Page 1

Technical Information

Displays

DP6XX Series

www.danfoss.com

Page 2

Technical Information

DP6XX Series Displays

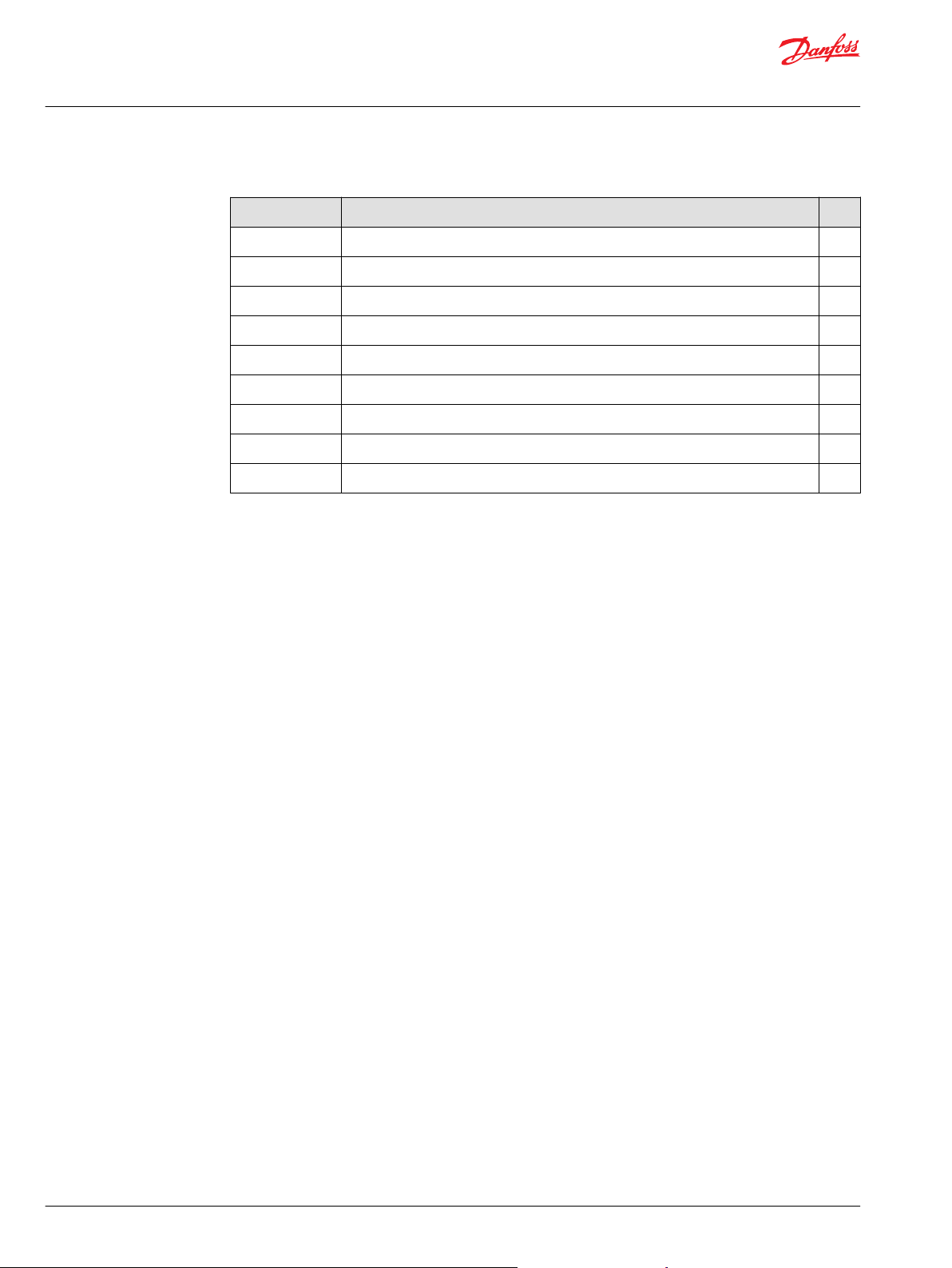

Revision history Table of revisions

Date Changed Rev

August 2018 Corrected pin assignments 0501

July 2018 Corrected pin assignments for 12 pin and removed redundant topic Pinout 0401

November 2017 Minor update 0303

June 2016 Various updates from PAE; updated to Engineering Tomorrow design 0301

December 2015 Converted to Danfoss layout 0204

June 2011 DC supply current maximum ratings BC

January 2007 Various BB

August 2005 Various BA

October 2005 First edition AA

2 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 3

Technical Information

DP6XX Series Displays

Contents

DP6XX literature references

Technical Information (TI)............................................................................................................................................................. 4

Data Sheet (DS)................................................................................................................................................................................. 4

PLUS+1® GUIDE User Manual....................................................................................................................................................... 4

Latest version of technical literature.........................................................................................................................................4

User liability and safety statements

OEM responsibility........................................................................................................................................................................... 5

Safety statements.............................................................................................................................................................................5

Display operation guidelines..................................................................................................................................................5

Machine wiring guidelines...................................................................................................................................................... 6

Machine welding guidelines...................................................................................................................................................6

Overview

DP6XX Series Displays.....................................................................................................................................................................7

PLUS+1® GUIDE..................................................................................................................................................................................8

Display features.................................................................................................................................................................................8

Ordering information

Model variants...................................................................................................................................................................................9

Model code.........................................................................................................................................................................................9

Model code key.................................................................................................................................................................................9

Related products...............................................................................................................................................................................9

Input/output types and specifications

Input types........................................................................................................................................................................................11

Digital/analog..................................................................................................................................................................................11

Multifunction...................................................................................................................................................................................12

USB...................................................................................................................................................................................................... 14

Video...................................................................................................................................................................................................14

CAN shield/analog inputs...........................................................................................................................................................14

CAN/RedCAN communication.................................................................................................................................................. 15

Product ratings

Specifications...................................................................................................................................................................................16

Supply voltage/maximum current ratings........................................................................................................................... 17

Electronic components environmental testing criteria................................................................................................... 18

Installation

Dimensions.......................................................................................................................................................................................19

Two mounting options................................................................................................................................................................ 20

Flush mounted.......................................................................................................................................................................... 20

Stand-alone on post................................................................................................................................................................ 21

Pin assignments..............................................................................................................................................................................22

