FCM 300

Operating Instructions

Profibus DP V1

FCD 300

VLT

®

2800

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■ Contents

Introduction

....................................................................................................... 2

Quick Start ......................................................................................................... 4

Profibus DP ............................................................................................................ 4

Baudrate ................................................................................................................ 4

Profibus DP V1 ....................................................................................................... 4

System layout ................................................................................................... 5

Master-controlled frequency converters .................................................................. 5

Bus topology .................................... ............................................................. ......... 6

Features of DP (Distributed Periphery) .................................................................... 6

Rapid Cyclical transmission with PPO using DP ..................................................... 6

Profibus DP V1 ....................................................................................................... 7

Principle of data exchange by Profibus DP V0/DP V1 ............................................. 7

The Profibus Interface .................................................................................. 9

Cable connection FCM 300 .................................................................................... 11

Cable connection FCD 300 .................................................................................... 14

Cable connection VLT 2800 ................................................................................... 17

Profibus DP ........................................................................................................ 20

DP V1 identifications .................................................................................... 30

Parameters ......................................................................................................... 31

Warnings and alarm messages ............................................................... 39

Station address ............................................................................................... 41

Glossary .............................................................................................................. 42

Parameter list .................................................................................................... 43

Index ...................................................................................................................... 50

MG.90.A5.02 - VLT is a registered D anfoss trademark

1

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Introduction

Copyrights, L imitation of Liability and Revision Rights.

This publication contains information proprietary to

Danfoss A/S. By accepting and using this manual the

user a grees that the information contained herein will

be used solely for operating equipment of Danfoss A/S

or equipment from other vendors provided that such

equipment is intended for communication with Danfoss

equipment over a PROFIBUS serial communication

link. This publication is protected under the Copyright

laws of Denmark and most other countries.

Danfoss A/S does not warrant that a software program

produced according to the guidelines provided in

this manual will function properly in every physical,

hardware or software environment.

Although Danfoss A/S has tested and reviewed the

documentation within this manual, Danfoss A/S makes

no warranty or representation, either express or implied,

with respect to this documentation, including its quality,

performance, or fitness for a particular purpose.

In no event shall Danfoss A/S be liable for direct,

indirect, special, incidental, or consequential damages

arising out of the use, or the inability to use information

contained in this m anual, even if advised of the

possibility of such damages. In particular, Danfoss

A/S is not responsible for any costs including b ut not

limited to those incurred as a result of lost profits

or revenue, loss or damage of equipment, loss

of computer programs, loss of data, the costs to

substitute these, or any claims by third parties.

Danfoss A/S reserves the right to revise this publication

at any time and to ma ke changes in its contents

without prior notice or any obligation to notify previous

users of such revisions or changes.

When reading through this manual, you will come

across various symbols that require special attention.

The symbols used are the following:

Indicates a general warning.

NB!:

Indicates something to be noted by the reader.

Indicates a high-voltage warning.

PROFIBUS is a registered trademark.

■About this manual

This manual describes the Profibus communication

in the following products:

- FCM 300

- FCD 300

- VLT 2800

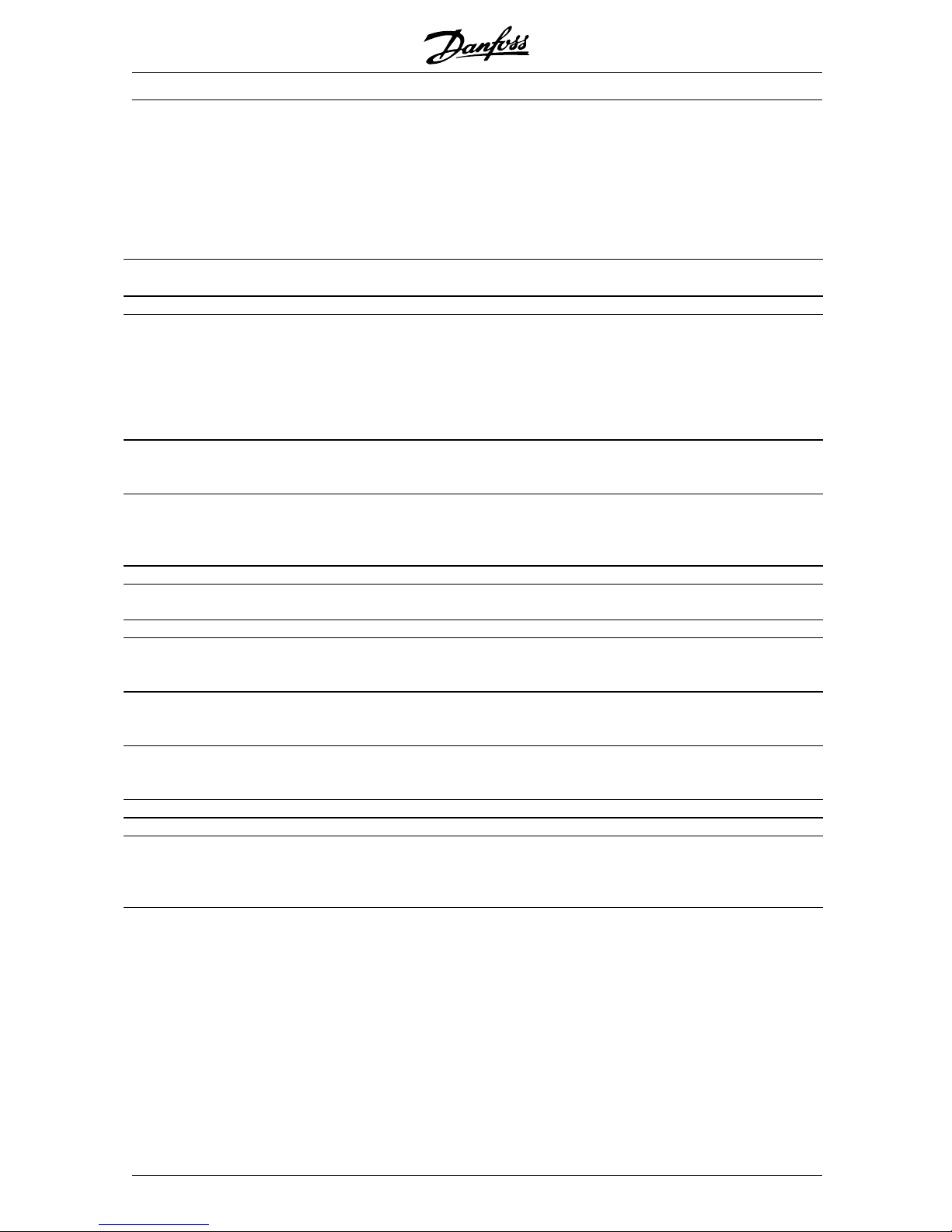

The following table shows from which software versions

Profibus DPV1 is supported. The software version can

be read-out in parameter 624 Software versions.

Unit Software version

FCM 300 Not supported

FCD 300 Ver. 1.3x/2.x

VLT 2800 Ver. 2.6x/2.x

This manual gives detailed information of the DP V0

features supported, sufficient for most programming

and maintenance activities. The DP V1 however

is briefly described. For programming purposes

the Profibus DP V1 Design Guide order number

MG.90.EX.YY (X is the version number, and YY the

language code) might be necessary.

It is suggested that readers who are not

completely familiar with PROFIBUS DP or the

profile for frequency converters review the relevant

literature on these subjects.

Even if you are an experienced PROFIBUS programmer,

we suggest that you read this manual in its entirety

before you start programming, since important

information can be found in all chapters.

■Assumptions

This manual assumes that you are using a DANFOSS

FCM 300, FCD 300 or VLT 2800 w ith PROFIBUS. It is

also assumed that you, as a master, are using a PLC or

PC that is equipped with a serial communication card

supporting all the PROFIBUS communication services

required by your application. Further, it is assumed

that all requirements stipulated in the PROFIBUS

standard as well as those set up in the PROFIBUS

frequency converters Profile and its company-specific

implementation PROFIDRIVE, as well as those

pertaining to the frequency converter are strictly

observed as well as all limitations therein fully respected.

MG.90.A5.02 - VLT is a registered Danfoss trademark

2

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Introduction

The Profibus DP V1 replaces the former

Profibus DP V0 functionality.

Note: The 3MB and 12MB Profibus option are separate

options and have different ordering numbers.

■What you should already know

The DANFOSS PROFIBUS is designed to communicate

with any master abiding by the PROFIBUS DP

standard. It is therefore assumed that you have full

knowledge of the PC or PLC you intend to use as

a master in your system. Any questions pertaining

to hardware or software produced by any other

manufacturer is beyond the scope of this manual

and is of no concern to DANFOSS.

If you have questions about how to set up master

- master communication or communication to

a non-Danfoss slave, the appropriate manuals

should be consulted.

MG.90.A5.02 - VLT is a registered Danfoss trademark

3

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Quick start

Details regarding the programming of the usual

frequency converter parameters may be gathered

from the Design Guide for the FCM 300, the

FCD 300 and VLT 2800.

The communication is established by setting the

parameters indicated below.

Details regarding the adjustment of the m aster

are provided by the master manual and by those

chapters in this manual that deal with the particulars

of the VLT PROFIBUS interface.

NB!:

The required GSD file is available on the internet

at http://www.danfoss.com/drives.

■Profibus DP

P

arameter 904

The desired informative data telegram (PPO) is setup

in master configuration. The actual PPO type c an be

read out in P904. The master sends the PPO type in a

configuration telegram in the Profibus DP start phase.

P

arameter 918

This sets the address of the frequency converter

station – one specific address per frequency converter.

For further information, please refer to the section

Station address in this manual.

P

arameter 502 -508

By setting the parameters 502-508 you will be able

to select have to control over the bus.

P

arameter 512

Allows the choice of Control word/Status word type.

For further information, please refer to the section

Control word/Status word this manual.

NB!:

In order to activate a change of parameter

918 the power of the frequency converter

must be cycled.

■Baudrate

The FCM 300, FCD 300 and VLT 2800 adjust

automatically to the Baudrate configurated

from the master.

NB!:

When configuring the PPO types, a distinction

is made between module consistency

andwordconsistency:

Module consistency means that a specific portion

of the PPO is defined as a connected module. The

parameter interface (PCV, length of 8 bytes) of the

PPO always has m odule consistency.

Word consistency means that a specific portion

of the PPO is divided into individual data sectors

of word length (16 bits).

The process data of the PPO may have either module

consistency or word consistency, as desired.

Some PLCs, such as Siemens S7, require special

functions to call m odules that are longer than 4

bytes (in the case of Siemens: "SFC", see master

manual). This means that the PCV interfaces of

the PPOs c an only be called through the SFC

functions in the case of Siemens (S7).

■Profibus DP V1

A detailed description of the DV V1 features supported

can be found in the "Profibus DP V1 Design

Guide" order number MG.90.EX.YY.

Further specifications might be helpful:

- Technical Guide "PROFIBUS -DP Extensions to EN

50170 (DPV1)" V2.0, April 1998, Order no. 2.082

- Draft PROFIBUS Profile PROFID RIV E Profile Drive

Technology V3.0 September 2000, Order no. 3.172

MG.90.A5.02 - VLT is a registered Danfoss trademark

4

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

System

layout

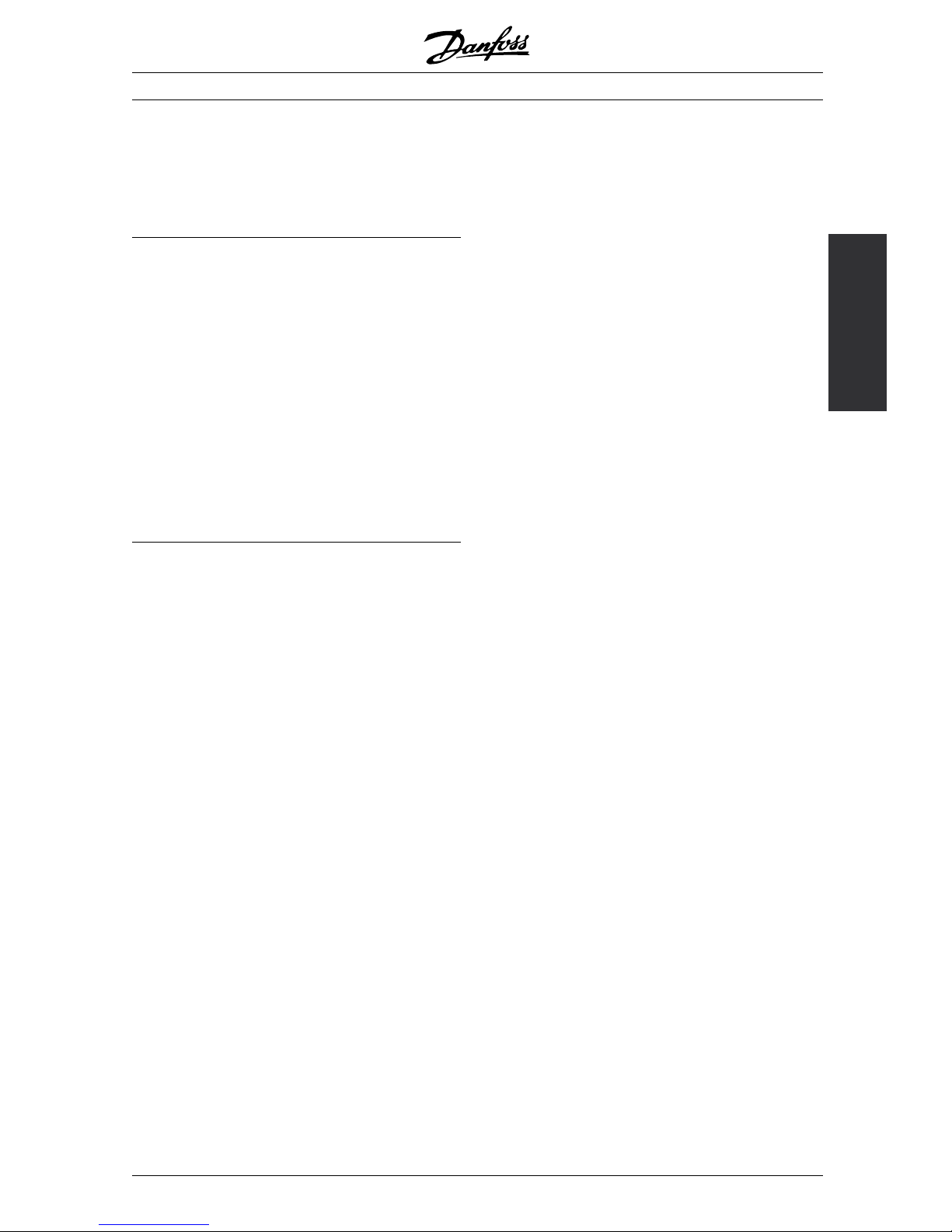

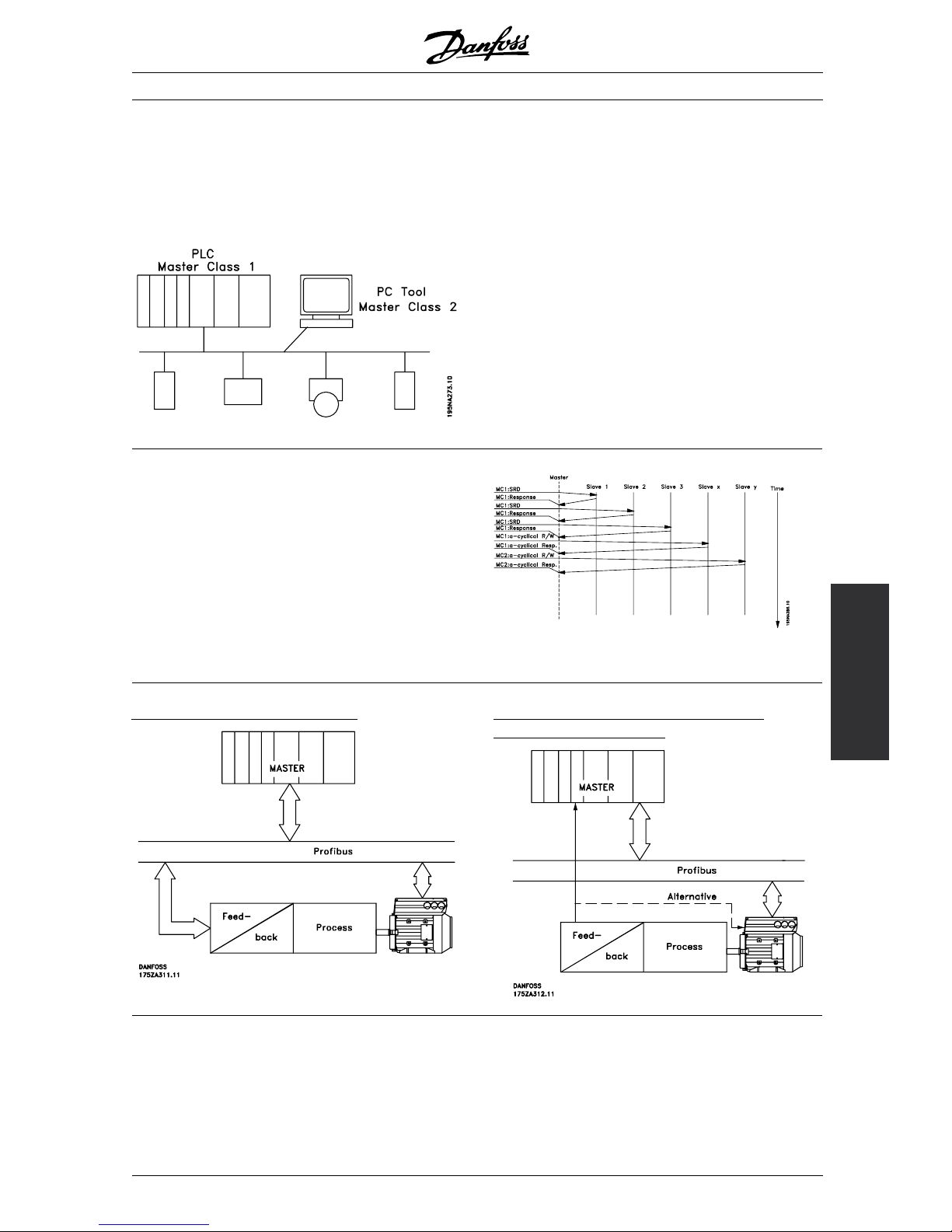

■Master-controlled frequency converters

The PROFIBUS Fieldbus was designed to give you

unprecedented flexibility and command over your

controlled system. The PROFIBUS will perform as an

integrated part of your frequency converter, giving you

access to all parameters relevant to your application.

The frequency converter will always act as a slave, and

together with a master it can exchange a multitude

of information and commands. Control signals such

as speed reference, start / stop of motor, reverse

operation, etc. are transmitted from the master in

the form of a telegramme. The frequency converter

acknowledges receipt by transmitting status signals,

such as running, on reference, motor stopped and so

on to the master. The frequency converter may also

transmit fault indications, alarms and warnings to the

master, such as Overcurrent or Phaseloss.

The PROFIBUS communicates in accordance with the

PROFIBUS field bus standard, EN 50170, part 3. It

can thus exchange data with all masters that me et

this standard; however, this does n ot mean that all

services ava ilable in the PROFIDRIVE profile standard

are supported. The PROFIBUS profile for frequency

converters (version 2 and partly version 3, PNO) is a

part of PROFIBUS which supports only those services

that concern applications with speed control.

C

ommunication partners

In a control system the frequency converter

will always act as a slave, and as such it may

communicate with a single master or multiple masters

depending on the nature of the application. A

master may be a PLC or a PC that is equipped

with a PROFIBUS communication card.

MG.90.A5.02 - VLT is a registered Danfoss trademark

5

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Bus topology

S

ingle master operation with DP V0

-Singlemaster

- PLC communicates with telegrams of

constant length

- Fits to t ime critical requirements

Cyclical transmis sion (PLC)

1. Setpoint transmission

2. Actual value feedback

3. New set points computed

4. New set point transmission

5. Parameter Read - using PCV channel

6. Parameter Write - using PCV channel

7. Read parameter description - using PCV channel

■Features of DP (Distributed Periphery)

- Is used by several PLC manufacturers for remote

peripheral I/O communication.

- Supports cyclical communication.

- SRD (Send Receive Data) service gives fast

cyclical exchange of process data between

master and slaves.

- Freeze and synchronize function is supported.

- Fixed data structure.

- Fixed telegramme size.

- Occupies I/O memory space in PLC proportional

to the number of slaves employed, which may

limit the number of participants. Additional data

require additio nal I/O memory space.

DP should be used when fast cyclical process control

is needed. Such a concept would typically call

for single master operation with a limited number

of slave stations. A high number of slaves will

increase the system response time.

This could also be the case where control

loops are closed over the bus. As a very fast

alternativeitisofcoursepossibletoclosethe

control loop outside the bus.

■Rapid Cyclical transmission with PPO using DP Control of the drives during normal operation is often

very time critical, but it involves very few data, such

as control commands and speed reference. DP is

optimized for fast cyclical communication.

Parameter up-/downloads can be achieved by

using the PCV part of the so-called Parameter Process data Objects - PPO types 1, 2 or 5, see

drawing in paragraph PPO description.

MG.90.A5.02 - VLT is a registered Danfoss trademark

6

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

System

layout

■Profibus DP V1

The Profibus DP extension DP V1 offers additional

to the cyclical data communication an acyclica l

communication. This feature can be used by a

DP master type 1 (e.g. PLC), as well as a DP

master type 2 (e.g. PC tool).

Features of a Master type 1 connection

- Cyclical data exchange (DP V0).

- Acyclical read/write on parameters.

The acyclical connection is fixed, and can not

be changed during operation.

Features of a Master type 2 connection:

- Initiate / Abort acyclical connection.

- Acyclical read/write on parameters.

The acyclical connection can dynamically be

established (Initiate) or removed (Abort) even when

a master class 1 is active on the network.

The DP V1 acyclical connection can be used

for general parameter access as an alternative

to the PCV parameter channel.

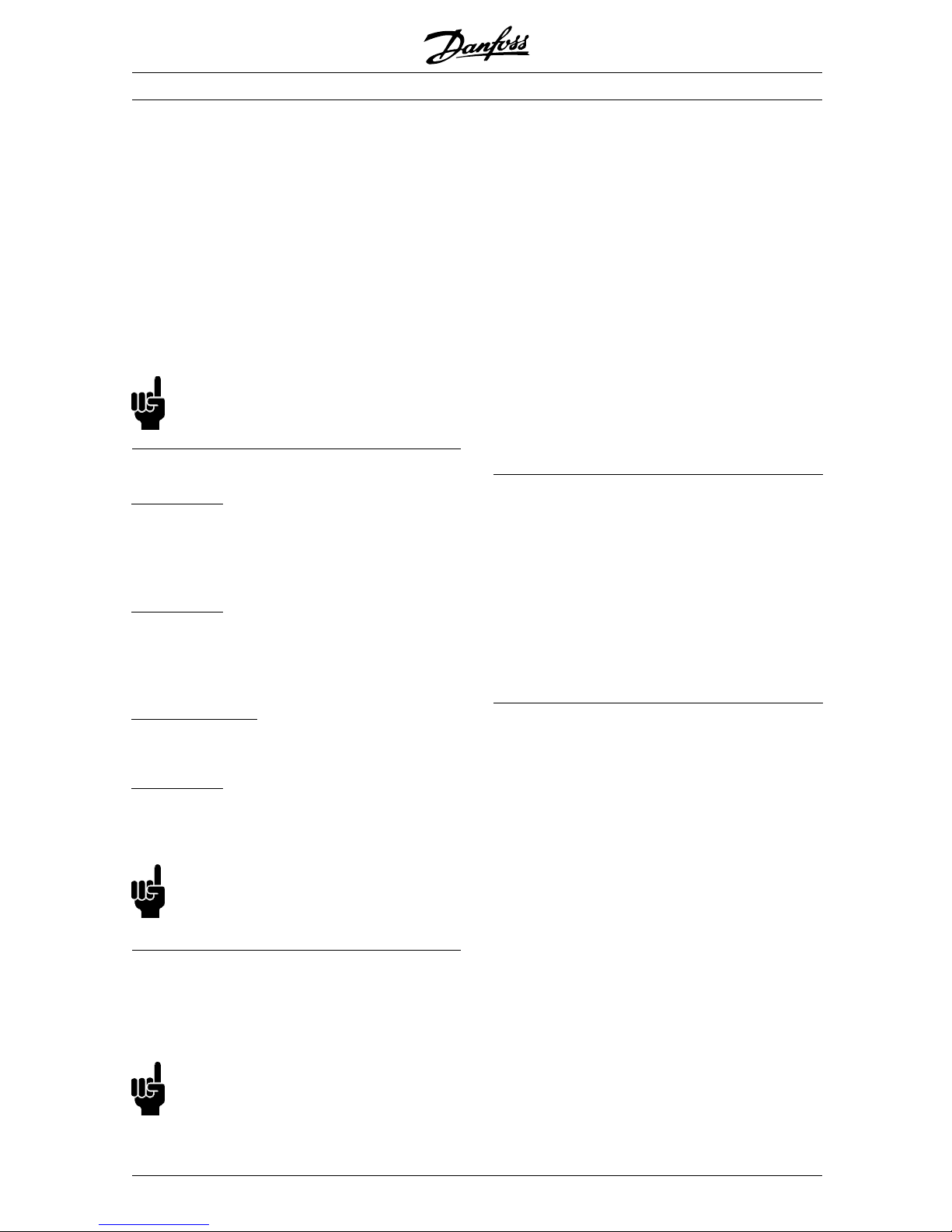

■Principleofdata exchange by ProfibusDPV0/DPV1

InaDPcycletheMC1willfirstupdatethecyclical

process da ta for all slaves in the system. After that

the MC 1 has the possibility of sending one acyclical

message to one slave. If a MC 2 is connected,

the MC 1 will handle over the Token to MC 2 who

now is a loud to send one acyclical message to one

slave. After that, the token is handled back to the

MC 1, and a new DP cycle is started.

MC1: Master Class 1

Closing the control loop over the bus Closing the control loop outside the fieldbus

