Page 1

Technical Information

Directional Control Valve

ECO 80

www.danfoss.com

Page 2

Technical Information

ECO 80 Directional Control Valve

Revision history Table of revisions

Date Changed Rev

September 2020 Document entirely re-worked - new version of document 0301

February 2020 Updated document number to match online reference 0201

August 2019 Updated code numbers for EVO end plates 0103

March 2017 Updated schematic 0102

October 2016 First edition 0101

2 | © Danfoss | September 2020 BC199786485316en-000301

Page 3

Technical Information

ECO 80 Directional Control Valve

Contents

General information

General description......................................................................................................................................................................... 5

ECO modules......................................................................................................................................................................................5

Safety in systems...............................................................................................................................................................................5

ECO 80 LS sectional view............................................................................................................................................................... 6

Mechanical acting ECO 80

ECO 80 mechanical modules overview.................................................................................................................................... 8

EVP inlet modules - mechanical acting

Open center EVP.............................................................................................................................................................................10

Closed center EVP.......................................................................................................................................................................... 12

EVB basic modules - mechanical acting

EVB low body...................................................................................................................................................................................15

EVB medium body......................................................................................................................................................................... 16

EVB basic modules accessories

PVLP shock/anti-cavitation valve............................................................................................................................................. 18

PVLA suction valve and cavity plug.........................................................................................................................................20

EVBS mechanical flow control spools

EVBS fluid flow characteristics - Theoretical performance..............................................................................................22

EVBS - female extension.............................................................................................................................................................. 24

EVBS - female extension and through acting...................................................................................................................... 25

EVBS - female extension and Detent 03 and 02 position spool out or in..................................................................26

EVBS - female extension and Micro Switch...........................................................................................................................27

ECO 80 mechanical - actuation

EVOS - open spool through action.......................................................................................................................................... 29

EVOS - open spool mechanical actuation............................................................................................................................. 31

EVME - open spool centering.................................................................................................................................................... 33

EVME - micro switch NO.............................................................................................................................................................. 35

EVOS x EVME combination overview......................................................................................................................................36

EVO - end plate

EVO......................................................................................................................................................................................................37

EVO with LX-connection..............................................................................................................................................................37

Electrical actuated ECO 80

ECO 80 electrical modules overview.......................................................................................................................................39

EVP inlet modules - electrical

Open center EVP with PPRV....................................................................................................................................................... 41

Closed center EVP with PPRV.....................................................................................................................................................44

EVP inlet module accessories

EVPX electrical LS pressure unloading valve........................................................................................................................46

Plug for external pilot oil supply.............................................................................................................................................. 47

EVB basic modules - electrical actuation

EVB low body...................................................................................................................................................................................49

EVB medium body......................................................................................................................................................................... 50

EVB basic modules accessories

PVLP shock/anti-cavitation valve............................................................................................................................................. 51

PVLA suction valve and cavity plug.........................................................................................................................................52

EVBS electrical flow control spools

EVBS fluid flow characteristics - Theoretical performance..............................................................................................54

EVBS - electrical flow control spool......................................................................................................................................... 55

EVBS - electrical flow control spool with soft spring for EVHCO...................................................................................56

EVBS - EVPN spool..........................................................................................................................................................................56

ECO 80 electrical - actuation

EVM mechanical actuation.........................................................................................................................................................57

©

Danfoss | September 2020 BC199786485316en-000301 | 3

Page 4

Technical Information

ECO 80 Directional Control Valve

Contents

EVM without adjustment screws........................................................................................................................................ 57

EVM with adjustment screws............................................................................................................................................... 57

EVM dimensions, torque, and part numbers..................................................................................................................57

EVC - cover for mechanical actuation.....................................................................................................................................59

EVH - hydraulic actuation............................................................................................................................................................60

EVHC - electrical actuation..........................................................................................................................................................61

EVHCO - Low current on/off electrical actuation................................................................................................................63

EVPN - pneumatic actuation......................................................................................................................................................64

EVPN - electrical pneumatic action..........................................................................................................................................65

EVO - end plate

EVO with pneumatic port............................................................................................................................................................68

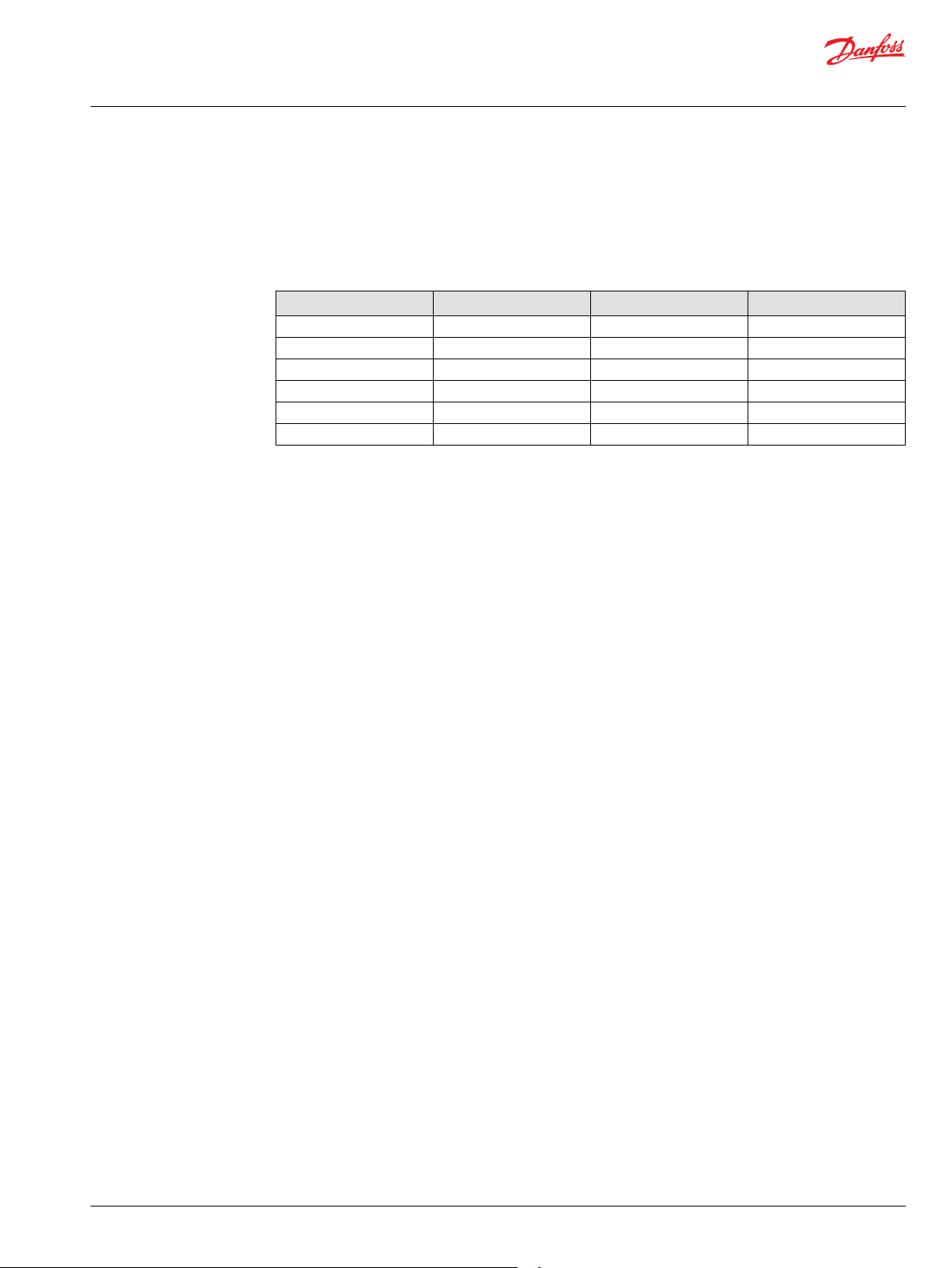

EVT - assembly kit for both mechanical and electrical acting

ECO 80 dimension overview

4 | © Danfoss | September 2020 BC199786485316en-000301

Page 5

Technical Information

ECO 80 Directional Control Valve

General information

General description

The ECO 80 LS is a hydraulic load sensing proportional valve group designed to give maximum flexibility

in design and build concept. The ECO 80 LS is designed as a load sensing directional control valve which

will lead to increased machine performance, higher efficiency, reduced cooling requirements and fuel

saving compared to conventional directional control valves.

ECO 80 LS features

PVG load-sensing proportional valves features and benefits summarized inb bullets below:

•

Load sensing directional control:

Proportional control of oil flow to a work function

‒

•

Modular build concept:

Up to 12 basic modules per ECO 80 LS valve group

‒

Different, interchangeable spool variants

‒

System pressure up to 280 bar

‒

Work port pressure up to 320 bar

‒

Compact design and installation

‒

ECO modules

EVP, pump side modules

•

Built-in pressure relief valve

•

Pressure gauge connection

•

Versions:

Open center version for systems with fixed displacement pumps

‒

Closed center version for systems with variable displacement pumps

‒

Integrated 25 bar pilot oil supply for hydraulic and electrohydraulic actuaqtion

‒

Versions prepared for electrical LS unloading valve

‒

EVB, basic modules

•

Interchangeable spools

•

Load holding check valve in channel P

•

Option for shock and suction valves for port A and B

Actuation modules

The basic module could be fitted with three main different actuation modules:

•

Mechanical

•

Electrical

•

Hydraulic

•

Pneumatic

Safety in systems

All makes and all types of control valves (incl. proportional valves) can fail, thus the necessary protection

against the serious consequences of function failure should always be built into the system. For each

application an assessment should be made for the consequences of pressure failure and uncontrolled or

blocked movements.