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 3

Page 4

Technical Information

DP6XX Series Displays

DP6XX literature references

Technical Information (TI)

Data Sheet (DS)

PLUS+1® GUIDE User Manual

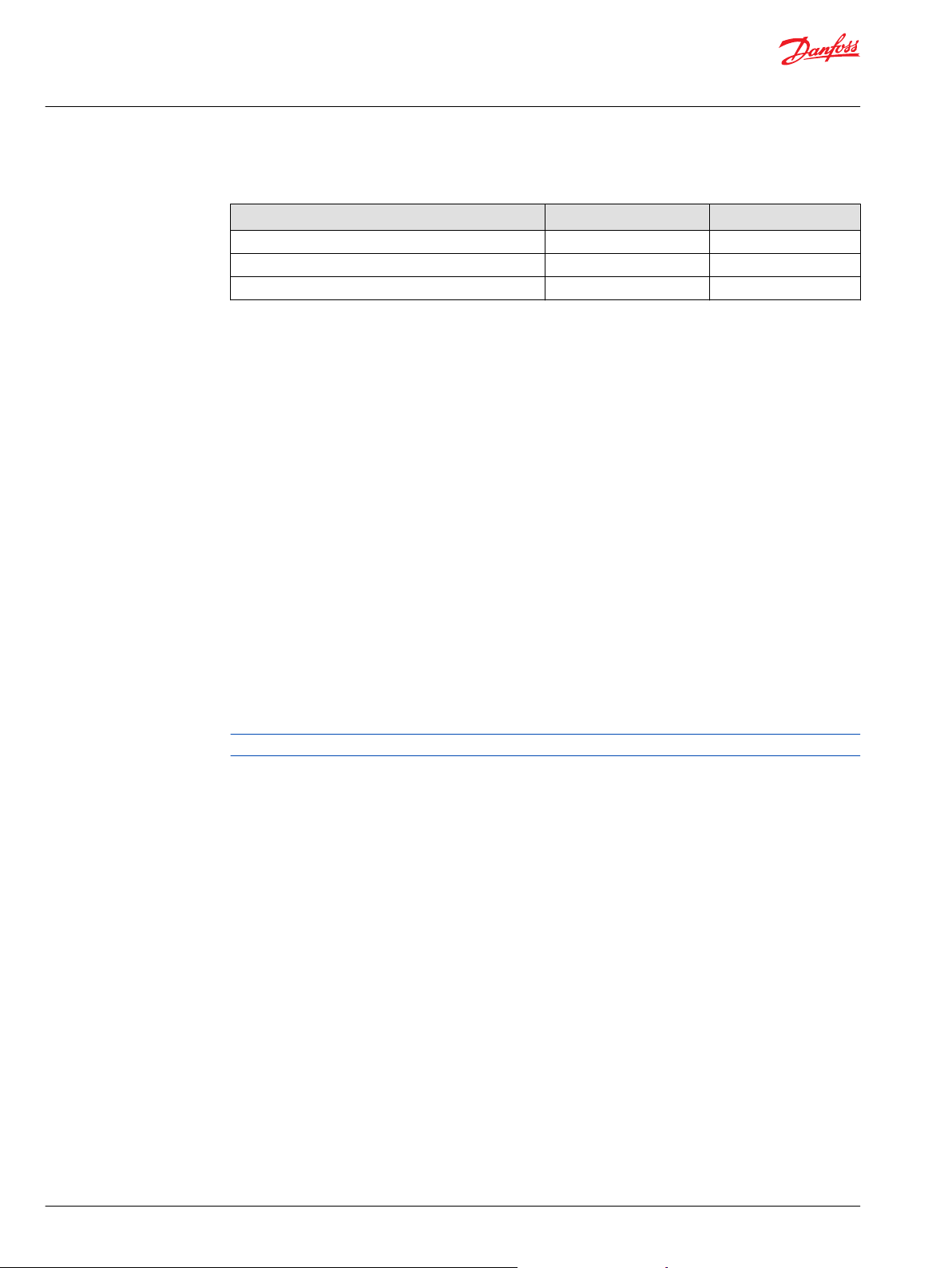

Reference literature

Literature title Literature type Literature number

DP6XX Series PLUS+1® Mobile Machine Displays

DP6XX Series PLUS+1® Mobile Machine Displays

PLUS+1® GUIDE Software User Manual

A TI is comprehensive information for engineering and service personnel to reference.

A DS is summarized information and parameters that are unique to a specific model.

The Operation Manual (OM) details information regarding the PLUS+1® GUIDE tool used in building PLUS

+1® applications. This OM covers the following broad topics:

How to use the PLUS+1® GUIDE graphical application development tool to create machine

•

applications

How to configure module input and output parameters

•

How to download PLUS+1® GUIDE applications to target PLUS+1® hardware modules

•

How to upload and download tuning parameters

•

How to use the PLUS+1® Service Tool

•

Technical Information

Data Sheet

Operation Manual

BC00000108

AI00000038

AQ00000026

Latest version of technical literature

Danfoss product literature is online at: https://www.danfoss.com/en/search/

4 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 5

Technical Information

DP6XX Series Displays

User liability and safety statements

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

•

equipment.

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

•

system being programmed in a manner that jeopardizes safety.

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

•

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

Safety statements

Display operation guidelines

•

Disconnect your machine's battery power before connecting power and signal cables to the display.

•

Before doing any electrical welding on your machine, disconnect all power and signal cables

connected to the display.

•

Do not exceed the display power supply voltage ratings. Using higher voltages may damage the

display and can create a fire or electrical shock hazard.

•

Do not use or store the display where flammable gases or chemicals are present. Using or storing the

display where flammable gases or chemicals are present may cause an explosion.

•

Software configures the keypad buttons on the display. Do not use these buttons to implement

critical safety features. Use separate mechanical switches to implement critical safety features such as

emergency stops.

•

Design systems that use the display so that a communication error or failure between the display and

other units cannot cause a malfunction that might injure people or damage material.

•

The protective glass over the display screen will break if hit with a hard or heavy object. Install the

display to reduce the possibility of it being hit by hard or heavy objects.

•

Storing or operating a display in an environment that exceeds the display specified temperature or

humidity rating may damage the display.

•

Always clean the display with a soft, damp cloth. Use a mild dishwashing detergent as needed. To

avoid scratching and discoloring the display, do not use abrasive pads, scouring powders, or solvents

such as alcohol, benzene, or paint thinner.

