Page 1

Page 2

Revision history

Date Chan ged Rev

February 2022 Corrected small errors in sections 9.3 and 9.5.1.4.2 0102

August 2021 First edition: software release 2.7.1 0101

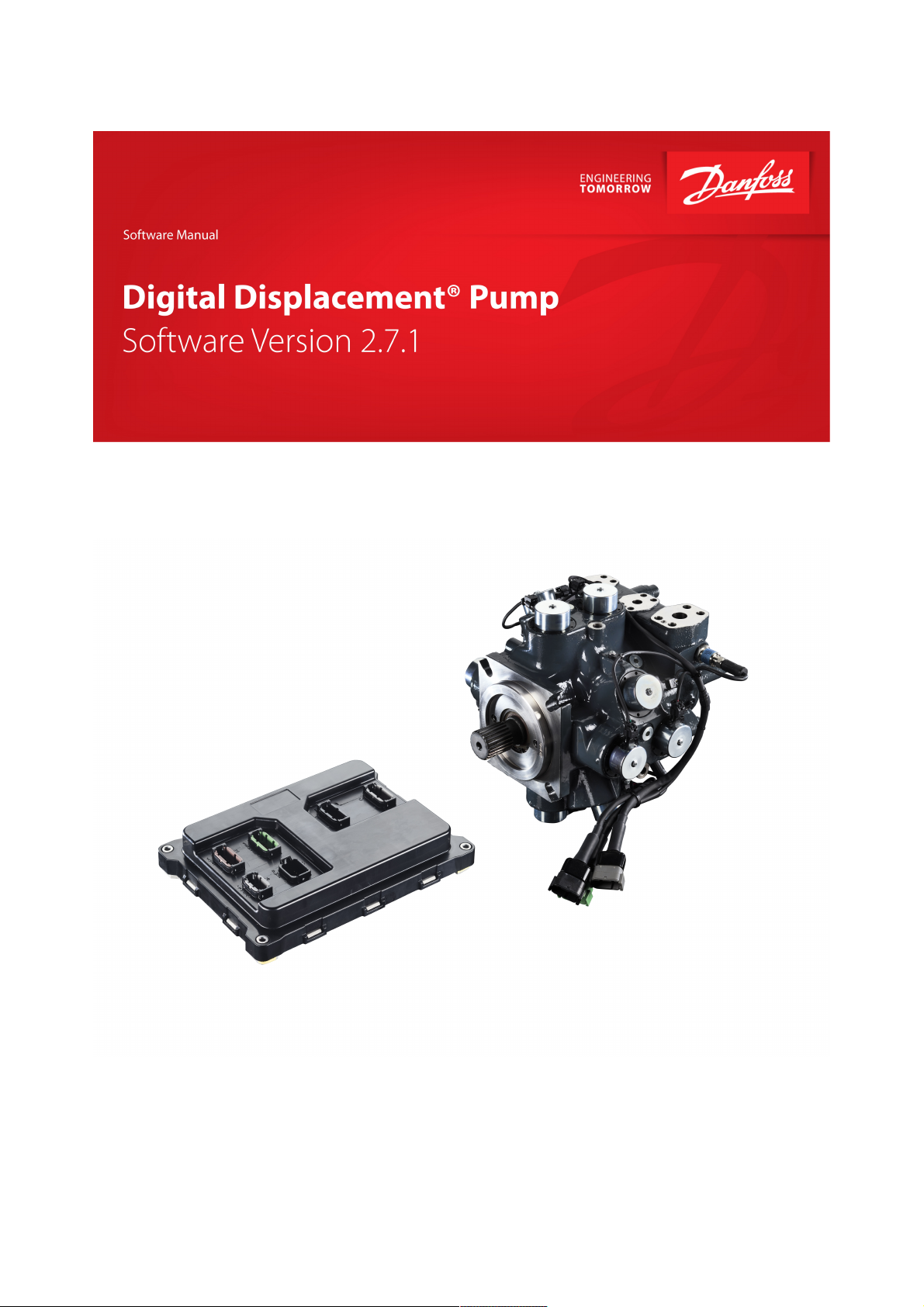

Software Manual

Digital Displacement® Pump Software Version 2.7.1

2 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 3

Contents

1 Rele ase notes

1.1 Ve rsion 2.7.1

1.2 Ve rsion 2.6.3 (originally labeled 2.63)

1.3 Ve rsion 2.5.1 (originally labeled 2.51)

2 Known issues

2.1 CAN Bus Off error after turning on a DPC12 (193548)

2.1.1 Description

2.1.2 Solutions

2.2 J1939 unused reference s req uire valid value (369615)

2.2.1 Description

2.2.2 Solutions

2.3 Not all e rror counters cleared by RESET_ERR_CNTR_CMD (338706)

2.3.1 Description

2.3.2 Solutions

2.4 PLUS+1® parameter value cannot be changed if its source is not set to 1 (346303)

2.4.1 Description

2.4.2 Solutions

2.5 Solenoid fault test fails for cylinder A1 (354599)

2.5.1 Description

2.5.2 Solutions

2.6 Pressure sensor invalid low error w ith sensor connec ted (361396)

2.6.1 Description

2.6.2 Solutions

2.7 Software update fails when using multiple CAN bus devices (400960)

2.7.1 Description

2.7.2 Solutions

2.8 Tw o CG150 gatew ays causes communications error (404422)

2.8.1 Description

2.8.2 Solutions

3 Configuring a new controller

3.1 Use of a CAN Bus

3.2 Control config uration required

3.3 Control loop gains

3.4 PLUS+1® Service Tool

3.5 Backup parameters

4 Commissioning mod e

4.1 Entering and exiting commissioning mode

4.2 Commissioning actions

4.2.1 Fire

4.2.2 Pump

4.2.3 Raw displacement

4.2.4 Coil numbe rs

5 Control configuration

5.1 Use case s

5.1.1 Single-service software

5.1.2 Two-service software

6 Two-service ope ration

6.1 Se rvice independence

6.2 Se rvice sw itching

7 Parame ters

7.1 Communication parameters

7.2 Pump setting parame ters

7.3 Pump and controller status parameters

7.4 Se rvice 1 parameters

7.4.1 Control mode paramete rs

7.4.2 Control reference p arameters

7.4.3 Limits parameters

7.4.4 Control loop gain parameters

Software Manual

Digital Displacement® Pump Software Version 2.7.1

3 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 4

7.4.5 Service status parameters

7.5 Se rvice 2 parameters

7.5.1 Control mode paramete rs

7.5.2 Control reference p arameters

7.5.3 Limits parameters

7.5.4 Control loop gain parameters

7.5.5 Service status parameters

7.6 Other parameters

7.7 Commissioning mode parameters

8 Errors

8.1 Error handler states

8.2 Error list

8.3 Diagnosing faults

8.3.1 Diag nostic LED

9 J1939 CAN p rotocol

9.1 Ad dre ss scheme

9.2 PGN priorities

9.3 SLOTs

9.4 Diagnostic messag es

9.4.1 DM1 PGN - active diagnostic trouble codes

9.4.1.1 Message information

9.4.1.2 Message d ata

9.4.1.3 DM1 e xample scenarios

9.4.2 DM2 PGN - pre viously active d iagnostics trouble cod es

9.4.2.1 Message information

9.4.2.2 Message d ata

9.4.2.3 DM2 e xample scenarios

9.4.3 DM3 PGN - diag nostics data clear of previously active DTCs

9.4.3.1 Message information

9.4.3.2 DM3 e xample scenarios

9.4.4 DM11 PGN - diagnostics data clear of active DTCs

9.4.4.1 Message information

9.4.4.2 DM11 example scenarios

9.4.5 DM13 PGN - ignore all info and w arning errors until DM13 is rece ived

9.4.5.1 Message information

9.4.5.2 Message d ata

9.4.5.3 DM13 example scenarios

9.4.6 Request PGN

9.4.6.1 Message information

9.4.6.2 Message d ata

9.4.7 Acknowledgment PGN

9.4.7.1 Message information

9.4.7.2 Message d ata

9.5 M anufacturer spe cific PGNs

9.5.1 Control PGNs

9.5.1.1 Pump setup A

9.5.1.2 Displacement reference A

9.5.1.3 Pressure reference A

9.5.1.4 Pressure margin reference A

9.5.1.5 Torque limit A

9.5.1.6 Flow limit A

9.5.1.7 Power limit A

9.5.2 Status PGNs

9.5.2.1 Pump info A

9.5.2.2 Service 1 status

9.5.2.3 Service 2 status

10 Updating software on the controller

11 Reference s

Software Manual

Digital Displacement® Pump Software Version 2.7.1

4 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 5

1 Release notes

1.1 Version 2.7.1

Reorganised J1939 protocol

Changed PGN framing to conform to Danfoss product compatibility standard

Changed scaling for SPNs to use standard SLOTs w here possible

Added J1939 address claim procedure support

New parame ter for controller instance

New errors for address claim failures

Improved PLUS+1® Se rvice Tool info block details

Service switching configuration can be set from PLUS+1® (as well as J1939)

Added parameter to read FPGA version

Added additional supp orted use cases

Sing le-service

Displacement control by PLUS+1®

Displacement control by PLUS+1® with torque limit

Two-service

Displacement control by PLUS+1®

Displacement control by PLUS+1® with torque limit

Industrial p ressure control by J1939 with flow limit

Industrial p ressure control by J1939 with flow limit and PLUS+1® service configuration

Industrial p ressure control by PLUS+1® w ith flow limit

Load-sense pressure control by J1939 with torq ue limit

Load-sense pressure control by PLUS+1® w ith torque limit

Mixed disp lacement/load-sense by J1939

1.2 Version 2.6.3 (originally labeled 2.63)

Added build for tw o-service pumps (ML)

Changed layout of control reference and limit parame ters from using enable paramete rs (EN_x) to

sourc e parame ters (x_SRC)

Added additional supp orted single-service use cases

Displacement control by J1939

Displacement control by J1939 with torque limit

Industrial p ressure control by PLUS+1®

Industrial p ressure control by PLUS+1® w ith flow limit

Load sensing pressure control by PLUS+1®

Load sensing pressure control by J1939

Load sensing pressure control by PLUS+1® w ith torque limit

Load sensing pressure control by J1939 with torque limit

1.3 Version 2.5.1 (originally labeled 2.51)

First release for sing le -service pumps (SS)

Software Manual

Digital Displacement® Pump Software Version 2.7.1

5 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 6

2 Known issues

2.1 CAN Bus Off error after turning on a DPC12 (193548)

2.1.1 Description

Othe r d evice s on the bus experience CAN faults which lead s to them declaring a CAN Bus Off error after the

DPC12 controlle r is powered on. This causes the devices to stop communicating with the system until their

faults are cleared.

The issue may also lead to difficulty using the PLUS+1® Service Tool Recover ECU function as controller is

power-cycled during this procedure.

The problem is caused by the power-up behavior of the DPC12 CAN transmitter. When the controlle r is

supplied from a current-limite d power supply, the controller can hit this current limit and brown out multiple

times during the initial pow er-up. On e ach brow nout an erroneous signal is transmitted on the CAN bus.

Multiple b row nouts lead to a high enough error count to trigger the CAN Bus Off error on other connecte d

devices.

2.1.2 Solutions

Use a pow er supply with a higher current limit or turn off soft-start behavior.

A hardware solution w ill be implemented in a future DPC12 controller revision.

2.2 J1939 unused references require valid value (369615)

2.2.1 Description

The M anufacturer specific PGNs use d to send the control references and limits to the DDP096 software

includ e sig nals for seve ral service s w ithin the same messag e. In the case w here the value for one of the

services is not being used (due to the correspond ing source parameter, _SRC, being set to unlimited or

PLUS+1®), the DDP096 softw are d oes not accept the correct value for the unuse d signals. To meet the J1939

stand ard the system controlle r should send a "not used/not req uested " value, however upon receiving this

value the DDP096 softw are w ill ge nerate an "Invalid d ata in J1939 message" error.

2.2.2 Solutions

Send value of zero instead of the "not used/not requested" value. This should b e zero in the physical units of

the message, with the rele vant scaling and offset applied.

This issue will be resolved in an upcoming software release.

2.3 Not all error counters cleared by RESET_ERR_CNTR_CMD (338706)

2.3.1 Description

Whe n using the RESET_ERR_CNTR_CMD parameter or DM 3 PGN - diagnostics data clear of previously active

DTCs to reset the error occurrence counte rs, only the first 29 counters with a value gre ater than zero w ill be

cleare d.

2.3.2 Solutions

Send multiple re quests to clear the error counters b y toggling RESET_ERR_CNTR_CMD or sending the DM 3

message repeatedly. This version of the softw are has 72 occurrence counte rs, so issuing the command three

times w ill cle ar all counters.

This issue will be resolved in an upcoming software release.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

6 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 7

2.4 PLUS+1® parameter value cannot be changed if its source is not set to 1

(346303)

2.4.1 Description

PLUS+1® p arameters w hich are read/w rite or read-only depending on the setting of the corresponding

sourc e parame ter (_SRC) cannot be changed until the source is set to PLUS+1®.

This issue is particularly apparent whe n dow nload ing paramete rs from an XM L file in Service Tool.

2.4.2 Solutions

Ensure that the corresponding source parameter is set to PLUS+1® before writing to the parameter. If

downloading an XML file in Service Tool, arrang e the p arameters so that the source paramete r comes earlie r

in the list than the parameter.

2.5 Solenoid fault test fails for cylinder A1 (354599)

2.5.1 Description

The solenoid fault te st occasionally fails for cylinder A1 in a healthy system. The e rror only occurs on the first

test after pow er-on.

2.5.2 Solutions

Disable the start-up solenoid fault te st by setting EN_STARTUP_SOLENOID_FAULT_TEST to 0.

Run the manual solenoid fault test using EN_MANUAL_SOLENOID_FAULT_TEST twice, disregarding the error

states after the first test.

This issue will be resolved in an upcoming software release.

2.6 Pressure sensor invalid low error with sensor connected (361396)

2.6.1 Description

A p ressure sensor invalid low error can be trig gered at low pressure in an e le ctrically noisy environme nt. The

following errors may be seen:

Service 1 outlet pressure reading below minimum (SPN 520960, FMI 18)

Service 2 outlet pressure reading below minimum (SPN 520961, FMI 18)

Service 1 external load-sense pressure reading below minimum (SPN 521020, FMI 18)

Service 2 external load-sense pressure reading below minimum (SPN 521021, FMI 18)

2.6.2 Solutions

Contact Danfoss for advice.

2.7 Software update fails when using multiple CAN bus devices (400960)

2.7.1 Description

Dow nloading new softw are to the DPC12 controller using the PLUS+1® Se rvice Tool can fail when other CAN

bus devices are communicating on the bus.

2.7.2 Solutions

Disconne ct or power-d own other CAN bus devices on the bus before updating the controller software.

If download failure occurs, follow the above ad vice and use the Recover ECU feature in the PLUS+1® Service

Tool to retry the download.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

7 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 8

2.8 Two CG150 gateways causes communications error (404422)

2.8.1 Description

Whe n two Danfoss CG150-2 CAN/USB inte rface gateway d evice s are present on the DPC12's CAN ne twork

parame ter w rite operations may fail.

2.8.2 Solutions

Ensure only one CG150 device is used on the CAN netw ork conne cted to the DPC12.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

8 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 9

3 Configuring a new controller

The DDP096 is a softw are-driven product and requires initial config uration to operate correctly in a hydraulic

system or vehicle. The follow ing items should be considered when setting up the DPC12 controller for the

first time. Failure to do so may result in the pump being unab le to ope rate reliably.

If you have any issues or require assistance with the initial setup, please contact your Danfoss representative.

3.1 Use of a CAN Bus

The DDP096 softw are is de signed to be setup and monitored using a CAN bus. It is recommended that a

diagnostic connector is available in every installation including a DPC12 controller.

