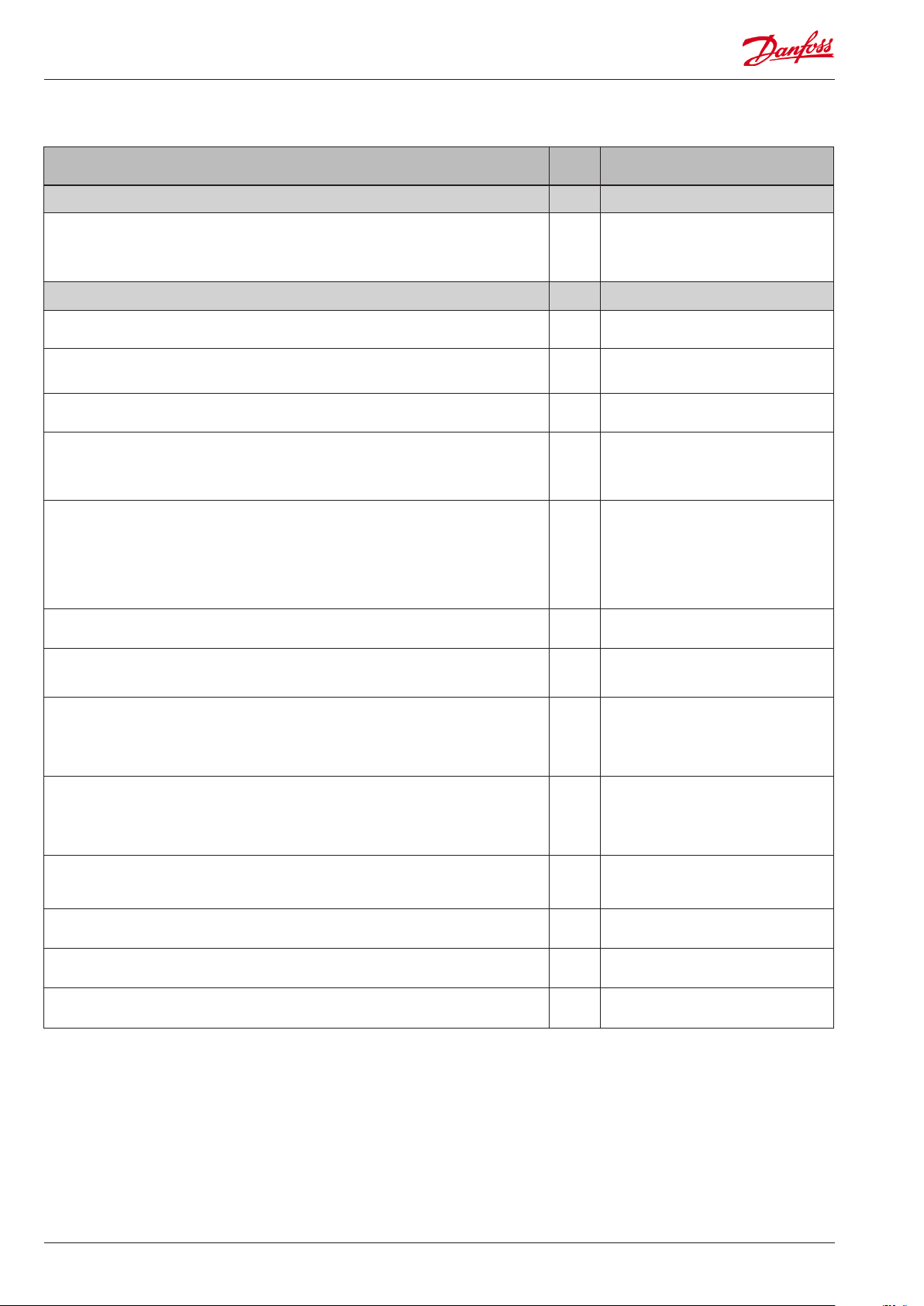

Menu survey

Function

Normal display

Displays either the valve's current opening degree or the current superheat value.

(Can be set in o17)

Briey pushing the bottom button will display one of the two readings.

Briey pushing both buttons will display the superheat reference (u22).

Start / stop

Start / stop af regulation r12 OFF (0) On (1) On (1)

Regulating parameters

Select valve type:

0=ETS 12,5 & 25 / CCM10 & CCM20

1=ETS 50 / CCM30, 2=ETS 100 / CCM40

3=ETS 250, 4=ETS 400,

5=User dened (set : n37 and n38)

6=0-10 V's output must control ICAD actuator

7=0-10 V's output must on/o control a solid

state relay.