•

Danfoss graphical displays are not user serviceable. Return the display to the factory in case of failure.

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 5

Page 6

W

C

W

Technical Information

DP6XX Series Displays

User liability and safety statements

Machine wiring guidelines

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Improperly protected power input lines against over current conditions may cause damage to the

hardware. Properly protect all power input lines against over-current conditions. To protect against

unintended movement, secure the machine.

Caution

Unused pins on mating connectors may cause intermittent product performance or premature failure.

Plug all pins on mating connectors.

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

Machine welding guidelines

Warning

High voltage from power and signal cables may cause fire or electrical shock, and cause an explosion if

flammable gasses or chemicals are present.

Disconnect all power and signal cables connected to the electronic component before performing any

electrical welding on a machine.

The following is recommended when welding on a machine equipped with electronic components:

•

Turn the engine off.

•

Remove electronic components from the machine before any arc welding.

•

Disconnect the negative battery cable from the battery.

•

Do not use electrical components to ground the welder.

•

Clamp the ground cable for the welder to the component that will be welded as close as possible to

the weld.

6 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 7

Technical Information

DP6XX Series Displays

Overview

DP6XX Series Displays

PLUS+1® Mobile Machine Displays are designed to provide flexible, expandable, powerful and cost

effective total machine management system displays for a wide variety of vehicle applications.

Features

•

External NAV button allows navigation through all DP6XX functions. Mount NAV button so that the

driver can navigate securely in all situations during work and travel.

•

Built-in real-time clock enables machine use time tracking as well as data logging.

•

CAN, RedCAN, RS-232, and USB interfaces as a gateway for updating and diagnosing all machine

control systems.

•

Powerful 32-bit microprocessor produces smooth, flicker-free movements of gauges and readouts in

the display screen.

•

Anti-glare display screen and sensor-controlled backlight levels provide superior legibility under all

operating conditions, whether freestanding or dash-mounted.

•

Video input option allows display of inputs from two standard composite video observation cameras.

•

Rugged, shock-resistant construction protects against dust and resists the effects of moisture by fresh

water.

•

GORE-TEX® membrane vent keeps moisture from fogging its display screen.

•

High brightness LED and digital alarm output alert the operator to alarm states under all operating

conditions.

•

Complete system software updates are possible through the CAN network.

•

Environmental and EMC standards are met according to Danfoss standards defined for mobile

applications.

•

High performance 32 bit microcontroller for real-time screen updates.

•

Smooth and flicker-free/accurate movement of virtual gauges and needles.

•

Ample onboard flash/RAM memory.

•

Data logging capabilities.

•

USB port for fast software download and uploads.

•

Same outside dimensions for screen variants.

Color: advanced TFT 400 x 240 pixels, transflective, 256 colors

‒

Monochrome: LED 320 x 240 pixels, transflective

‒

•

Two mounting options.

Flush mount in dashboard

‒

Stand alone on post according to VESA standard 75mm x 75mm [2.953 in x 2.953 in]

‒

•

Fully integrated connectors and silicone keypad provide water and dust protection from all sides.

•

Designed to withstand high-levels of shock/vibration.

•

Extremely wide storage and operating temperature range.

•

Keypad with 14 buttons (8 soft-keys + 6 buttons for navigation).

•

All buttons have green backlight design for low light and night use.

•

Ultra-bright red/amber/green alarm LED.

•

2 shielded Binder connectors for USB, RS-232 and camera inputs.

•

2 CAN ports, one fully compatible to RedCAN™, for enhanced safety and reliability in mobile control

systems.

•

Integrated light sensor for automatic backlight adjustment.

•

2 DEUTSCH DTM connectors.

•

Works with either 12 Vdc or 24 Vdc power supplies.

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 7

Page 8

Technical Information

DP6XX Series Displays

Overview

PLUS+1® GUIDE

Display features

PLUS+1® GUIDE (Graphical User Integrated Development Environment) is a complete toolbox that

generates downloadable applications for all programmable PLUS+1® Compliant products.

A screen editor allows easy development of applications by programmers without formal software

development training. The expertise from a software engineer is not needed to find your way around in

PLUS+1® GUIDE.