for extremely fast feed-back

MG.90.A5.02 - VLT is a registered Danfoss trademark

7

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

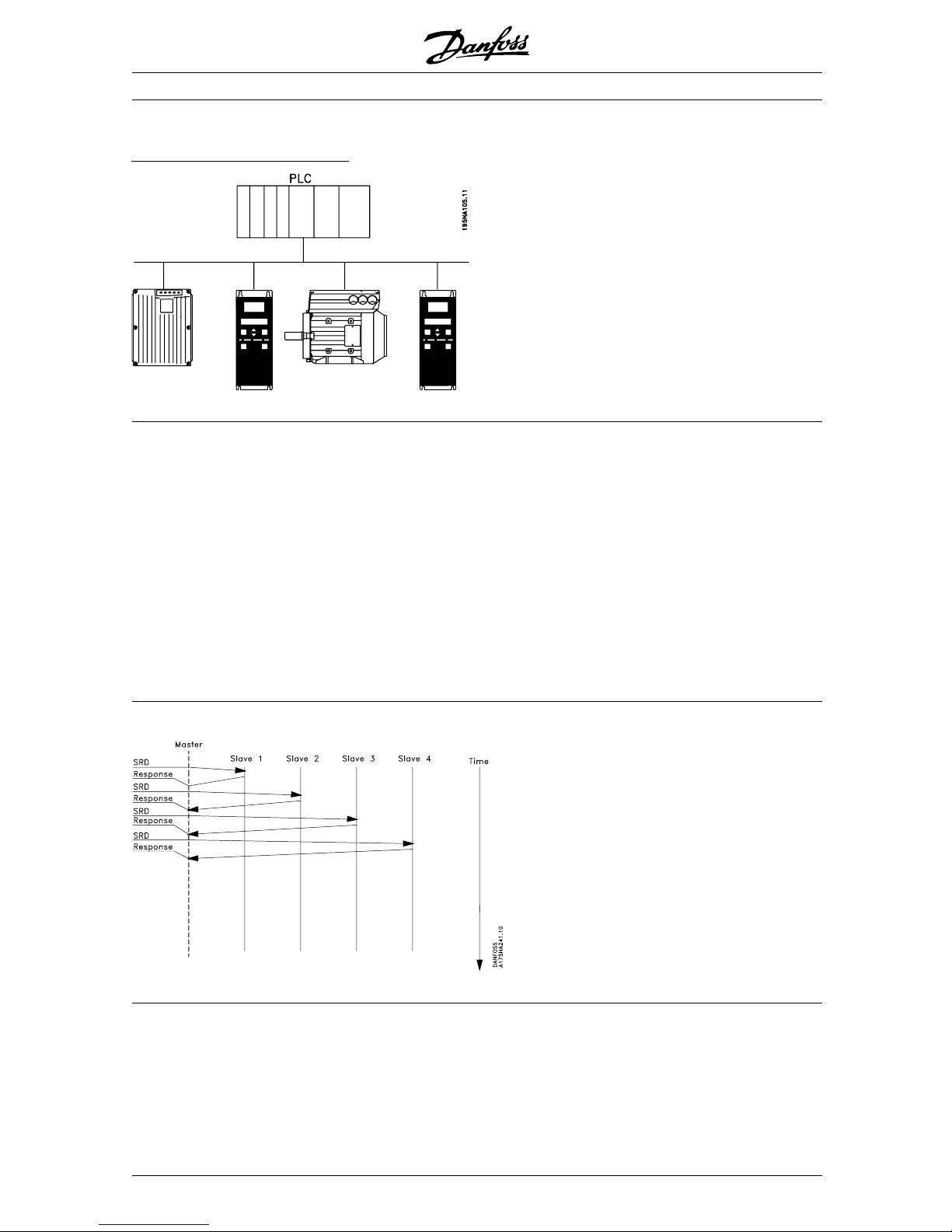

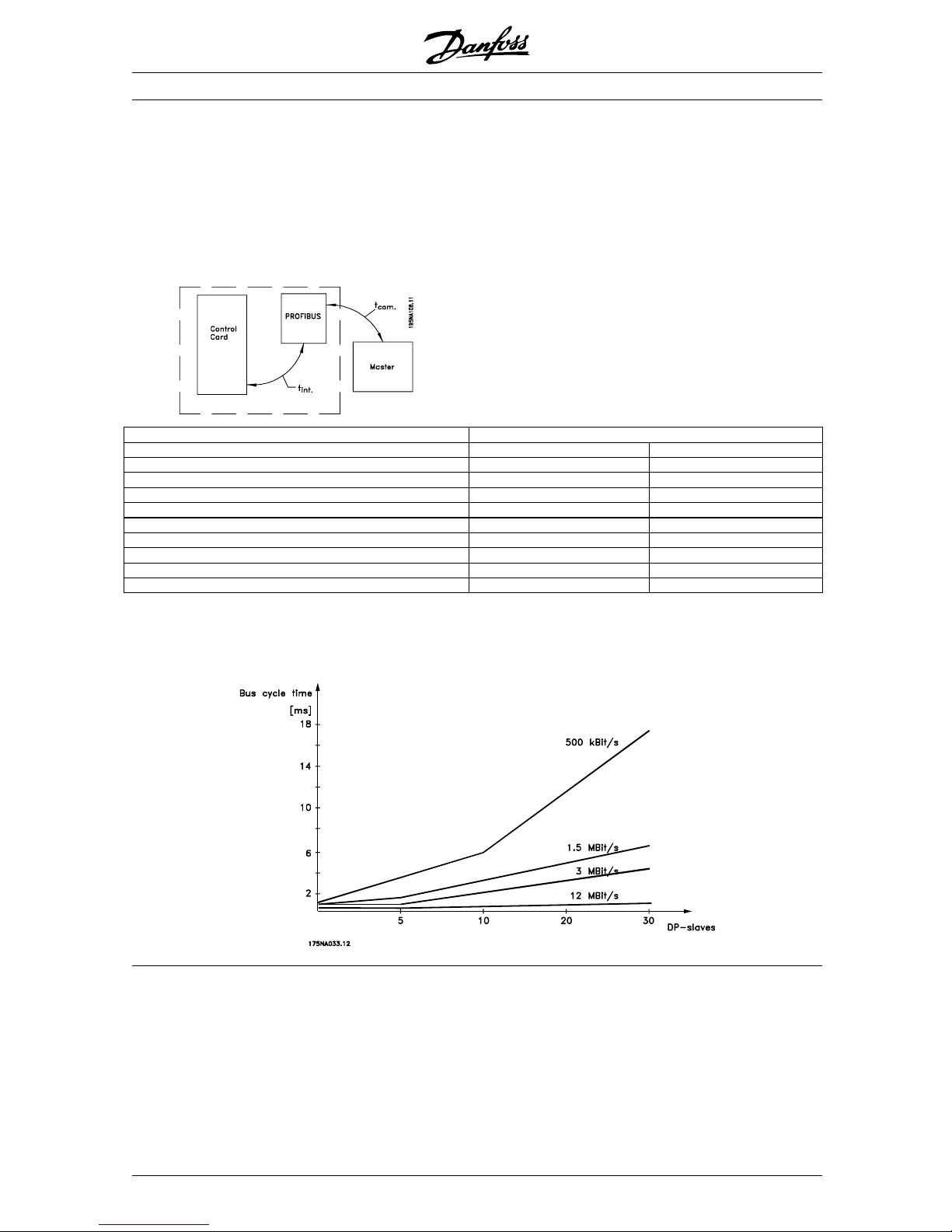

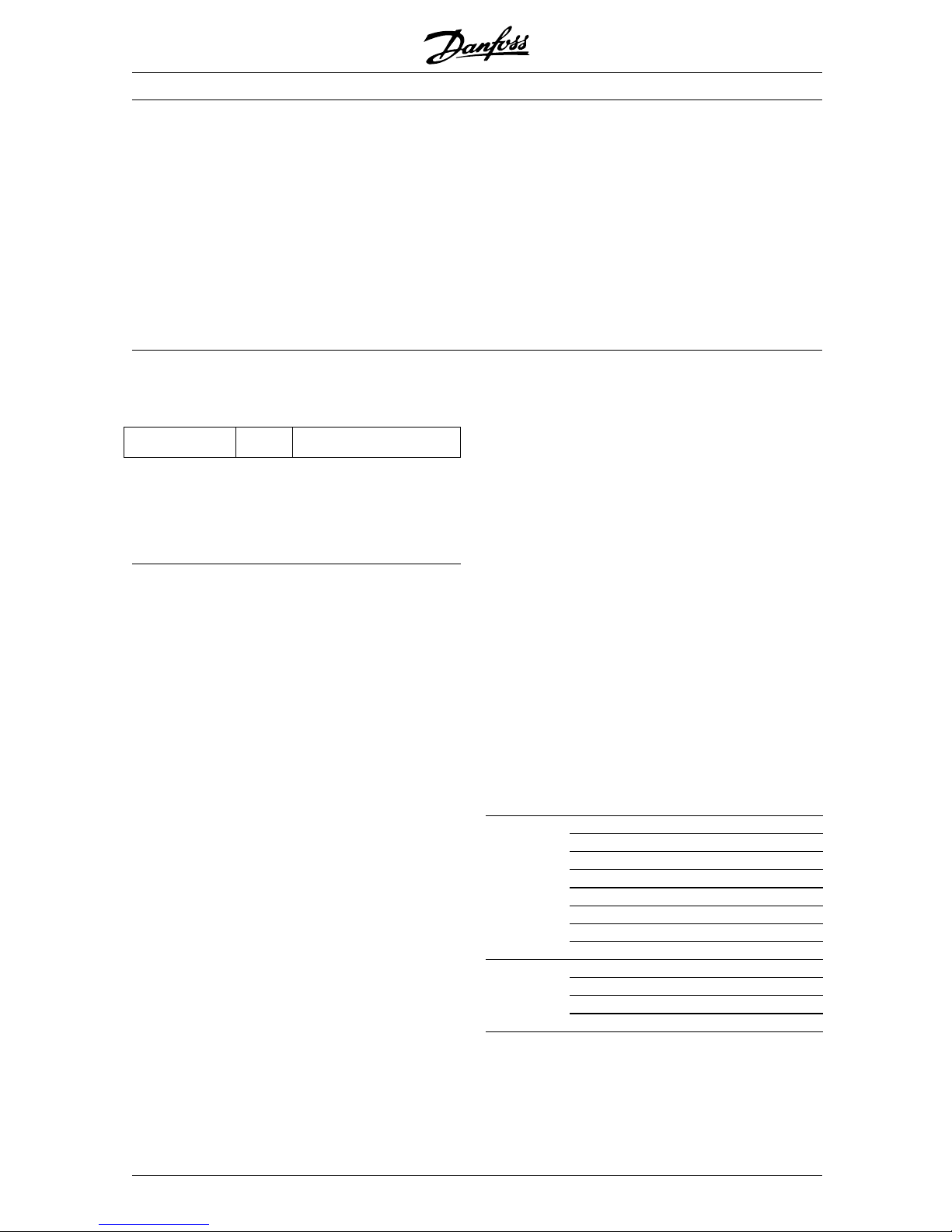

■FCM 300/FCD 300/VLT 2800 response time

The update time via the prodibus connection can be

divided in two parts: 1) The communication time, which

is the time it takes to transmit data from the master to

the slave (FCM 300/FCD 300/VLT 2800 with profibus),

and 2) the internal update time, which is the time it

takes to transmit data between the FCM 300/FCD

300/VLT 2800 control card and the profibus.

Communication time (t

com

) depends on the actual

transmission speed (baudrate) and the type of master

in use. The minimum obtainable communication

time with the FCM 300/FCD 300/VLT 2800 with

PROFIBUS is approx. 100 msec per slave, when

using DP communication with 4 bytes of data (PPO

type 3) at 3 Mbaud. More data or lower transmission

speed will increase the communication time.

The internal update time (t

int

) depends on the type

of data in question as there are different channels for

the data transfer where time critical data e.g. control

word has highest priority. The internal update time for

the different types of data are stated below.

Update tim e, t

int

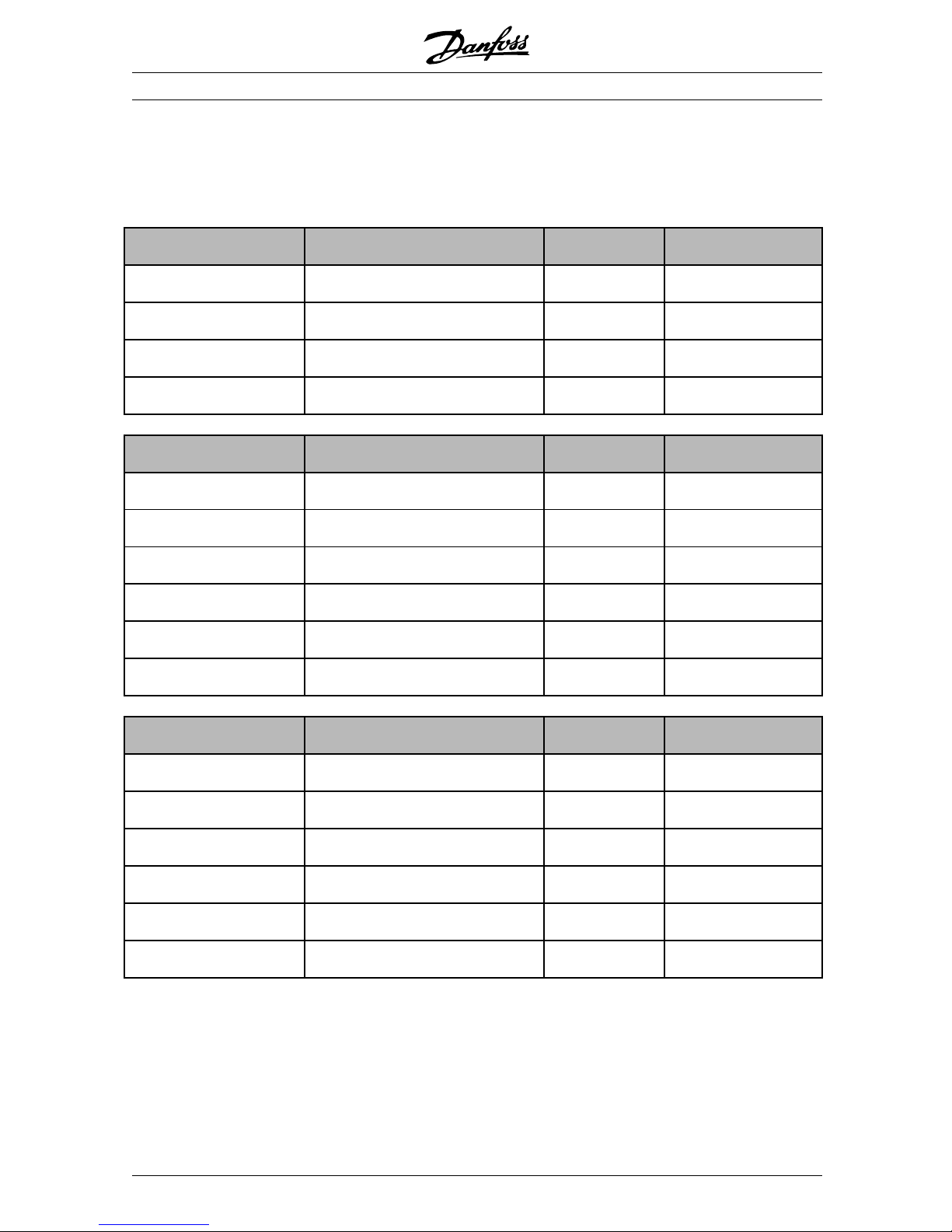

Data FCD 300/ VLT 2800 FCM 300

Control word/Main reference (part of PPO) Max. 26 msec. Max. 65 msec.

Status word/Actual output frequency (part of PPO) Max. 26 msec. Max. 65 msec.

Parameter read (PCD 1-8) 40 msec. 40 msec.

Parameter write (PCD 1-2) 160 msec. 160 msec.

Parameter write (PCD 3-4) 320 msec. 320 msec.

Parameter write (PCD 5-8) 640 msec. 640 msec.

Parameter read (PCV) 41 msec. 41 msec.

Parameter write (PCV) 40 msec. 40 msec.

Acyclical data (single read, write) - 40 msec.

■System update time

The system update time is the time it takes to

update all the slaves in the network when using

cyclical communication. The drawing below

shows the value which is obtainable in theory

at 2 input and 2 output bytes.

MG.90.A5.02 - VLT is a registered Danfoss trademark

8

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The Profibus

Interface

The Profibus Interface

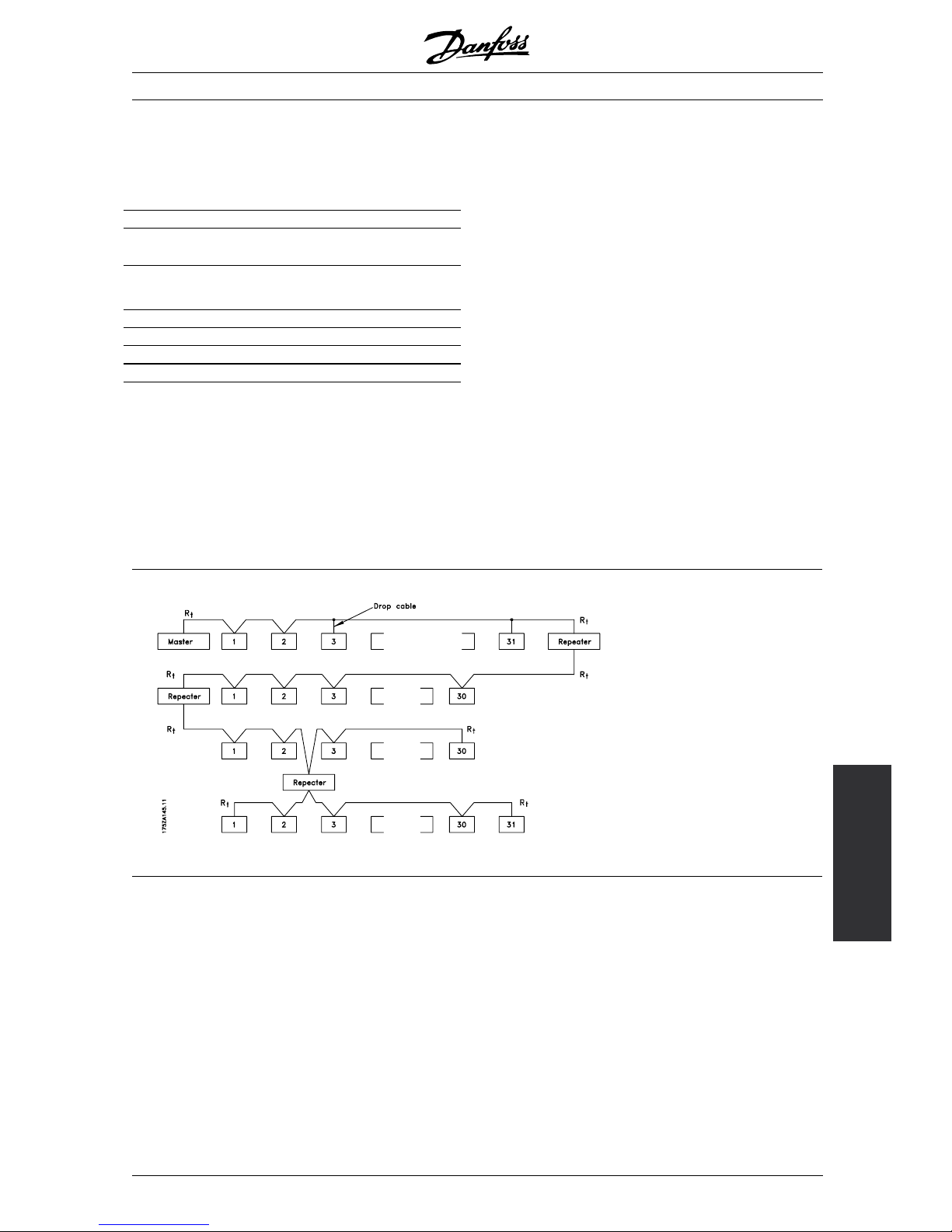

The total drop cable length for one segment is

limited as stated in the table below.

Drop cable length

Transmission speed Max. drop cable lenth

per segment [m]

9.6-93.75 kBaud 96

187.5 kBaud 75

500 kBaud 30

1.5 mBaud 10

3-12 MBaud none

The length statements in the tables above

are valid provided that bus cable with the

following properties

is used:

- Impedance: 135 to 165 ohm at a measuring

frequency from 3 to 20 MHz

- Resistance: < 110 ohm/km

- Capacity: < 30 pF/m

- Damping: max. 9 dB over the whole wire

length

- C ross section: max. 0.34 mm

2

, corresponding

to AWG 22

- Cable type: twisted in pairs,

1x2,or2x2,or1x4wires

- Screening: Copper-braided screen or

braided screen and foil screen

It is recommended to use the same cable type in the

entire network to avoid impedance mismatch.

