User Manual

DP2xx series – EIC Engine Information Center

powersolutions.danfoss.com

User Manual EIC-Engine Information Center – DP2xx

Contents

Before You Start ......................................................................................................................... 4

The Engine Information Center (EIC) .................................................................................5

Brightness/Contrast Adjustment ........................................................................................ 6

Navigation Using Soft Keys ................................................................................................... 6

EIC DP2xx Force and Inhibit Regeneration software function description .........8

Main Menu .................................................................................................................................10

Setup Options ..........................................................................................................................27

J1939 Monitor Controls .........................................................................................................31

LED Indicators ...........................................................................................................................35

Installation/Mounting Instructions ................................................................................. 36

Connection/Pinout settings ...............................................................................................42

DP2xx Series Accessories .................................................................................................... 44

Important Safety Information ............................................................................................47

2 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

311032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Before You Start

Thank you for purchasing the Danfoss DP2xx Series Graphical Terminal.

This package contains the following items:

y One (1) DP2xx Series Graphical Terminal

y One (1) Panel Seal Gasket

y One (1) Mounting Bracket

y Four (4) Bracket Mounting Screws

y One (1) DP2xx Series Graphical Terminals User Manual

Please ensure all parts are included prior to use.

4 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

The Engine Information Center (EIC)

The DP2xx Series Graphical Terminal comes installed with the powerful and

exible Danfoss Engine Information Center (EIC) J1939 engine monitor

software application. Use the application to customize the look and feel of

your individual engine monitoring needs by creating and controlling analog

and digital display information in the screen congurations that work best for

your performance requirements.

Navigate through diagnostic information and conguration screens with ease

by using the four context-dependent soft keys located at the front of the

display. Choose from 50 dierent monitoring parameter proles to customize

the DP2xx terminal.

Up to four signals can be monitored on each screen. Use the Engine

Information Center software to congure the DP2xx for alarms and alerts.

511032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Brightness/Contrast Adjustment

Adjust brightness and contrast levels by

pressing soft key 2. This will display the

brightness and contrast soft key bar.

The bar will disappear after 3 seconds of

inactivity.

Navigation Using Soft Keys

The DP2xx Series Graphical Terminal is controlled by navigation through a set

of four soft keys located at the lower front of the display. The keys are context

dependent. Soft key selection options are displayed above each key and are

dependent on the current navigation location within the engine monitor

software program. As a general rule, the far right soft key is the selector

button and the far left soft key is the step back one screen key. To optimize full

screen use, the on-screen selections are not displayed when not in use. Press

any soft key to display current selection options. The selection options will be

displayed for three seconds.

