Service and Parts Manual

Directional Valve Group

ECO 80

www.danfoss.com

Service and Parts Manual

Directional Valve Group ECO 80

Revision history Table of revisions

Date Changed Rev

December 2019 First edition 0101

2 | © Danfoss | December 2019 AX327462277301en-000101

Service and Parts Manual

Directional Valve Group ECO 80

Contents

Function

Safety.................................................................................................................................................................................................... 4

Sectional view....................................................................................................................................................................................5

Installation

Identification and oil flow direction for standard assembled ECO 80 LS.....................................................................6

Installation and plug orientation................................................................................................................................................7

Connections pump side and max flow setting......................................................................................................................8

Installation of lever...........................................................................................................................................................................9

Main spool assembly installation.............................................................................................................................................10

Service parts

EVP, pump side module...............................................................................................................................................................11

EVPX, electrical LS unloading valve.........................................................................................................................................13

EVB, basic module..........................................................................................................................................................................14

PVLP shock and PVLA suction valves......................................................................................................................................16

EVO, end plate.................................................................................................................................................................................18

EVBS spools...................................................................................................................................................................................... 19

EVM, mechanical actuation........................................................................................................................................................21

EVC, cover for mechanical actuation...................................................................................................................................... 22

EVOS, open spool through action............................................................................................................................................23

EVOS, open spool mechanical actuation...............................................................................................................................24

EVME, spring center/detent....................................................................................................................................................... 25

EVME through action....................................................................................................................................................................25

EVME, micro switch NO................................................................................................................................................................26

EVH, hydraulic actuation............................................................................................................................................................. 27

EVHC, proportional electrical control..................................................................................................................................... 28

EVHCO, ON/OFF..............................................................................................................................................................................29

EVPN, pneumatic actuator..........................................................................................................................................................30

EVPN, electrical pneumatic actuator.......................................................................................................................................31

EVT, assembly kit............................................................................................................................................................................32

Set of seals........................................................................................................................................................................................33

©

Danfoss | December 2019 AX327462277301en-000101 | 3

Service and Parts Manual

Directional Valve Group ECO 80

Function

Safety

It is the customer's responsibility to decide on the required degree of safety for the system. All marks and

all types of directional control and proportional valves can fail and cause serious damage. It is therefore

important to analyze all aspects of the application. Proportional valves are used in many different

operating conditions and applications; therefore the manufacturer of the application is responsible for

making the final selection of the products and assuring that all performance, safety and warning

requirements of the application are met.

Cost-free repairs, as mentioned in Danfoss General Conditions of Sale, are carried out only at Danfoss or

at service shops authorized by Danfoss.

