Domestic hot water

Domestic Hot Water

Application guide

Intelligent solutions

with lasting eect

Visit devi.com

Table of content

Our quality management

system

and compliances

Along with full compliance with EU

directives and product approvals

ISO 9001 TS 16949

ISO 14001 PED

Let DEVI do the work

1. Application overview 4

2. System Description 5

3. System design 7

3.1 Heat loss calculation 7

3.2 Product selection 9

3.2.1 Heating cable selection 9

3.2.2 Thermostat/Controller

selection 11

3.2.3 Accessories selection 14

4. Safety instruction 18

4.1 DO's 18

4.2 DON'Ts 18

5. Case stories 19

6. Technical support 19

DEVI - an abbreviation of Dansk El-Varme Industri - was established in

Copenhagen, Denmark, in 1942. As from January 1st 2003 DEVI has become

a part of the Danfoss Group - Denmark's largest industrial Group. Danfoss

is one of the world's leading companies within heating, cooling and airconditioning. The Danfoss Group has more than 23.000 employees and

serves customers in more than 100 countries.

DEVI is Europe’s leading brand of electric cable heating systems and electric

pipe heating systems with over 70 years of experience. The development of

electric floor heating system takes place in Denmark, where the head office

is situated while heating elements (cables and mats) are manufactured by

Danfoss in EU.

Domestic Hot Water temperature

maintenance system

This design guide presents DEVI’s recommendations for design and

installation of Domestic Hot Water system. It provides guidance for a heating

cable layout, electric data and system configurations.

Following DEVI’s recommendations will ensure energy efficient, reliable and

maintenance free solution for constant wattage heating cables with 20 year

warranty, self-limiting heating cables with 5 years of warranty.

1. Application

overview

Modern living requires buildings to

have hot water available whenever

and wherever needed – and preferably immediately. The building regulations demand domestic hot water

systems to ensure best comfort and

efficiency as well as the Legionella

control measures.

DEVIhotwatt™ systems ensure continuous and reliable supply of with

the possibility to disinfect Domestic

Hot Water (DHW). DEVIhotwatt™ is

a self-limiting heating cable that is

used for temperature maintenance of

hot water supply.

DEVIhotwatt™ systems compliments

domestic hot water systems and enables

the unique possibility to temperature

control and disinfect, both for circulation systems and uniquely also for single

pipe systems from source to tap.

DEVIhotwatt™ systems complies with

IEC 62395-2:2013.

Benefits

• Unique opportunity - allows the installation

of a single pipe hot-water system, that includes

thermally controlled and disinfected hot water

at the tap.

• Lower initial investment the electric

pipe tracing in DHW system without

circulation requires less pipes and insulation

(approximately 50%), less valves, less pumps

and installation labor compared to the

recirculating system.

• DEVI pipe tracing systems ensure hot water

in all taps and savings when a circulating pipe

system is unnecessary.

• DEVI heating cable reduces water waste as you

can get hot water immediately.

• Protection against Legionella – DEVI system

maintains water supply at the required

temperature level and provides disinfection to

combat the bacteria.

• DEVIhotwatt™ system is the Perfect solution

to be used in domestic hot water systems.

Including systems supplied by low temperature

district heating.

• Energy efficient - Self limiting heating cables

provide power where needed, adapting their

output according to the ambient temperature.

Less pipes and smaller boilers will in term mean

lower heat losses.

• The heating cable is flexible and easy to

install as it can be cut to length, right on site

and installed directly on the pipe system.

4 Application guide · Domestic hot water · ©DEVI

2. System Description

DEVI Pipe tracing systems

will be required in the

following cases:

• Low-temperature, heat

source is supplying DHW

at lower than 50 °C

• The ambient

temperature variation is

significant

• Tap is located so far

away that the hot water

temperature is not

properly maintained

1800

1600

1400

1200

1000

Since 1998 the EU Drinking Water

Directive (98/83/EG) in EN 806-2

has established standards for hot

water in pipes that should not drop

below 50 °C. The building regulations

as well as global trends are demanding DHW systems to provide the best

comfort, energy efficiency and the

Legionella mitigation measures.

General design principles aim to

provide uniform water temperature,

which should also enable temperatures to combat Legionella growth.

The general recommendation for

DHW is to maintain the heat source

temperature between 50-60 °C

(IEC 62395-2:2013).

Water heating is provided by centralized or decentralized sources, Centralized water heating systems (district

heating) often have large distribution

network that might contribute to

temperature inconsistencies.

According to IEC 62395-2:2013 guidelines:

”For disinfection purposes min 55 °C

is typically required for hot water installations fitted with mixing valves”.

In the case that the water temperature

of DHW systems cannot achieve the

recommended level, risks of possible

water waste and Legionella will arise,

therefore a supplementary electrical

tracing system is recommended.

The Legionella bacteria which is commonly found in many types of water

worldwide. The bacteria can create a

potentially fatal type of pneumonia

commonly by inhalation.

The Legionella bacteria multiply best

where temperatures are between

20-45 °C and nutrients are available. A

method used to reduce the risk from

the Legionella bacteria, is to control the

water temperature, which is easy to do

with help of DEVI pipe heating system .

The DEVI pipe heating system for

DHW, maintains the water at the desired nominal temperatures or heats

(disinfects) it when needed.

1389

800

600

400

200

0

FranceGermanyItaly Netherlands Spain

Source: ECDC Annual Epidemiological Report for 2017 Source: ECDC Annual Epidemiological Report for 2017

664

1535

1018

393

Temperature and disinfection time

Tempera-

ture of

disinfec-

tion [°C]

