Page 1

P30

P30

VI.7B.C5.02

2005.10

VI.7B.C5.02

2005.10

www.danfoss.com

User's Guide

Installer's Guide

www.danfoss.com

ECL Comfort

Installer's Guide

ECL Comfort

User's Guide

*087R8017*

*VI7BC502*

*087R8017*

*VI7BC502*

Mixing controller

Page 2

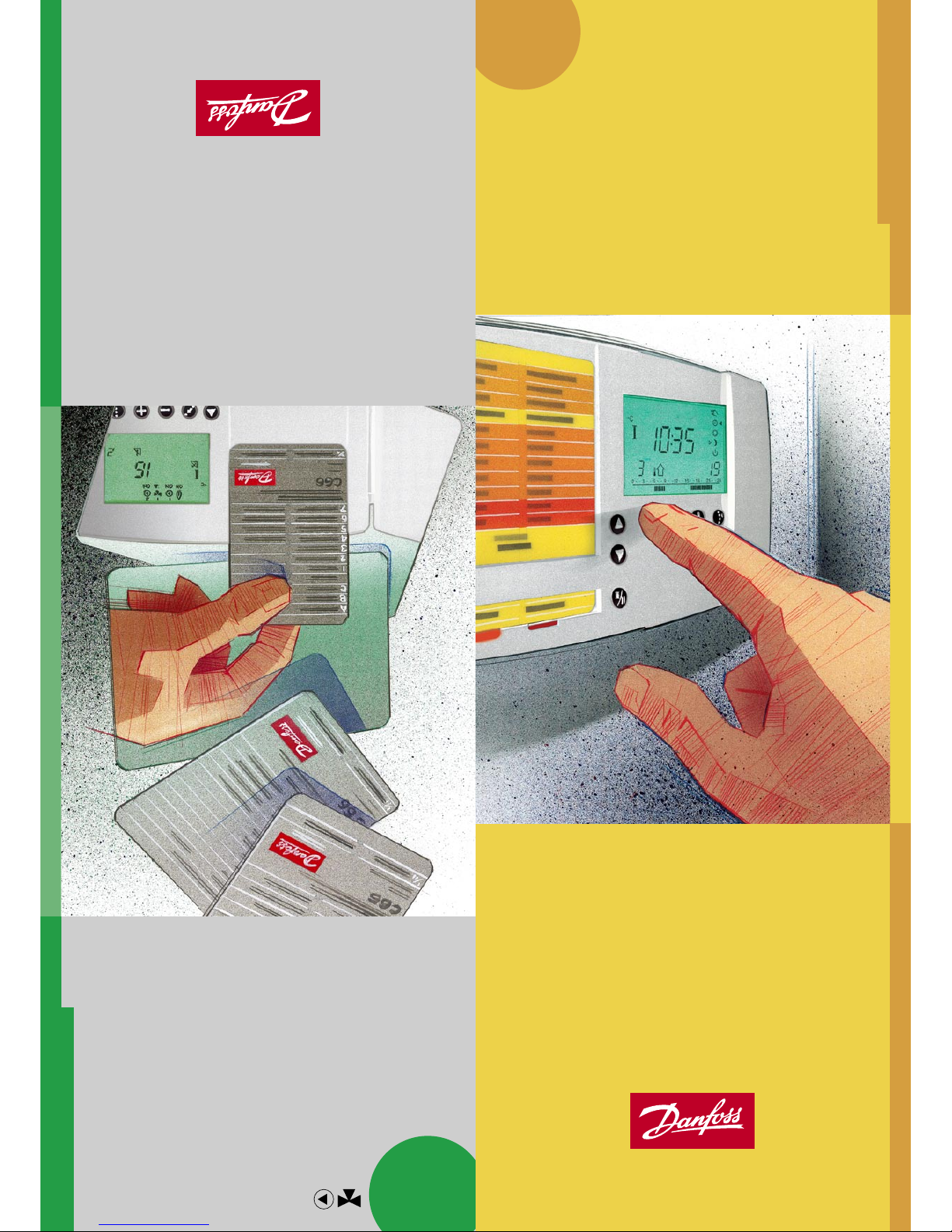

The shown diagram is a fundamental and simplified example and

does not contain all components that are necessary in a system.

If the system you are about to install differs from the shown

diagram of a standard heating system, feel free to sketch an outline

for comparison. Adaptation of systems, see section 10.

List of components:

ECL Comfort 200

S1 Outdoor temperature sensor

S2 Room temperature sensor

S3 Flow temperature sensor

S4 Return temperature sensor

P1 Circulation pump, heating

M1 Motorized control valve

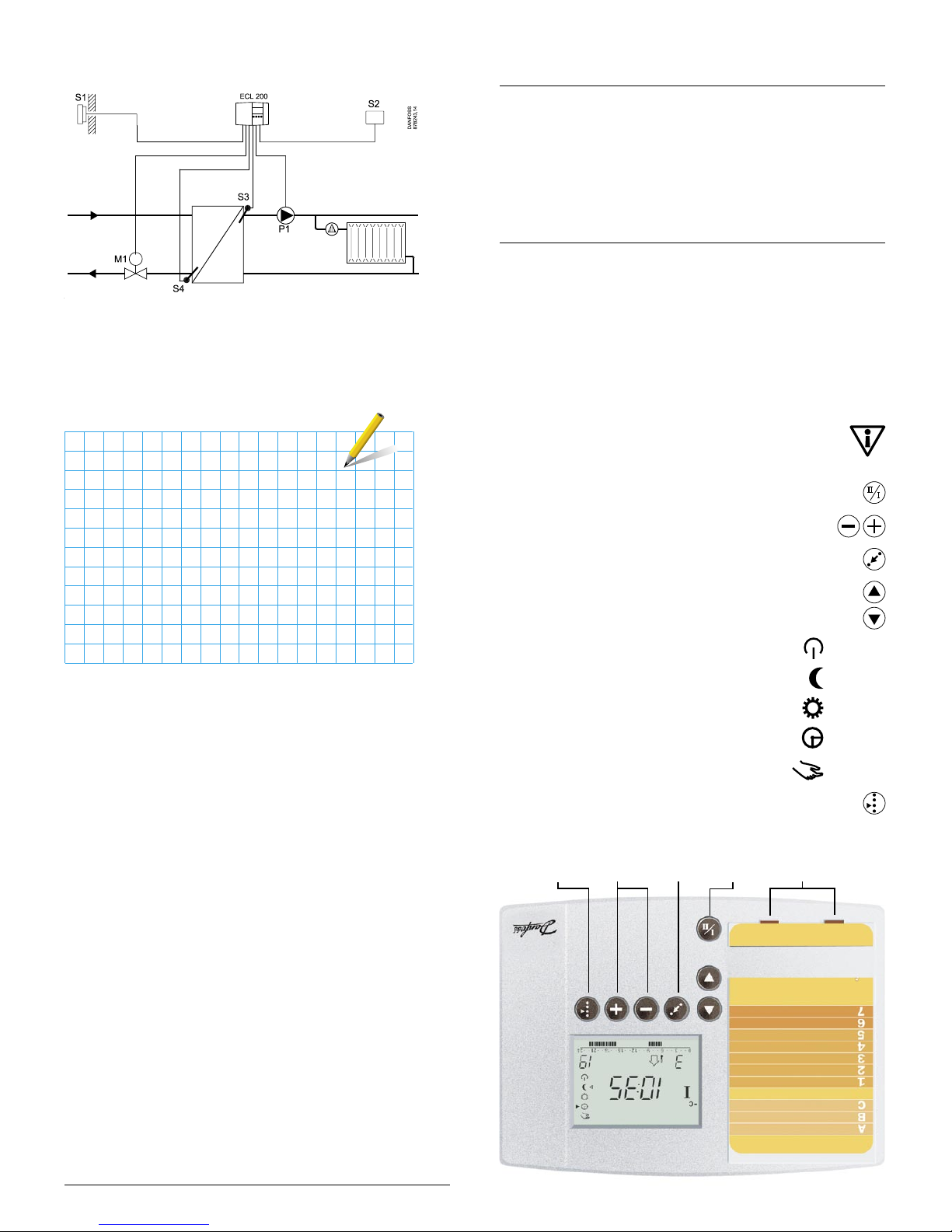

User / service

setting

indicator

User /

service

settings

Shift

button

Adjust-

ment

Controller

mode

Controller mode

Manual operation (used only at maintenance

and service)

Scheduled operation

Constant comfort temperature

Constant setback temperature

Standby mode

Arrow buttons. Switch between the lines of the ECL

Card

Shift button. Switches between temperatures,

changeover points etc.

Adjust temperatures and values etc.

Switch between user settings (yellow card side) and

service settings (grey card side).

Safety Note

To avoid injury of persons and damages to the device, it is

absolutely necessary to read and observe these instructions

carefully.

Necessary assembly, start-up, and maintenance work must be

performed by qualified and authorized personnel only.

This guide is associated with ECL Card 087B4653

Installer:

By:

Date:

Page 3

User's Guide (turn the guide over for sections 1-7)

1 Choose your favorite display

2 Select controller mode

3 Set your room temperature

4 Set your personal schedule

6 Hot points

7 Definitions

Table of Contents

Sections in the Installer’s Guide

The documentation for the ECL Comfort controller is

composed of numbered sections. Only sections relevant to

your ECL Comfort controller are included here.

Before you start

Installation

10 Identifying the system type

11 Mounting the ECL Comfort controller

12 Electrical connections 230 V a.c.

13 Electrical connections 24 V a.c.

14 Connecting and placing the temperature sensors

15 Adapting the ECL Comfort controller

Basic Set-up

16 Adjusting the ECL Card settings

17 Setting the time and date - line A

18 Monitoring temperatures and system units - line B

19 Manual control - line B

20 Setting the heat curve - line C

21 Heating cut-out - line 1

22 Flow temperature limits - line 2

23 Room temperature influence - line 3

26 Control parameters - lines 4-7

Control & Overviews

29 Check list

30 ECL Card settings

31 Service parameters

Extended Service

32 Adjusting the service parameters

Page 4

Page 5

VI.7B.C5.02

Card P30

2005.10

Sketch your application

The ECL Comfort controller series is designed for a wide

range of heating and hot-water systems with different

configurations and capacities.

If your system differs from the diagrams shown in section

10, you may want to make a sketch of the system about to

be installed. This makes it easier to use the Installer’s Guide,

which will guide you step-by-step from installation to final

adjustments before the end-user takes over.

The controller is pre-programmed with factory settings that are

shown in the relevant sections of this guide.

However, you might come across some settings that are not listed

in this instruc tion. These settings could be related either to recent

updates or the use of optional modules (which are described in

the instructions in question).

How to use this guide

This guide is divided into two parts:

• User’s Guide: Yellow sections 1-7

• Installer's Guide: Grey sections 10 and onwards

The application P30 is very flexible. These are the basic principles:

Typically, the flow temperature is always adjusted according to

your requirements.

The flow temperature sensor (S3) is the most important sensor.

The desired flow temperature at S3 is calculated in the ECL

Comfort controller, based on the outdoor temperature (S1). The

lower the outdoor temperature, the higher the desired flow

temperature.

The motorized control valve (M1) is opened gradually when the

flow temperature is lower than the desired flow temperature and

vice versa.

The return temperature (S4) to the district heating supply should

not be too high. If so, the desired flow temperature can be

adjusted (typically to a lower value) thus resulting in a gradual

closing of the motorized control valve. In boiler-based heating

supply the return temperature should not be too low (same

adjustment procedure as above).

If the measured room temperature does not equal the desired

room temperature, the desired flow temperature can be adjusted.

The circulation pump, P1, is ON when the desired flow

temperature is higher than 20 °C or the outdoor temperature is

lower than 2 °C.

Before you start

Page 6

Installation

The ECL Comfort controller is a universal controller that can

be used for various systems. Based on the shown standard

systems, it is possible to configure additional systems.

In this section you find the most frequently used systems. If

your system is not quite as shown below, find the diagram

which has the best resemblance with your system and make

your own combinations.