4 | © Danfoss | December 2019 AX327462277301en-000101

Service and Parts Manual

Directional Valve Group ECO 80

Function

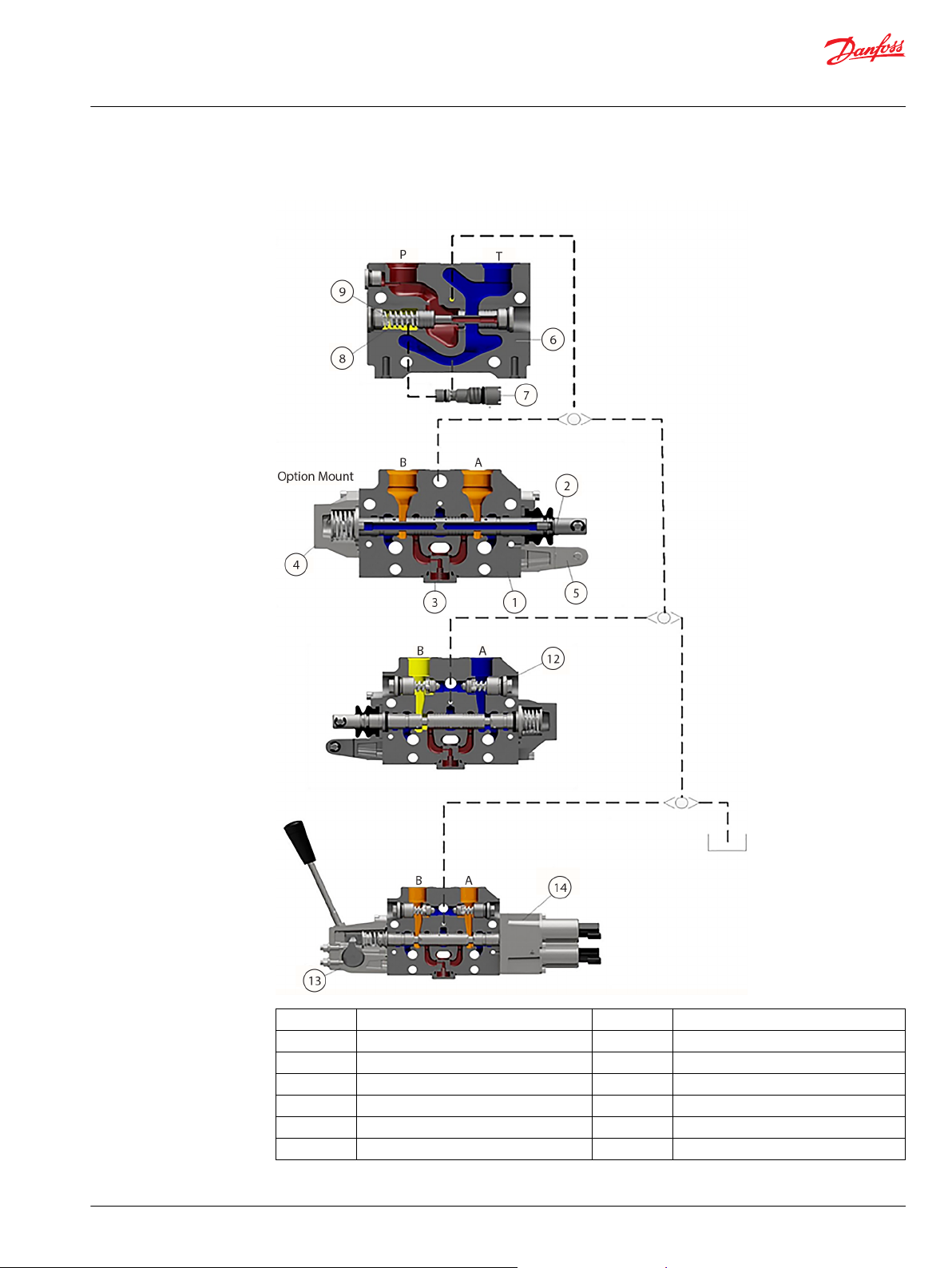

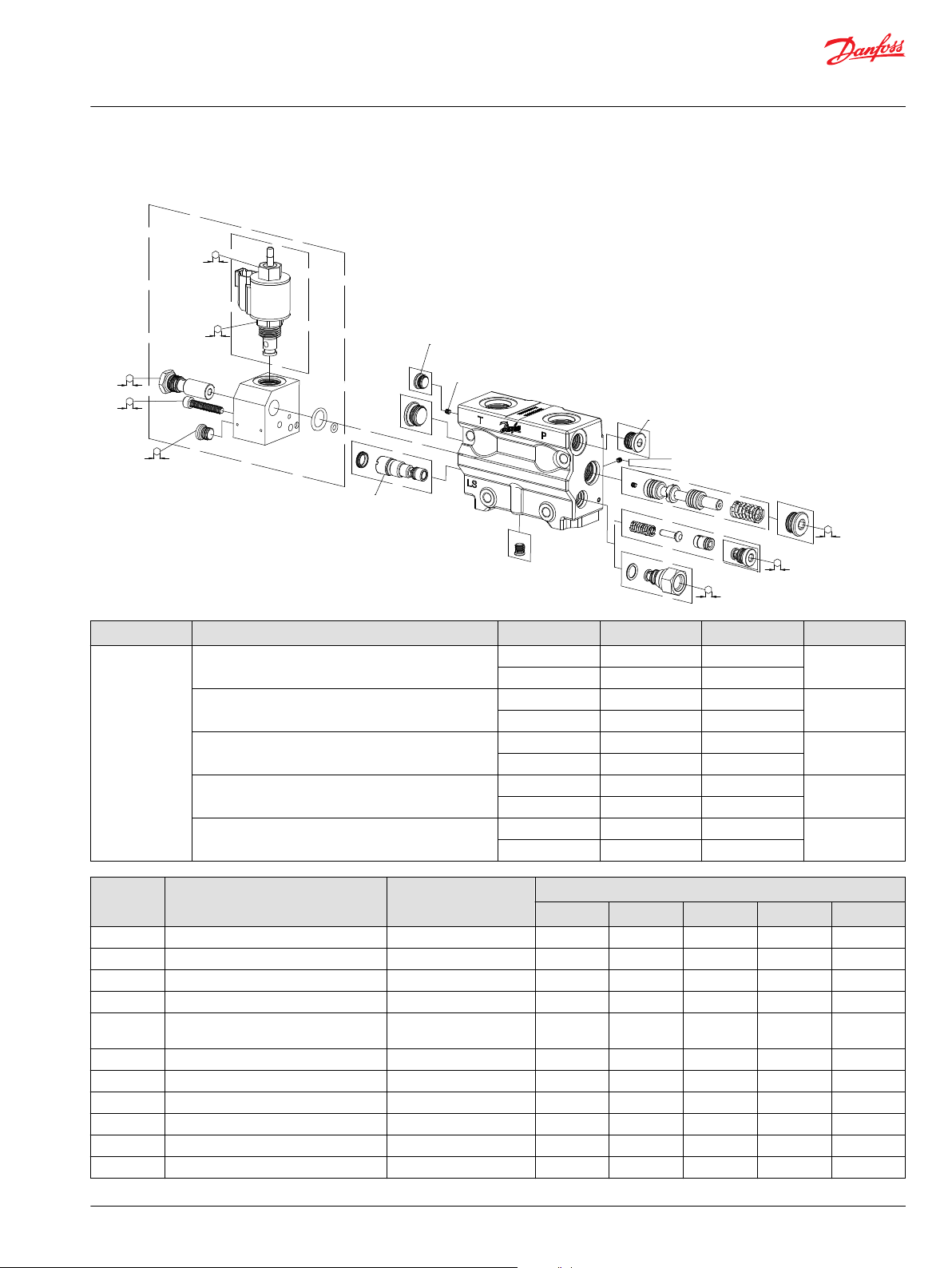

ECO 80 LS sectional view

1 Workstation EVB 8 Unloader spool

2 Spool EVBS 9 Unloader spool spring

3 Check valve 10 LS Shuttle

4 Spring center EVME 11 Load sensing

5 Actuator EVOS 12 Shock valve

6 Pump Inlet EVP 13 Spring center (EH) EVM

7 Load sense relief 14 Electric Actuator

©

Danfoss | December 2019 AX327462277301en-000101 | 5