The numbers on the following drawing indicate the

maximum number of stations in each segment. They

are not the station addresses as each station in the

network must have a unique address.

Segment 1

Segment 2

Segment 3

Segment 4

Rt= termination resistors

■Cable lengths/ number of nodes

The maximum cable length in one segment is

depending on the transmission speed. The total

cable length includes drop cables if any. A drop

cable is the connection from the main bus cable

to each node if a T-connection is used instead of

connecting the main bus cable directly to the nodes,

see drop cable ength. The table below shows the

maximum allowed cable length and maximum number

of nodes/frequency converters with 1, 2, 3 and 4 bus

segments. Note that a repeater is a node in both of the

two segments it connects. The number of frequency

converters is based on a single master system. If

there are more masters the number of frequency

converters must be reduced correspondingly.

MG.90.A5.02 - VLT is a registered Danfoss trademark

9

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

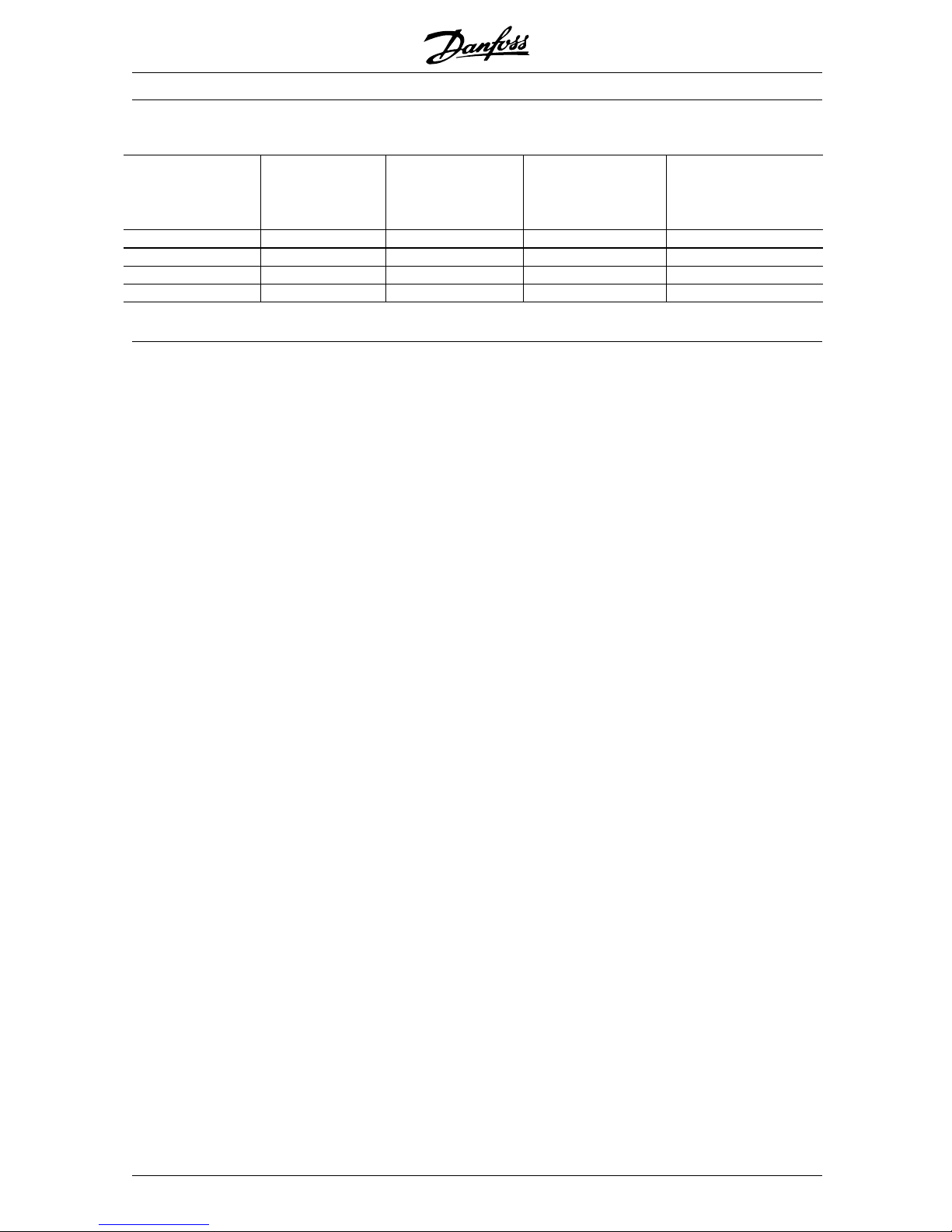

Max. total bus cable length

Transmission speed 1segment:

32 nodes

(31 VLT)

[m]

2segments:

64 nodes

(1 repeater, 61 VLT)

[m]

3segments:

96 nodes

(2 repeaters, 91 VLT)

[m]

4segments:

128 nodes

(3 repeaters, 121 VLT)

[m]

9.6-187.5 kBaud 1000 2000 3000 4000

500 kBaud 400 800 1200 1600

1.5 MBaud 200 400 600 800

3-12MBaud 100 200 300 400

MG.90.A5.02 - VLT is a registered Danfoss trademark

10

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The Profibus

Interface

■Physical connection

The PROFIBUS is connected to the bus line

via X100, terminals 1 and 2.

It is recommended to use a master with a

galvanic isolated bus driver and with over voltage

protection (e.g. zenerdiode).

E

MC precautions

The following EMC precautions are recommended to

obtain interference free operation of the PROFIBUS

network. Additional information on E MC can be found

in the design guide on the FCM 300 (MG.03.BX.02).

Please also consult the manual of the PROFIBUS

master for further installation guidelines.

■Connection of the cable screen

The screen of the PROFIBUS cable must always

be connected to ground at both ends, that means

the screen must be connected to ground in all

stations connected to the PROFIBUS network. It

is very important to have a low impedance ground

connection of the screen, also at high frequencies.This

can be obtained by connecting the surface of the

screen to ground, for example by means of a cable

clamp or a conductive cable gland.

The FCM 300 Series is provided with different clamps

and brackets to enable a proper ground connection of

the P ROFIBUS cable screen. The screen connection

is shown in the following drawing.

NB!:

Relevant national and local regulations,

for example regarding protective earth

connection, must be observe d.

■Cable connection F CM 300

The PROFIBUS communica tion cable must be kept

away from motor and brake resistor cables to avoid

coupling of high frequency noise from one cable to

the other. Normally a distance of 200 mm is sufficient,

but it is generally recommended to keep the greatest

possible distance between the cables, especially where

cables are running in parallel over long distances.

If the PROFIBUS cable has to cross a motor and

braking resistance cable, it should occur at a 90° angle.

■Earth connection

It is important that all stations connected to the

PROFIBUS network are connected to the same

earth potential. The earth connection must have

a low HF (high frequency) impedance. This c an

be achieved by connecting a large surface area of

the cabinet to earth, for example by mounting the

FC motor on a conductive rear plate.

Especially when having long distances between the

stations in a PROFIBUS network it can be necessary to

use additional potential equalizing cables, connecting

the individual stations to the same earth potential.

MG.90.A5.02 - VLT is a registered Danfoss trademark

11

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

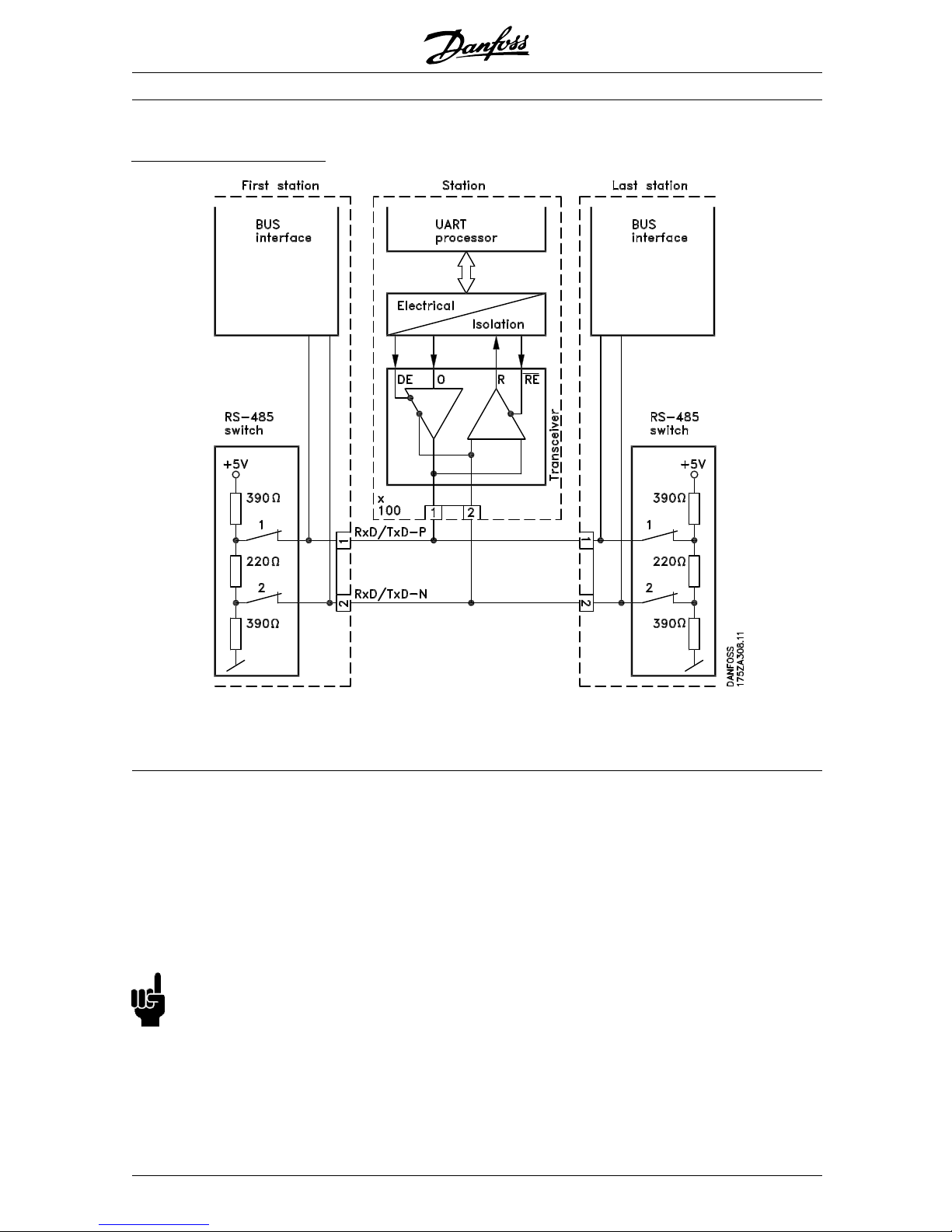

The bus termination - FCM 300

1 = RxD/TxD-P∼ (red cable) 2 = RxD/TxD-N∼ (green cable)

It is essential that the bus line is terminated properly.

A mismatch of impedance may result in reflections

onthelinethatwillcorruptdatatransmission.

- The PROFIBUS is provided with a suitable

termination which may be activated by the switches

of the RS485 switch block located just to the left of

the terminal block X100 (see drawing below). The

switches should be o n to terminate the bus.

NB!:

The switches should never be left in opposite

positions. They should either both be

ON or both be OFF!

- Most masters and repeaters are equipped

with their own termination.

- If an external termination circuit consisting of three

resistors is connected to the bus line a 5 V d.c.

power supply must be used, please note that this

must be galvanically isolated from the a.c. line.

MG.90.A5.02 - VLT is a registered Danfoss trademark

12

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The Profibus

Interface

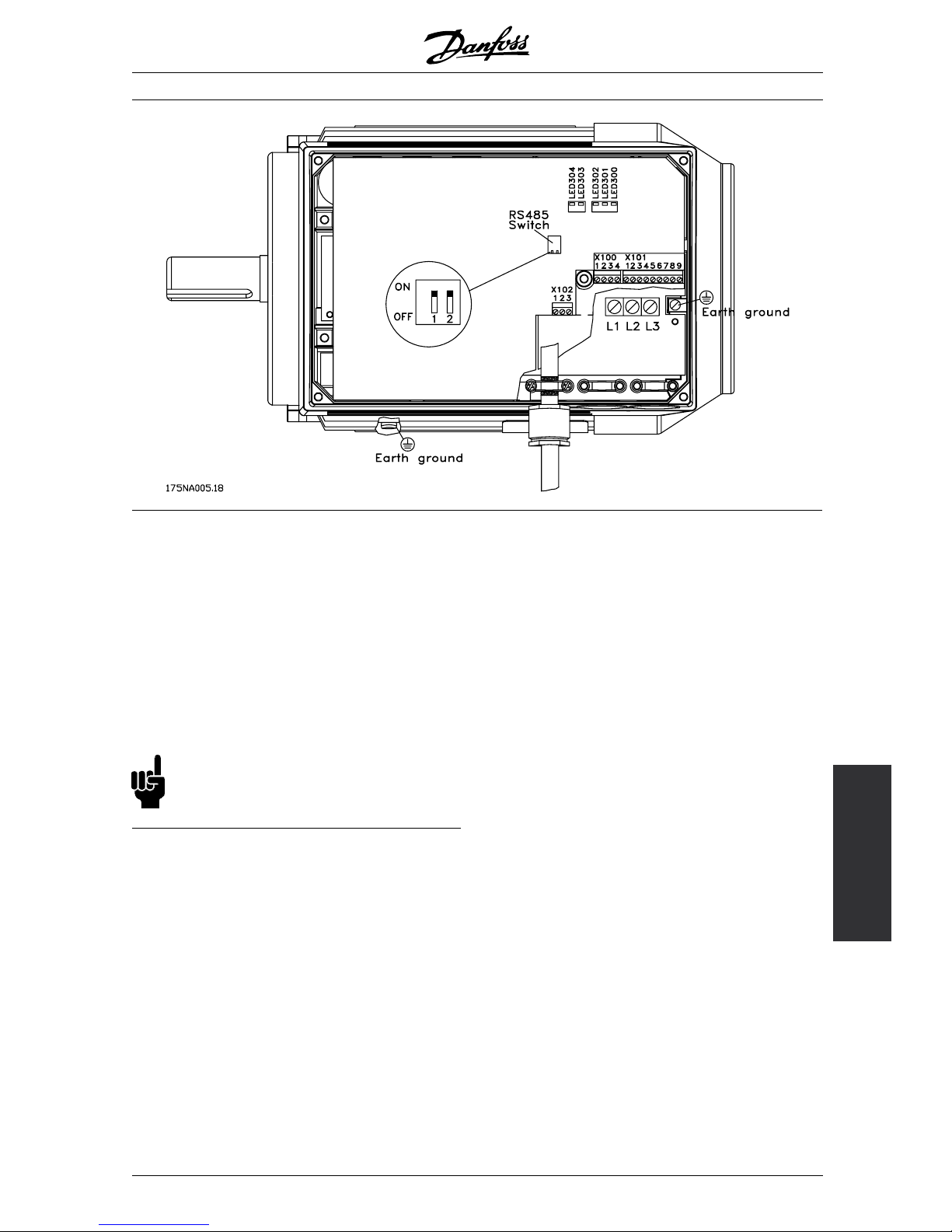

■FCM 300 LEDs

There are 2 LEDs on the PROFIBUS:

LED303: Lights up when the card is initialized

and ready to communicate. It will

flash while auto baudrate detection

is attemptin g to d etect the actual

baudrate.

