Page 1

DOMESTIC HEA TING CONTROLS ARE EASY

P ART 2 - TIMERS & PROGRAMMERS

T oday’s inescapable need to improve energy ef ficiency in UK homes has brought installers many opportunities to

make extra earnings through the upgrading of heating and DHW controls. Often, however , misunderstandings and

technical ‘mystique’ surrounding some of these products inhibits installers from fitting the most appropriate energy

saving devices that can cut household heating bills, improve comfort levels and reduce carbon dioxide emissions

into the atmosphere.

This series aims to remove some of the doubts and show that domestic heating controls really are easy .

TIME CONTROLS

Running a domestic central heating/hot water system continuously is prohibitively expensive for most users. One

certain way of holding down a home’s heating bills is to switch the system off as often as possible. Of course, this

can be done only when room and domestic water heating are not needed.

Time controls on most domestic heating/hot water systems are among the first essentials for improving home

comfort and reducing running costs. They trigger the controls ‘chain of command’, sending automatically timed

On and Off instructions to other system components. Each user-set, timed switching programme helps maintain

desired comfort levels and prevents excessive fuel consumption by inhibiting unnecessary boiler firing.

Winter temperatures in the UK are rarely low enough to keep the heating on overnight, so we usually cut heating

costs and sleep better in a cooler room by using a time control to automatically switch off the system late evening

and on again early morning. Also, we use the same timer to set Off and On periods during the daytime for

additional benefit.

Fig.1 shows a simplified typical heating controls wiring sequence. The time control governs when the heating

system operates whilst the thermostats and valve auxiliary switch provide the electrical interlock that prevents the

boiler firing if there is no demand for heat.

TIME

CONTROL

THERMOSTATS

(ROOM OR

CYLINDER)

RELEVANT

MOTORISED

VALVES

BOILER

AND

PUMP

Sends timed ON/OFF

signals to thermostat

If heat demand exists,

switches close and

pass signal to valve(s)

Motor opens valve(s),

activates auxiliary switch

to boiler/pump

Boiler can fire only

when a demand for heat

exists

Fig.1

Page 2

TYPES OF TIME CONTROLS

Domestic central heating time controls are essential components of the ‘Minimum Set’ recommendations in the

Government’s new Good Practice Guide 302 - Controls for domestic central heating and hot water – guidance for

specifiers and installers. They fall into four categories

- Time Switches

- Mini- Programmers

- Standard Programmers

- Full Programmers

Incorporating either electric or electronic timers, most models require mains power input. At desired times each

day , these timing mechanisms operate the units’ output relays to switch the heating system on or of f. Usually , the

regular switching programme can be overridden temporarily if required to cope with unexpected household events.

Both electro-mechanical and electronic time controls usually provide 2 or 3 On/Off settings a day . They are easily

programmable for either 24-hour, weekday/weekend (5/2 day) or 7-day periods; and some models of fer all these

options in one unit. Electronic models incorporate battery back-up to retain programme memory in the event of

power cuts.

Many time controls feed mains electricity to the control system through their output relays. If the control circuit

operates on a different voltage, however , output contact s need to be electrically isolated (voltage-free) from the

timer’s input.

Programmable room thermostats, combining the functions of programmer and room thermostat, will be explained

in a later article. Usually battery powered, these controls are placed in the ‘Best Practice’ category in Good

Practice Guide 302.

Danfoss Randall is the UK market leader for time controls and programmable room thermostats, offering

comprehensive electro-mechanical and electronic product ranges for all applications.

TIME SWITCHES

Time switches, electro-mechanical or electronic, have just one single ‘On’ output or a changeover ‘On/Off’ output

(Fig. 2). They are for controlling single circuits such as separate heating zones or the heating from combination

boilers.

