Data sheet

CI-tronic™ Electronic contactors

Type ECI

ECI electronic contactors are designed for fast

and demanding switching of loads such as

heaters, solenoids, transformers and motors.

ECI Electronic contactors utilize power chip with

LTE (Low Thermal Expansion) technology.

This unique power chip design ensures high

switching capacity and long life.

The contactors are burst fired for reduced EMC

emission, have LED status indicators and accept

universal control voltage ranges.

The units are DIN rail mountable, complete with

heatsink and require no additional components.

Features • Compact modular design complete with

heatsink

• DIN rail mountable

• Easy and quick installation

• Specification according to industry standard

• Available in single phase, dual phase or

three phase version

• Operational current up to 63 A (AC-1),

30 A (AC-3)

• LED Status indication

• Line voltage up to 600 V AC

• Universal control voltage

• Burst firing (zero cross)

• IP20 protection

• CE, cULus and C-tick approvals

• SCR power chip with LTE technology

• Built-in varistor protection

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.G4.02 | 1

Data sheet | CI-tronic™ Electronic contactors, Type ECI

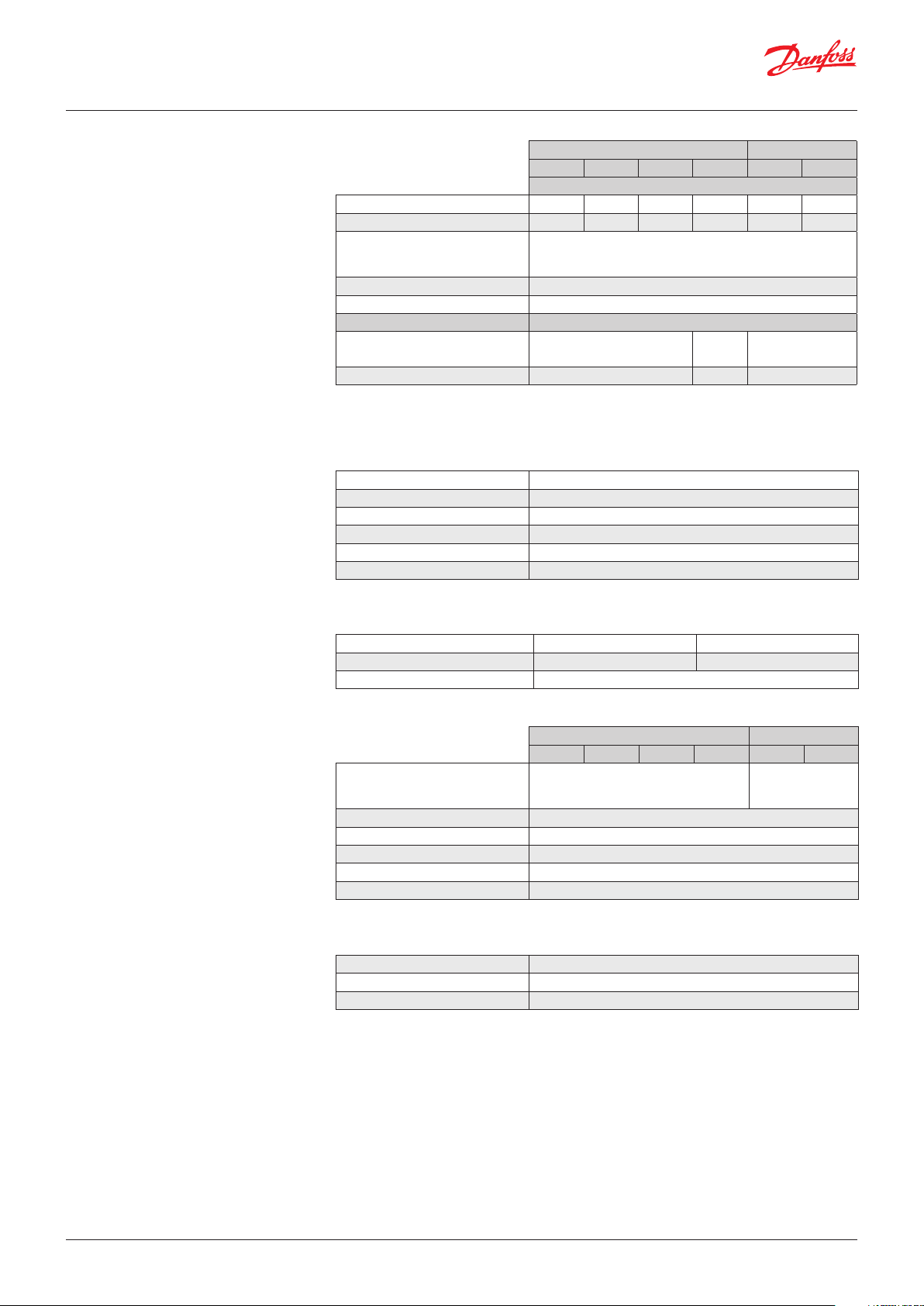

Technical data

Single and dual phase 1) Three phase

Output specification

ECI 15 ECI 30 ECI 50 ECI 63 ECI 10 ECI 20

Operational current [A]

AC-1, AC-51 (heater load) max. 15 30 50 63 10 20

AC-3, AC-53a (motor load) max. 15 2) 15 15 30 10 10

12 – 230 V AC

Operational voltage (50/60 Hz)

24 – 480 V AC

24 – 600 V AC

Leakage current max. 1 mA

Operational current min. 10 mA

Semiconductor protection fusing

Type 1 coordination

50 A gL /

gG

80 A gL

/ gG

35 A gL /

gG

Type 2 coordination Pt(t=10ms) 1800 A2s2) 6300 A2s 450 A2s

1

) Dual phase: Current rating is accumulated, i.e. the sum of current in L1 and L2

2

) Contactors designed for 600 V: AC-3 load 10 A max., type 2 coordination fuse 450 A2s

Control circuit specification

Control voltage range (±10%) 5 – 24 V DC / 24 – 230 V AC / DC

Pick-up voltage max. 4.25 V DC / 20.4 V AC / DC

Drop-out voltage min. 1.5 V DC / 7.2 V AC / DC

Control current / power max. 15 mA at 24 V DC / 1.5 VA at 24 V DC

Response time max. ½ cycle / 1 cycle

EMC immunity Meets requirements of EN 60947-4-3

Insulation

Rated insulation voltage U

