Page 1

Dimensioning mass flow

in hot gas defrost lines

Using Coolselector®2

Morten Juel Skovrup

2017-02-20

Version 1.32

Determining the dimensioning mass flow required for selecting the right pipes, fittings and

components in hot gas defrost lines in Coolselector2.

Page 2

Dimensioning mass flow in hot gas defrost lines

2

1 Introduction

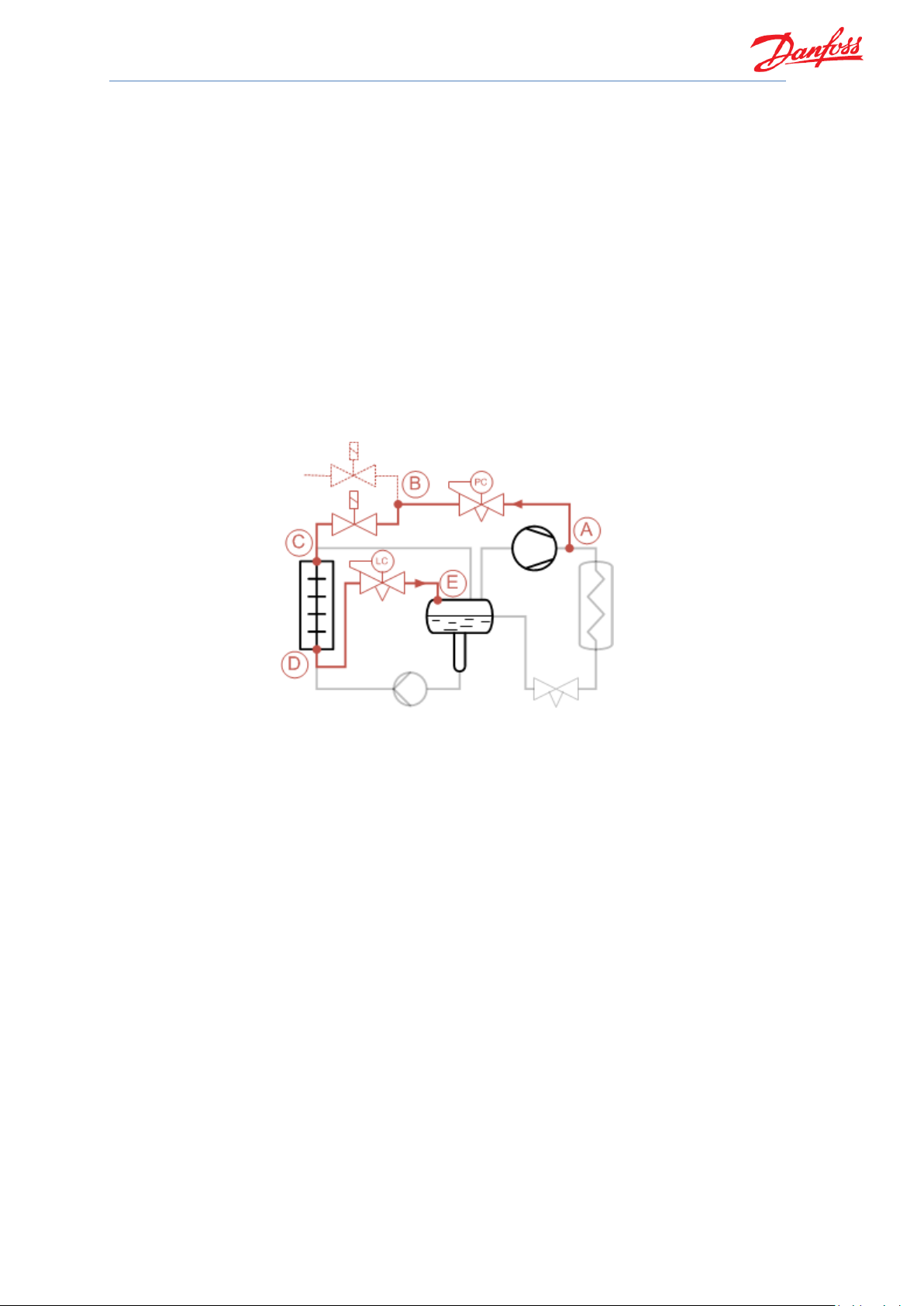

Hot gas defrost calculations in Coolselector®2 are implemented for pump and gravity systems,

i.e. systems where there is typically more than one evaporator.