The DDP096 softw are includes an error to detect electrical problems w ith the CAN bus during operation. This

error w ill be triggered in a system where no CAN bus is connected to the controller w hile it is operating. To

prevent the error being triggered and the pump disabled, the IGNORE_EPV_FLAG parameter must be

changed from its default value. See the Communication parame ters and Errors sections for further de tails.

Warning

Parameter IGNORE_EPV_FLAG must be set to 1 if no CAN bus connection is present in operation.

The DPC12 controller must be ab le to be uniquely addressed when using a J1939 CAN bus for control or

monitoring. For this it imp le ments the J1939 ad dress claim proced ure. Details of this procedure should be

understood as add ress claim errors w ill result in the pump being disabled. See the Address scheme and

Errors sections for further details.

Warning

If more than one DPC12 is connected to the CAN bus the controllers must be uniquely ad dressed.

3.2 Control configuration required

The factory default setting for the DPC12 controller sets the control method to a static displacement of zero

output. The DDP096 softw are must be config ured to the control method required b y the hydraulic system or

vehicle. Se e the Control configuration section for more de tails.

3.3 Control loop gains

A control loop w ith tuneable gains is used by the software in pressure control and load -sense control mode s.

These gains must be tuned to match the hydraulic characteristics of the system and the desire d pump

response. It is recommended to undergo training or receive assistance from your Danfoss representative

when doing first start-up of a new hydraulic system operating in either of these mod es to ensure that the

control loop g ains can be tuned for optimal system p erformance and response.

3.4 PLUS+1® Service Tool

The Danfoss PLUS+1® Service Tool is used to configure the DDP096 software. Service Tool pages are available

to make interacting w ith the DDP096 software parameters simple. The Service Tool can be downloaded from

the Danfoss w ebsite . Please contact your Danfoss re presentative for access to the DDP096 Service Tool pages.

3.5 Backup parameters

It is highly advisable to backup the DDP096 software paramete rs once setup is comp le te. In the event of

damage to the DPC12 controller or non-volatile memory corruption the backup parameters can be

downloaded to a new DPC12 controlle r to allow the DDP096 pump to function as desire d. Please contact your

Danfoss rep rese ntative for training on using the PLUS+1® Service Tool to export paramete rs from a DPC12

controller.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

9 | © Danfoss | Fe bruary 2022 BC404560709540en-000102

Page 10

Warning

Danfoss and the PLUS+1® Service Tool do not automatically store copies of DDP096 software parameters.

Backups should be made after the configuration is chang ed.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

10 | © Danfoss | February 2022 BC404560709540en-000102

Page 11

4 Commissioning mode

The DDP096 softw are includes a commissioning mode w hich is used to exercise pumping units when the

pump is not in normal operation. More d etail on commissioning a DDP096 pump and DPC12 in a hydraulic

system is provided in the Digital Displace ment® Pump Gen 1 DDP096 and DPC12 Te chnical Information.

Warning

Some error protection is disabled in commissioning mod e. The use r should e nsure that the system is properly

protected hydraulically (for instance with a pressure relief valve on e ach outlet) and is monitored carefully

throughout.

4.1 Entering and exiting commissioning mode

Commissioning mode is ente red by setting the EN_COMMISS parameter to "enabled" (1) and power cycling

the controller. The DEVICE_MODE paramete r can be used to check that the DDP096 software is in

commissioning mode - the value will be 2 w he n in commissioning mode.

Commissioning mode is left by setting the EN_COMMISS p arameter back to "disabled" (0) and power cycling

the controller.

4.2 Commissioning actions

Five actions are available to the user in commissioning mode:

fire

pump x1

pump x100

raw displacement, service 1

raw displacement, service 2

Each is described in the following sections.

To set up an action:

1. the COMMISS_ACT_TYPE paramete r should b e set to the value corresponding to the p articular action.

2. the COMMISS_VALUE parameter should be set to the required coil number or displacement p erce ntag e.

3. the COMMISS_CMD parame ter should be set to 1 to start the action.

4. the COMMISS_CMD parame ter should be set back to 0 w hen the action is comple te before starting the

next action.

Each action may be disabled due to the current shaft speed or active errors. The DDP096 softw are show s

which actions are allowed via the COMMISS_LEVEL parame ter, w hich has three levels:

0. Internal 24V power supply proble m, inc luding no power to coil supply pins, is indicated by the

ERR_AE_3599_02_LM_OUT24V error b eing active.

1. At least one severe error active (other than ERR_AE_3599_02_LM_OUT24V).

2. No severe errors active.

Whe n an action is requested, the DDP096 software reports the result of the request with the

COMMISS_STATUS parameter. It shows w hether a request was d enied , due to the COMMISS_LEVEL being

low er than that required for the requested command, and whe ther the action is in prog ress. For fire and

pump x1 actions the parameter is set to the in progress value only for a very short time.

4.2.1 Fire

The fire action allows the coil of a p articular pumping unit to be ene rgized. This is intend ed to allow the user

to check for correct w iring to the coil, either by listening for the audible click produced during the

energization or by using a current probe to view the current in the wire to the coil.

COMMISS_ACT_TYPE is 1 for the fire action and the COMMISS_VALUE paramete r selects the coil to be fire d (see

Coil numbers section).

Software Manual

Digital Displacement® Pump Software Version 2.7.1

11 | © Danfoss | February 2022 BC404560709540en-000102

Page 12

The fire action is available whether or not the shaft of the pump is sp inning , and requires the COMMISS_LEVEL

to be 1 or 2.

4.2.2 Pump

The pump action e nergizes the coil of a particular pumping unit at the correct shaft angle for pumping,

allowing the user to check that fluid is displaced by that pumping unit. This can be used in conjunction w ith a

flow meter or pressure sensor/gauge to verify the function of that pumping unit.

The COMMISS_VALUE parameter selects the coil to be fired (see Coil numbers section). A single pumping

stroke can b e requeste d using COMMISS_ACT_TYPE 2 and one hundred pumping strokes can be req uested

using COMMISS_ACT_TYPE 3.

The pump action is only available when the shaft is sp inning and the minimum pumping speed is reached (see

the ERR_AE_520975_17_LM_SHSPD error), and requires COMMISS_LEVEL to be 2.

4.2.3 Raw displacement

The raw displacement action allow s the use r to se t the DDP096 to pump indefinitely at a particular fraction of

its availab le flow.

The COMMISS_VALUE parameter sets the displaceme nt fraction, and is scaled the same way as the

DISP_REF_S1 parameter. COMMISS_ACT_TYPE 4 re que sts flow from service 1, and COMMISS_ACT_TYPE 5

requests flow from service 2 (in two-service DDP096 softw are). For two-service operation the selected service

config uration is always that correspond ing to index 0 of the SERV_CONF_INDEX parame ter (see the Service

sw itching section).

The raw displacement action is only available w hen the shaft is spinning and the minimum pumping speed is

reache d (see the ERR_AE_520975_17_LM_SHSPD error), and req uire s COMMISS_LEVEL to be 2.

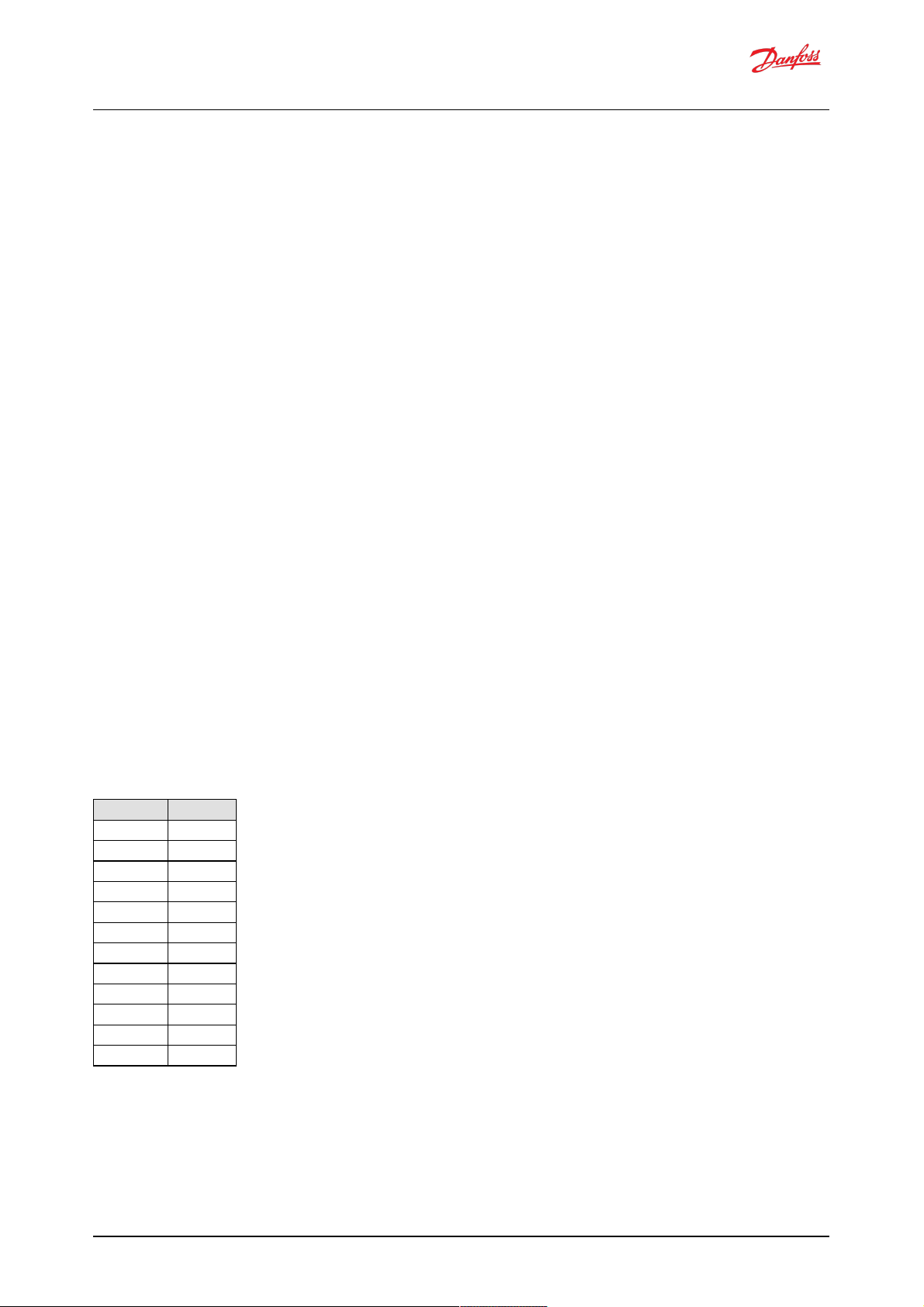

4.2.4 Coil numbers

For fire or p ump actions the user must send a particular coil numb er to set the DPC12 coil output w hich is to

be actuated.

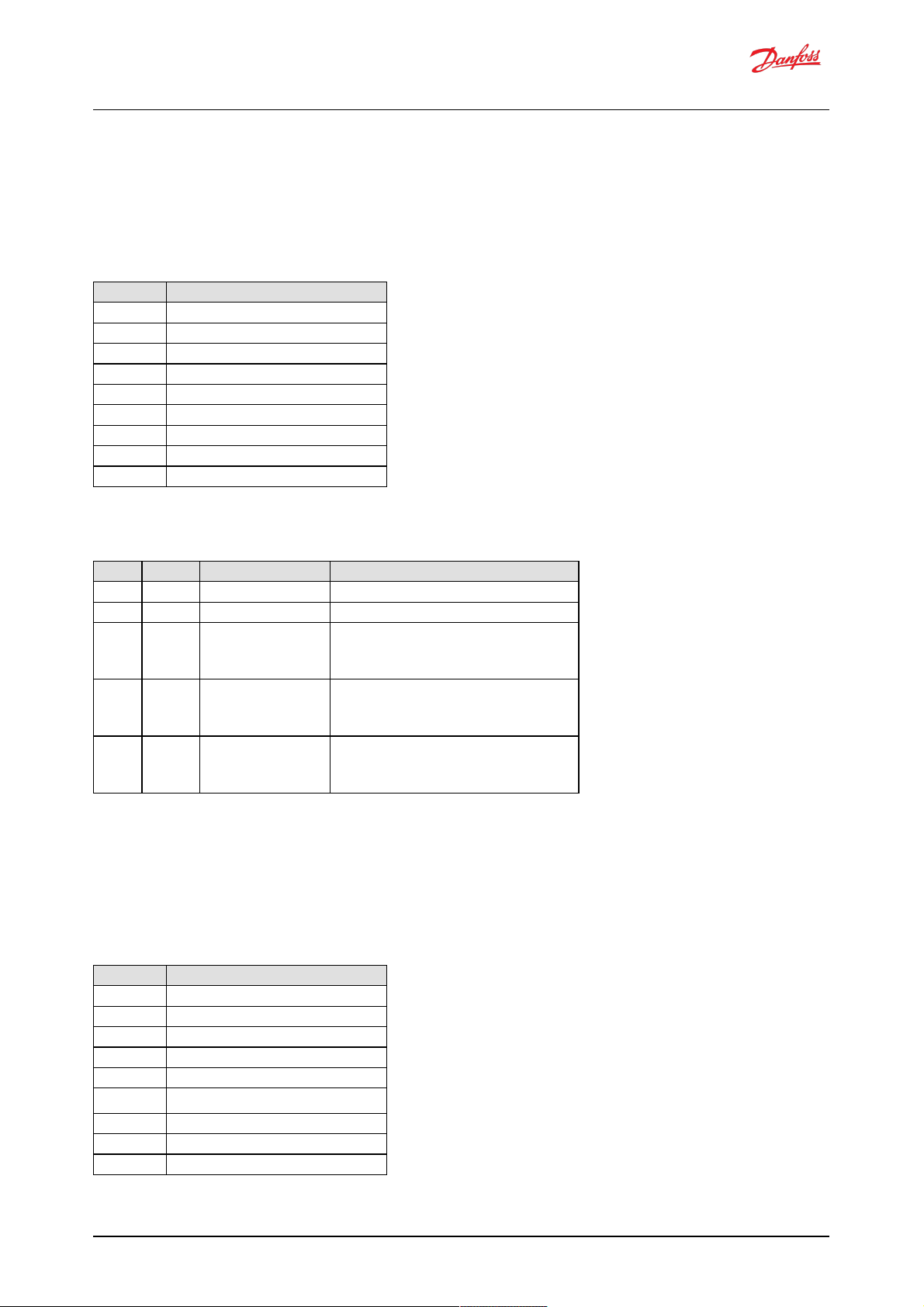

The map ping betw een pumping units and coil numbers is shown in the follow ing table. Please refe r to the

Dig ital Disp lacement® Pump Gen 1 DDP096 and DPC12 Technical Information for the physical locations of the

pump ing units within the DDP096 pump.

Pum ping unit Coil nu mber

A1 0

B1 1

C1 2

A2 3

B2 4

C2 5

A3 6

B3 7

C3 8

A4 9

B4 10

C4 11

Software Manual

Digital Displacement® Pump Software Version 2.7.1

12 | © Danfoss | February 2022 BC404560709540en-000102

Page 13

5 Control configuration

The DDP096 softw are is able to operate each service (hydraulic output) in one of se veral configurations to

provide the required control re sponse . Each service operates independently. The se configurations are

controlled by setting the value of the control mode p arameter and the limit source parameters (see Control

mode parameters and Limits paramete rs sections). The application of these different options is detailed in the

Dig ital Disp lacement® Pump Gen 1 DDP096 and DPC12 Technical Information. Please contact your Danfoss

representative for further help w ith DDP096 control options.