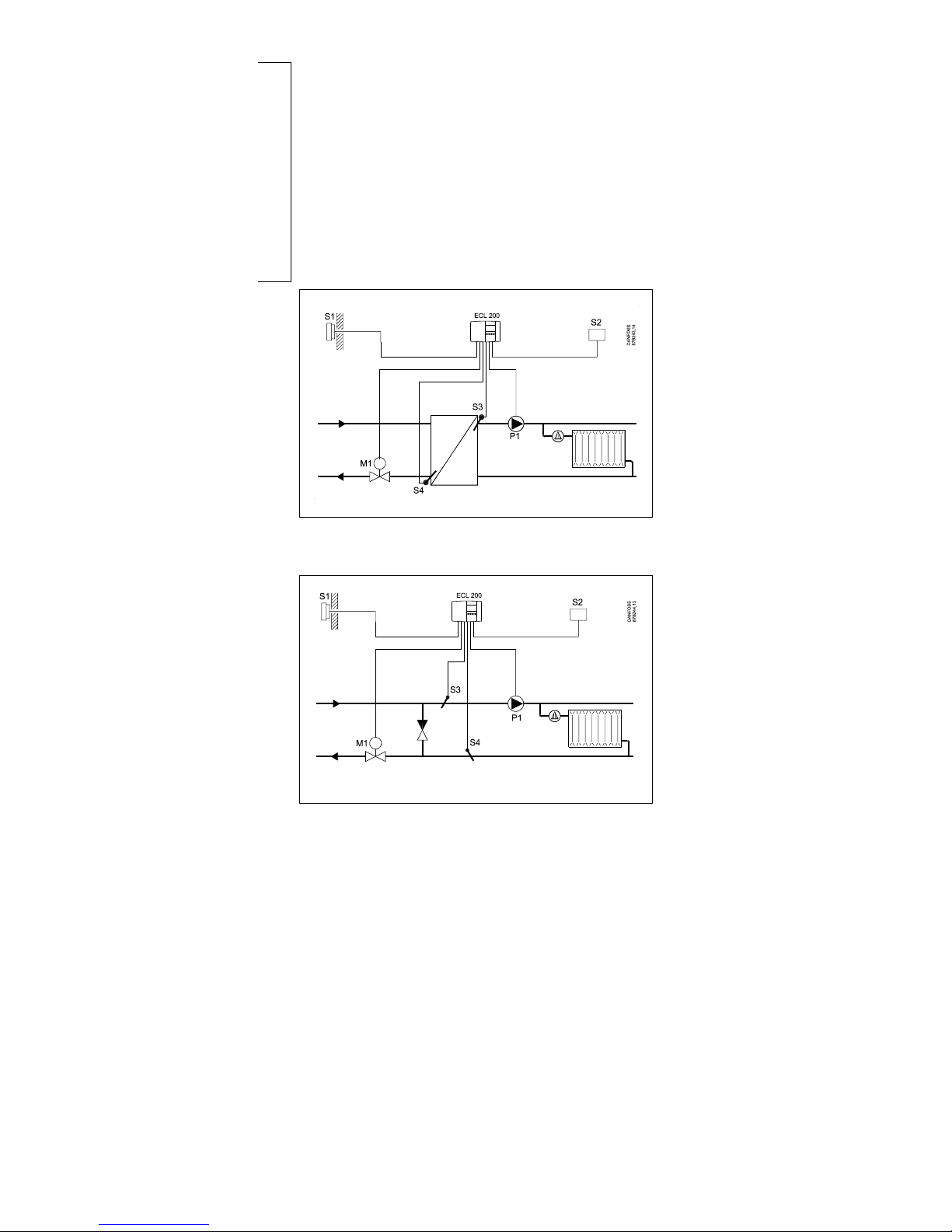

10.1 Indirectly connected heating system

10.2 Directly connected heating system

Identifying the system type

10a

Page 7

Installation

10b

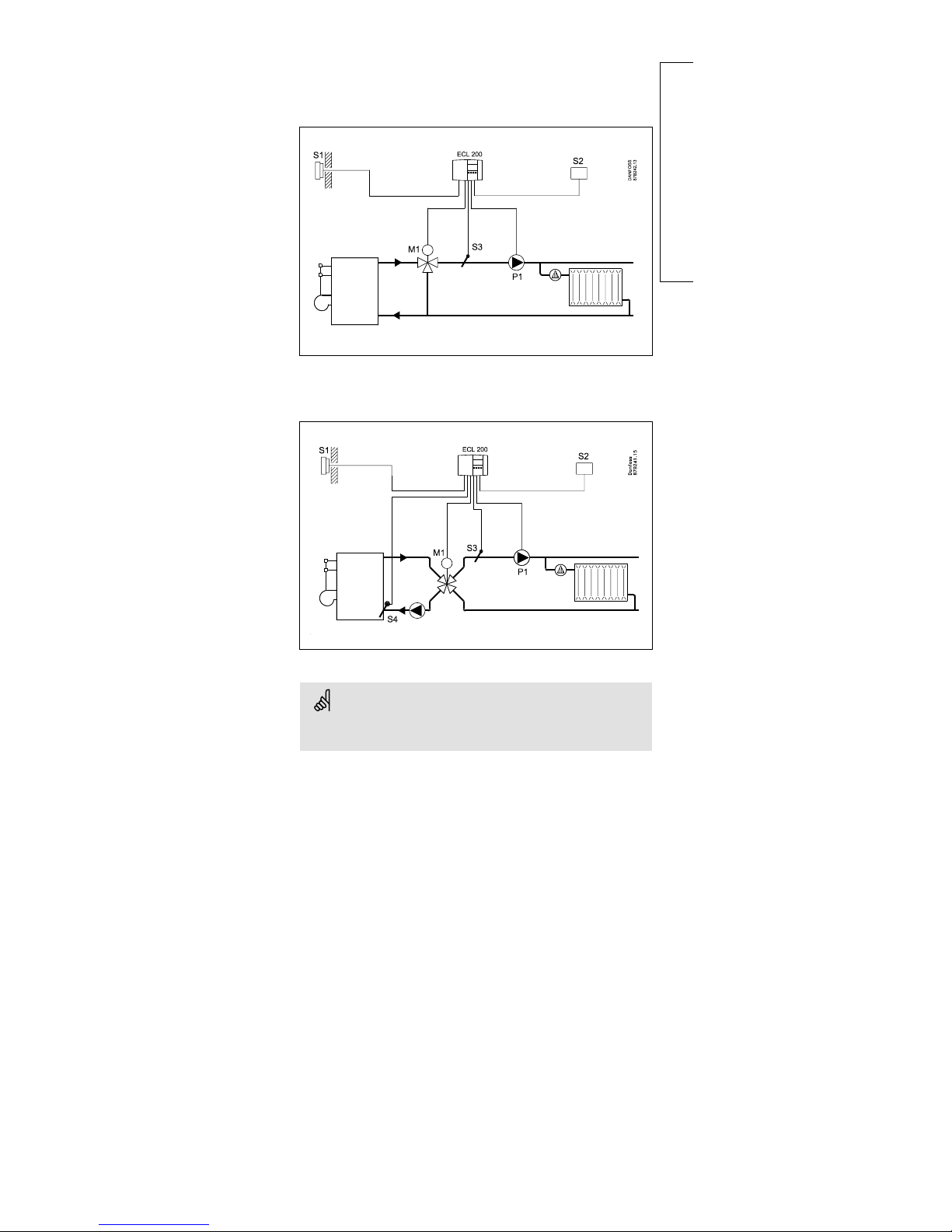

10.3 Boiler system with 3-way valve

10.4 Boiler system with 4-way rotary valve

System diagrams in this instruction are principal drawings and do

not contain all components which are necessary in your systems.

Page 8

Installation

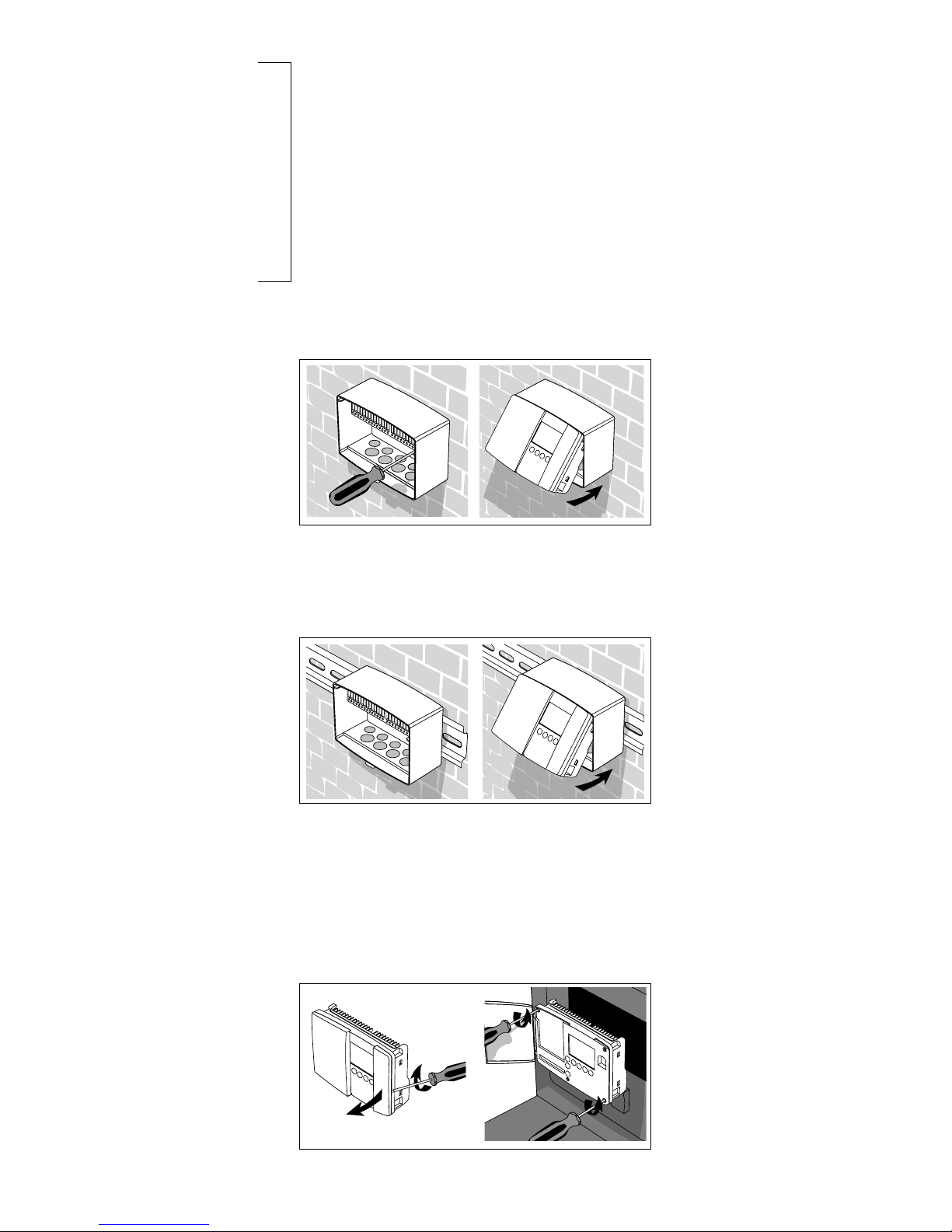

For easy access, you should mount the ECL Comfort

controller near the system. Select one of the three

following methods:

• Mounting on a wall

• Mounting on a DIN rail

• Mounting in a panel

Screws and rawlplugs are not supplied.

Mounting on a wall

Socket for mounting on wall: Order code No. 087B1149.

Mount the terminal box on a wall with a smooth surface.

Establish the electrical connections and position the

controller in the box. Secure the controller with the fixing

screw.

Mounting on a DIN rail

Mounting kit: Order code No. 087B1145.

A mounting kit is necessary to mount the box with the

controller on a DIN rail.

