Page 1

Directional Control Valve

Technical Information

powersolutions.danfoss.com

Page 2

Directional Control Valves Technical Information:

Contents

PRODUCT OVERVIEW Flexibility of design ........................................................................................................................................3

Circuit options ................................................................................................................................................. 3

Capability .......................................................................................................................................................... 3

Actuation options .......................................................................................................................................... 3

Modular valves ................................................................................................................................................ 4

FLUIDS AND FILTRATION

Fluids ................................................................................................................................................................... 5

Base stock and additives ........................................................................................................................ 5

Viscosity ........................................................................................................................................................5

Filtration ....................................................................................................................................................... 5

Return line filtration ................................................................................................................................. 5

Cleanliness ..................................................................................................................................................5

CDS 60 AND 100 Specifications ...................................................................................................................................................6

Typical performance .....................................................................................................................................7

Inlet covers order code ................................................................................................................................. 8

Inlet porting and relief valve options......................................................................................................9

Mid-inlet flow dividers and combiners order code ..........................................................................10

Mid-inlet flow dividers and combiners.................................................................................................11

Outlet covers order code ...........................................................................................................................12

Outlet porting and plug options ............................................................................................................13

Work section order code .....................................................................................................................14-17

Circuit types....................................................................................................................................................18

Spool types .....................................................................................................................................................19

Actuation options ................................................................................................................................. 20-21

Cabling and electrical options for actuator types G, H, and J ......................................................22

Actuation mounting side ..........................................................................................................................22

Spool centering and detent options .............................................................................................. 23-24

Auxiliary valves .......................................................................................................................................25-26

Dimensions CDS 100 ...................................................................................................................................26

Dimensions CDS 60 .....................................................................................................................................27

APPENDIX 1 ORDER

FORMS

2 | © Danfoss | March 2016

Spool valve order form ...............................................................................................................................28

CDS60 and CDS100 specification worksheet .....................................................................................28

CDS60 and CDS100 price worksheet ....................................................................................................28

520L0564 | BC00000105en-US0101

Page 3

Directional Control Valves Technical Information:

Product overview

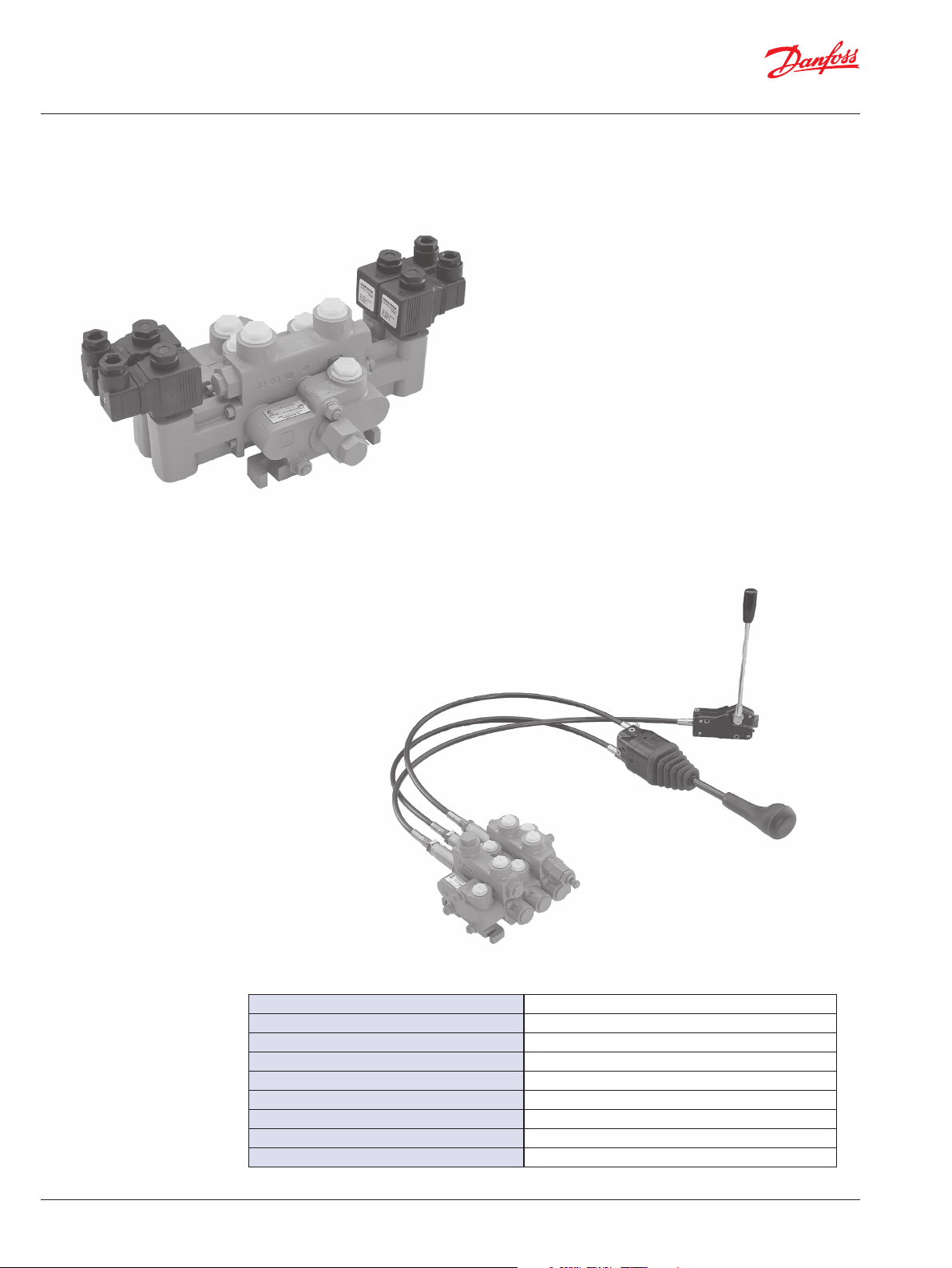

FLEXIBILITY OF DESIGN The Danfoss directional control valves are designed to give customer flexibility over a broad