Coolselector®2 supports 3 different types of hot gas defrost lines:

1. Main hot gas defrost line. Line that runs from compressor discharge to distribution

point where line is split into separate lines for each evaporator (from A to B in diagram

below).

2. Hot gas defrost line. Hot gas defrost supply line to each evaporator (from B to C in

diagram below).

3. Hot gas defrost drain line. Line out of evaporator and back to separator (from D to E in

diagram below).

The main functionality included in the three lines is often:

1. The main hot gas line is equipped with a control valve (ICS + CVC pilot) keeping the

supply pressure at point B constant (“regulated hot gas”).

2. The hot gas defrost line is equipped with a solenoid valve, enabling start/stop of hot gas

to the evaporator.

3. The defrost drain line is equipped with either:

a. A control valve (ICS + CVP pilot) keeping the defrost pressure constant – this is

called “Pressure controlled drain”

b. A float valve, which simply lets condensed liquid generated during defrost back

to the separator – this is called “Liquid drain”

Page 3

Dimensioning mass flow in hot gas defrost lines

3

2 Inputs

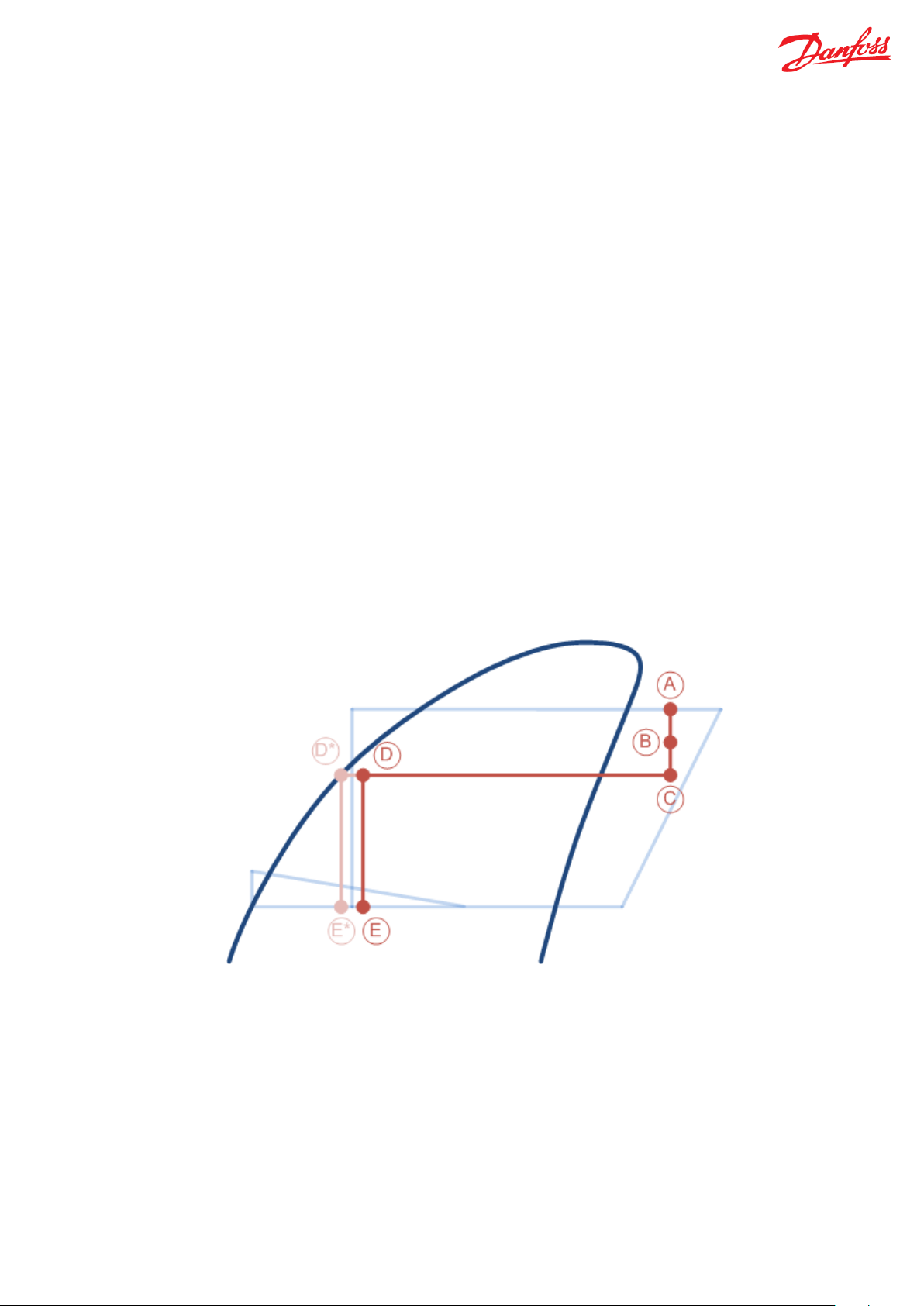

To define the condition of the hot gas used for defrost the following inputs are needed:

Condensing temperature. The condensing temperature determines the pressure in

point A in diagram below

Main hot gas supply temperature. The temperature in point A. It can be equal to the

compressor discharge temperature, but normally it is somewhat reduced due to heat

loss from the discharge line.

Reduced hot gas supply pressure. The pressure (or saturation temperature)

corresponding to point B. This pressure is equal to the set point of the control valve in

the main hot gas line.

Defrost pressure. The pressure (or saturation temperature) corresponding to point D.

This pressure is equal to the set point of the control valve (for pressure controlled drain)

in the defrost drain line.

Dimensioning quality. This will be treated separately below, but it is used to determine

the density of the refrigerant flowing into the components placed in the defrost drain

line – i.e. the dimensioning quality determines the position of point D.

Evaporating temperature. The evaporating temperature determines the pressure in

point E

The location of the points is illustrated in the following log(p)-h diagram:

Note: The pressure in point C is not defined. It is calculated based on components selected in to

the hot gas defrost line. Point C is illustrated as having same pressure as point D above, but that

is not automatically the case.