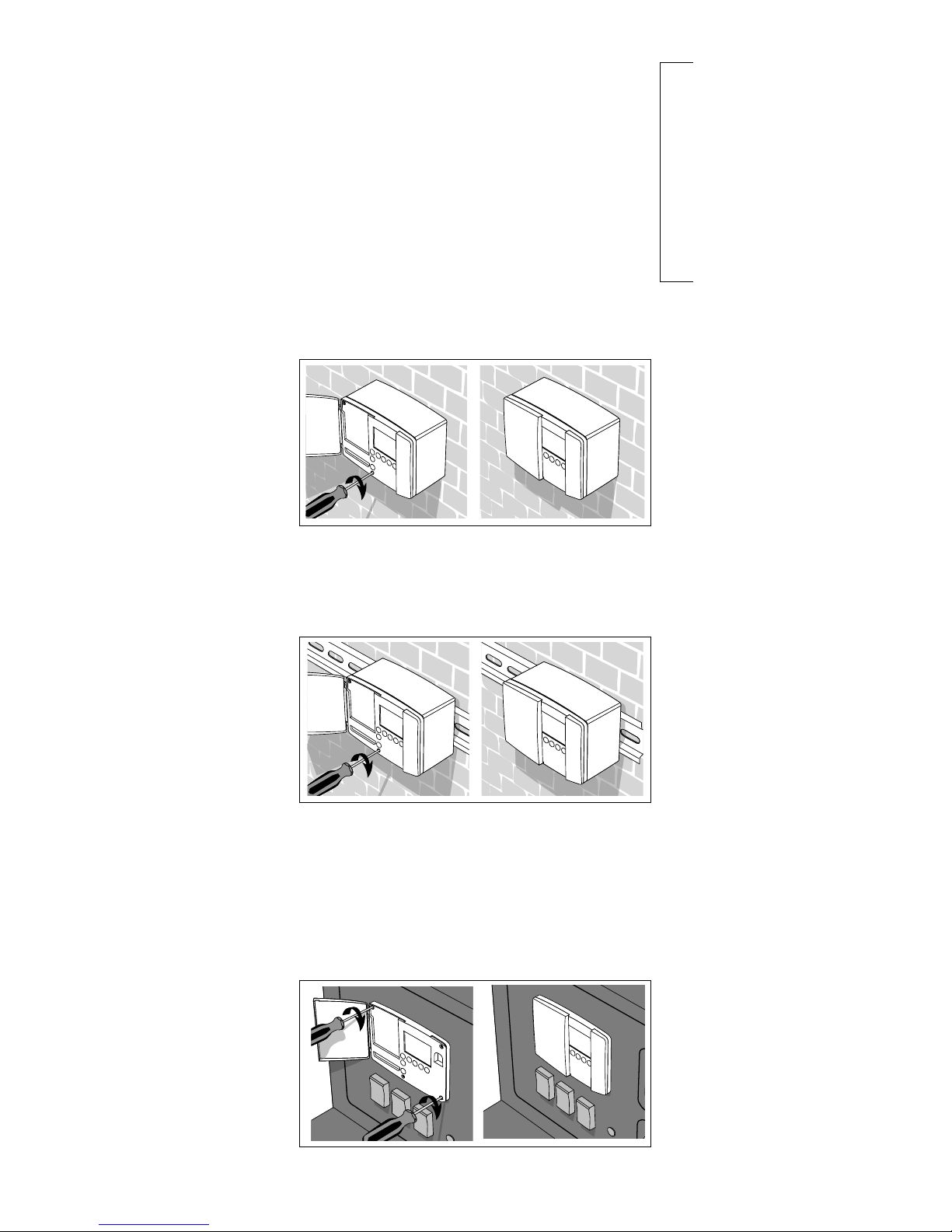

Mounting in a panel

Connector set: Order code No. 087B1148.

The panel plate thickness must not exceed 3 mm.

Prepare a cut-out with the dimensions 93 x 139 mm. Pull off

the right side of the lid by means of a screwdriver.

Insert the controller into the panel cut-out and fix it with the

two locks which are placed diagonally in two corners of the

controller.

Mounting the ECL Comfort

controller

11a

Page 9

Installation

11b

Page 10

Installation

Electrical connections 230 V a.c. - in general

12a

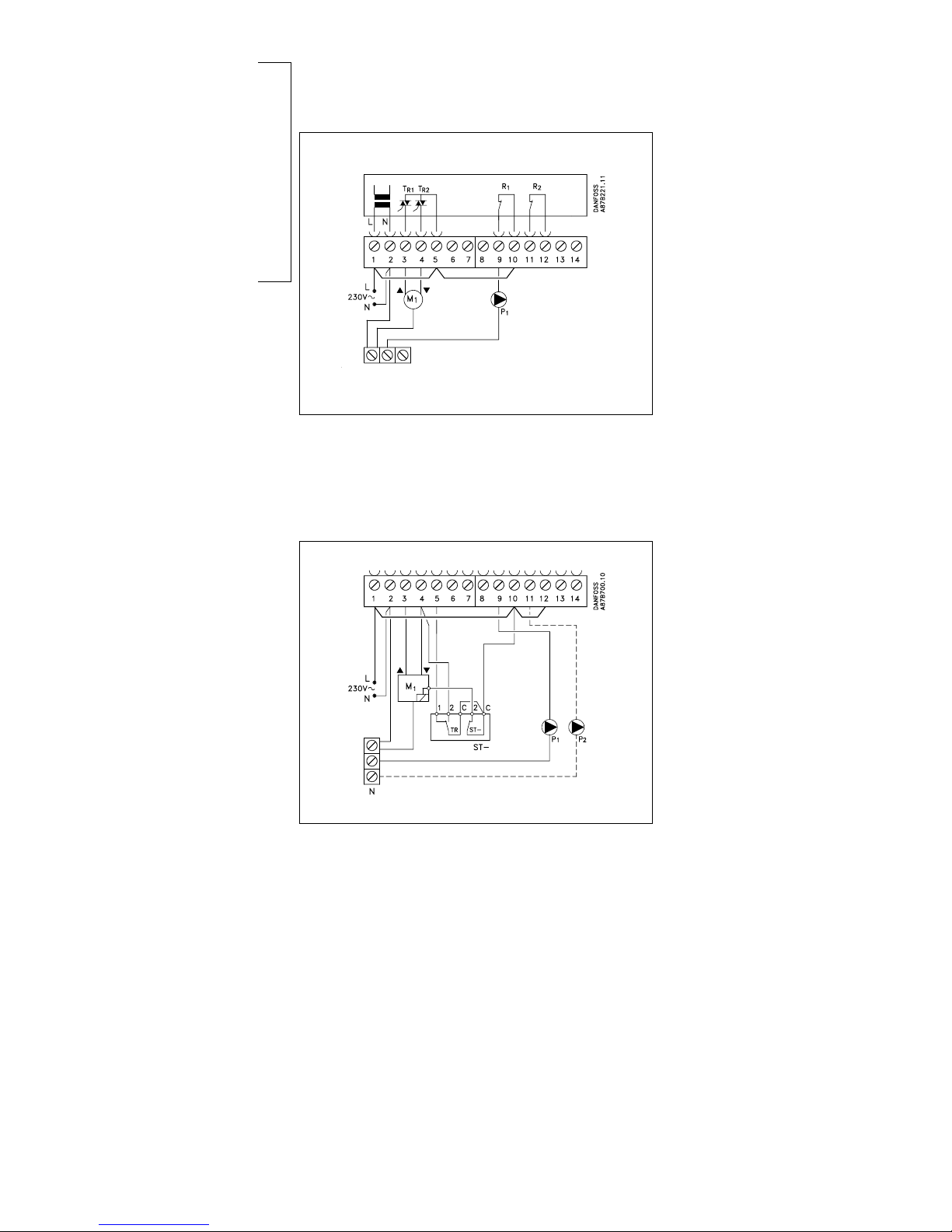

230 V a.c. connections - without safety thermostat

Establish these jumpers:

1-5-10

and 2 to common N-terminal.

230 V a.c. connections - with safety thermostat

This circuit diagram is only valid if Danfoss actuators are used

Establish these jumpers:

1-10-12

Safety thermostat:

4, 5 and 10 with ST- (safety thermostat)

and 2 to common N-terminal.

Page 11

Installation

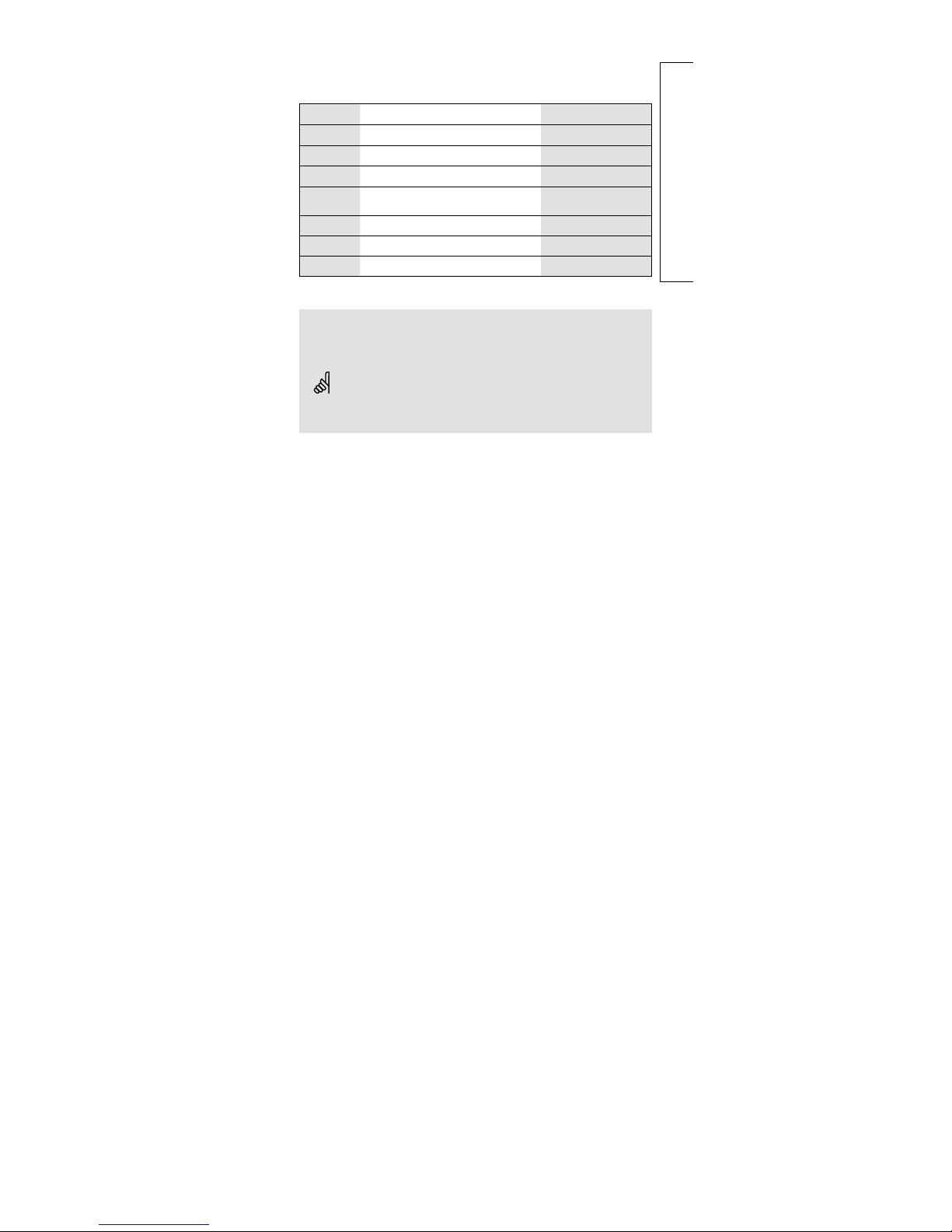

Terminal Description Max. load

1 (L) Supply voltage 230 V a.c.

2 (N) Supply voltage 230 V a.c.

3 M1 Actuator - open 0.2 A / 230 V a.c.

4 M1

Actuator - close

alt. thermo actuator

0.2 A / 230 V a.c.

5 Phase for motor output

9 P1 Circulation pump 4 (2) A / 230 V a.c.

10 Phase for pump relay R1

Wire cross section: 0.75 - 1.5 mm

2

Electrical connections

Max. 2 x 1.5 mm2 wires can be inserted into each screw terminal.

Incorrect connection can damage the TRIAC outputs. Max. load

(terminals 3, 4) 0.2 A / 230 V a.c. !