Rated impulse withstand voltage U

I

imp

Installation category III

Thermal specification

Power dissipation

continuous duty

intermittend duty

Single and dual phase Three phase

ECI 15 ECI 30 ECI 50 ECI 63 ECI 10 ECI 20

1.2 W/A (per phase)

1.2 W/A × duty cycle

(per phase)

Ambient temperature range -5 – 40 °C

Cooling method Natural convection

Mounting Vertical (see general mounting instruction)

Storage temperature range -20 – 80 °C

Enclosure degree/pollution degree IP20 / IP3

660 V AC

4 kV

3 W/A × duty

Materials

Housing Self-extinguishing PPO UL94V1

Heatsink Aluminium black anodized

Base Electroplated steel

3 W/A

cycle

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.G4.02 | 2

Data sheet | CI-tronic™ Electronic contactors, Type ECI

Ordering

Single phase

Operational

current [A]

AC-1 AC-3 12 – 230 24 – 480 24 – 600

15 15 5 – 24 V DC 22.5 mm module ECI 15-1 037N0063 037N0065 –

15 15

30 15 5 – 24 V DC 45 mm module ECI 30-1 037N0007 037N0009 –

30 15

50 15 5 – 24 V DC 90 mm module ECI 50-1 037N0008 037N0010 –

50 15

63 30 5 – 24 V DC 90 mm module ECI 63-1 037N0078 037N0080 037N0082

63 30

Dual phase

Operational

current 1) [A]

AC-1 AC-3 12 – 230 24 – 480 24 – 600

30 15 5 – 24 V DC 45 mm module ECI 30-2 037N0019 037N0021 037N0023

30 15

50 15 5 – 24 V DC 90 mm module ECI 50-2 037N0020 037N0022 –

50 15

1)

Rated as the maximum sum of current in L1 and L2

Three phase

Operational

current [A]

AC-1 AC-3 12 – 230 24 – 480 24 – 600

10 10 5 – 24 V DC 45 mm module ECI 10-3 037N0031 037N0033 037N0035

10 10

20 10 5 – 24 V DC 90 mm module ECI 20-3 037N0032 037N0034 037N0036

20 10

Control

voltage

24 – 230 V AC / DC

24 – 230 V AC / DC

24 – 230 V AC / DC

24 – 230 V AC / DC

Control

voltage

24 – 230 V AC / DC

24 – 230 V AC / DC

Control

voltage

24 – 230 V AC / DC

24 – 230 V AC / DC

Dimensions Type

22.5 mm module ECI 15-1 037N0064 037N0066 –

45 mm module ECI 30-1 037N0001 037N0003 037N0005

90 mm module ECI 50-1 – 037N0004 –

90 mm module ECI 63-1 037N0079 037N0081 037N0083

Dimensions Type

45 mm module ECI 30-2 037N0013 037N0015 –

90 mm module ECI 50-2 037N0014 037N0016 037N0018

Dimensions Type

45 mm module ECI 10-3 – 037N0027 037N0029

90 mm modul ECI 20-3 – 037N0028 037N0030

Operational voltage [V AC]

Operational voltage [V AC]

Operational voltage [V AC]

Code no.