LED304: Lights up when the card is

communicating, depending on

baudrate.

NB!:

A high baudrate results in dim light in LED304.

MG.90.A5.02 - VLT is a registered Danfoss trademark

13

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

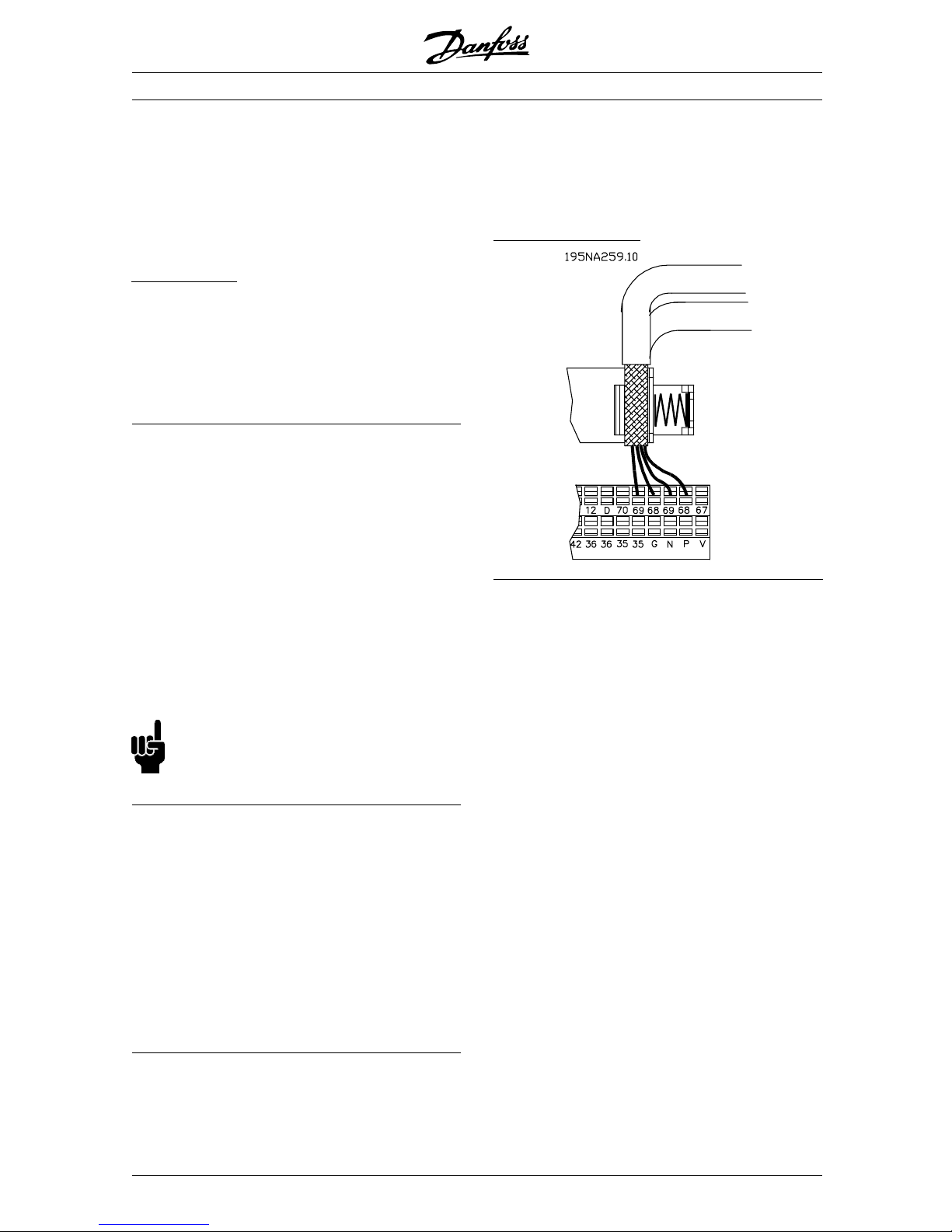

■Physical connection FCD 300

The PROFIBUS is connected to the bus line

via, terminals 68 and 69.

It is recommended to use a master with a

galvanic isolated bus driver and with over voltage

protection (e.g. zenerdiode).

E

MC precautions

The following EMC precautions are recommended to

obtain interference free operation of the PROFIBUS

network. Additional information on E MC can be found

in the design guide on the FCD 300 (MG.04.AX.02).

Please also consult the manual of the PROFIBUS

master for further installation guidelines.

■Connection of the cable screen

The screen of the PROFIBUS cable must always be

connected to ground at both ends, that means the

screen must be connected to ground in all stations

connected to the PROFIBUS network. It is very

important to have a low impedance ground connection

of the screen, also at high frequencies.This can be

obtained by connecting the surface of the screen to

ground, for example by means of a cable clamp.

The FCD 300 Series is provided with a sprin g loaded

clamp to enable a proper ground connection of the

PROFIBUS cable screen. The screen connection

is shown in the following drawing.

NB!:

Relevant national and local regulations,

for example regarding protective earth

connection, must be observe d.

■Cable connection F CD 300

The PROFIBUS communica tion cable must be kept

away from motor and brake resistor cables to avoid

coupling of high frequency noise from one cable to

the other. Normally a distance of 200 mm is sufficient,

but it is generally recommended to keep the greatest

possible distance between the cables, especially where

cables are running in parallel over long distances.

If the PROFIBUS cable has to cross a motor and

braking resistance cable, it should occur at a 90° angle.

■Earth connection FCD 300

It is important that all stations connected to the

PROFIBUS network are connected to the same

earth potential. The earth connection must have

a low HF (high frequency) impedance.

Especially when having long distances between the

stations in a PROFIBUS network it can be necessary to

use additional potential equalizing cables, connecting

the individual stations to the same earth potential.

C

onnecting the bus line

MG.90.A5.02 - VLT is a registered Danfoss trademark

14

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The Profibus

Interface

The bus termination

68 = RxD/TxD-P

∼ (red cable)

69 = RxD/TxD-N

∼ (green cable)

It is essential that the bus line be terminated properly.

A mismatch of impedance may result in reflections

onthelinethatwillcorruptdatatransmission.

- The PROFIBUS is provided with a suitable

termination which may be activated by the switches

of the RS485 switch block located on the bottom

of the electronics part (see drawing below). The

switches should be o n to terminate the bus.

- Most masters and repeaters are equipped

with their own termination.

NB!:

The switches should never be left in opposite

positions. They should either both be

ON or both be OFF!

NB!:

Is 126 or 127 selected the address is setting

via P 918, refer to chapter station address.

- If an external termination circuit consisting of three

resistors is connected to the bus line a 5 V d.c.

power supply must be used, please note that this

must be galvanically isolated from the a.c. line.

MG.90.A5.02 - VLT is a registered Danfoss trademark

15

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Switch 1 2 3 4 5 6 7 8

Address Switch s etting

0 OFF OFF OFF OFF OFF OFF OFF X

1 ON OFF OFF OFF OFF OFF OFF X

2 OFF ON OFF OFF OFF OFF OFF X

....125 ON ON ON ON ON OFF ON X

126 ON ON ON ON ON ON OFF X

127

(default)

ON ON ON ON ON ON ON X

■FCD 300 LEDs

The bus LED on the front:

LCP stop mode or

Operation site = local

Remote and bus control

Baud rate search LED is flashing LED is flashing

Baud rate found and drive is ready

to get and set cyclical data

Flashing 1.5 sec. On

Baud rate found and drive is not

set to state receive/send cyclical

data

Flashing 1.5 sec. Flashing: 2 sec. off, 320 ms on

Only acyclical communication (no

cyclical data)

Flashing 1.5 sec. Flashing: 2 sec. off, 320 ms on

In case that a cyclical communication is established,

the LED is on. If only a acyclical communication with

a master 2 is activ e the LED is flashing.

MG.90.A5.02 - VLT is a registered Danfoss trademark

16

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The Profibus

Interface

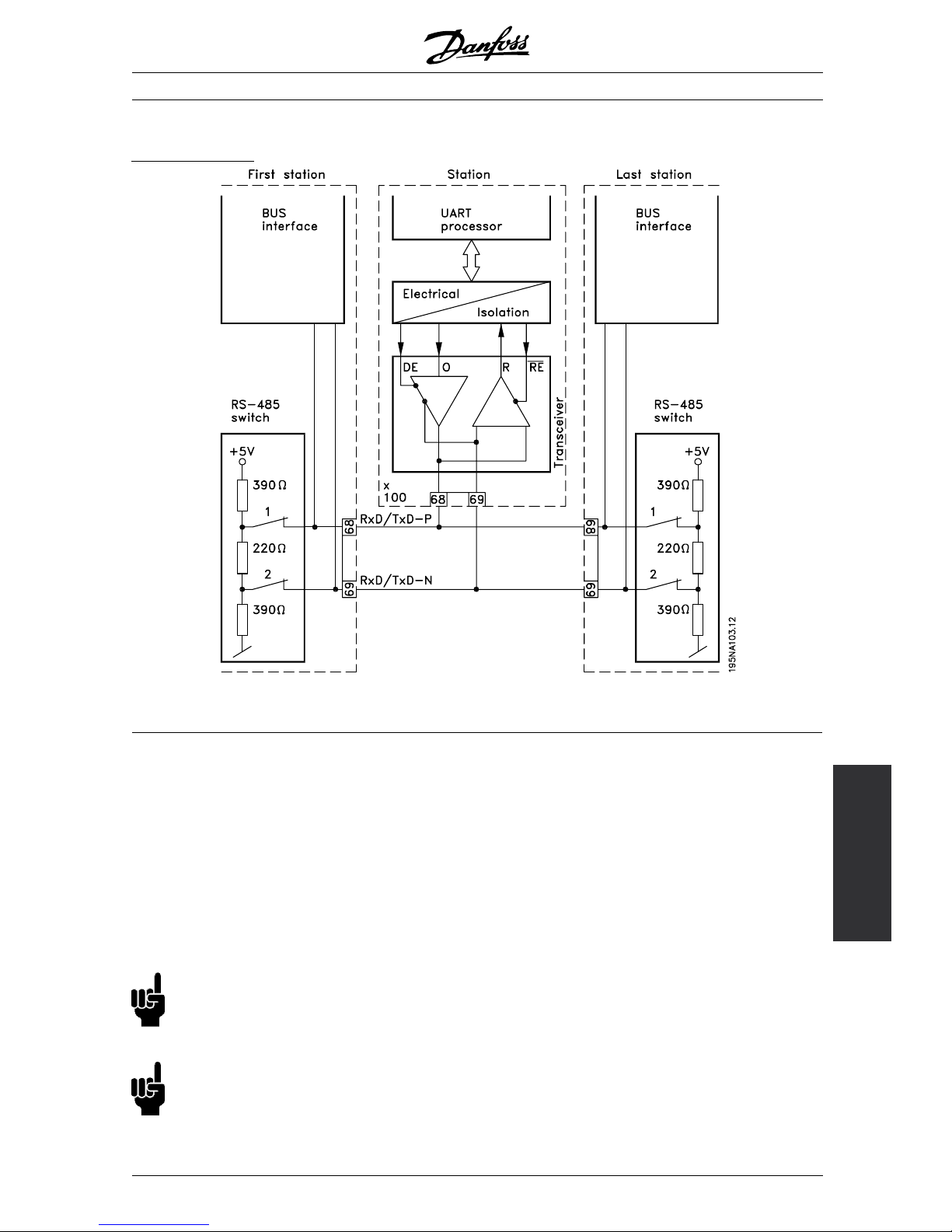

■Physical connection VLT 2800

The PROFIBUS is connected to the bus line

via, terminals 68 and 69.

It is recommended to use a master with a

galvanic isolated bus driver and with over voltage

protection (e.g. zenerdiode).

E

MC precautions

The following EMC precautions are recommended to

obtain interference free operation of the PROFIBUS

network. Additional information on E MC can be found

in the design guide on the VLT 2800 (MG.28.EX.02).

Please also consult the manual of the PROFIBUS

master for further installation guidelines.

■Connection of the cable screen

The screen of the PROFIBUS cable must always be

connected to ground at both ends, that means the

screen must be connected to ground in all stations

connected to the PROFIBUS network. It is very

important to have a low impedance ground connection

of the screen, also at high frequencies. This can be

obtained by connecting the surface of the screen to

ground, for example by means of a cable clamp.

The VLT 2800 Series is provided with different

clamps to enable a proper ground connection of the

PROFIBUS cable screen. The screen connection

is shown in the following drawing.

NB!:

Relevant national and local regulations,

for example regarding protective earth

connection, must be observe d.

■Cable connection VLT 2800

The PROFIBUS communica tion cable must be kept

away from motor and brake resistor cables to avoid

coupling of high frequency noise from one cable to

the other. Normally a distance of 200 mm is sufficient,

but it is generally recommended to keep the greatest

possible distance between the cables, especially where

cables are running in parallel over long distances.

If the PROFIBUS cable has to cross a motor and

braking resistance cable, it should occur at a 90° angle.

■Earth connection

It is important that all stations connected to the

PROFIBUS network are connected to the same

earth potential. The earth connection must have

a low HF (high frequency) impedance. This c an

be achieved by connecting a large surface area of

the cabinet to earth, for example by mounting the

VLT 2800 on a conductive rear plate.

Especially when having long distances between the

stations in a PROFIBUS network it can be necessary to

use additional potential equalizing cables, connecting

the individual stations to the same earth potential.

MG.90.A5.02 - VLT is a registered Danfoss trademark

17

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The bus termination

68 = RxD/TxD-P∼ (red cable) 69 = RxD/TxD-N∼ (green cable)

It is essential that the bus line be terminated properly.

A mismatch of impedance may result in reflections

onthelinethatwillcorruptdatatransmission.

- The PROFIBUS is provided with a suitable

termination which may be activated by the switches

of the RS485 switch block located just above the

terminal block 67-70 (see drawing below). The

switches 1 and 2 should be on to terminate the bus.

- Most masters and repeaters are equipped

with their own termination.

- If an external termination circuit consisting of three

resistors is connected to the bus line a 5 V d.c.

power supply must be used, please note that this

must be galvanically isolated from the a.c. line.

MG.90.A5.02 - VLT is a registered Danfoss trademark

18

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

The Profibus

Interface

■VLT 2800 LEDs

There are 2 LEDs on the PROFIBUS:

LD851: Lights up when the card is initialized and ready

to communicate. It will flash while auto baudrate

detection is attemp tin g to detect the ac tual baudrate .

LD852: Lights up when the card is communicating,

depending on baudrate.

NB!:

A high baudrate results in d

im light in LD852.

MG.90.A5.02 - VLT is a registered Danfoss trademark

19

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Profibus DP

■DP communication relations

Communication according to PROFIBUS DP, i.e. EN

50170 part 3, is supported. Consequently a master

that supports PROFIBUS DP must be used.

By DP communication one of the parameter-process

data objects (PPO’s) described below must be used.

■PPO description

A special feature of the PROFIBUS Profile for frequency

converters is the communication object called a PPO,

meaning Parameter-Process Data Object.

The PPO is well suited for fast cyclical data

transfer, and may, as the name implies, carry both

process data and parameters.

The selection of PPO type is made according

to the master configuration.

A PPO may consist of a parameter part and process

data part. The parameter part can be used for reading

and/or updating the parameters one by one. The

process data part consists of a fixed part (4 bytes)

and a parametrable part (8 or 16 bytes). In the fixed

part control word and speed reference are transfered

to the frequency converter while status word and

actual output frequency feedback are transfered

from the frequency converter. In the parametrable

part the user chooses which parameters ha ve to

be transfered to (parameter 915) and which from

(parameter 916) the frequency converter.