12b

Page 12

Installation

13a

Electrical connections 24 V a.c. - in general

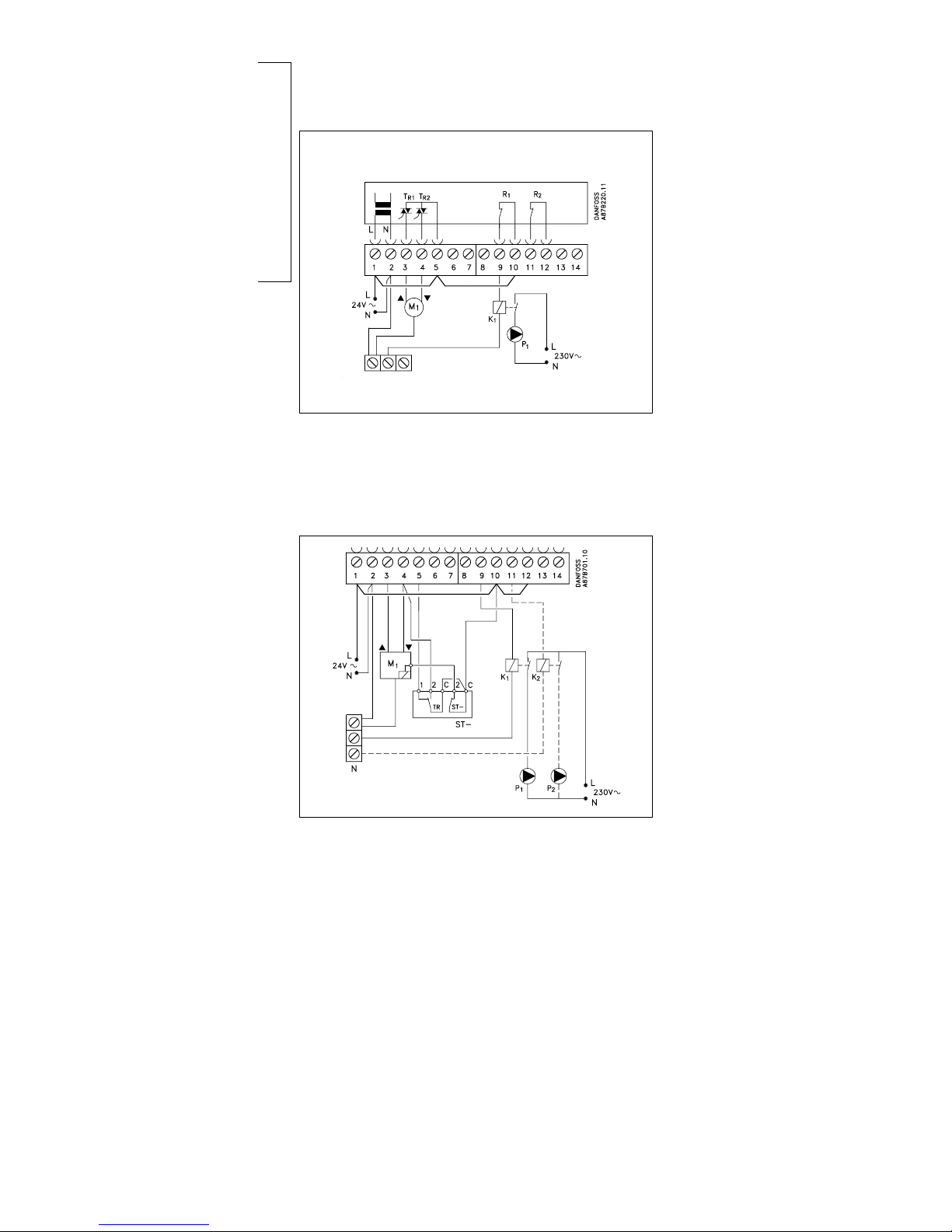

24 V a.c. connections - without safety thermostat

Establish these jumpers:

1-5-10

and 2 to common N-terminal.

24 V a.c. connections - with safety thermostat

This circuit diagram is only valid if Danfoss actuators are used

Establish these jumpers:

1-10-12

Safety thermostat:

4, 5 and 10 with ST- (safety thermostat)

and 2 to common N-terminal.

Page 13

Installation

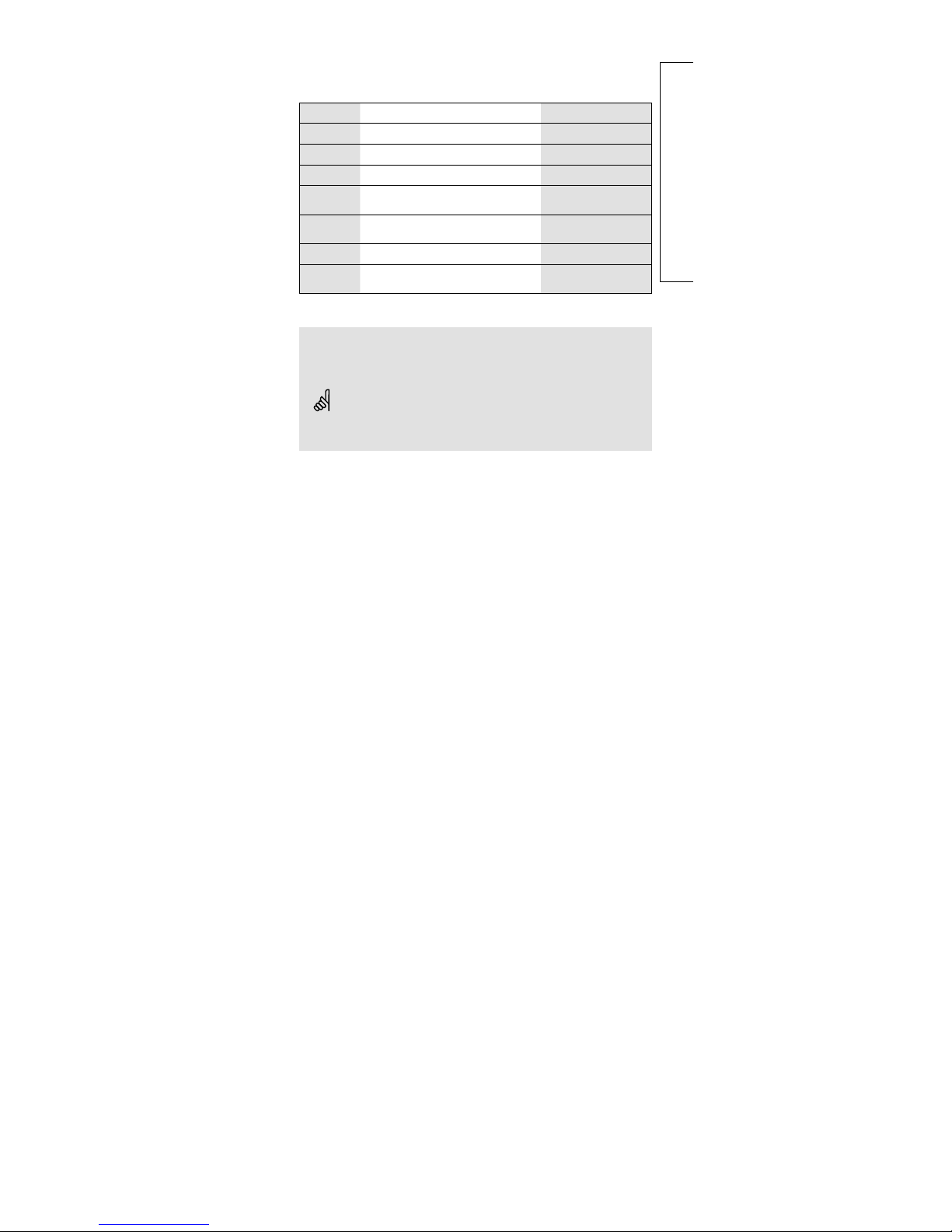

Terminal Description Max. load

1 (L) Supply voltage 24 V a.c.

2 (N) Supply voltage 24 V a.c.

3 M1 Actuator - open 1.0 A / 24 V a.c.

4 M1

Actuator - close

alt. thermo actuator

1.0 A / 24 V a.c.

5

24 V a.c. supply voltage for

motor output

9 K1* Relay for circulation pump 4 (2) A / 24 V a.c.

10

24 V a.c. supply voltage for

relay K1

* K1 auxilliar y relay coil 24 V a.c.

Wire cross section: 0.75 - 1.5 mm

2

Electrical connections

Max. 2 x 1.5 mm2 wires can be inserted into each screw terminal.

Incorrect connection can damage the TRIAC outputs. Max. load

(terminals 3, 4) 1.0 A / 24 V a.c. !

13b

Page 14

Installation

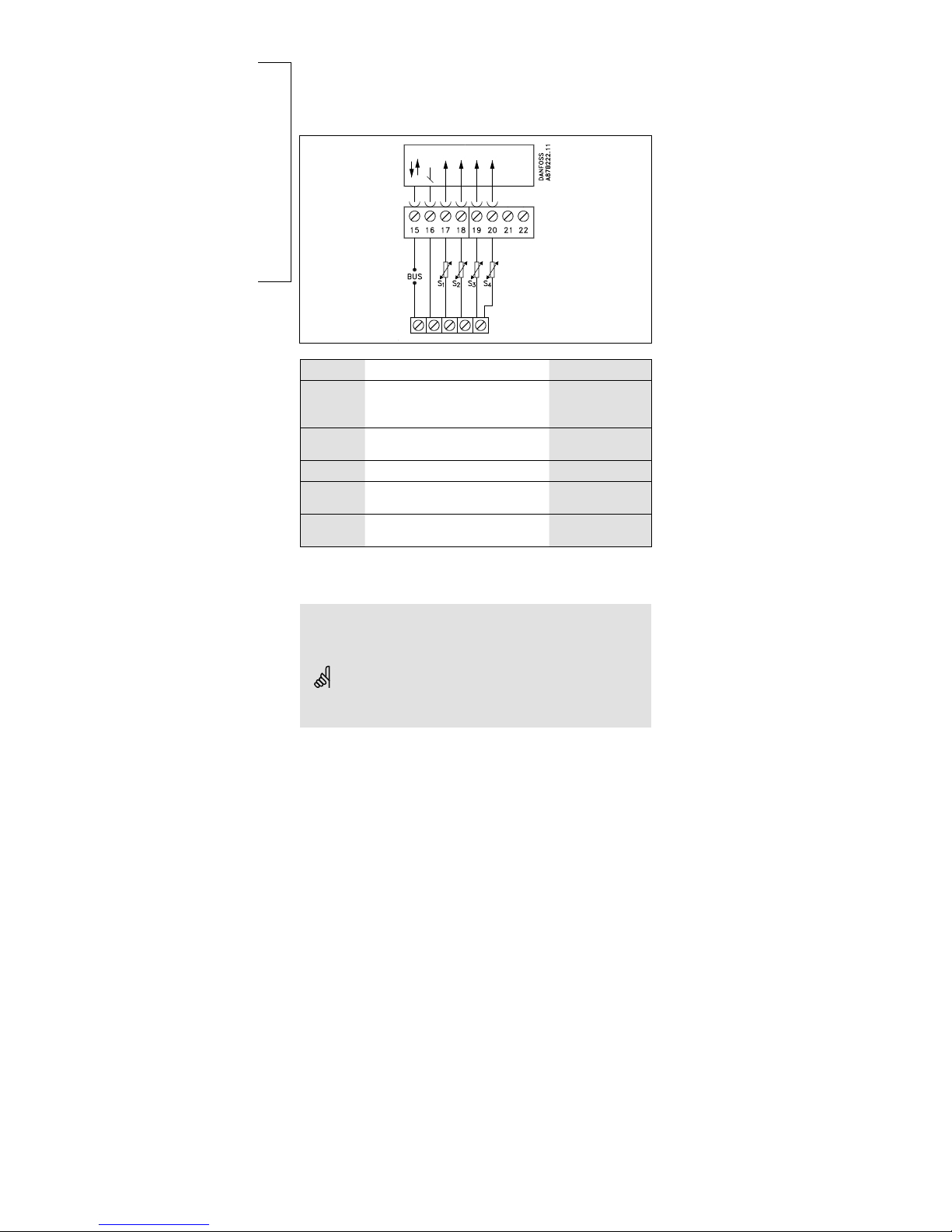

Connecting the temperature sensors and the bus

Terminal Description Type (recomm.)

15 and 16 System device bus,

connections for room

panel / remote control

ECA 60 / 62

ECA 61 / 63

17 and 16 S1 Outdoor temperature

sensor

ESMT

18 and 16 S2 Room temperature sensor ESM-10

19 and 16 S3 Flow temperature sensor ESM-11 / ESMC /

ESMU

20 and 16 S4 Return temperature

sensor

ESM-11 / ESMC /

ESMU

Establish the jumper from 16 to common terminal.

Wire cross section for sensor connections:

Min. 0.4 mm

2

Total cable length: Max. 125 m (all sensors incl. system device

bus)

Cable lengths of more than 125 m may cause noise sensibilit y

(EMC).

Connecting and placing the

temperature sensors

14a

Page 15

Installation

It is important that the sensors are mounted in the correct

position in your system.

The temperature sensor mentioned below are sensors used

for the ECL Comfort 200 and 300 series which not all will be

needed for your application!

Outdoor temperature sensor (ESMT)

The outdoor sensor should be mounted on that side of the

building where it is less likely to be exposed to direct

sunshine. It should not be placed close to doors, windows or

air outlets.

Flow temperature sensor (ESMU, ESM-11 or ESMC)

Place the sensor max. 15 cm from the mixing point. In

systems with heat exchanger, Danfoss recommends that the

ESMU-type to be inserted into the exchanger flow outlet.

Make sure that the surface of the pipe is clean and even

where the sensor is mounted.

Return temperature sensor (ESMU, ESM-11 or ESMC)

The return sensor should always be placed in / on a pipe with

return water flow.

