Page 1

Data Sheet

Hermetic filter drier

Type DMSC and DMT

Designed for CO2 with applications requiring the highest moisture capacity.

The lter drier is a vital element of the system’s

reliability as well as its lifespan. When you

choose Danfoss lter driers, you are guaranteed

a product that has been developed specically

for the challenges encountered in Air

Conditioning and Refrigeration Systems.

All ELIMINATOR® driers have a solid core with

binding material held to an absolute minimum.

For CO2 applications Danfoss oer one type of

ELIMINATOR® core.

Type DMSC and DMT driers have a core

composition of 100% Molecular Sieve.

ELIMINATOR® type DMSC and DMT driers are

designed for applications requiring the highest

moisture capacity.

Applications:

• Food retail

• Transport refrigeration

• Cold rooms

AI187586433425en-000502

Page 2

Hermetic lter drier, Type DMSC and DMT

Features

The Core

• 100% 3Å Molecular Sieve core

• High drying capacity minimizing the risk of acid formation (hydrolysis)

• Recommended for use with R744 (CO2) refrigerants

• Will not deplete oil additives

The Shell

• DMSC for Sub-critical application; supports PS/MWP up to 52 bar/754 psig

• DMT for Trans-critical application; supports PS/MWP up to 140 bar/2030 psig

• DMSC, available with solder (copper)

• DMT, available with solder (copper plated) and are connections (standard, are O-ring and NPT)

• Lowest leak rate

• Corrosion resistant powder-painted nish. Special coating for marine applications available upon request

• Allows installation with any orientation provided the arrow is in the ow direction

• DMSC, available in sizes from 03 to 08 cubic inches

• DMT, available in sizes from 08 to 13 cubic inches

The Filter

• 25 μm (0.001 in) lter provides high retention with minimal pressure drop

• Black paint gives a better look after brazing installation

• No residual moisture when delivered

• Thermally stable up to 120 °C (250 °F)