Note: For liquid drain, the pressure in point D still needs to be defined (even though the pressure

is not actually controlled). For liquid drain, the pressure in point D will in reality be a function of

valves in the hot gas defrost line and the evaporator pressure drop. But for dimensioning

purposes, a reasonable value a few degrees lower than point B will be sufficient.

Page 4

Dimensioning mass flow in hot gas defrost lines

4

2.1 Dimensioning quality

The dimensioning quality is used to determine position of point D at the inlet to the defrost

drain line.

The term “quality” is a measure of the mass of gas compared to the total mass of refrigerant.

The dimensioning quality will be quite different based on the drain control method you select:

For liquid drain the dimensioning quality should always be 0.0 – i.e. the refrigerant in

point D is saturated liquid. The function – or the purpose – of a float valve in the defrost

drain line is exactly to avoid (as far as possible) gas to pass through the float valve, but

only let liquid pass through.

For pressure controlled drain, the defrost process will be quite different. Initially, all hot

gas supplied to the evaporator will condense and the valve will only see liquid at the

inlet. Later in the process, some gas will not condense in the evaporator and the valve

will see a mixture of liquid and gas. This process is illustrated below (from D* to D):

Selecting the right dimensioning quality for pressure controlled drain is very important for

selecting the right valve size:

If a dimensioning quality of 0.0 is selected (saturated liquid) then the resulting valve will

be relatively small, which could mean that defrost will be prolonged at the end of the

defrost cycle (gas cannot efficiently be passed through the valve)

If a dimensioning quality of 1.0 is selected (saturated gas) then the resulting valve will be

relatively large, meaning that a lot of gas will be bypassed (equals larger energy

consumption), plus the valve can become unstable when pure liquid enters the valve in

beginning of the defrost cycle.

In Coolselector®2 we recommend using a relatively low value of dimensioning quality equal to

0.05. This ensures that the valve is stable when liquid enters it and that the amount of bypassed

gas is minimized.

Page 5

Dimensioning mass flow in hot gas defrost lines

5

2.2 Dimensioning capacity

Determining the hot gas capacity in the defrost lines is a question of defining the necessary hot

gas mass flow in the selected line.

Normally some rules of thumb are used, which relates to the dimensioning cooling capacity of

the evaporator (or evaporators) the selected hot gas line connects to.