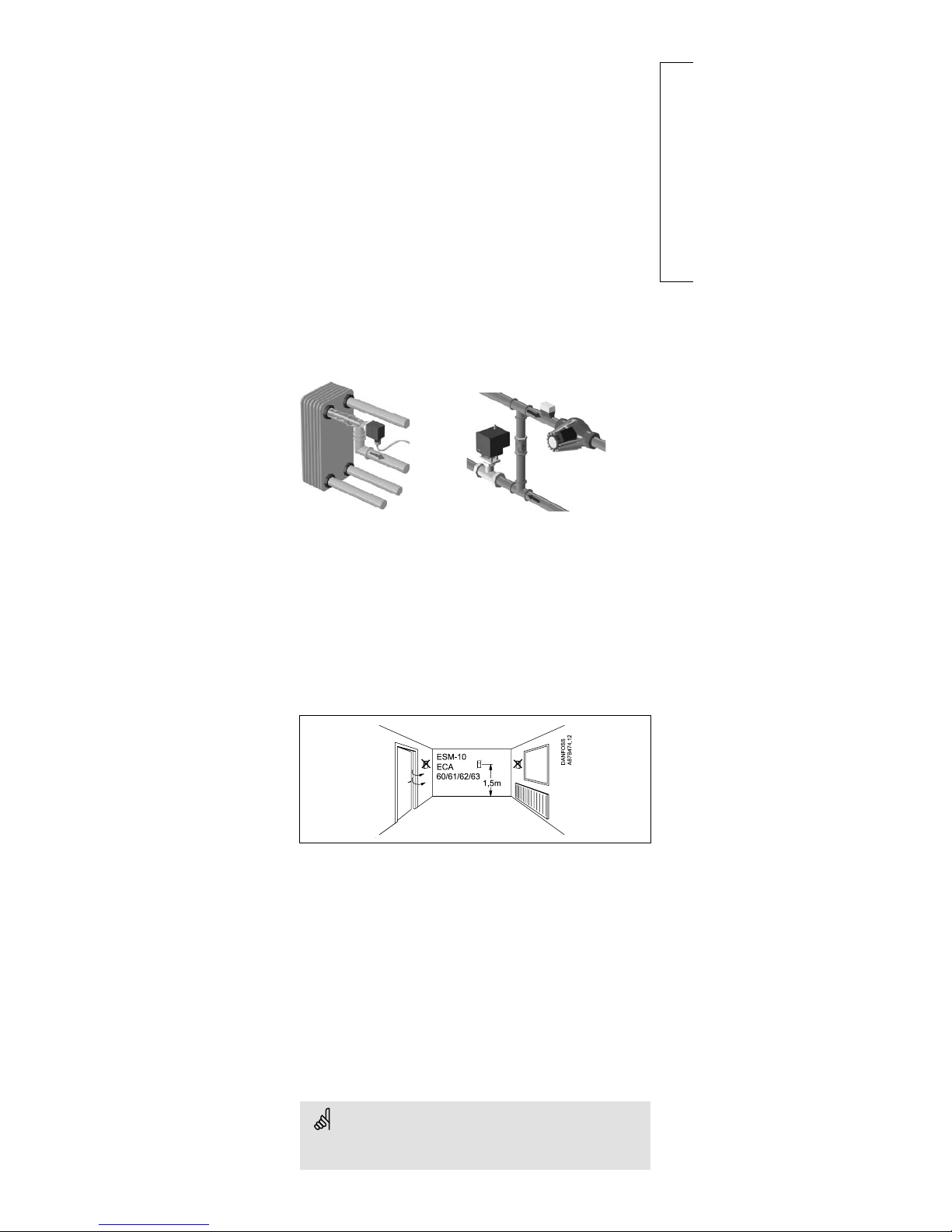

Room temperature sensor (ESM-10, ECA 60 / 62 room

panel or ECA 61 / 63 remote control)

Place the room sensor in the room where the temperature is

to be controlled. Do not place it on outside walls or close to

radiators, windows or doors.

DHW temperature sensor (ESMU or ESMB-12)

Place the DHW temperature sensor according to the

manufacturer’s specification.

Boiler temperature sensor (ESMU, ESM-11 or ESMC)

Place the sensor according to the boiler manufacturer’s

specification.

Flow / air duct temperature sensor (ESM-11, ESMB-12,

ESMC or ESMU types)

Place the sensor so that it measures a representative

temperature.

Surface temperature sensor (ESMB-12)

Place the sensor in the surface of the floor.

Valid for ESM-11: Do not move the sensor after it has been

fastened in order to avoid damage to the sensor element.

14b

Page 16

Installation

14c

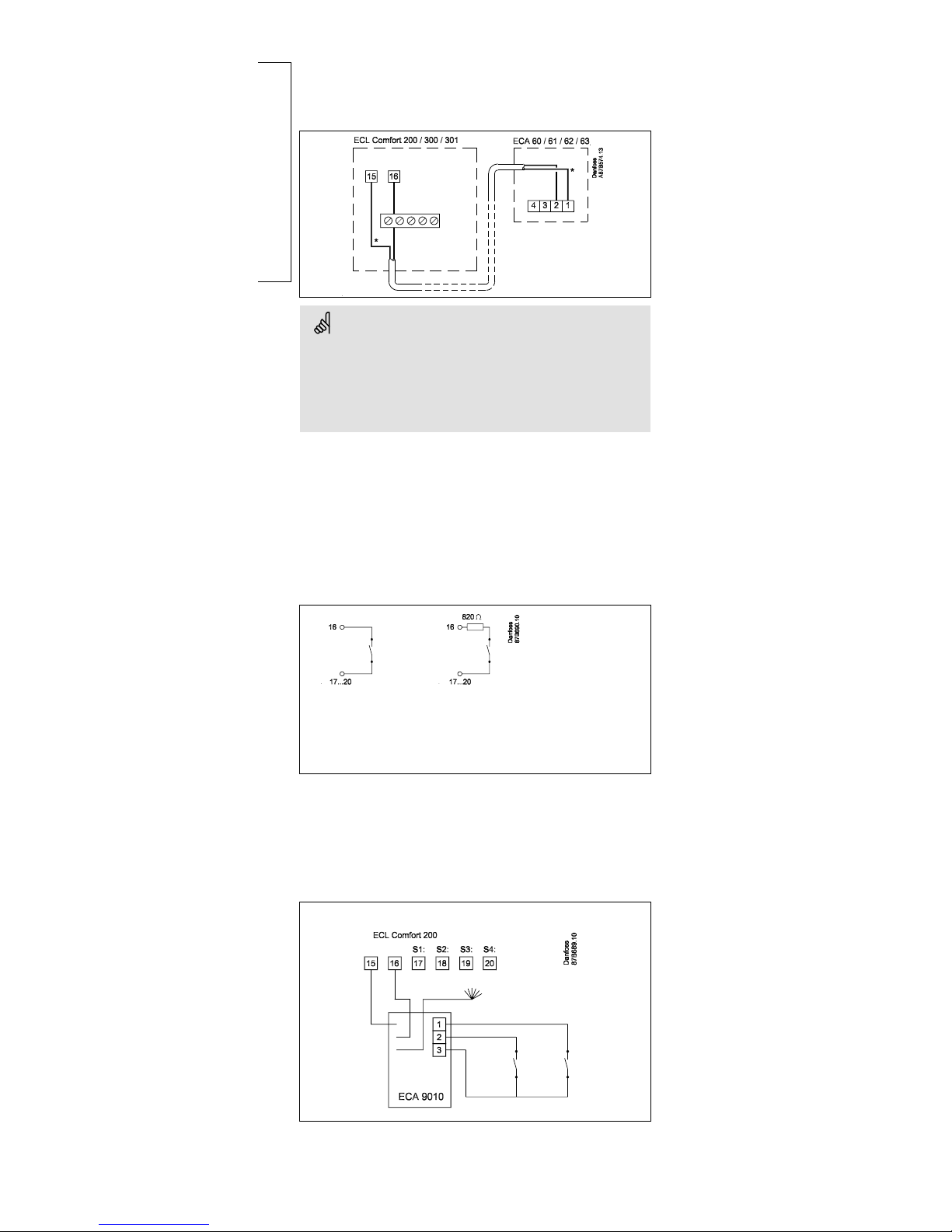

Connecting the room panel / remote control

The ECA 60 / 61 / 62 / 63 is activated by the setting in line 10

(section 32).

The ECA 60 / 61 / 62 / 63 is powered by the system device bus

which means that the bus must be active. The bus is activated by

setting the controller address to 15 (section 32, line 199).

Override

For an active override, you have to choose the mode

“scheduled operation”! Input S1 ... S4 can be used for override

purposes (section 32, line 141).

Connection example without ECA 9010

If the override switch has goldplated contacts, you can

choose one of the following solutions or a combination of

both:

Closed switch: Closed switch:

Comfort temperature Setb ack temperature

Open switch: Open switch:

Scheduled op eration Scheduled operation

Connection example with ECA 9010

The ECA 9010 module is powered by the system device

BUS, which means that the BUS must be active. The BUS is

activated by setting the controller address to 15 (line 199). To

avoid influence from contact resistance, the use of ECA 9010

is recommended.

Comfor t Setback

Red

Brown

Green S1 .. . S4

Page 17

Installation

15

Adapting the ECL Comfort

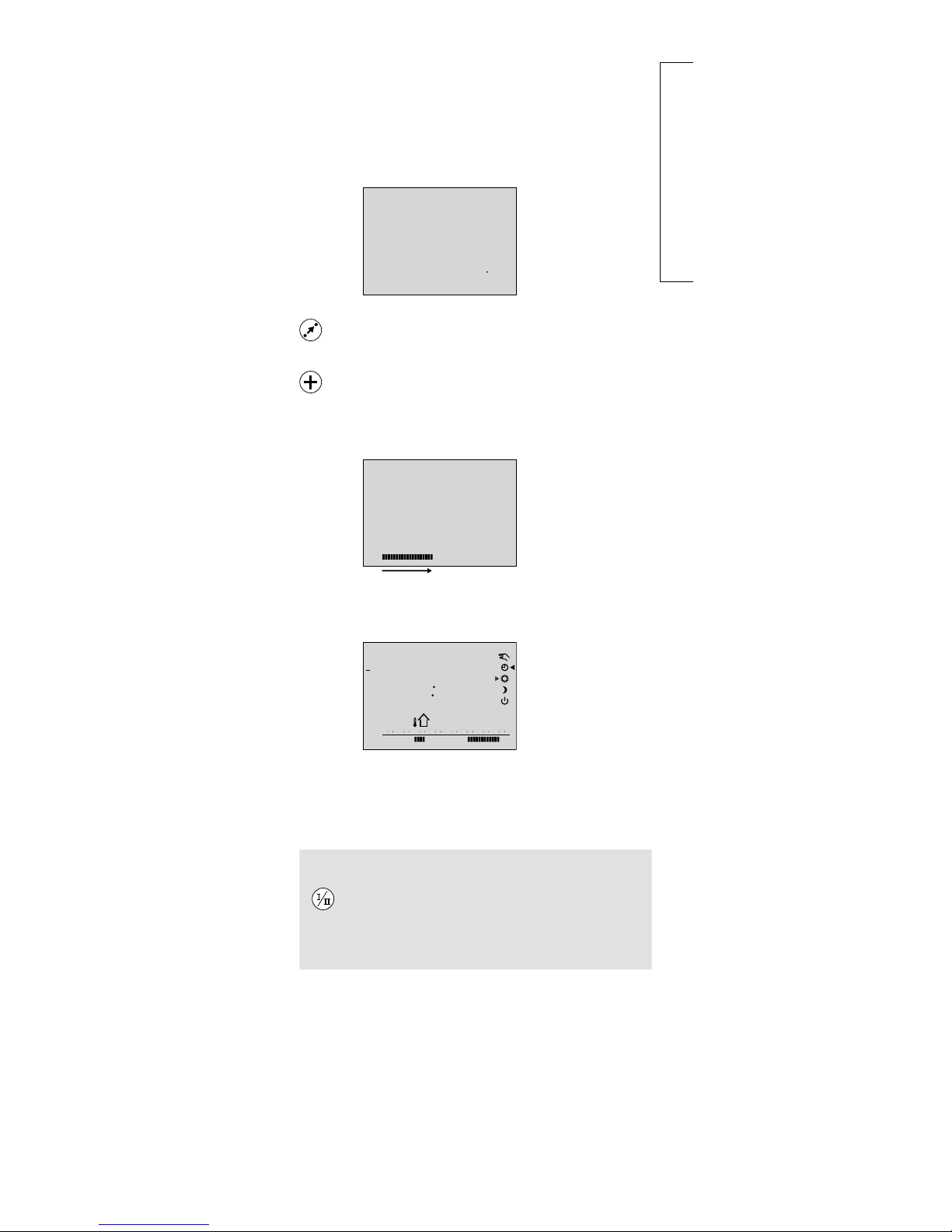

controller

Open the lid and switch on the controller. The display will

show you the system type (P16, P17, P20 or P30).

