Page 1

User Guide

Liquid cooled heavy duty inductor unit

EC-LTS1200-410

www.danfoss.com

Page 2

User Guide

EC-LTS1200-410

Revision history Table of revisions

Date Changed Rev

July 2021 Updated user guide 0201

2 | © Danfoss | July 2021 BC355449988603en-000201

Page 3

User Guide

EC-LTS1200-410

Contents

General information

Intended use of the user guide................................................................................................................................................... 4

Product naming convention........................................................................................................................................................ 4

Conformity according to standards...........................................................................................................................................4

Warranty.............................................................................................................................................................................................. 5

Terms and abbreviations...............................................................................................................................................................5

Responsibility of the manufacturer........................................................................................................................................... 6

Safety information

General safety statement...............................................................................................................................................................7

Safety message signal words....................................................................................................................................................... 7

Safety symbols...................................................................................................................................................................................7

Personal protective equipment.................................................................................................................................................. 8

Safety features...................................................................................................................................................................................9

Electromagnetic compatibility (EMC)....................................................................................................................................... 9

Installation safety..............................................................................................................................................................................9

Operation safety.............................................................................................................................................................................11

Product overview

Intended use of the electric device......................................................................................................................................... 13

System introduction..................................................................................................................................................................... 14

Cooling...............................................................................................................................................................................................14

Rating plate......................................................................................................................................................................................14

Tightening torques........................................................................................................................................................................15

Transportation and storage

Transportation................................................................................................................................................................................ 17

Receiving and unpacking............................................................................................................................................................17

Lifting................................................................................................................................................................................................. 17

Handling............................................................................................................................................................................................19

Storage...............................................................................................................................................................................................19

Installation

Required tools.................................................................................................................................................................................20

Mechanical installation................................................................................................................................................................20

Allowed mounting position..................................................................................................................................................20

Installation procedure.............................................................................................................................................................21

Cooling connections............................................................................................................................................................... 22

Recommended coolants........................................................................................................................................................22

Electrical installation.....................................................................................................................................................................23

Electrical connections............................................................................................................................................................. 23

Grounding...................................................................................................................................................................................23

Cable gland assembly and power line connection...................................................................................................... 25

Cabling and wiring...................................................................................................................................................................31

High voltage connections..................................................................................................................................................... 32

Low voltage connections.......................................................................................................................................................32

Operation

Operation conditions....................................................................................................................................................................34

Condition monitoring during operation...............................................................................................................................34

Maintenance

Regular maintenance................................................................................................................................................................... 35

Cooling system maintenance....................................................................................................................................................36

Cleaning............................................................................................................................................................................................ 36

Dismounting and disposal of the electric device

Troubleshooting

Aftersales

Service policy...................................................................................................................................................................................40

Service parts.....................................................................................................................................................................................40

©

Danfoss | July 2021 BC355449988603en-000201 | 3

Page 4

User Guide

EC-LTS1200-410

General information

Intended use of the user guide

Product naming convention

This user guide contains the installation, operation and maintenance instructions for the EC-LTS1200-410

liquid cooled heavy duty inductor unit.

This user guide contains instructions necessary to safely and properly handle, install and maintain the

electric device. They should be brought to the attention of anyone who installs or maintains the electric

device or associated equipment.

All of the safety warnings and instructions in this user guide must be followed to prevent injury to

personnel or damage to property. Only qualified and authorized personnel, familiar with health and

safety requirements and national legislation, shall be permitted to handle, install and maintain the

device.

This user guide must be kept for future reference during installation, operation and maintenance.

This user guide uses illustrations as examples only. Illustrations in this user guide may not necessarily

reflect all system features.

In this user guide the EC-LTS external inductance unit is referred to as the electric device.

The following naming convention is used to refer to electric device type code and options:

•

EC-LTS1200-XXX

Part of the name Explanation

EC Electric Converter

LTS1200 Type code part 1

XXX Type code part 2

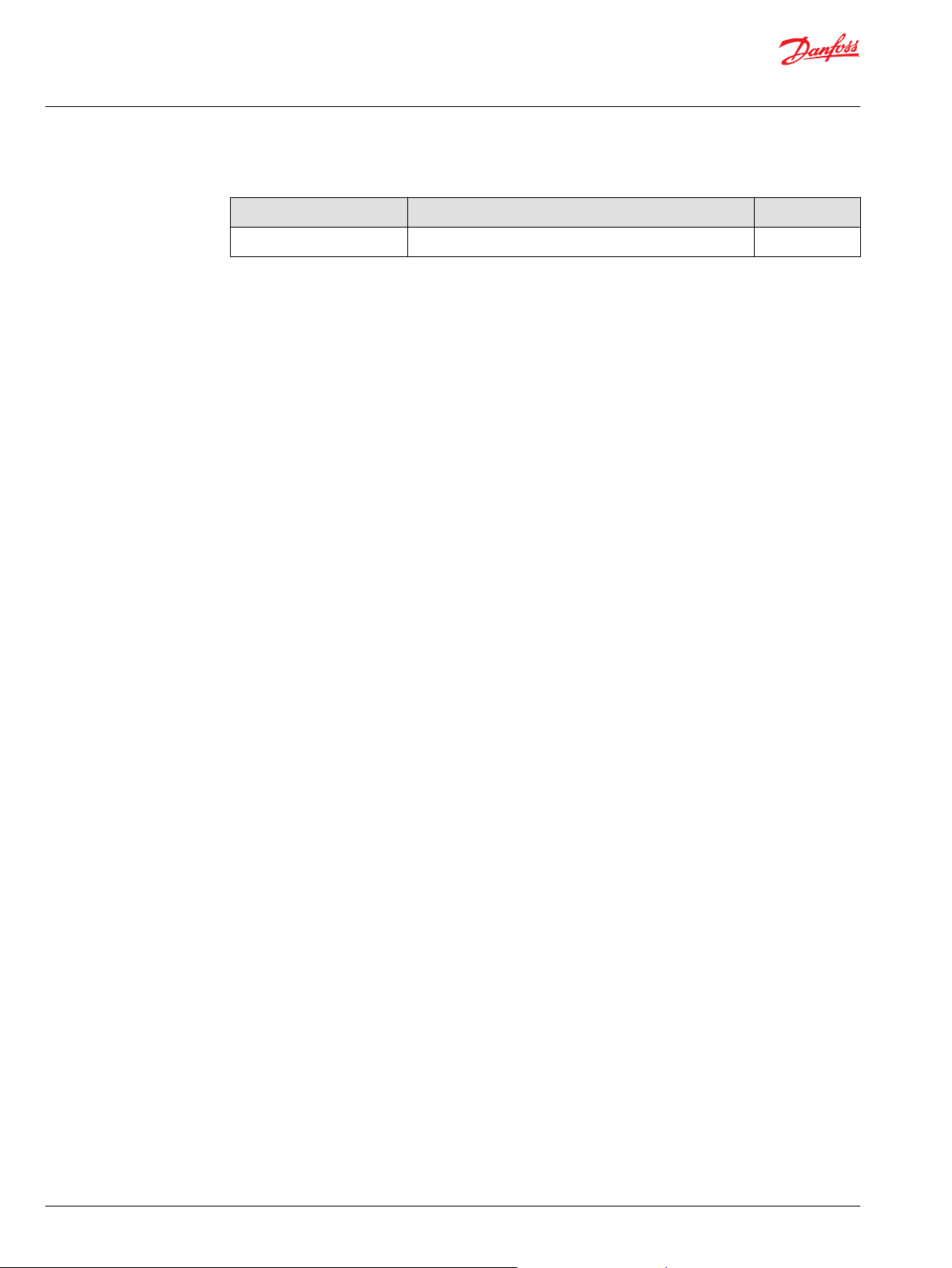

Options are presented in the Table below. Standard options are indicated by a star (*).

EC-LTS1200-410 options

Variant Code Description Additional information

Cable glands * No cable glands No cable glands or plugs

Marine classification * No marine classification

Conformity according to standards

The electric device has been designed in accordance with the essential parts of the following directives

and to meet the requirements of the standards:

+CG1 M25/M32 cable glands 3x M25 cable glands, 3x M32 cable glands and 2x M32 plugs

in delivery

+CL1 ABS American Bureau of Shipping

+CL2 BV Bureau Veritas

+CL3 DNV

+CL4 LR Lloyd’s Register

+CL5 RINA

4 | © Danfoss | July 2021 BC355449988603en-000201

Page 5

User Guide

EC-LTS1200-410

General information

Warranty

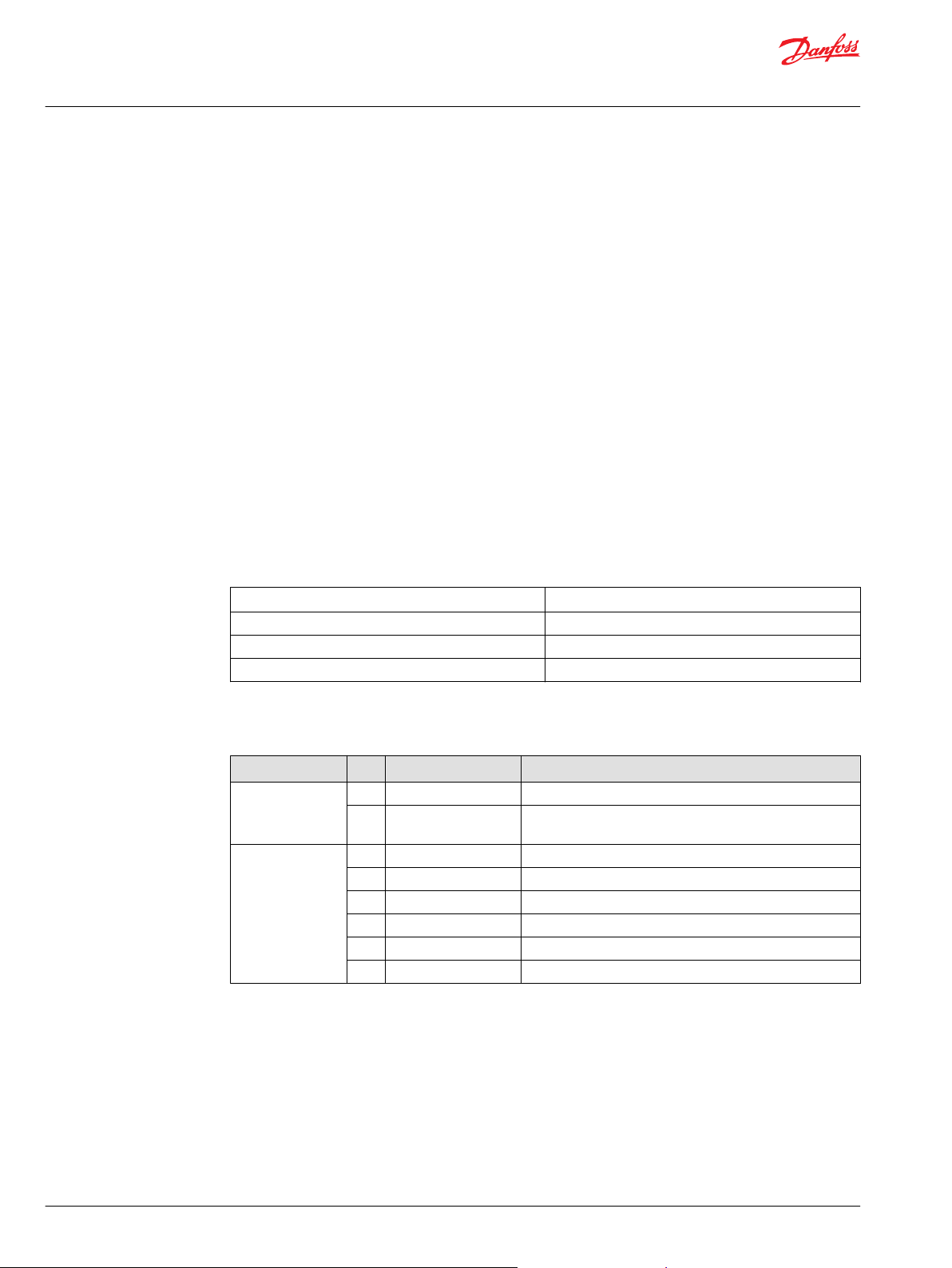

Applicable directives and standards

Directives / Standards Explanation

Low Voltage Directive 2014/35/EU Electrical equipment means any equipment designed for use with a voltage