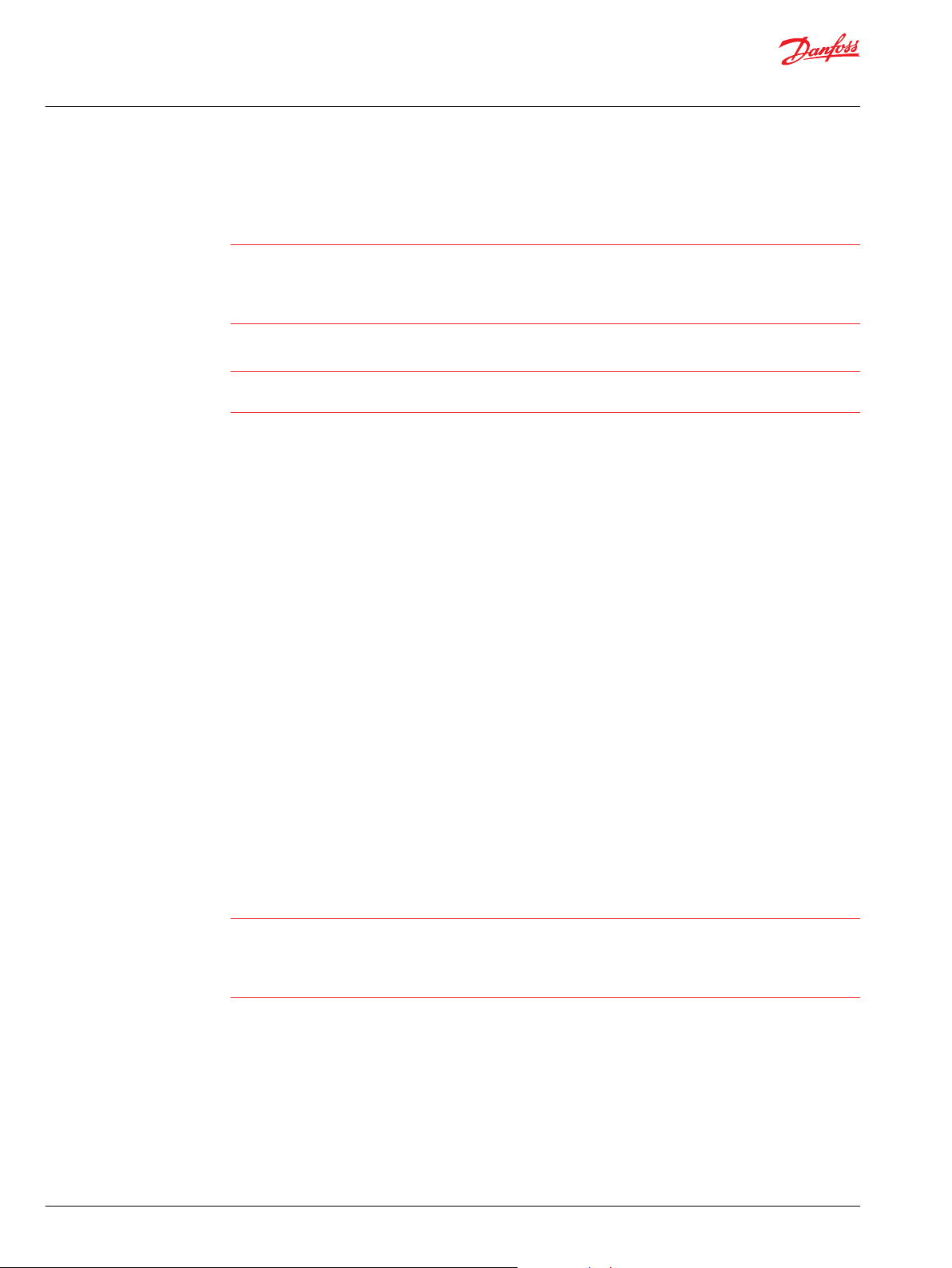

Display

Description DP600 DP610 DP620

Resolution (dpi) 400 x 240 pixels 320 x 240 pixels

Size/type 6.5 in/TFT Color 6 in/LCD Monochrome

Feature Transflective

8 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 9

Technical Information

DP6XX Series Displays

Ordering information

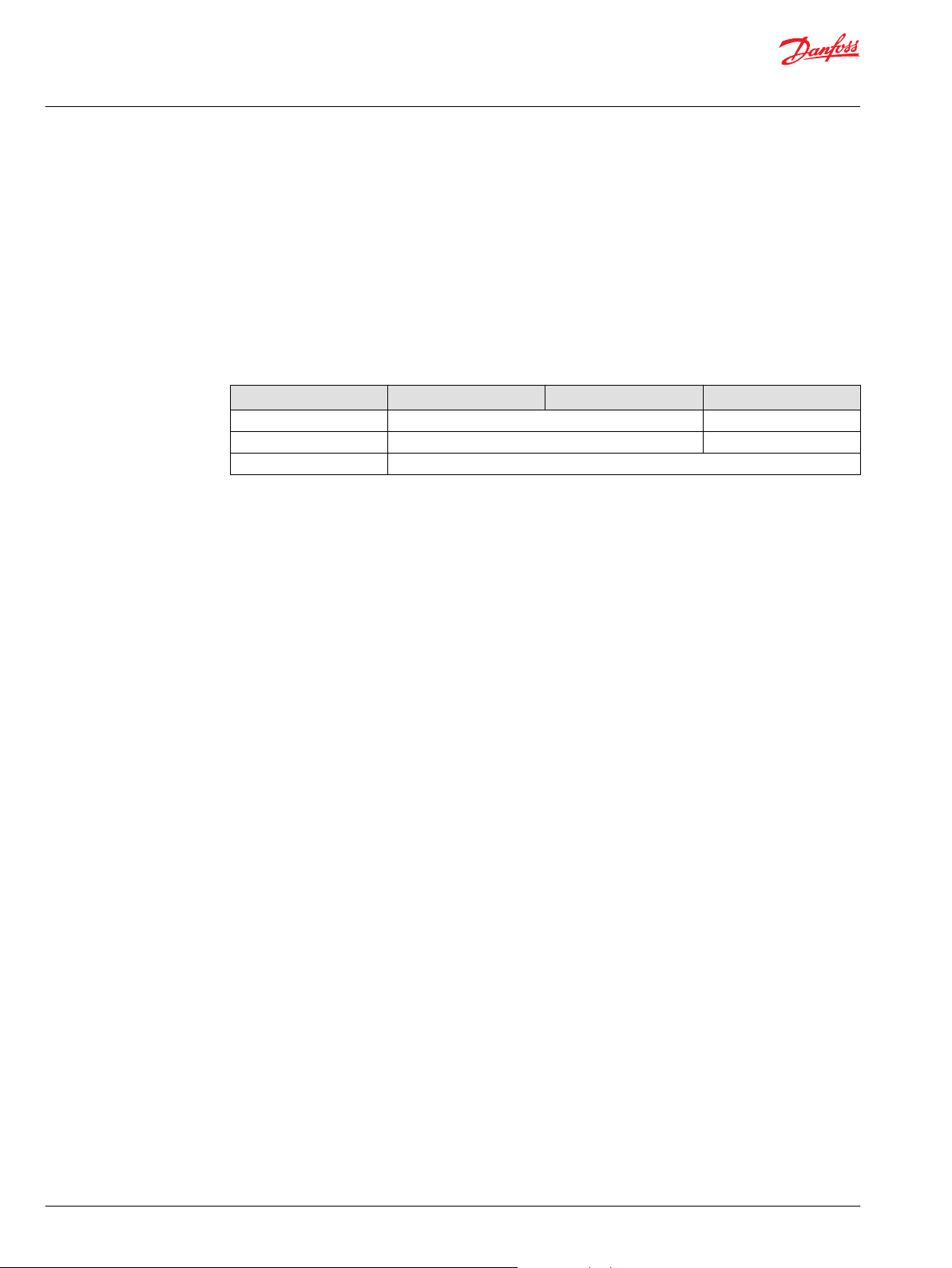

Model variants

Model code

Model code key

A B C D E Part number

DP600 SA CA V2 KS 10100890

DP610 SA CB V0 KS 10100889

DP620 SB CB V0 KS 10100888

A B C D E

D P 6 K S

A—Model name

Code Description

DP600 PLUS+1® Mobile Machine Displays

DP610

DP620

B—Screen variant

Code Description

SA 400 x 240 color advanced TFT transflective

SB 320 x 240 monochrome transflective

C—Connector

Code Description

CA

CB

C1 + C2 + C3 + C4 (only with video option D = V2)