Display examples:

P0171

1

Choose the system type printed on your ECL Card.

Accept to set up the chosen system type.

While the setup is in operation, the data transfer display will

appear.

P 71

After initializing, the display will return to the standard

display C on the yellow side of the ECL Card.

8

0 3 6 9 12 15 18 21 24

1

023

5

C

3

The controller is now ready to control the chosen system. You

can make your own adjustments / settings in daily use and in

the basic set-up and change the extended service settings.

Insert the ECL Card with the grey side facing you.

Select the grey side of the ECL Card for the basic

set-up and extended service parameters.

See section 16 for gene ral principles of operation and section 17 for

setting the time and date.

Page 18

Installation

General principles

When the controller is connected and operating you can

check and adjust all or some of the basic settings. Turn the

ECL Card so that the grey side is facing you (see the example

below).

Use the arrow buttons to move from line to line of

the ECL Card, for example line 2:

Line

Setting

to be

adjusted

1

1

ON

2

ON

09

2

04

2

3

ON

Value in range indicator

Use the plus / minus buttons to adjust the

settings.

In some displays more than one setting or value

can be adjusted. Use the shift button to switch

between the options.

Changing from one side of the ECL Card to the other

When changing from the grey side of the ECL Card to the

yellow side, you will always enter line C and the standard

display.

8

0 3 6 9 12 15 18 21 24

1

023

5

C

3

If you change from the yellow side to the grey side, you will

always enter line A - Time and date.

If several controllers are installed in the system, you can write

a title on the ECL Card with a permanent ink pen.

Adjusting the ECL Card

settings

16

Page 19

Installation

Actual time

Year

05

01

2 220

5

A

3

1

Month, day

Use the shift button to switch between minutes,

hours, years, months and days.

Set the correct time and date.

In case of a power break, which lasts longer than 12 hours, the

time and the date have to be set again. All other settings are

stored as programmed.

Use the yellow side of the card to change the schedules.

See User’s Guide, section 4.

Setting the time and date line A

17

Page 20

The grey

side of the

ECL Card

Basic set-up

Controlled units

Flow

temp.

5

1

1

ON

036

B

Return temp.

Push and hold the shift button to see:

- the calculated flow temperature

- the desired return temperature limitations.

The activity of the motorized control valve is shown as arrows

below the valve symbol. When the circulation pump is

operating, it is indicated as ON below the pump symbol.

If a sensor is not mounted or is disconnected, the display will

indicate it as “- -”.

If the sensor is short-circuited, the display will indicate

it as “- - -“.

If you are in doubt, remove the controller and check the

ohmic value between the relevant terminals.

Relationship between temperature and ohmic value

-50

800

900

1000

1100

1200

1300

1400

1500

1600

-25 0 25 50 7

5 100 125 150

°C

Ω

Ω

805

845

883

922

961

1000

1039

1078

1117

1155

1194

1232

1271

1309

1347

1385

1423

1462

1501

1539

1578

°C

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

Monitoring temperatures

and system units - line B

18

Page 21

The grey

side of the

ECL Card

Basic set-up

Shift to manual mode.

Controlled units

5

1

1

ON

036

B

Controller mode

Choose the unit you want to control. The selected

unit symbol will blink.

Controlled units are switched OFF or ON when

the relevant button is pushed.

The motorized actuator (gear motor /

damper)

closes or opens the controlled unit as long as

the relevant button is pushed. If pushed for more

than 3 seconds, the actuator continues to close or

open the valve.

The thermo actuator

activates the valve as long as the button is

pushed. If pushed for more than 3 seconds, the

actuator continues to open the valve.

Check the activation direction of the actuator either by

looking at it or by feeling whether the temperature of the

actual pipe changes as expected.

This operation applies to both circuits, if available.

During manual operation, all control functions are deactivated.

Manual control line B

19

Page 22

The grey

side of the

ECL Card

Basic set-up

1 2

8

C

1

0

3

ON

1ON2

ON

Slope

Displacement

Slope

Setting range Factory setting

0.2 ... 3.4 1.8

The symbol for the slope of the heat curve

will blink. Adjust the slope of the heat curve, if

required.

-20 -10 0 10 20-30

20

30

40

50

60

70

80

90

1.0

1.4

0.6

0.2

1.8 2.2 3.0 3.4

100

110

2.6

10

oC

oC

How to determine another heat curve, if necessary:

Choose the calculated flow temperature for your system and

the determined min. outdoor temperature for your area.

Pick the heat curve closest to the crossing point of these two

values.

The setting of the desired room temperature has an influence

on the calculated flow temperature (heat curve), no matter if

a room temperature sensor is connected or not.

Floor heating systems

This controller is factor y set for radiator systems, which typically

are high flow temperature systems.

To control floor heating systems, which typically are low flow

temperature systems, you need to change the heat curve

according to your type of system.

Slope

Setting range Typical setting

0.2 ... 3.4 1.0

Whether it is reasonable to change the slope or parallel

displacement will depend on the individual heat requirement.

Small increases or reductions in the heating temperature can be

implemented by means of the parallel displacement.

Setting the heat curve line C

20a

Page 23

The grey

side of the

ECL Card

Basic set-up

20b

Parallel displacement

Setting range Factory setting

-15 ... 20 0

If you want to adjust the parallel displacement of

the heat curve, push the shift button. The symbol

for the parallel displacement will blink.

Make your adjustments.

Page 24

The grey

side of the

ECL Card

Basic set-up

8

1

1

1

1

ON2ON

2

1 Limit for heating cut-out

Setting range Factory setting

10 ... 30 °C 18 °C

Set the outdoor temperature limit at which you

want the heating system to stop.

The valve closes and after about 3 min. the heating

circulation pump stops.

The min. limitation set in line 2 will be ignored.

18 °C

Temp.

Act ual Accumu lated

out door temp. ou tdoor temp.

Heati ng OFF

Tim e

Heati ng H eating

This function can save energy by stopping the heating system

when the outdoor temperature gets above a set limit. The heating

system switches ON again when the outdoor temperature and

the accumulated outdoor temperature become lower than the set

limit.

The heating cut-out is only active when the controller mode is

scheduled operation. When the limit value is set to 30, there is no

heating cut-out.

Heating cut-out line 1

21

Page 25

The grey

side of the

ECL Card

Basic set-up

Min. flow

temp.

0

1

1ON2

091

2

3

ON

2

ON

Max. flow

temp.

Setting range

2 Flow temperature limits, min. and max.

Setting range Factory setting

10 ... 110 °C min.10, max. 90 °C

The mentioned setting range and factory settings may vary from

the settings related to your ECL Card.

The left end of the setting range blinks. Adjust the

min. limit of your system temperature.

Choose the max. limit. The right end of the setting

range blinks.

Adjust the max. limit.

Flow temperature limits line 2

22

Page 26

The grey

side of the

ECL Card

Basic set-up

Room temperature influence line 3

23a

This section is only relevant if you have installed a room sensor or

ECA 60 / ECA 61 / ECA 62 / ECA 63.

Min.

influence

1

2

ON

0-4

0

3

1

ON

3

ON

Max.

influence

3 Room temperature influence

Setting range Factory setting

0 ... 99 / -99 ... 0 min. 0, max. -40

The bar below the min. value blinks. Adjust the

min. influence.

Select the max. influence.

The bar below the max. value blinks.

Adjust the max. influence.

There are two basic principles for control of the room

temperature influence:

A: Max. room temperature limitation

Use this limitation if your heating system is fully equipped

with radiator thermostats and you also want to obtain a max.

limitation of the room temperature. The controller will allow

for free heat gains, i.e. solar radiation or heat from a fire place,

etc.

Infl uence

De sired room

tem perature

Roo m

tem perature

Ma x.

lim itation

The max. influence determines how much the room

temperature should influence the desired flow temperature.

Page 27

The grey

side of the

ECL Card

Basic set-up

23b

B: Reference room temperature control

Used if your heating system is not equipped with radiator

thermostats and you select the room with room sensor as a

temperature reference for the rest of the rooms.

(However, should you have a few radiator thermostats

installed, make sure that they are fully open).

Set a positive value for the min. influence and a negative

value for the max. influence.

The room sensor in the reference room registers the

difference between the desired and the actual room

temperature. The desired flow temperature will be corrected

to eliminate this difference.

Example 1

The actual room temperature is 2 degrees too low.

The influence at max. limitation (right corner of the display) is

set to -35.

The influence at min. limitation (left corner of the display) is set

to 20.

Heat curve H is 1.8.

Result:

The desired flow temperature is changed by

2 x 20 x 1.8 x 0.1= 7.2 degrees.

Example 2

The actual room temperature is 2 degrees too high.

The influence at max. limitation (right corner of the display) is

set to -35.

The influence at min. limitation (left corner of the display) is set

to 20.

Heat curve H is 1.8.

Result:

The desired flow temperature is changed by

2 x (-35) x 1.8 x 0.1= -12.6 degrees.

Infl uence

Mi n. limitatio n

Desir ed room

temper ature

Roo m

tem perature

Max. li mitation

Page 28

The grey

side of the

ECL Card

Basic set-up

4 Proportional band, Xp

Setting range Factory setting

1 ... 250 K 80 K

Set the proportional band.

A higher value will result in a stable but slow

control of the flow temperature.

5 Integration time constant, Tn

Setting range Factory setting

5 ... 999 sec. 30 sec.

Set a high integration time constant to obtain a

slow but stable reaction to deviations.

A small integration constant will make the

controller react fast but with less stability

6 Running time of the motorized control valve

Setting range Factory setting

5 ... 250 sec. 35 sec.

Set the running time of the motorized control

valve according to the example. This is the time it

takes the controlled unit to move from fully closed

to fully open position.

How to calculate the running time of a motorized

control valve

The running time of the motorized control valve is calculated

using the following methods:

Seated valves

Running time = Valve stroke (mm) x actuator speed (sec. / mm)

Example: 5.0 mm x 15 sec. / mm = 75 sec.

Rotating valves

Running time = Turning degrees x actuator speed (sec. / degr.)

Example: 90 degrees x 2 = 180 sec.

Control parameters lines 4-7

26a

Page 29

The grey

side of the

ECL Card

Basic set-up

7 Neutral zone, Nz

Setting range Factory setting

0 ... 9 K 3 K

Set the neutral zone to a high value if you can

accept a high variation in flow temperature.

When the actual flow temperature is within the

neutral zone, the controller does not activate the

motorized valve.

The neutral zone is symmetrical around the desired flow

temperature value, i.e. half the value is above and half the value is

below this temperature.

If you want to tune the PI regulation precisely, you can

use the following method:

• Set the integration time (line 5) to its max. value

(999 sec.).

• Decrease the value for the proportional band (line 4) until the

system starts hunting with a constant amplitude (it might be

necessary to force the system by setting an extreme value).

• Find the critical time period on the temperature recording or

use a stop watch.

Temp.

Critica l time period

Time

This time period will be characteristic for the system, and you can

evaluate the set tings from this critical period.

Integration time = 0.85 x critical time period

Proportional band = 2.2 x propor tional band value in the

critical time period.

If the regulation seems to be too slow, you can decrease the

proportional band value by 10%.

Make sure there is a consumption when you set the parameters.

26b

Page 30

Control & overviews

Is the ECL Comfort controller ready for use?

Make sure that the correct power supply is

connected to terminals 1 (Live) and 2 (Neutral). See

section 12 or 13.

Check that the required actuators, pumps, fans,

dampers and burners are connected to the correct

terminals. See sections 12 or 13.

Check that all sensors are connected to the correct

terminals. See section 14.

Mount the controller and switch on the power.

Insert the ECL Card with the yellow side facing you

and push , if necessary. See section 15.

Choose manual operation as controller mode. See

section 2.

Check that valves open and close, and that

required pumps, fans, dampers and burners start

and stop when operated manually. See section 19.

Having completed the manual operation check,

choose scheduled operation as controller mode.

Check that the temperatures shown in display A

and B match the actual sensors. See section 1.

Check list

29a

✓

Page 31

Control & overviews

Adapting the ECL Comfort controller to the

system

Turn the ECL Card so that the grey side faces you

and push , if necessary.

Set the time and the date (line A). See section 17.

Check that all settings in the controller (sections 30

and 31) are set or that the factory settings comply

with your requirements.

If your system differs from the diagram shown on the

cover, you should check and alter your service parameters, if

necessary.

Check that the system settings mentioned in

section 10 have been set correctly.