EVB

Low Body

B

A

B

A

EVB

Medium Body

EVHC

EVP

EVS

EVM

EVH

B

A

B

A

A

B

EVB

Low Body

EVB

Medium Body

EVP

EVOS

EVS

XXX

XXX

XXX

XXX

XXX

XXX

XXX

C

C

EVHCO

EVPN Electro pneumatic

EVPN

EVC

ECO

ECO

Service and Parts Manual

Directional Valve Group ECO 80

Installation

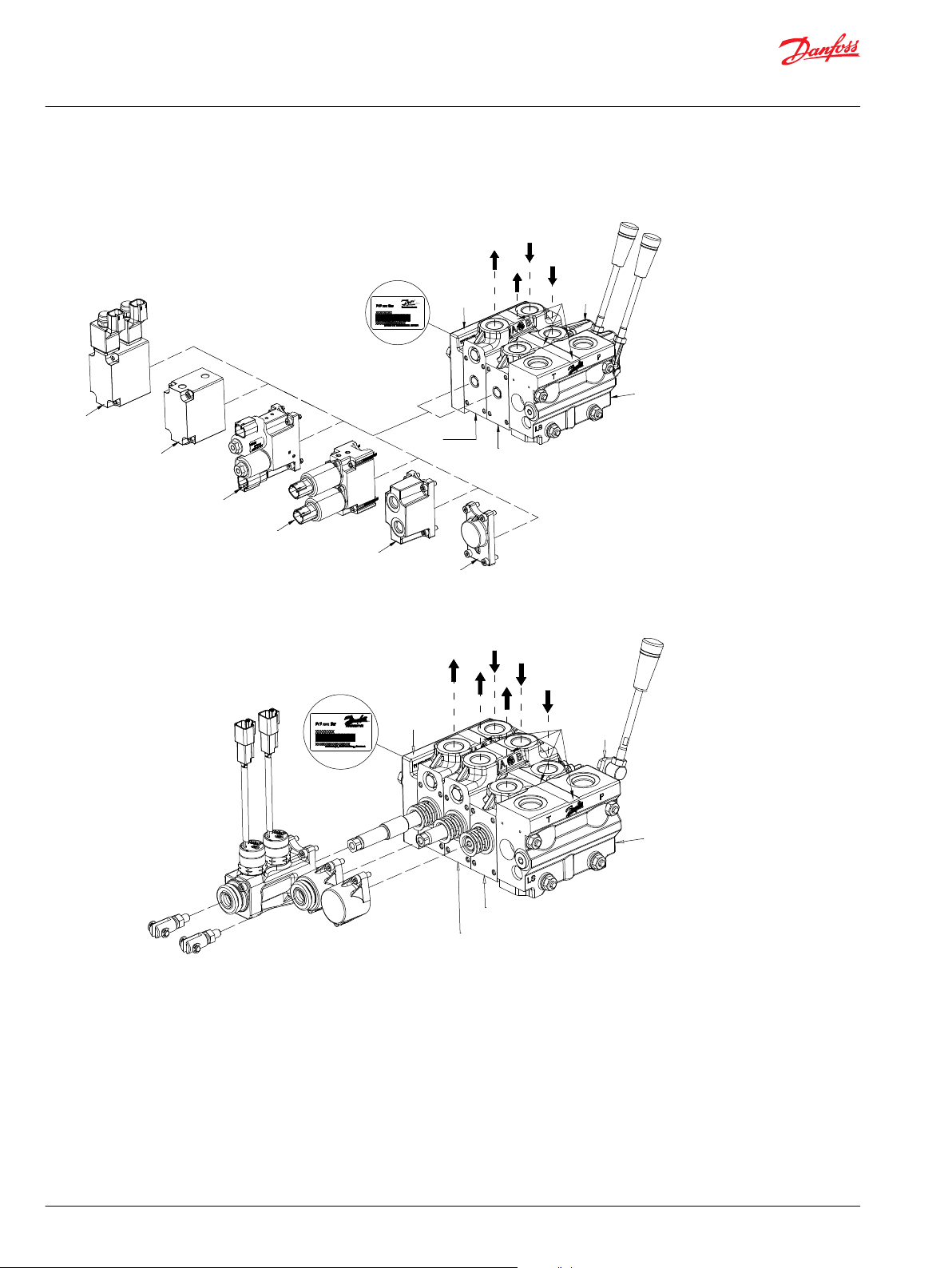

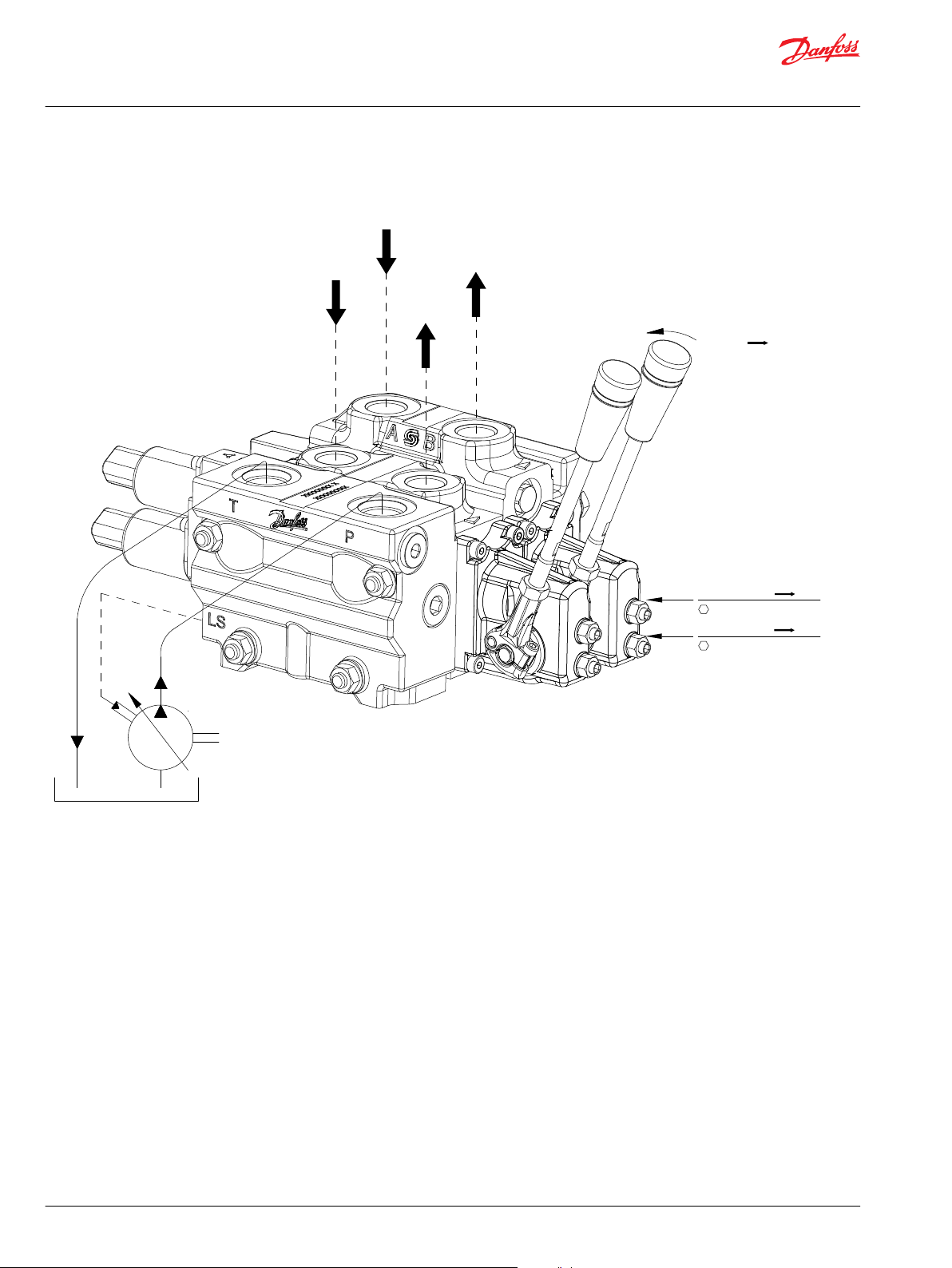

Identification and oil flow direction for standard assembled ECO 80 LS

C: Label with ECO 80 number, week and year of installation and series number.