The electromagnetic compatibility

(EMC) Directive 2014/30/EU

IEC/EN 61800-5-1: 2007 Adjustable speed electrical power drive systems - Part 5-1: Safety

EN 13766-1:2018 Construction machinery. Electromagnetic compatibility of machines with

UN Regulation No. 10 Revision 4 and

Revision 5

rating of between 50 and 1000 V for alternating current.

EMC directive ensures that electrical and electronic equipment does not

generate, or is affected by, electromagnetic disturbance.

requirements - Electrical, thermal and energy.

internal electrical power supply.

Uniform provisions concerning the approval of vehicles with regard to

electromagnetic compatibility.

Danfoss offers warranty against defects in workmanship and materials for its products for a period of

twelve (12) months from commissioning or eighteen months (18) from delivery (Incoterms-EXW),

whichever occurs first.

In order for the warranty to be valid, the customer must follow the requirements of this and all related

documents, especially those set out in the product installation and maintenance documents, as well as

the applicable standards and regulations in force in each country.

Defects arising from the improper or negligent use, operation, and/or installation of the equipment, nonexecution of regular preventive maintenance, as well as defects resulting from external factors or

equipment and components not supplied/recommended by Danfoss, will not be covered by the

warranty.

The warranty will not apply if the customer at its own discretion makes repairs and/or modifications to

the equipment without prior written consent from Danfoss.

Terms and abbreviations

Following symbols, terms and abbreviations may exist in this user guide.

Term/ Abbreviation Explanation

AC Alternating current

DC Direct current

MCB Miniature circuit breaker

EMC Electromagnetic compatibility

EMI Electromagnetic interference

Symbol Variable Unit

U

DC

U

ac

I

n

P

n

f

in/out

f

switch

I

peak

Q

c

T

c

DC link voltage V

AC output voltage V

Rated current A

Rated power kW

Input / Output frequency Hz

Switching frequency kHz

Overcurrent limit A

Rated coolant liquid flow l/min

Rated coolant liquid input

temperature

rms

°C

©

Danfoss | July 2021 BC355449988603en-000201 | 5

Page 6

User Guide

EC-LTS1200-410

General information

Symbol Variable Unit

T

amb

GND Ground in electrical connections

R Resistance Ω

Responsibility of the manufacturer

Danfoss is responsible for the safety, reliability and performance of the electric device only if:

Handling, mounting, installation, operation and maintenance are carried out by qualified and

•

authorized service personnel.

The installation of the system complies with the requirements of the appropriate regulations.

•

The electric device is used in accordance with the instructions in this user guide.

•

The electric device is installed, maintained and serviced in accordance with the instructions in this

•

user guide.

Rated ambient temperature °C

6 | © Danfoss | July 2021 BC355449988603en-000201

Page 7

User Guide

EC-LTS1200-410

Safety information

General safety statement

Safety message signal words

The electric device is intended for use as a component for industrial and commercial installations. The

end product containing the electric device must conform with all related regulations.

The use of the electric device is prohibited in hazardous areas unless it is expressly designed for such use.

The electric device is intended for installation, use and maintenance by qualified personnel, familiar with

health and safety requirements and national legislation. Ignoring these instructions may invalidate all

applicable warranties.

These instructions must be followed to ensure safe and proper installation, operation and maintenance

of the electric device. They should be brought to the attention of anyone who installs, operates or

maintains the electric device or associated equipment.

High voltage and rotating parts can cause serious or fatal injuries. For the electric device covered by this

user guide, it is important to observe safety precautions to protect personnel from possible injury.

Safety message signal words indicate the severity of a potential hazard.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. CAUTION may also alert against unsafe practices

NOTICE Indicates a potentially hazardous situation which, if not avoided, could result in property

damage.

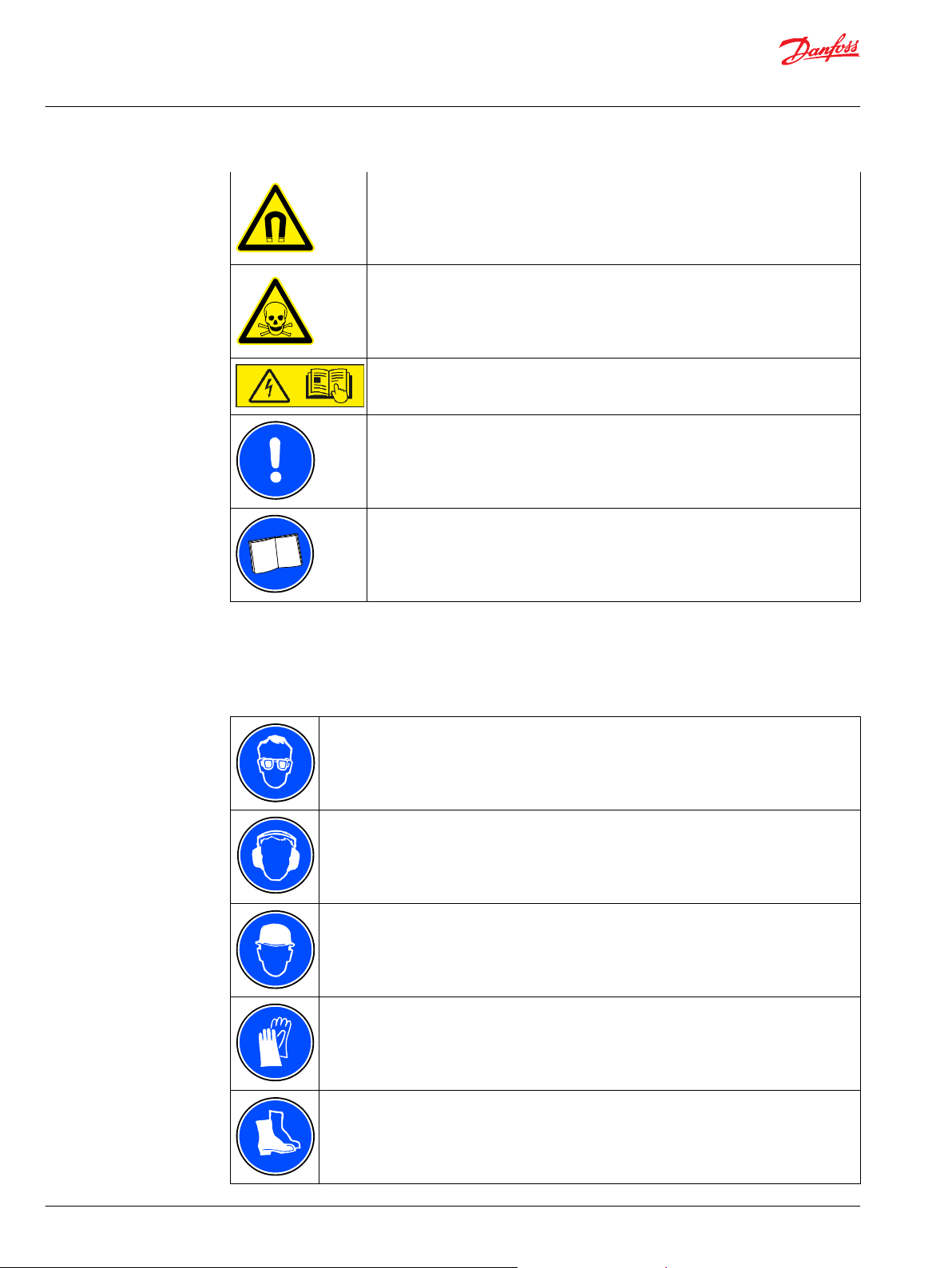

Safety symbols

The following safety and information related symbols may exist in this user guide and on the electric

device.

Danger

This symbol is identified by a yellow background, red octagonal band and a black

STOP text. It indicates a hazardous situation that causes severe injury or death.

Action indicated by this symbol may not be executed.

General warning

This symbol is identified by a yellow background, black triangular band, and a black

exclamation point symbol. It indicates a general potentially hazardous situation.

Electric shock warning

The symbol is identified by a yellow background, black triangular band, and a black

arrowhead symbol. It indicates dangerous electrical voltage that could cause an

electric shock to a person.

Burn warning

The symbol is identified by a yellow background, black triangular band, and a black

wavy lines- symbol. It indicates a hot device that could cause burns to a person.

The symbol also indicates that the device should be placed and installed so that

contact with its potentially hot surface is not possible.

©

Danfoss | July 2021 BC355449988603en-000201 | 7

Page 8

User Guide

EC-LTS1200-410

Safety information

Magnet warning

The symbol is identified by a yellow background, black triangular band, and a black

magnet symbol. It indicates strong magnetic field that could cause harm to a person

or property.

Poison warning

The symbol is identified by a yellow background, black triangular band, and a skull

and crossbones symbol. It indicates a poisonous substance that could kill or cause an

injury to a person.

Electric shock warning - Read the instructions in the user guide.

General Information.

Read the instructions in the manual.

Personal protective equipment

Personal protective equipment shall be used when necessary during handling, installation and

maintenance of the electric device to avoid injury.

Use eye protective equipment like safety goggles or mask when you work with the electric

device. Permanent damage to the eye could be caused if bearing grease, melted nitrile rubber

(radial lip seal), glycol or other fluids splash.

Use hearing protective equipment when you work on the electric device. Hearing injuries can

be caused by too loud noise (noise in excess of 85 dBA).

Use head protective equipment like helmet when you lift the electric device! Head injuries can

be caused by object impact.