©

Danfoss | September 2020 BC199786485316en-000301 | 5

Page 6

W

Technical Information

ECO 80 Directional Control Valve

General information

Warning

All makes/brands and types of directional control valves – inclusive proportional valves – can fail and

cause serious damage. It is therefore important to analyze all aspects of the application.

Because the proportional valves are used in many different operation conditions and applications, the

manufacturer of the application is alone responsible for making the final selection of the products – and

assuring that all performance, safety and warning requirements of the application are met.

The process of choosing the control system – and safety levels – is governed by the machine directives

EN 13849 (Safety related requirements for control systems).

ECO 80 LS sectional view

6 | © Danfoss | September 2020 BC199786485316en-000301

Page 7

Technical Information

ECO 80 Directional Control Valve

General information

1 Work Section (EVB)

2 Spool (EVBS)

3 Check valve

4 Open spool centering (EVME)

5 Mechanical actuator (EVOS)

6 Inlet module (EVP)

7 Load sense relief valve

8 Unloader spool

9 Uloader spool spring

10 Mechanical actuator (EVM)

11 Electrical actuator (EVHC)

12 Shock valve (PVLP)

13 Shuttle disc

Option moutn only possible with EVOS/EVME configuration

©

Danfoss | September 2020 BC199786485316en-000301 | 7

Page 8

Technical Information

ECO 80 Directional Control Valve

Mechanical acting ECO 80

This section will only be about the mechanical acting modules of the ECO 80 portfolio. For information on

the electrical actuated modules of the ECO80 portfolio, see Electrical actuated ECO 80 on page 39.

ECO 80 mechanical modules overview

8 | © Danfoss | September 2020 BC199786485316en-000301

Page 9

[3.86]

98

[3.86]

98

[2.10]

53,4

[4.90]

124,5

[0.17]

4,3

Technical Information

ECO 80 Directional Control Valve

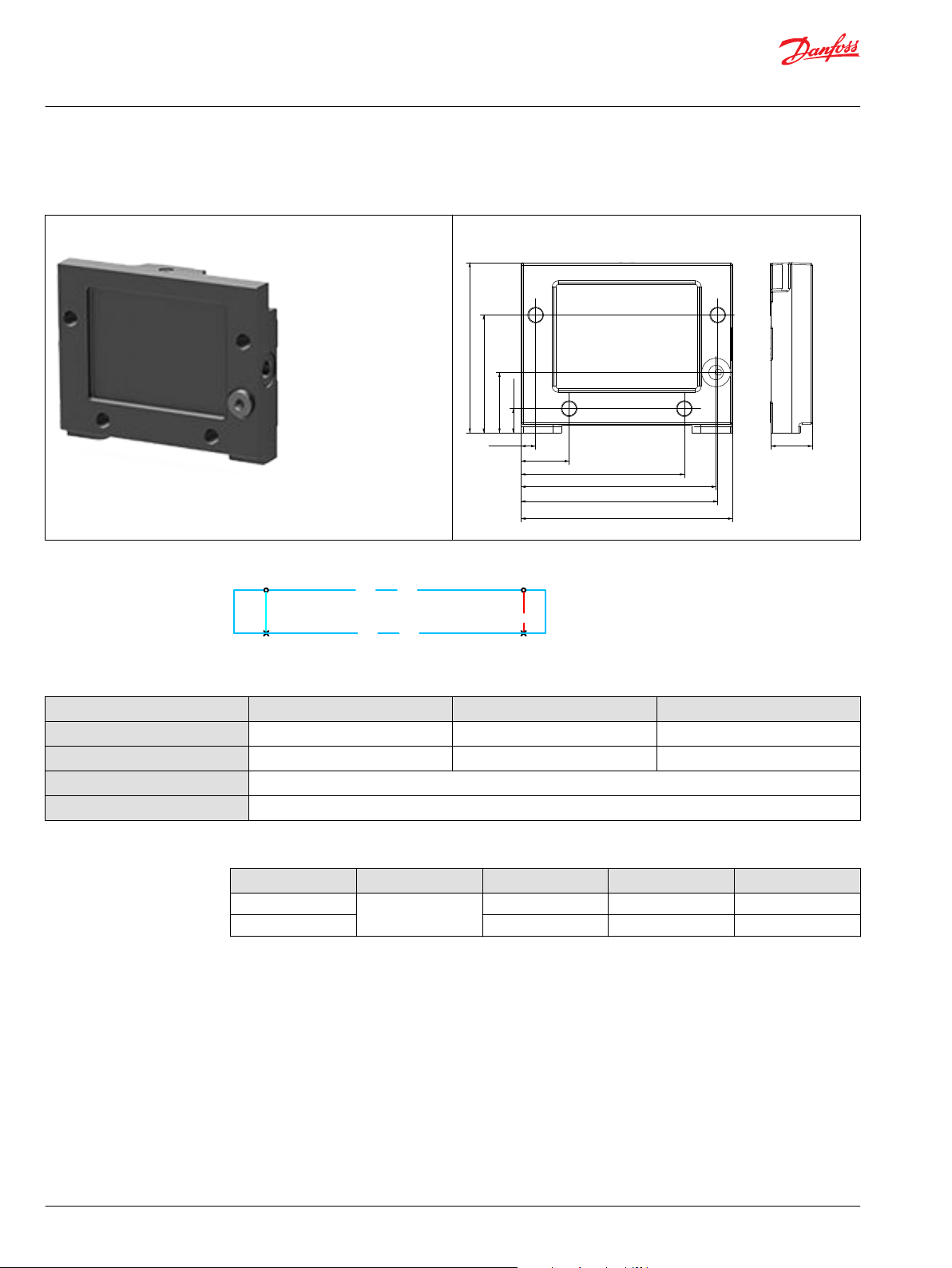

EVP inlet modules - mechanical acting

The ECO 80 EVP inlet modules, also referred to as pump side modules, act as an interface between the

ECO 80 directional valve group and the hydraulic pump and tank reservoir.

EVP Inlet module EVP Inlet module dimensions

Fixed displacement pump symbol Variable displacement pump symbol

The EVP inlet module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the EVP to suit the demands of any hydraulic system:

•

Open center EVP (for fixed displacement pumps)

•

Closed center EVP (for variable displacement pumps)

©

Danfoss | September 2020 BC199786485316en-000301 | 9

Page 10

LS

T

P

M

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - mechanical acting

Open center EVP

The basic Open Center EVP inlet module is intended for use with fixed displacement pumps in

applications, where a valve group with mechanically controlled work sections is desired.

The Open Center EVP features:

•

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

Open center EVP schematic

Technical specification for EVP

Max. P-port continuous Max. T-port static/dynamic Max. rated flow

280 bar [4061 psi] 25/40 bar [365/580 psi] 100 l/min [26.4 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

10 | © Danfoss | September 2020 BC199786485316en-000301

Page 11

20 40 60 80

[l/min]

[US gal/min]

4 8 12 16 20

300

250

200

150

100

50

0

Q

PP

4000

3000

2000

1000

0

0

[psi] [bar]

0

Q

10 30 50 70

50 bar

100 bar

150 bar

200 bar

250 bar

280 bar

24

90 100

Curves to inlet pressure x flow

20 40 60 80

[l/min]

[US gal/min]

4 8 12 16 20

20

16

12

8

4

0

Q

Δ PΔ P

240

160

80

0

0

[psi] [bar]

0

Q

100

24

24

320

Neutral flow pressure in EVP open center inlet

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - mechanical acting

Theoretical performance graphs

Pressure relief valve characteristics

Neutral by-pass pressure drop characteristics (open center)

Part numbers for Open Center EVP

Part numbers P-port T-port M-, LS-port Mounting

11173005

11172981

©

Danfoss | September 2020 BC199786485316en-000301 | 11

G 1/2 G 1/2 G 1/4 M8 x 1.25

7/8-14 UNF 7/8-14 UNF 9/16-18 UNF M8 x 1.25

Page 12

LS

T

P

M

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - mechanical acting

Closed center EVP

The basic Closed Center EVP inlet is intended for use with variable displacement pumps in applications

where a valve group with mechanically controlled work sections is desired.