C1 + C2 + C3 (without video option D = V0)

D—Video inputs

Code Description

V0 No video inputs

V2

Supports two external video signals (one at a time) as input (Either PAL or

NTSC format)

E—Keypad

Code Description

KS Standard keypads with 8 soft- and 6 function-keys

Related products

Electrical parts

10100728

10100729

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 9

5-pin male Binder connector (includes 2m cable)

7-pin male Binder connector (includes 2m cable)

Page 10

Technical Information

DP6XX Series Displays

Ordering information

Electrical parts (continued)

10100738

10100739

10100741

10100742

10100743

10103497

DTM06-12SA, 12-pin DEUTSCH connector

DTM06-6S 6-pin DEUTSCH connector

WM 12S locking plug for 10100738 DEUTSCH connector

WM6S locking plug for 10100739 DEUTSCH connector

0462-201-20141, DEUTSCH terminal for DTM06-xS

USB cable

Electrical connection kits

10100868

10100944

10103494

10103495

10103496

DP600 connection kit

Contents:

10100728 5-pin male Binder connector

10100729 7-pin male Binder connector

10100944 12-pin DEUTSCH connection kit

10103494 6-pin DEUTSCH connection kit

12-pin DEUTSCH connection kit

Contents:

10100738 DTM06-12SA 12-pin DEUTSCH connector

10100743 DEUTSCH terminal

10100741 WM 12S locking plug

6-pin DEUTSCH connection kit

Contents:

10100739 DTM06-6S 6-pin DEUTSCH connector

10100743 DEUTSCH terminal

10100742 WM 6S locking plug

DEUTSCH IP67 Seal Kit

Binder IP67 Seal Kit

Connection tools

10100744

10100745

DEUTSCH stamped contacts terminal crimp tool, size 20

DEUTSCH solid contacts terminal crimp tool

Software

PLUS+1® GUIDE Professional Software (includes 1 year of

software updates, a single user license, Service and Diagnostic

Tool and Screen Editor)

11179523

(annual renewal with 11179524 to keep the

software updates)

10 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 11

Technical Information

DP6XX Series Displays

Input/output types and specifications

Input types

This series of displays support the following pin types:

Digital or Analog (DIN/AIN)

•

Multifunction (DIN/AIN/FreqIN, Rheo, 4–20 mA)

•

Analog or Temperature or Rheostat (AIN/Temp/Rheo)

•

Fixed Range Analog or CAN shield (AIN/CAN shield)

•

This series of displays have input pins that support multiple functions. Pins that support multiple input

types are user-configurable using PLUS+1® GUIDE software.

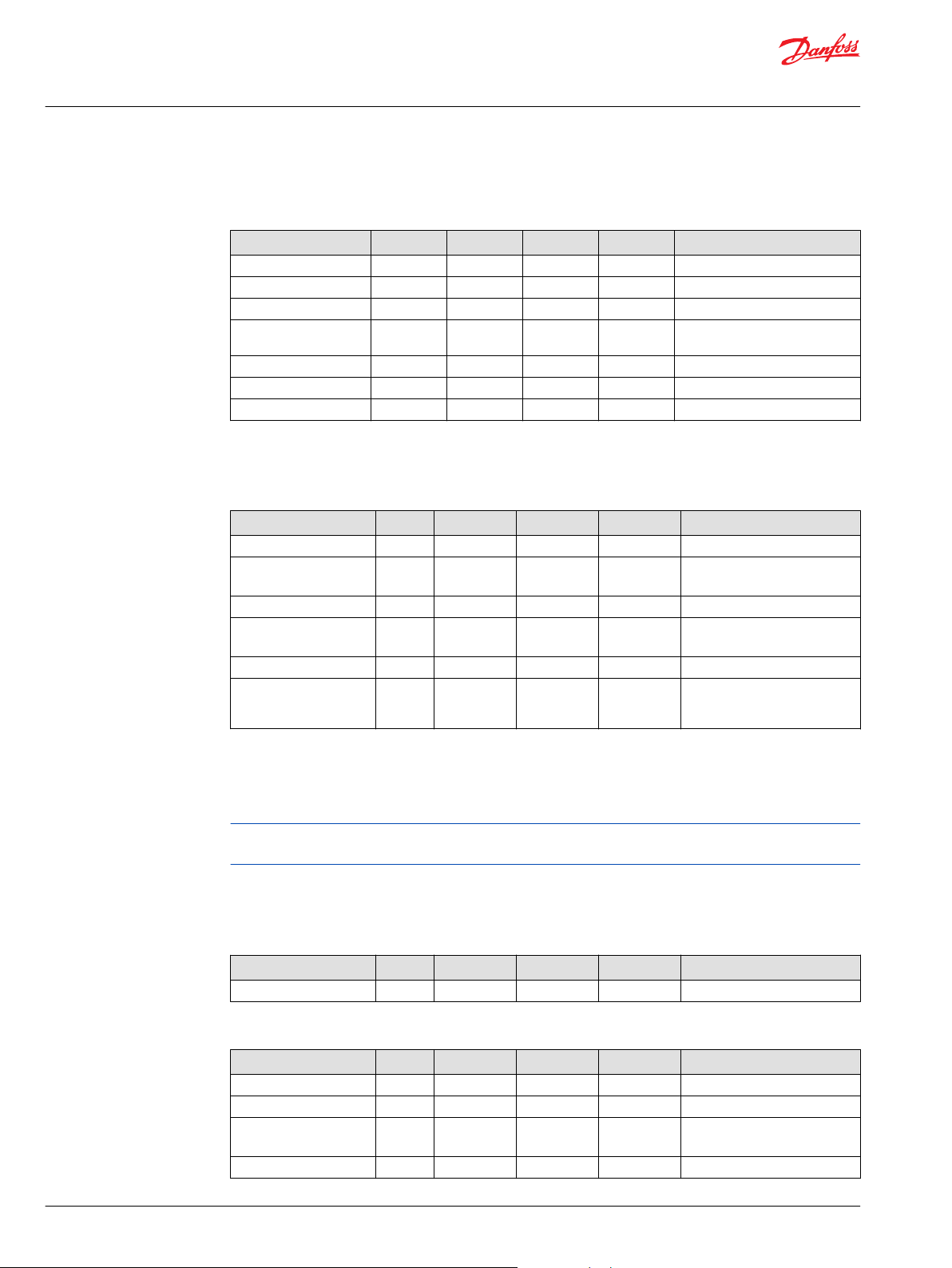

Digital/analog

High level digital input

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 to 69.3 0 to 84.7 — —

Input resistance kΩ — — 105 no pull up/

Programmable low threshold

voltage

Programmable high threshold

voltage

Rise time μs — — 20 —

Fall Time μs — — 20 —

down

13 With pull up to

5 V

13 Pull down to

ground

7 With pull up

and down to 5

V

V 0 ? — —

V 0 ? — —

High level analog input

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 to 69.3 0 to 84.7 — —

Input resistance kΩ — — 105 no pull up/

13 With pull up to

13 Pull down to

7 With pull up

Analog voltage error

(± 300 mV + Uin x 3.4%)