55 2 h 00 minute

60 0 h 40 minute

65 0 h 26 minute

70 0 h 20 minute

75 0 h 10 minute

Time settings for thermal

disinfection

Recomended

70°C

60°C

50°C

40°C

30°C

20°C

Any disease Legionella Higher risk

At 70°C pasteurization process takes 20 min

At 58°C pasteurization process takes 50 min

At 50°C Legionella will no longer multiply

Ideal growth range

35-46 °C

growth range

5Application guide · Domestic hot water · ©DEVI

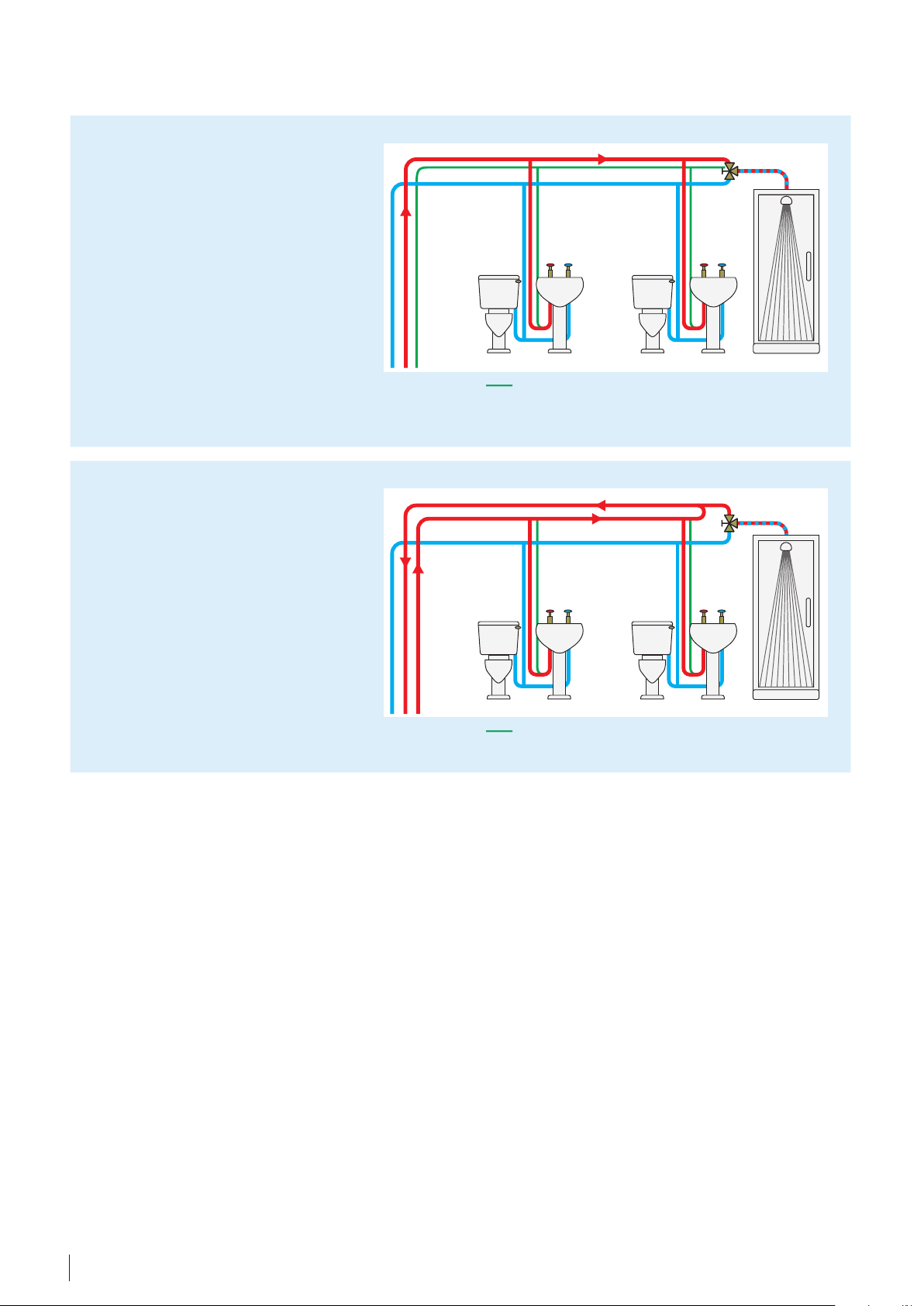

Heat tracing in DHW (Domestic Hot Water) systems

DHW system, single pipe system

(without circulation) - the cable

modifies its output and thereby

temperature according to the

conditions along the installation. This

means that the DHW system is heated

corresponding to heat losses, thus

maintaining and/or controlling the

temperature.

The more often the hot water tap is

turned on, the less the hot water temperature maintenance system needs to

be activated assuming a water supply

with a higher or equal temperature to

the respective requirement.

DHW system with circulation continuous circulation of hot water

to ensure that hot water is available

at any of the taps.

Self-limiting heating cable

In case of DHW with circulation - pipe

tracing can be installed to ensure

loop temperature. Thereby aiding the

system to maintain temperatures at

the required level.

DHW systems can also be installed to

secure pipes where circulation can't

be provided to ensure the wanted/

needed temperature.

The DEVIhotwatt™ pipe tracing in

DHW system without circulation

requires less pipes, less valves, less

pumps and installation labor compared to the Recirculating system.

• Approximately 50% less pipes – less

water volume in the pipes, thus

smaller boiler can be used.

• Energy consumption reduction, as

heat losses from the pipes will be

reduced by a significant amount.

Self-limiting heating cable

• Less maintenance cost, as less

mechanical parts and pumps.

• Saving water – DEVI pipe heating

system attached to the pipes keeps

water at the desired temperature

along the pipe system, so hot water

is immediately provided, when

demanded, and with minimum

water loss.

The DEVI pipe heating system insures

that DHW is supplied, independent of

the pipes length, and reduces the risk

of localized temperature fluctuations

by heating only where needed.

DEVI pipe heating system is insuring

automatic maintenance of the

required temperature 24/7.

6 Application guide · Domestic hot water · ©DEVI

3. System design

Following pages provide an easy design guide for selection of a Domestic hot water system.

The recommendations are provided relates to self-limiting cables, as well as thermostats and accessories.

