Page 1

Technical Information

PLUS+1® Mobile Machine Displays

DP7XX Series

www.danfoss.com

Page 2

Technical Information

DP7XX Series Displays

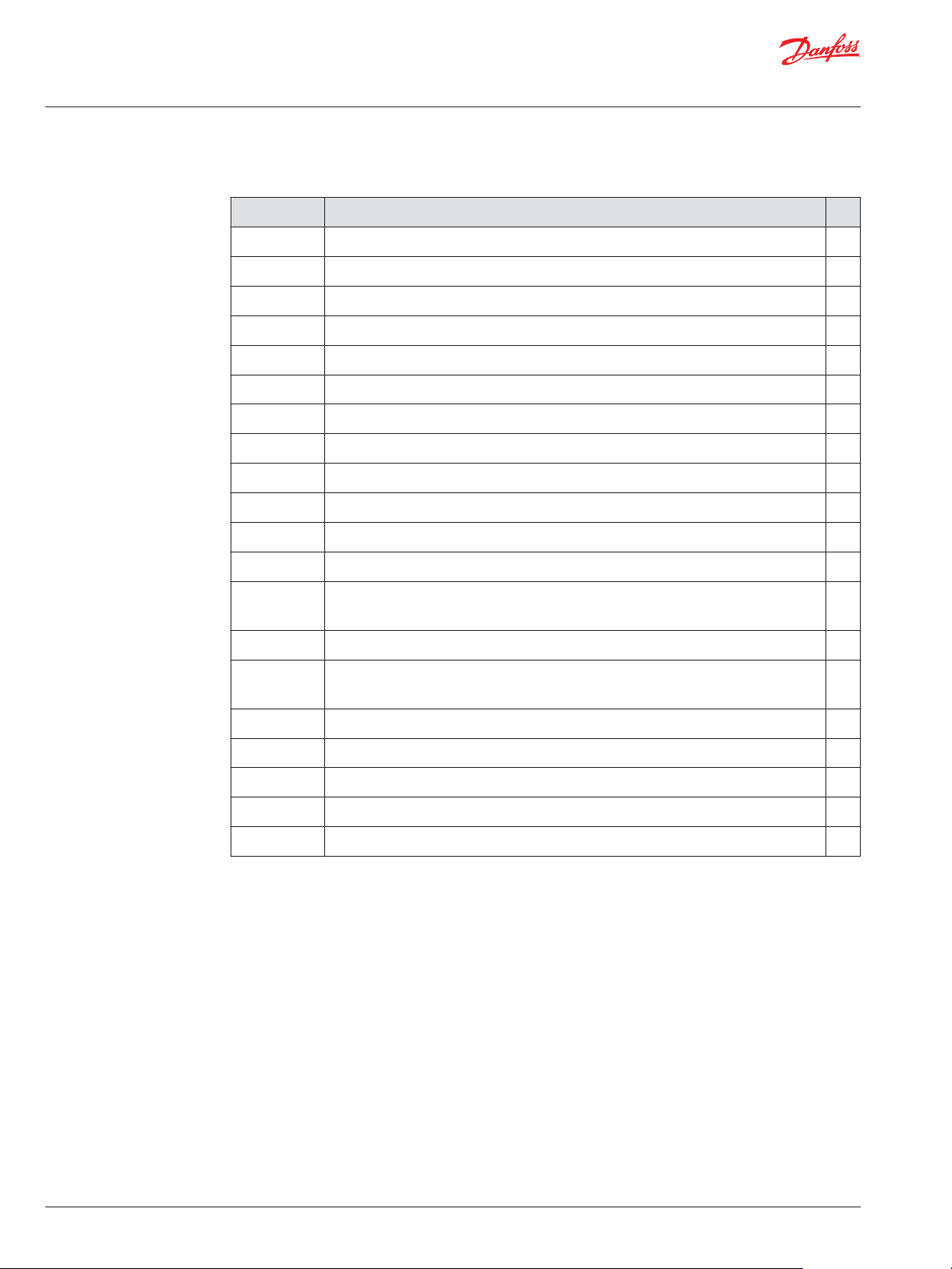

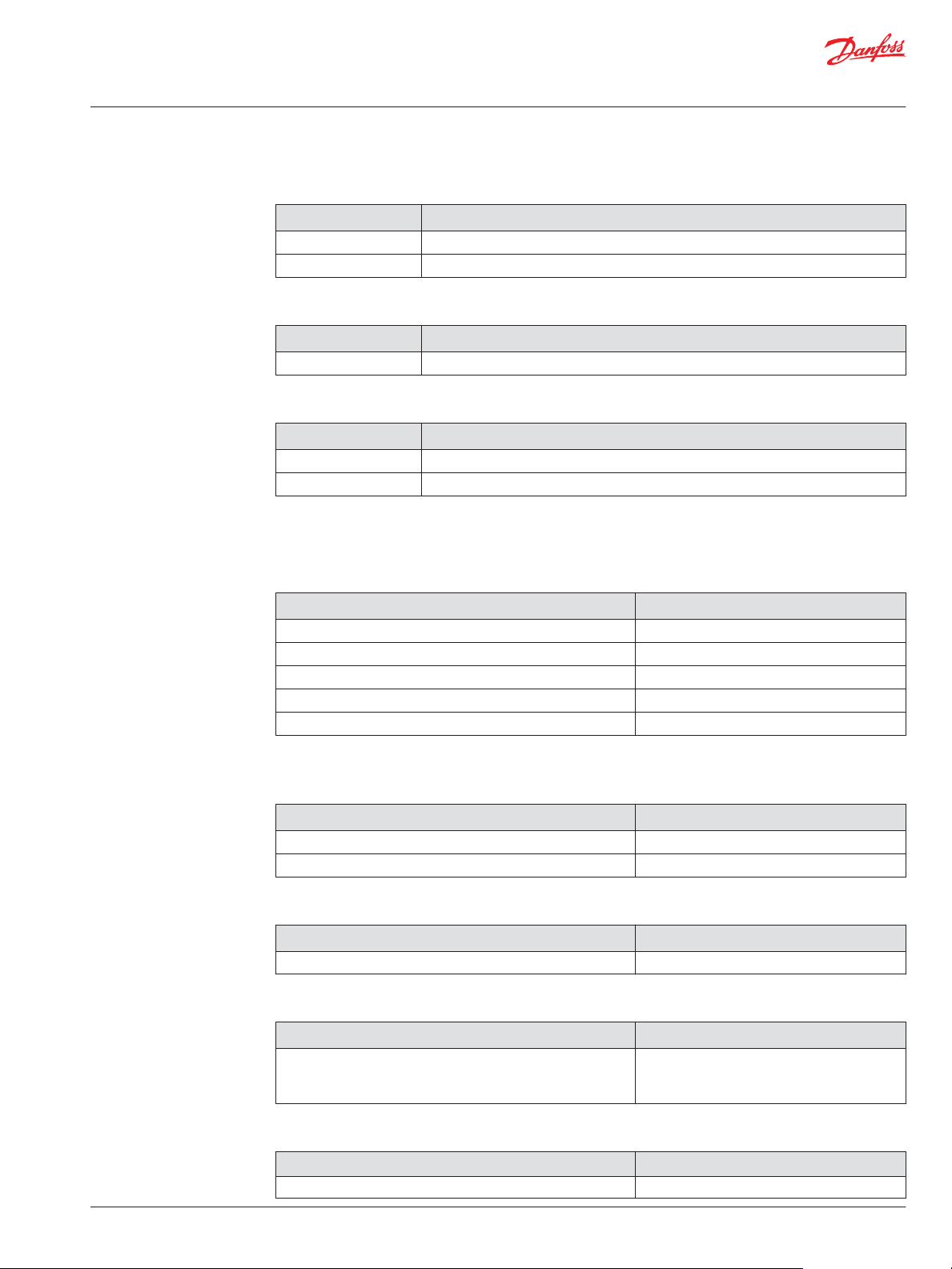

Revision history Table of revisions

Date Changed Rev

August 2020 Some test results updated, naming conventions updated 0901

January 2019 Removed references to obsoleted display 0802

August 2018 Changed the Pin assignments drawings and tables 0801

May 2018 Inputs Digital/analog, High range multifunction input table, Range unit changed to V 0703

March 2018 Added text to Flush mounting option drawing 0702

February 2018 Added Service Parts and included USB replacement kit 0701

December 2017 Filled in function of C3-P3 pin 0602

January 2017 Added topic: High range input impedance for analog inputs 0601

November 2016 Minor update 0504

March 2016 Corrected literature number 0503

Changed document number from 'BC00000223' and 'L1315553' to 'BC152986485519' XX

March 2016 Updated to Engineering Tomorrow Design 0502

February 2016 DP7XX overview text changes; Linux® operating system text changes; Updated flush

mounting option drawing with new bracket displayed

October 2015 Added the DP730 series information EA

November 2014 Added DP720 LCD statement; Corrected Pin Assignments callouts on image of back of

Display

March 2014 Changed note to warning DB

December 2013 LCD option table added, changed Panel Mounting Kit part number DA

October 2013 Various CA

July 2013 Added section BA

May 2013 First edition AA

0501

DC

2 |

Danfoss | August 2020 BC152986485519en-000901

Page 3

Technical Information

DP7XX Series Displays

Contents

Literature references

DP7XX reference literature........................................................................................................................................................... 5

Technical Information (TI)........................................................................................................................................................ 5

Data Sheet (DS)............................................................................................................................................................................ 5

API Specifications (API)............................................................................................................................................................. 5

®

PLUS+1

Latest version of technical literature....................................................................................................................................5

User liability and safety statements

OEM responsibility........................................................................................................................................................................... 6

Overview

DP7XX Series Displays.....................................................................................................................................................................7

Display options............................................................................................................................................................................ 7

PLUS+1

Linux

Ordering information

DP7XX naming convention.......................................................................................................................................................... 8

Related products...............................................................................................................................................................................9

Connector bag assemblies...................................................................................................................................................... 9

Connection tools.........................................................................................................................................................................9

Mounting kit................................................................................................................................................................................. 9

Software..........................................................................................................................................................................................9

Service Parts..................................................................................................................................................................................9

Inputs/outputs

Inputs..................................................................................................................................................................................................10

Digital/analog............................................................................................................................................................................ 10

Multifunction..............................................................................................................................................................................12

Encoder........................................................................................................................................................................................ 13

Outputs..............................................................................................................................................................................................13