Bandwidth kHz — — 6 —

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 11

mV 0 — ± 260 Uin = 0 V

± 2920 Uin = 70 V

down

5 V

ground

and down to 5

V

Page 12

Technical Information

DP6XX Series Displays

Input/output types and specifications

Multifunction

Low level digital input

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 63 — —

Input resistance kΩ — — 233 no pull up/

Programmable low threshold

voltage

Programmable high threshold

voltage

Rise time μs — — 20 —

down

14 With pull up to

5 V

14 Pull down to

ground

73 With pull up

and down to 5

V

V 0 ? — —

V 0 ? — —

Low level analog input

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 63 — —

Input resistance kΩ — — 233 no pull up/

14 With pull up to

14 Pull down to

7.3 With pull up

Analog voltage error mV — — ± 0.5 Uin = 0 V

± 19 Uin = 5 V

Bandwidth kHz — — 6.8 —

down

5 V

ground

and down to 5

V

High level digital input

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 70 — —

Input resistance kΩ — — 105 no pull up/

13 With pull up to

13 Pull down to

7 With pull up

Programmable low threshold

voltage

Programmable high threshold

voltage

V 0 ? — —

V 0 ? — —

down

5 V

ground

and down to 5

V

12 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 13

Technical Information

DP6XX Series Displays

Input/output types and specifications

High level digital input (continued)

Description Unit Minimum Maximum Typical Comment

Rise time μs — — 20 —

Fall time μs — — 20 —

High level analog input

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 70 — —

Input resistance kΩ — — 105 no pull up/

Analog voltage error

(± 300 mV + Uin x 3.4%)

Bandwidth kHz — — 7.1 —

down

13 With pull up to

5 V

13 Pull down to

ground

7 With pull up

and down to 5

V

mV — — ± 100 Uin = 0 V

± 2760 Uin = 70 V

Resistance input

Description Unit Minimum Maximum Typical Comment

Resistance range kΩ 0 10 — —

Input resistance Ω — 1.33 — Pull up to 5V

Resistance error Ω —

± 5

± 9

—

R = 0 kΩ

R = 10 kΩ

Current input

Description Unit Minimum Maximum Typical Comment

Current range — 0 to 53 0 to 65 — Shut off at 50

Input resistance Ω — — 100 2.0V at 20 mA

Current error

(± 3.5%)

mA —

± 0.08

± 0.7

—

mA

input current

Iin = 0 mA

Iin = 20 mA

Frequency input

Description Unit Minimum Maximum Typical Comment

Frequency range kHz 0 10 — —

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 13

Page 14

Technical Information

DP6XX Series Displays

Input/output types and specifications

USB

USB input/output parameters

Description Unit Minimum Typical Maximum Comment

2.0 full speed Mbit/s — 12 — —

Vbus input voltage Volt — > 4.4 — —

Vbus input resistance kΩ — 70 — Vbus > 5.25 V

Short circuit protection

(No damage)

Vbus output voltage V 4.75 — 5.25 —

Vbus output current A — 0.5 — —

Vbus short current A — — 1.1 —

Video

Video output

Description Unit Minimum Typical Maximum Comment

Short circuit protection V 0 — 70 —

12 V output voltage

(9 V > Ubat > 70 V)

12 V output current A — 0.5 — Vbus > 5.25 V

24 V output voltage

(9 V > Ubat > 70 V)

24 V output current A — — 0.25 —

Video formats NTSC,

V 0 — 70 —

V 11.5 12 12.7 —

V 23 24 26 —

— — — Composite video

PAL,

SECAM

CAN shield/analog inputs

To power the camera up, it is recommended to use the display as power supply. If using a different power

supply, it should meet the specification of the camera in regards of the voltage type and range, the

current and voltage amount it can supply to its load, stability of the output voltage and current under

varying line and load conditions, operating/storage temperature ranges.

The use of a different power supply for the camera can create “noise” on the signal line which will affect

its functionality.

CAN shield

Description Unit Minimum Maximum Typical Comment

Input impedance — — — 1 μF + 1 Ω —

Analog input (5 V only)

Description Unit Minimum Maximum Typical Comment

Voltage range V 0 5.4 —

Input resistance kΩ — — 233 —

Analog voltage error

± (20 mV + Uin x 1.6 %)

Bandwidth kHz — — 2 —

mV —

± 20

± 120

—

Uin = 0 V

Uin = 5 V

14 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 15

Technical Information

DP6XX Series Displays

Input/output types and specifications

CAN/RedCAN communication

CAN/RedCAN

Description Unit Minimum Maximum Typical Comment

Available Baud rates kbps 0.01 100 50 With 120 Ω termination

Maximum input

voltage range

100

125

250

500

1000

V 0 70 — —

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 15

Page 16

Technical Information

DP6XX Series Displays

Product ratings

Specifications

Characteristics

Operating voltage range

Power consumption

Digital Inputs (3)

Option: Video inputs (2)

Output for buzzer (1)

Camera power output

Camera video input

CAN interface for external NAV

Encoder inputs

Encoder supply

Communication

Memory

Electrical connections

Operating temperature

Storage temperature

Moisture Ingression

9 to 70 VDC

15 W max

Uin < 1.5 VDC logical low

Uin > 1.5 VDC logical high

2 inputs designed for 90° A/B encoder signals, menu NAV

button

Standard composite PAL video signal input.

low side, max 0.5 A

12V, Max. output current: 400 mA

Composite video, 1V peak-peak

2 CAN ports according to CAN specification 2.0 B (active).

250 kbit standard setting (recommended)

Baud rates: 111kbit, 250 kbit, 500kbit, 1 Mbit

2 pins for CAN shield according to J1939.