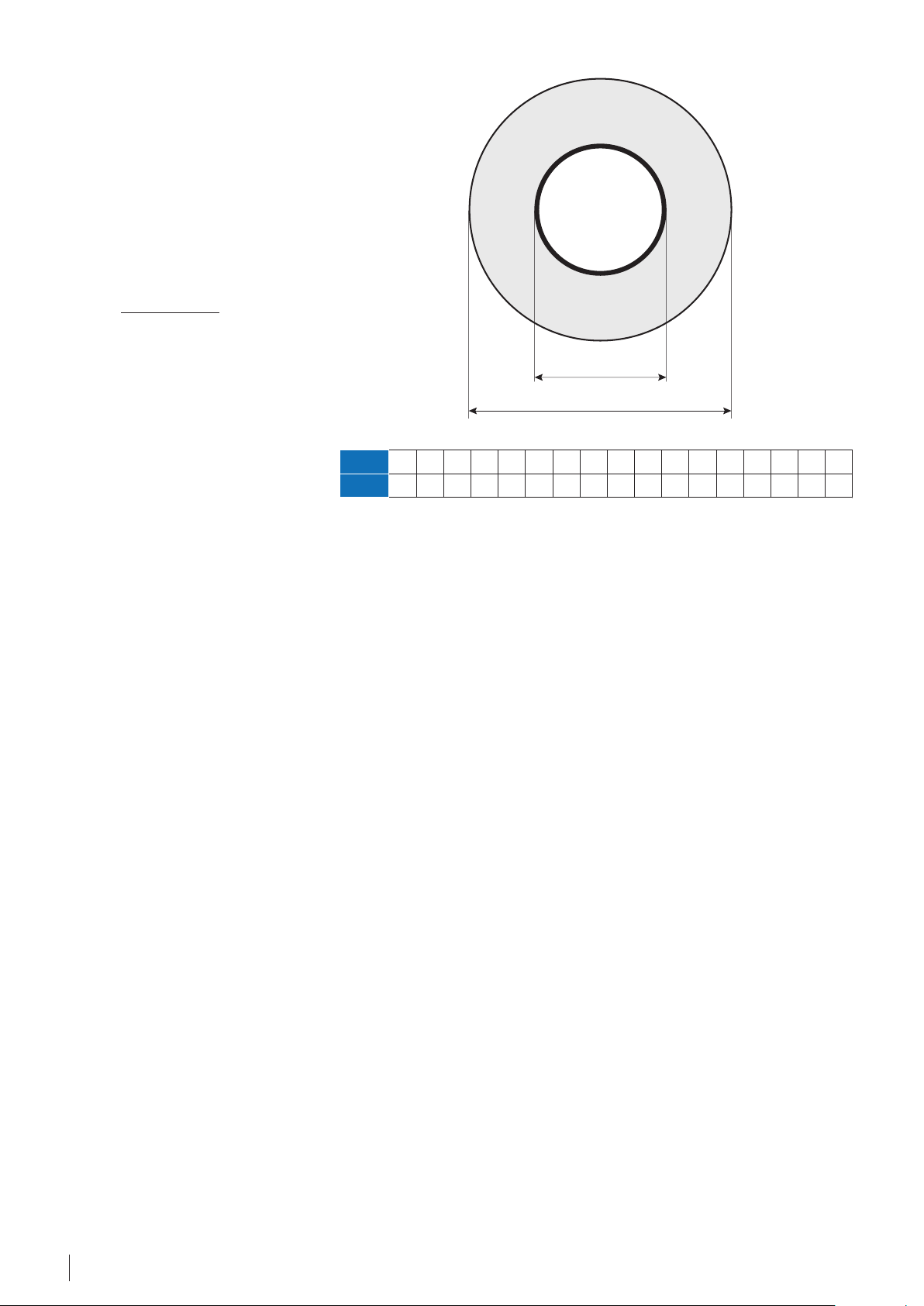

3.1 Heat loss calculation

Linear output of a heating cable (W/m),

which is installed on hot water pipe,

of heating cable along 1 pipe length

or a higher W/m cable.

should be at least the same as heat loss

(Q, W/m) of the pipe. Heat loss depends

on the following: pipe diameter, insula-

Heat and losses of pipe systems [W/m]

tion thickness, temperature inside pipe

and ambient/surrounding temperature.

Increased heat loss can lead to the

necessity of installing 2 or more lines

The table below shows the heat

loss for 1 meter of pipe (q

pipe

) for

various pipe dimensions, insulation

thicknesses and temperatures.

Required minimal outputs in [W/m], for straight pipelines (without flanges, valves or T-branches).

Inside pipe

diameter

Outside pipe

diameter*

Insulation

thickness

10 mm

20 mm

30 mm

40 mm

50 mm

75 mm

* NPS - Nominal Pipe Size, DN - diamètre nominal/nominal diameter/Durchmesser nach Norm.

Values in table can be calculated with help of formula on next page.

inch (NPS*) ½ ¾ 1 1¼ 1½ 2 2½ 3 3½ 4 4½ 5 6 8 10 12

mm (DN*) 15 20 25 32 40 50 65 80 90 100 115 125 150 200 250 300

mm 21 27 34 42 48 60 73 89 102 114 127 141 168 219 273 324

T, °C Heat loss for 1 meter of pipe, W/m ( λ = 0,04, Safety factor = 1,3)