In Coolselector®2 the following equation for determining the hot gas mass flow is used:

hot gas

Dimensioningcoolingcapacity

m Defrost capacity factor

Defrost enthalpydifference

The Dimensioning cooling capacity is the cooling capacity of the evaporator(s) being defrosted.

This value indirectly tells the size of the evaporator.

The Defrost enthalpy difference equals the energy content of the hot gas – it is equal to the

enthalpy difference between point C and D in the diagram below:

The Defrost capacity factor is a value selected based on experience. A default value of 2.0 is used

in Coolselector®2 but it is normally chosen between 1 and 3.

The larger Defrost capacity factor the larger the valves will be, and the shorter the defrost time

will be. The smaller Defrost capacity factor the smaller the valves will be, and the longer the

defrost time will be.

In general, you can say that the penalty of choosing too small valves is a longer defrost time.

Note: the equation above is also used when dimensioning the main hot gas defrost line. In this

case, the dimensioning cooling capacity is the sum of the cooling capacity of the evaporators,

which will be defrosted simultaneously.

Page 6

Dimensioning mass flow in hot gas defrost lines

6

3 Pressure in evaporator during defrost

If the hot gas supply is coming directly from the compressor discharge, then there is a risk of the

pressure in the evaporator raising to condensing pressure. This might be a problem if the

evaporator is not dimensioned for high pressure.

If a pressure controlled drain valve is selected using a dimensioning quality of 0.05, then the

pressure inside the evaporator can rise to condensing pressure at the end of the defrost process.

Simply because the capacity of the pressure controlled drain valve will be too low to allow all

uncondensed gas to pass.

For a float controlled drain valve, the pressure will always approach condensing pressure at the

end of the defrost process if there is no valve to reduce the hot gas pressure.

If a pressure controlled drain valve on the other hand is selected using a high value for the

dimensioning quality, then this valve will have a capacity high enough to let the uncondensed

gas pass, but it will:

- operate unstable in the beginning of the defrost process

- be associated with substantial energy losses (bypassed gas is essentially a loss)

If condensing pressure is not allowed in the evaporator, then the solution for both pressure

controlled and float controlled drain valve is to install a valve to reduce the hot gas pressure as

shown in the PI diagram:

Page 7

Dimensioning mass flow in hot gas defrost lines

7

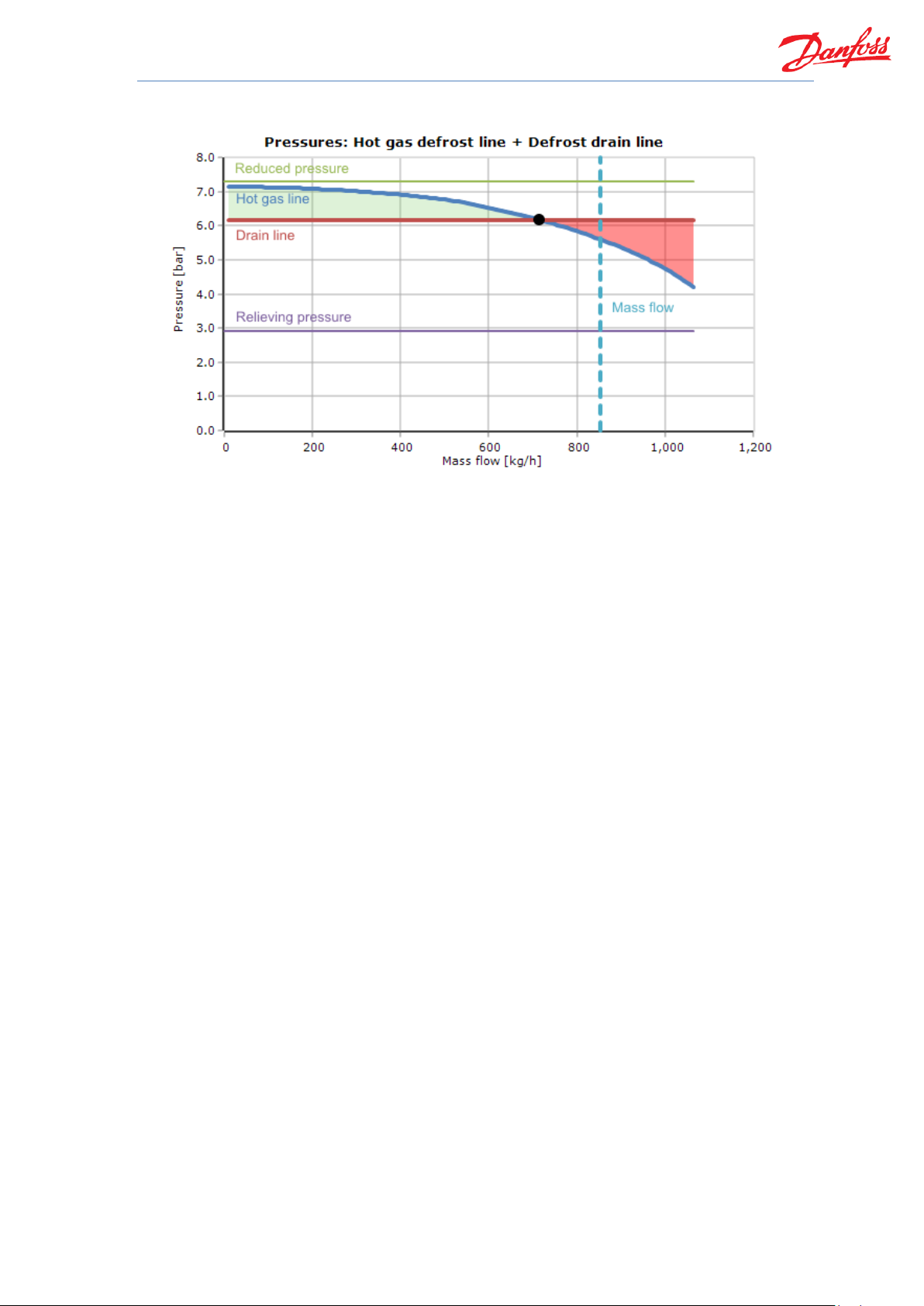

4 Defrost pressure graph

When you select the Evaporator Valve Station application in Coolselector2, you will be able to

(when the selection is done) switch to manual mode:

In Manual mode you will be able to change the components in the 4 lines as you want, but you

will not be able to return to the overview page. Also in manual mode, you will be able to review

the selections you’ve made in detail using the Defrost pressure graph:

Page 8

Dimensioning mass flow in hot gas defrost lines

8

The Defrost pressure graph shows a combination of the pressure at the end of the hot gas line

(point C), and the pressure at the beginning of the drain line (point D):

If you haven’t added components to the end of the hot gas line which simulate the pressure

drop in the evaporator, then the curves show the pressures at the evaporator inlet and the

evaporator outlet. The difference between the two lines then illustrate the pressure drop

available for the evaporator.

In the example above, the design mass flow (drawn as a vertical dotted line) is selected so that

there is about 0.4 bar left for the evaporator (the difference between the two curves)

If you include the evaporator in the hot gas line (for example by adding a constant Δp or a pipe

component), then the mass flow should be selected so that it approximately crosses the curves

where they cross each other – as illustrated by the black dot below:

Page 9

Dimensioning mass flow in hot gas defrost lines

9

If you select the mass flow so that it crosses the red area (instead of the green or exactly through

the black dot), then you expect the pressure in the hot gas line to be lower than the pressure in

the drain line, which is clearly not possible.

To fix this situation, you can do one of the following:

1. Raise the reduced pressure (and check against the condensation pressure – especially in

systems with floating head).

2. Lower the hot gas mass flow – at the price of a slower defrost.

3. Lower the defrost pressure (drain line pressure) – again at the price of a slower defrost.

If you increase the dimensioning quality (i.e. specify that the drain valve shall be able to handle

more gas) so that the pressure controlled drain valve is too small and will be fully open, then you

will see the following graph:

Page 10

Dimensioning mass flow in hot gas defrost lines

10

The graph illustrates that the defrost pressure (red curve) will no longer be constant but will

increase when the mass flow increases above the maximum capacity of the pressure controlled

drain valve. In the graph above, the maximum capacity of the drain valve is about 600 kg/h, but

the crossing point between the hot gas and the drain curves is at about 640 kg/h.

This illustrates what will happen at the end of a defrost period where the refrigerant entering

the drain valve will have an increasing share of gas. The defrost pressure will increase if the valve

is too small, until the system settles at the point indicated by the black dot (assuming that the

pressure drop in the evaporator is included in the hot gas line).

Loading...

Loading...