6 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

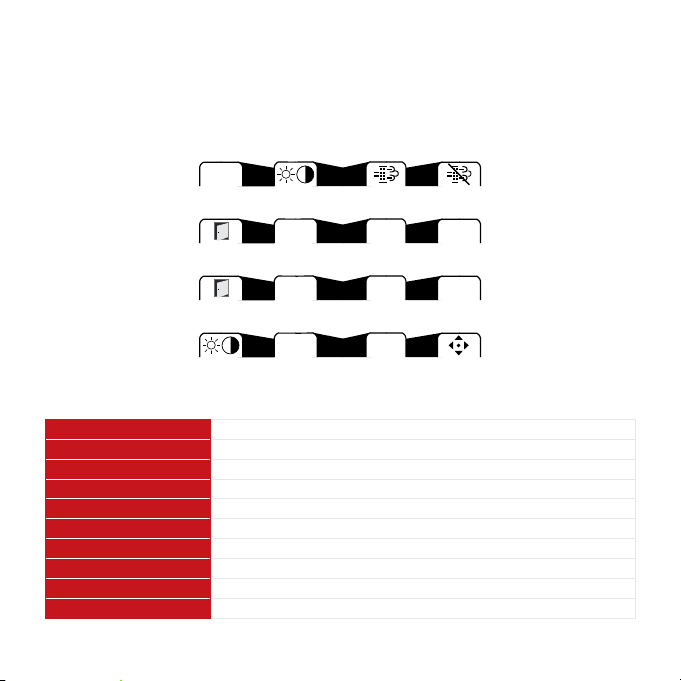

Navigation Using Soft Keys

Next Brightness/ Initiate Inhibit

Menu Contrast Switch Switch

Exit/Back Navigate Navigate Select

One Screen Up Down

Exit/Back Navigate Navigate Next

One Screen Up Down

Brightness/ Navigate Navigate Next

Contrast Up Down

Screen Navigation

Brightness/Contrast Press to access brightness and contrast settings

Navigate Up Press up to move up through menu items or screens

Navigate Down Press up to move down through menu items or screens

Main Menu Press to go to Main Menu screen

Exit/Back one screen Press to go back one screen

Select Press to accept selection

Next Press to select next digit or screen element

Initiate Switch Press to force regeneration of particulate lter

Inhibit Switch Press to inhibit particulate lter regeneration

Previous Press to navigate to previous menu

711032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

EIC DP2xx Force and Inhibit Regeneration software function description

While the unit is displaying one of the Monitor Screens, pressing any soft key

will show the available Navigation actions in an action menu. There are two

separate action menus on this level; the rst one to appear contains the

following actions (from left to right):

y Next Menu

y Screen Brightness/Contrast

y Initiate Switch (Force Regeneration)

y Inhibit Switch (Inhibit Regeneration)

Selecting ‘Next Menu’ will display the second action menu with actions

unrelated to the function described herein. Pressing it again will show the

rst set of actions once more. If no soft keys are pressed and released for

2.5 seconds while the action menu is shown the menu will disappear and the

actions are no longer available. Pressing (and releasing) any soft key will

activate the rst menu once more.

8 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

y Force Regeneration action

If the user selects the Force Regeneration action while the action menu is

being displayed; bit 2 (out of 0-7) in byte 5 (out of 0-7) will be set to 1 (true)

in the J1939 message PGN 57344 bound for the engine. This change

prompts the message to be transmitted. The bit will stay like this for the

duration of the soft key press or for the 2.5 second countdown to soft key

inactivity, whichever occurs rst. The bit is then reset to 0 (false).

The soft key press also prompts the display to show a popup lasting for

5 seconds. This popup simply says “Regeneration Forced”. If the display

does not receive an acknowledgement from the engine on the change to

message PGN 57344 the last half of the popup will say “No Engine Signal”.

This acknowledgement is the command that lights up the Forced

Regeneration LED on the display unit housing.

y Inhibit Regeneration action

If the user instead selects the Inhibit Regeneration action while the action

menu is being displayed the same function as described above will be

executed, with some dierences;

– Bit 0 (out of 0-7) in byte 5 (out of 0-7) is set to 1 (true) instead.

– The popup says “Regeneration Inhibit” instead.

– The acknowledgement lights up the Regeneration Inhibit LED instead.

911032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

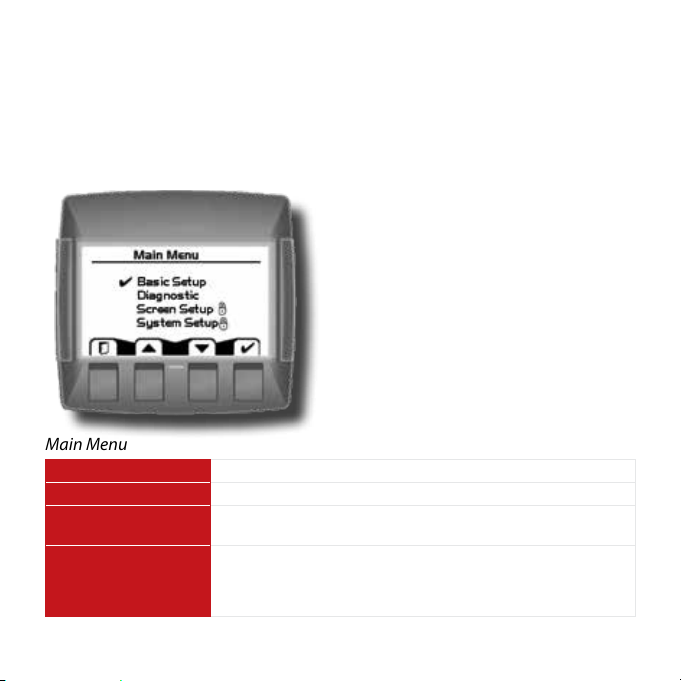

Main Menu

Start Menu

Start Menu – Main Menu

The Main Menu screen is the starting

point for conguring the DP2xx Series

Graphical Terminal.

Main Menu

Basic Setup Use to set Time/Date, Language and Units

Diagnostics Use to set System Info, access Fault Log and J1939 lists.