Digital output.............................................................................................................................................................................13

USB.................................................................................................................................................................................................13

Video............................................................................................................................................................................................. 14

Real Time Clock (RTC)..............................................................................................................................................................14

Controller Area Network (CAN) specifications

CAN shield/analog inputs........................................................................................................................................................... 15

Analog input...............................................................................................................................................................................15

CAN communication.....................................................................................................................................................................15

Gateway channels..........................................................................................................................................................................15

Memory

NV memory...................................................................................................................................................................................... 17

FRAM Memory........................................................................................................................................................................... 17

Vault Memory.............................................................................................................................................................................17

Product ratings

Electrical............................................................................................................................................................................................ 18

Environmental.................................................................................................................................................................................18

Testing criteria.................................................................................................................................................................................19

Maintenance guidelines

LCD module .................................................................................................................................................................................... 20

LCD press and hold feature........................................................................................................................................................20

Installation

DP700, DP710, DP720 dimensions.......................................................................................................................................... 21

DP730 dimensions.........................................................................................................................................................................22

Two mounting options................................................................................................................................................................ 23

Flush mounting option...........................................................................................................................................................23

GUIDE User Manual.................................................................................................................................................. 5

®

GUIDE............................................................................................................................................................................ 7

®

operating system...........................................................................................................................................................7

High range input impedance for analog inputs...................................................................................................... 11

Danfoss | August 2020 BC152986485519en-000901 | 3

Page 4

Technical Information

DP7XX Series Displays

Contents

Stand-alone on post mounting option.............................................................................................................................23

DP700, DP710, DP720 connectors pin assignments......................................................................................................... 24

DP730 connectors pin assignments........................................................................................................................................25

Machine wiring guidelines......................................................................................................................................................... 26

Machine welding guidelines......................................................................................................................................................26