The Closed Center EVP features:

•

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

Closed center EVP schematic

Technical specification for EVP

Max. P-port continuous Max. T-port static/dynamic Max. rated flow

280 bar [4061 psi] 25/40 bar [365/580 psi] 100 l/min [26.4 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

12 | © Danfoss | September 2020 BC199786485316en-000301

Page 13

20 40 60 80

[l/min]

[US gal/min]

4 8 12 16 20

300

250

200

150

100

50

0

Q

PP

4000

3000

2000

1000

0

0

[psi] [bar]

0

Q

10 30 50 70

50 bar

100 bar

150 bar

200 bar

250 bar

280 bar

24

90 100

Curves to inlet pressure x flow

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - mechanical acting

Theoretical performance graphs

Pressure relief valve characteristics

Part numbers for Mechanical Acting Closed Center EVP

Part numbers P-port T-port M-, LS-port Mounting

11173006

11173002

G 1/2 G 1/2 G 1/4 M8 x 1.25

7/8-14 UNF 7/8-14 UNF 9/16-18 UNF M8 x 1.25

©

Danfoss | September 2020 BC199786485316en-000301 | 13

Page 14

[2.70]68.5

[1.70]43

[0.35]9

[1.57]40

[1.38]35

[0.79]

20

[0.20]5

[0.19]4.8

[4.80]122

[3.58]91

[1.08]

27.5

[0.31]

8

[3.72]94.5

[4.49]114

[0.19]4.7

[3.07]78

[1.69]43

[2.70]68.5

[0.35]9

[1.57]40

[1.38]35

[0.79]

20

[0.20]5

[2.42]61.5

[4.49]114

[0.31]8

[3.72]94.5

[1.08]27.5

[0.28]7

Technical Information

ECO 80 Directional Control Valve

EVB basic modules - mechanical acting

The ECO 80 EVB basic modules, also referred to as work sections, are the interface between the ECO 80

directional control valve and the work function such as a cylinder or a motor. The EVB comes in two main

variants – a low body and a medium body with shock/anti-cavitation valve facility (PVLP)

EVB low basic module EVB low basic module dimensions

EVB medium basic module EVB medium basic module dimensions

The EVB basic module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the EVB to suit the demands of any hydraulic system:

•

EVB low body

•

EVB medium body

14 | © Danfoss | September 2020 BC199786485316en-000301

Page 15

A

B

1

0

2

Technical Information

ECO 80 Directional Control Valve

EVB basic modules - mechanical acting

EVB low body

The EVB low body is intended for controlling a work function where the function behavior in terms of

flow and pressures allows dependency on the load pressure of other functions used simultaneously. The

integrated load drop check valve prevents flow back from work ports influencing other functions.

The EVB low body features:

•

Integrated LS shuttle network

•

Load drop check valve

Schematic

Technical specification for A/B-port

Max. continuous pressure Max. intermittent pressure Max. rated flow

280 bar [4061 psi] 320 bar [4641 psi] 100 l/min [26.4 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers

Part numbers A/B-port

11168505

11168504

G 1/2

7/8-14 UNF

©

Danfoss | September 2020 BC199786485316en-000301 | 15

Page 16

A

B

1

0

2

Technical Information

ECO 80 Directional Control Valve

EVB basic modules - mechanical acting

EVB medium body

The EVB low body is intended for controlling a work function where the function behavior in terms of

flow and pressures allows dependency on the load pressure of other functions used simultaneously. The

integrated load drop check valve prevents flow back from work ports influencing other functions.

Compared to the EVB low body the medium body has the option of adding PVLP/PVLA to the work

section.

The EVB medium body features:

•

Integrated LS shuttle network

•

Load drop check valve

•

Shock/anti-cavitation valve and suction facility (PVLP/PVLA)

Schematic

Technical specification for A/B-port

Max. continuous pressure Max. intermittent pressure Max. rated flow

280 bar [4061 psi] 320 bar [4641 psi] 100 l/min [26.4 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers

Part number A/B-port

11168503

11168502

G 1/2

7/8-14 UNF

16 | © Danfoss | September 2020 BC199786485316en-000301

Page 17

Technical Information

ECO 80 Directional Control Valve

EVB basic modules accessories

The generic EVB module accessory platform include the PVLP shock and anti-cavitation valve and PVLA

suction valve.

•

PVLP Shock and Anti-cavitation valve

•

PVLA Suction valve

•

Cavity plug

©

Danfoss | September 2020 BC199786485316en-000301 | 17

Page 18

Port pressure

Technical Information

ECO 80 Directional Control Valve

EVB basic modules accessories

PVLP shock/anti-cavitation valve

The PVLP will relief a pressure peak to the internal tank galleries and will furthermore suck oil from the

tank to the work port to prevent cavitation. Pressure settings range 32-320 bar [460-4641 psi].

Features:

•

Shock valve

•

Anti-cavitation

•

Lifetime of 200,000 actuations

•

Optional fixed or adjustable

PVLP schematic

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for fixed PVLP

Part number Pressure setting in bar [psi]

157B2032 32 [460]

157B2050 50 [725]

157B2063 63 [914]

157B2080 80 [1160]

157B2100 100 [1450]

157B2125 125 [1813]

157B2140 140 [2031]

157B2150 150 [2175]

157B2160 160 [2320]

157B2175 175 [2538]

157B2190 190 [2755]

157B2210 210 [3045]

157B2230 230 [3335]

157B2240 240 [3480]

157B2250 250 [3625]

157B2265 265 [3845]

157B2280 280 [4061]

157B2300 300 [4351]

157B2320 320 [4641]

18 | © Danfoss | September 2020 BC199786485316en-000301

Page 19

Technical Information

ECO 80 Directional Control Valve

EVB basic modules accessories

Part numbers for adjustable PVLP

Part number Pressure setting in bar [psi]

11006594 121-250 [1755-3626]

11006595 251-285 [3640-4134]

©

Danfoss | September 2020 BC199786485316en-000301 | 19

Page 20

Port pressure

Technical Information

ECO 80 Directional Control Valve

EVB basic modules accessories

PVLA suction valve and cavity plug

The PVLA will suck oil from the tank to the work port to prevent cavitation by the 0.5 bar spring. The plug

will ensure that when using a single acting spool, all flow returning through the work port is led to tank.

PVLA schematic

Cavity plug schematic

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for PVLA and plug

PVLA Cavity plug

157B2001 11177714

20 | © Danfoss | September 2020 BC199786485316en-000301

Page 21

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

The mechanical acting EVBS spools determine the flow out of the work section and are based on a

generic platform with a wide selection of additional features, enabling you to tailor the EVBS to suit the

demands of any hydraulic system and any function.

The mechanical acting EVBS spool comes in four different main variants:

•

EVBS Female Extension

•

EVBS Female Extension and through acting

•

EVBS Female Extension and Detent 03 position and 02 position spool out or in

•

EVBS Female Extension and Micro Switch

1

1

For 02 position detent spool out is necessary to use an accessory part number 11173406, see EVME, detent 02 position spool to A or

B

©

Danfoss | September 2020 BC199786485316en-000301 | 21

Page 22

BP

5

10

15

20

25

30

35

40

45

50

55

60

65

[l/min]

[US gal/min]

70

75

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

A

P

[mm]

<-Spool stroke->

5

43

[in]

0-0.04-0.08-0.12

-0.16-0.20

2

-0.24

1

0

-0.28-0.31-0.35

-0.39

A

E

C

D

B

85

90

95

100

22

23

24

25

26

0-1

-2

-3

-4

-5

0.39

0.350.310.28

0.240.20

0.16

0.120.080.04

0

[mm]

[in]

Flow

105

110

115

120

27

28

29

30

31

32

Spool types:

A = 8/min

B = 25 l/min

C = 40 l/min

D = 60 l/min

E = 80 l/min

F = 100 l/min*

F

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

EVBS fluid flow characteristics - Theoretical performance

Oil flow as a function of spool travel

22 | © Danfoss | September 2020 BC199786485316en-000301

Page 23

40 80 120 160

[l/min]

[US gal/min]

8 16 24 32 40

50

40

30

20

10

0

600

400

200

0

0

[psi] [bar]

0

A

B

D

C

20 60 100 140

E

TA/B

A = Spool 8 l/min

B = Spool 25 l/min

C = Spool 40 l/min

D = Spool 60 l/min

E = Spool 80 l/min

F

F = Spool 100 l/min

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

Pressure drop at maximum spool travel (A/B-T)

©

Danfoss | September 2020 BC199786485316en-000301 | 23

Page 24

20.7 [0.81]

171.5 [6.75]

33 [1.30]

A

PT T

B

A

PT T

B

A

PT T

B

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

EVBS - female extension

EVBS Female Extension EVBS Female Extension dimensions mm [in]

Part numbers for EVBS Female Extension

Type Schematic Flow, l/min [US gal/min]

4-way, 3-position

Closed neutral position

8

[2.11]

11169728 11169733 11169737 11169741 11169745 11182571

25

[6.61]

40

[10.57]60[15.85]80[21.13]

100

[26.42]

4-way, 3-position

Throttled open neutral position

3-way, 3-position

Closed neutral position

11169725 11169730 11169735 11169739 11169743 11182572

11169729 11169734 11169738 11169742 11169746 -

24 | © Danfoss | September 2020 BC199786485316en-000301

Page 25

33 [1.3]171.5 [6.75]76.5 [3.0]

A

PT T

B

A

PT T

B

A

PT T

B

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

EVBS - female extension and through acting

EVBS Female Extension and through acting EVBS Female Extension and through acting dimensions mm [in]