6 | © Danfoss | December 2019 AX327462277301en-000101

L

*210[8.27]

*120[4.7]

*210[8.27]

*120[4.7]

98[3.86]

In particularly exposed applications, protection in the form of

screening of the electrical actuator is recommended

4x M8x1.25

EVP: Max. 40 Nm

EVO: Max. 20 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Installation

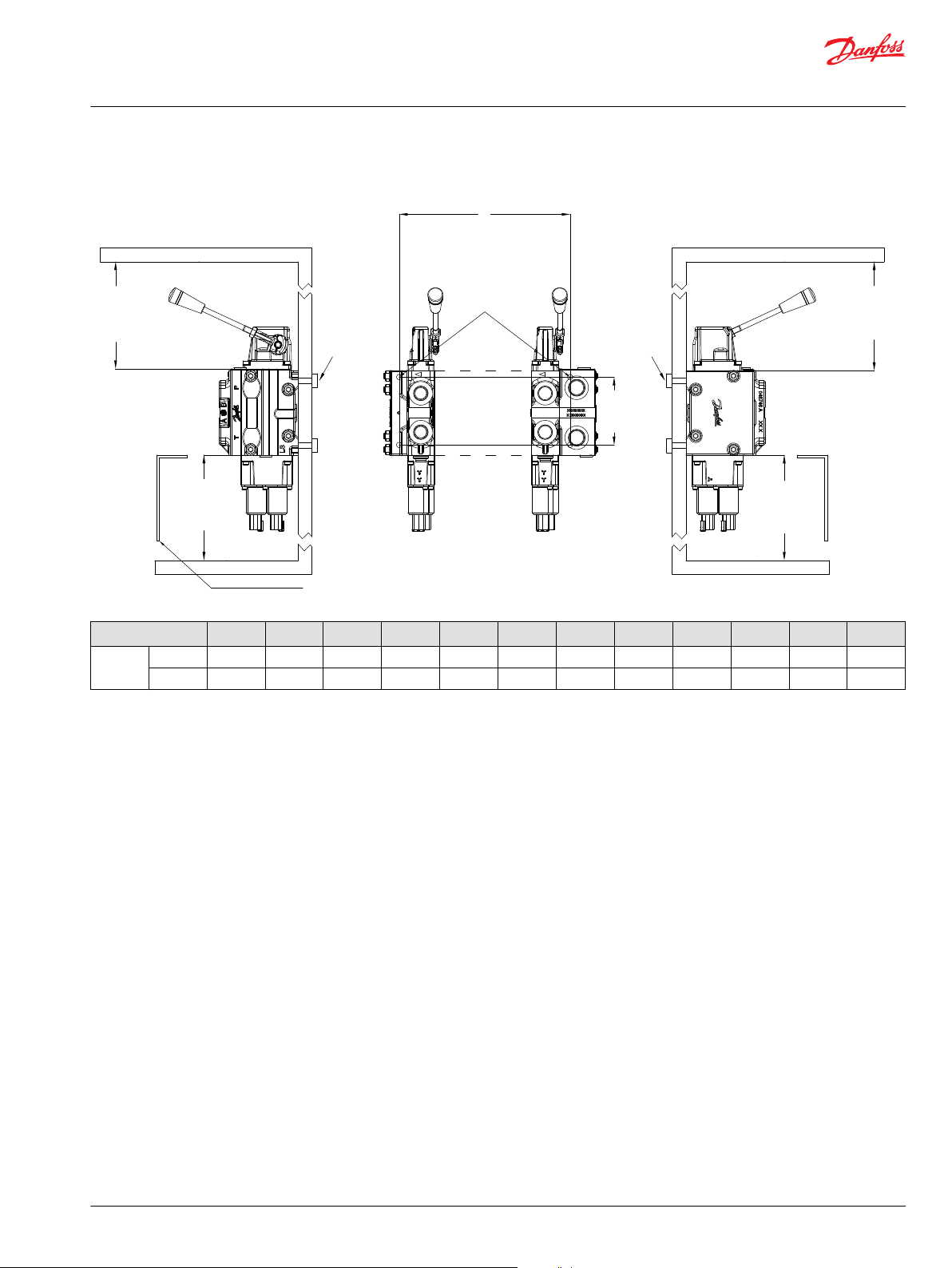

ECO 80 installation and plug orientation

No. of EVB 1 2 3 4 5 6 7 8 9 10 11 12

L mm 65 105 145 185 225 265 305 345 385 425 465 505

[in] 2.56 4.13 5.71 7.28 8.86 10.43 12.01 13.58 15.16 16.73 18.31 19.88

©

Danfoss | December 2019 AX327462277301en-000101 | 7

Flow P B

B

A

B

A

Max. flow: P A

6±1Nm[53±9lbf-in]

Max. flow: P B

6±1Nm[53±9lbf-in]