20 9,8 11,8 14,1 16,8 18,8 22,7 27,0 32 36 40 45 49 58 75 92 109

25 12,2 14,7 17,6 21,0 23,4 28,4 34 40 46 51 56 62 73 93 115 136

30 14,6 17,7 21,2 25,2 28,1 34 40 48 55 61 67 74 87 112 139 164

40 19,5 23,6 28,2 34 38 45 54 64 73 81 89 98 116 149 185 218

60 29,3 35 42 50 56 68 81 97 109 121 134 148 174 224 277 327

80 39,0 47 56 67 75 91 108 129 146 162 179 197 232 299 370 436

100 48,8 59 71 84 94 114 135 161 182 202 223 246 290 374 462 545

20 6,1 7,2 8,4 9,8 10,8 12,8 14,9 17,6 19,7 21,7 23,9 26,2 31 39 48 56

25 7,7 9,0 10,5 12,2 13,5 16,0 18,7 22,0 24,7 27,1 30 33 38 49 60 70

30 9,2 10,8 12,6 14,6 16,2 19,2 22,4 26,4 30 33 36 39 46 58 72 84

40 12,2 14,4 16,8 19,5 21,6 25,6 30 35 39 43 48 52 61 78 96 112

60 18,4 21,6 25,2 29,3 32 38 45 53 59 65 72 78 92 117 143 168

80 24,5 28,7 34 39 43 51 60 70 79 87 95 105 122 156 191 224

100 30,6 36 42 49 54 64 75 88 99 109 119 131 153 195 239 281

20 4,8 5,6 6,4 7,4 8,1 9,4 10,9 12,7 14,1 15,4 16,9 18,4 21,4 27,0 33 38

25 6,0 7,0 8,0 9,2 10,1 11,8 13,6 15,8 17,6 19,3 21,1 23,0 26,7 34 41 48

30 7,3 8,4 9,6 11,0 12,1 14,1 16,3 19,0 21,2 23,2 25,3 27,6 32 40 49 58

40 9,7 11,2 12,8 14,7 16,1 18,8 21,8 25,3 28,2 31 34 37 43 54 66 77

60 14,5 16,7 19,3 22,1 24,2 28,3 33 38 42 46 51 55 64 81 99 115

80 19,4 22,3 25,7 29,4 32 38 44 51 56 62 68 74 86 108 131 154

100 24,2 27,9 32 37 40 47 54 63 71 77 84 92 107 135 164 192

20 4,2 4,7 5,4 6,1 6,7 7,7 8,8 10,2 11,3 12,3 13,4 14,5 16,8 21,0 25,4 29,6

25 5,2 5,9 6,7 7,7 8,3 9,6 11,0 12,7 14,1 15,4 16,7 18,2 21,0 26,2 32 37

30 6,2 7,1 8,1 9,2 10,0 11,6 13,2 15,3 16,9 18,4 20,1 21,8 25,2 31 38 44

40 8,3 9,5 10,8 12,2 13,3 15,4 17,7 20,4 22,6 24,6 26,7 29,1 34 42 51 59

60 12,5 14,2 16,2 18,4 20,0 23,1 26,5 31 34 37 40 44 50 63 76 89

80 16,6 19,0 21,6 24,5 26,6 31 35 41 45 49 53 58 67 84 102 118

100 20,8 23,7 27,0 31 33 39 44 51 56 61 67 73 84 105 127 148

20 3,7 4,2 4,8 5,4 5,8 6,7 7,6 8,7 9,6 10,4 11,2 12,2 14,0 17,4 20,9 24,3

25 4,7 5,3 6,0 6,7 7,3 8,3 9,5 10,8 11,9 13,0 14,1 15,2 17,5 21,7 26,2 30,4

30 5,6 6,3 7,1 8,0 8,7 10,0 11,4 13,0 14,3 15,6 16,9 18,3 21,0 26,0 31 36

40 7,5 8,4 9,5 10,7 11,6 13,3 15,1 17,3 19,1 20,7 22,5 24,4 28,0 35 42 49

60 11,2 12,7 14,3 16,1 17,4 20,0 22,7 26,0 28,7 31 34 37 42 52 63 73

80 14,9 16,9 19,0 21,4 23,2 26,6 30 35 38 41 45 49 56 69 84 97

100 18,6 21,1 23,8 26,8 29,0 33 38 43 48 52 56 61 70 87 105 121

20 3,1 3,5 3,9 4,3 4,6 5,2 5,8 6,6 7,2 7,8 8,4 9,0 10,2 12,5 14,9 17,2

25 3,9 4,3 4,8 5,4 5,8 6,5 7,3 8,3 9,0 9,7 10,5 11,3 12,8 15,6 18,6 21,5

30 4,7 5,2 5,8 6,4 6,9 7,8 8,8 9,9 10,8 11,7 12,6 13,5 15,4 18,8 22,4 25,7

40 6,2 6,9 7,7 8,6 9,2 10,4 11,7 13,2 14,4 15,6 16,8 18,0 20,5 25,0 29,8 34

60 9,3 10,4 11,6 12,9 13,8 15,6 17,5 19,8 21,7 23,3 25,1 27,0 31 38 45 51

80 12,5 13,9 15,5 17,2 18,4 20,9 23,4 26,4 28,9 31 34 36 41 50 60 69

100 15,6 17,4 19,3 21,5 23,0 26,1 29,2 33 36 39 42 45 51 63 75 86

To define the heat loss follow the

pipe diameter (in [mm] or [inch]) at

the top bar of the table towards the

row with the insulation thickness and

using the appropriate temperature

difference you will find the heat loss

value at the crossing point.

For this table λ of insulation

material is 0,04 W/mK (e.g. mineral

wool) and safety factor is 1,3.

7Application guide · Domestic hot water · ©DEVI

The most important factors to define

the pipe heat losses are the following:

• Pipe diameter

• Insulation thickness

• Difference between inside

(desired maintained

temperature).

The following formula is used for

heat losses calculation for total

length of a pipe to be protected:

Q [W]=

2 · π · λ · l · (t

ln(D/d)

a

- tp)

1, 3 ,

where:

D - Outside pipe diameter incl. insulation, [m],

d - Pipe diameter without insulation [m],

l - Total length of pipe, [m],

tp - Desired maintained temperature, [°C],

ta - Outside temperature, [°C],

λ - Thermal conductivity of insulation, [W/m·K],

1,3 - Safety factor.

λ value for standard insulation

material (like glass wool or styropor),

is set to 0,04 W/m·K.

ln(D/d)

(D/d)

0,0

1,0

0,4

1,5

0,7

2,0

0,9

2,5

1,1

3,0

1,3

3,5

1,4

4,0

Heat loss values from the table on

the previous page calculated by the

above formula and divided by total

pipe length. The obtained values are

in [W/m].

t

a

t

p

d

D

1,5

1,6

1,8

1,9

2,1

2,2

2,3

2,7

4,5

5,0

6,0

7, 0

8,0

9,0

10,0

15, 0

Natural logarithm (ln) values for D/d

ratio: X = D/d.

3,0

20,0

3,2

25,0

8 Application guide · Domestic hot water · ©DEVI

3.2 Product selection

This section will show how to choose the correct heating element, control device and what accessories to use for the

installation.

3.2.1 Heating cable selection

Self-limiting cables are often used for

pipe systems with many branches,

because it's easier to adjust the cable

length to appropriate pipe length.

The self-limiting behavior of the cables,

provides output adjustment based on

the temperature (pipe and ambient),

this a rather useful feature. However

a thermostat for self-limiting cable

regulation is a must.

When choosing a self-limiting

heating cable it's essential to

investigate whether the heating

cable can provide the required

output at the desired temperature.

How to read the graph

Draw a line from the desired

temperature value (X-axis) and a

calculated heat loss output (Y-axis).

Afterwards find a heating cable with

output values higher (Y-axis) than

the cross point of temperature and

output lines.

Example (values from Previous page)

• Pipe diameter d = 25 mm

• Insulation thickness = 30 mm

• Thermal conductivity value for

insulation λ = 0,04

• Desired temperature tu = +45 °C

35

30

25

20

Emission of heat, W/m

15

Calculated

heat loss

Q = 8 W/m

10

5

5 10 15 20 25 30 35 40 45 50 55 60 65 70

• Minimum outside temperature

to = +20 °C

Heat loss Q is calculated by the

formula of Step 1 or from the table on

page 7: Q = 8 W/m.

This would then promt the choice to

be DEVIhotwatt 55 for an output of

9 W/m at 55 °C

DEVIhotwatt™ 70

DEVIhotwatt™ 55

DEVIhotwatt™ 45

12 W/m

7 W/m

Desired temperature

tu = +45 °C

9 W/m

Pipe temperature, °C

The pipe tracing system consists of a

self-limiting heating cable, installed

on a pipe along its whole length, and

providing hot water instantly, even

at faucets placed far away from pipe

draw off.

Overjacket

Protective braid

Insulation

Fig. 3 - Self-limiting cable construction

• 1,3 mm² nickel plated cooper bus wires

• Radiation Cross-linked Semiconductive

Heating Matrix

• Radiation Cross-linked Primary Dielectric

insulation

The system must be controlled by an

electronic regulator to maintain the

temperature and to run disinfection

ensuring safe and enabling the

option to maintain a Legionella free

water supply.

Self-limiting heating element

Bus wires

• Tinned copper braid

• Polyolen overjacket

The DEVIhotwatt™ is a self-limiting

heating cable that is used for

temperature maintenance of hot

water and other fluids which require

certain temperature levels.

The self-limiting capability of the

cable ensures cable output regulation

according to temperature to which

the cable is exposed, hence the selflimiting effect.

9Application guide · Domestic hot water · ©DEVI

DEVIhotwatt™ 45 (B), DEVIhotwatt™ 55 (B), DEVIhotwatt™ 70 (B)

The DEVIhotwatt™ is a self-limiting heating cable that is used for

temperature maintenance of hot water supply and other uids that need

to maintain a certain temperature.

The self-limiting capability of the cable ensures that the output of the

cable increase or decrease according to ambient temperature.

DEVIhotwatt™ ensures hot water in all taps and savings when circulation

of the whole pipe system is unnecessary.

The cable is not approved for use in drinking water.

Type

Nominal voltage 230 V AC

Nominal output (min-max) :

DEVIhotwatt™ 45

DEVIhotwatt™ 55

DEVIhotwatt™ 70

Outer sheath:

DEVIhotwatt™ 45

DEVIhotwatt™ 55

DEVIhotwatt™ 70

Maximum permissible use temperature

Minimum installation temperature -50 °C

Cable dimensions 11,8 mm × 5,8 mm

Minimum braid coverage 70%

Maximum resistance protective braid 18,2 Ω/Km

Bending Ø, min. 50 mm (Ø to the inside of the tape)

Max. installation length

- with 10 A circuit breaker 55 m

IP Class IPX7

Value

7 W/m @ 45 °C (6,5-9,5 W/m @ 45 °C)

9 W/m @ 55 °C (8,5-13,0 W/m @ 55 °C)

12 W/m @ 70 °C (11,3-15,2 W/m @ 70 °C)

Black, TPE

Green, TPE

Red, TPE

80 °C, powered

100 °C, unpowered

Maximum heating circuit length on a pipe, with circuit breaker

with C-characteristic

"Circuit breaker size" 6A 10A 16A

"start-up

temperature", [°C]

DEVI-hotwatt 45 72 77 86 92 119 129 144 153 191 203 230 231

DEVI-Hotwatt 55

-25 -10 +10 +20 -25 -10 +10 +20 -25 -10 +10 +20

52 56 61 65 86 93 102 108 138 148 164 173

Benefits

• The cables can

be cut to length

on site providing

quick installation.