PPO. Parameter-Process Data Object

By DP one of the following shown PPO’smustbeused:

PCD: Process Da

ta

PCV: Parameter-

Characteristics-Value

PCA: Parameter-C

haracteristics (Bytes 1, 2)

(PCA handling see sec tion PCA handling)

IND: Subindex (Byte 3), (Byte 4 is not u sed)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control word see section Control word

STW: Status word see section Status word

MRV: Main reference value

MAV: Main actual value (Actual outp ut frequency)

MG.90.A5.02 - VLT is a registered Danfoss trademark

20

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Profibus

DP

■PCA handling

The PCA portion of the PPO types 1, 2 and 5

will handle a number of tasks. The master may

control and supervise parameters and request a

response from the slave, while the slave, apart

from responding to a request from the master may

transmit a s pontaneous message.

Requests and responses is a handshake procedure

and cannot be batched, m eaning that if the master

sends out a Read/write request, it has to wait for the

response, before it sends a new request. The request

or response data value will be limited to max. 4 bytes,

which implies that text strings are not transferable. For

further information, please see section Examples .

PCA - Parameters Characteristics

15 14 13 12 11 109876543210

RC SMP PNU

RC: Request /respons Characteristics (Range 0..15)

SPM: Toggle-Bit for Spontaneous Messages

PNU: Parameter # (Range 1..1999)

Request/response handling

The RC portion of the PCA word defines the

requests that may be issued from the master to

the slave as well as what other portions of the

PCV (IND and PVA) are involved.

The PVA portion will transmit word-size parameter

values in bytes 7 and 8, while long word size

valuesrequirebytes5to8(32bits).

If the R esponse / Request contains array elements,

the IND will carry the A rray Subindex. If parameter

descriptions are involved, the IND will hold the Record

Subindex of the Parameter description.

RC content

Request Function

0Norequest

1 Request parameter value

2 Change parameter value (word)

3 Change parameter value (long word)

4 Request description element

5 Change description element

6 Request parameter value (array)

7 Change parameter value (array word)

8 Change parameter value (array long word)

9 Request number of array elements

10-15 Not used

Response

Function

0Noresponse

1 Transfer parameter value (word)

2 Transfer parameter value (long word)

3 Transfer description element

4 Transfer parameter value (array word)

5 Transfer parameter value (array long word)

6 Transfer number of array elements

7 Request rejected (incl. fault #, see below)

8 Not serviceable by PCV interface

9 Spontaneous message (word)

10 Spontaneous message (long word)

11 Spontaneous message (array word)

12 Spontaneous message (array long word)

13-15 Not used

If the slave rejects a request from the master, the

RC word in the PPO-read will indicate this by

assuming the value 7. The fault # will be carried

by bytes 7 and 8 in the PVA element.

Fault # Interpretation

0 Illegal PNU

1 Parameter value cannot be changed

2 Upper or lower limit exceeded

3 Subindex corrupted

4 No array

5Datatypefalse

6 Cannot be set by user (reset only)

7 Description element cannot be changed

8 IR required PP O -write not available

9 Description data not available

10 Access group

11 No parameter write access

12 Key word missing

13 Text in cyclical transmission not readable

14 Name in cyclical transmission not readable

15 Text array n ot available

16 PPO-write missing

17 Request temporarily rejected

18 Other fault

19 Date in cyclical transmission not readable

130 There is no bus access to the parameter called

131 Data change is not possible because factory

Setup has been selected

MG.90.A5.02 - VLT is a registered Danfoss trademark

21

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Parameter and data type structure description

Parameter description

DP has a number of describing attributes (see rigth).

Read/write on parameter description is made by

the PCV part using the RC commands 4/5 and

subindex of the desired description element.

Size attribute

The size index and the conversion index for each

parameter can be taken from the parameter list in

the respective Operating Instructions.

Physical unit Size index Measuring unit Designation Conversion

index

Conversion

factor

0Nodimension

second s 0 1

-1 0.1

-2 0.01

Time 4 millisecond ms -3 0.001

minute min 70 60

hour h 74 3600

day d 77 86400

watthour Wh 0 1

Energy 8 kilowatthour kWh 3 1000

megawatthour MWh 6 10

6

milliwatt mW -3 0.001

watt W 0 1

kilowatt kW 3 1000

Power 9

megawatt MW 6 10

6

Rotation 11 rotation per minute RPM 0 1

newtonmeter Nm 0 1

Torque 16

kilonewtonmeter kNm 3 1000

Temperature 17 degree Celsius °C 0 1

millivolt mV -3 0.001

Voltage 21 volt V 0 1

kilivolt kV 3 1000

milliampere mA -3 0.001

Current 22 ampere A 0 1

kiloampere kA 3 1000

milliohm mOhm -3 0.001

Resistance 23 ohm Ohm 0 1

kiloohm kOhm 3 1000

Ratio 24 per cent % 0 1

Relative change 27 per cent % 0 1

hertz Hz 0 1

kilohertz kHz 3 1000

megahertz MHz 6 10

6

Frequency 28

gigahertz GHz 9 10

9

MG.90.A5.02 - VLT is a registered Danfoss trademark

22

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Profibus

DP

■Object and data types supported by F CM

300, FCD 300 and VLT 2800

Data types supported by FCM 300, FCD 300 and

VLT 2800

Data

type

Object

code

Short

name

Description

3 5 12 In teger 16

55 Unsigned8

6 5 O2 Unsigned 16

7 5 O4 Unsigned 32

10 5 Byte string

13 5 Time difference

1)

33 5 N2 Standardized

value (16 bit)

1)

35 5 V2 Bit sequence

1)

1)

See elaboration below

Time difference

Thedatatypetimedifferenceisatime

indication in milliseconds.

Notation: Time difference

Value range: 0

i (232-1) milliseconds

Coding: The time is presented as a binary

value of 32 bits (4 bytes). Thge

first four (MSB) bits are always

zero.

Time difference is thus a byte

string of 4 bytes.

Data coding of the data type time difference

Bit Byte 1 Byte 2 Byte 3 Byte 4

80ms223ms 215ms 27ms MSB

70ms222ms 214ms 26ms MSB

60ms221ms 213ms 25ms MSB

50ms220ms 212ms 24ms MSB

4227ms 219ms 211ms 23ms

3226ms 218ms 210ms 22ms

2225ms 217ms 29ms 21ms

1224ms 216ms 28ms 20ms

Standardized value

A liniary value.

0% = 0 (0h), 100% is 2

14

(4000h)

Data type N 2

Range -200%...2000% -2

-14

Resolution 2

-14

=0.0061%

Length 2 bytes

Notation: 2’s complement notation.

MSB is 1st bit after sign bit in 1st by te.

Sign bit = 0 = positive number

Sign bit = 1 = negative number

Bit 8 7 6 5 4 3 2 1

Byte 1 SIGN 202-12-22-32-42

-52-6

Byte 2 2-72-82-92

-102-112-122-132-14

Bit sequence

16 boolean values for control and presentation of user functions

.

Notation is binary

Bit 8 7 6 5 4 3 2 1

Byte 1 15 14 13 12 11 10 9 8

Byte 2 7 6 5 4 3 2 1 0

■Spontaneous messages

The S pontaneous message is activated by the active

parameters i.e. 538, 540, or 953 and will be carried

with the PCV response, stating PNU and PVA of the

changed active parameter that triggered the message.

Spontaneous messages are generated when the value

is changed in one of the abovementioned parameters.

It means that a message will be sent when a warning

comes, and when a warning disappears.

Simultaneously the frequency converter will toggle the

SPM bit (11) of PCA word (see section PCA handling).

The Spontaneous messages will be transmitted

until the master has acknowledged reception of

the message by changing the SPM bit.

NB!:

Spontaneous messages are only active

when parameter 917 is "ON"!

Example of SPM execution

In the frequency converter the SPMs are temporarily

stored in a FIFO buffer. This means that up to 16

consecutive SPMs can be retained. If only one SPM

has entered the FIFO, the frequency converter will

resume normal communication as soon as the SPM has

been ack nowledged by the master (and the condition

causing the SPM been rectified). If more SPMs are

in the FIFO, these will be transmitted consecutively

upon acknowledgement. If more SPMs are triggered

when the FIFO is full, these will be ignored.

MG.90.A5.02 - VLT is a registered Danfoss trademark

23

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Synchronize and freeze

The control commands SYNC/UNSYNC and

FREEZE/UNFREEZE are broadcast functions.

SYNC/UNSYNC is used to send syncronized

control commands and/or speed reference to all

the connected slaves (FCM 300/FCD 300/VLT 2800

Series). FREEZE/UNFREEZE is used to freeze the

status feedback in the slaves to get syncronized

feedback from all connected slaves.

The synchronize and freeze commands only affect

Process Data (the PCD part of the PPO).

SYNC/UNSYNC

SYNC/UNSYNC can be used to obtain simultaneous

reactions in several slaves, for exa mple synchronised

start, stop or speed change. A SYNC command

will freeze the actual control word and speed

reference, incoming Process Data will b e stored

but not used until a new SYNC command or a

UNSYNC command is received.

See the example below where the left column

holds the speed reference send out by the master

and the three right columns hold the actual speed

reference used in each of the three slaves.

Actual slave speed reference

VLT VLT VLT

From DP master to address: Address 3 Address 4 Address 5

1. Speed reference = 50% to address 3 50% 0% 0%

2. Speed reference = 50% to address 4 50% 50% 0%

3. Speed reference = 50% to address 5 50% 50% 50%

4. SYNC command to all addresses 50% 50% 50%

5. Speed reference = 75% to address 3 50% 50% 50%

6. Speed reference = 75% to address 4 50% 50% 50%

7. Speed reference = 75% to address 5 50% 50% 50%

8. SYNC command to all addresses 75% 75% 75%

9. Speed reference = 100% to address 3 75% 75% 75%

10. Speed reference = 50% to address 4 75% 75% 75%

11. Speed reference = 25% to address 5 75% 75% 75%

12. UNSYNC command to all addresses 100% 50% 25%

13. Speed reference = 0% to address 3 0% 50% 25%

14. Speed reference = 0% to address 4 0% 0% 25%

15. Speed reference = 0% to address 5 0% 0% 0%

FREEZE/UNFREEZE

FREEZE/UNFREEZE can be used to get simultaneous

reading of Process Data for example output current

from several slav

es. A FREEZE command will freeze

the current actual values and on request the slave

will send back the value that was present when

the FREEZE comm

and was received. The actual

values will be update

d when a new FREEZE or

UNFREEZE command is received.

See the example below where the left column

holds the current

values read by the master and

the three right columns hold the actual output

current of the three slaves.

Actual

slave output current

VLT VLT VLT

DP maste

r reads address:

Address

3

Address

4

Address

5

1. Addres

s 3 output current = 2 A

⇐ 2A 3A 4A

2. Address

4 output current = 5 A

2A ⇐ 5A 2 A

3. Address 5

output current = 3 A

3A 2A ⇐ 3A

4. FREEZE com

mand to all addresses

1A 3A 3A

5. Address 3 o

utput current = 1 A

⇐ 4A 2A 5A

6. Address 4 ou

tput current = 3 A

2A ⇐ 2A 2 A

7. Address 5 out

put current = 3 A

3A 1A ⇐ 2A

8. UNFREEZE comm

and to all addresses

2A 3A 4A

Reading as by 1 , 2 a

nd 3

MG.90.A5.02 - VLT is a registered Danfoss trademark

24

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Profibus

DP

■Clear Mode / Fail Safe

If the PLC/Master functions are seriously disturbed, the

DP master will go into Clear Mode. The Drive can be

programmed to react in various ways on that incident.

Theseoptionsareshowninthetablebelow.

The drives which support the DP V1 features,

basically support the Fail Safe function for Clear

Mode as stated in the GSD attribute Fail_safe = 1.

Fail Safe means, that the slaves safely detect a clear

state of the maste r. The reaction however must be

programmed as shown in the table below.

For masters, that do not support Fails Safe Clear,

the drive will have the same reaction on a clear

mode as for Fail Safe Clear.

If a Clear appears, the control word and speed

reference is set to zero in the drive. The reaction

of the drive, however depends on the setting

of parameter 805 (control word validity) and

parameter 804 (Time Out function).

P804 P805 Drive Behaviour on Clear mode

Off Bit 10 = 1, Control Word valid The drive will continue with the previous send valid

Control word and speed reference

Off Bit 10 = 0, Control Word valid The Drinve Control Word and Speed Reference will

be set to zero, which will cause the drive to stop.

Off No function: Control Word always valid The Drinve Control Word and Speed Reference will

be set to zero, which will cause the drive to stop.

<>Off Bit 10 = 1, Control Word valid The drive will continue with the previous send valid

Control word and speed reference until the timer

programmed in P 803 expires. After that the drive

will do the action programmed in P 804.

The drive leaves the Clear Reaction STate when the

master sends process data values <> 0.

NB!:

The behaviour, which is described in the first

line is the factory setting. In critical applications

a time out function can be used. In case

of clear mode, the drive is working as described

in the selection of parameter 805.

MG.90.A5.02 - VLT is a registered Danfoss trademark

25

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Control word/Status word

The bits of the "Control word" tell the frequency

converter how to react, while the "Status word"

bit status will tell the master the condition of

the frequency converter.

Control word

The control words are used to send control

commands to the frequency converter when the

telegram is sent from the master.

Control word

AccordingtoPROFIDRIVEcontrolword(par. 512=0)

Bit Bit = 0 Bit = 1

00 (LSB) OFF 1 ON 1

01 OFF 2 ON 2

02 OFF 3 ON 3

03 Motor coasting Enable

04 Quick-stop Ramp

05 Freeze output frequency Ramp enable

06 Ramp stop Start

07 No function Reset

08 Jog1OFF ON

09 Jog2OFF ON

10 Data no t valid Valid

11 No func tion Slow down

12 No function Catch-up

13 Setup select LSB

14 Setup select MSB

15 (MSB) No function Reversing

Control word

AccordingtoFCControlWord(par. 512=1)

Bit Bit = 0 Bit = 1

00 (LSB) Preset reference LSB

01 Preset reference MSB

02 DC b rake Ramp

03 Coasting Enable

04 Quick-stop Ramp

05 Freeze output Ramp enable

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data no t valid Valid

11 Relay 01 active

1)

12 DO46

2)

13 Setup select LSB

14 Setup select MSB

15 (MSB) No function Reversing

1)

FCM digital output

2)

No function for FCM 300.

The FCM 300 Design Guide (MG.03.BX.02), the

FCD 300 Design Guide (MG.04.AX.02) and the VLT

2800 Series Design Guide (MG.28.EX.02) hold a

detailed description of the control word.

MG.90.A5.02 - VLT is a registered Danfoss trademark

26

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Profibus

DP

■Status word

When the frequency converter returns the frame to the

master, the same two bytes operate as s tatus from the

frequency converter with the following functions:

Status word

AccordingtoPROFIDRIVEcontrolword(par. 512=0)

Bit Bit = 0 Bit = 1

00 (LSB) Control not ready Ready

01 VLT no t ready Ready

02 Motor coasting Enable

03 No fault Trip

04 ON 2 OFF 2

05 ON 3 OFF 3

06 Stop en ab le Start disab le

07 No w arning Warning

08 Speed ≠ ref. Speed = ref.

09 Local operation Bus control

10 Out o f range Frequency OK

11 Not running Running

12

13 Voltage OK Limit

14 Torque OK Limit

15 (MSB) No thermal warning Thermal warning

Status word

AccordingtoFCControlWord(par. 512=1)

Bit Bit = 0 Bit = 1

00 (LSB) Control not ready Ready

01 VLT no t ready Ready

02 Coasting Enable

03 No fault Trip

04 R e s e r v e d

05 R e s e r v e d

06 No trip lock Trip lock

07 No w arning Warning

08 Speed ≠ ref. Speed = ref.

09 Local operation Bus control

10 Out o f range Frequency OK

11 Not running Running

12

13 Voltage OK Above limit

14 Current OK Above limit

15 (MSB) No thermal warning Thermal warning

The FCM 300 Design Guide (MG.03.BX.02), the

FCD 300 Design Guide (MG.04.AX.02) and the VLT

2800 Series Design Guide (MG.28.EX.02) hold a

detailed description of the control word.