The configuration must be set-up on each controller after delivery. As the DDP096 is a softw are-controlled

prod uct, the same software configuration w ill produce the same control response on all DDP096 and DPC12

hardware in a system w ith the same hyd raulic circuit configuration. For serie s production systems it is

recommended to setup the control config uration for the first product and export the paramete r file using the

PLUS+1® Service Tool. The same parame ters can then be imp orted and dow nloaded to each subsequent

DPC12 controlle r.

5.1 Use cases

Only a sp ecific subset of the available comb inations of control mode, control refe rence source and limit

sourc e parame ters are allow ed in this softw are version. These comb inations have been qualified b y Danfoss to

ensure the ir correct ope ration. Selection of any other combinations will result in an unsupp orted DD

config uration error (SPN 521006, FMI 2). Where the desired comb ination is not included in the list, it is often

possible to use another combination w hich include s enabling an additional limit. In this case the maximum

limit value can be set and the DDP096 p ump will operate as if the limit had be en se t to "unlimite d".

For the control mode parameters, named CONTROL_MODE_Sx (where x is number of the service the p arameter

applies to), the possible values are:

0 - displace ment control

1 - pressure control

2 - load -sense control (LS)

For the refe rence and limit source parameters, named parameter_SRC_Sx (w he re x is number of the service

the parameter applies to), the possible values are:

0 - unlimited

1 - PLUS+1® Service Tool

2 - J1939 CAN message

Further information on these parameters can be found in the Service 1 parameters section.

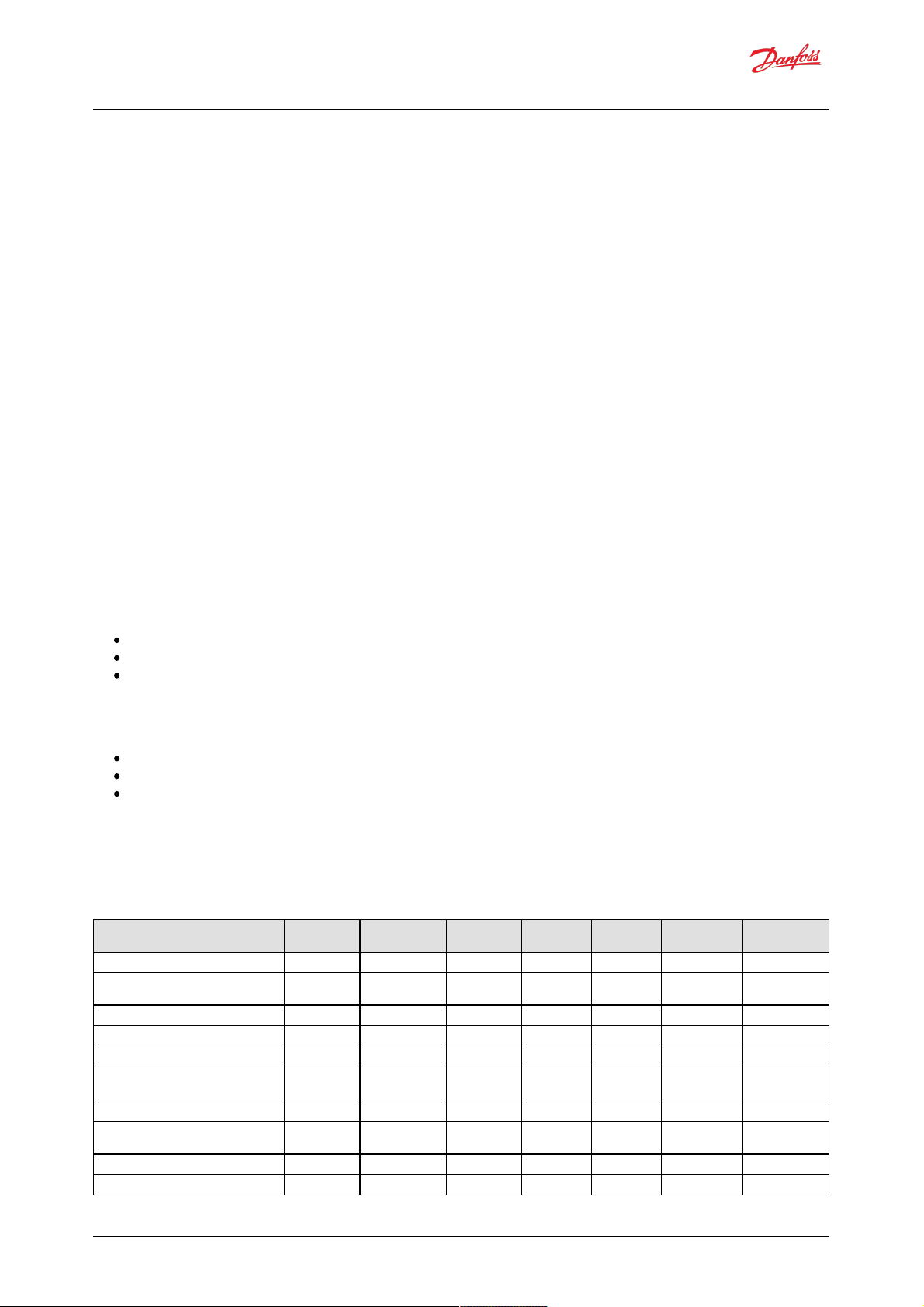

5.1.1 Single-service software

With single-service softw are the following comb inations are available:

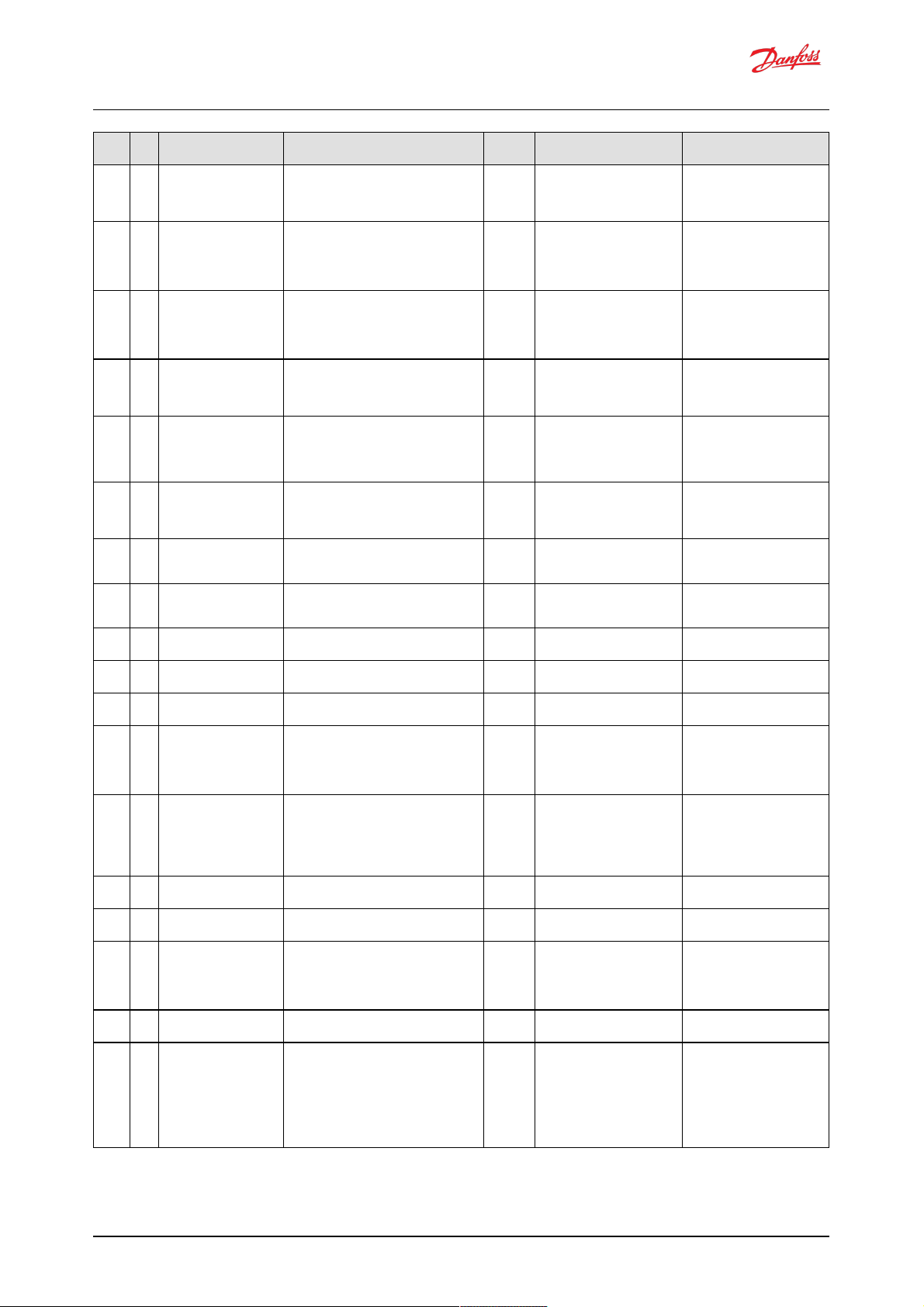

Use case name CONTROL_MODE

_S1

CONTROL_REF_SR

_S1

FLOW_LIM_SRC

_S1

PWR_LIM_SRC

_S1

TRQ_LIM_SRC

_S1

PRESS_LIM_SRC

_S1

PUMPING_ENABLE

_SRC

Displacement control by PLUS+1® 0 1 0 0 0 0 1

Displacement control by PLUS+1® with torque

limit

0 1 0 0 1 1 1

Displacement control by J1939 0 2 0 0 0 1 2

Displacement control by J1939 with torque limit 0 2 0 0 2 1 2

Industrial pressure control by PLUS+1® 1 1 0 1 0 0 1

Industrial pressure control by PLUS+1® with

flow limit

1 1 1 1 0 0 1

Industrial pressure control by J1939 1 2 0 1 0 0 2

Industrial pressure control by J1939 with flow

limit

1 2 2 1 0 0 2

Load sensing pressure control by PLUS+1® 2 1 0 0 0 0 1

Load sensing pressure control by J1939 2 2 0 0 0 0 2

Software Manual

Digital Displacement® Pump Software Version 2.7.1

13 | © Danfoss | February 2022 BC404560709540en-000102

Page 14

Load sensing pressure control by PLUS+1® with

torque limit

2 1 0 0 2 0 2

Load sensing pressure control by J1939 with

torque limit

2 2 0 0 2 0 2

Use case name CONTROL_MODE

_S1

CONTROL_REF_SR

_S1

FLOW_LIM_SRC

_S1

PWR_LIM_SRC

_S1

TRQ_LIM_SRC

_S1

PRESS_LIM_SRC

_S1

PUMPING_ENABLE

_SRC

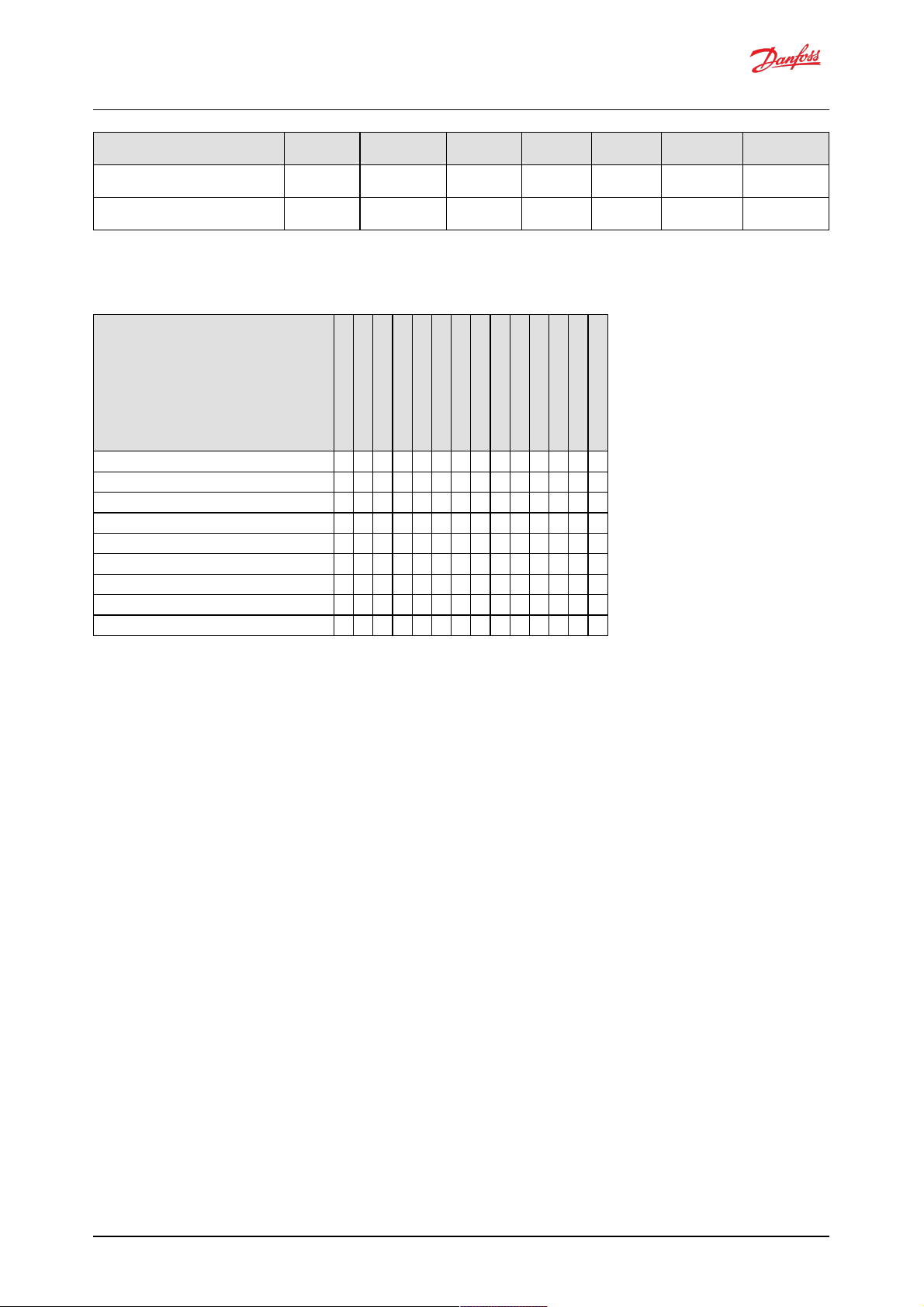

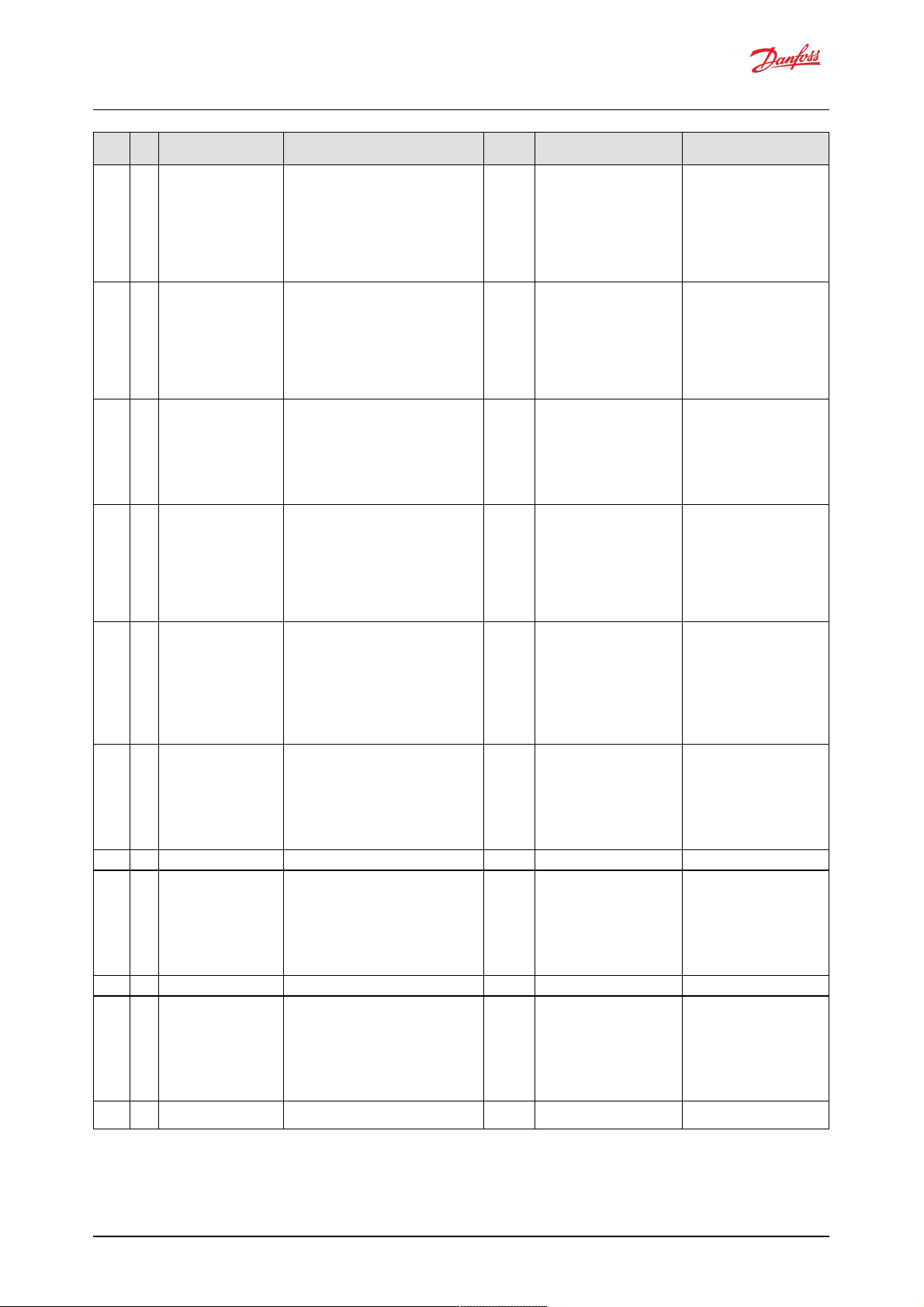

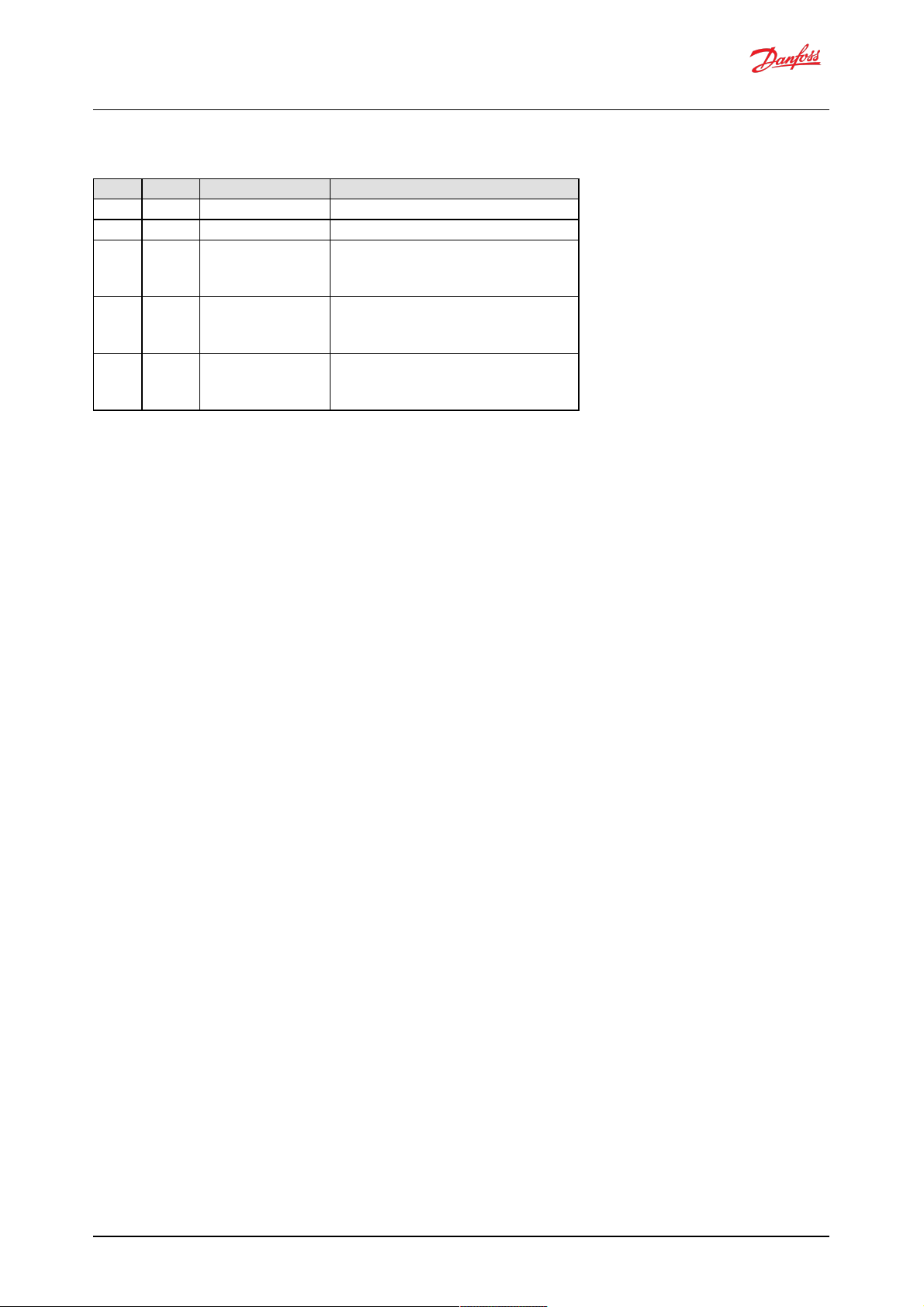

5.1.2 Two-service software

With tw o-service software the following combinations are available:

Use case name

Displacement control by PLUS+1® 0 0 1 1 0 0 0 0 0 0 0 0 1 1

Displacement control by J1939 with torque limit 0 0 2 2 0 0 0 0 2 2 1 1 2 2

Displacement control by PLUS+1® with torque limit 0 0 1 1 0 0 0 0 1 1 1 1 1 1

Industrial pressure control by J1939 with flow limit 1 1 2 2 2 2 0 0 0 0 0 0 1 2

Industrial pressure control by J1939 with flow limit #2 1 1 2 2 2 2 0 0 0 0 0 0 1 1

Industrial pressure control by PLUS+1® with flow limit 1 1 1 1 1 1 0 0 0 0 0 0 1 1

Load-sense pressure control by J1939 with torque limit 2 2 2 2 0 0 0 0 2 2 1 1 2 2

Load-sense pressure control by PLUS+1® with torque limit 2 2 1 1 0 0 0 0 1 1 1 1 1 1

Mixed displacement/LS by J1939 0 2 2 2 0 0 0 0 2 2 1 1 2 2

CO NTRO L_MODE_S1

CO NTRO L_MODE_S2

CO NTRO L_REF_SRC_ S1

CO NTRO L_REF_SRC_ S2

FLO W_LIM_ SRC_S1

FLO W_LIM_ SRC_S2

PW R_LIM_SRC _S1

PW R_LIM_SRC _S2

TR Q_LIM_SRC_S1

TR Q_LIM_SRC_S2

PRESS_L IM_SRC_S1

PRESS_L IM_SRC_S2

PUM PING_ENAB LE_SRC

SERV_ CONF_INDEX_SRC

Software Manual

Digital Displacement® Pump Software Version 2.7.1

14 | © Danfoss | February 2022 BC404560709540en-000102

Page 15

6 Two-service operation

Two-service DDP096 software (file named ML, marked GEN1_AB in Service Tool) is used w ith a DDP096 pump

fitte d with a multi-outlet endcap to allow the single pump and controlle r to provide flow to tw o hydraulic

circuits. The parame ters for both service 1 (marked _S1) and service 2 (marked _S2) must be configure d

suitably for the hyd raulic system or ve hicle.

6.1 Service independence

Each service controlled by the DDP096 software acts as an independe nt flow source.

Any coordination between the tw o services, for instance a whole-pump torque limit, must be calculated b y a

system controller and communicated to the pump as a control reference or limit per service.

6.2 Service switching

Service switching, also known as dynamic g anging, allows the allocation of some of the pumping units of the

pump to be switched from one control service to anothe r unde r the command of a system controller. The

DPC12 controlle r does not control the external valves or other hydraulic equipment needed to connect the

correct outlet ports of the DDP096 pump, this must be considered in the system controller design.

Warning

The physical hydraulic connections of the relevant output ports of the DDP096 pump must match the service

config uration selected. Mismatch could result in unintended flow to a particular service.

The twelve pumping units in the machine are group ed into four indepe nde nt groups, each consisting of three

interconnected pumping units. These groups are know n as "pump lets". An example of how the pumple ts,

pump ing units and outlet ports relate is shown below. Please refer to the Digital Displace ment® Pump Gen 1

DDP096 and DPC12 Technical Information for further information.

Pum plet Pum ping units O utlet port (three- outlet endcap)

1+3 A1, A3, B1, B3, C1, C3 P1

2 A2, B2, C2 P2

4 A4, B4, C4 P4

The service switching feature is controlled by supplying a config uration inde x (SERV_CONF_INDEX) to select

the active combination of pumplets assigned to the service . This index can be set statically in the PLUS+1®

Service Tool or commanded dynamically by a system controller over J1939. The following tab le describes the

pump let-to-service assignment for each available configuration:

Index Service 1 Service 2 No tes

0 1+3 2, 4

1 1+3 4 There is no flow from pumplet 2

2 1+3, 2 4

The service configuration can be change d w hile the pump is in operation. When command ing a service , the

flow, torque and power limit sig nals always re late to the real hydraulic output of the service. The

displace ment re ference is a fraction of the disp lacement available from the pumping units currently assigned

to a service; the available disp lacement may change as the service config uration is changed.

Warning

There will be a change in flow for a given displacement re ference command when the se rvice config uration is

changed under disp lacement control.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

15 | © Danfoss | February 2022 BC404560709540en-000102

Page 16

7 Parameters

The DDP096 is a softw are-driven product and many parame ters are available to configure the softw are to the

user's requirements. These parameters are accessed using the Danfoss PLUS+1® Service Tool. This section

provides a list of all available parame ters w ith a de scription of their e ffect. Default, maximum and minimum

valid value s are also detailed in raw (unscale d) units.

The parameter interface uses integer types, and there fore the corre ct scaling must be applied to interpret

the data for fractional values.

7.1 Communication parameters

The DDP096 softw are on the DPC12 can be configured , controlled and monitore d over its CAN bus connection

using two protocols, the Danfoss PLUS+1® Service Tool interface and the SAE J1939 standard.

These parameters set up the config uration required to communicate with the DPC12 over the se interfaces.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Baud Rate

(R/W)

CAN Bus baud rate. BAUD_RATE 125 1000 250 Valid values: 125,

250, 500, 1000

Node address

(R/W)

Node address of controller.

Recommended address range is 208-223

NODE_ID 0 238 208 Boot node address

(PLUS+1®) = App

Node address

(J1939)

Function and ECU

Instance

(R/W)

Function and ECU instance for J1939 NAME. Bit [2:0] ECU instance value for

NAME (0 to 7). Bit [7:3] Function instance value for NAME (0 to 31).

FUN_ECU_INSTANCE 0 255 0

Ignore Error Passive

Flag

(R/W)

When enabled, the controller will ignore a "CAN error passive flag" error from

the CAN interface. If the controller is used in a system without a CAN bus, this

parameter should be enabled to allow pumping.

IGNORE_EPV_FLAG 0 1 0 0 - disabled, 1 -

enabled

Support DM13 PGN

(R/W)

When enabled, the controller ignores all Warning and Info level errors and the

pump is not allowed to produce flow until the "Start Diagnostic DM13" CAN

message is received. Useful for machine startup and engine cranking when

the power supply voltage may be low.

SUPPORT_DM13_PGN 0 1 1 0 - disabled, 1 -

enabled

Reset Error Counter

Command

(R/W)

Resets error counters to zero.

Each time the command is issued, up to 29 error counters are reset. Issue

command three times to ensure all error counters are reset.

RESET_ERR_CNTR_CMD 0 1 0 0- off, 1- start

7.2 Pump setting parameters

These parameters control hydraulic output features which are common to all of the services of the pump.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

External Load-sense

Sensor Scale Service 1

(R/W)

The scale factor for the external load-sense sensor attached to the controller, if

used.

EXT_LS_SENS_SCALE_S1 625 6250 3750 in 0.01 bar/mA

External Load-sense

Sensor Scale Service 2

(R/W)

The scale factor for the external load-sense sensor attached to the controller, if

used.

EXT_LS_SENS_SCALE_S2 625 6250 3750 in 0.01 bar/mA

Pressure Error Limit

(R/W)

The pressure at which the "Pressure Too High Error" will be triggered. PRESS_ERROR_LIM 50 500 500 in bar

Shaft speed low Limit

(R/W)

Pump shaft speed below which the pump will not produce flow. Shaft speed

below limit error will be active below this speed.

SHAFT_SPD_LOW_LIM 300 3000 300 in rpm

Start Up Ramp Time

(R/W)

The start-up ramp limits the available displacement after reaching the

minimum allowed speed for pumping or enabling the pump for a set time. This

parameter sets the time over which this limit increases from 0% to 100%. The

output displacement set by the current control mode and references will be

restricted to this limit during this time. For further details see the Digital

Displacement® Pump Gen 1 DDP096 and DPC12 Technical Information.

START_UP_RAMP_TIME 0 100 0 in 0.1 seconds. Set to

0 to disable ramp.

Pumping Enable

Source

(R/W)

The source for the pumping enable signal. PUMPING_ENABLE_SRC 1 2 1 1- PLUS+1®, 2- J1939

Pumping Enable

(R/W)

Enables pumping of each service individually. PUMPING_ENABLE 0 255 0 Service 1 by bit 0,

Service 2 by bit 1.

Set other bits to 0.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

16 | © Danfoss | February 2022 BC404560709540en-000102

Page 17

Service Configuration

Index Source

(R/W)

The source for the service configuration selection index. SERV_CONF_INDEX_SRC 1 2 1 1- PLUS+1®, 2- J1939

Service Configuration

Index

(R/W)

Selects the service configuration, assigning particular pumplets to a service,

from the pre-configured options.

SERV_CONF_INDEX 0 2 0 Refer to the Service

switching section for

more details.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

7.3 Pump and controller status parameters

These parameters report status information which relates to the controlle r or entire pump.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Device Mode

(R)

Current mode of controller. DEVICE_MODE 0 2 0 0- Normal, 1- Limp,

2- Commissioning

Device State

(R)

Current state of controller when in Normal Mode. DEVICE_STATE 0 4 0 0 - Initialization, 1 -

Disabled, 2 - Active,

3 - Error, 4 - Error

Hold

Actual Shaft Speed

(R)

Current value of shaft speed read from pump shaft speed/temperature sensor.

Positive direction is clockwise when looking at the end of the input shaft.

ACTL_SHAFT_SPD -3500 3500 0 in rpm

Actual Pump

Temperature

(R)

Current value of pump temperature read from pump shaft speed/temperature

sensor.

ACTL_PUMP_TEMP -40 150 0 in °C

FPGA Revision Main

(R)

Build revision of the firmware running on the main controller's internal FPGA. FPGA_REVISION_MAIN 0 1060

7.4 Service 1 parameters

These parameters control hydraulic output features which are specific to Service 1 of the pump. Se e Control

config uration section for more details.