I: Integration time Tn n05 5 s 600 s 90

D: Dierentiation time Td n06 0 s 60 s 0

Max. value of superheat reference n09 3 K 60 K 40

Min. value of superheat reference n10 3 K 40 K 10

MOP (max. = O ) n11 0 bar 60 bar 60

Signal reliability during start-up. Time for safety.

Should only be changed by trained sta

Signal reliability during start-up – Opening

degree’s start value. Should only be changed by

trained sta.

Kp amplication just around reference value

Changes should only be made by trained sta

Amplication factor for superheat. (KpT0)

Changes should only be made by trained sta

Max. opening degree of valve n32 0% 100% 100

Number of steps from 0-100% opening degree

(x10) **

Number of steps per second n38 0 300 250

Max. Kp factor for PID-regulation (Kp max) n95 0 30 5

Calculation factor for superheat SH

Changes should only be made by trained sta

Filter constant for SH reference

Changes should only be made by trained sta

Lower limit value for the condensing pressure n98 -30°C 10°C -5

Miscellaneous

Controller’s address (0 = o) o03* 0 119 0

ON/OFF switch (service-pin message) o04* - - Set supply voltage frequency o12 50Hz (0)60 Hz (1) 0

Select display view for the "normal display"

1: Opening degree of the valve

2: Superheat

Manual control of outputs:

0: Normal regulation

1: Overriding. Manual control permitted

Pressure transmitter selection

1: AKS 32R / AKS 2050

2: Pressure transmitter with 0-10 V

3: Pressure transmitter with 1-5 V

Working range for pressure transmitter Pc - min. o20 -1 bar 5 bar -1

Working range for pressure transmitter Pc - max. o21 6 bar 199 bar 59

Refrigerant setting for P0 circuit

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717.

6=R13. 7=R13b1. 8=R23. 9=R500. 10=R503.

11=R114. 12=R142b. 13=User dened.

14=R32. 15=R227. 16=R401A. 17=R507.

18=R402A. 19=R404A. 20=R407C. 21=R407A.

22=R407B. 23=R410A. 24=R170. 25=R290.

26=R600. 27=R600a. 28=R744. 29=R1270.

30=R417A. 31=R422A. 32=R413A. 33=R422D.

34=R427A. 35=R438A

Relay application: 0=Alarm relay. 1=EVR valve i

liquid line

Forced control of the valves opening degree.

(Only if o18 is set to manual)

Working range for pressure transmitter P0 - min. o47 -1 bar 5 bar -1

Para-

Min. Max.

meter

n03 0 7 0

n15 0 s 240 s 0

n17 0% 100% 0

n19

0 30 3

n20 0 30 5

n37 0 500 263

n96 10 100 50

n97 5 s 600 s 60

o17 1 2 1

o18 0 1 0

o10 1 3 1

o30 0 35 0

o36 0 1 0

o45 0 100% 0

SW =2.0x

Fac.setting

8 User Guide RS8FZ402 © Danfoss 2015-07 EKC 313

Page 9

Working range for pressure transmitter P0 - max. o48 6 bar 199 bar 12

Refrigerant for Pc circuit

Can olny be changed via AKM / service tool

Service

Read status of input DI u10 on/o

Temperature at S3 sensor u12 °C

Temperature at S2 sensor u20 °C

Read actual superheat SH u21 K

Read actual superheat reference u22 K

Read ETS valves opening degree u24 %

Read pressure at pressure transmitter P0 u25 bar

Read P0 converted to temperature u26 °C

Read calculated SH closing value U19 K

Read Pc converted to temperature U20 °C

Read pressure at pressure transmitter Pc U21 bar

---- 0 35 28

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep both buttons depressed at the same time as you recon nect the supply voltage

EKC 313 User Guide RS8FZ402 © Danfoss 2015-07 9

Page 10

Connections

At opening degree: 10 V = 100% open valve

At signal to ICAD/ICMTS: 10 V = Open valve

5,6 25,26

l

Earthing will damage the

controller

Cable connection

060G1034

14 = black

15 = brown

16 = blue

Necessary connections

Terminals:

25-26 Supply voltage 24 V a.c.

18-19 Pt 1000 sensor at the heat exchanger discharge on

the cool side (S2)

18-20 Pt 1000 sensor at the heat exchanger input on

the warm side (S3)

14,15,16 Type AKS 2050* pressure transmitter, -1 to 59 bar.

Mounted at the heat exchanger's inlet on

the warm side (Pc)

14,16,17 Type AKS 32R* pressure transmitter, -1 to 12 bar.