• Automatic

compensation for

heat loss along

the pipe assuming

cable has more

output capability

than heat loss

present.

• Economical, selflimitting

• PVC free

• Limited preplaning of the

installation

DEVI-Hotwatt 70 24 27 42 59 37 45 71 99 64 72 113 146

"Circuit breaker size" 20A 25A 32A

"start-up

temperature", [°C]

DEVI-hotwatt 45 231 231 231 231 231 231 231 231 231 231 231 231

DEVI-Hotwatt 55 173 185 188 188 188 188 188 188 188 188 188 188

DEVI-Hotwatt 70 80 90 142 146 103 113 146 146 133 143 146 146

-25 -10 +10 +20 -25 -10 +10 +20 -25 -10 +10 +20

10 Application guide · Domestic hot water · ©DEVI

3.2.2 Thermostat/Controller selection

Temperature regulation

Self-limiting heating cables require a

thermostat for temperature control.

The thermostat ensures maintaining

desired temperature.

Domestic hot water systems are

required to have sensors mounted on

each hot water pipe system to ensure

proper control.

thermostat

on-pipe mounted sensor

thermostat

on-pipe mounted sensor

If the size of the heating cable

exceeds the maximum limit defined

by the thermostat or fuse.

The load of the heating cables

can be distributed by means of

external relays / contactors or by

use of the multiple relays within the

DEVIreg Hotwater controller. In such

installations, one thermostat can

regulate several heating elements.

When load distributing, please

do not exceed maximum cable

lengths mentioned on step 10.

Temperature regulation using onpipe sensors

This type of installation, where the

sensor is placed directly on pipe

under insulation, is more precise and

energy efficient way of regulation.

thermostat

on-pipe mounted sensor

Pipe of different lengths. Installation completed with 3 individual thermostats, this could also be

achieved using one DEVIreg Hotwater.

Sensor placing

Sensors for Domestic hot water

systems should be installed, at the

estimated most representative

position on the pipe.

Sensor placement for DEVIReg

Hotwater should be done such,

that the hottest and coldest

spot on pipe is measured, as the

DEVIreg Hotwater calculates a user

configurable mean temperature.