Service and Parts Manual

Directional Valve Group ECO 80

Installation

ECO 80 connections pump side and max flow setting

8 | © Danfoss | December 2019 AX327462277301en-000101

22.5°

22.5°

8±1Nm

22.5°

22.5°

52.5 °

22.5 °

82.5 °

112.5 °

67.5 °

97.5 °

127.5 °

157.5 °

187.5 °

Service and Parts Manual

Directional Valve Group ECO 80

Installation

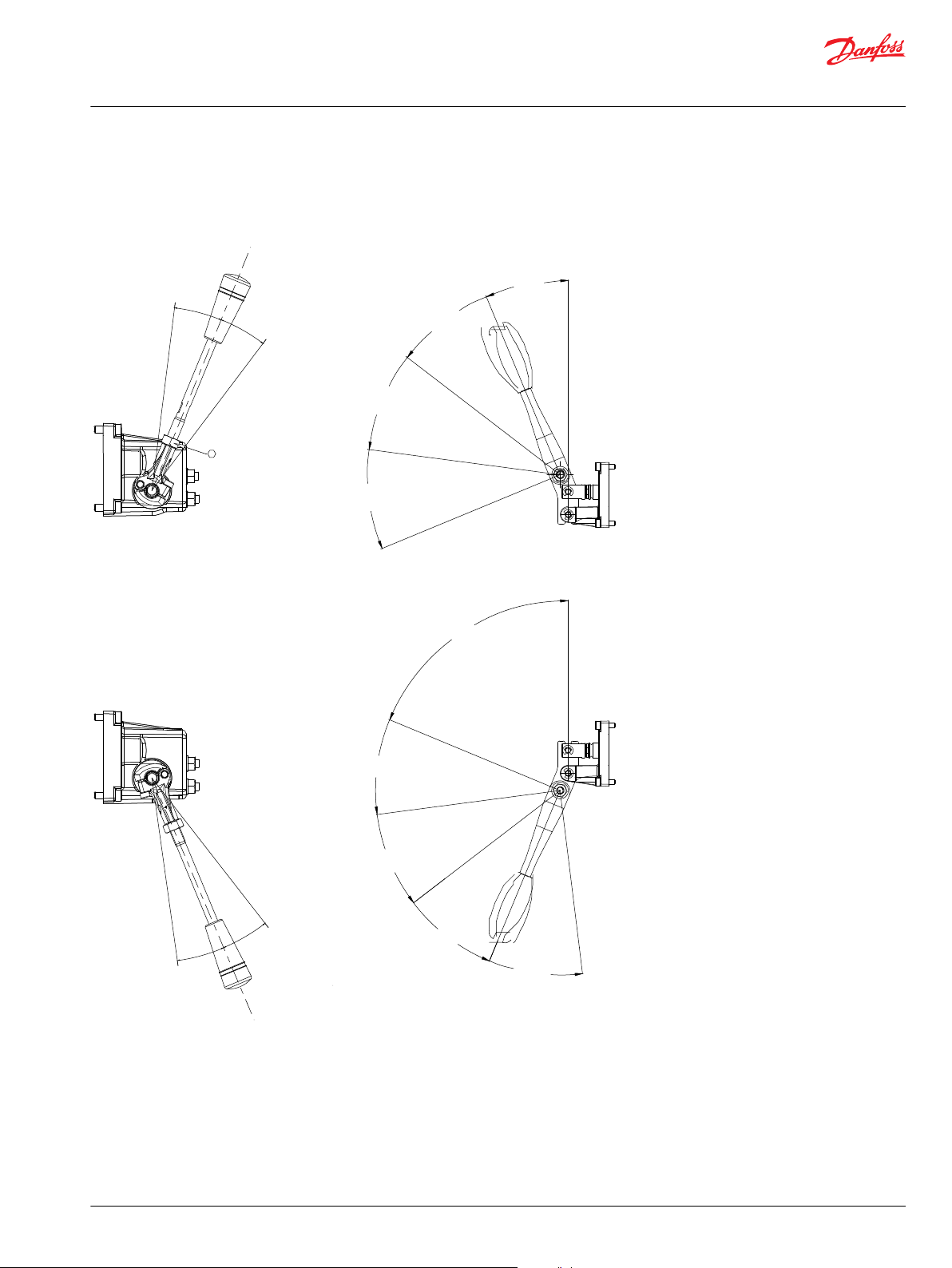

ECO 80 installation of lever

Remember to screw the lever all the way in.