29b

✓

Page 32

Control & overviews

ECL Comfort settings

30

A Time and date Section 17

B System information Sections 18 & 19

C Heat curve

Section 20

Setting ranges Factory settings Your settings

Slope

0.2 ... 3.4 1.8

See section 20

Parallel displacement

-15 ... 20 0 K

See section 20

1

Limit for heating cut-out

10 ... 30 °C 18 °C

See section 21

2

Flow temperature , min. / max. limits

10 ... 110 °C min. 10, max. 90 °C

See section 22

3

Room temperature influence

0 ... 99 / -99 ... 0 min. 0, max. -40

See section 23

4

Proportional band, Xp

1 ... 250 K 80 K

See section 26

5

Integration time constant, Tn

5 ... 999 sec. 30 sec.

See section 26

6

Running time of the motorized control

valve

5 ... 250 sec. 35 sec.

See section 26

7

Neutral zone, Nz

0 ... 9 K 3 K

See section 26

Page 33

Control & overviews

Service parameters (10-199)

31

Circuit I

Lines Setting ranges Factory settings Your settings

10 Choice of room panel / remote control

0 ... 5 0

11 Setback temperature dependent

on outdoor temperature

OFF / -29 ... 10 °C -15 °C °C

12 Boost

0 ... 99% 0% %

14 Optimizing time constant

OFF / 10 ... 59 OFF

15 Adaptive function of room

temperature

OFF / 1 ... 30 OFF

20 Optimization based on room /

outdoor temperature

ON / OFF OFF

21 Total stop

ON / OFF OFF

22 Pump exercise

ON / OFF ON

23 Valve exercise

ON / OFF OFF

24 Gear motor / thermo actuator

ON / OFF ON

30 Return temperature limitation

10 ... 110 °C 50 °C °C

35 Return temperature influence

- max. limitation

-9.9 ... 0 ... 9.9 -2.0

36 Return temperature influence

- min. limitation

-9.9 ... 0 ... 9.9 0.0

37 Time constant for return temperature

limitation

OFF / 1 ... 50 25

52 Closed valve / normal operation

ON / OFF OFF

85 Priority for return temperature

limitation

ON / OFF OFF

141 Override input selection

OFF / 1 ... 4 OFF

174 Motor protection

OFF / 10 ... 59 min. OFF min.

189 Min. activation time, gear motor

2 ... 10 6

196 Service pin LON

ON / OFF OFF

197 LON reset

ON / OFF ON

198 Daylight saving time changeover

ON / OFF ON

199 Master / slave address

0 ... 9, 15 15

Page 34

The grey

side of the

ECL Card

Extended service

Adjusting the service

parameters

32

In addition to the settings in line 1 to 7 on the grey side of the

ECL Card, there is an extended service menu from line 10 and

onwards.

Push repeatedly to reach the lines numbered 10

and onwards.

Line

0

01

Value

Range indicator

Now you can move to any line of your choice.

Set the parameter value.

Check that you have entered all the required settings.

Make a note of your new settings in the parameter list in section

31.

When you have entered all your personal settings, turn the ECL

Card over so that the yellow side faces you.

32

Adjusting the service

parameters

Page 35

The grey

side of the

ECL Card

Extended service

32a

Service parameter(s) 10-11

10 Choice of room panel / remote control

Setting range Factory setting

0 ... 5 0

Decides the communication with the room panel or remote

control.

Please note that the room panel / remote control is only active

if the system device bus is active. The bus is active when the

outdoor temperature sensor is connected.

Choose between

0: No room panel / remote control

1: Room panel ECA 60 / 62 or remote control

ECA 61 / 63 with address A

2: Room panel ECA 60 / 62 or remote control

ECA 61 / 63 with address B

3 ... 5: Not used

11 Setback temperature dependent on outdoor

temperature

Setting range Factory setting

OFF / -29 ... 10 °C -15 °C

Below this outdoor temperature, the setback temperature setting

has no influence.

-29 ... 10:

The setback temperature depends on the

outdoor temperature, when the outdoor

temperature is above the set limit. The

lower the outdoor temperature, the less the

temperature reduction. When the outdoor

temperature is below the set limit, there is

no temperature reduction.

OFF: The setback temperature does not depend

on the outdoor temperature.

100%

0%

-20 -10-29 0 2

0

10

Reduct ion

Outdoo r

temper ature

°C

Setti ng line 11

Page 36

The grey

side of the

ECL Card

Extended service

32b

Service parameter(s) 12-14

12 Boost

Setting range Factory setting

0 ... 99% 0%

Shortens the heating-up period by increasing the desired flow

temperature by the percentage you set.

Set the percentage at which you want the desired

flow temperature increased temporarily.

In order to shorten the heating-up period after a setback

temperature period, the desired flow temperature can be

increased temporarily (max. 1 hour). At optimizing the boost

is active in the optimization period (line 14).

If a room temperature sensor or an ECA 60 / 61 / 62 / 63 is

connected, the boost stops when the room temperature has

been reached.

The boost also stops at the end of an optimizing period.

14 Optimizing time constant

Setting range Factory setting

OFF / 10 ... 59 OFF

Optimizes the start and stop times for the comfort temperature

period to obtain the best comfort at the lowest energy

consumption. The lower the outdoor temperature, the earlier the

heating cut-in.

Adjust the optimizing time constant. The value

consists of a two digit number.

The two digits have the following meaning:

Digit 1 Heat accumulation of

the building

System type

1

light Radiator

systems

2

medium

3

heavy

4

medium Floor heating

systems

5

heavy

Digit 2 Dimensioning

temperature

Capacity

0

- 50 °C large

1

- 45 °C

•

• • •

5

- 25 °C normal

• • •

9

- 5 °C small

OFF: No optimization. The heating starts and

stops at the times set in the schedule.

Dimensioning temperature:

The lowest outdoor temperature (usually determined by your

system designer in connec tion with the design of the heating

system) at which the heating system can maintain the designed

room temperature.

Page 37

The grey

side of the

ECL Card

Extended service

Service parameter(s) 15-20

32c

15 Adaptive function of room temperature

Setting range Factory setting

OFF / 1 ... 30 OFF

Controls how fast the room temperature adapts to the desired

room temperature.

The adaptive funtion will eliminate the difference

between the desired and the actual room

temperature. This is done by integrating the

difference and adjusting the desired flow

temperature.

OFF: The adaptive funtion is cancelled.

1: The desired temperature is adapted quickly.

30: The desired temperature is adapted slowly.

20 Optimization based on room / outdoor temperature

Setting range

Factory setting

ON / OFF

OFF

The optimized start and stop time can be based on either room or

outdoor temperature.

ON: Optimization based on room temperature, if

measured.

OFF: Optimization based on outdoor

temperature. Use this setting if the room

temperature is not measured.

Page 38

The grey

side of the

ECL Card

Extended service

32d

Service parameter(s) 21-22

21 Total stop

Setting range Factory setting

ON / OFF OFF

Decide whether you want a total stop during the setback

temperature period.

ON: The desired system temperature is lowered

to 10 °C. The min. setting of the temperature

(line 2, section 22) is overruled.

De sired system

tem p. (°C)

10 °C

Time

OFF: No total stop

De sired system

tem p. (°C)

10 °C

Time

22 Pump exercise

Setting range Factory setting

ON / OFF ON

Exercises the pump to avoid blocking in periods without heat

demand.

ON: The pump is switched ON for 1 minute every

third day around noon.

OFF: The pump exercise is not active.

Page 39

The grey

side of the

ECL Card

Extended service

Service parameter(s)23-30

32e

23 Valve exercise

Setting range

Factory setting

ON / OFF OFF

Exercises the valve to avoid blocking in periods without heat

demand.

ON: The valve receives a signal to open and

close every third day around noon.

OFF: The valve exercise is not active.

24 Gear motor / thermo actuator

Setting range Factory setting

ON / OFF ON

Choose the actuator type for your valve.

ON: Gear motor

OFF: Thermo actuator (ABV type)

Control parameters (lines 4-7) are overruled if thermo actuator is

chosen (OFF).

30 Return temperature limitation

Setting range Factory setting

10 ... 110 °C 50 °C

Set the return temperature you accept for the system.

Set the acceptable return temperature limit.

When the return temperature falls below or gets higher

than the set value, the controller automatically changes the

desired flow temperature to obtain an acceptable return

temperature. The influence is set in lines 35 and 36.

Page 40

The grey

side of the

ECL Card

Extended service

32f

Service parameter(s) 35

35 Return temperature influence - max. limitation

Setting range Factory setting

-9.9 ... 0 ... 9.9 -2.0

Set the influence from the return temperature on the desired flow

temperature.

Set the influence of the max. return temperature

limitation (set in line 30).

Influence higher than 0:

The desired flow temperature is increased, when

the return temperature gets higher than the set

limit.

Influence lower than 0:

The desired flow temperature is decreased, when

the return temperature gets higher than the set

limit.

0

Influe nce

Max. li mitation > 0

Return l imit

R eturn temp.

Max. li mitation < 0

Example

The return limit is active from 50 °C.

The influence is set to -2.0.

The actual return temperature is 2 degrees too high.

Result:

The desired flow temperature is changed by -2.0 x 2 = -4 degrees.

Normally, the set ting in line 35 is lower than 0 in district heating

systems to avoid a too high return temperature.

Typically, the setting in line 35 is 0 in boiler systems because a

higher return temperature is acceptable (see also line 36).

Page 41

The grey

side of the

ECL Card

Extended service

Service parameter(s) 36

32g

36 Return temperature influence - min. limitation

Setting range Factory setting

-9.9 ... 0 ... 9.9 0.0

Set the influence from the return temperature on the desired flow

temperature.

Set the influence of the min. return temperature

limitation (set in line 30).

Influence higher than 0:

The desired flow temperature is increased, when

the return temperature gets below the set limit.

Influence lower than 0:

The desired flow temperature is decreased, when

the return temperature gets below the set limit.

0

Influe nce

Mi n. limitatio n > 0

Return l imit Return te mp.

Min. li mitation < 0

Example

The return limit is active up to 50 °C.

The influence is set to -3.0.

The actual return temperature is 2 degrees too low.

Result:

The desired flow temperature is changed by -3.0 x 2 = - 6 degrees.

Normally, the set ting in line 36 is 0 in district heating systems

because a lower return temperature is acceptable.

Typically, the setting in line 36 is higher than 0 in boiler systems to

avoid a too low return temperature (see also line 35).

Page 42

The grey

side of the

ECL Card

Extended service

Service parameter(s) 37-85

32h

37 Time constant for return temperature limitation

Setting range Factory setting

OFF / 1 ... 50 25

Controls how fast the actual return temperature adapts to the

desired return temperature limitation.

Adjust the time constant for the return limitation.

The setting will eliminate the difference

between the acceptable and the actual return

temperature.

The difference is integrated to adjust the desired

flow temperature.

OFF: The desired flow temperature will not be

adjusted any further.

1: The desired flow temperature will be

adjusted quickly.

50: The desired flow temperature will be

adjusted slowly.

52 Closed valve / normal operation

Setting range Factory setting

ON / OFF OFF

The heating circuit can be closed when the controller acts as slave

and when DHW charging is active in the master.

ON: The valve in the heating circuit is closed*

during active DHW charging in the master

controller.

OFF: The flow temperature control remains

unchanged during active DHW charging in

the master controller.

* The desired flow temperature is se t to 10 °C.

The setting in line 52 must be considered if this controller is a

slave.

85 Priority for return temperature limitation

Setting range Factory setting

ON / OFF OFF

Choose whether the return temperature limitation should

overrule the set min. flow temperature limit (line 2).

ON: The min. flow temperature limit is overruled.

OFF: The min. flow temperature limit is not

overruled.

Page 43

The grey

side of the

ECL Card

Extended service

Service parameter(s) 141

32i

141 Override input selection

Setting range Factory setting

OFF / 1 ... 4 OFF

Choose an unused temperature sensor input for overriding the

schedule.

The override can be activated for comfort or setback mode.

For override the controller's mode must be in 'scheduled

operation'!

OFF: The controller's schedule is not overridden.

1 ... 4: Select an unused sensor input S1... S4 for

the override.

Connection example

If the override switch has gold-plated contacts, you can

choose one of the following solutions:

Closed switch:

Comfort temperature

Closed switch:

Setback tempe rature

Changeover switch:

Setback or comfort temperature

Connection example with ECA 9010

(used if the override switch does not have gold-plated

contacts).

Brown

Red

Green (S1 ... S4)

The ECA 9010 module is powered by the system device bus, which

means that the bus must be active. The bus is activated by setting

the controller address to 15 (line 199).

Page 44

The grey

side of the

ECL Card

Extended service

Service parameter(s) 174-197

32j

174 Motor protection

Setting range Factory setting

OFF / 10 ... 59 min. OFF

Prevents the controller from unstable temperature control (and

resulting actuator oscillations). This can occur when there is

no DHW tapping, i.e. when the load is only due to the DHW

circulation, or when the heating demand in the heating circuit

is very low. The motor protection increases the lifetime of all

involved components.