11Application guide · Domestic hot water · ©DEVI

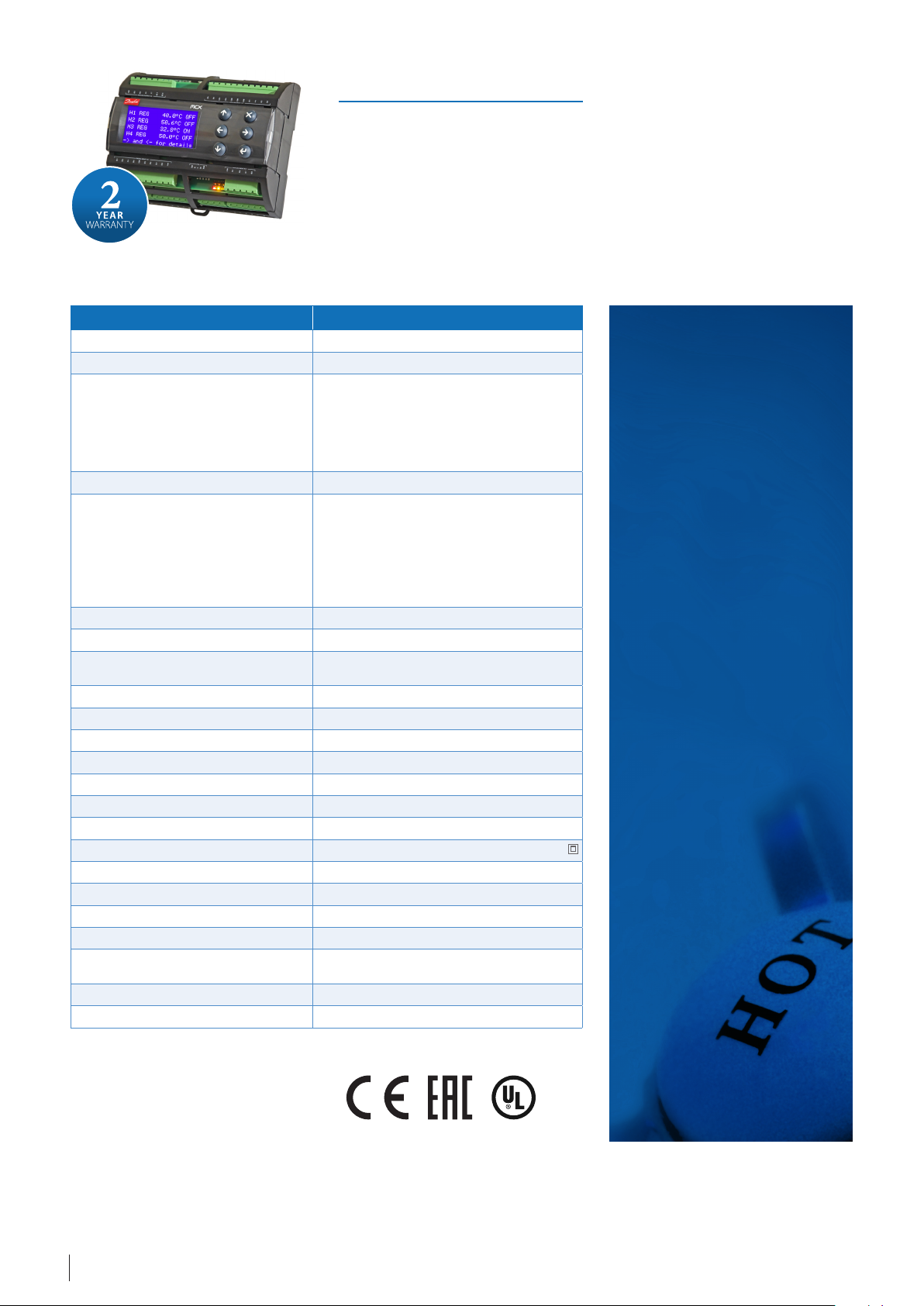

DEVIreg™ Hotwater

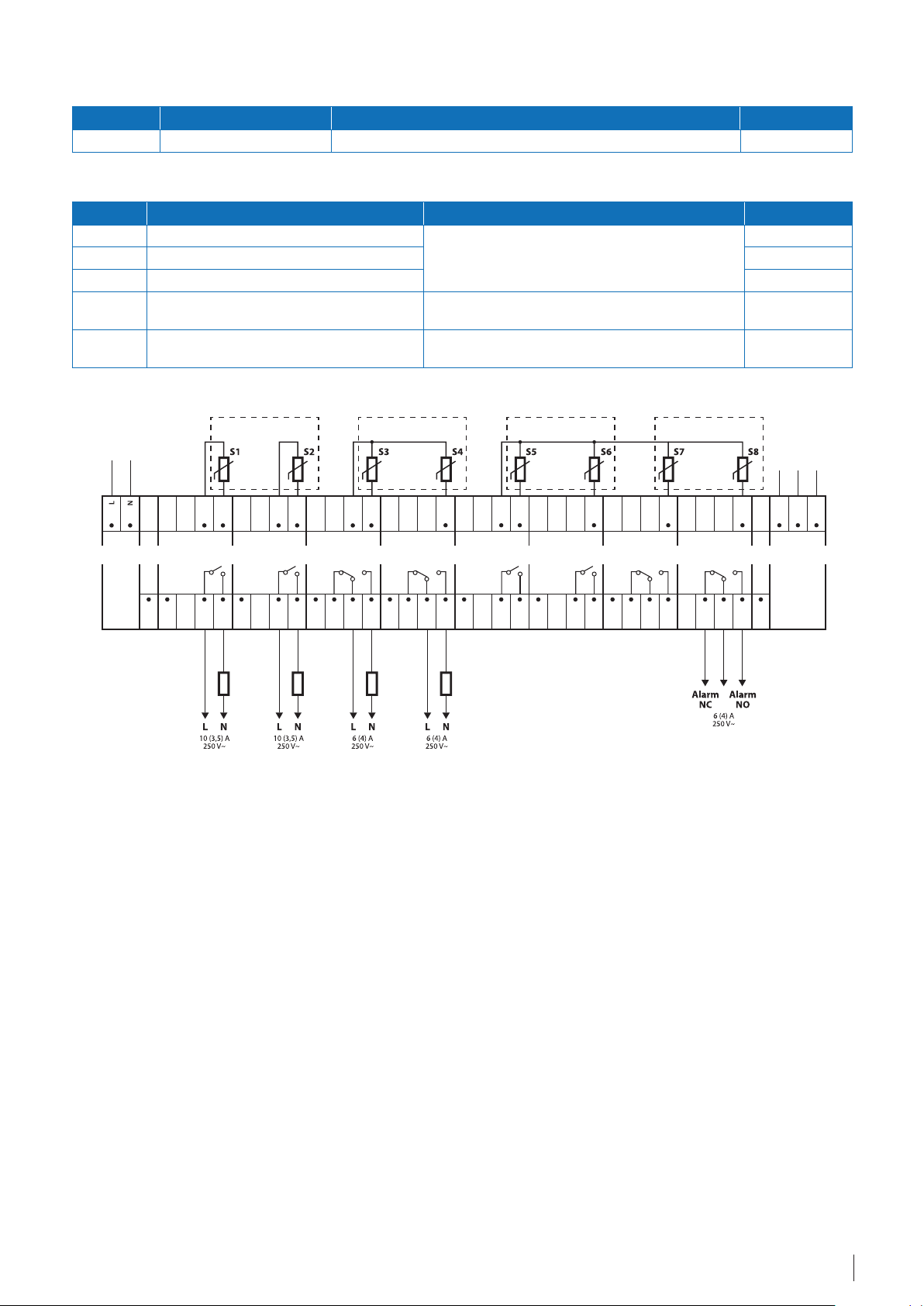

DEVIreg™ Hotwater is an electronic programmable controller with 4 channels

for on DIN rail mounting. Every channel can be set Individually to maintain hot

water with the option to disinfect manually, or on a schedule. The channels sensors can be selected between 7 dierent temperature sensors including NTC 15

kOhm at 25 °C. Building Management System (BMS) control is possible through

the Modbus RS485 serial interface.

DEVIreg™ Hotwater has been developed to give the user easy setup, control

of their hot water system, along with the option to disinfect. The controller allows up to 4 channels to be operated, each

capable of controlling a separate pipe system. 2 sensors have to be used to measure the temperature for each channel.

Type

Nominal voltage 110/230 V AC, 50–60 Hz

Power consumption, max. 20 V A

Relay load:

Resistive (inductive, cos(phi sign) = 0,6)

Total current load limit

C1-NO1, C2-NO2

C3-NO3-NC3, C4-NO4-NC4

C8-NO8-NC8

Sensor inputs Analog inputs AI1-AI8

Compatible sensors NTC15k (15 kOhm @ 25 °C) (standard)

Digital inputs DI1-DI8, voltage free contacts, on/o inputs

Connection specication Grouped screws plug-in connectors

Cable specication for connectors termi-

nals

Battery back-up time, min. 48 hours

Ball pressure test 125 °C

Pollution degree 2 (domestic use)

Controller type 1 C

Operating temperatures and conditions CE: -20T60 / UL: 0T55, 90% RH non-condensing

Storage temperature and conditions -3085, 90% RH non-condensing

IP class IP40 only on the front cover

Protection class Class II Immunity against voltage surges Over Voltage Category II

Dimensions (H/W/D), DIN dimension : 110(122) 138 70 mm, 8 DIN modules

Mounting method DIN rail, complying with EN 60715

Weight, net 511 g

Menu languages:

Base controller Danfoss MCX08M2, item no. 080G0307

Software class A

Value

32 A

10 (3,5) A (100 000 cycles)

6 (4) A (100 000 cycles)

6 (4) A (100 000 cycles)

NTC10k (10 kOhm @ 25 °C)

NTC5k (5 kOhm @ 25 °C)

NTC2k (2 kOhm @ 25 °C)

NTC100 (100 kOhm @ 25 °C)

NTC16k (16,7 kOhm @ 100 °C)

PT1000 (1000 Ohm @ 0 °C)

0,2-2,5 mm²

GB,DE,BG,CZ,DK,ES,EE,FI,FR,HR,HU,LT,LV,NL,NO,

PL,PT,RO,RU,SE,SR,SI,SK,TR,UA,CN.

Benefits

• 4 independent channels

• 2 control modes:

– Hot water

maintenance

– Hot water

maintenance with

disinfection

• User denable

accuracy

• Compatible with 7

sensors types

• Sensor failure

monitoring

• Accurate temperature

control

• Alarm functions

• Multilanguage menu

• Graphic LCD display

• BMS control

Compliance:

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

EN/IEC 60730-1 + EN/IEC 60730-2-9

12 Application guide · Domestic hot water · ©DEVI

Certicates:

DEVIreg™ Hotwater + 2 sensor NTC 15kOhm

110/230 V AC

Item no. Product name Type EAN no.

140F1133 DEVIreg™ Hotwater Programmable controller with 2 Wire sensor NTC 15 kOhm at 25 °C, 3 m 5703466249680

Accessories

Item no. Product name Description EAN no.