• Manufactured according to IATF 16949:2016

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 2

Page 3

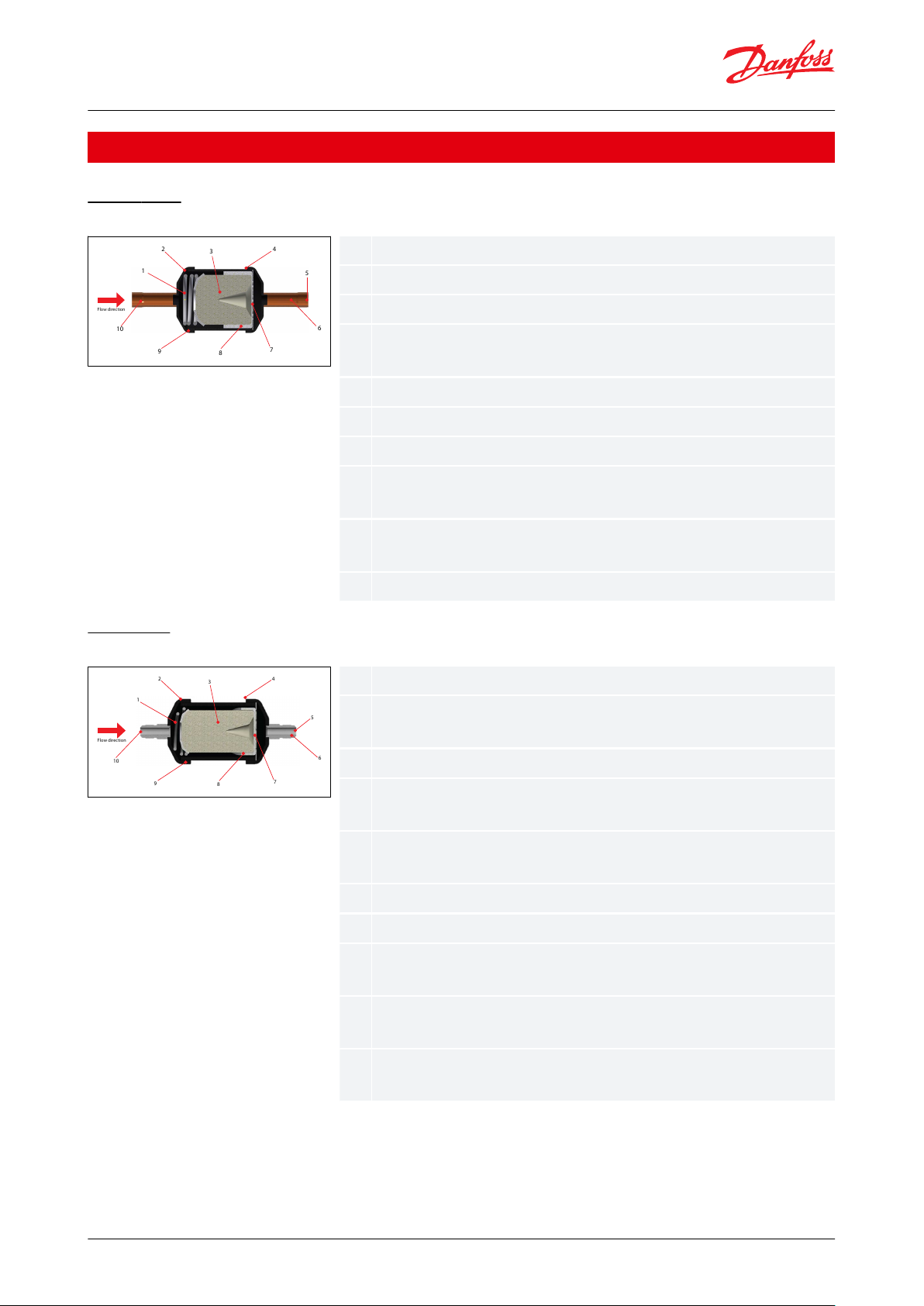

Flow direction

1

2

3

4

5

6

7

8

9

10

1234567

8

9

10

Spring to keep core in xed position

Powder painted surface supports corrosion classication C5, 1440 hrs

ELIMINATOR® core for highest possible drying capacity

Steel housing supports more pressure, high steel thickness on the

shell, MWP = 52 bar

Easy to remove pull-o cap for sweat

Solder connector sizes available for inches and millimetric versions

Perforated plate to keep internal parts in position

High dirt retention, down to 25 μm particles, with minimal pressure

drop

Black, high quality and durable coating oers a cleaner appearance

after brazing

Pure copper connector with high thickness and extended length

Flow direction

1

2

3

4

5

6

7

8

9

10

123

4

5

6

7

8910

Spring to keep core in xed position

Corrosion resistant powder-painted nish. Special coating for marine

applications available upon request

ELIMINATOR® core for highest possible drying capacity

Steel housing supports more pressure, high steel thickness on the

shell, MWP=140 bar

Easy to remove pull-o cap for sweat or twist-o cap for are, NPT, FO

connectors

Solder connector sizes available for inches and millimetric versions

Perforated plate to keep internal parts in position

High dirt retention, down to 25 μm particles, with minimal pressure

drop

Black, high quality and durable coating oers a cleaner appearance

after brazing

Available designs for Steel version (Flare, FO, NPT) and Solder Cuplated connector

Hermetic lter drier, Type DMSC and DMT

Functions

DMSC lter

Figure 1: Solder connection (Copper)

DMT lter

Figure 2: Flare connection (Steel)

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 3

Page 4

(

D

1

)

A±1.5

L±2

(

D

2

)

B±2

(

D

1

)

L±2

A±1.5

(

D

2

)

B±2

Characteristic

DMSC

DMT

Compatible refrigerant

CO₂ (R744)

Refrigerant oil

POE, PVE, All mineral oils, ester oils and supports oil free

Application

Sub-critical

Trans-critical

Complies with PED

Fluid Group II, Category Art 4, par. 3

Max. working pressure PS/MWP

52 bar/754 psig

140 bar/2030 psig

Temperature range

-30 – 17 °C/-22 - 63 °F

-40 – 100 °C/-40 – 212 °F

Environmental transport/storage temperature and

humidity

Max. 70 °C/160 °F, Humidity: <100% RH

Material of construction

Body: steel Connector: copper

Body: steel Connector: steel

Core type

DM (100% molecular sieve)

Drier Capacities

03, 05 and 08 cu.in.

08 and 13 cu.in.

Connection size

1

⁄4, 3⁄8, 1⁄2

6 mm, 10 mm, 12 mm

1

⁄4, 3⁄8, 1⁄2

Connection type

ODF Extended, extra wall thickness

ODF, Flare, Flare O-ring, NPT

Connectors material

Copper

Steel, Cu-plated

Country of Origin

Mexico

Code no.

Description

SizeLB

A

D1D

2

Connector

DWG

Net weight

[kg]

023Z8500

DMSC 033s

03 cu.in.

14987685854

inch10.4

023Z8501

DMSC 032s / 6mm

03 cu.in.

14584685854mm1

0.4

023Z8512

DMSC 032s

03 cu.in.

14784685854

inch10.4

023Z8502

DMSC 053s / 10mm

05 cu.in.

15696775854mm2

0.5

023Z8503

DMSC 053s

05 cu.in.

15896775854

inch10.5

023Z8504

DMSC 052s / 6mm

05 cu.in.

15493775854mm1

0.5

023Z8505

DMSC 083s / 10mm

08 cu.in.

182

122

1035854mm2

0.6

023Z8506

DMSC 084s / 12mm

08 cu.in.