4 |

Danfoss | August 2020 BC152986485519en-000901

Page 5

Technical Information

DP7XX Series Displays

Literature references

DP7XX reference literature

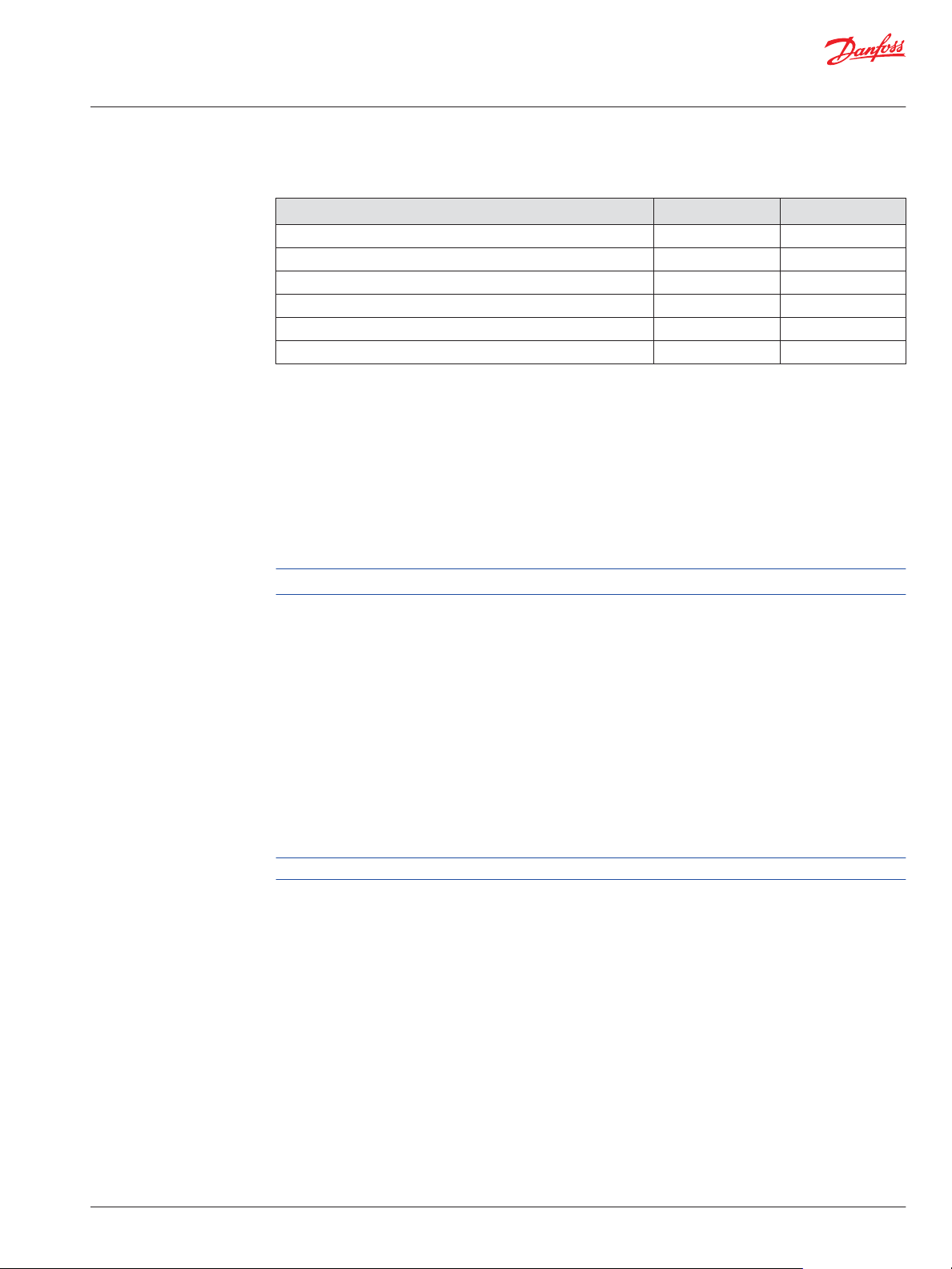

Literature title Literature type Literature number

DP7XX Series PLUS+1

DP700 Series PLUS+1

DP710 Series PLUS+1

DP720 Series PLUS+1

DP730 Series (black and gray bezel) PLUS+1

®

GUIDE Software User Manual

PLUS+1

®

Mobile Machine Displays

®

Mobile Machine Displays

®

Mobile Machine Displays

®

Mobile Machine Displays

®

Mobile Machine Displays

Technical Information BC152986485519

Data Sheet L1205618

Data Sheet L1205246

Data Sheet L1205154

Data Sheet AI174886484297

Operation Manual AQ152886483724

Technical Information (TI)

A TI is comprehensive information for engineering and service personnel to reference.

Data Sheet (DS)

A DS is summarized information and parameters that are unique to a specific model.

API Specifications (API)

An API is specifications for programming variable settings.

API specifications are the definitive source of information regarding pin characteristics.

PLUS+1® GUIDE User Manual

®

The Operation Manual (OM) details information regarding the PLUS+1

®

applications. This OM covers the following broad topics:

+1

How to use the PLUS+1® GUIDE graphical application development tool to create machine

•

GUIDE tool used in building PLUS

applications

How to configure module input and output parameters

•

How to download PLUS+1® GUIDE applications to target PLUS+1® hardware modules

•

How to upload and download tuning parameters

•

How to use the PLUS+1® Service Tool

•

Latest version of technical literature

Comprehensive technical literature is online at www.danfoss.com

Danfoss | August 2020 BC152986485519en-000901 | 5

Page 6

Technical Information

DP7XX Series Displays

User liability and safety statements

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

•

equipment.

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

•

system being programmed in a manner that jeopardizes safety.

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

•

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

6 |

Danfoss | August 2020 BC152986485519en-000901

Page 7

Technical Information

DP7XX Series Displays

Overview

PLUS+1® Mobile Machine Displays are designed to provide flexible, expandable, powerful and cost

effective total machine management system displays for a wide variety of vehicle applications.

DP7XX Series Displays

DP7XX Series Displays are designed to perform in the most extreme mobile machine environments. The

latest technology with back-light provides outstanding brightness and contrast performance resulting in

an easy-to-read screen. Develop your own software and layout using the PLUS+1

Integrated Development Environment) and the GUIDE Vector Based Screen Editor (VBSE). A basic graphic

library is available.

Display options

The DP7XX offers different display options to meet your application needs. An optional projective

capacitive touch screen that works through mud, water and with gloves is available for the DP720 model.

The DP730 model is equipped by default with the projective capacitive touch screen.

LCD options

LCD option Type Contrast Brightness

Wide View Transmissive In-Plane

*

Viewing angle: Up, Down, Right, Left

Switching (IPS)

1000:1 >800 88°, 89°, 89°, 89° In and out of cab

(cd/m2)

Viewing angle

®

GUIDE (Graphical User

*

For application use

PLUS+1® GUIDE

®

PLUS+1

generates downloadable applications for all programmable PLUS+1

GUIDE (Graphical User Integrated Development Environment) is a complete toolbox that

®

Compliant products.