©

Danfoss | December 2019 AX327462277301en-000101 | 9

EVBS, MECHANICAL FLOW CONTROL SPOOLS,THROUGH ACTING

13mm HEX

8-10Nm

EVBS, MECHANICAL FLOW CONTROL SPOOLS,FEMALE EXTENSION

EVBS, MECHANICAL FLOW CONTROL SPOOLS,DETENT 03/02 POSITION

EVBS, ELECTRICAL FLOW CONTROL SPOOLS

EVBS, MECHANICAL FLOW CONTROL SPOOLS,MICRO SWITCH

8-10Nm

8-10Nm

6 mm

8-10 Nm

8-10Nm

8-10Nm

8-10Nm

11 mm

8-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Installation

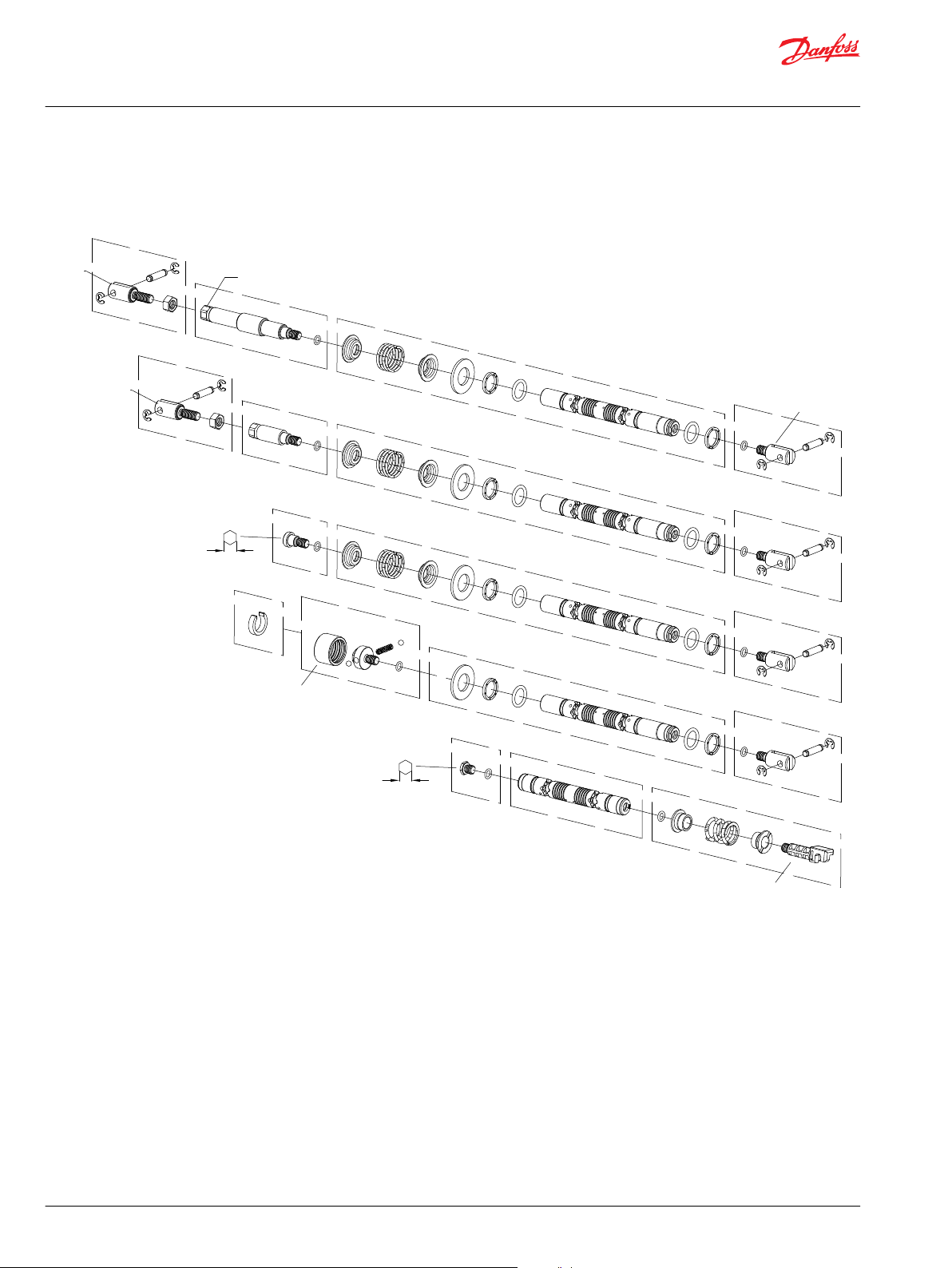

ECO 80 main spool assembly installation

Standard main spool assembly

10 | © Danfoss | December 2019 AX327462277301en-000101

7/8"

29-35Nm

7/8"

25-27Nm

3/4"

6-7Nm

OPEN CENTER

SAE PLUG HEX 1/4"(18-20Nm)

BSP PLUG HEX 6mm(29-35Nm)

13) CLOSED CENTER

SAE PLUG HEX 1/4"(18-20Nm)

BSP PLUG HEX 6MM(29-35Nm)

8 mm

22-26 Nm

6mm

29-35Nm

3/4"

18-20 Nm

5 mm

12-14 Nm

3/16"

4-5 Nm

ACCESS TO

RELIEF VALVE

RELIEF VALVE

4MM HEX

360° = 100 BAR

(CLOCKWISE)

1

2

3

4

5

11

10

3

4

7

12

9

6)Closed Center

8)Open Center

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVP, pump side module

Type Description Code number P-port T-port* Letter

EVP Open center 11173005 G1/2” G1/2” A

11172981 7/18-14 7/18-14

Closed center 11173006 G1/2” G1/2” B

11173002 7/18-14 7/18-14

Open center with pilot supply 11172996 G1/2” G1/2” C

11173010 7/18-14 7/18-14

Closed center with pilot supply 11172997 G1/2” G1/2” D

11173011 7/18-14 7/18-14

Open center with pilot supply and facilities for EVPX 11173023 G1/2” G1/2” E

11173000 7/18-14 7/18-14

Item Description Code number Letter

1 EVPX housing incl. EVPX See section EVPX - - - - 2 EVPX coil See section EVPX - - - - 3 Plug - 2 2 2 2 2

4 Plug - 2 2 2 2 2

5 Relief valve incl. sealed plastic adjusting

6 Orifice for closed center EVP (Ø0,8 x M6) - - 1 - 1 7 Inlet compensator assembly - 1 1 1 1 1

8 Plug for open center EVP (Pipe M6 x 1) - 1 - 1 - 1

9 Plug - - - 1 1 1

10 Pilot supply - - - 1 1 1

11 Plug for external pilot oil supply - 1 1 - - -

©

screw

- 1 1 1 1 1

Danfoss | December 2019 AX327462277301en-000101 | 11

A B C D E

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

Item Description Code number Letter

A B C D E

12 Plug - 1 1 1 1 1

13 Plug for closed center EVP (Pipe M6 x 1) - - 1 - 1 *

Conversion kit open to closed – and

closed to open – center (Including item

3, 6, 8 and 13)

11177668 - - - - -

12 | © Danfoss | December 2019 AX327462277301en-000101

7/8"

25-27Nm

3/4"

6-7Nm

5MM

12-14Nm

3/16"

4-5Nm

ACCESS TO

RELIEF VALVE

1

2

3/4”

18-20 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVPX, electrical LS unloading valve

EVPX

Description Code number

Normally open: LS pressure relieved with no signal to EVPX – 12 V 11172430

Normally open: LS pressure relieved with no signal to EVPX - 24 V 11172429

©

Danfoss | December 2019 AX327462277301en-000101 | 13

7/8" HEX

20-23Nm

2

1

PLVP

PLVA

Cavity-Plug

13mm HEX

29-35Nm

PLVP

PLVA

Cavity-Plug

13mm HEX

29-35Nm

8mm HEX

29-35Nm

8mm HEX

29-35Nm

7/8" HEX

20-23Nm

4

5

6

2

3

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVB, basic module

Low body, no facilities for PVLP/PVLA

Medium body, with facilities for PVLP/PVLA

14 | © Danfoss | December 2019 AX327462277301en-000101

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

Mechanical and electrical EVB

Type Description Code

EVB

Mechanical

EVB Electrical Low body without facilities for PVLP/PVLA 11168506 G1/2” G1/2” C

Item Description Code number Letter

1 Low body EVB See above 1 - 1 2 Check valve assembly - 1 1 1 1

3 High body EVB See above - 1 - 1

4 PVLA valve assembly See page (PVLP/PVLA) - - - 5 PVLP, shock and suction valve assembly See page (PVLP/PVLA) - - - 6 Anti-cavitation plug See page (PVLP/PVLA) - - - -