Screen Setup Use to set Parameters, choose number of screens and select

System Setup Use to reset trip and default settings,

10 11032748_Rev DA_Sep2014

screen. (PIN protected)

access CAN information,

select display settings and set PIN information.

(PIN protected)

User Manual EIC-Engine Information Center – DP2xx

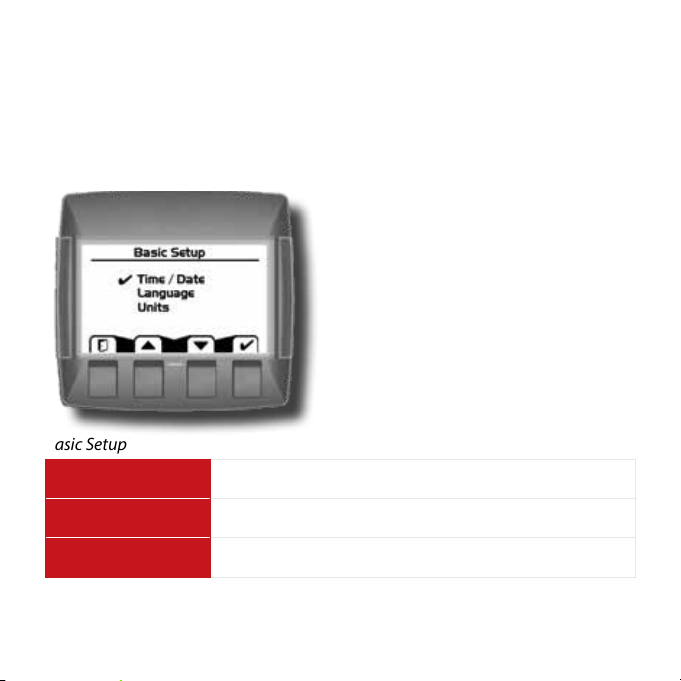

Main Menu

Basic Setup

Overview

Use the Basic setup screen to set time,

language and display units for the

DP2xx series terminal.

Basic Setup

Time/Date Use Time/Date to set, date and display style for time and date

information.

Language Use Language to set the system language. The default

language is English.

Units Use Units to set speed, distance, pressure, volume,

temperature, fuel rate and economy settings.

1111032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Basic Setup

Time/Date

Use Time/Date screen to set Time, Date, calendar

style and time style. Use up, down select and next

soft keys to navigate.

Language

Use Language screen to select program language.

Languages available, English, French, German,

Italian, Swedish and Spanish.

The default language setting is English.

12 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

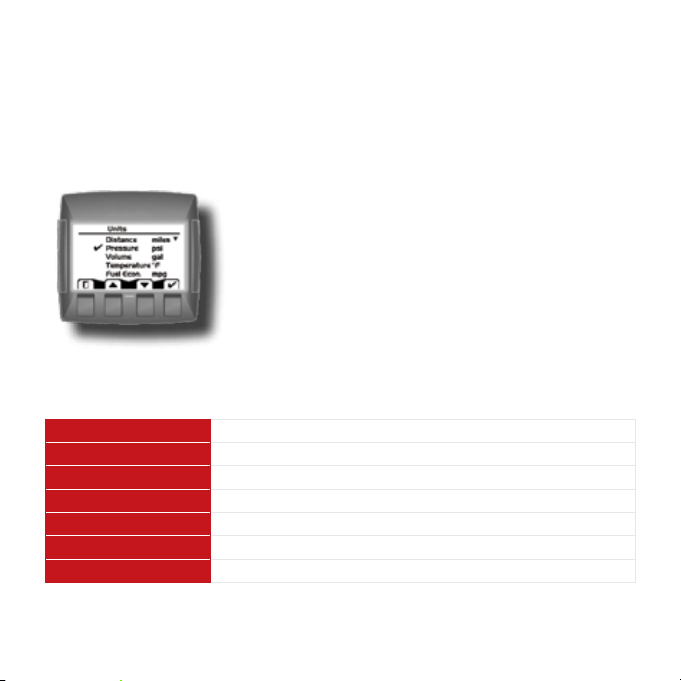

Main Menu

Basic Setup

Units

Use the up, down, select and next soft keys to

dene unit measurements.