A screen editor allows easy development of applications by programmers without formal software

development training. The expertise from a software engineer is not needed to find your way around in

®

PLUS+1

Linux

DP7XX Series Displays contain embedded Linux

GUIDE

®

operating system

®

operating system software that is copyrighted software

licensed under the GPL Version 2.0 or LGPL Version 2.1.

®

Linux

operating system software is free software; you can redistribute it and/or modify it under the terms

of the GNU General Public License as published by the Free Software Foundation; Licenses full notice

available:

GPL Version 2.0 http://www.gnu.org/licenses/old-licenses/gpl-2.0.html

LGPL Version 2.1 http://www.gnu.org/licenses/old-licenses/lgpl-2.1.html

As an installer of Linux

®

operating system you will have your own obligations under the licensing

agreements, which may include among other things the obligation to include a copy of these licenses or

to include an offer of a physical copy of the source code for such software with your distributions of the

equipment. You should carefully review the licenses to determine what your obligations and options may

be for your intended use.

Anyone in receipt of this program may obtain the complete corresponding source code from Danfoss for

a period of three years after the last shipment of this product and/or spare parts by going on line at

http://www.danfoss.com or include “source code for DP7XX” in your written request to:

®

PLUS+1

Helpdesk Danfoss (US) Company, 3500 Annapolis Lane North Plymouth, MN 55447 USA

Danfoss | August 2020 BC152986485519en-000901 | 7

Page 8

A DCB E F G

P200152

DP7

Technical Information

DP7XX Series Displays

Ordering information

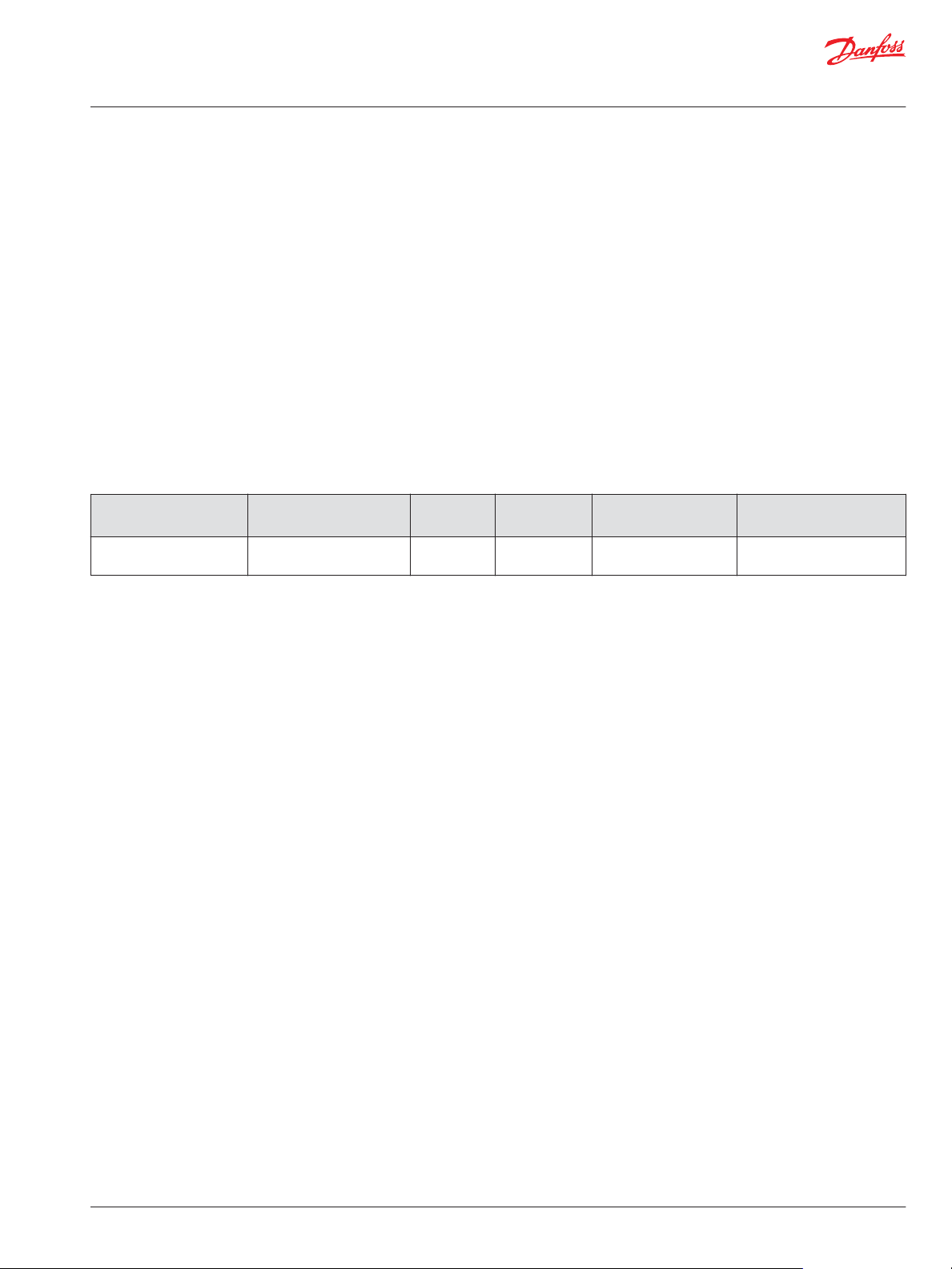

DP7XX naming convention

DP7XX model code

This is not a variant configurator.