Low body without facilities for PVLP/PVLA 11168505 G1/2” G1/2” A

Medium body with facilities for PVLP/PVLA 11168503 G1/2” G1/2” B

Medium body with facilities for PVLP/PVLA 11168509 G1/2” G1/2” D

number

11168504 7/18-14 7/18-14

11168502 7/18-14 7/18-14

11168507 7/18-14 7/18-14

11168508 7/18-14 7/18-14

P-port T-port* Letter

A B C D

©

Danfoss | December 2019 AX327462277301en-000101 | 15

35±3 Nm

[310±27 lbf·in]

13 [0.50]

35±3 Nm

[310±27 lbf·in]

13 [0.50]

1

2

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 PVLP shock and PVLA suction valves

PVLP/PVLA

16 | © Danfoss | December 2019 AX327462277301en-000101

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

Type Part number

PVLA 157B2001

PVLP 157B2032

157B2050

157B2063

157B2080

157B2100

157B2125

157B2140

157B2150

157B2160

157B2175

157B2190

157B2210

157B2230

157B2240

157B2250

157B2265

157B2280

157B2300

157B2320

Adjustable PVLP 11006594 (121-250 bar [1755-3626 psi])

11006596 (251-285 bar [3640-4134 psi])

Cavity plug 11177714

©

Danfoss | December 2019 AX327462277301en-000101 | 17

3

2

1

3/16”

12-13 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVO, end plate

Type Description Code number LX-port Letter

EVO End plate without LX-connection 11191585 - A

End plate with LX-connection 11191583 1/8 BSP B

11191582 7/16-20

End plate with Pneumatic port 11191584 1/8 BSP C

Item Description Code number Letter

1 EVO End Plate See above 1 1 1

2 Plug for LX port - - 1 3 Plug for pneumatic port - - 1 1

A B C

New EVO end plates released October 2018. See PIB (link) for details.

18 | © Danfoss | December 2019 AX327462277301en-000101

EVBS, MECHANICAL FLOW CONTROL SPOOLS,THROUGH ACTING

13mm HEX

8-10Nm

EVBS, MECHANICAL FLOW CONTROL SPOOLS,FEMALE EXTENSION

EVBS, MECHANICAL FLOW CONTROL SPOOLS,DETENT 03/02 POSITION

EVBS, ELECTRICAL FLOW CONTROL SPOOLS

EVBS, MECHANICAL FLOW CONTROL SPOOLS,MICRO SWITCH

8-10Nm

8-10Nm

6 mm

8-10 Nm

8-10Nm

8-10Nm

8-10Nm

11 mm

8-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVBS spools

Type Description Letter

EVBS Mechanical flow control spool, female extension and micro switch A

Mechanical flow control spool, female extension and through acting B

Mechanical flow control spool, female extension and detent 03/02 position C

Mechanical flow control spool, female extension D

Electrical flow control spool E

Item Description Code number Letter

1 Female extension 050548 1 1 - - 2 Screw including O-ring Ø 6.0 x 1.5 - 1 - - - 3 Main spool assembly - 1 1 1 - 4 Female extension 11169581 1 1 1 1 5 Screw incl. O-ring Ø 6.0 x 1.5 - - 1 - - -

A B C D E

©

Danfoss | December 2019 AX327462277301en-000101 | 19

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

Item Description Code number Letter

A B C D E

6 Screw incl. O-ring Ø 6.0 x 1.5 - - - 1 - 7 Main spool assembly without spring and spring

stop

8 Detent kit 11177713 - - - 1 9 Plug incl. O-ring Ø 6.0 x 1.5 - - - - - 1

10 Main spool - - - - - 1

11 Tension rod incl. spring, spring stop and O-ring Ø

6.0 x 1.5

For EVBS spool part numbers, see ECO 80 Technical Information.

- - - 1 - -

- - - - - 1

20 | © Danfoss | December 2019 AX327462277301en-000101

1

2

3

3

3

3

4

3 mm

1.5-3.5 Nm

13 mm

7-9 Nm

10 mm

5-7 Nm

3 mm

4 mm

9-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVM, mechanical actuation

Type Description Code number Letter

EVM EVM actuator 11119157 A

EVM actuator with lever 11167001 B

EVM actuator with adjustment screws 11145204 C

EVM actuator with adjustment screws and lever 11167002 D

Item Description Code number Letter

1 EVM - 1 1 1 1

2 Lever with handle and base 11107587 - 1 - 1

3 Screw M5 x 16 (12.9) - 4 4 4 4

4 Profile O-ring - 1 1 1 1

A B C D

©

Danfoss | December 2019 AX327462277301en-000101 | 21

2

1

4 mm

9-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVC, cover for mechanical actuation

Type Description Code number

EVC Cover for mechanical activation 11171318

Item Description

1 Screw M5 x 16 (12.9)

2 O-ring Ø 20.35 x 1.78

22 | © Danfoss | December 2019 AX327462277301en-000101

1

4 mm

9-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVOS, open spool through action

Type Description Code number

EVOS EVOS80LS-Actuator-Thru 11175233

Item Description

1 Screw M5 x 16 (12.9)

©

Danfoss | December 2019 AX327462277301en-000101 | 23

1

2

3

3

3

3

1

4

3

3

3

3

4 mm

9-10 Nm

4 mm

9-10 Nm

13 mm

9-10 Nm

13 mm

9-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVOS, open spool mechanical actuation

Type Description Code number

EVOS EVOS80LS-Actuator-Mech 047768

EVOS80LS-Actuator-Mech with lever 11175314

EVOS80LS-Actuator-Mech with robust lever 11227308

Item Description Code number

1 Housing incl. screws 2 Lever with handle and base 11170923

24 | © Danfoss | December 2019 AX327462277301en-000101

4 mm

9-10 Nm

1

4 mm

9-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

Item Description Code number

3 Screw M5 x 16 (12.9) 4 Robust lever with handle and base 11194826

ECO 80 EVME, spring center/detent

Type Description Code number

EVME Spring centering, detent 03/02 position 11169579

ECO 80 EVME, through action

Type Description Code number

EVME Through action 11169580

©

Danfoss | December 2019 AX327462277301en-000101 | 25

2

1

4 mm

9-10 Nm

1”