Use cut resistant gloves when you handle and maintain the electric device. There is a risk of

cut injuries.

Use protective footwear when you lift or move the electric device! Foot injuries could be

caused if lifting system or lifting brackets fail.

8 | © Danfoss | July 2021 BC355449988603en-000201

Page 9

User Guide

EC-LTS1200-410

Safety information

Safety features

Electromagnetic compatibility (EMC)

EMC stands for Electromagnetic compatibility. It is the ability of electric equipment to operate without

problems within an electromagnetic environment. Likewise, the equipment must not disturb or interfere

with any other product or system within its locality. This is a legal requirement for all equipment taken

into service within the European Economic Area (EEA).

Our products are designed with high standards of EMC in mind. Connect the power lines and groundings

along the instructions in this user guide to achieve the required level of EMI protection.

It is the responsibility of the installer to make sure that the equipment or system into which the product is

incorporated complies with the EMC legislation of the country of use. Within the European Union,

equipment into which this product is incorporated must comply with the EMC Directive 2014/30/EU.

When interfacing other equipment, connect only equipment that are specified as part of the

system and that are compatible.

Magnetic and electromagnetic fields generated near the current-carrying conductors and

permanent magnets in electric machines represent a health danger to persons with heart

pacemakers, metal implants and hearing aids. Persons with a heart pacemaker, metal

implants or hearing aids must consult a doctor before they enter the following areas:

•

Areas in which electric equipment and parts are operated

•

Areas in which electric equipment with permanent magnets are stored, mounted,

operated or repaired

If necessary, perform a special electromagnetic compatibility (EMC) test on the installation.

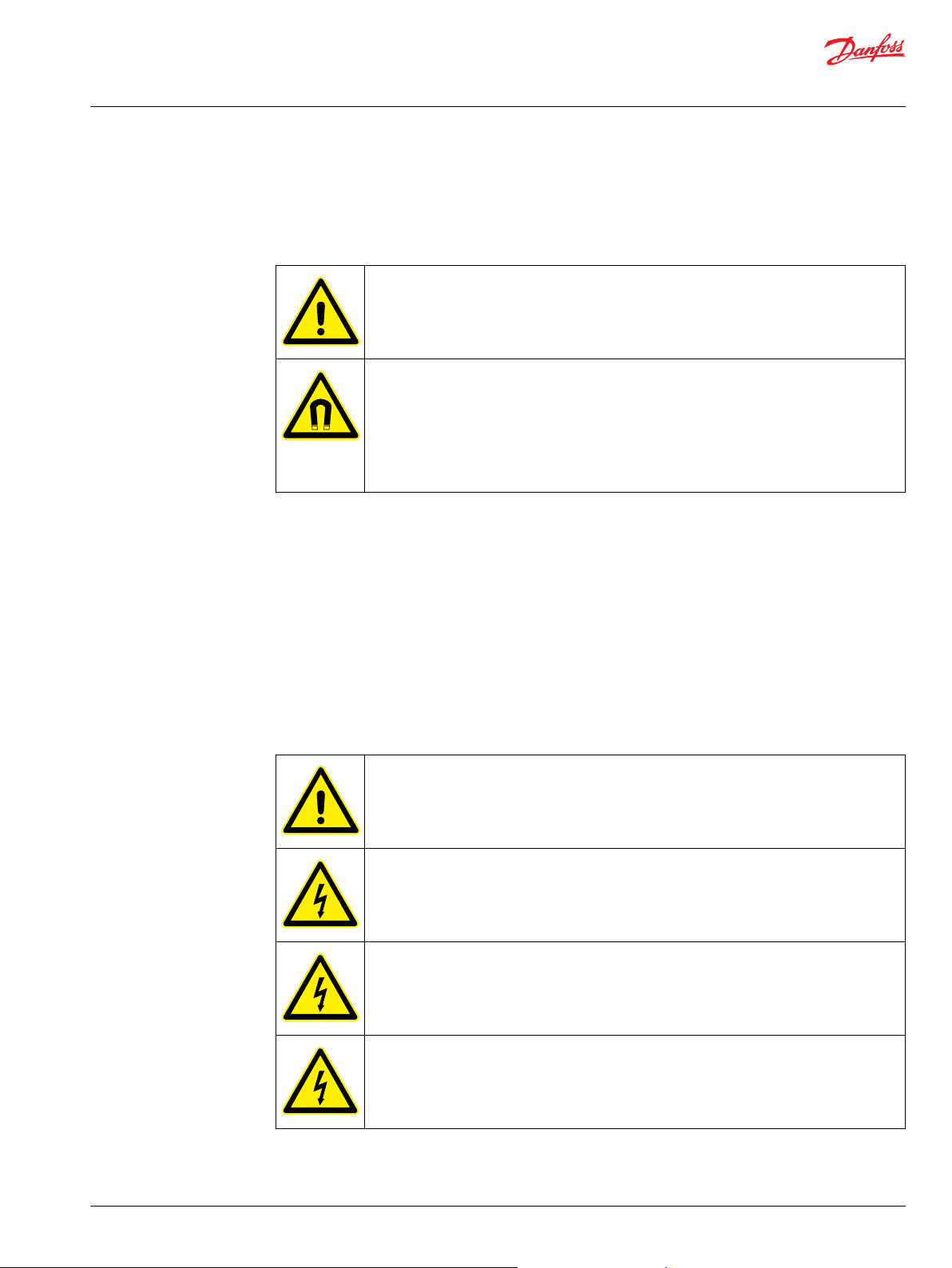

Installation safety

Only trained and qualified personnel familiar with the relevant safety requirements can

install the electric device. If the electric device is installed incorrectly it may lead to safety

hazard.

Make sure of correct grounding connections. Do not run the electric device without correctly

attached protective earth conductor. The grounding cable must be sufficient to carry the

maximum supply fault current which is normally limited by the fuses or Miniature Circuit

Breaker (MCB). Suitably rated fuses or MCB should be fitted in the mains supply of the electric

device, by the local legislation and recommendations.

Use only correct (type and value) protective fuses with the high voltage DC-system.

Do not do any work on the electric device control cables when the power is applied to the

electric device or to the external control circuits.

©

Danfoss | July 2021 BC355449988603en-000201 | 9

Page 10

User Guide

EC-LTS1200-410

Safety information

The control input functions of the electric device – for example stop/start must be secured

using independent channel protection in safety critical applications. All applications where

malfunction could cause injury or loss of life must be subject to a risk assessment and improve

control signal protection if needed.

Do not activate the automatic fault reset function on any system, where this may cause a

potentially dangerous situation. Reason for every fault situation should be determined

before resetting the fault.

Make sure that the supply voltage corresponds to the specification of the electric device.

Do not attempt to repair the electric device. In the case of suspected fault or malfunction,

contact Danfoss or Danfoss authorized service center for further assistance.

When you install the electric device, make sure that the cooling system and the used coolant

meet the specifications of the manufacturer. Make sure that the cooling system is in use when

the DC-link is powered.

If the control cabling is installed close with the power cabling, make sure that minimum

separation distance is 100 mm and crossings are at 90 degrees. Make sure that all terminal

connections are tightened correctly by the instructions.

Electric device must not be opened (excluding the connection box lid). Any attempt causes

loss of warranty.

Within the European Union, all machinery in which this product is used must comply with

Directive 98/37/EC, Safety of Machinery. In particular, the machine manufacturer is

responsible for providing a main switch and ensuring the electrical equipment complies with

EN60204-1.

Use correct personal protective equipment when you are near the electric device.

10 | © Danfoss | July 2021 BC355449988603en-000201

Page 11

User Guide

EC-LTS1200-410

Safety information

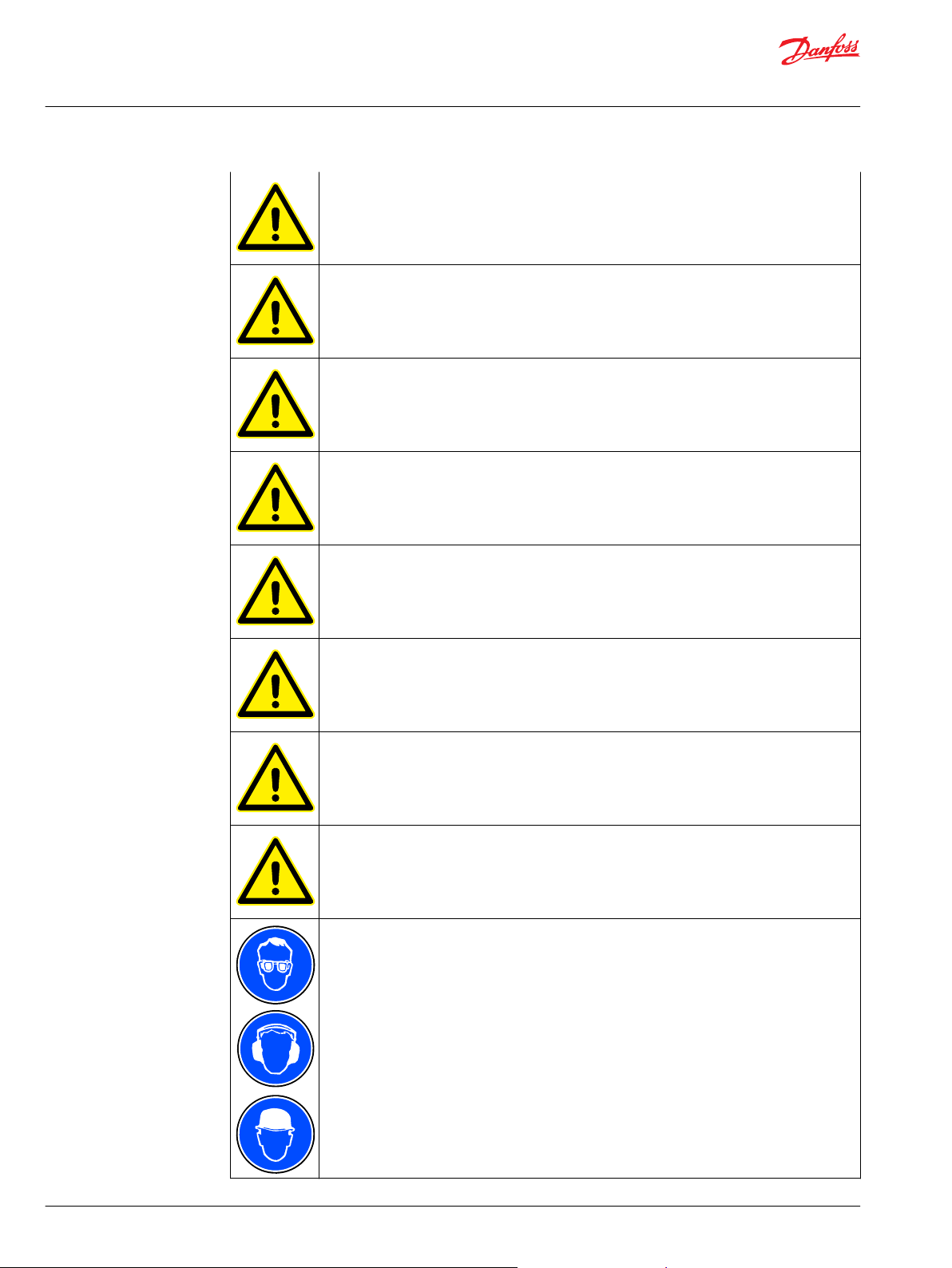

Operation safety

Read the instructions in this user guide before you start to install the electric device.