One CAN port, fully compatible to Danfoss RedCAN standard.

Logical inputs: 5V

Logical 0: Uin < 1.5V

Logical 1: Uin > 3.5V

Input impedance: 100kΩ

Max. frequency input: 100 Hz

5V, Max. output current 400 mA

USB

RS-232: Baud rates: 1200, 2400, 9600, 19200, 28800,38400,

115200 baud. No handshake available.

8MB RAM

8K FRAM parameter memory (256 byte available for

application data storage).

1 Deutsch DTM 12-pin connector, Code C1

1 Deutsch DTM 6-pin connector, Code C2

1 Binder 7-pin connector for USB/RS-232, Code C3

1 Binder 5-pin connector for video-signals, Code C4

DP600; DP610: –30 °C — +70°C [–22°F — +158° F]

DP620: –20 °C — +70°C [–4°F — +158°F]

DP600; DP610: –40 °C — +85°C [–40°F — +185° F]

DP620: –30 °C — +80°C [–22°F — +176°F]

IP67, in accordance with SS-EN 60 529

Unused connections must have sealing plugs for IP rating to

be valid.

Vibration

Shock

Electrical

EMC emission

EMC immunity

IEC 60068-2-64-Fh with severity according to IEC TR 60721-4-5

environmental class 5M3

IEC 60068-2-27-Ea with severity according to IEC TR 60721-4-5

environmental class 5M3; free fall according to IEC 68-2-32Ed

Automotive transients ISO 7637/1-2

Automotive transients ISO 7637/3

EN 61000-6-3

EN 61000-6-2

16 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 17

Technical Information

DP6XX Series Displays

Product ratings

Characteristics (continued)

Membrane switches

Real time clock

Programmable ambient light sensor

Faceplate

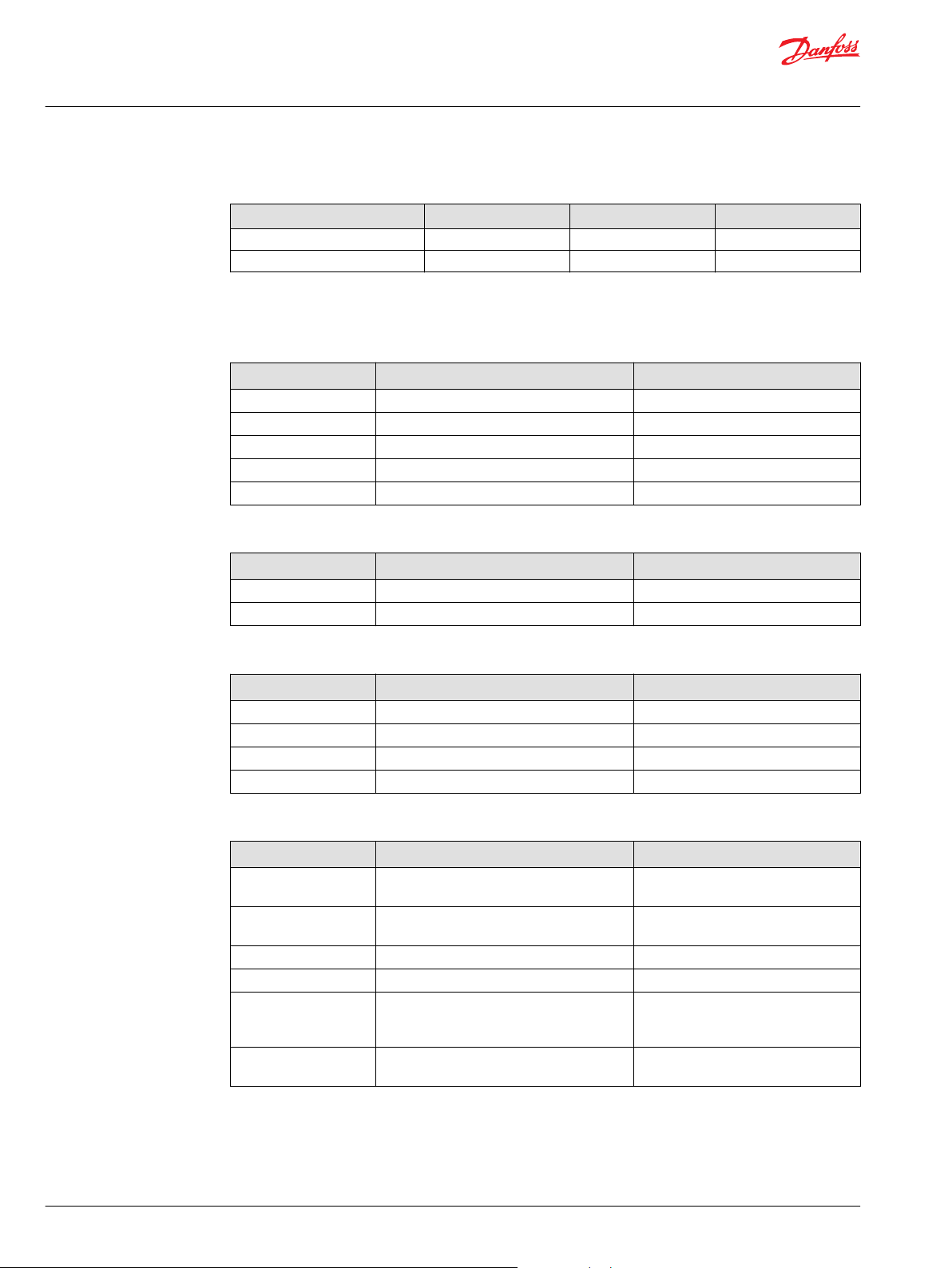

Supply voltage/maximum current ratings

DP6XX graphical displays are designed to operate with a nominal 9 to 63 Vdc power supply with reverse

polarity protection.