Part numbers for EVBS Female Extension

Type Schematic Flow, l/min [US gal/min]

4-way, 3-position

Closed neutral position

8

[2.11]

11170744 11170747 11170750 11170753 11170756 11187072

25

[6.61]

40

[10.57]60[15.85]80[21.13]

100

[26.42]

4-way, 3-position

Throttled open neutral position

3-way, 3-position

Closed neutral position

11170743 11170746 11170749 11170752 11170755 11187061

11170745 11170748 11170751 11170754 11170757 -

©

Danfoss | September 2020 BC199786485316en-000301 | 25

Page 26

Ø

16

Ø

33

[1.10]28

[0.90]

23

[5.55]141

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

EVBS - female extension and Detent 03 and 02 position spool out or in

EVBS Female Extension and Detent EVBS Female Extension and Detent dimensions mm [in]

For 02 position detent spool out is necessary to use an accessory part number 11173406, see EVME,

detent 02 position spool to A or B

Part numbers for EVBS Female Extension

Type Schematic Flow, l/min [US gal/min]

4-way, 3-position

Closed neutral position

4-way, 3-position

Throttled open neutral position

3-way, 3-position

Closed neutral position

8

[2.11]

11170627 11170634 11170638 11170642 11170646 11182609

11170625 11170632 11170636 11170640 11170644 11182610

11170631 11170635 1117639 11170643 11170647 -

25

[6.61]

40

[10.57]60[15.85]80[21.13]

100

[26.42]

26 | © Danfoss | September 2020 BC199786485316en-000301

Page 27

33 [1.3]

171.5 [6.75]134.5 [5.3]

A

PT T

B

A

PT T

B

A

PT T

B

Technical Information

ECO 80 Directional Control Valve

EVBS mechanical flow control spools

EVBS - female extension and Micro Switch

EVBS Female Extension and Micro Switch EVBS Female Extension and Micro Switch dimensions mm [in]

Part numbers for EVBS Female Extension

Type Schematic Flow, l/min [US gal/min]

4-way, 3-position

Closed neutral position

8

[2.11]

11170264 11170268 11170272 11170276 11170280 11187073

25

[6.61]

40

[10.57]60[15.85]80[21.13]

100

[26.42]

4-way, 3-position

Throttled open neutral position

3-way, 3-position

Closed neutral position

11170262 11170266 11170270 11170274 11170278 11187074

11170265 11170269 11170273 11170277 11170281 -

©

Danfoss | September 2020 BC199786485316en-000301 | 27

Page 28

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

ECO80 Mechanical actuation can be done manually or mechanically

ECO80 mechanical actuation overview:

•

EVOS - Open spool through action

•

EVOS - Open spool mechanical actuation

•

EVME - Open spool centering

•

EVME - Micro switch NO

28 | © Danfoss | September 2020 BC199786485316en-000301

Page 29

9 [0.35]

[0.77]

19.6

[2.78]70.5

[1.55]39.4

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

EVOS - open spool through action

The EVOS open spool through action consists of an aluminum base with a rubber boot to protect the

spool, mounted on the end of the valve slice, the connection with application is a female extension

assembled on the main spool.

The valve is actuated by directly pulling or pushing the main spool inside the valve hence controlling the

flow. Actuating the spool fully will move all 5 mm and give full flow. The EVOS should be used with open

spool mechanical actuation and can be combined with any EVME, spring center, detent, through action

and micro switch.

EVOS through action EVOS through action dimensions mm [in]

Operating force for EVOS through action

Spool displacement Operating linear force

EVOS + EVME (Through Acting)

From neutral position 135 ± 5 [N]

Maximum spool travel 180 ± 5 [N]

EVOS through action function

©

Danfoss | September 2020 BC199786485316en-000301 | 29

Page 30

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

Part numbers for EVOS mechanical actuation

Description Part number

EVOS80LS Through action 11172533

30 | © Danfoss | September 2020 BC199786485316en-000301

Page 31

64 [2.52]

[4.50]114.4

[7.47]189.8

[1.54]39

125.6 [4.95]

[2.11]53.5

[8.50]215.7

[1.54]39

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

EVOS - open spool mechanical actuation

The EVOS mechanical actuation consists of an aluminum base with a lever and a rubber boot to protect

the spool, mounted on the end of the valve slice. When actuating the lever, the operator is directly

pulling or pushing on the main spool inside the valve hence controlling the flow.

The lever has a travel of 14° in either direction from neutral. Actuating the lever fully will move the spool

all 5 mm and give full flow. The lever can be mounted / removed without having to remove the EVOS

base.

The EVOS should be used with open spool mechanical actuation and can be combined with any EVME,

spring center, detent, through action and micro switch.

EVOS mechanical actuation Dimensions in mm [in]

EVOS mechanical actuation power lever Dimensions in mm [in]

©

Danfoss | September 2020 BC199786485316en-000301 | 31

Page 32

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

Operating torque for EVOS mechanical actuation

Spool displacement

From neutral position

Maximum spool travel

No control level position

Control lever range

Part numbers for EVOS mechanical actuation

Description Part number

EVOS80LS Mechanical Actuator 047768

EVOS80 Mechanical Actuator with lever 11175314

EVOS80 Mechanical Actuator with power lever 11227308

Accessories - Base handle black 11170923

Accessories - Base handle black power lever 11194826

Operating torque N·m

EVOS + EVME (sspring center, Micro Switch)

3.5 ± 0.2

4.5 ± 0.2

2 x 6

±14°

32 | © Danfoss | September 2020 BC199786485316en-000301

Page 33

[1.34]34

[2.70]68.5

[1.74]44.2

[2.70]68.5

[1.34]34

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

EVME - open spool centering

The EVME spring centering consists of an aluminum cover mounted on the end of the valve slice which

ensures the position of the spool in neutral positions and spool in/out. The EVME spring centering should

be used with spool option: Mechanical flow control spools, Female Extension. And can be combined with

any EVOS, Open spool actuators.

EVME spring centering Dimensions in mm [in]

EVME through action Dimensions mm [in]

©

Danfoss | September 2020 BC199786485316en-000301 | 33

Page 34

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

Detent positions

EVME, detent 03 position

The EVME detent 03 positions consists of an aluminum cover mounted on the end of the valve slice

which keep the position of the spool in neutral positions and spool in/out.

The EVME detent 03 positions should be used with spool option: Mechanical flow control spools, Female

Extension and Detent 03 position. And can be combined with any EVOS, Open spool actuators.

EVME, detent 02 position spool to A or B

The EVME detent 02 positions consists of an aluminum cover mounted on the end of the valve slice

which keep the position of the spool in neutral positions and spool out, position spool in is blocked.

The EVME detent 02 positions should be used with spool option: Mechanical flow control spools, Female

Extension and Detent 03 position with accessory part number 11173406. And can be combined with any

EVOS, Open spool actuators.

EVME, through action

The EVME through action consists of an aluminum cover with a rubber boot to protect the spool,

mounted on the end of the valve slice which ensures the position of the spool in neutral positions and

spool in/out.

The valve is actuated by directly pulling or pushing the main spool inside the valve hence controlling the

flow. Actuating the spool fully will move all 5 mm and give full flow. The EVME through action should be

used with spool option: Mechanical flow control spools, Female Extension and through acting. Can be

combined with any EVOS, Open spool actuators.

Part numbers for EVME Spring centering

Description Part number

EVME80LS-COVER 11169579

Accessory Detent 02 Position 11173406

EVME80LS Through action 11169580

34 | © Danfoss | September 2020 BC199786485316en-000301

Page 35

[3.51]89.1

[3.56]90.5

[4.14]105.2

[8.92]226.6

[1.54]39

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

EVME - micro switch NO

The EVME Micro Switch consists of an aluminum cover mounted on the end of the valve slice, which

enables by two micro switches know which side the spool is being stroked, in or out.

The micro switches can have contacts in the configuration normally open “NO”. The EVME Micro Switch

should be used with spool option: Mechanical flow control spools, Female Extension and Micro Switch.

And can be combined with any EVOS, Open spool actuators.

EVME Micro switch Dimensions mm [in]

Technical data for EVME Micro Switch

Parameter Voltage

12 V 24 V

Max. current 10 A

Resistance 0.010 Ω ± 15 %

Part numbers for EVME micro switch

Description Connector type Protection class Part number

EVME80LS Micro Switch DEUTSCH DT04-2P IP 67 11170841

©

Danfoss | September 2020 BC199786485316en-000301 | 35

Page 36

Technical Information

ECO 80 Directional Control Valve

ECO 80 mechanical - actuation

EVOS x EVME combination overview

Work port A Work port B

EVOS, Open spool mechanical actuation EVME, Open spool centering

Mechanical

actuator

EVME,

Open spool centering

EVOS,

Open spool mechanical

actuation

Cover,

Spring center and

detent

Cover through action x x x

Micro Switch x x x

Mechanical actuator x x x

Mechanical actuator

with lever/power

lever

Through action x x x

x x x

Mechanical

actuator with

lever/power lever

Through

action

Cover,

Spring

center and

detent

x x x

Cover

through

action

Micro

Switch

36 | © Danfoss | September 2020 BC199786485316en-000301

Page 37

[4.51]114.5

[3.74]95

[1.10]

28

[4.84]123

[0.94]

24

[3.90]99

[2.70]68.5

[0.55]14

[0.33]8.5

Technical Information

ECO 80 Directional Control Valve

EVO - end plate

The ECO80 EVO end plates close off the valve stack section by placing them at the end. Furthermore, the

end plate is ensuring Load Sense (LS) is relieved to tank pressure when the valve is not operated.