Mounted at the heat exchanger discharge on

the cold side (P0)

8 VA

L > 5 m, see page 12

AKS 11: Max. 100°C

AKS 21: Max. 180°C

Application dependent connections

Terminals:

1-2 DI input for external main switch (also see r12). If no

switch is mounted, the terminals should be short circuited.

12-13 Relay for controlling solenoid valve in liquid line or the

relay can be used as alarm relay (see o36).

Valve control: 12 and 13 are connected under normal

operating conditions and interrupted supply voltage.

Disconnects when regulation requires a low valve opening degree.

Alarm relay: 12 and 13 are connected in case of alarm.

21,22,23,24 Connecting an ETS valve. (Terminals 21 through 24

should not be used when using an ICMTS valve instead

of an ETS valve. ICMTS valves should be controlled via the

0-10 V signal on terminals 5 and 6.)

5-6 Voltage output 0-10 V. Can be used for the valve's opening

degree signal or to control an ICMTS valve.

(For a special use with a solid state relay and AKV, the

output will pulse with 10 V on/o)

3-4 Data communication

Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communication cable be done correctly. Cf. separate literature No.

RC8AC...

*) For explosive applications an intrinsically safe pressure transmitter can

be used. Connection is shown on page 12.

10 User Guide RS8FZ402 © Danfoss 2015-07 EKC 313

Page 11

Data

Supply voltage 24 V a.c. +/-15% 50/60 Hz

Power consumption Controller 8 VA

Ratiometric, AKS 32R

2 Pressure transmitter

Input signal

Digital input from external contact function

Sensor input 2 pcs. Pt 1000 ohm

Alarm relay / solenoid

valve relay

Actuator

Output signal

Data communication

Environments

Enclosure IP 20

Weight 300 g

Mounting DIN rail

Display LED, 3 digits

Terminals max. 2.5 mm2 multicore

Approvals

NB

EKC 313 does not support valve type ETS 6.

1 pcs. SPST

ETS /CCM / CCMT Step motor

ICAD mounted on

ICMTS

Voltage signal 0-10 V to either ICAD-control or to

signal for valves opening degree

Possible to connect a data communication mod-

ule type EKA 174

-10 to +55°C, during operations

-40 to +70°C, during transport

20 - 80% Rh, not condensed

No shock inuence / vibrations

EMC acc. EN 61000-6-3 and EN 61000-4-(2-6, 8,11)

LVD acc. EN 60730-1 and EN 60730-2-9

Ratiometric, AKS 2050

or 0-10 V / 1-5V

AC-1: 4 A (ohmic)

AC-15: 3 A (inductive)

Voltage signal 0-10 V

Ordering

Type Function Code no.

EKC 313 Cascade controller 084B7253

EKA 174

Temperature sensor Pt 1000 ohm and pressure transmitter:

Kindly refer to catalogue RK0YG

Data communication module

(accessories), (RS 485 module)

with galvanic separation

084B7124

EKC 313 User Guide RS8FZ402 © Danfoss 2015-07 11

Page 12

ETS connection

If the distance between EKC 313 and the ETS valve exceeds 5 m a

lter must be mounted to obtain the correct valve function.

L < 5 m

5 m < L < 50 m

Connection

The lter must be installed close to EKC 313

Dimensions

DIN-rail mounting

EX

Explosive application

Here the controller can receive a voltage signal of either 0-10 V or

1-5 V.

If the pressure transmitter supplies a current signal, a resistance of

250 ohm must be installed over the terminals.

The supply must be taken from the zener barrier.

Ordering

Type Description Code no.

AKA 211 Filter

4 x 10 mH

084B2238

List of literature

Accidental damage, poor installation, or site conditions, can give

rise to malfunctions of the control system, and ultimately lead to a

Installation considerations

Instructions RI8PB (extract from this manual).

Here you can see how controllers are mounted and

programmed.

plant breakdown.

Every possible safeguard is incorporated into our products to

prevent this. However, a wrong installation, for example, could still

present problems. Electronic controls are no substitute for normal,

Installation guide for extended operation RC8AC

Here you can see how a data communication

connection to ADAP-KOOL® Refrigeration control

systems can be established.

good engineering practice.

Danfoss will not be responsible for any goods, or plant components, damaged as a result of the above defects. It is the installer's

responsibility to check the installation thoroughly, and to t the

necessary safety devices.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

12 User Guide RS8FZ402 © Danfoss 2015-07 EKC 313

ADAP-KOOL®

Loading...

Loading...