Code no.

Code no.

Operating at high

temperature

Ambient temperature

[ºC] ECI 15 ECI 30 ECI 50 ECI 63 ECI 10 ECI 20

40 15 30 50 63 10 20

50 12.5 25 40 50 8 16

60 10 20 30 35 6.5 13

Continuous current [A]

Single and dual phase Three phase

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.G4.02 | 3

Data sheet | CI-tronic™ Electronic contactors, Type ECI

Wiring diagram

Applications

Single phase Dual phase

Three phase

Terminals 11 and 12 have no conection to the internal circuit but are intended for

connection to an optional overload protection

(see overheat protection instruction, page 4).

Single phase

P = IL * U

L

Max. heater power [kW]

230 V 400 V 575 V

ECI 15-1 3.5 6 8.7

ECI 30-1 6.9 12 17.3

ECI 50-1 11.5 20 28.8

ECI 63-1 14.5 25.1 36.2

Max. heater power [kW]

230 V 400 V 575 V

ECI 15-1 6 10.3 15

ECI 30-1 11.9 20.8 29.9

ECI 50-1 19.9 34.6 49.7

ECI 63-1 25.1 43.6 62.6

Dual phase

P = 1.73 * IL *U

Max. heater power [kW]

230 V 400 V 575 V

ECI 30-2 6.9 12 17.3

ECI 50-2 11.5 20 28.8

L

Max. heater power [kW]

ECI 30-2 6.9 12 17.3

ECI 50-2 11.5 20 28.8

P = 1.73 * IL *U

230 V 400 V 575 V

Three phase

P = 1.73 * IL *U

Max. heater power [kW] Max. heater power [kW]

230 V 400 V 575 V

ECI 30-2 4 6.9 10

ECI 50-2 8 13.8 20

L

P = 1.73 * IL *U

230 V 400 V 575 V

ECI 30-2 4 6.9 10

ECI 50-2 8 13.8 20

L

L

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.G4.02 | 4

Data sheet | CI-tronic™ Electronic contactors, Type ECI

Duty cycle rating

If the ECI contactor

load factor is not 100%,

the ECI can be selected

for a higher current

than the rated value

according to table

below.

On-time

ECI 15-1

Load current On-time max. Load factor max.

[A] [min.] [%]

17.5 15 85

20 13 75

22.5 11 67

25 9 60

27.5 7 55

30 5 50

ECI 15-1 for 600 V

Load current On-time max. Load factor max.

[A] [min.] [%]

17.5 15 85

20 13 75

ECI 30-1 and ECI 30-2

Load current On-time max. Load factor max.

[A] [min.] [%]

35 15 85

40 13 75

45 11.5 67

50 10 60

On-time max.

(heat up period)

Load factor = On-time / duty cycle

Time

Duty cycle

ECI 10-3

Load current On-time max. Load factor max.

[A] [min.] [%]

12.5 15 85

15 13 75

17.5 11.5 67

20 10 60

Overheat protection If required the controller can be protected

against overheating by inserting a thermostat in the slot on the right-hand side of the

controller.

Order: UP 62 thermostat 037N0050

The thermostat is connected in series with

the control circuit of the main contactor.

When the temperature of the heat sink

exceeds 100 °C the main contactor will be

switched OFF. A manual reset is necessary

to restart this circuit.

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.G4.02 | 5

Mounting instruction The controller is designed for vertical mounting.

If the controller is mounted horizontally the load

current must be reduced by 50%.

The controller needs no side clearance.

Clearance between two vertical mounted

controller must be minimum 80 mm / 3.15”.

Clearance between controller and top and

bottom walls must be minimum 30 mm / 1.2”.

Dimensions [mm / inches]

ECI 15 ECI 10, ECI 30

ECI 20, ECI 50, ECI 63

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.G4.02 | 6

Loading...

Loading...