The EVO end plate variants are based on a generic platform with a selection of additional features,

enabling you to tailor the EVO to suit the demands of any hydraulic system.

The generic EVO end plate platform includes the following main variants:

•

EVO

•

EVO with LX-connection and pneumatic port

•

EVO with pneumatic port

EVO

The EVO end plate closes off the valve stack section by placing it at the end. Furthermore, the end plate is

ensuring Load Sense (LS) is relieved to tank pressure when the valve is not operated

EVO EVO dimensions mm [in]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

EVO with LX-connection

©

Danfoss | September 2020 BC199786485316en-000301 | 37

Schematic

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for EVO end plate

Part number Description Mounting

11191585 EVO End plate M8

The EVO end plate closes off the valve stack section by placing it at the end. Furthermore, the end plate is

ensuring Load Sense (LS) is relieved to tank pressure when the valve is not operated. The LX port enables

Page 38

[4.51]114.5

[4.47]113.5

[3.74]95

[1.10]28

[4.84]123

[0.94]24

[1.38]35

[3.90]99

[2.70]68.5

[0.55]14

[0.33]8.5

Lx Pneumatic

Technical Information

ECO 80 Directional Control Valve

EVO - end plate

other remote valves to be connected onto the Load Sense shuttle network. The end plate also features a

blocked pneumatic port.

EVO with LX-connection Dimensions mm [in]

Schematic

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

Part numbers for EVO wioth LX-connection end plate

Part number Description LX port Pneumatic port Mounting

11191583 EVO End plate with

11191582 7/16-20 UNF G1/8-28 M8

LX connection

G1/8-28 G1/8-28 M8

38 | © Danfoss | September 2020 BC199786485316en-000301

Page 39

Technical Information

ECO 80 Directional Control Valve

Electrical actuated ECO 80

This section will only be about the electrical actuated modules of the ECO 80 portfolio. For information

on the mechanical acting modules of the ECO80 portfolio, see…

ECO 80 electrical modules overview

Electrical modules exploded view

©

Danfoss | September 2020 BC199786485316en-000301 | 39

Page 40

[2.10]53.4

[4.90]124.5

[3.72]94.5

[2.70]68.5

[0.33]8

[0.55]14

[2.17]55

[4.49]114

[5.34]135.6

[1.08]

27.5

[0.79]2

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - electrical

The ECO 80 EVP inlet modules, also referred to as pump side modules, act as an interface between the

ECO 80 directional valve group and the hydraulic pump and tank reservoir.

EVP Inlet Module Dimensions mm [in]

Fixed displacement pump symbol Variable displacement pump symbol

The EVP inlet module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the EVP to suit the demands of any hydraulic system:

•

Open center EVP with PPRV on page 41 (for fixed displacement pumps)

•

Closed center EVP with PPRV on page 44 (for variable displacement pumps

40 | © Danfoss | September 2020 BC199786485316en-000301

Page 41

LS

T

P

M

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - electrical

Open center EVP with PPRV

The Open Center EVP inlet with integrated pilot pressure reduction valve (PPRV) is intended for use with

fixed displacement pumps in applications, where a valve group with electro-hydraulically or hydraulically

controlled work sections is desired (EVH, EVHC or EVHCO).

The Open Center EVP with PPRV features:

•

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure Reducing valve (PPRV) for EVH, EVHC, or EVHCO

•

Optional LS unloading valve, EVPX

•

Optional plug for external pilot oil supply

Schematic

Technical specification for EVP with PPRV

Max. P-port continuous Max. T-port static/dynamic Max. rated flow

280 bar [4061 psi] 25/40 bar [365/580 psi] 100 l/min [26.4 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

©

Danfoss | September 2020 BC199786485316en-000301 | 41

Page 42

20 40 60 80

[l/min]

[US gal/min]

4 8 12 16 20

300

250

200

150

100

50

0

Q

PP

4000

3000

2000

1000

0

0

[psi] [bar]

0

Q

10 30 50 70

50 bar

100 bar

150 bar

200 bar

250 bar

280 bar

24

90 100

Curves to inlet pressure x flow

20 40 60 80

[l/min]

[US gal/min]

4 8 12 16 20

20

16

12

8

4

0

Q

Δ PΔ P

240

160

80

0

0

[psi] [bar]

0

Q

100

24

24

320

Neutral flow pressure in EVP open center inlet

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - electrical

Theoretical performance graphs

Pressure relief valve characteristics

Neutral by-pass pressure drop characteristics (open center)

Part numbers for Open Center EVP with PPRV

Part numbers P-port T-port M-, S-port Mounting EVPX

11172996 G 1/2 G 1/2 G 1/4 M8 x 1.25 11173010 7/8-14 UNF 7/8-14 UNF 9/16-18 UNF M8 x 1.25 -

42 | © Danfoss | September 2020 BC199786485316en-000301

Page 43

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - electrical

Part numbers for Open Center EVP with PPRV (continued)

Part numbers P-port T-port M-, S-port Mounting EVPX

11173023 G 1/2 G 1/2 G 1/4 M8 x 1.25 Yes

11173000 7/8-14 UNF 7/8-14 UNF 9/16-18 UNF M8 x 1.25 Yes

©

Danfoss | September 2020 BC199786485316en-000301 | 43

Page 44

LS

T

P

M

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - electrical

Closed center EVP with PPRV

The Closed Center EVP inlet with integrated pilot pressure reduction valve (PPRV) is intended for use with

variable displacement pumps in applications, where a valve group with electro-hydraulically or

hydraulically controlled work sections is desired (EVH, EVHC or EVHCO).

The Closed Center EVP with PPRV features:

•

Integrated LS pressure relief valve

•

Threaded ports for P/T/LS and M measuring gauge

•

Integrated pilot pressure Reducting valve (PPRV) for EVH, EVHC, or EVHCO

•

Optional plug for external pilot oil supply

Closed center EVP with PPRV schematic

Technical specification for EVP with PPRV

Max. P-port continuous Max. T-port static/dynamic Max. rated flow

280 bar [4061 psi] 25/40 bar [365/580 psi] 100 l/min [26.4 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

44 | © Danfoss | September 2020 BC199786485316en-000301

Page 45

20 40 60 80

[l/min]

[US gal/min]

4 8 12 16 20

300

250

200

150

100

50

0

Q

PP

4000

3000

2000

1000

0

0

[psi] [bar]

0

Q

10 30 50 70

50 bar

100 bar

150 bar

200 bar

250 bar

280 bar

24

90 100

Curves to inlet pressure x flow

Technical Information

ECO 80 Directional Control Valve

EVP inlet modules - electrical

Theoretical performance graphs

Pressure relief valve characteristics

Part numbers for Closed Center EVP with PPRV

Part number P-port T-port M-, LS-port Mounting

11172997 G 1/2 G 1/2 G 1/4 M8 x 1.25

11173011 7/8-14 UNF 7/8-14 UNF 9/16-18 UNF M8 x 1.25

©

Danfoss | September 2020 BC199786485316en-000301 | 45

Page 46

LS

T

P

M

Technical Information

ECO 80 Directional Control Valve

EVP inlet module accessories

The generic EVP inlet module accessory platform includes the EVPX Electrical LS pressure unloading valve

and a plug for external pilot oil supply.