Do not use the electric device without correctly dimensioned and operating cooling system.

Maximum operation temperature must not be exceeded to avoid permanent damage to the

electrical device.

The requirements of this user guide and other related instructions and standards must be

followed.

Do not touch the electric device during operation. The surface of the electric device can be

hot.

This electric device is intended for professional use as complete equipment or system and as

part of a fixed installation. The electric device uses high voltages and currents, and it has

large amounts of stored electrical energy. Close attention is required to system design and

electrical installation to avoid hazards in either normal operation or in the event of

equipment malfunction.

The electric device can only be used in the applications it is intended for. The rated nominal

values and operational conditions are shown in the rating plate.

©

Danfoss | July 2021 BC355449988603en-000201 | 11

Page 12

User Guide

EC-LTS1200-410

Product overview

The advantages and features of the electric device:

Extremely compact design – 410 A.

•

High enclosure class IP67 – sealed from moisture and dust.

•

Ambient temperature -40ºC...105ºC.

•

Robust design withstanding high levels of mechanical vibrations and shocks.

•

Designed especially for highly cyclical loads typical in heavy mobile work machines.

•

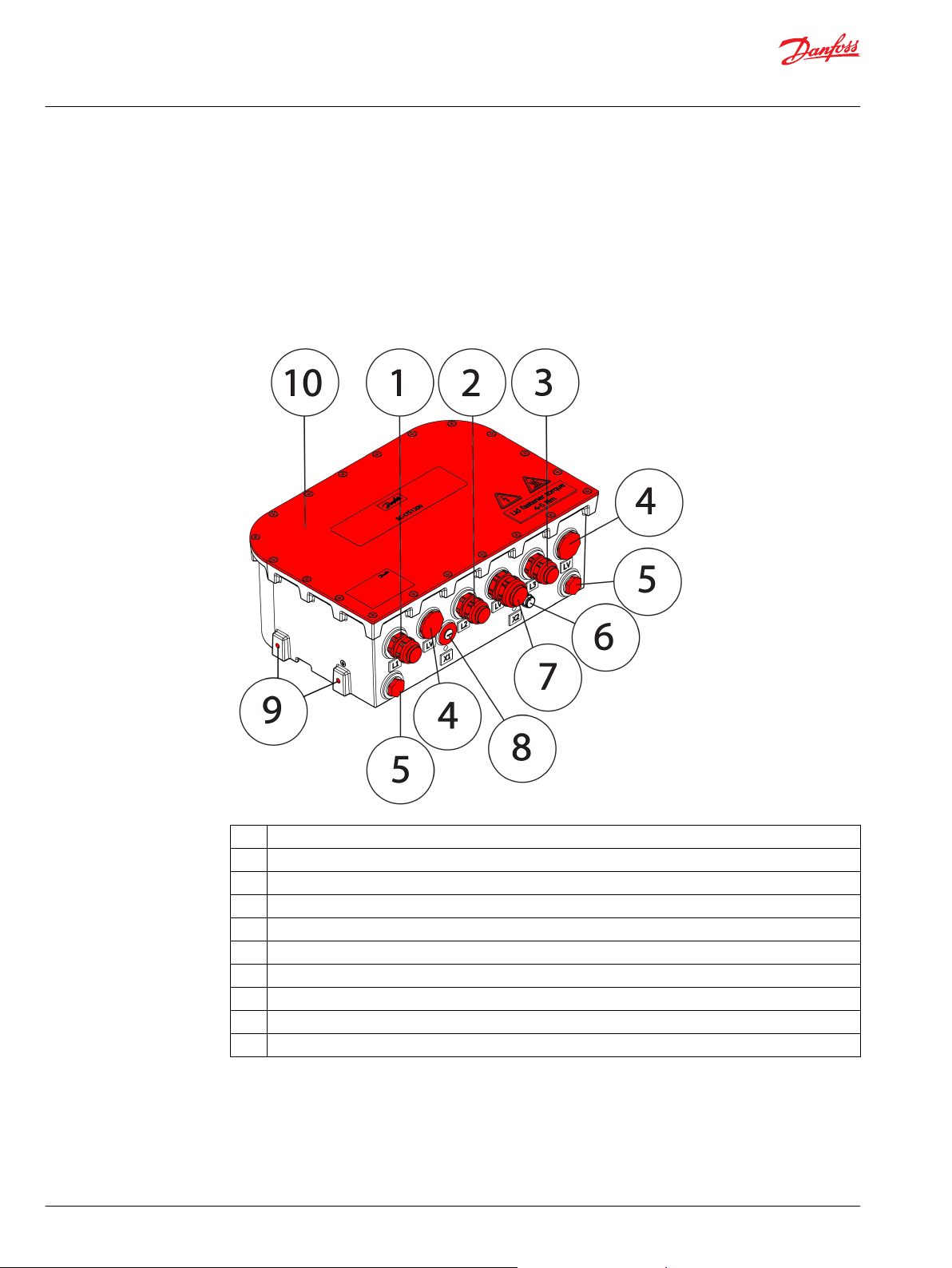

Main components

1 L1 connection

2 L2 connection

3 L3 connection

4 +LV connection plugged (configurable, see +CG option below)

5 Cooling inlet / outlet connections

6 X2 temperature measurement connector

7 +LV connection cable gland (configurable, see +CG option below)

8 X1 plugged, not in use

9 M8 Mounting points, 6 pcs on the sides and 8 pcs on the bottom

10 Connection box lid

+CG1 option comes with a selection of cable glands and plugs. Typical cable gland configurations are

shown in the Table below.

12 | © Danfoss | July 2021 BC355449988603en-000201

Page 13

User Guide

EC-LTS1200-410

Product overview

Typical cable gland configurations for option +CG1

Connections Typical cable gland applications

Connection to DC/DCconverter (L1, L2, L3)

Low voltage side positive

connection (+LV)

Intended use of the electric device

3x M25 cable glands 3x M25 cable glands 3x M25 cable glands

1x M32 cable gland, 2x

M32 plugs

The electric device is intended only for professional use. Installation, operation and

maintenance of the electric device is permitted only for trained personnel and professionals.

The electric device is intended for fixed installation, as a part of complete power generation

equipment or system.

2x M32 cable glands, 1x

M32 plugs

3x M32 cable glands, no

plugs

Typical applications for the electric device are:

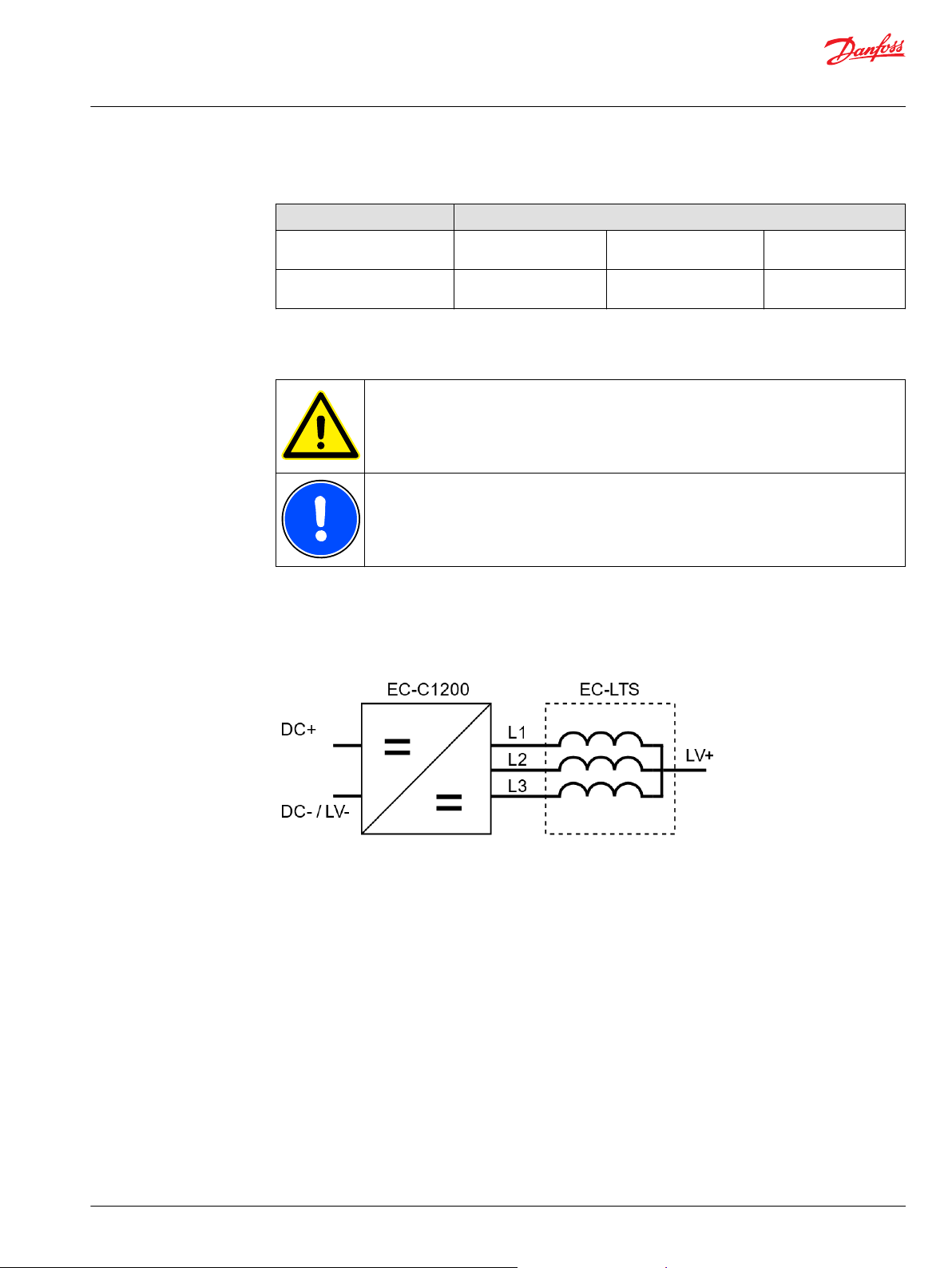

System component designed to be combined with EC-C1200-450 DCDC-converter, used to transfer

•

energy between two different voltage levels.