25-27 Nm

4 mm

4-5 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

Item Description

1 Screw M5 x 16 (12.9)

ECO 80 EVME, micro switch NO

Type Description Code number

EVME Micro switch NO 11170841

Item Description Code number

1 Rubber boot 11177717

2 Micro switch 11178486

26 | © Danfoss | December 2019 AX327462277301en-000101

2

1

4 mm

9-10 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVH, hydraulic actuation

Type Description Code number Letter

EVH Cover for hydraulic actuation – 9/16-18 UNF 11169487 A

Cover for hydraulic actuation – G1/4 11169486 B

Item Description Code number Letter

A B

1 Screw M5 x 16 (12.9) - 4 4

2 Set of seals - 1 1

©

Danfoss | December 2019 AX327462277301en-000101 | 27

1

2

3

4 mm

7 ± 0.5 Nm

3 mm

5 ± 0.5 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVHC, proportional electrical control

Type Description Code number Letter

EVHC DEUTSCH connector 12 V 11162297 A

DEUTSCH connector 24 V 11162298 B

Item Description Code number Letter

A B C D

1 Screw M5 x 16 (12.9) - 4 4 4 4

2 Proportional Coil 12 V, DEUTSCH connector incl. 4

3 Set of seals - 1 1 1 1

screws

Proportional Coil 24 V, DEUTSCH connector incl. 4

screws

11061233 2 - 2 -

11061234 - 2 - 2

28 | © Danfoss | December 2019 AX327462277301en-000101

1

2

3

4

4 mm

7 ± 0.5 Nm

13 mm

2 ± 0.5 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVHCO, ON/OFF

Type Description Code number Letter

EVHCO DEUTSCH connector 12 V 11186922 A

DEUTSCH connector 24 V 11186911 B

Item Description Code number Letter

A B

1 Housing - 1 1

2 Screw M5 x 16 - 4 4

3 Coil DEUTSCH connector 12 V 11198786 2 -

Coil DEUTSCH connector 24 V 11198787 - 2

4 Set of seals 11198712 1 1

This is a new version of the EVHCO ON/OFF actuator released June 2019. See PIB PV2019-419 for details.

©

Danfoss | December 2019 AX327462277301en-000101 | 29

3

1

2

2

4 mm

7 ± 0.5 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVPN, pneumatic actuator

Type Description Code number Letter

EVPN Pneumatic actuator module 11198492 A

Item Description Code number Letter

1 EVPN - 1

2 Plug for Air Inlet supply 1/8 BSP – ISO1179 N-NBR90 - 2

3 Screw M5 x 65 - 4

* Set of seals 11230331 1

A

30 | © Danfoss | December 2019 AX327462277301en-000101

1

2

3

4

3

5

17 mm

1-1.5 Nm

4 mm

7 ± 0.5 Nm

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVPN, electrical pneumatic actuator

Type Description Code number Letter

EVPN Electric pneumatic actuator module – DEUTSCH connector 12 V 11193722 A

Electric pneumatic actuator module – DEUTSCH connector 24 V 11193723 B

Electric pneumatic actuator module – AMP connector 24 V 11194345 C

Item Description Code number Letter

A B C

1 EVPN - 1 1 1

2 Screw M5 x 65 - 4 4 4

3+4+5 Coil DEUTSCH connector 12 V 11234123 2 - -

* Set of seals 11230331 1 1 1

Coil DEUTSCH connector 24 V 11234124 - 2 Coil AMP connector 24 V 11142988 - - 2

©

Danfoss | December 2019 AX327462277301en-000101 | 31

1

1

1

1

1

1

18-20 Nm

13 mm [0.50 in]

18-20 Nm

13 mm [0.50 in]

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 EVT, assembly kit

Item Description Code number

1 Set of seals for ECO 80 wit 7 work sections: EVB 80 11178489

32 | © Danfoss | December 2019 AX327462277301en-000101

Service and Parts Manual

Directional Valve Group ECO 80

Service parts

ECO 80 set of seals

Type Code number Letter

EVP Module 11177669 A

EVP with facilities for EVPX Module 11177670 B

EVB, Low & High body Module 11177712 C

EVT For ECO 80 wit 7 work sections: EVB8011178489 D

EVBS, Mechanical spools Module 11177715 E

EVM Module 11177716 F

EVHC/O and EVH Module 11177718 G

EVC Module 11187093 H

Description Letter

A B C D E F G H

O-ring Ø 11.0 x 2.0 1 1 - - - - - O-ring Ø 15.3 x 2.4 (NBR D-90) 2 2 - - - - - O-ring Ø 11.89 x 1.98 (NBR D-90) 2 1 - - - - - O-ring Ø 1.98 x 11.89 (NBR D-90) - 1 - - - - - Plug 7/16-20 UNF-2A - 1 - - - - - O-ring Ø 16.36 x 2.21 (NBR D-90) - - 1 - - - - O-ring Ø 15.6 x 1.78 - - 2 - - - - O-ring Ø 7.65 x 1.78 (NBR D-90) - - 2 - - - - O-ring Ø 2.5 x 11 (NBR D-90) - - - 24 - - - O-ring Ø 2 x 5 (NBR D-70) - 1 - 16 - - - O-ring Ø 2.62 x 15.54 (Viton) - 1 - 16 - - - O-ring Ø 2.62 x 15.54 (NBR D-70) - - - - 2 - - Backup - - - - 2 - - Seal nut - - - - - 2 - Screw M5 x 16 (12.9) - - - - - 4 4 4

Profile O-ring - - - - - 1 - Profile ring - - - - - - 2 Profile ring - - - - - - 2 O-ring Ø 20.35 x 1.78 (NBR D-70) - - - - - - 1 O-ring Ø 41 x 1.78 (NBR D-70) - - - - - - - 1

O-ring Ø 3.68 x 1.78 (NBR D-70) - - - - - - - 1

©

Danfoss | December 2019 AX327462277301en-000101 | 33

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | December 2019 AX327462277301en-000101

Loading...

Loading...