•

EVPX Electrical LS Pressure Unloading Valve

•

PLug for external pilot oil supply

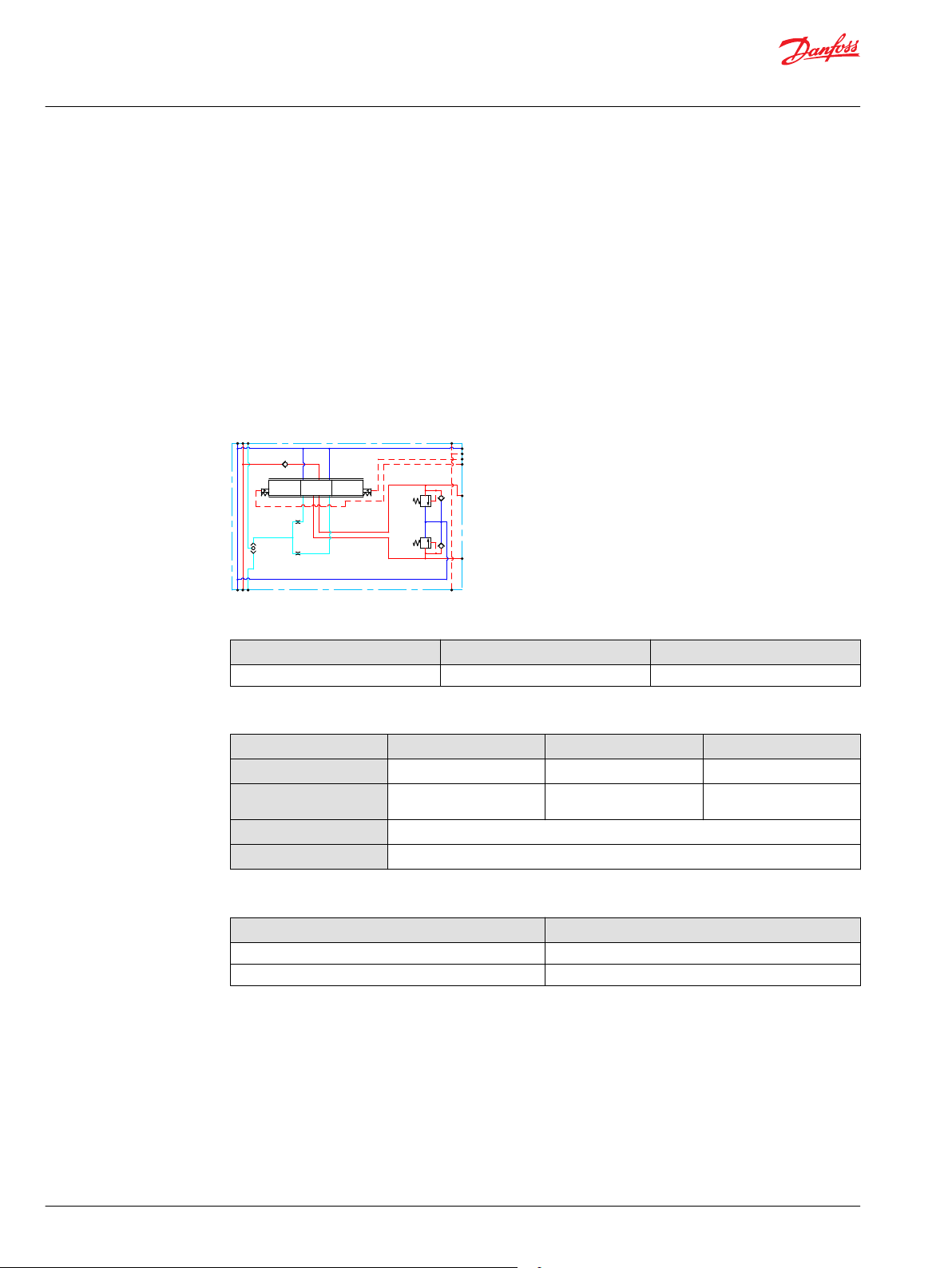

EVPX electrical LS pressure unloading valve

The electrical LS pressure unloading valve is an accessory available for EVP inlet modules with EVPX

facility. The EVPX consist of a solenoid valve and a magnetic coil package, allowing the operator to relieve

the LS pressure to tank electrically.

Normally open (NO)

Relieving the LS pressure to tank results in a reduced system pressure level, which is determined by the

sum of the tank and neutral by-pass pressure drop in an Open Center PVP configuration

Open center EVP with PPRV and EVPX (NO)

EVPX technical data

Voltage supply

Resistance @ 12 V

Resistance @ 24 V

Power consumption

Maximum LS response time

Max. pressure drop @ 0.1 l/min [2.6 US gal/min]

Max. coil surface temperature

12/24 V ± 10 %

7.2 Ω ± 7 %

28.2 Ω ± 7 %

20 W

300 ms

2 bar [30 psi]

155°C [311°F]

Part numbers for EVPX electrical LS pressure unloading valve

Part number Description Voltage supply Thread

11172430 EVPX 12 V -

46 | © Danfoss | September 2020 BC199786485316en-000301

11172429 EVPX 24 V -

Page 47

LS

T

P

M

Pp

Technical Information

ECO 80 Directional Control Valve

EVP inlet module accessories

Plug for external pilot oil supply

The plug for external pilot oil supply is an accessory available for EVP inlet modules with integrated pilot

pressure reducing valve (PPRV), this plug consists in a connection to send out of the EVP inlet a signal

with 27 bar and 5 l/min.

Closed center EVP with PPRV and Pp-port

Closed center EVP with PPRV and Pp-port

Part number Description Voltage supply Thread

11177014 Plug for external pilot oil

supply

11177013 Plug for external pilot oil

supply

- G1/4-19 in

- 9/16-18 UNF

©

Danfoss | September 2020 BC199786485316en-000301 | 47

Page 48

[2.70]68.5

[1.70]43

[0.35]9

[1.57]40

[1.38]35

[0.79]

20

[0.20]5

[0.19]4.8

[4.80]122

[3.58]91

[1.08]

27.5

[0.31]

8

[3.72]94.5

[4.49]114

[0.19]4.7

[3.07]78

[1.69]43

[2.70]68.5

[0.35]9

[1.57]40

[1.38]35

[0.79]

20

[0.20]5

[2.42]61.5

[4.49]114

[0.31]8

[3.72]94.5

[1.08]27.5

[0.28]7

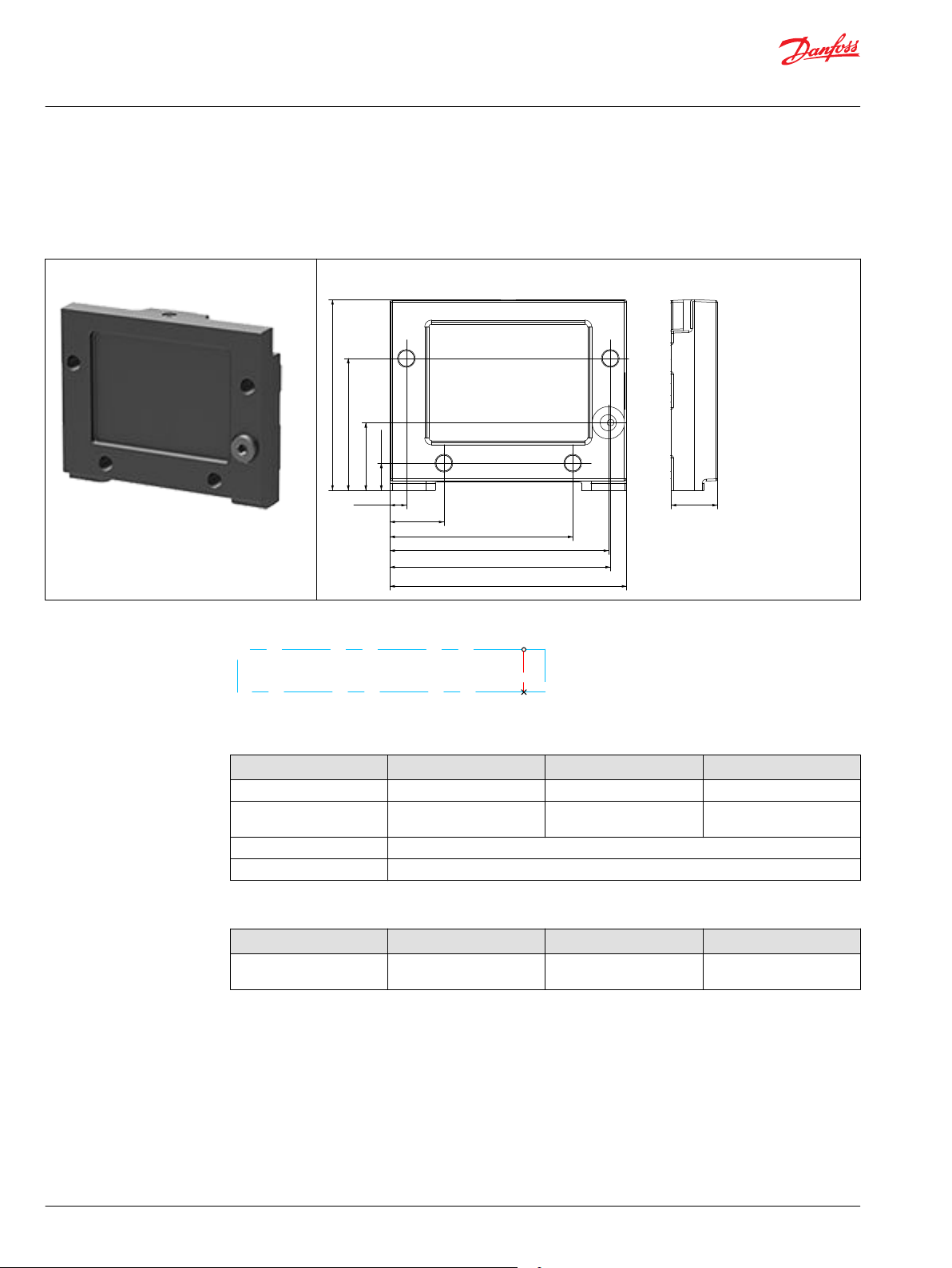

Technical Information

ECO 80 Directional Control Valve

EVB basic modules - electrical actuation

The ECO 80 EVB basic modules, also referred to as work sections, are the interface between the ECO 80

directional control valve and the work function such as a cylinder or a motor.