Application example

EC-C1200 DC/DC converter combined with the EC-LTS unit. LV+ and LV- can be connected, for example,

to battery and DC+ and DC- to DC-link. EC-C1200 would then control the battery discharging and

charging.

Not allowed use of the electric device

It is forbidden to use, handle, maintain and storage the electric device in following ways (including but

not limited to):

Using the electric device for other purposes than defined in the user guide.

•

Disregarding the obligation to comply with the user guide, safety signs and rating plate of the

•

electrical device.

Using the electric device, making adjustments and maintenance without first reading the user guide.

•

Exceeding the designed limits during the operation.

•

Using non-original service parts of wrong material causing corrosion problems and mechanical

•

failures in time.

Operating and performing maintenance on the electric device without appropriate personal

•

protective equipment.

Using the electric device for supporting other structures or indirect movements.

•

©

Danfoss | July 2021 BC355449988603en-000201 | 13

Page 14

User Guide

EC-LTS1200-410

Product overview

Causing any kind of impact forces to the electric device (for example hitting or hammering or

•

dropping objects).

Operating the electric device with electric connections other than defined in the user guide.

•

Operating the electric device with insufficiently tightened connections or cable glands.

•

Operating the electric device with power cables routed against the instructions.

•

Operating the electric device without properly dimensioned and operating cooling system.

•

Accessing the connection box(es) of the electric device, performing maintenance or adjustment

•

operations without securing that the electricity is disconnected and electric device is discharged as

defined in the user guide.

Lifting the electric device with additional load attached.

•

Using the electric device in potentially explosive environment.

•

Allowing dirt or liquid to enter into the electric device or connection box.

•

Using cables that can't withstand the maximum current values of the electric device.

•

Using dirty cable lugs or broken tools.

•

Connecting power cables so that there is less than 10 mm air gap between the cable lug and other

•

metallic structure (including the braid of the cable).

Storing the electric device contrary to the guidelines presented in this user guide, for

•

example, outdoors in wet or dusty conditions.

Storing the electric device without proper support that prevents overturning and falling.

•

System introduction

Cooling

Rating plate

For product specific and up to date information see product data sheets at https://www.danfoss.com/.

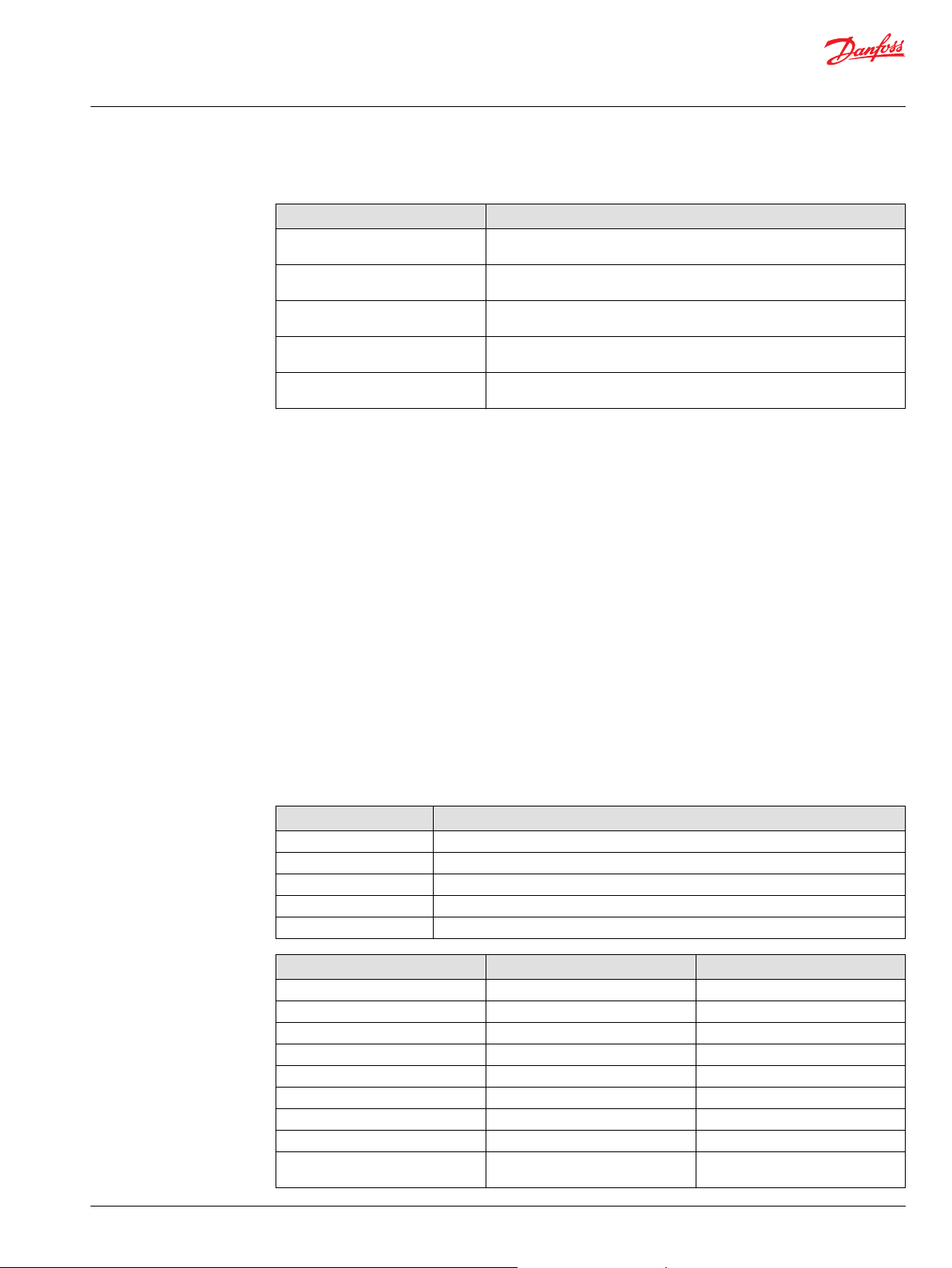

Cooling system requirements

Cooling system properties Specification

Cooling type Liquid cooling

Coolant type Water or water glycol mixture (glycol max. 50 %)

Coolant temperature -40º…+65 ºC

Coolant flow minimum 10 l/min

Maximum operating pressure 2 bar

Pressure drop 40 mbar with 10 l/min (+25 °C coolant)

See detailed information and specifications from the product data sheets at https://www.danfoss.com/.

Rated values can be found from the rating plate.

Each electric device has a rating plate (also called product label) which can be found on top of the electric

device. The rating plate contains device rating and identification details. The figure below shows an

example of a rating plate. The rating values in the Figure are illustrations only. For the exact information,

see the rating plate on the electric device and product data sheets at https://www.danfoss.com/.

14 | © Danfoss | July 2021 BC355449988603en-000201

Page 15

User Guide

EC-LTS1200-410

Product overview

Rating plate example

Rating plate fields

Field Explanation Unit

1 Electric device product family

2 Electric device device full type code including possible options

Serial No. Serial number

n ph Number of phases

U nom Nominal voltage V

U range Voltage range V

f1 Frequency Hz

I nom Nominal current A

P nom Nominal power VA

Manuf.

Duty Duty class

Cooling Cooling type

T

C

Q

C

IP rating Enclosure class according to IEC60034-5

Mass Total weight of the electric device

T

amb

T

storage

Max. pressure Coolant maximum pressure

Manufacturing year

Coolant temperature °C

Coolant flow l/min

Ambient temperature limits

Storage temperature limits °C

kg

°C

bar

The rating plate and its values shown here may not all be relevant for every electric device.

Tightening torques

For correct and safe operation, it is essential to use specified tightening torques for the electric device

screws. Tightening torques (screw preloads) used in the electric device are shown in the Table below.

©

Danfoss | July 2021 BC355449988603en-000201 | 15

Page 16

User Guide

EC-LTS1200-410

Product overview

Tightening torque tolerance is +/- 5% of the specified tightening torque.

Tightening torques

Connection Torque

Electric device mounting screws, M8 20 Nm

Connection box lid (power terminal cover) mounting screws 4 Nm

Cable lug mounting screws 15 Nm

Grounding cable mounting screws, M8 20 Nm

Cable gland (tighten from the frame of the gland) 15 Nm

16 | © Danfoss | July 2021 BC355449988603en-000201

Page 17

User Guide

EC-LTS1200-410

Transportation and storage

Transportation

Receiving and unpacking

Do not apply any excess weight on the electric device during transportation.

See the weight of the electric device from the product data sheets at https://

www.danfoss.com/.

The electric device is shipped in first class condition. Products are inspected and packed correctly to

prevent damage from ordinary handling during the transportation. Transportation conditions shall be in

accordance with the product specification, any kind of shocks must be avoided.

Plug and seal the cabling and cooling connections for transportation.

Lifting

Inspect the electric device and the package immediately upon arrival. Ensure that the rating plate data in

the cover letter complies with the purchase order. All external damage in the package or in the electric

device must be photographed and reported to Danfoss immediately.

Use correct, adequately dimensioned lifting devices and inspect them before lifting.

Do not apply any excess weight on the electric device when lifting it.

Use correct lifting slings. Use correct position and angle of lifting. The maximum permissible

range of lifting angles is shown in lifting figures.

Make sure that lifting slings are correctly routed so that they do not cause momentum on any

of the signal connectors.

See the rating plate and data sheets for weight information.

Lift the electric device using the correct lifting lugs/eyes only. See the lifting Figures in this

Chapter.

©

Danfoss | July 2021 BC355449988603en-000201 | 17

Page 18

User Guide

EC-LTS1200-410

Transportation and storage

Do not go under a lifted load.

The weight of the electric device is under 25 kg, so lifting it by hand is possible in most cases.

If it is necessary to lift the electric device with a lifting device, install two lifting eyes in the

threaded installation holes and lift from them. Obey the local legislation and

recommendations.

Correct lifting and incorrect lifting

Horizontal lifting

Maximum permissible lifting angles

18 | © Danfoss | July 2021 BC355449988603en-000201

Page 19

User Guide

EC-LTS1200-410

Transportation and storage

Horizontal lifting

Handling

Storage

1. M8 lifting eye, DIN580.

When turning or lifting the electric device, lift it in the air in order to prevent damage to the

frame or other parts of the electric device.

Although the electric device is designed to operate in harsh and demanding environment, any misuse or

improper handling of the electric device is prohibited to avoid malfunctions later.

When the device is dismounted and stored and packed for delivery, measure that there is no

voltage and then install short circuit wire to the conductor rails to prevent charge from

building up.

Do not apply any excess weight on the electric device during storage.

Store the electric device always indoors having the storage temperature preferably above -20 ºC and the

relative humidity less than 60 %. Storage conditions should be dry, dust free and vibration free.

Make sure that the cabling and cooling connections are plugged and sealed before storage.

The electric device must not be subjected to any external vibrations during storage to avoid possible

hidden structural damages.