Product configuration model code

A B C D E F G H Part

DP700

DP710 04 01 02 02 04 01 -- 11264353

DP720 04 02 02 02 04 01 -- 11264358

DP730 04 02 02 02 02 01 00 11264362

DP730 04 02 02 02 02 01 01 11264363

04 01 01 02 04 01 -- 11264179

number

A—Model name

Code Description

DP700 PLUS+1

DP710

DP720

DP730

®

Mobile Machine Displays

B—LCD options

Code

04 Transmissive In-Plane Switching

Description

C—Touch screen options

Code Description

01 None

02 Projective Capacitive touch

D—Input/output options

Code Description

01 User configurable

02 User configurable

1 CAN, 2 AIN/DIN, 2 DIN/AIN/FreqIN/Rheo/4-20 mA IN, DOUT

2 CAN, 2 DIN/AIN/FreqIN/Rheo/4-20 mA IN, DOUT

1 CAN, 2 AIN/DIN, 2 DIN/AIN/FreqIN/Rheo/4-20 mA IN, 2 Video IN, DOUT

2 CAN, 2 DIN/AIN/FreqIN/Rheo/4-20 mA IN, 2 Video IN, DOUT

E—Flash memory/application key

Code Description

02 512 MB/without application key

8 |

Danfoss | August 2020 BC152986485519en-000901

Page 9

Technical Information

DP7XX Series Displays

Ordering information

Related products

F—USB port type

Code Description

04 USB device rear/USB host rear or front

02 USB device rear/USB host rear

G—Application log (vault memory)

Code Description

01 16 MB

H—Bezel color

Code Description

00 Black

01 Gray

Connector bag assemblies

Description Part numbers

12-pin connector kit (16 to 20 AWG) 10102025

12-pin connector kit (20 to 24 AWG) 10100944

Mating connector kit with camera cable

USB cable (device only) 11130518

USB cable (device and host) 11130519

*

Only valid for DP710, DP720, and DP730.

*

11130520

Connection tools

Description Part numbers

Crimp tool 16 to 20 AWG 10100744

Crimp tool 20 to 24 AWG 10100745

Mounting kit

Description Part number

Panel mounting kit 11144800

Software

Description Part number

®

PLUS+1

GUIDE Professional Software (includes 1 year of software

updates, a single user license, Service and Diagnostic Tool and

Screen Editor)

11179523

(annual renewal with 11179524 to keep the

software updates)

Service Parts

Description Part number

USB replacement kit 11202184

Danfoss | August 2020 BC152986485519en-000901 | 9

Page 10

Technical Information

DP7XX Series Displays

Inputs/outputs

Inputs

DP7XX Series displays support the following pin types:

Digital or Analog (DIN/AIN)

•

Multifunction (DIN/AIN/FreqIN, Rheo, 4–20 mA)

•

Fixed Range Analog or CAN shield (AIN/CAN shield)

•

DP7XX Series displays have input pins that support multiple functions. Pins that support multiple input

®

types are user-configurable using PLUS+1

GUIDE software.

Digital/analog

Middle range

Description Unit Minimum Typical Maximum Comment

Minimum

discernible

voltage

Minimum

discernible

voltage

Resolution mV — 1.4 — —

Worst case offset

and gain error

Non-linearity mV — — ±8.5 —

Input impedance kΩ 230 233 236 No pull up or pull

Input impedance

(5V/GND)

Input impedance

(2.5V)

mV —

mV 5.64 5.78 5.92 —

mV — — ±0.14 V

kΩ 13.9 14.1 14.3 Pull up or pull

kΩ 7.1 7.3 7.4 Pull up and pull

—

0.03 —

Measure

down

down

down

= 5.78 V

High range

Description Unit Minimum Typical Maximum Comment

Minimum

discernible

voltage

Minimum

discernible

voltage

Resolution mV — 9.5 — —

Worst case offset

and gain error

Non-linearity mV — — ±56.8 —

Input impedance kΩ 108.2 109.3 110.4 No pull up or pull

Input impedance

(5V/GND)

Pull up and pull

down input

impedance (2.5V)

mV —

mV 37.5 38.8 40.1 —

mV — — ±1.3 V

kΩ 13.0 13.2 13.4 Pull up or pull

kΩ 6.9 7.0 7.1 Pull up and pull

—

0.16 —

= 38.8 V

Measure

down (Vin < 5.7

V)

down (Vin < 5.7

V)

down (Vin < 5.7

V)

10 |

Danfoss | August 2020 BC152986485519en-000901

Page 11

Voltage

Ohms

Rxhi

nopull.HiV

(Vin)

Rxhi

pullup.HiV

(Vin)

Rxhi

pulldn.HiV

(Vin)

Rxhi

pullboth.HiV

(Vin)

Vin

9 12 15 18 21 24 27 30 33 36

5000

11500

18000

24500

31000

37500

44000

50500

57000

63500

70000

70000

5000

369

yru148581580292

Technical Information

DP7XX Series Displays

Inputs/outputs

High range input impedance for analog inputs

Danfoss | August 2020 BC152986485519en-000901 | 11

Page 12

Technical Information

DP7XX Series Displays

Inputs/outputs

Multifunction

Frequency input low range (PPU)

Description Unit Minimum Maximum Comment

Range Hz 0 10000 In steps of 1 Hz

Sensitivity mVpp 1000 — Sinus peak-to-peak

Low threshold voltage mV 75 200 —

High threshold voltage mV 150 350 —

Input impedance kΩ 233 ± 3 To 0 V

Input impedance with pull-down kΩ 14.1 ± 0.3 To 0 V

Input impedance with pull-up kΩ 14.1 ± 0.3 To 5 V

Input impedance with pull-up/down kΩ 7.27 ± 0.2 To 2.5 V

Frequency input normal range (PPU)

Description Unit Minimum Maximum Comment

Range Hz 0 10000 In steps of 1 Hz

Range (phase and quad) Hz 0 5000 When measuring phase or

quadrature counts

Low threshold voltage V 1.1 2.6 —

High threshold voltage V 2.2 4.4 —

Input impedance kΩ 233 ± 3 To 0 V

Input impedance with pull-down kΩ 14.1 ± 0.3 To 0 V

Input impedance with pull-up kΩ 14.1 ± 0.3 To 5 V

Input impedance with pull-up/down kΩ 7.27 ± 0.2 To 2.5 V

Resistance input

Description Unit Minimum Maximum Comment

Range Ω 0 10000 In steps of 1 Ω

Resolution 1 @ 0 Ω

2 @ 1 kΩ

42 @ 10 kΩ

Source current m 0 4 —

4–20 mA input

Description Unit Minimum Maximum Comment

Range mA 0 50 —

Resolution μA 22 —

Worst case error mA ±(0.2 + I*3%) —

Input impedance Ω 100 ± 2 To 0 V

Shut-off current mA 54 —

12 |

Danfoss | August 2020 BC152986485519en-000901

Page 13

W

Technical Information

DP7XX Series Displays

Inputs/outputs

Warning

Using these inputs can affect the accuracy of any Safety Critical closed loop control. These displays do not

have a Real Time Operating System (RTOS). Do not use these displays as the master control for any type

of safety critical control, or closed loop control system. Frequency inputs are managed by the operating

system. Accuracy can be affected by processor load. These displays should only be used for non-safety

critical related functions.