MG.90.A5.02 - VLT is a registered Danfoss trademark

27

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■Example

This example shows how PPO type 1 is used

for changing the ramp-up time (parameter 207)

to 10 seconds and for commanding a start

and speed reference of 50%.

Frequency converter parameter settings:

P502: serial port

P512: Fieldbus profile (Profidrive profile)

PPO. Parameter-Process Data Object

PCD: Process Data

PCV: Parameter-Characteristics-Value

PCA: Parameter-Characteristics (Bytes 1, 2)

PCA handling below

IND: Subindex (Byte 3), (Byte 4 is not used)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control w ord see section Control word

STW: Status word see section Status word

MRV: Main reference value

MAV: Main actual value

PCV

PCA - Parameters Characteristics

15 14 13 12 11 109876543210

RC SMP PNU

RC: Request /respons Characteristics (Range 0..15)

SPM: Toggle-Bit for Spontaneous Messages

PNU: Parameter # (Range 1..1999)

PCA part (byte 1-2) The RC part tells what the PCV

part must be used for. The functions available appear

from the table, see section PCA handling.

When a parameter is to be changed, choose value 2

or 3, in this example 3 is chosen, because parameter

207 covers a long word (32 bits).

SPM bit:

The function is explained in section Spontaneous

messages, in the example the function Spontaneous

Messages is not applied (parameter 917 = OFF),

therefore SPM is set for 0. PNU = Parameter number:

Parameter number is set for: 207 = CF Hex. This

means that the value of the PCA part is 30CF Hex.

IND (bytes 3-4):

Used when reading/changing parameters with

subindex, for example parameter 915. In the example

bytes 3 and 4 are set to 00 Hex.

PVA (bytes 5-8):

The data value of parameter 207 must be changed

to 10.00 seconds. The value transmitted must be

1000, because the conversion index for parameter

207 is -2, this means that the value received by

the frequency converter is divided by 100, making

the frequency converter perceive 1000 as 10.00.

Bytes 5-8 = 1000 = 03E8 Hex.

PCD

CTW according to Profidrive profile:

Control words consisting of 16 bi

ts, the meaning of

the various bits appears from the table, see section

Control word/Status word. The following bit pattern

sets all neces sary start com

mands:

0000 0100 0111 1111 = 047F Hex.*

0000 0100 0111 1110 = 047E Hex.*

0000 0100 0111 1111 = 047F Hex

.

Quickstop: 0000 0100 0110 1111 = 046F Hex.

Stop: 0000 0100 0011 1111 = 043F Hex.

* For restart after power up: Tr

ip OFF 2 and 3.

MRV:

Speed reference, the data format is "Standardized

value". 0 Hex = 0% and 4000 Hex = 100%.

In the example 2000 Hex is used corresponding to

50% of maximum frequency

(parameter 202).

The whole PPO therefore

gets the following value in Hex:

Byte Value

PCA 1 30

PCA 2 CF

IND 3 00

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 03

PCV

PVA 8 E8

CTW 9 04

CTW 10 7F

MRV 11 20

PCD

MRV 12 00

The Process data within the PCD part is acting on the

frequency converter immediately, and can be updated

from the master as quickly as possible.

MG.90.A5.02 - VLT is a registered Danfoss trademark

28

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Profibus

DP

The PCV part is a "hand shake" procedure which means

that the frequency converter has to acknowledge the

command, before a new one can be written.

- A positive response of the above example

may look like this:

Byte Value

PCA 1 20

PCA 2 CF

IND 3 00

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 03

PCV

PVA 8 E8

STW 9 0F

STW 10 07

MAV 11 20

PCD

MAV 12 00

The PCD part responds according to the state and

parametration of the frequency converter.

The PCV part responds as: PCA: As the request

telegram, but here the RC part is taken from the

response table s ee section PCA handling.In

this example RC is 2Hex, which is a confirmation

that a parameter value of the type long word

(32 bit) has been transferred.

IND is not used in this example.

PVA: 03E8Hex in the PVA part tells that the

value of the parameter in question (207) is 1000

which corresponds to 10.00.

STW: 0F07 Hex means that the motor is running

and there are no warnings or faults (for details see

Status word table in section Status word).

MAV: 2000 Hex tells that the output frequency

is 50% of max. frequency.

- A negative response may look like this:

Byte Value

PCA 1 70

PCA 2 00

IND 3 0 0

IND 4 0 0

PVA 5 00

PVA 6 00

PVA 7 00

PCV

PVA 8 02

STW 9 0F

STW 10 07

MAV 11 20

PCD

MAV 12 00

RC is 7 Hex which means that the request has been

rejected, and the fault number can be found in the PVA

part. In this case the fault number is 2 which means that

the upper or lower limit of the parame ter is exceeded.

See fault number table in section PCA handling.

MG.90.A5.02 - VLT is a registered Danfoss trademark

29

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

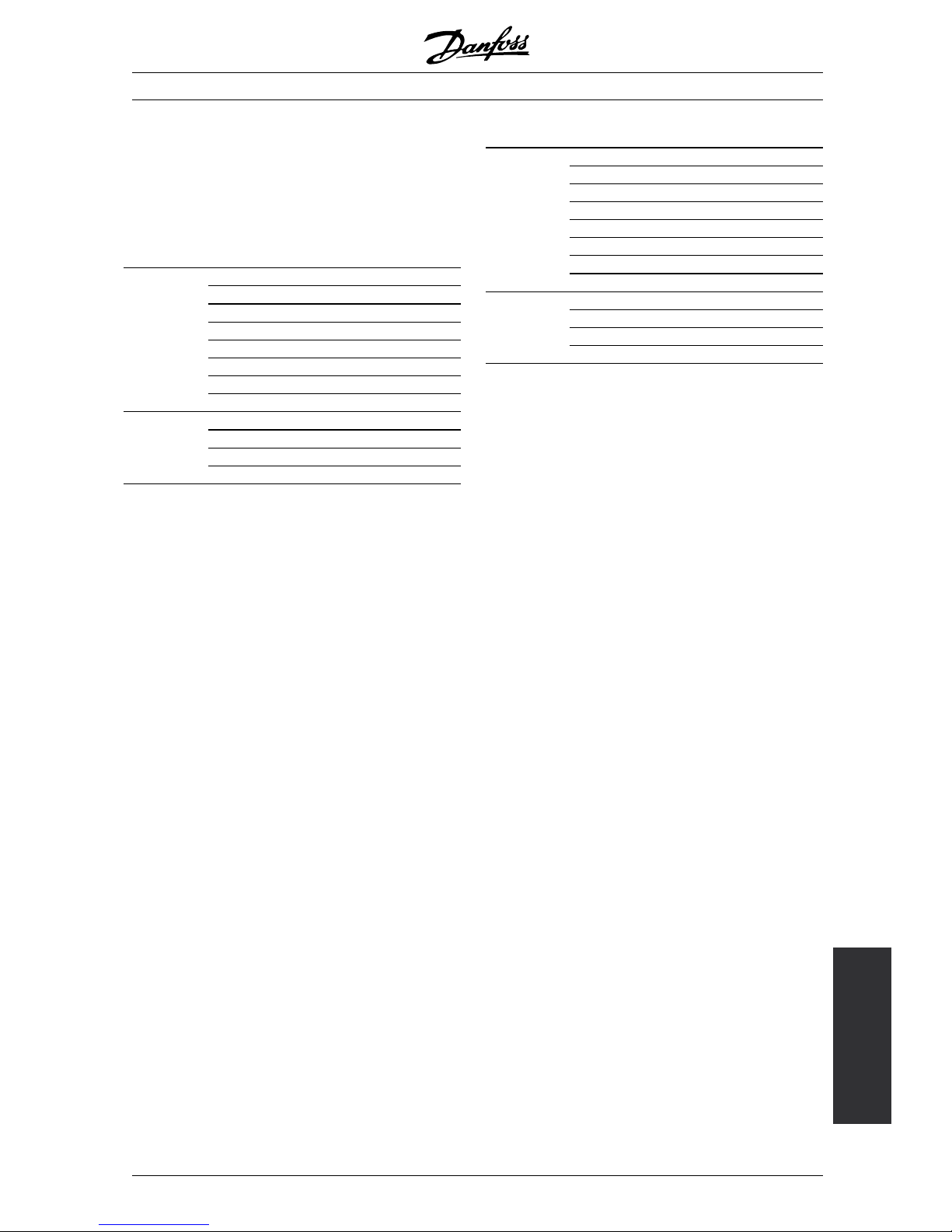

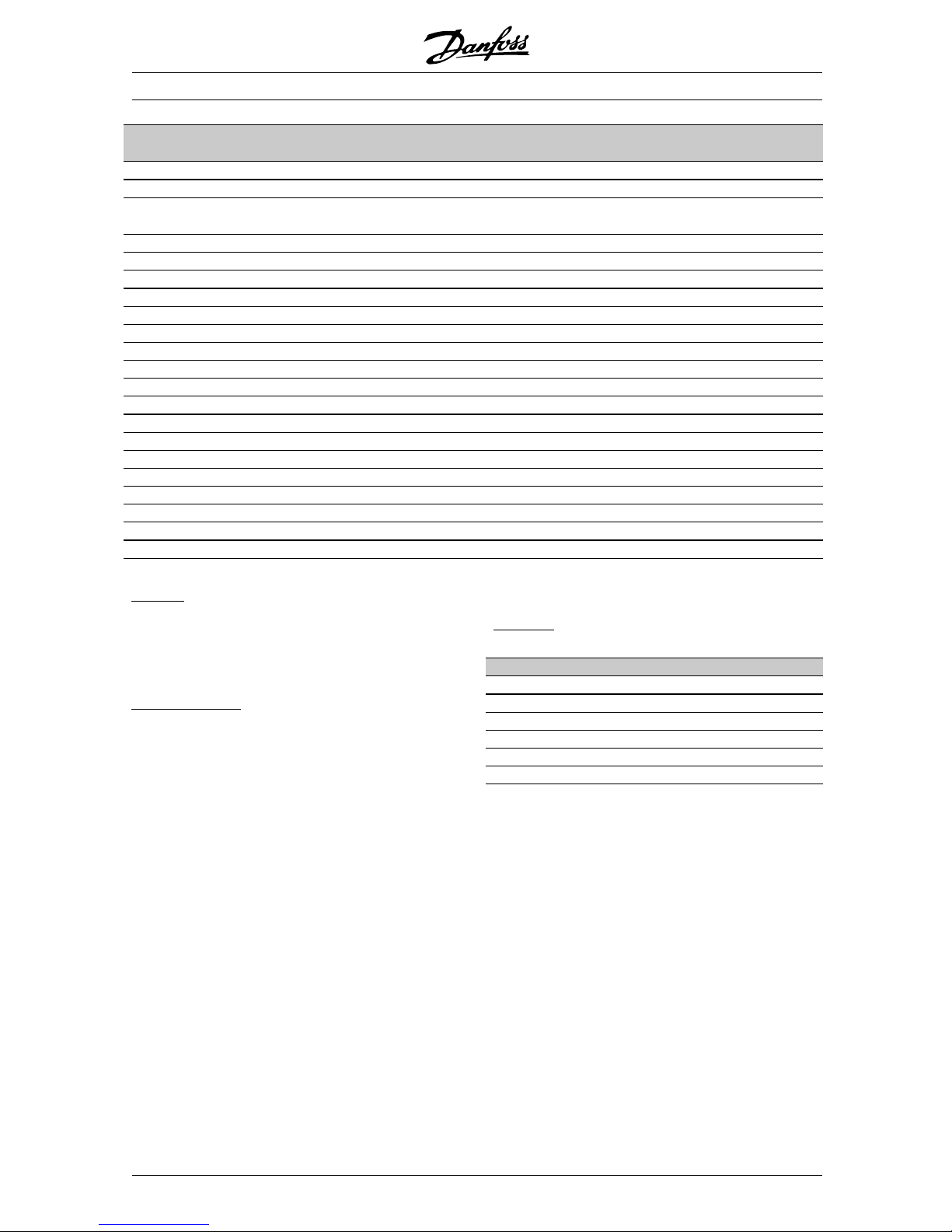

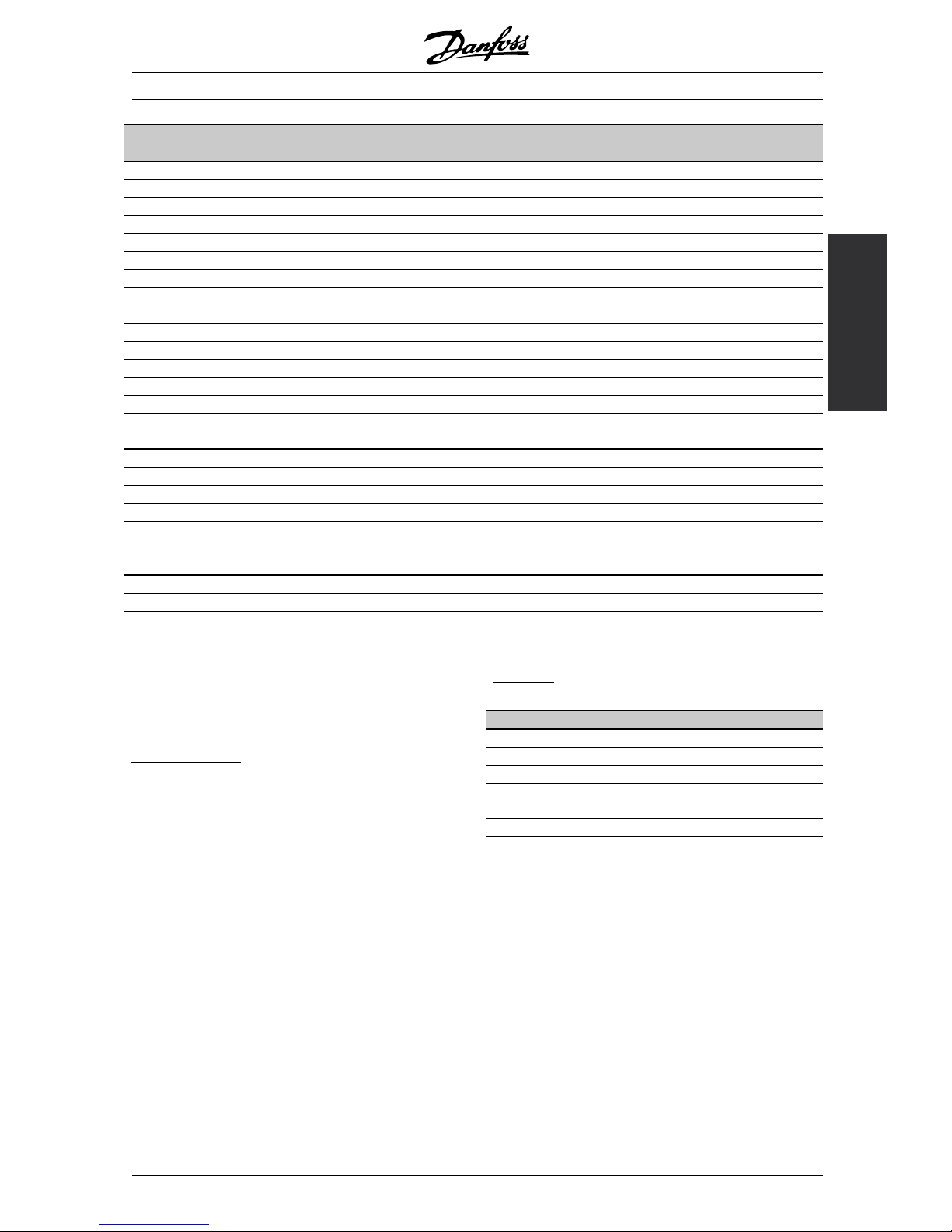

■DP V1 Identifications

The V1 functionalities require a GSD file supporting

V1. Of compatibility reasons in general the V1

versions got the same DP ident number as the

corresponding V0 version. This means, that a V1 unit

can replace a V0 unit without changing the master

configuration. The table shows the available GSD

files for FCM 300/FCD3 00/VLT 2800.