182

124

1035854mm1

0.6

023Z8513

DMSC 084s

08 cu.in.

182

124

1035854

inch10.6

Hermetic lter drier, Type DMSC and DMT

Product specication

Technical data

Table 1: DMSC and DMT

Dimensions and weight

Figure 3: DMSC Solder Straight Connector

Table 2: DMSC Solder Expanded Connector

Figure 4: DMSC Solder Expanded Connector

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 4

Page 5

D

2

L

A

D

1

Danfoss

23Z8400.11

Type

A

L

D1D

2

Net weight [kg]

DMT 082

106.0

150.0

68.0

60.0

0.8

DMT 083

106.0

163.0

68.0

60.0

0.9

DMT 132 NPT

156.0

212.0

68.0

60.0

1.2

DMT 133

156.0

213.0

68.0

60.0

1.3

D

2

D

1

L

A

Danfoss

23Z8412.10

Type

A

L

D1D

2

Net weight [kg]

DMT 082s

106.0

138.0

68.0

60.0

0.8

DMT 083s

106.0

144.0

68.0

60.0

0.8

DMT 084s

106.0

148.0

68.0

60.0

0.9

DMT 133s

156.0

194.0

68.0

60.0

1.2

DMT 134s

156.0

198.0

68.0

60.0

1.3

Hermetic lter drier, Type DMSC and DMT

Figure 5: Flare connections

Table 3: Flare connections

Figure 6: Solder connection (cu-plated steel)

Table 4: Solder connection (cu-plated steel)

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 5

Page 6

Danfoss

23Z7016.10

Hermetic lter drier, Type DMSC and DMT

Filter Driers –Installation Warning

Figure 7: Installation Warning

NOTE:

Keep ames away from body

• When soldering, only apply heat to the connection with the ame pointed away from the lter drier

• Excess heating of the paint may damage it

• When soldering is important to use a wet rag

• Use wet wrap when installing

• Braze the joints

• Let them cool down

• Clean the welding area after the installation (remove remaining ux with a brush)

• This is an important operation and needs to be done with great care to remove all remaining ux

• Paint\Anti-corrosive needs to cover all open steel parts, areas where the black original paint has been burnt due to

brazing and at least 3 cm approx of the copper tube

• Paint the joints twice

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 6

Page 7

Type

Size

Connection

Multi-pack

[in]

[mm]

Qty.

Code no.

DMSC 032s / 6mm

03 cu.in.–624023Z8501

DMSC 032s

03 cu.in.

1

⁄4

–24023Z8512

DMSC 033s

03 cu.in.

3

⁄8

–24023Z8500

DMSC 052s / 6mm

05 cu.in.–624023Z8504

DMSC 053s / 10mm

05 cu.in.–1024023Z8502

DMSC 053s

05 cu.in.

3

⁄8

–24023Z8503

DMSC 083s / 10mm

08 cu.in.–1012023Z8505

DMSC 084s / 12mm

08 cu.in.–1212023Z8506

DMSC 084s

08 cu.in.

1

⁄2

–12023Z8513

Danfoss

23Z8414.10

Danfoss

23Z8413.10

Type

Connection

Industrial pack

[in]

Qty.

Code no.

DMT 082

1

⁄4

12

023Z8407

DMT 083

3

⁄8

12

023Z8406

DMT 132 NPT

1

⁄4

8

023Z8410

DMT 133

3

⁄8

8

023Z8405

Hermetic lter drier, Type DMSC and DMT

Ordering

Type DMSC and DMT

Figure 8: Type DMSC

Table 5: Type DMSC, Solder

Figure 9: Type DMT

Table 6: Type DMT, are

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 7

Page 8

Type

Connection

Industrial pack

Multi-pack

[in]

Qty.

Code no.

Code no.

DMT 082s

1

⁄4

12

023Z8408

023Z8415

DMT 083s

3

⁄8

12

023Z8409

023Z8416

DMT 084s

1

⁄2

12

023Z8412

023Z8417

DMT 133s

3

⁄8

8

023Z8402

023Z8418

DMT 134s

1

⁄2

8

023Z8411

023Z8419

Hermetic lter drier, Type DMSC and DMT

Table 7: Type DMT, solder

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 8

Page 9

Document name

Document type

Document topic

Approval authority

SA 6398

UL Certicate

Mechanical Safety Certicate

UL

023Z9601.AF

Manufacturers Declaration

ATEX/PED/RoHS

Danfoss

023Z9610.AA

Manufacturers Declaration

China RoHs

Danfoss

RU Д-DK.БЛ08.B.00828_19

EAC Declaration

Machinery & Equipment

EAC

Hermetic lter drier, Type DMSC and DMT

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: Certicates, declarations and approvals

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 9

Page 10

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.08 AI187586433425en-000502 | 10

Loading...

Loading...