Encoder

The encoder input is only suitable for user interface functions, such as, navigating in menus and adjusting

values because there is no guarantee that all pulses are detected and the detected direction can be false.

The rate of pulses should be kept at a few tens per second to minimize the loss of detected position

changes.

The encoder function samples the A and B signals from the encoder and increments or decrements the

counter according to the phase sequence. The counter is incremented/decremented on every low to

high and high to low edge of the A signal. Some encoders with detents give a complete pulse between

detents and the counter will be incremented/decremented by two for every detent. The counter is

incremented when the A signal is the leading phase and decremented in the opposite case.

Outputs

Digital output

Only to be used for buzzer output.

USB

USB Input/Output

Description Unit Minimum Maximum Typical Comment

2.0 full speed Mbit/s — — 12 —

Vbus input voltage V — — > 4.4 —

Vbus input resistance kΩ — — 70 Vbus < 5.25 V

Short circuit protection

(No damage)

Vbus output voltage V 4.75 5.25 — —

Vbus output current A — — 0.5 —

Vbus short current A — 1.1 — —

V0 36 — —

The DP7XX series displays all have USB ports that support memory sticks and computer connection. The

DP7XX functions as a device when connected to a computer for diagnosis purposes or software

download. The DP7XX functions as a host when a standard USB memory stick is connected so log-data

can be transferred. There is also an option for a front type-A USB connector. The front connector is USB

host, the rear connector is USB host and device. You can only use one host connection at a time (either

front or rear), but you can use front host and rear device at the same time.

Other than supporting memory sticks and computer connection, the DP7XX series display USB port does

not support any other standard computer peripherals.

Danfoss | August 2020 BC152986485519en-000901 | 13

Page 14

Technical Information

DP7XX Series Displays

Inputs/outputs

Video

Video output

Description Unit Minimum Maximum Typical Comment

Short circuit protection V 0 36 — —

12 V output voltage

(9 V < Ubat < 70 V)

12 V output current A — — 0.5 Vbus < 5.25 V

24 V output voltage

(9 V < Ubat < 70 V)

24 V output current A — 0.5 — —

Video inputs — — — — Both NTSC and PAL support

V 11.5 12.5 12 —

V232424—

To power the camera up, it is recommended to use the display as power supply. If using a different power

supply, it should meet the specification of the camera in regards of the voltage type and range, the

current and voltage amount it can supply to its load, stability of the output voltage and current under

varying line and load conditions, operating/storage temperature ranges.

The use of a different power supply for the camera can create “noise” on the signal line which will affect

its functionality.

Real Time Clock (RTC)

Parameter Min Max Units

Backup Time 1 month

Drift 10 s/day

14 |

Danfoss | August 2020 BC152986485519en-000901

Page 15

Technical Information

DP7XX Series Displays

Controller Area Network (CAN) specifications

CAN shield/analog inputs

The CAN shield pin on the unit can be used as a non-configurable analog input.

The values in the following table assumes that software compensates for errors in the analog to digital

(A/D) converter.

CAN shield

Description Unit Minimum Maximum Typical Comment

Input impedance — — — 0.68 μF + 1 Ω —

Analog input (5 V only)

Description Unit Minimum Maximum Comment

Allowed voltage at pin V 0 36 —

Measuring range V 0 5.75 —

Resolution mV 1.4 —

Worst case error mV ±(20 + U*2%) —

Input impedance kΩ 233 ± 3 —

CAN communication

Analog input

Analog input (5 V only)

Description Unit Minimum Maximum Comment

Allowed voltage at pin V 0 36 —

Measuring range V 0 5.75 —

Resolution mV 1.4 —

Worst case error mV ±(20 + U*2%) —

Input impedance kΩ 233 ± 3 —

CAN communication

Description Unit Minimum Maximum Typical Comment

Available baud rates kBd 50 1000 50 With 120 Ω termination.

100

125

250

500

1000

Maximum input voltage

range

V0 36 — —

The default baud rate is

250kbit.

Gateway channels

®

PLUS+1

Danfoss | August 2020 BC152986485519en-000901 | 15

Service Tool can be connected to the CAN bus by using the following gateway channels.

Page 16

Technical Information

DP7XX Series Displays

Controller Area Network (CAN) specifications

Gateway channels

Channel Description

0 Display only

1 Display + CAN0

2 Display + CAN1

3 Display + CAN0+1

4 CAN0

5 CAN1

6 CAN0+1

Selecting channel zero will not increase CAN traffic because of the PLUS+1® Service Tool communication.

Another PLUS+1® Service Tool can be connected to the CAN bus by using the following gateway

channels.

Simultaneous usage gateway channels

Channel Description

0 CAN[0] and CAN[1]

1 or 4 CAN[1]

2 or 5 CAN[0]

3 or 6 No CAN port

16 |

Danfoss | August 2020 BC152986485519en-000901

Page 17

C

Technical Information

DP7XX Series Displays

Memory

NV memory

Caution

Non-volatile (NV) memory data loss is possible when the NV write cycle is not fully completed. When

downloading a new application ensure data is not being written to NV memory.

FRAM Memory

DP7XX Series Displays use Ferroelectric Random Access Memory (FRAM). FRAM has a write endurance of

over 100 trillion cycles, which is ideal for datalogging. 2kB is available for application.

Vault Memory

DP7XX Series Displays have 16 MB of flash vault memory (application logging memory). Application

developers use this memory to log machine event data then use the PLUS+1

logged data.

Accessing non-volatile or application log memory can delay the service tool scan.

®

Service Tool to extract the

Danfoss | August 2020 BC152986485519en-000901 | 17

Page 18

W

W

Technical Information

DP7XX Series Displays

Product ratings

Electrical

Supply voltage

Description Unit Minimum Maximum Comment

DC supply voltage V 9 36 With reverse polarity protection

DC supply current (circuit board only) A 0 1 UBat = 14 V

0 0.5 UBat = 28 V

Power supply interruption

(without rebooting)

ms — — 200 ms

5 V reference output

Description Unit Minimum Maximum

Output voltage V 4.8 5.2

Output current A 0 0.5

Output short circuit A — 1

Short circuit protection V 0 36

Measuring of output voltage V 0 5.75

Resolution mV 1.4

Worst case error mV ± (20+U*2%)

Environmental

Warning

Output pins produce high voltage. High voltage can cause fire and/or electrical shock, if flammable

gasses or chemicals are present, can cause an explosion. To protect against product damage and possible

injury, do not exceed power supply voltage ratings and do not store this product where flammable

gasses or chemicals are present.