COM

TIMER

N/O N/C

E

5 6

N

Mains

L

1 2 3

ON

Voltage Free Outputs

Fig. 2. Typical time switch configuration with changeover output contacts

OFF

COM

Page 3

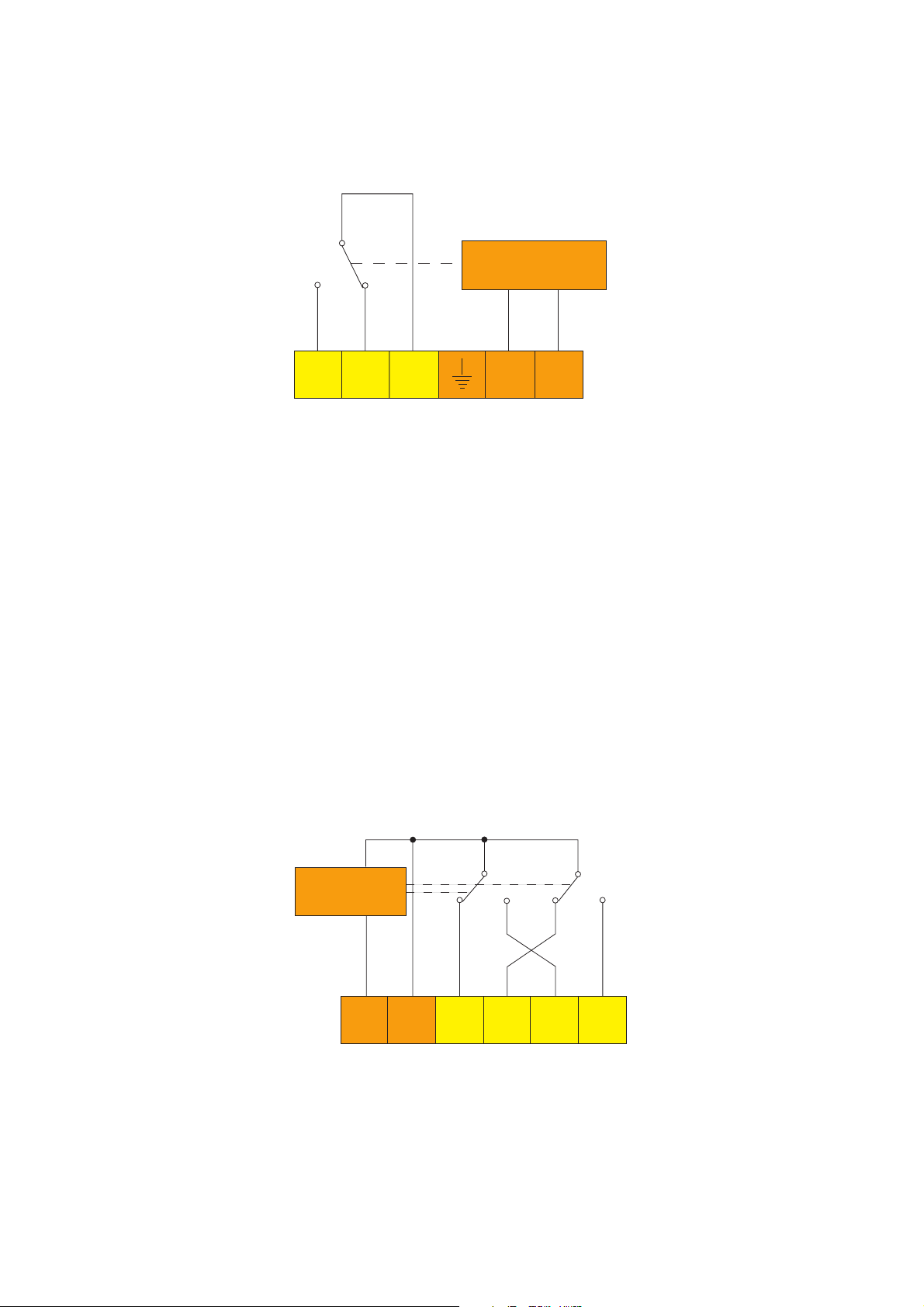

MINI-PROGRAMMERS

A mini-programmer is simply a time switch with a slave Heating terminal (Fig. 3). It can control both Heating and

Hot Water simultaneously , and allow Heating to be switched on/off manually . These controls do not allow Heating

without Hot Water .

COM

TIMER

N/O N/C

E

5 6

N

Mains

L

1 2 3

ON

OFF

COM

Voltage Free Outputs

Fig. 3. Typical Mini-programmer internal wiring configuration

STANDARD PROGRAMMERS

Standard programmers provide reasonably independent control of Heating and Hot W ater in fully pumped systems.

They have two output channels (Fig. 4) but, because both channels operate on a common time-base, they require

the same time settings for heating and hot water. Within these time settings, selection of continuously On,

continuously Off, Timed (follows switching programme) and All Day (from first On to last Off) is possible. There

is usually a means of linking both outputs to prevent Heating operating without Hot Water when used with semigravity systems.

FULL PROGRAMMERS

These have two output channels (Fig. 4) operating on totally independent time-bases. This means that Heating

and Hot water can be programmed to switch On and Off whenever needed, irrespective of the other channel’s time

settings. As with standard programmers, a means is provided of linking both output s to prevent Heating operating

without Hot Water when used with semi-gravity systems.

TIMER

N/C

N/O

N/C

N/O

N L 1 2 3 4

ON

OFF

Mains

Fig. 4. Typical internal circuit covering both standard and full programmers

OFF

DHW

HTG

DHW

Fully independent electronic programmers provide the benefit of totally different switching programmes for both

channels, allowing greater flexibility and savings. They can also provide many additional features such as Heating

boosts, optimum start control and holiday programming.

ON

HTG

Page 4

INSTALLATION

Installing most modern time controls involves fixing a wall plate, making simple connections from this to a wiring

centre and then attaching the front unit. Considerable wiring interchangeability exists between different makes,

often allowing use of the existing wall plate when upgrading. Even when this is not possible, removing the existing

plate and fitting the new one is not a major job. Danfoss Randall can supply a free interchangeability guide

covering many popular makes of time controls. Wall plates in common use are: -

Danfoss Randall MK18 Wall Plate - ‘Industry Standard’ Wall Plate (Fig. 5)

Fig. 5. Mk18 Wall Plate and FP715 Full Programmer

Most time controls manufacturers produce models that utilise wall plates of this general design. These will fit

directly onto the wall plate of an early ‘industry standard’ electro-mechanical programmer of which several million

units were sold in the UK.