range of flow and pressure capabilities. Actuator options include a range of levers, cable

actuators, hydraulic and pneumatic pilot controls, two-axis joysticks, and electrohydraulic

solenoids. Flow rates range from 0 to 100 l/min [26 US gal/min].

CIRCUIT OPTIONS

CAPABILITY

ACTUATION OPTIONS

• Parallel circuits

• Series circuits

• Tandem circuits

• Prioritay circuits

• Regenerative circuits

• Power beyond

• Flow rates from 0 to 100 l/.min [26 US gal/min]

• System pressure up to 250 BAR

• Up to 12 work sections

• 12 cm³/min [0.7 in³/min] leakage

• Handles and levers

• Mechanical two-axis joystick

• Spool ends

• ElectroHydraulic Control (EHC) on/off solenoid

• Cable control

• Pneumatic pilot control

• Dual spool ends

3 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 4

Directional Control Valves Technical Information:

Product overview

MODULAR VALVES

Valve

model

CDS-100 100 [26] 1 to 12

CDS-60 60 [16] 1 to 12

20 [5] 40 [11] 60 [16] 80 [21] 100 [26]

l/min [US gal/min]

Number

of Spools

Circuit Page

Parallel

Tandem

Series

Parallel

Tandem

Series

Indicates Maximum Working Pressure Rated At 210 bar [3000 psi]

4 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 5

Directional Control Valves Technical Information:

Fluids and Filtration

FLUIDS Hydraulic fluid performs three basic functions in a hydraulic system: It transfers energy,

lubricates moving components, and transports heat and contaminants out of the system.

Base stock and additives

Danfoss valves are designed to operate with mineral-based fluids containing oxidation, rust,

and foam inhibitors, compatible with fluoroelastomer seals. Consult your fluid supplier for

information on seal compatibility.

Viscosity

Viscosity is the most important property of a hydraulic fluid. It is a measurement of how the

fluid resists flow. Low viscosity fluids increase internal leakage; high viscosity fluids increase

pressure drop through the valve. Use a fluid that meets the viscosity limits published in this

catalog. For specific requirements, see technical data in each section.

Temperature

Temperature affects a fluid’s viscosity. Higher temperature fluid has lower viscosity.

Operating at excessive temperatures may have other detrimental effects on your hydraulic

fluid. Design your hydraulic system to operate within the specified temperature range.

Specific requirements are published in each section.

For more information

For more information on hydraulic fluid selection refer to Hydraulic Fluids and Lubricants

Technical Information, Danfoss publication 520L0463.

FILTRATION

Effective filtration is critical to a hydraulic system’s performance and working life. Employ

system filtration capable of meeting the published requirements in each valve section. Be

aware that other components in the system may have more stringent requirements. Design

your filtration system to satisfy the requirements of the most sensitive component.

Return line filtration

Return line filtration is generally adequate for Danfoss valves. We recommend a 10 micron

nominal (20 micron absolute) or finer filter. Insure the filter in your system is properly sized

and maintained. To facilitate proper filter maintenance, use a pressure gauge or other

indicator to signal when it is necessary to change the filter. Never allow filter to reach its

bypass condition. Follow the filter manufacturer’s maintenance recommendations.

Cleanliness

Hydraulic system contamination must not exceed the limits published for each valve. Limits

are specified per ISO 4406 (1999). When measuring system contamination, calibrate test

equipment in accordance with the ACFTD method.

For more information

For more information on system filtration, refer to Design Guidelines for hydraulic fluid

cleanliness, Danfoss publication 520L0467.

5 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 6

Directional Control Valves Technical Information:

CDS 60 and 100

CDS 100

SPECIFICATIONS

6 | © Danfoss | March 2016

CDS 60

Maximum flow (CDS 100) 100 l/min [26.4 US gal/min]

Maximum flow (CDS 60) 60 l/min [15.8 US gal/min]

Work pressure 210 bar [3050 psi]

Maximum pressure 250 bar [3625 psi]

Maximum pressure (outlet section) 40 bar [580 psi]

Temperature range -40º to 80º C [-40 to 176º F]

Recommended fluid type Mineral based hydraulic oil

Recommended viscosity 26-55 mm²/sec (cSt) [123-255 SUS]

Minimum fluid cleanliness (per ISO 4406) 19/16

520L0564 | BC00000105en-US0101

Page 7

12 sections

11 sections

10 sections

Pressure - bar [psi]

Flow - l/min [US gal/min]

100

250

Pressure - bar [psi]

[26]

Flow - l/min [US gal/min]

12 sections

11 sections

10 sections

Pressure - bar [psi]

Directional Control Valves Technical Information:

CDS 60 and 100

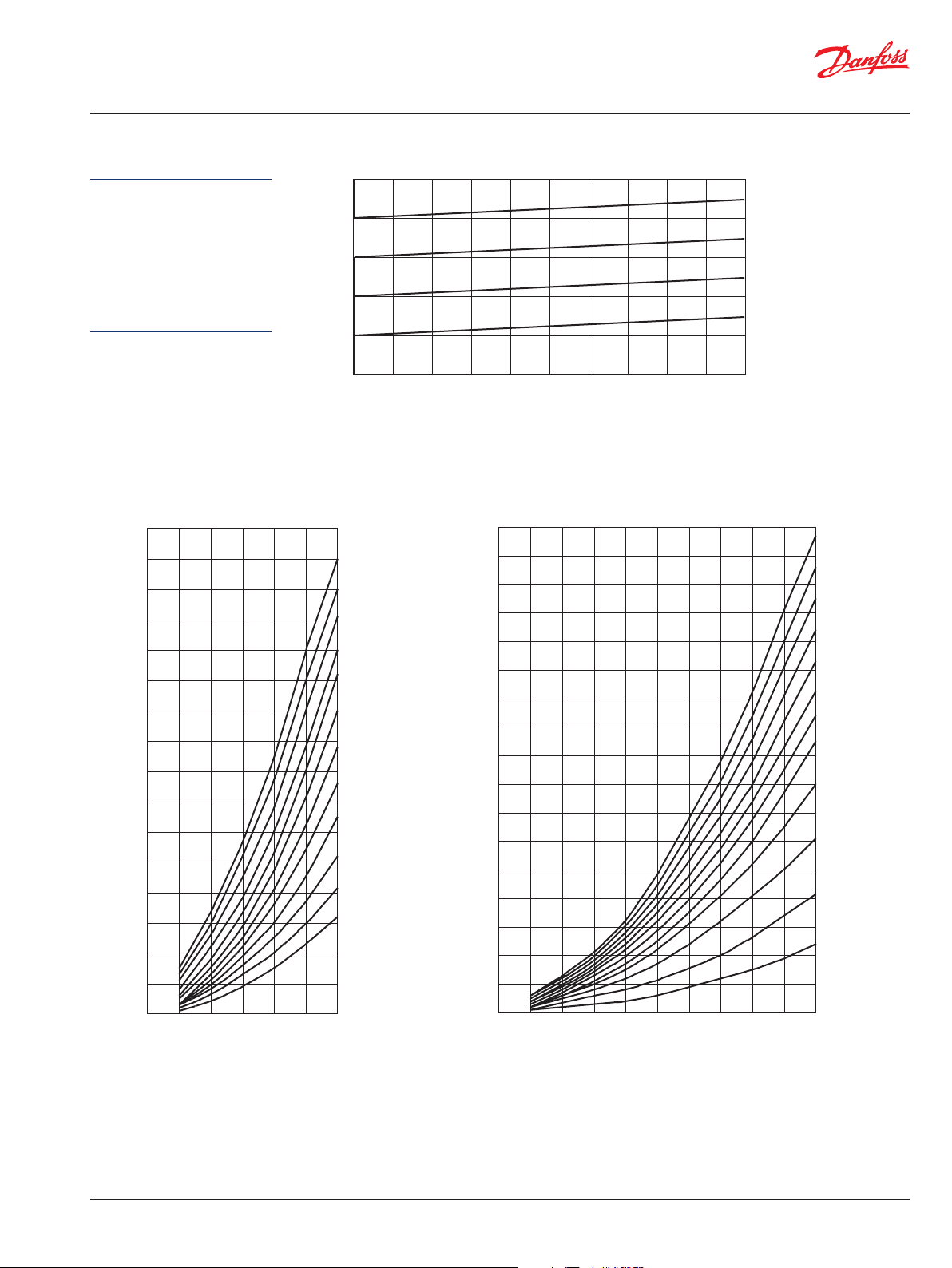

TYPICAL PERFORMANCE

Based on oil temperature

of 45°–50°C [113°–122° F].

Viscosity 32 mm²/sec

(cSt) [151 SUS]. CDS

spool leakage (standard)

at 70 bar [1015 psi],

50°C [122°F], ISO VG46:

10 cm³/min [0.61 in³/min]

16

[232]

14

[203]

12

[174]

10

[145]

[116]

[87]

8

6

Pressure vs. flow curves for main relief valve

[3625]

200

[2900]

150

[2176]

100

[1450]

50

[725]

0

0102030405060708090

[2.6] [5.3] [7.9] [10] [13] [16] [19] [21] [24]

Pressure drop (P-T) CDS 100Pressure drop (P-T) CDS 60

16

[232]

14

[203]

9 sections

8 sections

7 sections

6 sections

5 sections

4 sections

3 sections

12

[174]

10

[145]

[116]

[87]

8

6

9 sections

8 sections

7 sections

6 sections

5 sections

4 sections

3 sections

7 | © Danfoss | March 2016

4

[58]

2

[29]

0

0 10 20 30 40 50 60

[2.6] [5.3] [7.9] [10] [13] [16]

Flow - l/min [US gal/min]

2 sections

1 sections

4

[58]

2

[29]

0

0 10 20 30 40 50 60 70 80 90 100

[2.6] [5.3] [7.9] [10] [13] [16] [19] [21] [24] [26]

520L0564 | BC00000105en-US0101

2 sections

1 sections

Page 8

Directional Control Valves Technical Information:

CDS 60 and 100

INLET COVERS ORDER

CODE

Inlet covers order code (example)