7.4.1 Control mode parameters

These parameters select the control mode of the pump and the source of the reference for the selected

control mode.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Control Mode Service

1

(R/W)

Sets the mode by which the service outlet flow is controlled. CONTROL_MODE_S1 0 2 0 0- Displacement

control, 1- Pressure

control, 2- Loadsense

Control Reference

Source Service 1

(R/W)

Interface to set the reference input to the selected control mode. CONTROL_REF_SRC_S1 1 2 1 1- PLUS+1®, 2- J1939

7.4.2 Control reference parameters

These parameters represent the refere nce values which are used in the current control mod e.

Only the paramete r for the currently selected control mode is used by the softw are.

The parameter operates differe ntly depe nd ing on the reference source selected. With the source set to

PLUS+1®, the value is set using this parameter. With the source se t to J1939, the value becomes read -only and

shows the last value received by the controller.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Displacement

Reference Service 1

(R/W)

The target displacement the pump should try to produce on this service as a

fraction of the available displacement.

DISP_REF_S1 0 10000 0 in 0.01 %

Pressure Reference

Service 1

(R/W)

The target pressure for the pump to maintain at its outlet when in pressure

control mode.

PRESS_REF_S1 0 420 0 in bar

Software Manual

Digital Displacement® Pump Software Version 2.7.1

17 | © Danfoss | February 2022 BC404560709540en-000102

Page 18

Pressure Margin

Reference Service 1

(R/W)

The target margin pressure for the pump to maintain between its outlet and

the external load-sense pressure sensor when in load-sense control mode.

PRESS_MARGIN_REF_S1 0 100 0 in bar

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

7.4.3 Limits parameters

The limits available are ap plied to the d isplacement de mand from the selecte d control mode. Each limit is

applied such that the output of the service will be restricted to the lowest limit supplied. Each limit can be

supplied by either J1939 or PLUS+1®.

Each limit parameter operates differently depending on the re ference source selected. With the source set to

PLUS+1®, the value is set using the limit parameter. With the source set to J1939, the value becomes read only and the limit parameter shows the last value re ceive d by the controller.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Pressure Limit Source

Service 1

(R/W)

The limit value source for the service pressure limiting feature. PRESS_LIM_SRC_S1 0 1 0 0- Unlimited, 1-

PLUS+1®

Pressure Low Limit

Service 1

(R/W)

The pressure at which the displacement limit for pressure equals 100%. The

displacement limit for pressure decreases linearly between Pressure Low Limit

and Pressure High Limit as pressure increases.

PRESS_LOW_LIM_S1 0 420 0 in bar

Pressure High Limit

Service 1

(R/W)

The pressure at which the displacement limit for pressure equals 0%. The

displacement limit for pressure decreases linearly between Pressure Low Limit

and Pressure High Limit as pressure increases.

PRESS_HIGH_LIM_S1 0 450 0 in bar

Flow Limit Source

Service 1

(R/W)

The limit value source for the service flow limiting feature. FLOW_LIM_SRC_S1 0 2 0 0- Unlimited, 1-

PLUS+1®, 2- J1939

Flow Limit Service 1

(R/W)

The maximum allowed flow in terms of theoretical displacement of the pump,

which does not account for oil compressibility and pump shrinkage. The pump

will adjust the service displacement according to the shaft speed in order to

stay below this limit.

FLOW_LIM_S1 0 300 0 in L/min

Torque Limit Source

Service 1

(R/W)

The limit value source for the service torque limiting feature. TRQ_LIM_SRC_S1 0 2 0 0- Unlimited, 1-

PLUS+1®, 2- J1939

Torque Limit Service 1

(R/W)

The maximum torque allowed to be applied by the service. The pump will

adjust the service displacement according to the outlet pressure in order to stay

below this limit.

TRQ_LIM_S1 0 1500 0 in Nm

Power Limit Source

Service 1

(R/W)

The limit value source for the service power limiting feature. PWR_LIM_SRC_S1 0 2 0 0- Unlimited, 1-

PLUS+1®, 2- J1939

Power Limit Service 1

(R/W)

The maximum power allowed to be consumed by the service. The pump will

adjust the service displacement according to the outlet pressure and shaft

speed in order to stay below this limit.

PWR_LIM_S1 0 500 0 in kW

7.4.4 Control loop gain parameters

These parameters allow the user to tune the pressure control loop proportional-integrator (PI) gains to give

the pump the best pressure response in their particular system. The gains are used in both pressure control

and load -sense control modes.

The read-only parameters in the service status section allow various parts of the PI loop to be inspecte d while

the pump is running.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Pressure Reference

Limit Service 1

(R/W)

Limits maximum value of Actual Reference Pressure, the pressure the pump

tries to maintain on its outlet in pressure control or load-sense control modes.

PRESS_REF_LIM_S1 0 420 0 in bar

Pressure Small Gain

Service 1

(R/W)

The small proportional gain in the pressure control loop. PRESS_SMALL_GAIN_S1 0 10000 0 in 0.001 %/bar

Pressure Small Gain

Threshold Service 1

(R/W)

The minimum pressure error needed for the small gain to take effect. PRESS_SMALL_GAIN_THR

ESH_S1

0 600 0 in bar

Software Manual

Digital Displacement® Pump Software Version 2.7.1

18 | © Danfoss | February 2022 BC404560709540en-000102

Page 19

Pressure Gain Big Gain

Service 1

(R/W)

The big proportional gain in the pressure control loop. PRESS_BIG_GAIN_S1 0 50000 0 in 0.001 %/bar

Pressure Big Gain

Threshold Service 1

(R/W)

The minimum pressure error needed for the big gain to take effect. PRESS_BIG_GAIN_THRES

H_S1

0 600 600 in bar

Pressure Integration

Time Service 1

(R/W)

The integration time for the integrator in the pressure control loop. PRESS_INTEG_TIME_S1 0 10000 0 in ms

Pressure Integration

Max Disp Service 1

(R/W)

The maximum displacement of the integrator in the pressure control loop. PRESS_INTEG_MAX_DISP

_S1

0 10000 10000 in 0.01 %

Pressure Integration

Min Disp Service 1

(R/W)

The minimum displacement of the integrator in the pressure control loop. PRESS_INTEG_MIN_DISP

_S1

-10000 0 0 in 0.01 %

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

7.4.5 Service status parameters

These parameters report the current values produced by the software's control loop and the hyd raulic outp ut

of the service .

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Actual Displacement

Service 1

(R)

Current value of displacement after all limits have been applied. ACTL_DISP_S1 0 10000 0 in 0.01%

Actual Pressure

Reference Service 1

(R)

Current value of pressure used for the pressure control loop after pressure

margin reference (load-sense control only) and pressure reference limit are

applied.

ACTL_PRESS_REF_S1 0 600 0 in bar

Actual Pressure

Service 1

(R)

The current pressure read from the outlet pressure sensor. ACTL_PRESS_S1 0 600 0 in bar

Actual Pressure

Margin Reference

Service 1

(R)

Current value of margin pressure setpoint for used in the control loop. ACTL_PRESS_MARGIN_RE

F_S1

0 100 0 in bar

Actual Load Sensing

Pressure Service 1

(R)

The current pressure read from the external load sense pressure sensor in loadsense control mode.

ACTL_LS_PRESS_S1 0 1000 0 in bar

Actual Small Gain

Displacement Service

1

(R)

Current value of displacement commanded by the small gain portion of the

pressure control loop.

ACTL_SMALL_GAIN_DISP

_S1

-1091090 in 0.01%

Actual Big Gain

Displacement Service

1

(R)

Current value of displacement commanded by the big gain portion of the

pressure control loop.

ACTL_BIG_GAIN_DISP_S1-1091090 in 0.01%

Actual Integrator

Displacement Service

1

(R)

Current value of displacement commanded by the integrator portion of the

pressure control loop.

ACTL_INTEG_DISP_S1 -10000 10000 0 in 0.01%

Actual Pressure

Control Loop

Displacement Service

1

(R)

Current value of displacement commanded by the pressure control loop before

limiting.

ACTL_PRESS_CTRL_LOOP

_DISP_S1

0 10000 0 in 0.01%

7.5 Service 2 parameters

The Service 2 parameters are used to control Service 2 in two-service software. The function of each is the

same as the correspond ing Se rvice 1 parameter — refe r to the Service 1 parameters section further

descriptions. When using singe-service softw are the Service 2 parameters have no effect and may be

remove d from single-service software in a future release.

Software Manual

Digital Displacement® Pump Software Version 2.7.1

19 | © Danfoss | February 2022 BC404560709540en-000102

Page 20

7.5.1 Control mode parameters

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Control Mode Service

2

(R/W)

Sets the mode by which the service outlet flow is controlled. CONTROL_MODE_S2 0 2 0 0- Displacement

control, 1- Pressure

control, 2- Loadsense

Control Reference

Source Service 2

(R/W)

Interface to set the reference input to the selected control mode. CONTROL_REF_SRC_S2 1 2 1 1- PLUS+1®, 2- J1939

7.5.2 Control reference parameters

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Displacement

Reference Service 2

(R/W)

The target displacement the pump should try to produce on this service as a

fraction of the available displacement.

DISP_REF_S2 0 10000 0 in 0.01 %

Pressure Reference

Service 2

(R/W)

The target pressure for the pump to maintain at its outlet when in pressure

control mode.

PRESS_REF_S2 0 420 0 in bar

Pressure Margin

Reference Service 2

(R/W)

The target margin pressure for the pump to maintain between its outlet and

the external load-sense pressure sensor when in load-sense control mode.

PRESS_MARGIN_REF_S2 0 100 0 in bar

7.5.3 Limits parameters

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Pressure Limit Source

Service 2

(R/W)

The limit value source for the service pressure limiting feature. PRESS_LIM_SRC_S2 0 1 0 0- Unlimited, 1-

PLUS+1®

Pressure Low Limit

Service 2

(R/W)

The pressure at which the displacement limit for pressure equals 100%. The

displacement limit for pressure decreases linearly between Pressure Low Limit

and Pressure High Limit as pressure increases.

PRESS_LOW_LIM_S2 0 420 0 in bar

Pressure High Limit

Service 2

(R/W)

The pressure at which the displacement limit for pressure equals 0%. The

displacement limit for pressure decreases linearly between Pressure Low Limit

and Pressure High Limit as pressure increases.

PRESS_HIGH_LIM_S2 0 450 0 in bar

Flow Limit Source

Service 2

(R/W)

The limit value source for the service flow limiting feature. FLOW_LIM_SRC_S2 0 2 0 0- Unlimited, 1-

PLUS+1®, 2- J1939

Flow Limit Service 2

(R/W)

The maximum allowed flow in terms of theoretical displacement of the pump,

which does not account for oil compressibility and pump shrinkage. The pump

will adjust the service displacement according to the shaft speed in order to

stay below this limit.

FLOW_LIM_S2 0 300 0 in L/min

Torque Limit Source

Service 2

(R/W)

The limit value source for the service torque limiting feature. TRQ_LIM_SRC_S2 0 2 0 0- Unlimited, 1-

PLUS+1®, 2- J1939

Torque Limit Service 2

(R/W)

The maximum torque allowed to be applied by the service. The pump will

adjust the service displacement according to the outlet pressure in order to stay

below this limit.

TRQ_LIM_S2 0 1500 0 in Nm

Power Limit Source

Service 2

(R/W)

The limit value source for the service power limiting feature. PWR_LIM_SRC_S2 0 2 0 0- Unlimited, 1-

PLUS+1®, 2- J1939

Power Limit Service 2

(R/W)

The maximum power allowed to be consumed by the service. The pump will

adjust the service displacement according to the outlet pressure and shaft

speed in order to stay below this limit.

PWR_LIM_S2 0 500 0 in kW

7.5.4 Control loop gain parameters

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Pressure Reference

Limit Service 2

(R/W)

Limits maximum value of Actual Reference Pressure, the pressure the pump

tries to maintain on its outlet in pressure control or load-sense control modes.

PRESS_REF_LIM_S2 0 420 0 in bar

Pressure Small Gain

Service 2

(R/W)

The small proportional gain in the pressure control loop. PRESS_SMALL_GAIN_S2 0 10000 0 in 0.001 %/bar

Software Manual

Digital Displacement® Pump Software Version 2.7.1

20 | © Danfoss | February 2022 BC404560709540en-000102

Page 21

Pressure Small Gain

Threshold Service 2

(R/W)

The minimum pressure error needed for the small gain to take effect. PRESS_SMALL_GAIN_THR

ESH_S2

0 600 0 in bar

Pressure Gain Big Gain

Service 2

(R/W)

The big proportional gain in the pressure control loop. PRESS_BIG_GAIN_S2 0 50000 0 in 0.001 %/bar

Pressure Big Gain

Threshold Service 2

(R/W)

The minimum pressure error needed for the big gain to take effect. PRESS_BIG_GAIN_THRES

H_S2

0 600 600 in bar

Pressure Integration

Time Service 2

(R/W)

The integration time for the integrator in the pressure control loop. PRESS_INTEG_TIME_S2 0 10000 0 in ms

Pressure Integration

Max Disp Service 2

(R/W)

The maximum displacement of the integrator in the pressure control loop. PRESS_INTEG_MAX_DISP

_S2

0 10000 10000 in 0.01 %

Pressure Integration

Min Disp Service 2

(R/W)

The minimum displacement of the integrator in the pressure control loop. PRESS_INTEG_MIN_DISP

_S2

-10000 0 0 in 0.01 %

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

7.5.5 Service status parameters

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Actual Displacement

Service 2

(R)

Current value of displacement after all limits have been applied. ACTL_DISP_S2 0 10000 0 in 0.01%

Actual Pressure

Reference Service 2

(R)

Current value of pressure used for the pressure control loop after pressure

margin reference (load-sense control only) and pressure reference limit are

applied.

ACTL_PRESS_REF_S2 0 600 0 in bar

Actual Pressure

Service 2

(R)

The current pressure read from the outlet pressure sensor. ACTL_PRESS_S2 0 600 0 in bar

Actual Pressure

Margin Reference

Service 2

(R)

Current value of margin pressure setpoint for used in the control loop. ACTL_PRESS_MARGIN_RE

F_S2

0 100 0 in bar

Actual Load Sensing

Pressure Service 2

(R)

The current pressure read from the external load sense pressure sensor in loadsense control mode.

ACTL_LS_PRESS_S2 0 1000 0 in bar

Actual Small Gain

Displacement Service

2

(R)

Current value of displacement commanded by the small gain portion of the

pressure control loop.

ACTL_SMALL_GAIN_DISP

_S2

-1091090 in 0.01%

Actual Big Gain

Displacement Service

2

(R)

Current value of displacement commanded by the big gain portion of the

pressure control loop.

ACTL_BIG_GAIN_DISP_S2-1091090 in 0.01%

Actual Integrator

Displacement Service

2

(R)

Current value of displacement commanded by the integrator portion of the

pressure control loop.

ACTL_INTEG_DISP_S2 -10000 10000 0 in 0.01%

Actual Pressure

Control Loop

Displacement Service

2

(R)

Current value of displacement commanded by the pressure control loop before

limiting.

ACTL_PRESS_CTRL_LOOP

_DISP_S2

0 10000 0 in 0.01%

7.6 Other parameters

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Suppress Power

Supply below limit

error when Shaft

speed below low limit

(R/W)

When enabled, the Power Supply Below Limit error will not be triggered when

the shaft speed is below its low limit. Useful during engine cranking when the

power supply voltage may be low and Support DM13 PGN is disabled.

SUPPRESS_PWR_SUPPLY_

ERR_BLW_LOW_SPD

0 1 0 0 - disabled, 1 -

enabled

Shaft Max Smoothing

Count

(R/W)

Used to interpret the speed sensor signal. Danfoss recommends using the

default value. If tuning is required, contact Danfoss.