Unit Selection Options

Speed km/h, mph

Distance km, mi

Pressure kPa, bar, lbs/sq in

Volume l, gal, imp gal

Temperature °C, °F

Fuel Economy 1/100 km, mpg, mpig

Fuel Rate l/h, g/h, ig/h

1311032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

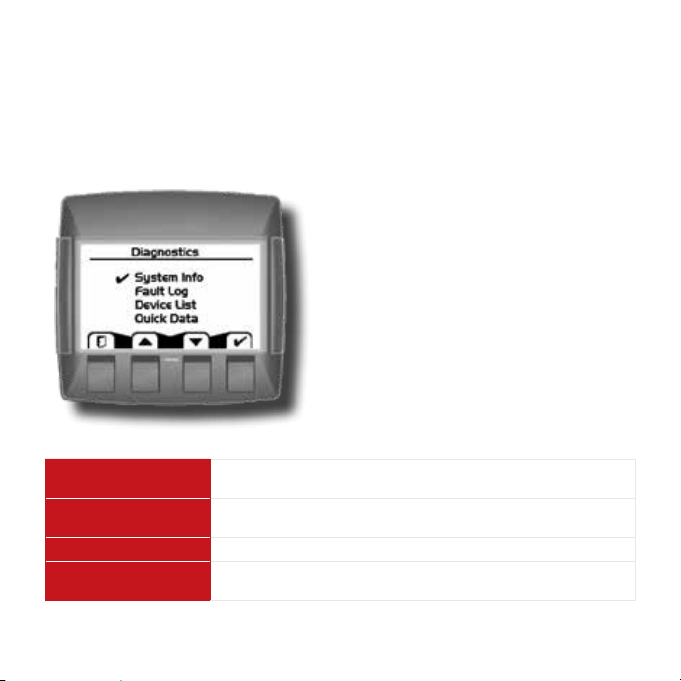

Diagnostics

Overview

Use the Diagnostics screen to display

current system information, view and

monitor fault logs and display all J1939

devices connected to the graphical

terminal.

Diagnostics

System Info Selecting System Info will display hardware, software, system

Fault Log Use Fault Log to view and monitor current and previous fault

Device List The Device List will list all currently connected J1939 devices.

Quick Data Use Quick Data to set up a customized signal list that can be

14 11032748_Rev DA_Sep2014

and node information for connected devices.

information.

quickly scrolled through in one signal per page format.

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Diagnostics

System Info

The system info screen displays the hardware

system serial number, current software version,

current system version and node number. Only

information is displayed in the System Info

window. No changes can be made.

Fault Log

Fault information is saved and stored to the fault

log. Select either Active or Previous Faults to

monitor fault activity. Select specic faults to list

more information.

1511032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Diagnostics

Fault Log: Active and Previous Faults

Selecting Active Faults in the Fault Menu will

display all active faults on the CAN network.

Selecting Previous Faults in the Fault Menu will

display all previously active faults on the CAN

network.

16 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Diagnostics

Fault Pop-Up Alarms

When a fault is detected on the CAN network, a

ashing red warning alarm will be activated and a

fault information pop-up window will be displayed

listing current fault information.

Warning lights will ash when a pop-up alarm

occurs and will stay ashing until acknowledged.

Warning lights will remain lit until the fault is no

longer on the CAN network.

Fault pop-up soft key actions

Select to clear pop-up and return directly to previous display

information

▼

▲

✔

Select to go to next fault information

Select to go to previous pop- up information

Select to clear pop-up and go to the current active fault

complete information screen

1711032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Diagnostics

Fault Pop-Up Alarms

y Faults that have been acknowledged and are no longer active will be

shown in the Currently Active Faults log in italics.

y Faults no longer active will also be displayed in the Previous Faults log.

y Pop-up fault alarms can be disabled by setting the Fault Pop-Up to o in

the CAN section of the System Setup menu.

18 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Diagnostics

Device List

The Device List page will list all J1939 devices and

addresses that are currently being monitored on

the network.

1911032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Diagnostics

Quick Data

The Quick Data function allows selected signals to

be monitored in a scrollable single view display.

To select signals for display, press the far right soft

key.

Quick Data softkey

Scroll through signal list using the up and down

arrow soft keys and select/deselect signals for

Quick View monitoring by pressing the far right

(check mark) soft key. Signals selected for display

will show an asterisks to the left of the signal

name.

20 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Screen Setup

Overview

Use Screen Setup to enter parameter

settings, select number of signal screens

and select individual screens for setup.

Screen Setup

Parameters Set Parameters for RPM, Speed, Fuel, Wheel and Pulse/

Revolutions information.

Number of Screens Select Number of Screens for information display. Select

from 1 to 4 screens for display.