©

Danfoss | July 2021 BC355449988603en-000201 | 19

Page 20

User Guide

EC-LTS1200-410

Installation

Required tools

Mechanical installation

Risk of electric shock during electrical installations. Use insulated tools..

Following tools are required to install the electric device:

•

Ratchet torque wrench.

•

Hex head wrench kit with different metric sizes.

•

Socket wrench kit with different metric sizes.

•

Cable gland tightening tool. Size according to cable glands.

•

Cable skinning knife.

•

Crimping tool for cable lugs.

For more detailed information, see appropriate Chapters in this user guide and product data sheets at

https://www.danfoss.com.

Allowed mounting position

Do not place the electric device on the ground without proper mounting or protective

structure.

The electric device must be mounted on a flat, heat- and flame-resistant mounting place (for example

•

on a bracket).

The electric device can be mounted in any direction. Mount the electric device permanently

•

from the mounting points.

Mounting points are shown in the Figure below.

•

Location of the mounting points

20 | © Danfoss | July 2021 BC355449988603en-000201

Page 21

User Guide

EC-LTS1200-410

Installation

1. M8x1.25 (18 mm Deep ) 14 pcs (6 pcs on the sides, 8 pcs on the bottom)

To fulfill the mechanical and environmental standards, for example vibration and shock, it is

recommended to mount the electric device from the bottom or from the side, with at least 6

pcs of M8 screws.

Selected mounting position must allow the cooling system to work properly. Bleed the air away from the

cooling channels to prevent air pockets.

Installation procedure

Risk of electric shock when the connection box lid is open. Make sure that the electric device is

discharged; measure the voltage to make sure of safety.

Heavy electric device. Handle with care. Handle the electric device correctly when you

install it to the correct mounting position. See Chapter Handling on page 19.

Measure the insulation resistance of the electric device before and after the installation of the

electric device.

When installing the connection box lid, make sure there are no foreign particles between the

connection box lid and the insulation and that all connection box fasteners are in place.

Missing or loose screws can compromise the insulation.

Preparations

Make sure that the chosen installation place fulfills the environmental requirements specified for the

•

electric device.

Protect the electric device against corrosive gases, liquids, conductive contaminants (such as

•

condensation, carbon dust, and metallic particles) and sprays or splashing water from all directions.

Protect the electric device in high humidity, salty or chemical content environments with suitable

•

additional enclosure.

The mounting place and mounting interfaces should be sufficient to carry the weight of the electric

•

device.

Make sure that the electric device has sufficient mounting and operating clearances for maintenance

•

work.

Installation procedure may vary from that shown in this user guide. All steps must be included in the

•

procedure, although the order of the steps can be different.

Installation procedure

1. Prepare the installation place and make sure that it meets the requirements for the product.

2. Lift and support the electrical device for the mounting. Refer to Chapter Lifting on page 17.

3. Install all appropriate mounting screws, do not tighten the screws until they are aligned and preinstalled. See the tightening torques from Chapter Tightening torques on page 15.

©

Danfoss | July 2021 BC355449988603en-000201 | 21

Page 22

User Guide

EC-LTS1200-410

Installation

4. Connect the cooling system. See Chapter Cooling connections on page 22 or the Main dimension

drawing for connection details. Make sure that there are no air pockets in the cooling channels and that

the coolant goes freely in and out. Make sure that the cooling system operates correctly.

5. Make sure that the devices and machines you will connect to the electric device have no voltage.

6. Make the grounding of the frame of the electric device by direct contact between it and the metal

bracket and / or from the protective earth contacts. The grounding contacts must be paint-free. See

Chapter Grounding on page 23.

Cooling connections

Make sure that cooling liquid runs freely in and out from the electric device.

When selecting cooling liquid nipples, choose nipples that can resist galvanic corrosion.

To prevent damage to the cooling connectors, refer to the documentation of the

manufacturer for the correct tightening torque of the cooling liquid nipples.

Connect the electric device directly to the cooling circuit.

•

Make sure that the coolant flow is equal or higher than rated and the coolant temperature at the inlet

•

of the electric device is lower or equal to the rated temperature.

For more information, see Chapter Recommended coolants on page 22 and product data sheets.

•

Rated values can be found on the rating plate of the electric device.

It is recommended to fix the hose on the coolant connection with a hose clamp or a hose clip after

•

the protection cap has been removed.

Use water/glycol mix or pure water with corrosion inhibitor as the coolant.

•

Recommended coolants

Ethylene glycol is a toxic compound. Avoid exposure to the coolant. Handle with care. Use

appropriate personal protective equipment when you handle the coolant.

The electric device works correctly with water based coolant. Plain water with appropriate corrosive

inhibitor is acceptable, for example water with maximum of 50% glycol coolant. Ethylene glycol based

Glysantin® G48® (includes also corrosion inhibitors) or similar can be used. Propylene glycol based

coolants, like Splash® RV&Marine antifreeze, can also be used. Propylene glycol is relatively safe

compound for humans and the environment.

22 | © Danfoss | July 2021 BC355449988603en-000201

Page 23

User Guide

EC-LTS1200-410

Installation

Electrical installation

Electrical connections

Before you start the electrical installation make sure that the frame of the electric device is

grounded correctly. Refer to Chapter Grounding on page 23.

Risk of electric shock when power terminal cover is open. When working with the power

connections make sure that electricity has been disconnected and the electric device has

discharged.

Cable lugs are not included in the delivery.

Grounding

Make sure that the electric device is correctly grounded. Do not operate the electric device

without correctly attached protective earth conductor. Obey the installation instructions and

the guidelines for component selection given in this user guide.

The grounding cable must be able to carry the maximum supply fault current which normally

will be limited by the fuses or the Miniature Circuit Breaker (MCB). Put correctly rated fuses or

MCB in the mains supply of the electrical device: obey the local legislation and

recommendations.

Obey the installation instructions and the guidelines for component selection given in this

user guide.

Make sure that the safety grounding is correct. Refer to Chapter Mechanical installation.

Generic grounding guidelines

•

Connect the ground terminal of each electric device individually to the site grounding bus bar

(through the filter if installed).

•

The grounding connections cannot loop from one electric device to another electric device, or to any

other piece of equipment, or from any other piece of equipment.

•

Ground impedance must be compliant with local industrial safety regulations.

•

The protective ground of the unit must be connected to the system ground. Ground impedance must

meet with the requirements of national and local industrial safety regulations and electrical

requirements. The condition of the grounding connections must be checked periodically.

•

Make sure that all grounding surfaces are clean and remove paint from the contact areas.

•

For detailed information, see appropriate Chapters in this user guide.

©

Danfoss | July 2021 BC355449988603en-000201 | 23

Page 24

User Guide

EC-LTS1200-410

Installation

Main frame

The best grounding is achieved when the main frame of each electric device is directly connected to the

ground. If this is not possible, the electric device must be grounded at least from one of the safety

grounding points with an appropriate grounding cable. For good functional grounding use wide flat

grounding braid. Round grounding wires are adequate for safety grounding but it does not provide very

good functional grounding because of its higher impedance at high frequencies. The grounding points

are marked to the electric device.

There are two marked safety grounding points, however, any of the mounting points can be used for

grounding.

Grounding points

1. Grounding connection: M8 hole. Refer to Main dimension drawing if necessary.

Safety grounding points and protective earth conductor

Touch current in the protective earth conductor exceeds 3,5 mA AC and 10 mA DC.

The cross sectional area of the protective earth conductor must be at least equal to that of the

incoming supply conductor.

One of the safety grounding points must be connected to adjacent building steel (girder, joist), a floor

ground rod, or bus bar. Grounding points must comply with national and local industrial safety

regulations and/or electrical codes.

Cabling and wiring

To make sure that the electric device functions correctly and to minimize the radiated emissions, all

connected cables and wires must be EMC-shielded. Shieldings must be connected to the ground at both

ends of the cable or wire. All power connections must be secured with cable lugs and cable glands. EMCshielded cable glands are used in all Danfoss products for the power connections. Make sure that the low

voltage cable (control signal cable) shield is also grounded from the both ends.

24 | © Danfoss | July 2021 BC355449988603en-000201

Page 25

User Guide

EC-LTS1200-410

Installation

Cable gland assembly and power line connection

Risk of electric shock when the connection box lid is not installed.

When you work with the power connections make sure that electricity has been disconnected

and the electric device has discharged. Measure the level of the remaining voltage before you

touch the power terminals.

Blueglobe cable gland tightening torques

Metric thread Nominal torque

M10x1,0 3,0 Nm

M12x1,5 5,0 Nm

M16x1,5 8,0 Nm

M20x1,5 10,0 Nm

M25x1,5 15,0 Nm

M32x1,5 15,0 Nm

M40x1,5 20,0 Nm

M50x1,5 30,0 Nm

M63x1,5 35,0 Nm

M75x1,5 80,0 Nm

M85x2,0 100,0 Nm

All electrical connections must be done according to instructions. It is essential to make sure that all

terminal connections are installed properly and the and the intended application is suitable for the

product in terms of electrical requirements/characteristics.

The cable harness for electric connections needs to be terminated with cable lugs and cable glands. It is

recommended to use IP67/68 rated, 360º shielded cable glands and single core automotive rated

screened cable.

The cable gland has three functions, it works as a stress relief, it seals the connection against water and

dirt and provides appropriate EMI shielding. Advanced cable glands could achieve high EMI attenuation

over a wide frequency range.

The cable lug and cable gland must be assembled according to instructions. For correct assembly of the

cable gland, it is recommended to use a torque key with a turnkey head and a key to adapt the cable

gland. The cable lug is connected to terminal with a M8 screw. Shielding of the power cable must be

connected to the electric device body by the cable gland. Recommendations for the tightening torques

must be followed. See the manufacturer's instructions on how to install the cable glands and the cable

lugs. The following instructions may not apply to every type of connection this electric device has.

©

Danfoss | July 2021 BC355449988603en-000201 | 25

Page 26

User Guide

EC-LTS1200-410

Installation

Cable harness connection with the cable lug and the cable gland (for illustration only)

EC-LTS1200-410 internal connections

Description

1 LV1

2 LV2

3 LV3

4 LV

The information below describes how to assemble screened power cables to the electric device. Pflitsch

BlueGlobe-series cable glands and H+S Radox Elastomer S automotive cables are recommended.

Cable gland assembly instruction can also be found from Pflitsch gland catalogue available from https://

www.pflitsch.de.

Cable lug and cable gland assembly steps

26 | © Danfoss | July 2021 BC355449988603en-000201

Page 27

User Guide

EC-LTS1200-410

Installation

1. Remove the small hexagonal piece from the BlueGlobe-sealing insert as shown in Figure below.

BlueGlobe-sealing

2. Cut the cable sheath at the distance A from the end of the cable, see Figure below. Pull the cut part of

the sheath partly (length B is from 10 to 15 mm) off the cable as shown in the figure. Distance A depends

of the length of the used cable lug. Measure with the cable lug that is used and cut to suitable length.