The EVB comes in two main variants – a low body and a medium body with shock/anti-cavitation valve

facility (PVLP)

EVB low basic module EVB low basic module dimensions

EVB medium basic module EVB medium basic module dimensions

The EVB basic module variants are based on a generic platform with a selection of additional features,

enabling you to tailor the EVB to suit the demands of any hydraulic system:

•

EVB low body

•

EVB medium body

48 | © Danfoss | September 2020 BC199786485316en-000301

Page 49

A

B

1

0

2

Technical Information

ECO 80 Directional Control Valve

EVB basic modules - electrical actuation

EVB low body

The EVB low body is intended for controlling a work function where the function behavior in terms of

flow and pressures allows dependency on the load pressure of other functions used simultaneously. The

integrated load drop check valve prevents flow back from work ports influencing other functions.

The EVB low body features:

•

Integrated LS shuttle network

•

Load drop check valve

Schematic

Technical specifications for A/B port

Max. continuous pressure Max. intermittent pressure Max. rated flow

280 bar [4061 psi] 320 bar [4641 psi] 100 l/min [26.4 US gal/min]

Technical specifications

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

- 30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194 °F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347

SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

460 mm2/s [2128 SUS]

Ordering information

Part numbers A/B-port

11168506 G 1/2

11168507 7/8-14 UNF

©

Danfoss | September 2020 BC199786485316en-000301 | 49

Page 50

A

B

1

0

2

Technical Information

ECO 80 Directional Control Valve

EVB basic modules - electrical actuation

EVB medium body

The EVB low body is intended for controlling a work function where the function behavior in terms of

flow and pressures allows dependency on the load pressure of other functions used simultaneously. The

integrated load drop check valve prevents flow back from work ports influencing other functions.

Compared to the EVB low body the medium body has the option of adding PVLP/PVLA to the work

section.

EVB medium body features

•

Integrated LS shuttle network

•

Load drop check valve

•

Shock/anti-cavitation valve and suction facility (PVLP/PVLA)

Schematic

Technical specifications for A/B port

Max. continuous pressure Max. intermittent pressure Max. rated flow

280 bar [4061 psi] 320 bar [4641 psi] 100 l/min [26.4 US gal/min]

Technical specifications

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

- 30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194 °F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347

SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

460 mm2/s [2128 SUS]

Ordering information

Part numbers A/B-port

11168509 G 1/2

11168508 7/8-14 UNF

50 | © Danfoss | September 2020 BC199786485316en-000301

Page 51

Port pressure

Technical Information

ECO 80 Directional Control Valve

EVB basic modules accessories

The generic EVB module accessory platform include the PVLP shock and anti-cavitation valve and PVLA

suction valve.

PVLP Shock and Anti-Cavitation Valve

•

PVLA Suction Valve

•

Cavity plug

•

PVLP shock/anti-cavitation valve

The PVLP will relief a pressure peak to the internal tank galleries and will furthermore suck oil from the

tank to the work port to prevent cavitation. Pressure settings range 32-320 bar [460-4641 psi].

Features

•

Shock valve

•

Anti-cavitation

•

Lifetime of 200,000 actuations

PVLP schematic

Technical specifications

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

- 30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194 °F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347

SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

460 mm2/s [2128 SUS]

Part numbers for fixed PVLP

Part number Pressure setting in bar

[psi]

157B2032 32 [460] 157B2190 190 [2755]

157B2050 50 [725] 157B2210 210 [3045]

157B2063 63 [914] 157B2230 230 [3335]

157B2080 80 [1160] 157B2240 240 [3480]

157B2100 100 [1450] 157B2250 250 [3625]

157B2125 125 [1813] 157B2265 265 [3845]

157B2140 140 [2031] 157B2280 280 [4061]

157B2150 150 [2175] 157B2300 300 [4351]

157B2160 160 [2320] 157B2320 320 [4641]

157B2175 175 [2538]

Part number Pressure setting in bar

[psi]

©

Danfoss | September 2020 BC199786485316en-000301 | 51

Page 52

Port pressure

Technical Information

ECO 80 Directional Control Valve

EVB basic modules accessories

PVLA suction valve and cavity plug

The PVLA will suck oil from the tank to the work port to prevent cavitation by the 0.5 bar spring. The plug

will ensure that when using a single acting spool, all flow returning through the work port is led to tank.

PVLA schematic

Cavity plug schematic

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

PVLA Cavity plug

157B2001 11177714

- 30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194 °F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347

SUS]

23/19/16 (according to ISO 4406)

Ambient: -30 to 60°C [-22 to 140°F]

460 mm2/s [2128 SUS]

52 | © Danfoss | September 2020 BC199786485316en-000301

Page 53

Technical Information

ECO 80 Directional Control Valve

EVBS electrical flow control spools

The electrical acting EVBS spools determine the flow out of the work section and are based on a generic

platform with a wide selection of additional features, enabling you to tailor the EVBS to suit the demands

of any hydraulic system and any function.

The electrical acting EVBS spool comes in three different main variants:

•

EVBS electrical flow control spool

•

EVBS electrical flow control spool with soft spring

•

EVBS EVPN Spool

©

Danfoss | September 2020 BC199786485316en-000301 | 53

Page 54

BP

5

10

15

20

25

30

35

40

45

50

55

60

65

[l/min]

[US gal/min]

70

75

80

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

A

P

[mm]

<-Spool stroke->

5

43

[in]

0-0.04-0.08-0.12

-0.16-0.20

2

-0.24

1

0

-0.28-0.31-0.35

-0.39

A

E

C

D

B

85

90

95

100

22

23

24

25

26

0-1

-2

-3

-4

-5

0.39

0.350.310.28

0.240.20

0.16

0.120.080.04

0

[mm]

[in]

Flow

105

110

115

120

27

28

29

30

31

32

Spool types:

A = 8/min

B = 25 l/min

C = 40 l/min

D = 60 l/min

E = 80 l/min

F = 100 l/min*

F

Technical Information

ECO 80 Directional Control Valve

EVBS electrical flow control spools

EVBS fluid flow characteristics - Theoretical performance

Oil flow as a function of spool travel

EH spools size F = 100 l/min are not recommended to use as proportional control due to curve

characteristic

54 | © Danfoss | September 2020 BC199786485316en-000301

Page 55

40 80 120 160

[l/min]

[US gal/min]

8 16 24 32 40

50

40

30

20

10

0

600

400

200

0

0

[psi] [bar]

0

A

B

D

C

20 60 100 140

E

TA/B

A = Spool 8 l/min

B = Spool 25 l/min

C = Spool 40 l/min

D = Spool 60 l/min

E = Spool 80 l/min

F

F = Spool 100 l/min

Ø 21.5

[0.12]3 [4.80]122 [1.81]46

A

PT T

B

A

PT T

B

A

PT T

B

Technical Information

ECO 80 Directional Control Valve

EVBS electrical flow control spools

Pressure drop at maximum spool travel (A/B-T)

EVBS - electrical flow control spool

EVBS electrical flow controls spool Dimensions

Part numbers

Type Schematic Flow, l/min [US gal/min]

8 [2.11] 25 [6.61] 40 [10.57] 60 [15.85] 80 [21.13] 100 [26.42]

4-way. 3-position

Closed neutral position

4-way. 3-position

Throttled open neutral

position

3-way. 3-position

Closed neutral position

11170445 11170449 11170453 11170457 11170461 11182178

11170443 11170447 11170451 11170455 11170459 11182177

11170446 11170450 11170454 11170458 11170462 -

©

Danfoss | September 2020 BC199786485316en-000301 | 55

Page 56

Ø 21.5

[0.12]3 [4.80]122 [1.81]46

A

PT T

B

A

PT T

B

A

PT T

B

[2.76]

70.5

[2.60]

66

[0.26]6.5

[1.54]

39

[1.36]

34.5

[0.18]4.5

[0.39]10

[1.81]46[4.89]149.5

A

PT T

B

A

PT T

B

A

PT T

B

Technical Information

ECO 80 Directional Control Valve

EVBS electrical flow control spools

EVBS - electrical flow control spool with soft spring for EVHCO

EVBS electrical flow controls spool Dimensions

Part numbers

Type Schematic Flow, l/min [US gal/min]

8 [2.11] 25 [6.61] 40 [10.57] 60 [15.85] 80 [21.13] 100 [26.42]

4-way. 3-position

Closed neutral position

11192205 11192207 11192209 11192252 11192257 11192264

4-way. 3-position

11192206 11192208 11192239 11192262 11192259 11192265

Throttled open neutral

postion

3-way. 3-position

11192236 11192238 11192241 11192255 11192263 Closed neutral position

EVBS - EVPN spool

EVBS EVPN spool Dimensions

Part numbers

Type Schematic Flow, l/min [US gal/min]

40 [10.57] 80 [21.13]

4-way, 3-position

Closed neutral position

11194018 11194024

4-way, 3-position

11194019 11194025

Throttled open neutral position

3-way, 3-position

11194020 11194026

Closed neutral position

56 | © Danfoss | September 2020 BC199786485316en-000301

Page 57

[7.24]184.1

[2.78]70.5

[2.60]66

[0.26]6.5

[2.00]50.9

[1.54]39

[1.36]34.5

[0.18]4.5[2.48]63 [0.37]9.5

[4.41]112.1

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

ECO 80 electrical actuation can be done mechanically, hydraulically and electrically.