Select Screen Use to Select Screen to set up signal information. Number of

screens available are dependent on number of screens

selected.

2111032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

Screen Setup

Parameters

Dene system parameter ranges for revolutions

per minute, speed, fuel, wheel diameter and

pulses per revolution display settings.

Number of Screens

Select number of screens for display. Choose from

1 to 4 screens. See page 22 for detailed screen set

up tutorial.

Select Screen

Select screen to customize. See page 27 for

detailed screen setup tutorial.

22 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

System Setup

Overview

Use System Setup to monitor and

control application systems. Reset to

default settings, make CAN selections,

control display settings, set PIN

congurations and reset trip functions.

System Setup

Reset Defaults Select to reset all system information to the default settings

status.

CAN Select to customize CAN settings.

Display Select to customize display settings.

PIN Setup Use to set custom PIN settings.

Trip Reset Select to reset all trip information.

2311032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

System Setup

Reset Defaults

Select Reset Defaults to reset all EIC settings to

original factory default settings.

CAN Settings

Use the CAN settings selection to make the

following selections:

CAN Settings

Engine Address Select engine address. Selection range is 0–253.

CAN Select 1, 2 or 3 to determine how to interpret non-standard

Fault Popup Select on or o to enable or disable on screen popup

24 11032748_Rev DA_Sep2014

fault messages. Consult engine manufacturer for correct

setting.

messages.

User Manual EIC-Engine Information Center – DP2xx

Main Menu

System Setup

Display Setting

Startup Screen Select to enable/disable logo

display at startup

Buzzer Output Select to enable/disable

warning buzzer functionality.

Demo Mode Select on/o to enable

demonstration mode.

2511032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Main Menu

PIN Protection

Change PIN Code

To reduce the potential for errors, Screen Setup

and System Setup menu options can only be

accessed after entering a PIN code. The default

code is 1-2-3-4. The PIN number can be changed

by using PIN Setup located in the System Setup

menu.

Trip Reset

Select Yes to reset all trip data.

26 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Setup Options

Selecting Screen Number and Types

1. Select from one to four screens for

signal monitoring.

Navigate to Main Menu>Screen

Setup>Number of Screens.

2. Select screen type for each of the

screens selected.

Navigate to Main Menu>Screen

Setup>Select Screen.

Choose from three types of screen

setups. Select screen type and press the

far right soft key (check mark) to go to

signal monitoring options.

2711032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Setup Options

Screen Variants

Screen Type 1

Type 1 is a two-up screen view with

two signal capacity.

Screen Type 2

Type 2 is a three-up screen view with

one large and two small signal

display capacities.

Screen Type 3

Type 3 is a four-up display with four

small signal display capacity.

28 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Setup Options

Selecting J1939 Monitor Signals

3. After screen type selection, select

signals to monitor. Use the up and down

arrow soft keys to cycle through

available signal selections.

4. After making a signal selection, press

the right arrow (Next) soft key to go to

the next selection area. Use the up,

down arrow, next and select soft keys to

select signal. Select the right arrow soft

key to move to the next selection area.

2911032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Setup Options

Selecting J1939 Monitor Signals

5. Using the right arrow soft key will

rotate through the selections in a

clockwise rotation.

When nished with all screen signal

selections press the exit (door symbol)

soft key to return to previous menus.

6. Navigate back for more screen

selections or press the Exit soft key 5

times to display current selections.

30 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

J1939 Monitor Controls

The following tables list the J1939 engine and transmission parameters that

are available and can be monitored in the DP2xx Graphical Terminal.

For more information on setting up monitor controls in using the Engine

Information Center, please refer to Selecting J1939 Signals on page 29.

3111032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

J1939 Monitor Controls

Symbols

Signal monitor functions

Symbol Name/Function Units

Actual Engine Torque %

Engine Air Inlet Temperature Pa × 1000

Engine Coolant Level %

Engine Coolant Pressure Pa × 1000

Engine Coolant Temperature °C

Engine Exhaust Gas Temperature °C

Engine Hours Hours

Engine Intake Manifold Temperature °C

Engine Oil Level Max = 100, min = 0

Engine Oil Pressure Pa × 1000

Engine Oil Temperature °C

Engine RPM RPM

Engine Turbocharger Boost Pressure Pa × 1000

Fuel Level %

Wheel-based Vehicle Speed kph/mph

32 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Symbol Name/Function Units