SHAFT_SPD_SMTH_COUNT 0 100 13 Number of shaft

sensor edges

Software Manual

Digital Displacement® Pump Software Version 2.7.1

21 | © Danfoss | February 2022 BC404560709540en-000102

Page 22

Shaft Max Smoothing

Period

(R/W)

Used to interpret the speed sensor signal. Danfoss recommends using the

default value. If tuning is required, contact Danfoss.

SHAFT_SPD_SMTH_PERIOD0 32767 32767 x 0.02 ms

Shaft Max Smoothing

Angle

(R/W)

Used to interpret the speed sensor signal. Danfoss recommends using the

default value. If tuning is required, contact Danfoss.

SHAFT_SPD_SMTH_ANGLE 0 7200 7200 x 0.1 degrees

Enable Manual

Solenoid Test

(R/W)

Causes the DPC12 to perform a user-initiated test on the electrical

characteristics of the low pressure valve solenoids to determine if they are

present and to detect wiring faults.

EN_MANUAL_SOLENOID_F

AULT_TEST

0 1 0 0 - disabled, 1 -

manual trigger

Enable Startup

Solenoid Test

(R/W)

Sets the controller to automatically perform a test at startup on the electrical

characteristics of the low pressure valve solenoids to determine if they are

present and to detect wiring faults. In order to protect the output electronics,

this diagnostic test runs before any solenoids are used normally.

EN_STARTUP_SOLENOID_

FAULT_TEST

0 1 1 0 - disabled, 1 -

enabled at startup

Solenoid Test

Execution Counter

(R)

Number of solenoid fault tests carried out. SOLENOID_FAULT_TEST_

CNTR

0 255 0 Number of tests

Valve Adaptation

Algorithm Maximum

Broken Valves Limit

Service 1

(R/W)

Maximum number of broken valves assigned to Service 1 to maintain

operation with valve adaptation algorithm. If more valves are broken, the

"Valve adaptation algorithm failed - too many valves broken" error is triggered.

VALVE_ADPT_ALG_MAX_B

RKN_VALVS_LIM_S1

0 11 0 Number of broken

valves

Valve Adaptation

Algorithm Maximum

Broken Valves Limit

Service 2

(R/W)

Maximum number of broken valves assigned to Service 2 to maintain

operation with valve adaptation algorithm. If more valves are broken, the

"Valve adaptation algorithm failed - too many valves broken" error is triggered.

VALVE_ADPT_ALG_MAX_B

RKN_VALVS_LIM_S2

0 11 0 Number of broken

valves

Limp Mode Number

of Required Valves

Service 1

(R/W)

The number of cylinders which should be enabled for the service when Limp

Home Mode is active.

LIMP_MODE_NUM_REQ_VA

LVES_S1

1 3 1 Limp Home Mode is

not included in this

release

Limp Mode Number

of Required Valves

Service 2

(R/W)

The number of cylinders which should be enabled for the service when Limp

Home Mode is active.

LIMP_MODE_NUM_REQ_VA

LVES_S2

1 3 1 Limp Home Mode is

not included in this

release

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

7.7 Commissioning mode parameters

The parameters are used during Commissioning mode.

Name

(r ead, write)

Descrip tion Service T ool Param eter

Name

Limit

Min

Limit

Max

Default

Valu e

Notes

Enable

Commissioning

(R/W)

To enter Commissioning Mode, set to "enabled", then power cycle the

controller. To exit, set to "disabled", then power cycle the controller.

EN_COMMISS 0 1 0 0 - disabled, 1 -

enabled

Commissioning Action

Type

(R/W)

Chooses between different Commissioning Mode actions. Fire: actuates the

specified coil as soon as possible. Pump: actuates the specified coil at the correct

shaft position to enable the cylinder to pump a full stroke. Raw Displacement:

actuates coils as necessary to achieve the desired percentage of displacement.

COMMISS_ACT_TYPE 0 5 0 0- off, 1- fire, 2-

pump 1x, 3- pump

100x, 4- raw

displacement

Service 1, 5- raw

displacement

Service 2

Commissioning Value

(R/W)

Specifies the coil or raw displacement for the corresponding Commissioning

Action Type.

COMMISS_VALUE 0 10000 0 coil number OR raw

displacement value

Commissioning

Command

(R/W)

For Fire and Pump actions, transition from 0 to 1 starts the action. Must be reset

to 0 before starting action again. For Raw Displacement action, pump will

produce desired displacement while set to 1 and stop pumping when set to 0.

COMMISS_CMD 0 1 0 0- off, 1- start

Commissioning Level

(R)

Indicates what level of commissioning operation can be done on the pump

due to severity of active errors.

COMMISS_LEVEL 0 2 0 0 - disabled, 1 -

firing, 2 - pumping

Commissioning Status

(R)

Indicates if an action is off, running, or denied. COMMISS_STATUS 0 2 0 0- off, 1- running, 2-

denied

Software Manual

Digital Displacement® Pump Software Version 2.7.1

22 | © Danfoss | February 2022 BC404560709540en-000102

Page 23

8 Errors

The DDP096 softw are contains an error-handling system w hich is d esigned to protect the pump and system

from undesirable be havior when there is an error de tected w ith the software, communications, DPC12

hardware, sensors or DDP096 pump.

The e rror handling system consists of a number of errors (see Error list section) each of which has a severity

which governs the error handler's response when the error is detecte d. The effect of each severity is:

Info: no effect on operation.

Warning: normal operation stopped. error ig nored in disable d state (when SUPPORT_DM13_PGN

parame ter is enabled).

Critical: normal operation stoppe d.

Severe: normal operation stoppe d. Fault state cannot be reset by DM 11 message.

Two me chanisms e xist to return the controlle r to an active state following a fault - the J1939 DM11 message

(see DM 11 PGN - diagnostics data clear of active DTCs section) or power-cycling the DPC12 controller.

Active and previously active errors can be read over CAN bus using standard J1939 me chanisms (see DM1

PGN - active diagnostic trouble codes and DM 2 PGN - previously active diagnostics trouble codes sections) or

by using the PLUS+1® Se rvice Tool to read the associated parameters. The PLUS+1® Service Tool can also

display counters for the numbe r of times each error has occurred since the last error counter reset (via the

DM3 messag e, se e DM3 PGN - diagnostics d ata clear of p reviously active DTCs section, or

RESET_ERR_CNTR_CMD paramete r).

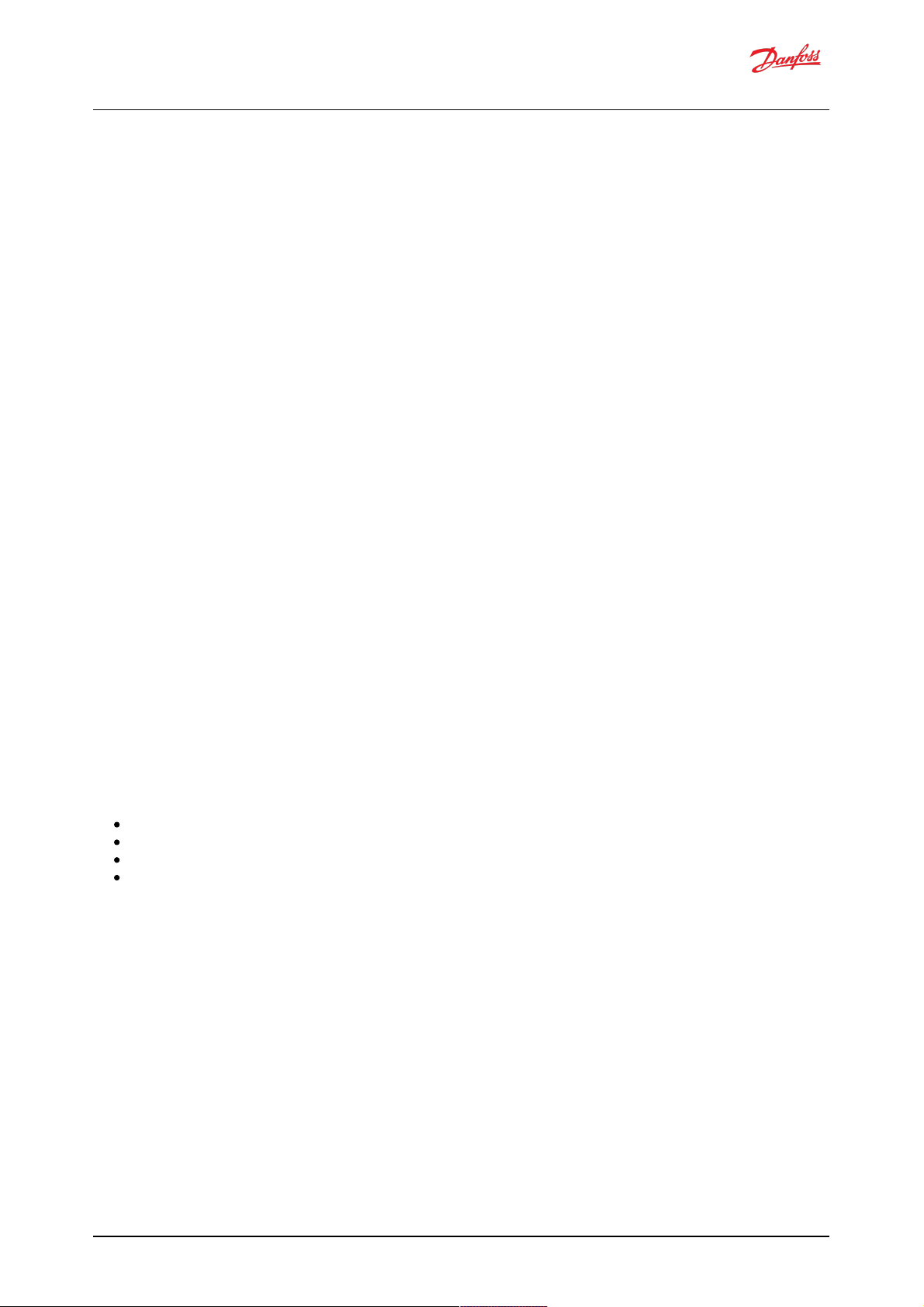

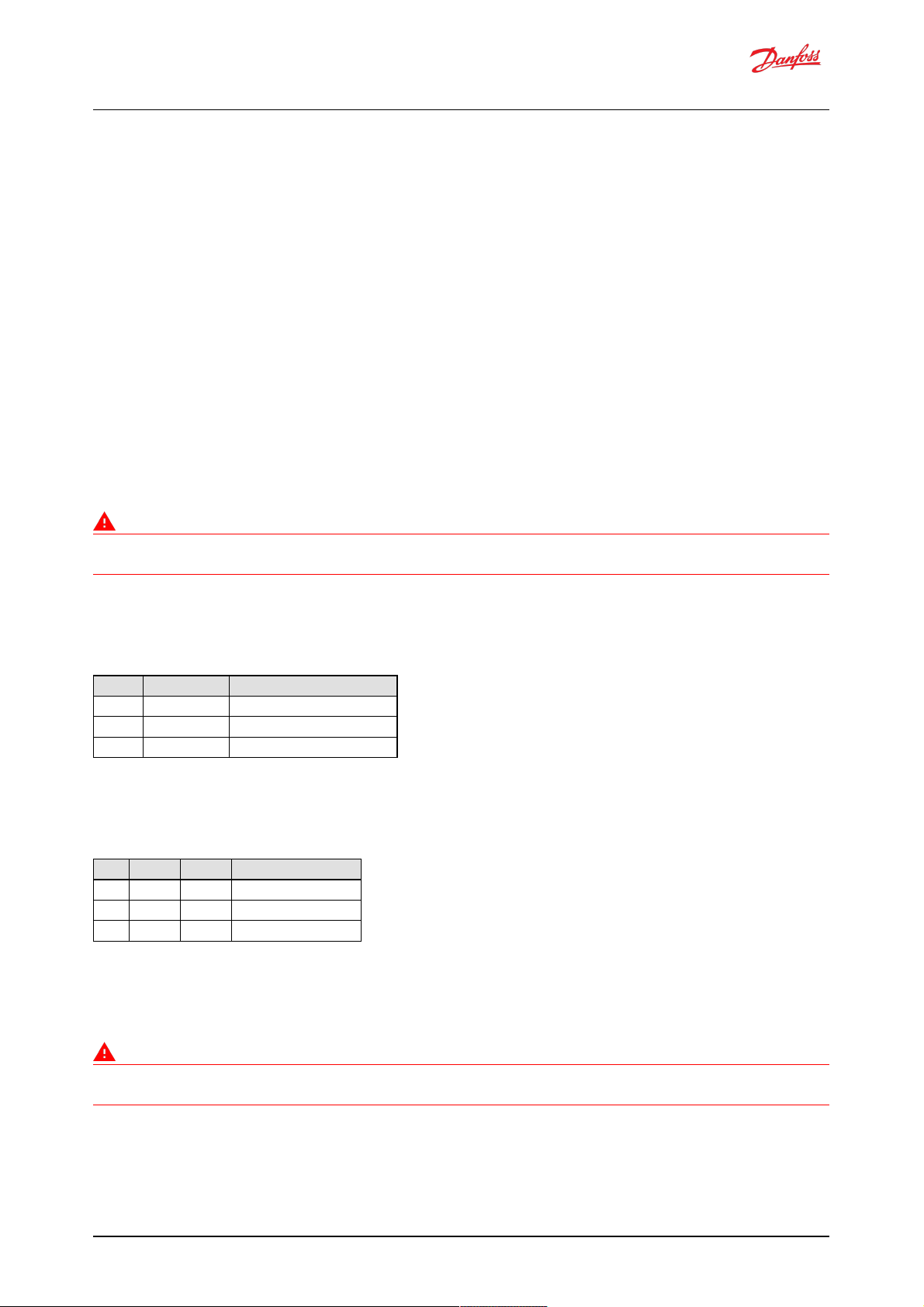

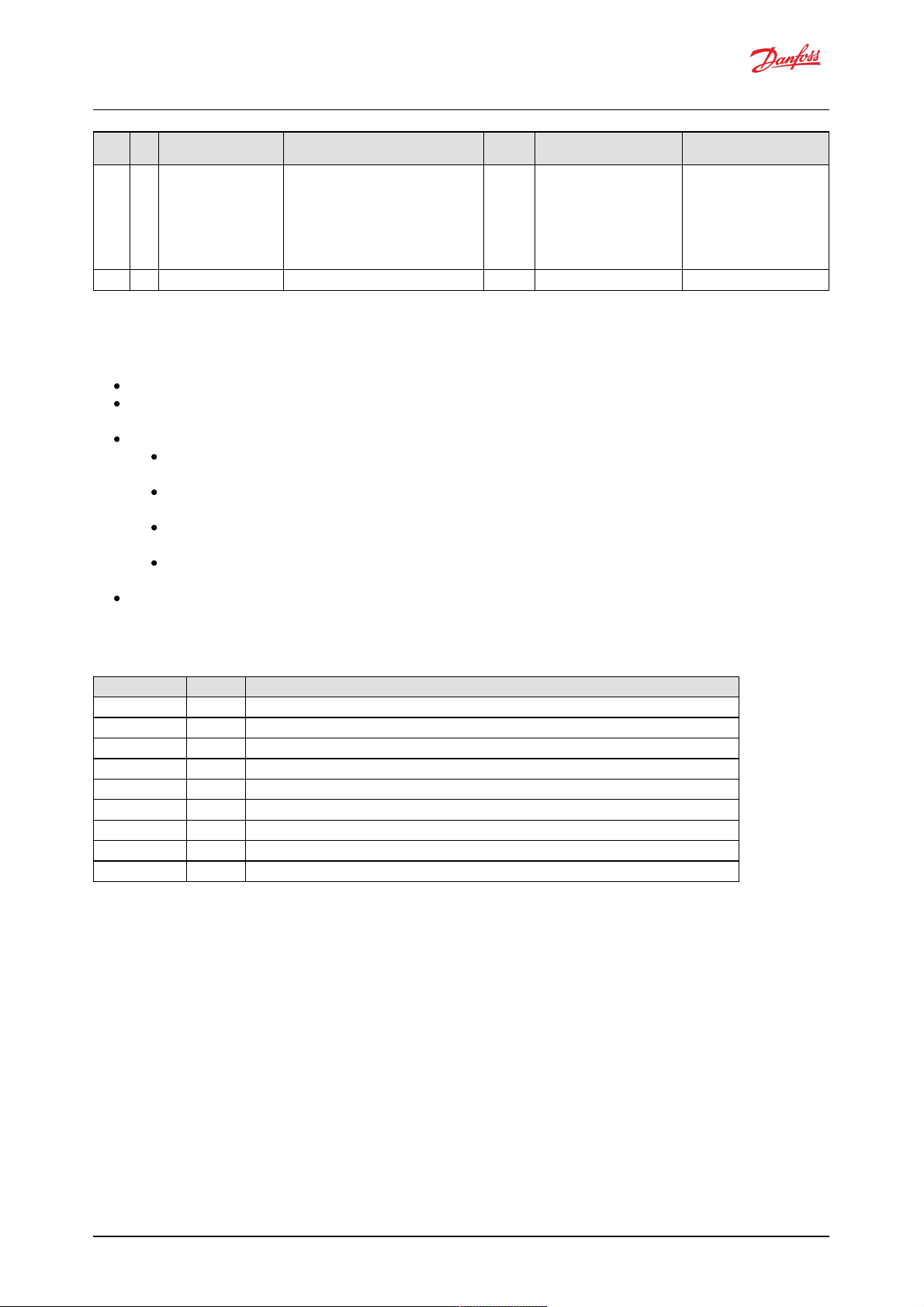

8.1 Error handler states

The e rror handler component op erates as a state machine for the w hole DDP096 software. The states are

explained in the table below.