E60 A C 2 140/40*

Models

Code Description

E100 CDS100

E60 CDS60

Port locations

Code Description

A Top port

B Side port, top port plugged

C Top port, with side gauge port (9/16-18UNF)

D Top inlet and outlet ports (use H, I, J on outlet)

Main relief valves

Code Description

A No valve, with plastic plug

B No valve, with special plug

C Valve, with direct valve and external adjustment

D Valve, with direct valve and internal adjustment

E* Valve, pilot operated and external adjustment

* on request

Port types

Code 1 2 3 4 5 7 8 X

SAE - ORB BSP - Parallel Metric - ISO 6149

Threads

Model

CDS100

Model

CDS60

Inlet

outlet

Section

Inlet

outlet

Section

#8

3/4 -16UNF

m m

m m m m

#10

7/8 -14UNF

m m

m m

#12

1 1/16-12UNF

3/8 -19 1/2 -14 M18x1.5 M22x1.5

m

m

available

m on request

Special porting, specify

8 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 9

Directional Control Valves Technical Information:

CDS 60 and 100

INLET PORTING AND

RELIEF VALVE OPTIONS

E100 inlet cover

Port location

D*

Top inlet and outlet (use with H,I,J,and L outlet covers)

A Top inlet

C Top inlet,gauge port side (9/16 - 18 UNF)

A

Shipping Plug

B Side inlet

(top plugged)

B

h1 in

PT

[0.43]

Inlet covers order code (example)

E60 A C 2 140/40*

11

E60 inlet cover

C

D

E*

Drawing

h 1 in h 7/8 h 7/16

67

[2.64]

max

h1 in

47

[1.85]

9 | © Danfoss | March 2016

P101 798

* On request

mm [in]

520L0564 | BC00000105en-US0101

Page 10

Directional Control Valves Technical Information:

CDS 60 and 100

OUTLET COVERS ORDER

CODE

Outlet covers order code (example)

S60

Models

Code Description

S100 CDS 100

S60 CDS 60

Ports

Code Description

A Top outlet

B Side outlet, top plugged

C Side outlet for power beyond (top to tank)

D Top outlet (with closed bypass)

E Top outlet (for electrical control)

F Top outlet (for electrical control, with power beyond)

G Side outlet (for electrical control, top plugged)

H* Top plugged

I* Top plugged, use with power beyond

J* Top plugged for electrical control

L* Top plugged for electrical control, use with power beyond

* On request ( use D on inlet)

Port types

Code 1 2 3 4 5 7 8 X

SAE - ORB BSP - Parallel Metric - ISO 6149

Threads

Model

CDS100

Model

CDS60

outlet

outlet

#8

3/4 -16UNF

m m m m

#10

7/8 -14UNF

m m

#12

1 1/16-12UNF

3/8 -19 1/2 -14 M18x1.5 M22x1.5

available

m on request

A 2

specify

Special porting,

10 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 11

** On request

Directional Control Valves Technical Information:

CDS 60 and 100

OUTLET PORTING AND

PLUG OPTIONS

S100 outlet cover

H** Top plugged

A

Top outlet (side plugged)

C

I

D*

Bypass

Pressure

Outlet

Bypass

Pressure

Outlet

Bypass

Pressure

Outlet

Outlet covers order code (example)

A 2

S60

T

PB

T

PB

T

30

[1.18]

25

[0.98]

B Side outlet (top plugged)

S60 outlet cover

mm [in]

P101 799E

E

F

L

G

Bypass

Pressure

Outlet

J

Bypass

Pressure

Outlet

Bypass

Pressure

Outlet

Bypass

Pressure

Outlet

Bypass

Pressure

Outlet

T

T

T

PB

T

PB

T

PB

*Typically used for high pressure standby.

CDS 60

CDS 100

CDS 60

CDS 100

30.5

[1.20]

32

[1.25]

30.5

[1.20]

32

[1.25]

30

[1.18]

11 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 12

Directional Control Valves Technical Information:

Parallel (no priority)

Tandem (priority)

Series (no priority)

Actuator mounted on A port side

Actuator mounted on B port side

Electrical A and B (use L centering type)