By providing this ready interchangeability , other manufacturers were able to offer easy upgrades when the original

units became unserviceable. A word of caution – these alternative wall plates are not exact copies of the original

and one manufacturer’s modern time control may not necessarily fit onto another’s wall plate.

The original wall plate for the electro-mechanical programme incorporated an Earth terminal. Modern electronic

programmers, like the Danfoss Randall Mk18, are double insulated and do not require this terminal.

Danfoss Randall GP Wall Plate (Fig. 6)

Fig. 6. Wall Plate for GP electro-mechanical and electronic time controls.

This is the wall plate for the original 24-hour large dial, electro-mechanical Randall 103 time switches and 102

mini-programmers, which are still available. Countless numbers of these controls can still be seen on installations

all over the country , all of which can be upgraded easily and directly by fitting electronic versions onto the existing

wall plates. Electronic GP’s are available as either 24hr-weekday/weekend or 24hr-7day models.

Danfoss Randall SET Wall Plate – British Gas Standard Wall Plate (Fig. 7)

Fig. 7. Wall Plate for SET electro-mechanical and electronic time controls.

Page 5

This was a design initiated by British Gas that sought to overcome the limitations of having just 6 terminals. It did

not become generally adopted but can be found on the Danfoss Randall SET range as well as on some Horstmann

models.

Danfoss Randall MK3 Wall Plate (Fig. 8)

Fig. 8. Wall Plate for MK3 electro-mechanical basic programmers.

MK3 programmers were among the first Randall time controls and many are still in use today . For users who do

not wish to change them, Danfoss Randall can supply Factory Replacement Units (FRU’s) that simply plug into

the existing wall plate. Upgrading to an electronic programmer will necessitate changing the wall plate.

Danfoss Randall MK9 Wall Plate (Fig. 9)

Fig. 9. Wall Plate for MK9 electronic programmers and their TS975/FP975 replacements..

Where Randall MK9 programmers (now obsolete) need to be replaced, current models TS975 (time switch) and

FP975 (full programmer) can be fitted on to the original wall plates. The new controls must be set in ‘MK9 Mode’.

PROGRAMMING

For time controls to perform their function, the following information needs to be entered into them: -

The TIME of day

The actual DA Y (applies to weekday/weekend and 7 day models only)

A programme of On/Off switching times.

Then, for each output circuit, the following options can usually be selected: -

On (all the time)

Off (all the time)

Timed (set programme) or

Allday (first On till last Off)

Page 6

Programming an electro-mechanical timer simply involves rotating a dial to set the time of day , positioning pointers

or tappets at desired switching points and then making selections as above. These units usually provide two On/

Offs during a 24-hour period, repeated every day . Switching events can rarely be set closer than 10-15 minutes.

Setting the time (and day) on modern electronic programmers is a simple push button job; and they have ‘readyto-go’ built-in switching programmes that are easily modified by the user . To change the programme, simply put

the control in its programming mode (e.g. press a button called PROG) and follow the logical programming sequence

explained in the unit’s accompanying instructions. After the required changes have been made, press the RUN

button to return to normal control mode. Selecting the options is simply done by pressing buttons also.

Electronic controls offer greater accuracy, better timing resolution (typically 1 min.), solid-state reliability, more

energy saving features and noiseless operation. They also allow 7-day or weekday/weekend programming plus

totally independent timing of heating and DHW .

Installers must choose appropriate programmers for each user . Electronic time controls provide the best energy

saving options and are recommended wherever possible.

WIDE CHOICE

Danfoss Randall’s wide choice of time controls, even without programmable room thermostats, enables installers

to provide customers with the most suitable devices for their needs. The following table will assist locate suitable

model references for which further details can be obtained from the freely available Product Selection Guide.

Category DR Model Ref. Type 24 hr. 5/2 day 7 day

Time Switches 103 Electro-mechanical z

103E5 Electronic zz

103E7 Electronic zz

SET1E Electronic z

TS975 Electronic zz

TS715 Electronic zzz

Mini-Programmers 3020P Electro-mechanical z

SET2E Electronic z

102 Electro-mechanical z

102E5 Electronic zz

102E7 Electronic zz

Std. Programmers 3060 Electro-mechanical z

4033 Electro-mechanical z

SET3M Electro-mechanical z

SET3E Electronic z

CP715 Electronic zzz

Full Programmers FP715 Electronic zzz

FP975 Electronic zz

ADDITIONAL HELP

Should any additional help be needed in the selection or application of time controls, please do not hesitate to

contact Danfoss Randall –full contact details are shown below. Most product Data Sheets and instructions are

available as downloads from the company’s web site.

Loading...

Loading...