Accelerator Pedal Position %

Alternator Current Amp

Alternator Voltage Volts

Auxiliary Temperature °C

Average Fuel Economy km/l

Trip Average Fuel Rate l/h

Barometric Pressure Pa × 1000

Current Gear N/A

Distance Remaining Undened

Engine Air Filter Dierential Pressure Pa × 1000

Engine Air Inlet Temperature °C

Engine Injector Metering Rail 1 Pressure MPa

Engine Injector Metering Rail 2 Pressure MPa

Engine Intercooler Temperature °C

Engine Turbocharger Oil Temperature °C

Fan Speed %

Engine Fuel Delivery Pressure Pa × 1000

Fuel Rate l/h

3311032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Symbol Name/Function Units

Fuel Remaining %

Engine Fuel Temperature 1 °C

Instantaneous Fuel Economy km/l

Internal Voltage Volts

Net Battery Current Amps

Selected Gear N/A

Torque Convertor Lock-up Engaged Conditional

Total Distance Variable

Engine Total Fuel Used Variable

Transmission Input Shaft Speed RPM

Transmission Oil Pressure Pa × 1000

Transmission Oil Temperature °C

Transmission Output Shaft Speed RPM

Trip Distance km

Trip Engine Hours hrs

Trip Fue l l

% Soot Soot level percent %

% Ash Ash level percent %

34 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

LED Indicators

Lamps

Particulate Filter Lamp

Stage 1 The right Amber LED indicates the initial need for regeneration.

The lamp is on solid.

Stage 2 The right Amber LED indicates an urgent regeneration.

Lamp ashes with 1 Hz.

Stage 3 Same as Stage 2 but check engine lamp will also turn on.

High Exhaust System Temperature Lamp

The left Amber LED indicates the increase of exhaust system temperature due

to regeneration.

Regeneration Disabled Lamp

The left Amber LED indicates that the regeneration disabled switch is active.

3511032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Installation/Mounting Instructions

Panel Bracket Assembly

Mounting and fastening Installation

y Fastening hole depth: 11 mm

y May be threaded M3/ST3 and used with standard

screws. Reassembly with self-tapping screws may

damage existing threads in housing.

y Maximum torque: 0.9 Nm.

36 11032748_Rev DA_Sep2014

W Caution:

Excessive screw

torque force may

cause damage to

housing.

User Manual EIC-Engine Information Center – DP2xx

Mounting screws

DP2xx - M3×10 screw (×4) - 10107464

DP250 - ST3×12 screw (×4) - 11089413

Panel mounting bracket

DP2xx - 10105917

DP250 - 11072811

Panel gasket seal

DP200 -10107631

DP211 - 10107355

DP250 - 11075186

Installation/Mounting Instructions

Surface Mount

3711032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

105.5 mm [4.15 in] (±0.7 mm[0.027 in])

100.5 mm [3.95 in] (±0.7 mm [0.27 in])