Install two layers of copper tape on the cable so that the distance B is covered. Use 3M

Copper Foil Tape 1181 or similar.

Do not remove the cable sheath completely at this point and do not cut the braid screen of

the cable.

™

Cut length of the cable sheath

3. Insert the cable to the cable gland with slight turning motion. This helps the cable go through the

spring inside the cable gland. Push the cable gland against the sheath of the cable as shown in Figure

below.

©

Danfoss | July 2021 BC355449988603en-000201 | 27

Page 28

User Guide

EC-LTS1200-410

Installation

Cable to the gland assembly

4. After the cable gland is in place remove the length A piece of the sheath and cut the braid screen

(cover) from 10 mm (distance C) from the gland bottom as shown in Figure below.

Make sure that the cable gland spring is against the cable sheath (that is protected with

copper tape) before cutting the braid screen.

Cut the braid screen

5. Cut a piece of length D of the inner sheath shown in Figure below. The length D must be equal to the

length of the cable lug body.

28 | © Danfoss | July 2021 BC355449988603en-000201

Page 29

User Guide

EC-LTS1200-410

Installation

Cutting the inner sheath

6. Make sure that the conducting strands of the cable are completely free of silicone and other impurities.

Place the cable inside the cable lug body, and crimp the cable lug twice in different places. See Figure

below.

Connecting cable lug

7. Cut piece of shrink tube and shrink it over the cable lug and braid screen as shown in Figure below.

This is done to keep the braid screen in place and for extra insulation.

The shrink tube must be specified for operating temperature range from -40 ºC to 150 ºC. Self

gluing shrink tube is recommended.

©

Danfoss | July 2021 BC355449988603en-000201 | 29

Page 30

User Guide

EC-LTS1200-410

Installation

Shrink tube

8. Insert the cable through the corresponding hole in the electric device frame and connect the cable lug

to the power terminal with the correct screw. Use spring washer between the cable lug and the

connection screw or nut. Do not tighten the cable lug screw at this point to ensure fitting of the cable

gland.

Make sure that there is at least 10 mm air gap between the cable lug and other metallic

structures including the braid of the cable. If the air gap is smaller, use extra insulation shrink

tube to cover the lug.

9. Screw the cable gland to the power terminals of the electric device according to instructions. Tighten

the cable gland with the specified torque.

Tighten the gable gland from the gable gland body to enclosure with torque 15 Nm. Then

tighten the cap of the gable gland according to the instructions provided by gable gland

manufacturer (recommendation Pflitsch).

10. Tighten the cable lug using the specified torque.

11. Repeat the procedure to the other cables and connections.

12. Close the power terminal cover and install the connector shield.

13. Make sure that the power cable shields are grounded properly.

30 | © Danfoss | July 2021 BC355449988603en-000201

Page 31

User Guide

EC-LTS1200-410

Installation

Cable lug and cable gland assembly cross section

Example of the equipment needed for the assembly

Description Manufacturer's homepage Art.No./Part No.

Assembly equipment (example) Torque key and turnkey

Assembly example for a 50 mm

cable

head

Key http://www.pflitsch.de SE30

2

Cable with nominal

cross-section of 50 mm

Cable lug http://www.druseidt.de 03903

Cable gland http://www.pflitsch.de

Screw http://www.wuerth.com DIN 912 M8x16 (item:

Washer http://www.wuerth.com DIN 2093, 8,2 x 16 x 0,9

Washer http://www.wuerth.com

Cabling and wiring

Route the power cables as far from the control signal wires as possible. The minimum

separating distance is 100 mm. The crossings must be in an angle of 90º. Power cables and

control wires should be routed near the frame of the application. Make sure that all terminal

connections are tightened correctly.

http://www.pflitsch.de 730N/10-50

http://www.hubersuhner.com Radox Elastomer S

2

Pflitsch blueglobe TRI bg

225ms tri

10285)

(item: 17332)

DIN 125 D8

(item: 10285)

Install the electric device by the instructions. Make sure that all the applications of the system, for

example, batteries are connected to the electric device by the instructions of this user guide and the

product specific guidelines.

©

Danfoss | July 2021 BC355449988603en-000201 | 31

Page 32

User Guide

EC-LTS1200-410

Installation

Cabling

•

For the power cables, it is recommended to use Radox Elastomer S, screened automotive cable or

equivalent cable with similar specifications.

•

Use only EMI-shielded power cables to make sure the correct operation of the electric device and to

minimize the radiated emissions. Cable shields must be connected to the electric device ground at

both ends of the cable. All Danfoss products use EMI-shielded cable glands for power connections.

Wiring

To make sure of correct and steady operation, use EMI-shielded cables for the control signals of the

electric device. Cable shields must be connected to the electric device ground at both ends of the cable.

Recommendations for control signal cables

Cable Cable type and properties

External temperature measurement (PT100/PT1000) shielded cable (twisted pair)

High voltage connections

The high voltage connections have a common ground connector.

U

≥ U

HV

LV

Make sure the power cables exit straight from the terminals and do not rub against the sharp

cable through-holes or other sharp edges which could wear out the cable insulation over

time.

Do not place any excess weight on the connection box lid(s).

The electric device must be installed and connected according to the instructions.

•

Make sure that all the connected applications are connected to the electric device according to the

•

product specific operating voltage.

The electric device is delivered with the power terminal cover mounted. To access the power

•

connections, remove the mechanical safety feature and the connection box lid.

For more information, see appropriate chapters in this user guide and the product data sheets.

Low voltage connections

See the correct signal connections and product specific pin-layout from product data sheets,

http://www.danfoss.com.

32 | © Danfoss | July 2021 BC355449988603en-000201

Page 33

User Guide

EC-LTS1200-410

Installation

Control signal connector information

Description Part number Supplier example

X2 temperature measurement connector M16 male 7.840.200.000 www.hummel.com

Insert 10-pole insert: 7.003.910.101

Pin: 7.010.981.001

Mating connector M16 female 7.810.400.000

Insert 10-pole, M16, RCPT 7.003.910.102

Sensor Connector Socket 7.010.981.002

M16 connector

Pin configuration of temperature measurements (M16 connector, one sensor per inductor)

PIN Description

1 Temperature 1, PT100 (P), inductor

2 Temperature 1, PT100 (N), inductor

3 Temperature 2, PT100 (P), inductor

4 Temperature 2, PT100 (N), inductor

5 Temperature 3, PT100 (P), inductor

6 Temperature 3, PT100 (N), inductor

7 Enclosure ground (shield)

8 Reserve

©

Danfoss | July 2021 BC355449988603en-000201 | 33

Page 34

User Guide

EC-LTS1200-410

Operation

Operation conditions

The electric device should be used for its intended purpose only and within limits specified by the

manufacturer, concerning:

Loading.

•

Cooling.

•

Service interval.

•

Ambient conditions such as temperature and moisture.

•

The electric device is designed for these conditions:

Maximum altitude 4000 m above sea level.

•

If the operation limits are exceeded and the electric device is damaged, please contact local Danfoss

representative.

Condition monitoring during operation

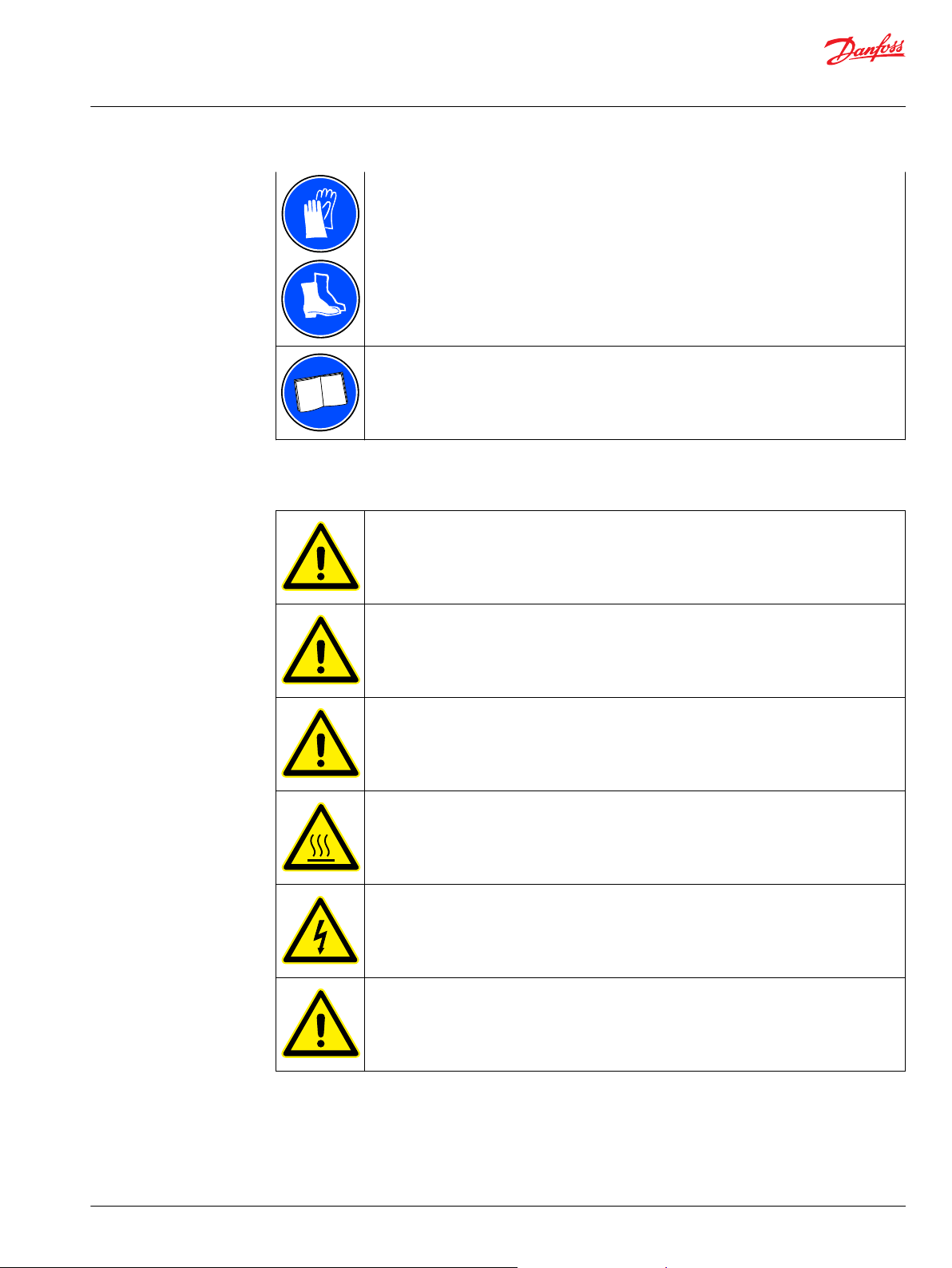

Risk of permanent damage to the electric device. Use the electric device only in the ambient

conditions given in this user guide and in the data sheet.