Temperature

Description Units Minimum Maximum Comment

Operating temperature ˚C [˚F] -30 [-22] +60 [+140] —

Storage temperature ˚C [˚F] -30 [-22] +80 [+176] —

Ingress Protection (IP) rating

Series Rating Comment

DP700, DP710, DP720 IP67

DP730 Front: IP69K

Rear: IP67

With mating connector installed and sealing plugs in

unused connections.

Warning

Excessive high/low operating/storage temperatures can damage electronics. Damaged electronics can

result in performance failure. To protect against product damage and possible injury, do not operate/

store product in a environment that exceeds specified temperature ratings.

18 |

Danfoss | August 2020 BC152986485519en-000901

Page 19

Technical Information

DP7XX Series Displays

Product ratings

Testing criteria

Climatic

Condition Rating

Cold/heat storage and operation IEC 60068-2-1, IEC 60068-2-2

Fogging IEC 60068

Temperature change IEC 60068-2-14

UV tests ASTM G155

Sunlight radiation ISO 16750-4

Temp humidity voltage IEC 60068-2-38

Chemical

Condition Rating

Chemical resistance ISO 16750-5

Mechanical

Condition Rating

Vibration, resonance IEC 60068-2-6

Vibration, operation IEC 60068-2-64

Bump IEC 60068-2-29

Shock IEC 60068-2-27

Free fall IEC 60068-2-32

Danfoss | August 2020 BC152986485519en-000901 | 19

Page 20

C

C

C

Technical Information

DP7XX Series Displays

Maintenance guidelines

LCD module

Caution

Warranty will be voided if device is opened.

Device is not field serviceable. Do not open the device.

Caution

Prolonged exposure to direct intense sunlight can cause premature failure of the LCD module. This risk

can be reduced by providing shading or mounting the display at an incline rather than the horizontal.

Caution

The protective glass will break if hit with a hard or heavy object. If the protective glass is broken, remove

the display from your machine then return the display to Danfoss to be serviced.

Clean the display's housing and protective glass with a clean, soft, damp cloth, or mild dishwashing

detergent because abrasive pads or solvents, including alcohol, benzene, and paint thinner can cause

scratching and discoloration.

LCD press and hold feature

The DP7XX LCD press and hold registers for 5 to 6 seconds then releases. The software inside the touch

screen controller prevents permanent items (such as mud on the screen) from registering as a continuous

press and hold.

20 |

Danfoss | August 2020 BC152986485519en-000901

Page 21

75.00 ± 0.50 80.08 ± 0.50

75.00 ± 0.50

27.60 ± 0.50

4X M4

kwa1427228052758

235.20

163.50

9.90

[0.39]

42.60

[1.68]

177.80 REF

Technical Information

DP7XX Series Displays

Installation

DP700, DP710, DP720 dimensions

Dimensions in millimeters

Danfoss | August 2020 BC152986485519en-000901 | 21

Page 22

233.70

161.90

12.00

40.50

75.00 ± 0.50 80.08 ± 0.50

75.00 ± 0.50

27.60 ± 0.50

4X M4

kwa1427228061493

Technical Information

DP7XX Series Displays

Installation

DP730 dimensions

Dimensions in millimeters

22 |

Danfoss | August 2020 BC152986485519en-000901

Page 23

4X M4

219.2 ± 0.5

147.2 ± 0.5

4 x 70˚ ± 1˚

4X 6 ± 0.25

Panel thickness 6.00 mm (0.24 in) max

Torque all screws to

2.82 ± 0.034 N-m

(25.00 ± 3.00 lb-in)

75.00 ± 0.50 80.08 ± 0.50

75.00 ± 0.50

27.60 ± 0.50

4X M4

kwa1402426014677

Technical Information

DP7XX Series Displays

Installation

Two mounting options

Flush mounting option

Use the Danfoss panel mounting kit (Danfoss part number 11144800) to flush-mount into a dashboard.

Panel cutout, dimensions in millimeters

Stand-alone on post mounting option

Mount according to VESA (Video Electronics Standards Association) Mount Standards The VESA hole

pattern for these displays is: 75.00 mm x 75.00 mm (02.95 in x 02.95 in). There are four holes for four M4

screws, 0.7 mm (0.3 in) thread x 12 mm (0.47 in) maximum depth.

Dimensions in millimeters

Disconnect your machine's battery power before connecting power and signal cables to the display.