Installation/Mounting Instructions

Panel Gasket Dimensions

y Gasket seal area crosshatched

y Panel thickness: 2-5 mm

y Interior edges chamfered 0.2- 0.5 mm

38 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

DP200 Series Model Code Variants

A

Model Name

DP200 Graphic al Display, IP 67 above pan el

B

Inputs/Outputs

00 1 CAN por t, 2 DIN/AIN

01 1 C AN port, 6 DIN/AIN

04 2 CAN por ts, 2 DIN/AIN

C

Real Time Clock / Low Temperature Functionality

00 No RTC, fu ll LTF

01 R TC and LTF

D

Flash Memory/Application Key

02 2MB wi thout Applicati on Key

03 2MB with Application Key

E

Application Log

00 None

04 4 MB

F

USB Port Type

00 None

01 USB Dev ice

3911032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

DP211 Series Model Code Variants

A

Model Name

DP 211 Graphic al Display with inte grated USB port

B

Inputs/Outputs

04 2 CAN por ts, 2 multifun ction

C

Real Time Clock / Low Temperature Functionality

01 R TC and LTF

D

Flash Memory/Application Key

02 2MB wi thout Applicati on Key

03 2MB with Application Key

E

Application Log

04 2 MB

F

USB Port Type

01 USB Dev ice

40 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

DP250 Series Model Code Variants

Model Name

DP250

Inputs/Outputs (All models have 2 multifunction

00 1 CAN port

01 1 CAN p ort, 4 DIN/AIN

04 2 CAN port s

05 User Congurable

06 User Congurable:

Real Time Clock / Low Temperature Functionality

00 No RTC and LTF

01 RTC an d LTF

Flash Memory/Application Key

04

05

Application Log

00 None

05 16 MB

USB Port Type

00 None

01

02

Color Graphical Display

2 CAN, 2 DIN /AIN or

1 CAN por t, 4 DIN/AIN

1 RedCA N port, 1 CAN por t or

1 RedCA N port, 2 DIN/AIN

16 MB without A pplication Key

16 MB with Appli cation Key

USB Device i n front

USB Device i n rear

4111032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

1

6

7

12

Connection/Pinout settings

DP200 Series- Deutsch Connector

DP200 Series pin assignments

Code B 00 Code B 01 Code B 04

1 Power ground–

2 Power supply+

3 CAN 0+

4 CAN 0–

5 AIN/ CAN Shield

6 See Code B option N/C DIN/AIN N/C

7 See Code B option N/C DIN/AIN N/C

8 See Code B option N/C DIN/AIN C AN 1+

9 See Code B option N/C DIN/AIN CAN 1–

10 DIN/AIN/FREQ IN/CURRENT IN

11 DIN/AIN/FREQ IN/CURRENT IN

12 DOUT (0.5A)

42 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

1

6

7

12

Connection/Pinout settings

DP250 Series- Deutsch Connector

DP250 Series pin assignments

1 Power ground-

2 Power supply+

3 CAN 0+

4 CAN 0–

5 AIN/ CAN Shield

6 See Code B option/TI

7 See Code B option/TI

8 See Code B option/TI

9 See Code B option/TI

10 DIN/AIN/FREQ IN/CURRENT IN, RHEOSTAT

11 DIN/AIN/FREQ IN/CURRENT IN, RHEOSTAT

12 DOUT (0.5A)

4311032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Connection/Pinout settings

Related Parts & Kits

DP200 Series Related Products Part Numbers

10100944 Deutsch Mating Connector Bag Assembly (20-24 AWG)

10102025 Deutsch Mating Connector Bag Assembly (16-20 AWG)

Electrical Connection Kits

10100944 12-pin Deutsch connection Kit

Contents:

10100738 DTM06-12SA 12-pin Deutsch connec tor

10100743 Deutsch terminal

10100741 WM 12S locking plug

Connection Tools

1010074 4 Deutsch stamped contacts terminal crimp tool, size 20

10100745 Deutsch solid contacts terminal crimp tool

44 11032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Connection/Pinout settings

Related Parts & Kits (Continued)

DP200 Mounting Kit

1010735 4 DP200 Series Mounting Hardware Kit

Contents:

10107464 Mounting screws (×4), M3 × 10

10107631 Panel gasket seal

10105917 Panel mounting bracket

DP211 Mounting Kit

10107264 DP211 Series Mounting Hardware Kit

Contents:

10107464 Mounting screws (×4), M3 × 10

10107355 Panel gasket seal

10105917 Panel mounting bracket

DP250 Mounting Kit

11079236 DP250 Series Mounting Hardware Kit

Contents:

11089413 Mounting screws (×4), ST3 × 12

11075786 Panel gasket seal

11072811 Panel mounting bracket

4511032748_Rev DA_Sep2014

User Manual EIC-Engine Information Center – DP2xx

Connection/Pinout settings

Related Parts & Kits (Continued)

Software

10101000 PLUS+1 GUIDE Software Application ( including Service Tool and

46 11032748_Rev DA_Sep2014

Screen Editor)

User Manual EIC-Engine Information Center – DP2xx

W Important Safety Information

y Disconnect your machine’s battery power before connecting power and signal cables to

the DP2xx.

y Before doing any electrical welding on your machine, disconnec t all power and signal

cable cables connected to the DP2x x.

y Do not exceed the DP2xx power supply voltage ratings. Using higher voltages may

damage the DP2xx and can create a re or electrical shock hazard.

y Do not use or store the DP2xx where ammable gases or chemicals are present.

y Using or storing the DP2xx where ammable gases or chemicals are present may cause an

explosion.

y Software congures the keypad buttons on the DP2xx. Do not use these buttons to

implement critical safety features. Use separate mechanical switches to implement critical

safety features such as emergency stops.

y Design systems that use the DP2xx so that a communication error or failure between the

DP2xx and other units cannot cause a malfunction that might injure people or damage

material.

y The protective glass over the DP2xx display screen will break if hit with a hard or heavy

object. Install the DP2xx to reduce the possibility of it being hit by hard or heavy objects.

y If you break the protective glass of the DP2xx screen, remove the DP2xx and immediately

return it to Danfoss for service.

y Storing or operating a DP2x x in an environment that exceeds the DP2xx specied

temperature or humidity rating may damage the DP2xx.

y Always clean the DP2xx with a soft, damp cloth. Use a mild dishwashing detergent as

needed.

y The DP2xx is not user serviceable. Return the DP2xx to the factory in case of failure.