140F1091

140F1098

Sensor 3 m, 15 kOhm, Santropene

Temperature Sensor 10 m NTC 15k Santropene

Wire sensor, 2x0,75 mm², NTC 15 kOhm at 25 °C, Ø5x18

mm, black Santropene (TPV), IP 67

19121445 Sensor cable 40 m, 15 kOhm, Santropene 5703466115015

140F1092 Outdoor sensor 2,5 m, 15 kOhm, PVC

140F1097

Silicon sensor for DEVIreg™ 330

(60-160°C), NTC 16,7 kOhm @ 100°C

Wire sensor, 2x0,75 mm², NTC 15 kOhm at 25 °C, Ø8 mm,

white PVC outer sheath, IP 67

Wire silicon sensor, 2,5 m, 2x0,75 mm²,

NTC 16,7 kOhm at 100 °C, IP 65

Connection scheme DEVIreg™ Hotwater

5703466209301

5703466210734

5703466209318

5703466209707

Power

COM

DI 1-4

DI 1

S - temperature Sensor

H - Heating element

for H2 for H3for H1

AI 1

COM

C 1

NO 1

DI 2

AI 2

COM

C 2

NO 2

DI 3

NC 3

AI 3

COM

AI 3-4

C 3

NO 3

DI 4

H1 H2 H3 H4

NC 4

for H4

RS485

(Modbus)

D -

AI 4

AI 5

COM

AI 5-8

AI 6

AI 7

AI 8

D +

GND

RS485

C 4

NO 4

DI 5

C 5

NO 5

DI 6

C 6

NO 6

DI 7

NC 7

C 7

NO 7

NC 8

DI 8

C 8

NO 8

COM

DI 5-8

13Application guide · Domestic hot water · ©DEVI

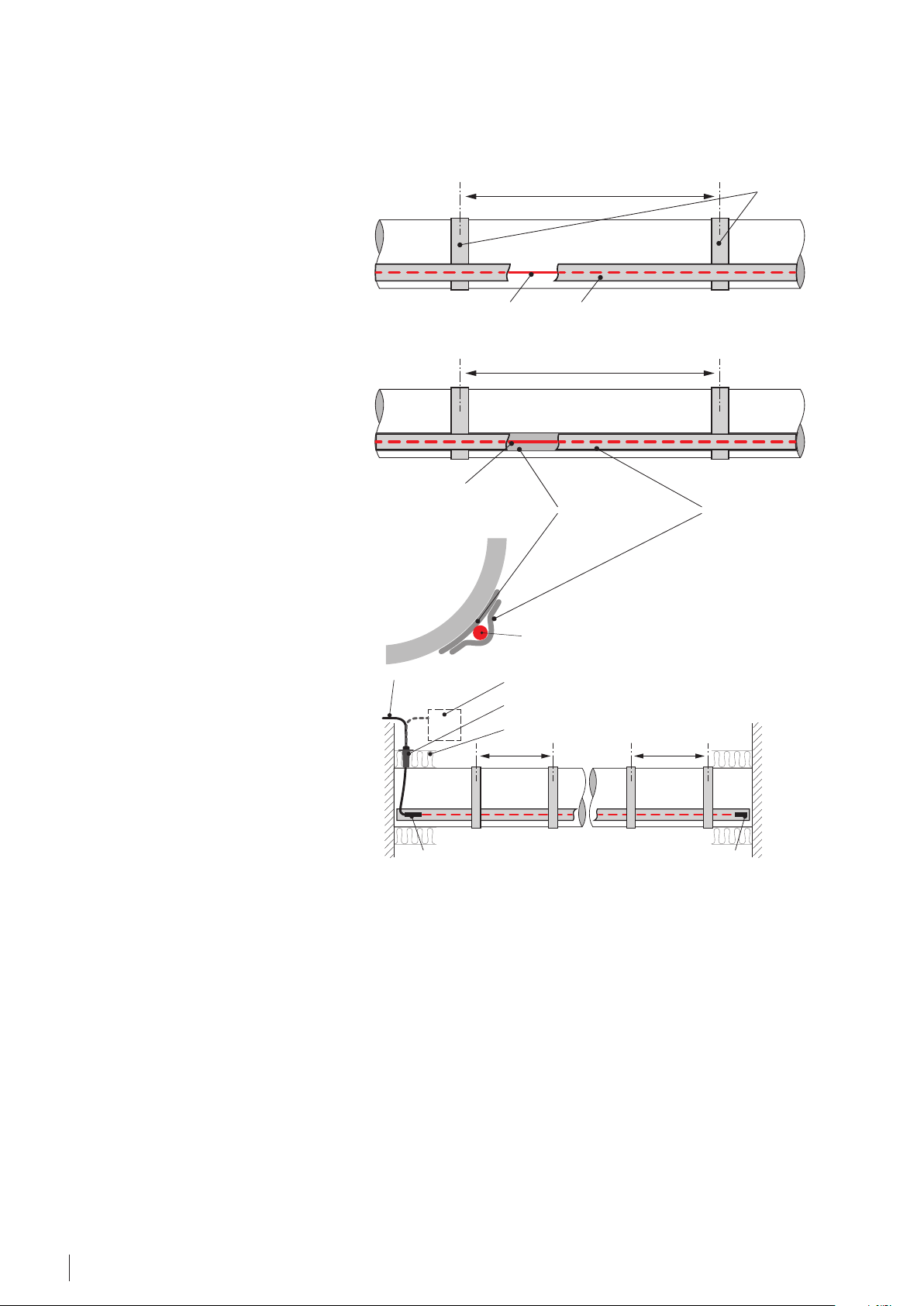

connection box

Output from

(part of a heating cable)

(part of a heating cable)

aluminum tapes

(pipe dimension Ø 150 mm)

heating cable

(under the tape)

aluminum tape

aluminum tapes

for cable attachment

to the pipe

metal

pipe

~1 m

app. 1,5 m tape

on 1 m of pipe

(pipe dimension Ø 150 mm)

3.2.3 Accessories selection

In case of metal pipes the heating cable

can be attached to the pipe by means

of an aluminum tape placed at intervals

of approx. 1 meter. Subsequently, the

total length of the heating cable needs

to be covered with aluminum tape,

securing cables to the pipe.

In case of the plastic pipes, before

mounting the cable onto the pipe, the

aluminum tape needs to be applied

on the pipe where the heating cable

will be placed. Other part of the

installation steps resembles that of the

installation on metal pipe.

For plastic pipe a temperature of

more than 60 degrees can't be

recommended, as this might weaken

the connections of the pipes.

The cable installed throughout the

pipe length needs to be covered

along its whole length with

aluminum tape to ensure good

contact with the pipe.

(between layers of aluminum tape)

metal

pipe

plastic

pipe

heating cable

heating cable

(under the tape)

~1 m

aluminum tape

~1 m

1st layer of tape

for cable attachment

to the pipe

app. 1,5 m tape

on 1 m of pipe

2nd layer of tape

app. 2,5 m tape

on 1 m of pipe

(pipe dimension Ø 150 mm)

On plastic pipes aluminum tape is

necessary both below and above

cable to ensure heat transfer.

All cables must be installed in parallel

passes; no spiral wrapping is allowed.

Hot water pipes shall be pressure

tested prior to installation of heating

cable and thermal insulation. Thermal

insulation shall not be installed until

heating cable installation is complete

and tested.

Cables must be fitted as shown

at 5 or 7 o’clock positions

when mounting two cables, or

alternatively at 6 o'clock when

mounting a single cable.