State DEVICE_STATE code Descriptio n

Initialization 0 Start-up state

Disabled 1 Software is held in this state until reception of DM13 message if SUPPORT_DM13_PGN parameter is enabled.

Active 2 Normal operation

Fault 3 There is an active fault of severity warning, critical or severe, or there was previously a severe fault. Pump does not operate.

Fault hold 4 All previous faults non-severe faults have been cleared, but software remains inactive until reception of DM11 message.

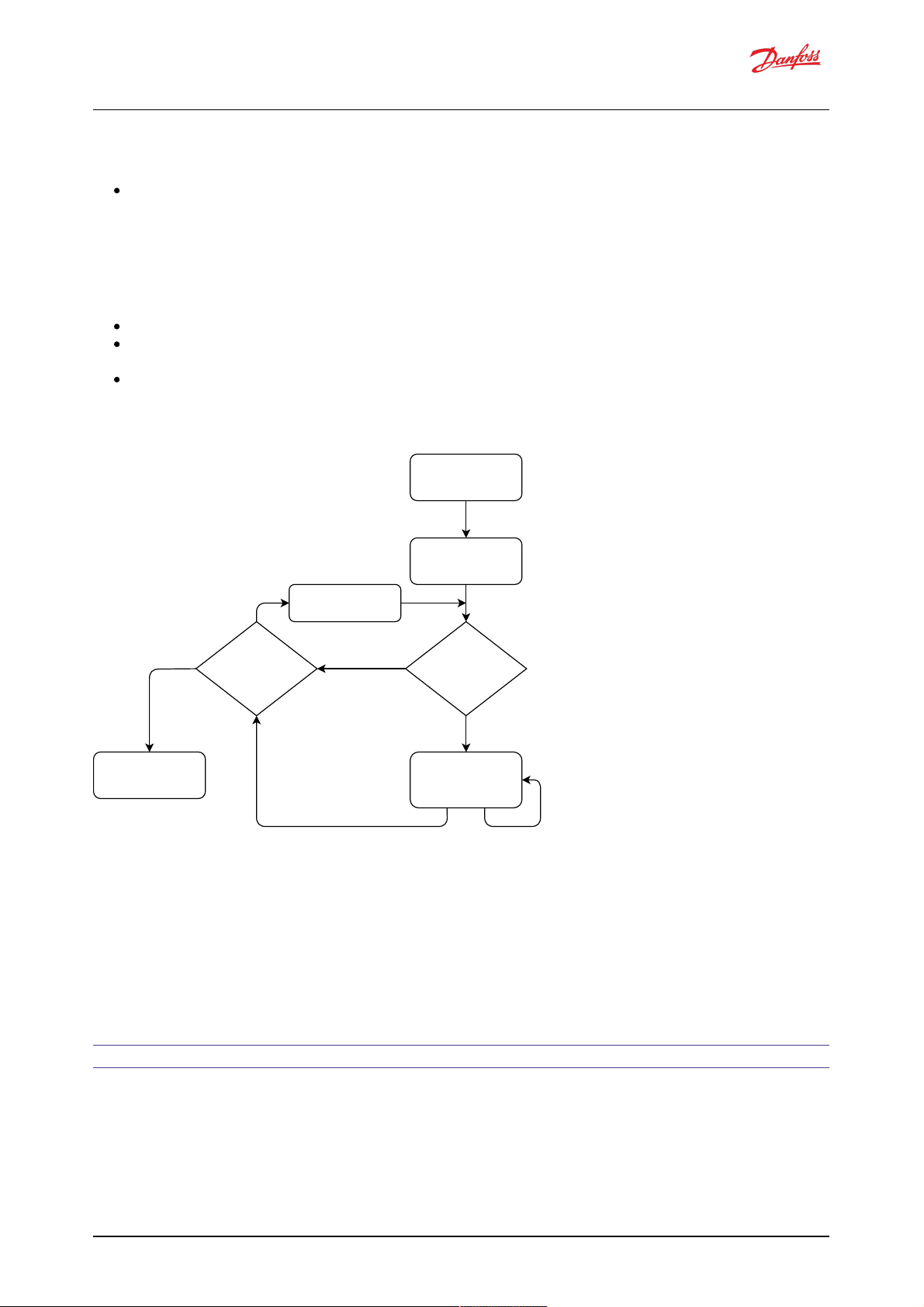

The transitions be tween states are show n in the flowchart below .

Software Manual

Digital Displacement® Pump Software Version 2.7.1

23 | © Danfoss | February 2022 BC404560709540en-000102

Page 24

Initialization

Disabled Fault hold

Active Fault

1 =

enabled

0 = disabled

SUPPORT_

DM13_PGN

Yes

No

DM13

received since

startup? Yes

No

Was there a

severe error?

Yes

No

Are all

non-info errors

cleared?

No

Yes

Critical

or severe errors

active

Yes

No

Non-info

error active

Yes

No

DM11

received

No

Yes

Non-info

error active

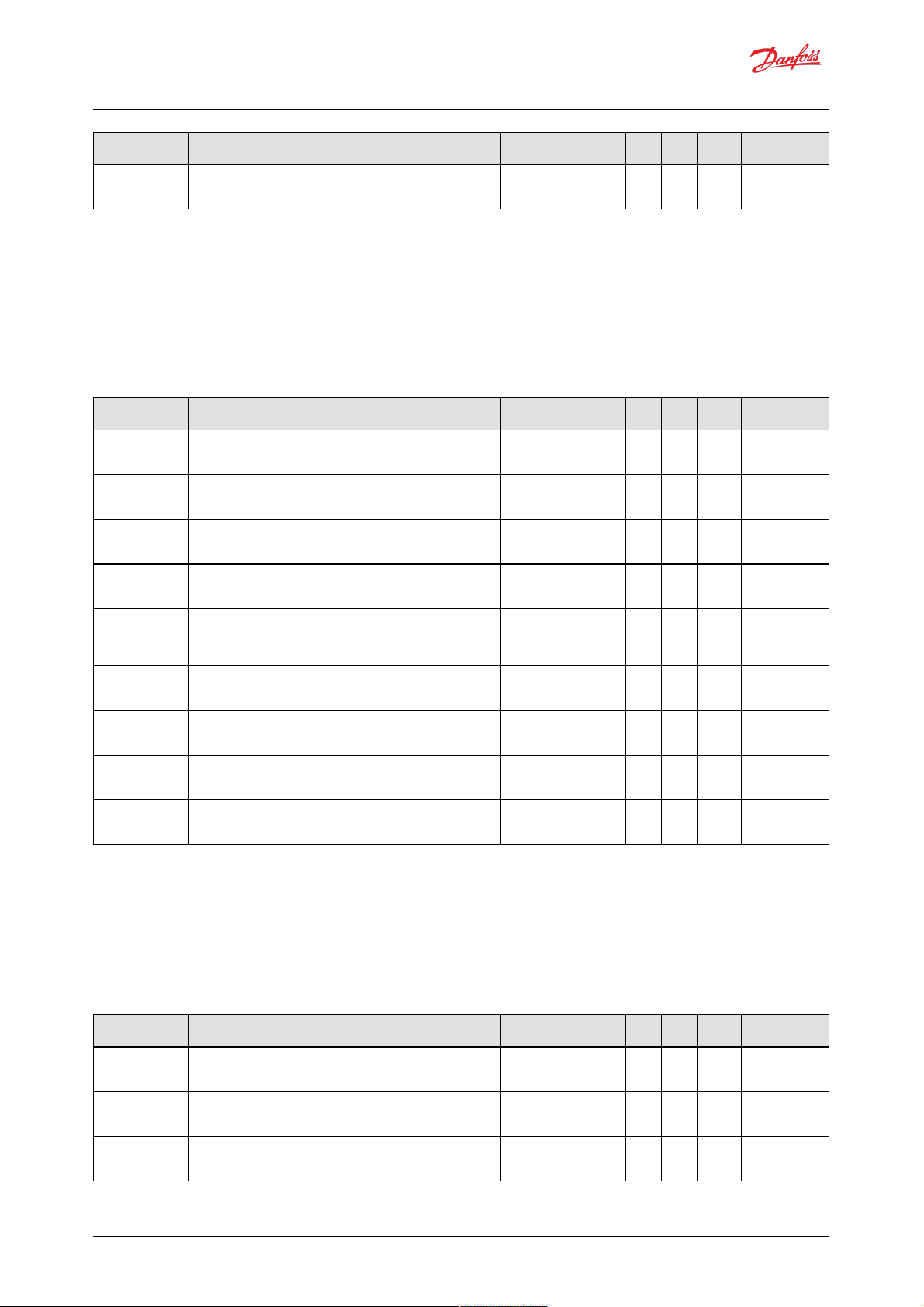

8.2 Error list

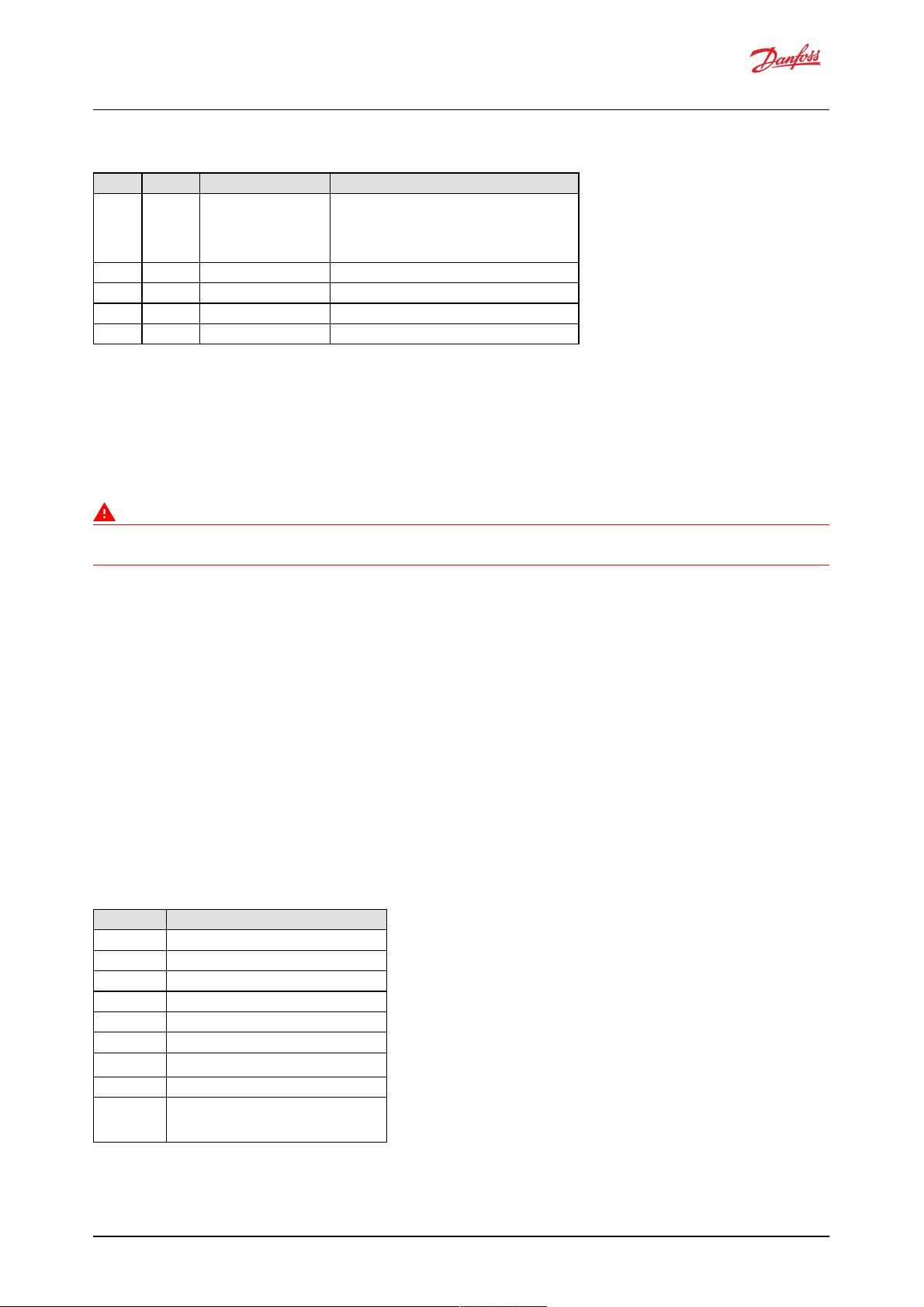

SPN FMI Name Des criptio n Severity Ser vice Tool nam e for active

err or

Service T ool name for erro r

coun ter

168 3 Power supply above limit Power supply voltage greater than 36V. WARNING ERR_AE_168_03_LM_SPLYVIN ERR_OC_168_03_LM_SPLYVIN

168 4 Power supply below limit Power supply voltage less than 9V. WARNING ERR_AE_168_04_LM_SPLYVIN ERR_OC_168_04_LM_SPLYVIN

441 16 Controller temperature above

limit

Internal controller temperature above limit. CRITICAL ERR_AE_441_16_LM_CTEMP ERR_OC_441_16_LM_CTEMP

441 17 Controller temperature below

limit

Controller temperature below -40°C. Pumping will

not be affected.

INFO ERR_AE_441_17_LM_CTEMP ERR_OC_441_17_LM_CTEMP

442 16 Pump temperature above

limit

Pump temperature above 90°C. CRITICAL ERR_AE_442_16_LM_PTEMP ERR_OC_442_16_LM_PTEMP

442 17 Pump temperature below limit Pump temperature below -20°C. Pumping will not

be affected. Error will clear once temperature rises

above limit.

INFO ERR_AE_442_17_LM_PTEMP ERR_OC_442_17_LM_PTEMP

2848 31 J1939 Name conflict The configured J1939 Name of the DPC12

controller conflicted with another device on the

CAN bus during the address claim procedure.

The controller will not comminucate over J1939.

Ensure all DPC12 controllers on the bus have their

FUN_ECU_INSTANCE parameters set to a

unique value.