4711032748_Rev DA_Sep2014

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-

inverter.com

Turolla

www.turollaocg.com

Danfoss Power Solutio ns is a global manufacturer and supplier of high-qu ality hydraulic and

electronic components. We spe cialize in providing state-of-the-art techno logy and solutions that

excel in the harsh operating conditions of the mobil e o -highway market. Build ing on our extensive

applications expertise, we work cl osely with our customers to ensure exceptional performance for a

broad range of o -highway vehicles.

We help OEMs around the world speed up system d evelopment, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever o -highway vehicles are at work, so is Danfoss.

We o er expert worldwide support for our c ustomers, ensuring the best possible solutions for

outstanding perfo rmance. And with an extensive network of Global Ser vice Partners, we also provide

comprehensive global service for all of o ur components.

Please contact the Danfoss Power Solutions representative ne arest you.

Products we o er:

Bent A xis Motors

Close d Circuit Axial Piston

Pumps and Motors

Di splays

Elec trohydraulic Power

Steering

Elec trohydraulics

Hydraulic Power Steering

Inte grated Systems

Joysti cks and Control

Handles

Micro controllers and

Software

Op en Circuit Axial Piston

Pumps

Orbital Motors

P LUS +1® GUIDE

Propor tional Valves

Sensors

Steering

Transit Mixer Drives

Local address:

Danfoss Power Solutio ns is a global manufacturer and supplier of high-qu ality hydraulic and

electronic components. We spe cialize in providing state-of-the-art techno logy and solutions that

excel in the harsh operating conditions of the mobil e o -highway market. Build ing on our extensive

applications expertise, we work cl osely with our customers to ensure exceptional performance for a

broad range of o -highway vehicles.

We help OEMs around the world speed up system d evelopment, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever o -highway vehicles are at work, so is Danfoss.

We o er expert worldwide support for our c ustomers, ensuring the best possible solutions for

outstanding perfo rmance. And with an extensive network of Global Ser vice Partners, we also provide

comprehensive global service for all of o ur components.

Please contact the Danfoss Power Solutions representative ne arest you.

Products we o er:

Bent A xis Motors

Close d Circuit Axial Piston

Pumps and Motors

Di splays

Elec trohydraulic Power

Steering

Elec trohydraulics

Hydraulic Power Steering

Inte grated Systems

Joysti cks and Control

Handles

Micro controllers and

Software

Op en Circuit Axial Piston

Pumps

Orbital Motors

P LUS +1® GUIDE

Propor tional Valves

Sensors

Steering

Transit Mixer Drives

Local address:

Products we o er:

Bent A xis Motors

Close d Circuit Axial Piston

Pumps and Motors

Di splays

Elec trohydraulic Power

Steering

Elec trohydraulics

Hydraulic Power Steering

Inte grated Systems

Joysti cks and Control

Handles

Micro controllers and

Software

Op en Circuit Axial Piston

Pumps

Orbital Motors

P LUS +1® GUIDE

Propor tional Valves

Sensors

Steering

Transit Mixer Drives

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss Power Solutio ns is a global manufacturer and supplier of high-qu ality hydraulic and

electronic components. We spe cialize in providing state-of-the-art techno logy and solutions that

excel in the harsh operating conditions of the mobil e o -highway market. Build ing on our extensive

applications expertise, we work cl osely with our customers to ensure exceptional performance for a

broad range of o -highway vehicles.

We help OEMs around the world speed up system d evelopment, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever o -highway vehicles are at work, so is Danfoss.

We o er expert worldwide support for our c ustomers, ensuring the best possible solutions for

outstanding perfo rmance. And with an extensive network of Global Ser vice Partners, we also provide

comprehensive global service for all of o ur components.

Please contact the Danfoss Power Solutions representative ne arest you.

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

11032748_Rev DA_Sep2014 www.danfoss.com © Danfoss A/S

Loading...

Loading...