When the heating cable is

thermostat

connection mu

installed on pipes, the insulation

should be clearly marked with a

warning sign, e.g. “WARNING: 230

VOLT HEATING CABLES“ as stated

on our aluminum tape.

heating cable

(between layers of aluminum tape)

installation through the insulation

pipe insulation

~1 m~1 m

end mu

14 Application guide · Domestic hot water · ©DEVI

List of accessories:

Picture Name

Tape aluminium

38 mm x 50 m

DEVIconnecto B-A

Connection

DEVIconnecto

B-C Heating cable

connection

DEVIconnecto B-E End

termination

Description/Technical data

Self-adhesive, with 2-colour warning text,

max. 75 °C

Backing Aluminium foil

Adhesive Waterbased Acrylic

Liner Monosiliconized Paper

Adhesion/Steel 8 N/ 38 mm

Tensile strength 57,5 N/ 38 mm

Total thickness 60 m

Package 130 x 265 x 75 mm Art. no. 19808360

130 x 265 x 75 mm Art. no. 19808361

130 x 265 x 75 mm Art. no. 19808362

Art. no. 19805076

EAN no. 5703435003053

EAN no. 5703466103067

EAN no. 5703466103074

EAN no. 5703466103081

DEVIconnecto

B-S Connection

termination

DEVIconnecto B-T,

T-Junction + End

termination

DEVIconnecto B-TE2

Junction + 2 End

termination

DEVIconnecto B-TE3

Junction + 3 End

termination

DEVIconnecto B-X,

X-Junction + 2 End

termination

130 x 265 x 75 mm Art. no. 19808363

EAN no. 5703466103098

130 x 265 x 75 mm Art. no. 19808364

EAN no. 5703466103104

130 x 265 x 75 mm Art. no. 19808365

EAN no. 5703466103111

130 x 265 x 75 mm Art. no. 19808366

EAN no. 5703466103128

130 x 265 x 75 mm Art. no. 19808367

EAN no. 5703466103135

DEVIconnecto Bracket,

ref AH 61400005

Braket for installation outside the insulation Art. no. 19808390

EAN no. 5703466125021

15Application guide · Domestic hot water · ©DEVI

Picture Name

Sensor cable 3 m, 15

kOhm, Santropene

Temperature Sensor 10 m

NTC 15k Santropene

Temperature Sensor 40 m

NTC15k Santropene

Description/Technical data

Wire sensor

2x0,75 mm²,

NTC 15 kOhm

at 25 °C,

Ø5 mm, black

Santropene

(TPV) outer

sheath, IP 67,

Temp. range

-25 °C to 90 °C

Temp., ° Resistanse,

kOhm

-10 66,1

-5 52,5

0 41,1

5 33,2

10 27,0

15 22,1

20 18,2

25 15,0

30 12,3

35 10,4

40 8,7

45 7,4

50 6,2

Art. no. 140F1091

EAN no. 5703466209301

Art. no. 140F1098

EAN no. 5703466210734

Art. no. 19121445

EAN no. 5703466115015

Outdoor sensor 2,5 m,

15 kOhm, PVC, DIN

44574

Silicon temperature

sensor

for DEVIreg™ 330

(60-160°C),

NTC 16,7 kOhm @ 100°C

Wire sensor, 2x0,75 mm²,

NTC 15 kOhm at 25 °C,

Ø8 mm,

white PVC outer sheath, IP 67,

Temp. range -25 °C to 70 °C

Wire sensor, 2,5 m, 2x0,75 mm²,

NTC 16,7 kOhm at 100 °C,

Ø9 mm, IP 65,

Temp. range 50 °C to 170 °C

Art. no. 140F1092

EAN no. 5703466209318

Art. no. 140F1097

EAN no. 5703466209707

16 Application guide · Domestic hot water · ©DEVI

Insulation

bracket

Output from

Heating cable

Aluminium tape

Sensor

The recommended ways to mount the cable lines on the pipe

Selection of connection accessories for self-limiting heating cables

connection to box

thermostat

230V

Output from thermostat

230V

power cable

connection to box

17Application guide · Domestic hot water · ©DEVI

4. Safety instruction

Heating cables must always be installed

according to local building regulations

and wiring rules as well as the

guidelines in this installation manual.

De-energize all power circuits before

installation and service.

Residual current device (RCD)

protection is required.RCD trip rating

is max.30 mA.

The screen from each heating cable

must be connected to earthing

terminal in accordance with local

electricity regulations.

4.1 DO's

• For installation of cable and

thermostat/controller, always refer

to the local regulations/legislations

and respective manuals.

• Remember to fill out the warranty

sheet with the required information

as this will not be valid otherwise.

• Carefully complete the installation,

the cable can break when

overloaded.

• If any doubt arises consult you

manual or local DEVI department.

• Ensure that the cable is sufficiently

fixed and mounted according to

the manual.

Heating cables must be connected

via a switch providing all pole

disconnection.

The heating cable must be equipped

with a correctly sized fuse or circuit

breaker according to local regulations.

Never exceed the maximum heat

density (W/m or W/m²) for the actual

application.

Strongly recommended to use the

heating cable together with an

appropriate thermostat to secure

against overheating.

• Ensure that warning labels and

stickers (potentially tape) with

warning text is used to inform

about the heat traced cable.

• Install sensors where the

temperature is estimated to be

representative for the whole

installation, where 2 sensors

are needed for the thermostat/

controller please install at the

estimated extreme points (coldest

and hottest).

• To get the best performance of

the system and avoid failures it is

necessary to follow the installation

descriptions.

The presence of a heating cable

must be made evident by affixing

caution signs in the fuse box and in

the distribution board or markings

at the power connection fittings

and/or frequently along the circuit

line where clearly visible (tracing)

must be stated in any electrical

documentation following the

installation.

• To get the best performance of

the system it is strictly necessary

to calculate the correct heat

losses, for all dimensions of pipes

and the whole system. Using this

knowledge the cable with right

output can be chosen.

• Plan every installation step and

fixing point of the traced pipes

ahead of time and ensure that the

"run" is proper and possible.

• Ensure sensors are connected

according to the applicable

installation guide and/or

application guide.

4.2 DON'Ts

• Never make an installation without

thermostat.

• Never install cables where the heat

can't be dissipated, even with a

self-limiting cable the output will

never become zero and the cable

can overheat.

18 Application guide · Domestic hot water · ©DEVI

• Never let unauthorized personnel

install controllers/thermostats or

heating elements.

• Never use unauthorized

accessories.

• Never use our products (cables,

controllers, sensors, etc.) outside

provided temperature range.

5. Case stories

https://devi.danfoss.com/en/case-stories/?page=1

6. Technical support

The Electric Heating team is offering

valuable support to professionals

when it comes to preparing your

new projects.

We offer support for:

• Calculation of Electric Heating

system

• Development of drawings for

projects

• Preparation of the BoM (Bill of

Material)

• Recommendations for the

installation and operation of the

system

In order to clarify the project data

for different applications use the

following technical request forms, fill

in with your specifications and send it

to: EH@danfoss.com

https://devi.danfoss.com/en/support/

19Application guide · Domestic hot water · ©DEVI

08097147 & AB381952809354EN000101 | JUN 16, 2021

Intelligent solutions

with lasting eect

Visit devi.com

Loading...

Loading...