ECO 80 actuation overview:

•

EVM mechanical actuation

•

EVC cover for mechanical actuation

•

EVH hydraulic actuation

•

EVHC electrical actuation

•

EVHCO On/Off Electrical actuation

EVM mechanical actuation

The EVM consists of an aluminum base with a lever mounted on the end of the valve slice on side B.

When actuating the lever the operator is directly pulling or pushing on the main spool inside the valve

hence controlling the flow. Actuating the lever fully will move the spool all 5 mm and give full flow. The

lever can be mounted / removed without having to remove the EVM base. The EVM should be used with

Electrical flow control spools and can be combined with any EVHC, EVH or Pneumatic actuator.

EVM without adjustment screws

The standard EVM without adjustment screws will allow a spool travel of 5 mm in either direction. Full

lever movement to one side will give full flow to the work ports. When the spool is moved 5mm it will

stop due to a mechanical limitation build into the EVM base.

EVM with adjustment screws

The spool travel in either direction can be limited by the adjustment screws. This will limit the flow out of

the work ports thereby reducing the speed of an application. The spool travel is adjusted by first

loosening the nut then adjusting the pin screw. After adjustment the nut must be tightened again

applying 8 ±1 [N•m] of torque.

EVM dimensions, torque, and part numbers

EVM cover Dimensions

©

Danfoss | September 2020 BC199786485316en-000301 | 57

Page 58

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

Operating torque

Spool displacement Operating torque for EVM + EVHC and EVM +

EVH

From neutral position 1.5 ± 0.2 N·m [13.3 ± 1.8 in·lbs] 2 ± 0.2 N·m [17.7 ± 1.8 in·lbs]

Maximum spool travel 6.6 ± 0.2 N·m [58.4 ± 1.8 in·lbs] 2.7 ± 0.2 N·m [23.9 ± 1.8 in·lbs]

No control lever position 2 x 6

Control lever range ± 13.8°

Part numbers

Part number Description Lever Adjustment screws

11119157 EVM-ACTUATOR - 11167001 EVM-ACTUATOR-LEVER Yes 11145204 EVM-ACTUATOR-ADJ SCREW - Yes

11167002 EVM-ACTUATOR-ADJ SCREW-LEVER Yes Yes

Operating torque for EVM + EVHCO

58 | © Danfoss | September 2020 BC199786485316en-000301

Page 59

[2.58]65.5

[1.55]39.4

[2.76]70.5

[0.24]6

[1.37]34.7

[0.19]4.7[0.79]20

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

EVC - cover for mechanical actuation

The EVC is an aluminum plate mounted on the end of the valve slice on side A for purely mechanically

operated valve with EVM style. The EVC is to be combined with an EVM.

EVC cover Dimensions

Part numbers

Part number Description

11171318 EVC-COVER

©

Danfoss | September 2020 BC199786485316en-000301 | 59

Page 60

[2.91]74

[2.64]67

[2.05]52

[0.87]22

[0.30]7.5

[1.36]34.5

[0.93]23.5

[0.61]15.5

[0.18]4.5

[1.75]44.5

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

EVH - hydraulic actuation

The EVH is an aluminum plate with two threaded connections mounted on the end of the valve slice on

side A. When applying pressure through one of the ports, one side of the spool is pushed to one direction

hence flow is coming from the work ports. The EVH is to be combined with an EVM.

EVH Dimensions

Technical data

Control range pressure from neutral to max A/B

Maximum pilot pressure

Maximum pressure on port T

1

The hydraulic remote-control lever should be connected directly to tank

1

3.5-18 bar [50-261 psi]

35 bar [507 psi]

10 bar [145 psi]

Part numbers

Part number Name Connection

11169486 EVH-ACTUATOR-BSP 1/4 BSP

11169487 EVH-ACTUATOR-SAE 9/16 SAE

60 | © Danfoss | September 2020 BC199786485316en-000301

Page 61

[2.91]74

[2.64]67

[0.30]7.5

[1.54]39

[1.36]

34.5

[0.18]4.5[3.37]85.5

[4.31]109.5

AP

1

2

3

4

5

0

0

200

100

400

200

600

300

800

400

1000

500

BP

400

200

200

100

0

0

1200

600

1400

700

0

mm

[in]

800

400

600

300

1000

500

1200

600

1400

700

0.04

0.08

0.12

0.16

0.20

[Current in mA]

@ 12V

@ 24V

[Current in mA]

@ 12V

@ 24V

Ideal curve

Hysteresis

Spool stroke

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

EVHC - electrical actuation

The EVHC consists of an aluminum base with two solenoids pressure reducing valves mounted on the

end of the valve slice. When actuating with electrical proportional actuation, the main spool position is

adjusted so that its position corresponds to an electrical control signal.

The control signal is converted into a hydraulic pressure signal that moves the main spool in the EVB. This

is done by means of two proportional pressure-reducing valves. The electrical actuator can be controlled

either by a current amplifier card, or directly from a programmable microcontroller.

The actuator controls the spool by building up pilot oil pressure on the end of the spool. For the EVHC is

necessary a pilot oil pressure between 25 and 30 bar.

The EVHC should be used with Electrical FLOW CONTROL spools and can be combined with any EVM.

EVHC Dimensions

Schematic

Schematic is not available.

EVHC spool stroke vs current characteristics

EVHC current response and hysteresis @ 25 bar Pp, 32 ctS, 55 °C. The ideal curve (red line) is determined

by the main spool neutral spring. The EVHC hysteresis is around ±7.5% (grey region).

The hysteresis is affected by viscosity, friction, flow forces, dither frequency and modulation frequency.

The spool position will shift when conditions are changed e.g. temperature change.

©

Danfoss | September 2020 BC199786485316en-000301 | 61

Page 62

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

Technical data

Parameter Supply voltage

12 V 24 V

Controller output current range 0 - 1500 mA 0 - 750 mA

Resistance 4.75 Ω ± 5% 20.8 Ω ± 5%

Frequency 100 - 400 Hz

Pilot oil pressure range 25 - 30 bar [362 – 435 psi]

Pressure control range 8 – 23 bar [116 – 333 psi]

Ambient temperature range -30°C to 80°C [-22 °F to 176°F]

Temperature range -20°C to 80°C [-4 °F to 176°F]

Fluid cleanliness 23/19/16 (according to ISO 4406)

Operating conditions

Parameter Minimum Recommended range Maximum

Fluid temperature - 30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194 °F]

Fluid viscosity 4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

Fluid cleanliness 23/19/16 (according to ISO 4406)

Operating temperature Ambient: -30 to 60°C [-22 to 140°F]

Part numbers

Part number Voltage supply Connector type Protection class

11162297 12 V 2x2 DEUTSCH IP 67

11162298 24 V 2x2 DEUTSCH IP 67

62 | © Danfoss | September 2020 BC199786485316en-000301

Page 63

[0.30]7.5

[2.91]74

[2.64]67

[1.54]39

[1.67]42.5

[3.44]87.3

[0.18]4.5

[1.36]34.5

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

EVHCO - Low current on/off electrical actuation

The EVHCO consists of an aluminum base with two solenoids valves mounted on the end of the valve

slice. When active with electrical signal the main spool goes straight to end of stroke, A or B side.

The electrical signal is converted into a hydraulic pressure signal that moves the main spool in the EVB.

This is done by means of two on/off solenoid valves.

The actuator controls the spool by building up pilot oil pressure on the end of the spool. For the EVHCO is

necessary a pilot oil pressure between 10 and 28 bar. The EVHCO should be used with Electrical flow

control soft spring spools and can be combined with any EVM.

EVHCO Dimensions

Schematic

Schematic is unavailable.

Technical data

Supply voltage (Udc) Rated 12 V 24 V

Range 11 – 15 Vdc 22 – 30 Vdc

Current 22°C [71°F]– Coil temperature 0.36 A 0.18 A

Power 22°C [71°F]– Coil temperature 4.33 W 4.40 W

Resistance at 20°C [68°F] 33.26 Ω ± 10% 130.91 Ω ± 10%

Pressure control range 10 – 28 bar [145 – 406 psi]

Duty cycle 100 %

Reaction time from neutral position to max. spool travel max. 300 ms

Operating conditions

Parameter Minimum Recommended range Maximum

Fluid temperature - 30°C [-22°F] 30 to 60°C [86 to 140°F] 90°C [194 °F]

Fluid viscosity 4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

Fluid cleanliness 23/19/16 (according to ISO 4406)

Operating temperature Ambient: -30 to 60°C [-22 to 140°F]

Part numbers

Part number Voltage supply Connector type Protection class

11186922 12 V 2x2 DEUTSCH IP 67

11186911 24 V 2x2 DEUTSCH IP 67

©

Danfoss | September 2020 BC199786485316en-000301 | 63

Page 64

34.5 [1.36]

4.5 [1.18]

70.5 [2.78]

70.5 [2.78]

6.5 [0.26]

66 [2.6]

3.8 [0.15]

39 [0.54]

60 [2.36] 10 [0.39]

Technical Information

ECO 80 Directional Control Valve

ECO 80 electrical - actuation

EVPN - pneumatic actuation