CDS 60 and 100

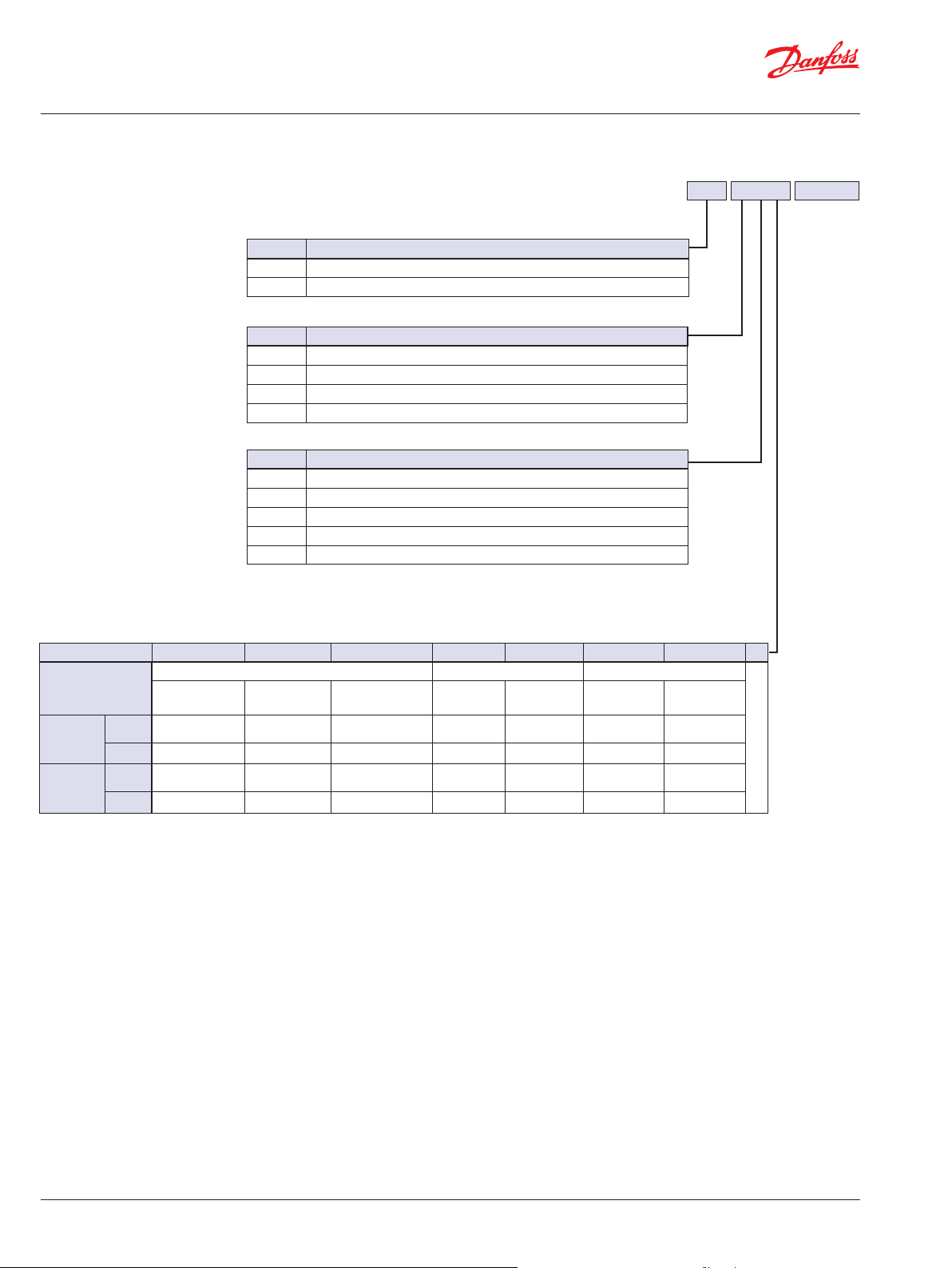

WORK SECTION ORDER CODE

Model

A100 CDS 100 body for supporting valves

B100 CDS 100 normal body (no valves)

A60 CDS 60 body for supporting valves

B60 CDS 60 normal body (no valves)

Circuit types, page 15

1

2*

3*

Spool types, page 16

A 4-way, closed center

B 4-way, open center

C 4-way, closed center, port A plugged

D 4-way, closed center, port B plugged

E 3-way, closed center, port A plugged

F 3-way, closed center, port B plugged

G 4-way, open center, port A plugged

H 4-way, open center, port B plugged

I Float-spool in (use centering option J )

J Float-spool out (use centering option J)

Spool actuation, pages 17–18

A No extension

B Female spool end + Clevis

C Male spool end + Tang

D With support (no lever)

E With lever

F Pneumatic (use centering option A)

G Cable with lever

H Cable with joystick (use A for the adjacent body)

I/M With mechanical joystick (use A for the adjacent body)

J Electrical

R Female spool end

S Male spool end

T Female Spool end with adjust

Spool actuation mounting side, page 20

1

2

3

* On request

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

See cabling and

electrical options,

page 22.

12 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 13

Directional Control Valves Technical Information:

CDS 60 and 100

WORK SECTION ORDER CODE (continued)

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

Spool centering and detents, page 20-21

A Spring centered

B 3 position detent

C Spring centered, detent in A

D Spring centered, detent in B

E Spring centered, detent in A and B

F Spring centered, hydraulic kickout

H Spring centered, female extension

I Spring centered, male extension

J Spring centered, detent in float: use for floatation spool

L Spring centered, use for electrical command

N 2-position detent, spool in

O 2-position detent, spool out

P* With switch, activates spool in

Q* With switch, activates spool in and out

R* With switch, activates two motors

* on request

Port types

Code 1 2 3 4 5 7 8 X

SAE - ORB BSP - Parallel Metric - ISO 6149

Threads

Model

CDS100

Model

CDS60

Section

Section

Auxiliary valves, page 22-23

A Plug

B Direct relief with external adjustment (except electrical actuation)

C Direct relief with internal adjustment

D Pilot check valve

E* Flow control valve (Except electrical actuation)

F Anti-cavitation

G

I Direct relief with anti-cavitation and internal adjustment (electrical only)

J Plug, for 3-way spools

K Plug, for valves D and E

For valves B, C, G, and I, specify pressure and flow

Example: B(140/40) Pressure 140 bar flow 40 l/min

* On request

Direct relief with anti-cavitation and external adjustment

(except electrical actuation)

#8

3/4 -16UNF

m m m

#10

7/8 -14UNF

m m

#12

1 1/16-12UNF

3/8 -19 1/2 -14 M18x1.5 M22x1.5

Work port side A

Work port side B

available

m on request

specify

Special porting,

13 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 14

Directional Control Valves Technical Information:

ACTINGS AND CENTERING COMBINATIONS AVAILABLE

CDS 60 and 100

Actings

A B C D E F G H I/M J

A

B

C

D

E

•••••••••

••••••••

••••••••

••••••••

••••••••

F

G

H

I

Centerings

J

L

N

O

P

Q

R

••••••••

•••••••••

•••••••

•

•••••••••

••••••••

••••••••

••••••••

•••••••••

•••••••••

•••••••••

•

14 | © Danfoss | March 2016

available

520L0564 | BC00000105en-US0101

Page 15

Directional Control Valves Technical Information:

PABABT

OutletWork sectionsInlet

TTP A

A

B

B

Inlet and Outlet

Work Sections

Outlet

PABABT

OutletWork sectionsInlet

CDS 60 and 100

CIRCUIT TYPES

1 Parallel circuit (no priority)

When two or more sections operate simultaneously, flow favors the lowest pressure.

2 Tandem circuit (priority)*

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

Bypass

Pressure

P101 696

When two or more sections operate simultaneously, only the section closest to the inlet receives flow.

3 Series circuit (no priority)*

Bypass

P101 697

Pressure

Bypass

P101 698

15 | © Danfoss | March 2016

When two or more sections operate simultaneously, the section closest to the inlet receives flow. Return flow

feeds the sections downstream.

* on request

520L0564 | BC00000105en-US0101

Page 16

Bypass core

Directional Control Valves Technical Information:

CDS 60 and 100

SPOOL TYPES

Standard central body

Tank (x2)

Pump load check

standard on all bodies

P101 743

Pressure core

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

Ref. Description Symbol

A

B

C

D

E

4-way closed center

4-way open center

4-way closed center

port A plugged

4-way closed center

port B plugged

3-way closed center

port A plugged

AB

P

T

AB

T

P

AB

P

T

AB

P

T

AB

Central body for use with auxiliary valves

Pump load check

standard on all bodies

F

G

H

I

J

3-way closed center

port B plugged

4-way open center

port A plugged

4-way open center

port B plugged

Float spool in (inner

inverter)

Float spool out (outer

inverter)

P

AB

P

AB

P

AB

P

AB

T

P

T

T

T

T

AB

16 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 17

Directional Control Valves Technical Information:

50

66

[0.31]

30

[0.31]

30

8

CDS 60 and 100

ACTUATION OPTIONS

A Without spool end

C Male spool end (tang)

[0.31]

6.5

[0.26]

M8 x1.25

M10 x 1.5

CDS 100

CDS 60

[1.18]

34

[1.34]

CDS 60

CDS 100

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

B Female spool end (clevis)

F

D With support

[1.18]

34

[1.34]

ø 8

CDS 60

CDS 100

M10x1.5

CDS 60

CDS 100

[2.60]

70

[2.76]

6.4

[0.25]

8.4

[0.33]

CDS 60

CDS 100

E With lever

8.3

[0.33]

M

ø 8

113

[4.45]

15º

15º

213

[8.39]

F Pneumatic

[1.97]

(2x)

1/8" NPT

Minimum air pressure CDS 60: 5 bar [73 psi]

Minimum air pressure CDS 100: 8 bar [116 psi]

Maximum air pressure: 12 bar [174 psi]

mm [in]

17 | © Danfoss | March 2016

* Default relief setting if not specified

520L0564 | BC00000105en-US0101

Page 18

C2

A

*

Directional Control Valves Technical Information:

CDS 60 and 100

ACTUATION OPTIONS (continued)

97

[3.82]

157

[6.18]

ø 6

[0.24]

30º

118.5

[4.66]

30º

[1.02]

[0.28]

[0.28]

40

[1.57]

50

[1.97]

26

7

7

50

[1.97]

280

[11.02]

48

[1.89]

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

H Cable with joystick**G Cable with lever**

395

25°

[15.55]

Ø

70

[2.76]

25°

I/M Mechanical joystick

J Electrical**

Flying leads

12VCC

90

[3.54]

(Ref.)

1.5m

24VC

[5 ft]

83

[3.27]

(Ref.)

2

1

307

[12.09]

15º

2

15º

117

[4.61]

(Ref.)

DIN43650

1

**See cabling and electrical

options, page 20.

I

1

2

M

2

1

Standard sections cannot be

converted to electrical due to

12VCC

4VCC

Manual override

P101781a

96

[3.78]

(Ref.)

internal pilot.

Minimum pilot pressure to

actuate: 35 bar [500 psi]

mm [in]

18 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 19

Directional Control Valves Technical Information:

CDS 60 and 100

CABLING AND ELECTRICAL

OPTIONS FOR ACTUATOR

TYPES G, H, AND J

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

G: Flexible cable and lock options for spool control lever

A B C

Lever lock options Without lock Lock in A and/or B Lock in central position

Standard cables 100 - 125 - 150 - 175 - 200- 250 - 275- 300 - 325 - 350 - 400 - 450 - 500 cm (other: consult)

Example: how to order

A60 - 1AG2A1 - AB - A100 - 140/40 (lever without lock, 100 cm cable)

H: Flexible cable and handle options controls for joystick

A

Joystick handle options Without switches

Standard cables 100 - 125 - 150 - 175 - 200 - 250 - 275 - 300 - 325 - 350 - 400 - 450 - 500 cm (other: consult)

Example: how to order

A60 - 1AH2A1 - AB - A100 - 140/40 (handle without switches, 100 cm cable)

J: Electrical spool voltage and termination options

Voltage A 12 VDC -lead wires B 24 VDC - lead wires E

Example: how to order

A60 - 1AJ3L1 - AC - A 140/40 (12 VDC coil with lead wires)

Force requirements

kgf [lbf] CDS 60 CDS 100

Push/pull

min.