Risk of permanent damage to the electric device. Use the electric device only if the technical

guidelines given in this user guide and in the data sheet are met.

Risk of permanent damage to the electric device. If you notice deviations from the normal

operation (for example: high temperatures or noise), stop the electric device. Find the reason

for the deviation and take action to repair the functionality of the electric device. Refer to

Chapter Troubleshooting on page 39 for more information.

Temperature trip on the electric device is 155°C. Connect the three PT-100 temperature

sensors to the converter.

Monitor the electric device regularly during operation to make sure of reliable operation, to foresee

possible upcoming failures and to help to reach the designed lifetime of the product.

34 | © Danfoss | July 2021 BC355449988603en-000201

Page 35

User Guide

EC-LTS1200-410

Maintenance

Regular maintenance

Do not disassemble the electric device. You can do only procedures described in this user

guide. For further information contact Danfoss representative.

Only trained and qualified personnel that are familiar with the relevant safety requirements

can do any maintenance to the electric device.

Risk of electric shock when the connection box lid is removed.

Inspect the electric device at regular intervals. Use the regular maintenance checklists in the

inspections.

Do not attempt to tighten or release any screws, nuts or joints which are not shown in this

user guide and that are not involved in the normal installation and maintenance procedures.

Use correct personal protective equipment when you are near the electric device.

Read the instructions in the user guide before you install the electric device. To make sure of

safe and reliable operation of the electric device, obey the maintenance instructions.

©

Danfoss | July 2021 BC355449988603en-000201 | 35

Page 36

User Guide

EC-LTS1200-410

Maintenance

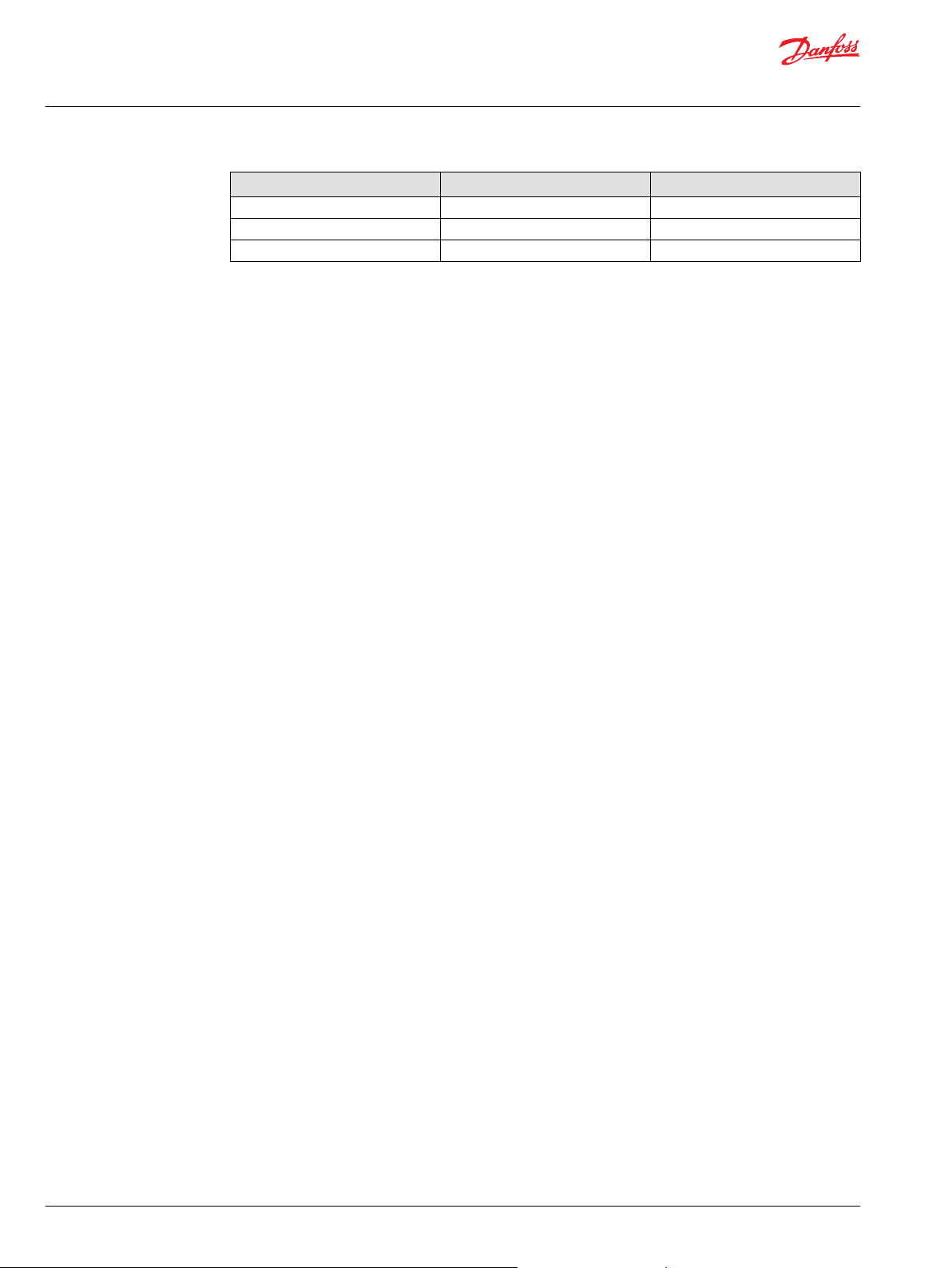

Maintenance intervals

Object Check/Task Weekly Monthly Yearly

General

construction

Electrical system Cables Visual check, for example wear. Replace if

Cooling system Operation Functioning. Cooling system functions as

Operation Abnormal phenomenon, for example noise or

Mounting Tightness of the screws. Tighten to proper

Enclosure and

connected parts

Electrical

connections

Groundings

(earthings)

Ventilation plug Cleanliness. Clean if necessary. See Chapter

heating. If clearly increased, contact Danfoss

representative.

value if necessary. Applies to screws that are

presented in this user guide. See Chapter

Tightening torques on page 15.

Check cleanliness. Clean if necessary. See

Chapter Cleaning on page 36.

necessary.

Check connections. Ensure that sufficient

tightening torque is applied to cable glands.

See Chapter Tightening torques on page 15.

Check groundings (earthings). Ensure that the

connection resistance is valid. Re-connect if

necessary.

specified.

Cleaning on page 36.

X

X

X

X

X

X

X

X

Cooling system maintenance

Cleaning

The cooling system of the electric device requires regular observation and maintenance

activities. Observe weekly that the cooling system operates correctly and check monthly that there are no

leakages in the cooling system. The quality of the coolant must be checked yearly. The mixture of water

and glycol as well as the type of the glycol used must be as specified. See Chapter Recommended coolants

on page 22.

Do not use pressure washer for cleaning. High water pressure may damage the gaskets

allowing water to go in to the electric device.

Never open or remove the watertight ventilation plugs. Clean them only from the outside.

Risk of electric shock if the electric device is cleaned against instructions allowing water to go

in to the electric device.

Keep the electric device clean. For cleaning, use non-abrasive and non-corrosive cleaning products. Make

sure that the detergent can be used for aluminum.

36 | © Danfoss | July 2021 BC355449988603en-000201

Page 37

User Guide

EC-LTS1200-410

Maintenance

Ventilation plug

©

Danfoss | July 2021 BC355449988603en-000201 | 37

Page 38

User Guide

EC-LTS1200-410

Dismounting and disposal of the electric device

Risk of electric shock if dismounting steps are continued before the electric device is

discharged and a safe voltage level has been measured.

Do not touch the electric device or continue to work with the electric device until it cools

down.

Support the electric device during dismounting, handle it with care.

Refer to Chapter Installation procedure on page 21 for additional information.

Dismounting procedure

1. Switch off the electric device.

2. Make sure that the cooling system remains operational.

3. Always measure that no voltage is present on the power terminals before you proceed.

4. Wait until the temperature of the electric device and cooling liquid has decreased below +40 °C.

5. Disconnect the power terminal cabling.

6. Disconnect grounding cables (protective earth).

7. Disconnect the liquid cooling system.

8. Remove the mounting screws and dismount the electric device from the mounting base.

9. Install the connection box lid and other parts and plug all electrical and cooling connections for longer

storage.

10. Lift the electric device off.

Disposal of the electric device

Dispose of the electric device and any of its parts by local laws and regulations.

38 | © Danfoss | July 2021 BC355449988603en-000201

Page 39

User Guide

EC-LTS1200-410

Troubleshooting

Do not activate the automatic fault reset function on any system where it can be the cause of a

potentially dangerous situation.

Do not try to repair the electric device. In the case of suspected fault or malfunction, contact

Danfoss or authorized service center for further assistance.

For the reason of general safety and correct operative actions, read the instructions carefully

before you start any analyses or work with the electric device.

Use correct personal protective equipment when you are near the electric device.

Some unexpected situations may occur while operating the electric device. Some of the possible causes

and actions are given in table below. If an unexpected situation occurs, it should be corrected as soon as

possible.

These instructions do not cover all details or variations in the equipment nor provide information for

every possible condition to be met in connection with installation, operation or maintenance.

Troubleshooting

Fault description Possible cause Action

Electric device

overheating

Significant coolant leak Loose connection in the

Electric device does not

work correctly or the

performance is poor

Cooling system failure. Inspect the cooling system operation and functionality,

especially possible leaks, flow rate and fluid temperature.

Change the cooling flow direction to flush the cooling

system from sediment possibly accumulated.

Leakage in the cooling

system.

Rigid particle inside the

cooling channel of the

electric device.

coolingsystem.

Broken cooling hose. Replace the cooling hose.

Poor powerline contacts

(high voltage)

Inspect the cooling system circuit and connections.

Try to pulsate coolant to open the channels.

Contact Danfoss representative.

Inspect, clean and tighten the connections. Replace them if

neccessary.

Inspect, clean and tighten the contacts.

©

Danfoss | July 2021 BC355449988603en-000201 | 39

Page 40

User Guide

EC-LTS1200-410

Aftersales

Service policy

Service parts

Maintenance and service of the electric device is limited to the procedures described in this user guide.

See Chapter Service parts on page 40 below for available service and accessory parts. For further

information, contact Danfoss representative.

The recommended service parts are listed in the Table below. Contact Danfoss representative for more

information and purchasing.

Service parts

Service parts

Position Item / order number Quantity Description

1 35409 1 Lid with extruded gasket

2 10348 3 Cable gland, M25 x 1,5 BG PFLITSCH, BG225MSTRI

3 10473 3 Cable gland, M32 x 1,5 BG PFLITSCH, BG232MSTRI

4 34099 20 Lid screws, M5 x 12, DIN 965 A2 TX

40 | © Danfoss | July 2021 BC355449988603en-000201

Page 41

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | July 2021 BC355449988603en-000201

Loading...

Loading...