OFF: Motor protection is not activated.

10 ... 59:

Motor protection is activated after the set

activation delay.

A high value should be used for DHW

installations with many consumers.

189 Min. activation time, gear motor

Setting range Factory setting

2 ... 10

6

The min. pulse length in milliseconds for activation of the gear

motor.

Setting Pulse length

2 40 ms

3 60 ms

6 120 ms

10 200 ms

The setting should be corrected if the gear motor is too sensitive

to short activation pulses.

196 Service pin - LON

Setting range Factory setting

ON / OFF OFF

This setting is only used in connection with LON communication

(see the documentation for the used communication unit).

197 LON reset

Setting range Factory setting

ON / OFF ON

This setting is only used in connection with LON communication

(see the documentation for the used communication unit).

Page 45

The grey

side of the

ECL Card

Extended service

32k

Service parameter(s) 198-199

198 Daylight saving time changeover

Setting range Factory setting

ON / OFF ON

Choose whether you want the change to summer / winter time to

be automatic or manual.

ON: The controller’s built-in clock automatically

changes + / - one hour on the standardized

days for daylight saving time changeover for

Central Europe.

OFF: You change manually between summer and

winter time by setting the clock backward

or forward.

199 Master / slave address

Setting range Factory setting

0 ... 9, 15 15

The setting is relevant when more controllers are working in the

same ECL Comfort system (connected via the system device bus

(ECL Comfort BUS)).

0: The slave receives information about the

outdoor temperature (S1), system time, and

signal for DHW demand in the master.

1 ... 9: The slave receives information about the

outdoor temperature (S1), system time, and

signal for DHW demand in the master.

The slave sends information about the

desired flow temperature to the master.

15: The controller is master. The master sends

information about the outdoor temperature

(S1) and system time.

The bus is active and connected ECAs are

powered.

The ECL Comfort controllers can be connected via the bus to

perform a larger system. The controller, which is physically

connected with the outdoor temperature sensor, is the

master of the entire system and automatically gets the

address 15.

Each slave must be configured with its own address (1 ... 9).

However, more slaves can have the address 0 if they only

have to receive information about outdoor temperature and

system time.

Page 46

7a

Definitions

Air duct temperature

Temperature measured in the air duct where the temperature is

to be controlled.

Balance temperature

This setpoint is the basis for the flow / air duct temperature. The

balance temperature can be adjusted by the room temperature,

the compensation temperature and the return temperature.

The balance temperature is only active if a room temperature

sensor is connected.

Comfort operation

Normal temperature in the system controlled by the schedule.

During heating the flow temperature in the system is higher

to maintain the desired room temperature. During cooling the

flow temperature in the system is lower to maintain the desired

room temperature.

Comfort temperature

Temperature maintained in the circuits during comfort periods.

Normally during daytime.

Compensation temperature

A measured temperature influencing the flow temperature

reference / balance temperature.

Controller mode indicator

Black arrow to the right of the symbols indicating the present

mode.

Desired room temperature

Temperature which is set as the desired room temperature.

The temperature can only be controlled by the ECL Comfort

controller if a room temperature sensor is installed.

If a sensor is not installed, the set desired room temperature

however still influences the flow temperature.

In both cases the room temperature in each room is typically

controlled by radiator thermostats / valves.

Desired temperature

Temperature based on a setting or a controller calculation.

Dew point temperature

Temperature at which the humidity in the air condensates.

Factory settings

Settings stored on the ECL Card to simplify the set up of your

controller the first time.

Flow temperature

Temperature measured in the flow at any time.

Flow temperature reference

Temperature calculated by the controller on basis of the

outdoor temperature and influences from the room and / or

return temperatures. This temperature is used as a reference for

the control.

Heating circuit

The circuit for heating the room / building.

Heat curve

A curve showing the relationship between actual outdoor

temperature and required flow temperature.

DHW circuit

The circuit for heating the domestic hot water (DHW).

Page 47

7b

Humidity, relative

This value (stated in %) refers to the indoor moisture content

compared to the max. moisture content. The relative humidity

is measured by the ECA 62 / 63 and is used for the calculation of

the dew point temperature.

Limitation temperature

Temperature that influences the desired flow / balance

temperature.

Pt 1000 sensor

All sensors used with the ECL Comfort controller are based

on the Pt 1000 type. The resistance is 1000 ohm at 0 °C and it

changes with 3.9 ohm / degree.

Optimization

The controller optimizes the start time of the scheduled

temperature periods. Based on the outdoor temperature, the

controller automatically calculates when to start in order to

reach the comfort temperature at the set time. The lower the

outdoor temperature, the earlier the start time.

Return temperature

The temperature measured in the return influences the desired

flow temperature.

Room temperature sensor

Temperature sensor placed in the room (reference room,

typically the living room) where the temperature is to be

controlled.

Room temperature

Temperature measured by the room temperature sensor,

room panel or remote control. The room temperature can

only be controlled directly if a sensor is installed. The room

temperature influences the desired flow temperature.

Schedule

Schedule for periods with comfort and setback temperatures.

The schedule can be made individually for each week day and

may consist of up to 3 comfort periods per day.

Setback temperature

Temperature maintained in the heating / DHW circuit during

setback temperature periods.

State / mode indicators

White arrow to the left of the symbols (sun / moon). The white

arrow indicates the present state, comfort (sun) or setback

(moon), when the controller is in scheduled operation mode.

The black arrow symbol indicates the mode of the controller.

Time line / bar

Line with numbers representing the hours. Below the time

line, time bars represent scheduled periods with comfort

temperature. The bar is divided into half hour sections.

Weather compensation

Flow temperature control based on the outdoor temperature.

The control is related to a user-defined heat curve.

The definitions apply to the Comfort 200 as well as ECL Comfort

300 series. Consequently, you might come across expressions

that are not mentioned in your guide.

Page 48

The time shown in the display is one hour off?

See the summer time changeover in line 198, section 32.

The time shown in the display is not correct?

The internal clock may have been reset, if there has been a

power break for more than 12 hours.

Set time and date.

See section 17.

The ECL Card is lost?

Switch the power off and on again to see the

system type and the software generation of the controller.

Order a replacement from your Danfoss representative.

Insert the new ECL Card with the yellow side facing you and

make sure that you copy your personal settings from the

controller to the ECL Card.

See section 34.

The room temperature is too low?

Make sure that the radiator thermostat does not limit the

room temperature.

If you still cannot obtain the desired room temperature by

adjusting the radiator thermostats, the flow temperature

is too low. Increase the desired room temperature (section

3). If this does not help, adjust the heat curve / balance

temperature (section 20).

The room temperature is too high during setback

periods?

Make sure that the min. flow temperature limitation is not too

high. See section 22.

The temperature is unstable?

Check that the flow temperature sensor is correctly

connected and in the right place. Adjust the control

parameters (section 26).

If the controller has a room temperature signal, see section

23.

The controller does not operate and the control

valve is closed?

Check that the flow temperature sensor is measuring the

correct value, see section 1.

Check the influence from other measured temperatures.

Hot points

6a

Page 49

How to make an extra comfort period in the

schedule?

You can make an additional comfort period by pushing the

shift and + buttons simultaneously for 2 seconds.

See section 4.

How to remove a comfort period in the schedule?

You can remove a comfort period by pushing the shift and

- buttons simultaneously for 2 seconds.

See section 4.

How to restore your personal settings?

Insert the ECL Card with the yellow side facing you. Go to line

9 (is not displayed), which is the second line below line 7.

Select copy direction 'card to controller' (left to right) by

using the shift button. Push the + button to copy.

See section 5.

This is a collection of frequently asked questions for the ECL

Comfort 200 as well as ECL Comfor t 300 series. Consequently,

you might come across some questions that do not apply to your

application.

6b

Page 50

The yellow

side of the

ECL Card

Monitor the current schedules

Select between lines 1-7 (Monday, Tuesday ......

Sunday) to see your individual schedules.

Line

Changeover ime

Periods with comfor t temp. are

shown as black bars

Time line

Change the schedules

Select appropriate day.

The changeover p oint blinks

Adjust the first blinking changeover point, if

required. The end of the bar moves, extending or

reducing the comfort period.

Shift to next changeover point and adjust

accordingly.

4a

Set your personal schedule

Page 51

The yellow

side of the

ECL Card

4b

Add an extra comfort period

Push the shift and + button simultaneously for

2 seconds.

The new perio d appears

Adjust the new period.

Remove a comfort period

Select the period to be removed (blinking

changeover point)

Push shift and - buttons simultaneously for

2 seconds.

Cancel changes in your personal settings

Push - and + buttons simultaneously for

2 seconds to restore the factory settings of the

actual schedule.

Page 52

The yellow

side of the

ECL Card

During scheduled operation (clock), the state indicator (a

white arrow) will show you the control mode of the selected

circuit. The white arrow will blink when this is a heating

circuit and it is in the optimizing period.

State indicator

(white arrow)

02

Function selec tor

(black arrow)

Function selector. Push the button to change the

mode of the circuit. The black arrow shows you

which of the modes you have chosen.

What do the symbols mean?

Manual operation

Used only at maintenance and service.

Note! The protection against frost is switched off

when this mode is selected.

Scheduled operation

This is the normal mode. The temperature is

controlled according to your schedule with

automatic changeover to / from comfort and

setback temperature periods.

Constant comfort temperature

The schedule is not in operation. Use this mode

when a constant comfort temperature is desired.

Constant setback temperature

The schedule is not in operation. Use this mode

when you are away on holiday, etc.

Standby

The selected circuit is stopped. The system is still

protected against frost.

Select circuit mode

2

Page 53

The yellow

side of the

ECL Card

Go to display C.

Setting the desired room temperature

02

Desired room

temp. in

comfort mode

61

Desired room

temp. in

setback mode

Select the constant comfort mode.

Set the desired room temperature for the comfort

mode.

Select the constant setback mode.

Set the desired room temperature for the setback

mode.

Select the desired mode (section 2).

The setting of the desired room temperature is important even if

a room temperature sensor / room panel / remote control is not

connected.

Is the room temperature too low?

Make sure that the radiator thermostat does not limit the room

temperature.

If you still cannot obtain the desired room temperature by

adjusting the radiator thermostats, the flow temperature is too

low. Increase the desired room temperature.

Set your room temperature

3

Page 54

The yellow

side of the

ECL Card

1

Choose your favorite display

Choose the display - A, B, or C - for daily

operations.

Room temperature - display A

Line

Outdoor

temp.

Room temp.

913

20

A

Desired room tem p.

The display will show the room temperature if a room

temperature sensor, a room panel or a remote control is installed.

If not, two bars will be shown.

System information - display B

Line

Flow

temp.

State of controlled compo nents

5

1

1

ON

036

B

Return temp.

Today's schedule - display C

Line

Outdoor

temp.

Time

8

0 3 6 9 12 15 18 21 24

1

023

5

C

3

Today's schedule

Desired room tem p.

The controller automatically reverts to display C if the power

supply has been interrupted.

If the temperature value is displayed as "- -", the sensor in

question is not connected. "- - -" means that the sensor is shor tcircuited.

Page 55

Save energy - save money - improve

your comfort temperature

The ECL Comfort controller is designed by Danfoss for the

automatic temperature control of heating and hot-water

systems.

Some of the advantages of the ECL Comfort controller system

are:

• Secure control and the optimum use of energy resources.

• Control of system temperatures according to seasonal

changes and variations in outdoor temperatures.

• Setback temperature periods and low energy consumption

while you are out or asleep save heating costs.

Operating the ECL Comfort controller

When operating the controller it is advisable to keep the lid

open in order to view the entire display.

The ECL Card is divided vertically into two columns each

representing a circuit.

Horizontally the ECL Card is divided into lines that

represent the different control and programming options.

Each line is shown in the display of the controller, which gives

you an instant overview of the operation, settings etc.

How to use the ECL Comfort User's Guide

This guide provides you with an easy instruction for the ECL

Comfort controller.

The Installer's Guide, the grey section (turn the guide over),

contains the complete list of factory settings and various

detailed adjustments that ensure an efficient and continuous

operation of your system.

Page 56

Table of Contents

Daily use

Section

1 Choose your favorite display

2 Select controller mode

3 Set your room temperature

4 Set your personal schedule

6 Hot points

7 Definitions

The documentation for the ECL Comfort controller is composed

of numbered sections. Only sections that are relevant to your

ECL Comfort controller are included here.

Installer's Guide:

Grey sections 10 and onwards. Turn the guide over.

Your personal schedule:

Factory set tings are grey.

6-8 16-22

8-23

Heating 0 3 6 9 12 15 18 21 24

1 Monday

2 Tuesday

3 Wednesday

4 Thursday

5 Friday

6 Saturday

7 Sunday

Loading...

Loading...