Max. tension 250 [551] 250 [551]

2 [4.4] 3.5 [7.7]

ACTUATION MOUNTING

SIDE

B

B

T

A

P

A

12 VDC - DIN 43650

conn.

24 VDC - DIN 43650

F

conn.

Electrical specifications

Voltage Amperage (A) Resistance (Ω)

12 VDC 1.75 6.85

24 VDC 0.88 27

Power: 21 W

2 Actuation on B port side (LH inlet shown)1 Actuation on A port side (RH inlet shown)

CDS100 CDS60

AA

BPBT

A

BPB

A

T

19 | © Danfoss | March 2016

CDS100

P101 822

CDS60

P101 796

520L0564 | BC00000105en-US0101

Page 20

Directional Control Valves Technical Information:

CDS 60 and 100

SPOOL CENTERING AND DETENT OPTIONS

3 position detent

Spring centered

A

32

CDS 60

[1.25]

40

CDS 100

[1.57]

Spring force

CDS 60: 145-155 N [32-35 lbf]

CDS 100: 240-245 N [54-55 lbf]

Spring center out,detent in

D

56

CDS 60

[2.20]

73

CDS 100

[2.87]

B

Spring centered,detent in A and B

E

56

[2.20]

73

[2.87]

32

[1.25]

40

[1.57]

CDS 60

CDS 100

CDS 60

CDS 100

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

Spring center in,detent out

C

56

CDS 60

[2.20]

73

CDS 100

[2.87]

Spring centered,h

F

92

CDS 60

[3.62]

96

CDS 100

[3.78]

ydraulic kickout

Spring centered,female extension

H

88±5

CDS 60

[3.46±0.2]

93 ±5

CDS 100

[3.66± 0.2]

8

Ø

[0.31]

CDS 60

6.4

[0.251]

8.4

[0.331]

CDS 100

F

Spring centered,floatation spool

J

20.5

[0.81]

65

[2.56]

78

[3.07]

CDS 60

CDS 100

Spring centered,male extension

I

88±5

CDS 60

[3.46±0.2]

93 ±5

CDS 100

[3.66± 0.2]

8

Ø

[0.31]

8.3

[0.33]

10

[0.39]

12.5

[0.49]

CDS 60

CDS 100

20

[0.79]

Note:Float body section required

82

[3.23]

101

[3.97]

CDS 60

CDS 100

Note:Unlock body section

required for use with hydraulic

unlock kit.

20 | © Danfoss | March 2016

Float in

Float out

mm [in]

* Default relief setting if not specified

520L0564 | BC00000105en-US0101

Page 21

Directional Control Valves Technical Information:

*on request

P106 330E

CDS 60 and 100

SPOOL CENTERING AND DETENT OPTIONS (continued)

Two-position detent:

N

neutral and spool in

Spring centered with switch:

P*

activates on spool in

32

CDS 60

[1.26]

40

CDS 60

6.5 [0.26]

8.0 [0.32]

CDS 100

[1.57]

CDS 100

Spring centered with switch:

Q*

activates on spool in and out

CDS 60

CDS 100

CDS 60

6.5 [0.26]

8.0 [0.32]

CDS 100

32

[1.26]

40

[1.57]

6.5 [0.26]

8.0 [0.32]

CDS 60

CDS 100

32

[1.26]

40

[1.57]

CDS 60

CDS 100

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

Two-position detent:

O

neutral and spool out

Spring centered with switch:

R*

activates two motors

32

[1.26]

40

[1.57]

CDS 60

CDS 100

21 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 22

AKJ

Directional Control Valves Technical Information:

CDS 60 and 100

AUXILIARY VALVES

Central body for use with auxiliary valves

For3ways spools.

TP

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

11

[0.43]

For valves B,C, F, G, and I

B

C

D

11

[0.43]

1 in1 in

ForvalvesDandE.

1 in 11/16 7/16

67

[2.64]

Max

1 in

47

Standard

[1.85]

29

Short version

[1.14]

(use with electrical

actuation)

1 in

10

[0.39]

1 in

mm [in]

P101 746E

E*

F

G

I

16

[0.63]

7/8

1 in

5/8

1 in

[1.14]

CDS 60

Knob

29

62

[2.44]

Max

1 in

12

[0.47]

1 in 11/16 7/16

70

[2.76]

Max

22 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 23

Directional Control Valves Technical Information:

10

152

[0.59]

Y

[1.49]

CDS 60 and 100

AUXILIARY VALVES (continued)

Auxiliary valves compatibility

A B C D E F G I J K

A

B

C

D

E

F

G

I

J

K

— — —

— — — —

—

— — —

— Not compatible

Compatible (EXCEPT electrical) Compatible (ONLY electrical)

DIMENSIONS CDS 100

30

[1.18]

46

[1.81]

—

46

[1.81]

Work section order code (example)

1 A E 2 A 1 A B 140/40*A100A100

— —

— —

— —

— —

— —

— —

— —

Compatible

— — — — —

— — — —

— — — —

—

—

—

[5.98]

82

[3.23]

— —

— —

—

—

—

—

—

38

100

[3.94]