GSD files are placed on http://www.danfoss.com/drives.

GSD File Name

FCM 300

Description Ident nr. GSD revision

DA010403.GSD FCM 300 V0 3 Mbaud

(old version)

0403H 01

DA020403.GSD FCM 300 V0 3 Mbaud

(actual version)

0403H 02

DA010408.GSD FCM 300 V0 12 Mbaud

(old version)

0408H 01

DA020408.GSD FCM 300 V0 12 Mbaud

(actual version)

0408H 02

GSD File Name

FCD 300

Description Ident nr. GSD revision

DA010406.GSD FCD 300 V0 3 Mbaud

(old version)

0406H 01

DA010407.GSD FCD 300 V0 12 Mbaud

(old version)

0407H 01

DA020406.GSD FCD 300 V0 3 Mbaud

(actual version)

0406H 02

DA020407.GSD FCD 300 V0 12 Mbaud

(actual version)

0407H 02

DA030406.GSD FCD 300 V1 3 Mbaud

(actual version)

0406H 03

DA030407.GSD FCD 300 V1 12 Mbaud

(actual version)

0407H 03

GSD File Name

VLT 2800

Description Ident nr. GSD revision

DA010404.GSD VLT2800V03Mbaud

(old version)

0404H 01

DA010405.GSD VLT 2800 V0 12 Mbaud

(old version)

0405H 01

DA020404.GSD VLT2800V03Mbaud

(actual version)

0404H 02

DA020405.GSD VLT 2800 V0 12 Mbaud

(actual version)

0405H 02

DA030405.GSD VLT 2800 V1 12 Mbaud

(actual version)

0405H 03

DA030404.GSD VLT2800V13Mbaud

(actual version)

0404H 03

MG.90.A5.02 - VLT is a registered Danfoss trademark

30

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Parameters

■FCM 300, FCD 300, VLT 2800 parameters

Only the P ROFIBUS specific parameters (800 - 805

and 904 . . ) are described in this manual. All other

parameters and their functions are unaffected by

the PROFIBUS option. We refer to the parameter

description in the design guide on the FCM 300

Series (MG.03.Bx.02), the design guide on the FCD

300 (MG.04.Ax.02) and the design guide on the VLT

2800 Series (MG.28.EX.02). Please note, that some

parameters might not be active in all products.

Special attention must be given to the following

parameters that are not described in this manual:

- 502- 508: Selection of how to gate PROFIBUS

control commands with control commands on the

digital i nputs of the FCM 300/FCD 300/VLT2800.

- 512: Control word profile, selects a control

word according to profidrive or a Danfoss

specified control word.

- 515 - 543: Data readout parameters that can be

used to read various actual data from the frequency

converter, as for example actual status on the analog

and digital inputs of the FCM 300/FCD 300/VLT 2800

thus using these as inputs to the master.

MG.90.A5.02 - VLT is a registered Danfoss trademark

31

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

■PROFIBUS specific parameters

800 Protocol select

(PROTO COL SELECT)

Value:

✭PROFIBUS DP V1

[30]

Function:

Selection of the PRO FIBUS protocol supported

by the master.

Description of choice:

DP: Communication according to EN 50170, part 3

NB!:

In the event of an update of parameter 800, even

with an unchanged data value, the PROFIBUS

option is initializ ed , which means that all

communication parameters 801, 802, ..., e.g. slave

address, baud rate, PPO type etc., are being updated.

803 Bustimeout

(BUS TIME OUT)

Value:

1-99sec.

✭ 1 sec.

804 Bus time out function

(TIME OUT FUNCT.)

Value:

✭Off (OFF)

[0]

Freeze output frequency (FREEZE OUTPUT)

[1]

Stop with auto restart (STOP)

[2]

Output frequency = JOG freq. (JOGGING )

[3]

Output freq. = Max. freq. (MAX SPEED)

[4]

Stop with trip (STOP AND TRIP)

[5]

No comm. option control

(NO COMM OPT CONTROL)

[6]

Select setup 4 (SELECT SET UP 4)

[7]

Select setup 2

[8]

Function:

The time out counter is triggered at the first reception of

a valid control word i.e. bit 10 = ok, when DP is used.

The time out function can be activated in

two different ways:

1. CTW is not updated within the time specified

in parameter 803.

2. Time out is triggered if the CTW is not

valid, see p arameter 805.

The FCM 300/FCD 300/VLT 2800 remains in time out

state until one of the following conditions is true:

1. Valid control word (Bit 10 = ok) is received. If Stop

with trip is selected, reset must also be activated. If

Select setup 2 is selected, the FCM 300/FCD 300 / VLT

2800 will remain in Setup 2 until parameter 4 is changed.

2. Parame ter 804 = Off Þ control via PROFIBUS is

resumed and the most recent control word is used.

Description of choice:

- Freeze output frequency: Freeze output frequency

until communication is resumed.

- Stop with auto restart: Stop with auto restart

when communication is resumed.

- Output frequency = JOG freq.: Motor will run at

JOG frequency until communication is resumed.

- Output frequency = Max. freq.: Motor will run at

max. frequency until communication is resumed.

- Stop with trip: Motor is stopped, reset needed

for restart, see explanation above.

- No communication option control: enable the

process control via the serial port or digital input.

- Select setup 4

- Select setup 2.

805 Function of control word bit 10

(BIT 10 FUNCTION)

Value:

No function (NO FUNCTION)

[0]

✭Bit 10 = 1 CTW active

(BIT 10 = 1 CTW ACTIVE)

[1]

Bit 10 = 0 CTW active

(BIT 10 = 0 CTW ACTIVE)

[2]

Bit 10 = 0 time out (BIT 10 = 0 TIME OUT)

[3]

Function:

Control word and speed reference will be ignored if

bit 10 of the control word is 0, b ut parameter 805

lets the user change the function of bit 10. This is

some times necessary as some masters are setting

all bits to 0 in various fault situations. In these cases

it makes sense to change the function of bit 10 so

that the FCM 300/FCD 300/VLT 2800 is commanded

to stop (coast) when all bits are 0.

Description of choice:

- Bit 10 = 1

CTW active: Control word and

speed reference is ignored if bit 10 = 0.

- Bit 10 = 0

CTW active: Control word and

speed reference is ignored if bit 10 = 1. If all bits

of the control word are 0 the FCM 300/FCD 300/

VLT 2800 reaction will be coasting.

- Bit10=0

timeout: The time out function selected

in parameter 804 is activated w hen bit 10 is 0.

- No function: Bit 10 is ignored, i.e. control word

and speed reference is always valid.

MG.90.A5.02 - VLT is a registered Danfoss trademark

32

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Parameters

825 Delayed speed change delay

(SPEED CNG. DELAY)

Value:

20 - 10000 (20 m s-10 s)

✭ 500

Function:

The delay will under certain conditions (see

parameter 826) perform a fixed de lay before a

speed change will be activated.

Description of choice:

Select the wanted delay time.

The status of the timer can be read:

Timer expired: Parameter 528 Bit 7

Timer active: Parameter 528 Bit 8

826 Application control word

(APPL.CTRL.WORD)

Value:

Bus

Bit Bit = 0 Bit = 1

0Nofunction

1 No function Delayed speed change

Function:

The function will perform a precise timing of a

speed change. The speed change can also

be to set speed = 0.

Description of choice:

SettingtheACWbit1to1willfreezeany

following change of the set speed until following

conditions are fulfilled:

- Delayed speed change input (sensor)

changed from 1 to 0

- Delayed speed change delay time is expired

Delayed speed change input:

FCM300 terminal 5, parameter 335 set to (Delayed

speed change) (23) FCD300/VLT 2800 terminal 33,

parameter 307 set to (Delayed s peed change) (26)

TheACWbit1mustberesetandsetbeforethenext

delayed speed change can be initiated.

833 Fieldbus enabled

(FIELDBUS ENABLED)

Value:

Disable (DISABLE)

[0]

✭Enable (ENABLE)

[1]

Function:

This function allows to disable the communication interface.

Description of choice:

If Disable[0] is selected no communication warning will

appear, since the communication interface is d isabled.

Select Enable [1] to activate the communication.

NB!:

Please note that a change in this parameter

will not be executed until the next power

up has been carried through.

849 Extend Diagnosis

(EXTEND DIAGNOSIS)

Value:

✭Disable (DISABLE)

[0]

Alarms (ALARMS)

[1]

Alarm and Warnings (ALARM AND WARNINGS)

[2]

Function:

This function allows to expand the diagnosis data

to 24 Byte, if this parameter is set to Alarm [1]

and Alarm and Warning [2].

Description of choice:

Please refer to the section Extend diagnosis

in this manual.

MG.90.A5.02 - VLT is a registered Danfoss trademark

33

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

904 PPO type select for DP

(PPO TYPE SELECT)

Value:

✭PPO type 1 (PPO TYPE 1)

[900]

PPO type 2 (PPO TYPE 2)

[901]

PPO type 3 (PPO TYPE 3)

[902]

PPO type 4 (PPO TYPE 4)

[903]

PPO type 5 (PPO TYPE 5)

[905]

PPO type 6 (PPO TYPE 6)

[906]

PPO type 7 (PPO TYPE 7)

[907]

PPO type 8 (PPO TYPE 8)

[908]

Function:

Read out of PPO type set by the master.

Description of choice:

- PPO type 1: 12 byte PPO with parameter

channel for read and write of parameters and 4

bytes of process data (control/status word and

reference/actual output frequency).

- PPO type 2: 20 byte PPO as PPO type 1 with 8

additional bytes of selectable process data.

- PPO type 3: 4 byte process data (control/status

word and reference/actual output frequency).

- PPO type 4: 12 byte process data, as process

data part of PPO type 2.

- PPO type 5: 28 byte as PPO type 2 with 8

additional bytes of selectable process data.

- PPO type 6: control/status word and

reference/actual output frequency and additional

4 byte process data.

- PPO type 7: control/status word and

reference/actual output frequency and additional

12 byte process data.

- PPO type 8: control/status word and

reference/actual output frequency and additional

16 byte process data.

A detailed description of the PPO types can be

found in section PPO description.

915 PCD config. write

(PCD IN WR-)

Value:

Sub index 1 (PCD 3)

[Parameter #]

Sub index 2

[Parameter #]

Sub index 3

[Parameter #]

Sub index 4

[Parameter #]

Sub index 5

[Parameter #]

Sub index 6

[Parameter #]

Sub index 7

[Parameter #]

Sub index 8

[Parameter #]

Function:

Different parameters m ay be assigned to the PCD 3-10

of the PPOs (the max.number of the PCD depends on

the PPO type). The values in PCD 3-10 are written to

the selected parameters in form of data values.

Write access to parameter 915 via Profibus or

standard RS 485 or LCP2.

Description of choice:

The s equence of the sub-indexes corresponds to the

sequence of the PCD in the PPO, i.e. sub-index 1 =

PCD 3, sub-index 2 = PCD 4 etc. Each sub-index

may contain the number of any frequency converter

parameter that can be written to. Each PCD is defined

as a word. If data should be written to a parameter

that has an attribute of Integer 32 or Unsigned 32

the parameter number should be defined twice in

the following PCD’s: PCD 3 and 4, PCD 5 and 6,

PCD 7 and 8 or PCD 9 and 10. See example by

parameter 916 PCD config. Read.

NB!:

First the odd subindex must be written.

Otherwise the data will be interpreted

as 2 low words.

916 PCD config. read

(PCD IN RD-)

Value:

Sub index 1 (PCD 3)

[Parameter #]

Sub index 2

[Parameter #]

Sub index 3

[Parameter #]

Sub index 4

[Parameter #]

Sub index 5

[Parameter #]

Sub index 6

[Parameter #]

Sub index 7

[Parameter #]

Sub index 8

[Parameter #]

Function:

Different parameters m ay be assigned to the PCD 3-10

of the PPOs (the max.number of the PCD depends on

the PPO type). The values in PCD 3-10 are read from

the selected parameters in form of data values.

Write access to parameter 916 via Profibus or

standard RS 485 or LCP2.

Description of choice:

The s equence of the sub-indexes corresponds to the

sequence of the PCD in the PPO, i.e. sub-index 1 =

PCD 3, sub-index 2 = PCD 4 etc. Each sub-index

may contain the number of any VLT parameter.

MG.90.A5.02 - VLT is a registered Danfoss trademark

34

FCM 300 / FCD 300 / VLT®2800 / DP V1 PROFIBUS

Parameters

Each PCD is defined as a word. If data should be

read from a parameter that has an attribute of Integer

32 or Unsigned 32 the parameter should be defined

twice in the following PCD’s: PCD 3 and 4, PCD 5

and6,PCD7and8orPCD9and10.

NB!:

The odd subindex must be written first.

Otherwise the data will be interpreted

as 2 low words.1

Example PPO type 6:

PCD 1 CTW/STW

PCD 2 MRV/MAV

PCD 3 Par 515

PCD 4 Par 518

PCD 5 Par 520 High word

PCD 6 Par 520 Low word

PCD 7 Par 538 High word

PCD 8 Par 538 Low word

CTW/STW = Control word / Status word = 16 bit

MRV/MAV = Main Reference Value / Main Actual Value = 16 bit

Par 515 Data readout: Reference % = Datatype 3=>Integer 16

Par 518 data readout: Frequency = Datatype 3 => Integer 16

Par 520 Data readout= Motor current =Datatype 7 =>Unsigned

32

Par 538 Data readout: Alarm Word = Datatype 7 => Unsigned

32

917 Active spontaneous messages

(SPONT. M ES)

Value:

✭Off (OFF)

[0]

On (ON)

[1]

Function:

The spontaneous messages function can be

switched on if it is desired to mak e the FCM

300/FCD 300/VLT 2800 issue a message when

a warning or an alarm comes up.

NB!:

Unread spontaneous messages will be stored

in a 16 elements FIFO buffer.

Description of choice:

- OFF: The FCM 300/FCD 300/VLT 2800 will not

issue spontane ous messages or event notification

in case of a warning or an alarm.

- ON: The FCM 300/FCD 300/VLT 2800 will

issue a spontaneous message when warnings

or alarms are coming up.

918 Station address

(STATION ADD R)

Value:

0-125

✭126

Function:

All stations connected to the same bus must

have a unique address. The station address

can be set in parameter 918.

NB!:

A change in parameter 918 is executed

at next power up or if parameter 800 is

updated. Please see section S tation address

in this manual for further information.

927 PCV Operating authority

(PARAMETER EDIT)

Value:

Disable (DISABLE)

[0]

✭Enable (ENABLE)

[1]

Function:

The parameter channel PCV can be blocked m eaning

that the modification of parameters through this

channel is not possible. Access through standard

RS 485 interface is still possible.

Description of choice:

If Disable[0] is selected, parameter processing through

Profibus is not active. If Enable [1] is selected,