Supply voltage

Description Unit Minimum Maximum Comment

DC supply voltage Volt 9 70 With reverse polarity protection

DC supply current (circuit

board only)

Power supply interruption

(without rebooting)

Load dump protection, 12V

systems, % pulses, cycle

time 100 s, criteria C

Load dump protection, 28V

systems, % pulses, cycle

time 100 s, criteria C

Load dump protection, 36V

systems, % pulses, cycle

time 100 s, criteria C

Load dump protection, 48V

systems, % pulses, cycle

time 100 s, criteria C

14 keys

1 million cycles endurance

Pressure force: 300 gram (+/- 30 grams)

Date & Time

Backup time: minimum 1 month

Accuracy: 1 sec/24 hours

OSRAM SFH3410

Ultra bright faceplate-integrated red LED alarm

mA 2.5 Ubat = 8V

30 UBat =14V

70 UBat = 28V

40 Ubat = 70V

ms 34

36

46

100

V 87 According to ISO 7637-2

Ω 1

ms 200

ms 5

V 183 According to ISO 7637-2

Ω 3

ms 200

ms 10

V 200 According to ISO 7637-2

Ω 4.3

ms 200

ms 10

V 200 According to ISO 7637-2

Ω 6.3

ms 200

ms 10

5 V reference output

Description Unit Minimum Maximum

Output voltage V 4.8 5.2

Output current A 0.5 —

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 17

Page 18

Technical Information

DP6XX Series Displays

Product ratings

5 V reference output (continued)

Description Unit Minimum Maximum

Output short circuit A — 0.9

Short circuit protection V 0 70

Electronic components environmental testing criteria

Climate environment

Description Applicable standard Comment

Storage temperature IEC 60068-2-1, test Ab, IEC 60068-2-2 test Bb

Operating temperature IEC 60068-2-1, test Ab, IEC 60068-2-2 test Bd

Thermal cycle IEC 60068-2-2, test Na, IEC 60068-2-38 (partial)

Humidity IEC 60068-2-78, IEC 60068-2-30 test Db Damp heat steady state and cyclic.

Degree of protection IEC 60529

Chemical environment

Description Applicable standard Comment

Salt mist IEC 60068-2-58 test Kb

Chemical resistance ISO 16750-5

Mechanical environment

Description Applicable standard Comment

Vibration IEC 60068-2-6 test Fc, IEC6008-2-64 test Fh

Bump IEC 60068-2-29 test Eb

Shock IEC 60068-2-27 test Ea

Free fall IEC 60068-2-32 test Ed

Electrical/electromagnetic

Description Applicable standard Comment

EMC emission ISO 13766, SAE J1113-13 Electromagnetic compatibility for earth

moving machinery.

EMC immunity ISO 13766 Electromagnetic compatibility for earth

moving machinery.

Electrostatic discharge EN 60-1 000-4-2

Auto electrical transients ISO 7637-2, ISO 7637-3

Short circuit protection Danfoss test Inputs and outputs survive continuous

short circuit. Normal function resumes

when short is removed.

Reversed polarity

protection

Danfoss test Survives reverse polarity at supply

voltage for at least five minutes.

18 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 19

155.0 ± 0.5

[6.102 ± 0.02]

225.0 ± 0.5

[8.858 ± 0.02]

13.3 ± 0.5

[0.524 ± 0.02]

51.2 ± 0.5

[2.016 ± 0.02]

55.2 ± 0.5

[2.173 ± 0.02]

75.00 ± 0.50

[2.95 ± 0.02]

75.00 ± 0.50

[2.95 ± 0.02]

75.00 ± 0.50

[2.95 ± 0.02]

23.50 ± 0.50

[0.93 ± 0.02]

kwa1463500663772

(DP600, DP610)

(DP620)

150.00 [5.90]

165.10 [6.50]

Technical Information

DP6XX Series Displays

Installation

Dimensions

DP600, DP610, DP620 Series Displays dimensions in millimeter [inches]

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 19

Page 20

1

20.00 ± 0.50

[0.79 ± 0.02]

105.00 ± 0.50

[4.13 ± 0.02]

145.00 ± 0.50

[5.71 ± 0.02]

210.00 ± 0.50

[8.268 ± 0.02]

4.20 ± 0.50

[0.17 ± 0.02]

201.50 ± 0.50

[7.93 ± 0.02]

2

77

5

6

4

3

Technical Information

DP6XX Series Displays

Installation

Two mounting options

Flush mounted

Use the DP600 panel mounting spring clip to flush-mount display into a dashboard.

Panel cutout and panel mounting spring clip

mm [in]

1. 4 holes for M4 x 4 screws

2. Panel cutout

3. Display assembly

4. Snap in

5. M4 x 4 screw

6. Spring clip

7. Panel

20 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 21

75.00 ± 0.50

[2.95 ± 0.02]

75.00 ± 0.50

[2.95 ± 0.02]

75.00 ± 0.12

[2.95 ± 0.005]

23.50 ± 0.50

[0.93 ± 0.02]

4XØ

Technical Information

DP6XX Series Displays

Installation

Stand-alone on post

Mount according to VESA (Video Electronics Standards Association) Mount Standards The VESA hole

pattern for this display is: 75.00 mm x 75.00 mm (02.95 in x 02.95 in).

Post mounting option

mm [in]

4XØ Hole x 4 for M4 screw x 0.7 mm (0.03 in) x 11 mm (0.43 in) maximum depth

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 21

Page 22

C1-P1

C1-P12

C2-P1

C2-P6

C3-P7

C3-P1

C4-P5

C4-P1

C1

C2

C3

C4

kwa1448992797040

C4 C3 C2 C1

Technical Information

DP6XX Series Displays

Installation

Pin assignments

DP6XX series, pin assignments

Pin connectors

Pin assignments

Binder 702 series 5-pin Binder 702 series 8-pin DEUTSCH DTMO6 6-pin DEUTSCH DTMO6 12-pin

C4 pin Function C3 pin Function C2 pin Function C1 pin Function

1 Video power ground 1 USB power bus 1 Redundant power ground 1 Main power ground

2 Video power 12/24 Vdc out 2 USB data – 2 Redundant power supply 2 Main power supply

3 Video input 1 3 USB data + 3 RedCAN left bus – CAN0 + 3 CAN bus – CAN1 +

4 Video ground 4 USB ground 4 RedCAN left bus – CAN0 - 4 CAN bus – CAN1 5 Video input 2 5 Ground 5 CAN shield 5 CAN shield

6 RS-232 RxD 6

7 RS-232 TxD 7 RedCAN right bus – CAN0 -

Analog in

6 RedCAN right bus – CAN0 +

8 Encoder supply

9 Encoder pulse A input

10 Encoder pulse B input

11 Encoder enter input

12 Buzzer – ground

22 | © Danfoss | August 2018 520L0699 | BC00000108en-US0501

Page 23

Technical Information

DP6XX Series Displays

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | August 2018 520L0699 | BC00000108en-US0501

Loading...

Loading...