25

[0.98]

X

25

[0.98]

15

127

[5.00]

Reference dimensions

AA

BPBT

44.5

[0.39]

R

t 27 N•m

5.5

[0.22]

20 lbf•ft

Number of

sections

X Y

1 95 [3.74] 137 [5.39]

2 139 [5.47] 181 [7.13]

3 184 [7.24] 226 [8.89]

4 229 [9.02] 270 [10.63]

5 273 [10.75] 314 [12.36]

6 318 [12.52] 359 [14.13]

7 362 [14.25] 403 [15.87]

8 406 [15.98] 448 [17.64]

9 451 [17.76] 492 [19.37]

10 495 [19.49] 537 [21.14]

11 540 [21.26] 581 [22.87]

12 584 [22.99] 626 [24.65]

mm [in]

23 | © Danfoss | March 2016

520L0564 | BC00000105en-US0101

Page 24

[1.02]

120

Y

Directional Control Valves Technical Information:

DIMENSIONS CDS 60

24

[0.94]

32

[1.26]

38

[1.50]

38

[1.50]

CDS 60 and 100

82

[3.23]

[4.72]

56 74*

[2.20] [2.91]

18

[0.71]

14

[0.55]

18

[0.71]

X

Reference dimensions

Number of

sections

98

[3.86]

X Y

1 72 [2.83] 112 [4.41]

2 108 [4.25] 148 [5.83]

3 144 [5.67] 184 [7.42]

A

A

26

P

B

B

36

[1.42]

T

P101 795

r.

[0.51]

4.5

[0.18]

13

28.5

[1.12]

t 18 N•m

13 lbf•ft

4 180 [7.09] 220 [8.66]

5 216 [8.50] 256 [10.08]

6 252 [9.92] 292 [11.50]

7 288 [11.34] 328 [12.91]

8 324 [12.76] 364 [14.33]

9 360 [14.17] 400 [15.75]

10 396 [15.59] 436 [17.17]

11 432 [17.01] 472 [18.58]

12 468 [18.43] 508 [20.00]

Mounting requirements

24 | © Danfoss | March 2016

A

Flatness 0.5-0.8 [0.02 to 0.03] max Flatness 0.5-0.8 [0.02 to 0.03] max

B

77 78

P106 331E

520L0564 | BC00000105en-US0101

Page 25

Directional Control Valves Technical Information:

CDS60 AND CDS100 SPECIFICATION WORKSHEET

Appendix 1 - Order forms

“B” Port

Side Flow (l/

min)

Threads

Options

Control No.

Subsidiary/Dealer

Model Model Size Ports

None

Black Primer

Black Paint

“B” Port

Side

“A” Port Side

“A” Port Side

Pressure

Cable

Length

Cable or

Electrical

Aux Valves

Aux Valves

Threads

Pressure

(Bar)

Flow (l/min)

(Bar)

Centi-

meters

Control

Options

“B”

“A”

Directional Control Valves CDS60 and CDS100

Specification Order Form

Customer Application

25 | © Danfoss | March 2016

Inlet Section Paint Outlet Section

Port Side

Flow

Pressure

Threads Port Side

Main

relief

Port

Size

Side

Model Model

Center

Type

Spool

Control

Side

Spool

Controls

Spool

Types

Valves

Work Sections

Circuit

Type

Model

Size

Model

Work

section

1st

2nd

3rd

4th

5th

6th

7th

8th

9th

10th

11th

12th

Number of sections =

Price US $: Delivery: Date:

520L0564 | BC00000105en-US0101

Page 26

OUR PRODUCTS

Hydrostatic transmissions

Danfoss Mobile Power and Control Systems

– Market Leaders Worldwide

Danfoss is a comprehensive supplier providing complete systems

to the global mobile market.

Hydraulic power steering

Electric power steering

Electrohydraulic power steering

Closed and open circuit axial piston

pumps and motors

Gear pumps and motors

Bent axis motors

Orbital motors

Transit mixer drives

Planetary compact gears

Proportional valves

Directional spool valves

Cartridge valves

Hydraulic integrated circuits

Hydrostatic transaxles

Integrated systems

Fan drive systems

Danfoss serves markets such as agriculture, construction, road

building, material handling, municipal, forestry, turf care, and many

others.

We offer our customers optimum solutions for their needs and

develop new products and systems in close cooperation and

partner ship with them.

Danfoss specializes in integrating a full range of system

components to provide vehicle designers with the most advanced

total system design.

Danfoss provides comprehensive worldwide service for its

products through an extensive network of Global Service Partners

strategically located in all parts of the world.

Local address:

Electrohydraulics

Microcontrollers and software

Electric motors and inverters

Joysticks and control handles

Displays

Sensors

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice.

This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are registered trademarks of Danfoss A/S. All rights reserved.

26 | © Danfoss | March 2016

Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000

Fax: +1 515 239-6618

Danfoss GmbH & Co. OHG

Postfach 2460, D-24531 Neumünster

Krokamp 35, D-24539 Neumünster, Germany

Phone: +49 4321 871-0

Fax: +49 4321 871 122

Danfoss ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444

Fax: +45 7488 4400

Danfoss-Daikin LTD

Sannomiya Grand Bldg. 8F

2-2-21 Isogami-dori, Chuo-ku

Kobe, Hyogo 651-0086, Japan

Phone: +81 78 231 5001

Fax: +81 78 231 5004

520L0564 | BC00000105en-US0101

Loading...

Loading...