Danfoss | August 2020 BC152986485519en-000901 | 23

Page 24

C1

C3

C4

C5

C5-P8

C4-P5

C4-P1

C3-P5

C1-P1

C3-P1

C1-P12

C5-P1

USB

C6

USB

C4 M12 5-pin

C3 M12 5-pinC5 M12 8-pin

C1 DEUTSCH DTM06 12-pin

Technical Information

DP7XX Series Displays

Installation

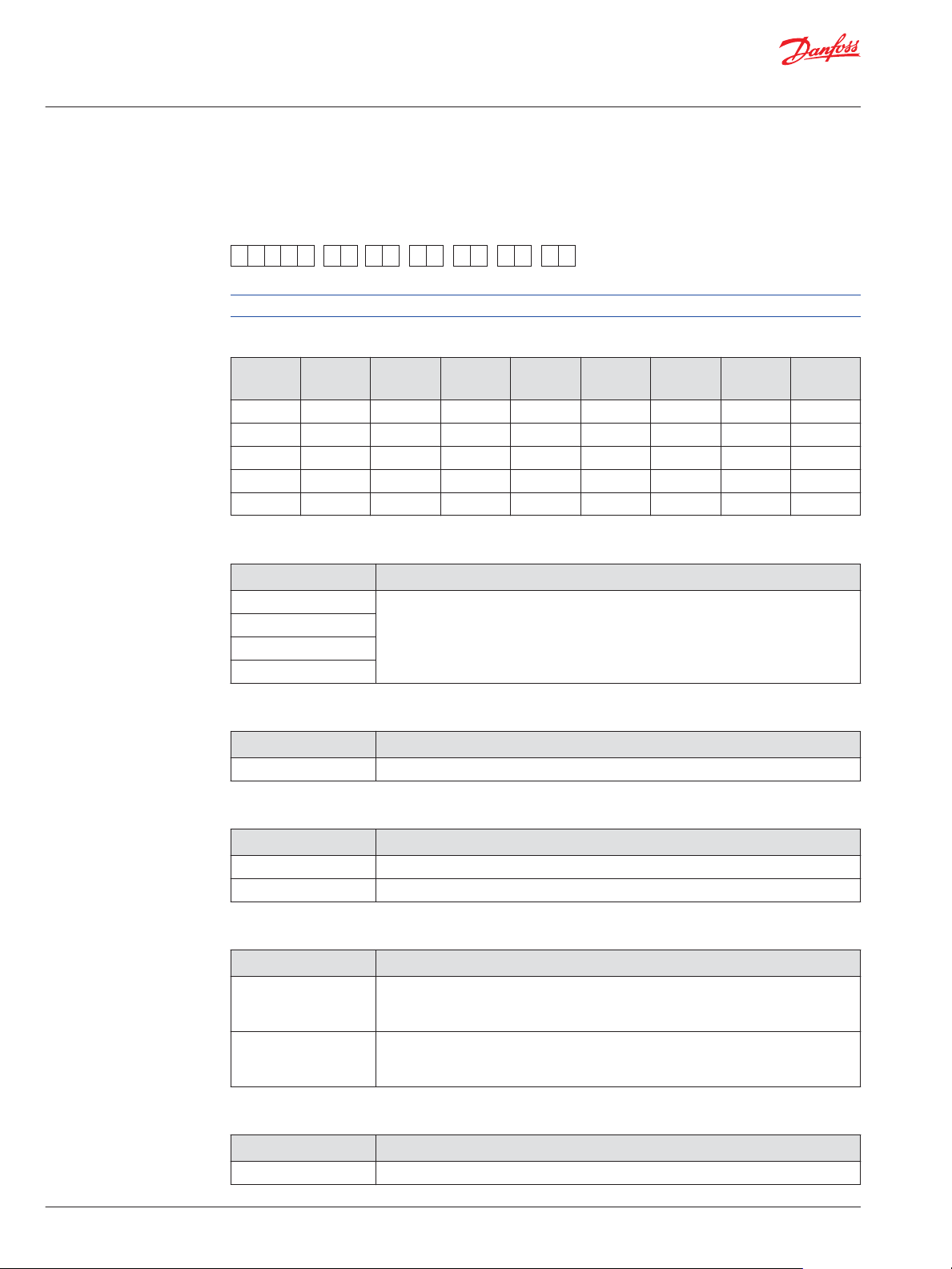

DP700, DP710, DP720 connectors pin assignments

C6 pin Function C5 pin Function C4 pin Function C3 pin Function C1 pin Function

C6-P1 USB host VBus C5-P1 USB device Vbus C4-P1 Video power

ground

C6-P2 USB host D- C5-P2 USB device D- C4-P2 Video power

supply

C3-P1 Video power

ground

C3-P2 Video power

supply

C1-P1 Power ground -

C1-P2 Power supply +

C6-P3 USB host D+ C5-P3 USB device D+ C4-P3 Video signal input1C3-P3 Video signal input2C1-P3 CAN0 High +

C6-P4 USB host GND C5-P4 USB device GND C4-P4 Video signal input

ground

C5-P5 USB host GND/

C4-P5 NC C3-P5 NC C1-P5 AIN/CAN Shield

C3-P4 Video signal input

ground

C1-P4 CAN0 Low -

RS232 GND

C5-P6 USB host D+/

RS232 RxD

C5-P7 USB host D-/RS232

TxD

C5-P8 USB host Vbus

C1-P6 CAN1 High +/

(AIN/DIN)

C1-P7 CAN1 Low -/(AIN/

DIN)

C1-P8 Sensor power/

(AIN/DIN)

C1-P9 Sensor ground

C1-P10 Multifunction-

input

C1-P11 Multifunction-

input

C1-P12 DOUT

24 |

Danfoss | August 2020 BC152986485519en-000901

Page 25

C1

C3

C4

C5

C5-P8

C4-P5

C4-P1

C3-P5

C1-P1

C3-P1

C1-P12

C5-P1

USB

C4 M12 5-pin

C3 M12 5-pinC5 M12 8-pin

C1 DEUTSCH DTM06 12-pin

Technical Information

DP7XX Series Displays

Installation

DP730 connectors pin assignments

C5 pin Function C4 pin Function C3 pin Function C1 pin Function

C5-P1 USB device Vbus C4-P1 Video power ground C3-P1 Video power ground C1-P1 Power ground -

C5-P2 USB device D- C4-P2 Video power supply C3-P2 Video power supply C1-P2 Power supply +

C5-P3 USB device D+ C4-P3 Video signal input 2 C3-P3 Video signal input 1 C1-P3 CAN0 High +

C5-P4 USB device GND C4-P4 Video signal input

ground

C5-P5 USB host GND/RS232

C4-P5 NC C3-P5 NC C1-P5 CAN shield/AIN

C3-P4 Video signal input

ground

C1-P4 CAN0 Low -

GND

C5-P6 USB host D+/RS232

C1-P6 CAN1 High +/(AIN/DIN)

RxD

C5-P7 USB host D-/RS232 TxD C1-P7 CAN1 Low -/(AIN/DIN)

C5-P8 USB host Vbus C1-P8 Sensor power/(AIN/

DIN)

C1-P9 Sensor ground

C1-P10 Multifunction-input

C1-P11 Multifunction-input

C1-P12 DOUT

Danfoss | August 2020 BC152986485519en-000901 | 25

Page 26

W

C

W

Technical Information

DP7XX Series Displays

Installation

Machine wiring guidelines

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Improperly protected power input lines against over current conditions may cause damage to the

hardware. Properly protect all power input lines against over-current conditions. To protect against

unintended movement, secure the machine.

Caution

Unused pins on mating connectors may cause intermittent product performance or premature failure.

Plug all pins on mating connectors.

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

Machine welding guidelines

26 |

Danfoss | August 2020 BC152986485519en-000901

Warning

High voltage from power and signal cables may cause fire or electrical shock, and cause an explosion if

flammable gasses or chemicals are present.

Disconnect all power and signal cables connected to the electronic component before performing any

electrical welding on a machine.

The following is recommended when welding on a machine equipped with electronic components:

•

Turn the engine off.

•

Remove electronic components from the machine before any arc welding.

•

Disconnect the negative battery cable from the battery.

•

Do not use electrical components to ground the welder.

•

Clamp the ground cable for the welder to the component that will be welded as close as possible to

the weld.

Page 27

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss | August 2020 BC152986485519en-000901

Loading...

Loading...