SEVERE ERR_AE_2848_31_CA_NAME_CLM ERR_OC_2848_31_CA_NAME_CLM

3599 2 Internal 24V out of range Internal 24V power supply is out of range. Check

that coil power supply pins are powered with the

correct voltage. If error persists, contact Danfoss for

help.

SEVERE ERR_AE_3599_02_LM_OUT24V ERR_OC_3599_02_LM_OUT24V

8621 2 EEPROM CRC fault Parameter data in non-volatile memory is

corrupted and pump cannot operate. Connect

with PLUS+1® Service Tool and reset values in

controller.

SEVERE ERR_AE_8621_02_COM_ROMCRC ERR_OC_8621_02_COM_ROMCRC

8621 11 EEPROM SPI fault A communication error has occurred when

accessing non-volatile memory. No action is

required.

INFO ERR_AE_8621_11_COM_ROMSPI ERR_OC_8621_11_COM_ROMSPI

8621 31 EEPROM occurrence counter

CRC fault

Error occurrence counter data in non-volatile

memory is corrupted. Counters will be reset to

zero.

WARNING ERR_AE_8621_31_COM_ROMCRC_OCERR_OC_8621_31_COM_ROMCRC_

OC

Software Manual

Digital Displacement® Pump Software Version 2.7.1

24 | © Danfoss | February 2022 BC404560709540en-000102

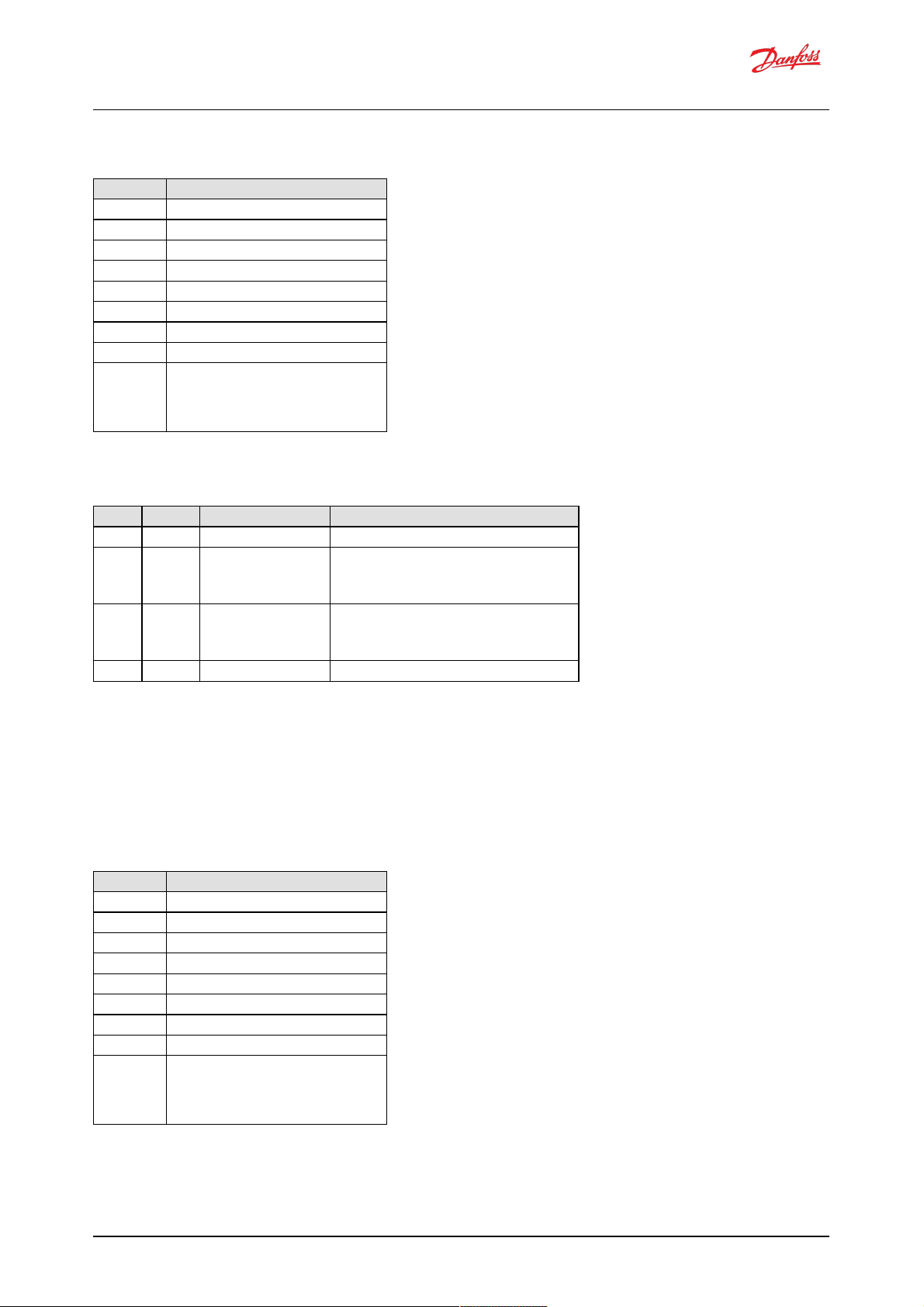

Page 25

520960 0 Service 1 outlet pressure too

high

Outlet pump pressure above pressure limit, as set

by PRESS_ERROR_LIM parameter.

SEVERE ERR_AE_520960_00_SENSOR_OUTP

RESS_S1

ERR_OC_520960_00_SENSOR_OUT

PRESS_S1

520960 2 Service 1 outlet pressure

sensor incorrect

Analogue outlet pressure sensor signal is erratic or

unstable. Check that sensor and connectors are

properly secured and for damage to sensor wires

or sensor. Repair as necessary. If no damage exists

and error persists, or to obtain replacement parts,

contact Danfoss for help.

SEVERE ERR_AE_520960_02_SENSOR_OUTP

RESS_S1

ERR_OC_520960_02_SENSOR_OUT

PRESS_S1

520960 16 Service 1 outlet pressure

reading above maximu m

Analogue outlet pressure sensor signal is above

the valid 4-20 mA range. Check that sensor and

connectors are properly secu red and for damage

to sensor wires or sensor. Repair as necessary. If no

damage exists and error persists, or to obtain

replacement parts, contact Danfoss for help.

SEVERE ERR_AE_520960_16_SENSOR_OUTP

RESS_S1

ERR_OC_520960_16_SENSOR_OUT

PRESS_S1

520960 18 Service 1 outlet pressure

reading below minimum

Analogue outlet pressure sensor signal is below

the valid 4-20 mA range. Check that sensor and

connectors are properly secu red and for damage

to sensor wires or sensor. Repair as necessary. If no

damage exists and error persists, or to obtain

replacement parts, contact Danfoss for help.

SEVERE ERR_AE_520960_18_SENSOR_OUTP

RESS_S1

ERR_OC_520960_18_SENSOR_OUT

PRESS_S1

520961 0 Service 2 outlet pressure too

high

Outlet pump pressure above pressure limit, as set

by PRESS_ERROR_LIM parameter.

SEVERE ERR_AE_520961_00_SENSOR_OUTP

RESS_S2

ERR_OC_520961_00_SENSOR_OUT

PRESS_S2

520961 2 Service 2 outlet pressure

sensor incorrect

Analogue outlet pressure sensor signal is erratic or

unstable. Check that sensor and connectors are

properly secured and for damage to sensor wires

or sensor. Repair as necessary. If no damage exists

and error persists, or to obtain replacement parts,

contact Danfoss for help.

SEVERE ERR_AE_520961_02_SENSOR_OUTP

RESS_S2

ERR_OC_520961_02_SENSOR_OUT

PRESS_S2

520961 16 Service 2 outlet pressure

reading above maximu m

Analogue outlet pressure sensor signal is above

the valid 4-20 mA range. Check that sensor and

connectors are properly secu red and for damage

to sensor wires or sensor. Repair as necessary. If no

damage exists and error persists, or to obtain

replacement parts, contact Danfoss for help.

SEVERE ERR_AE_520961_16_SENSOR_OUTP

RESS_S2

ERR_OC_520961_16_SENSOR_OUT

PRESS_S2

520961 18 Service 2 outlet pressure

reading below minimum

Analogue outlet pressure sensor signal is below

the valid 4-20 mA range. Check that sensor and

connectors are properly secu red and for damage

to sensor wires or sensor. Repair as necessary. If no

damage exists and error persists, or to obtain

replacement parts, contact Danfoss for help.

SEVERE ERR_AE_520961_18_SENSOR_OUTP

RESS_S2

ERR_OC_520961_18_SENSOR_OUT

PRESS_S2

520972 2 J1939 address invalid The stored configuration for J1939 Name

(FUN_ECU_INSTANCE and NODE_ID are

invalid. Check the parameters are in the valid

range.

SEVERE ERR_AE_520972_02_CA_ADDRS_CFGERR_OC_520972_02_CA_ADDRS_C

FG

520972 31 J1939 address claim failure The DPC12 controller has lost arbitration for the

configured J1939 address. The controller will not

communicate over J1939. Review device address

configuration in the CAN bus system.

SEVERE ERR_AE_520972_31_CA_ADDRS_CLMERR_OC_520972_31_CA_ADDRS_C

LM

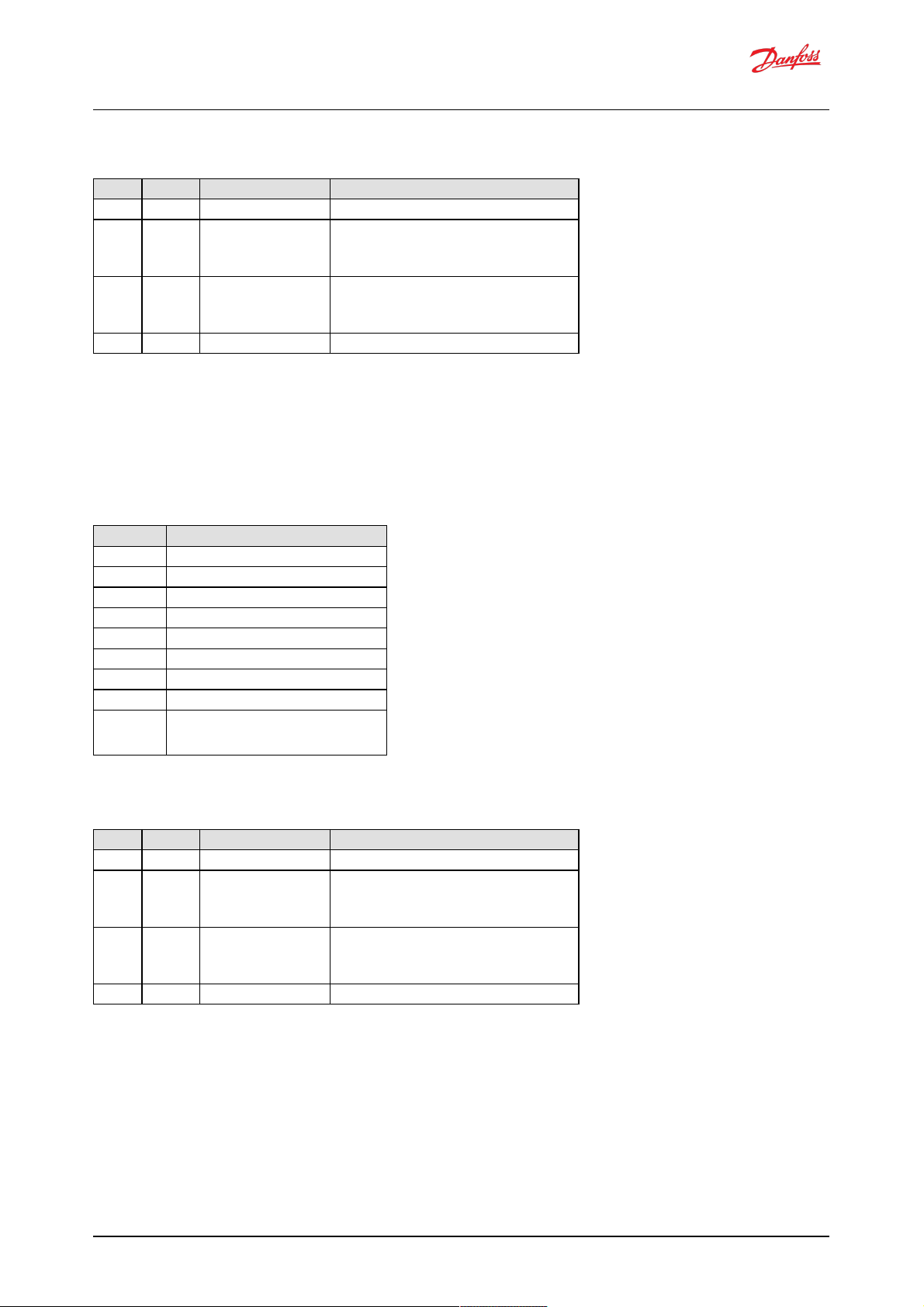

520975 0 Shaft speed above limit Shaft speed is too high to pump. CRITICAL ERR_AE_520975_00_LM_SHSPD ERR_OC_520975_00_LM_SHSPD

520975 2 Shaft sensor detection fault Shaft speed sensor not working properly. Power

cycle controller to enable pumping. If error

persists, check that connectors are properly

secu red and for damage to sensor wires or sensor.

Repair as necessary. If no damage exists and error

persists, or to obtain replacement parts, contact

Danfoss for help.

SEVERE ERR_AE_520975_02_LM_SHSPD ERR_OC_520975_02_LM_SHSPD

520975 8 Reverse shaft direction Shaft is rotating in reverse direction (counter-

clockwise when looking at input shaft) which is

not supported. Correct the direction of rotation.

WARNING ERR_AE_520975_08_LM_SHSPD ERR_OC_520975_08_LM_SHSPD

520975 17 Shaft speed below limit Shaft speed is too low to pump. Pumping

disabled. Increase shaft speed to enable

pumping.

INFO ERR_AE_520975_17_LM_SHSPD ERR_OC_520975_17_LM_SHSPD

520976 2 EEPROM value out of range A parameter value stored in non-volatile memory

is outside its allowed range. Connect with

PLUS+1® Service Tool and check values.

CRITICAL ERR_AE_520976_02_LM_NVDATA ERR_OC_520976_02_LM_NVDATA

520977 16 Too many errors to handle by

J1939 DM1

More than 29 errors active (or previously active) at

the same time. J1939 Diagnostic messages DM1

and DM2 are not able to show them all.

CRITICAL ERR_AE_520977_16_LM_FAULTMAXERR_OC_520977_16_LM_FAULTMA

X

520978 9 CAN bus displacement

reference timeout

J1939 displacement reference message is

required by current control mode configuration

and was not received within the timeout window.

Check configuration, message content and

sending frequency.

WARNING ERR_AE_520978_09_TL_DSREF ERR_OC_520978_09_TL_DSREF

SPN FMI Name Des criptio n Severity Ser vice Tool nam e for active

err or

Service T ool name for erro r

coun ter

Software Manual

Digital Displacement® Pump Software Version 2.7.1

25 | © Danfoss | February 2022 BC404560709540en-000102

Page 26

520979 9 CAN bus torque limit timeout J1939 torque limit message is required by current

limit configuration and was not received within

the timeout window. Check configuration,

message content and sendin g frequency.

WARNING ERR_AE_520979_09_TL_TQLIM ERR_OC_520979_09_TL_TQLIM

520980 9 CAN bus pressure reference

timeout

J1939 pressure reference message is required by

current control mode configuration and was not

received within the timeout window. Check

configuration, message content and sending

frequency.

WARNING ERR_AE_520980_09_TL_PRREF ERR_OC_520980_09_TL_PRREF

520981 9 CAN bus pressure margin

timeout

J1939 pressure margin reference message is

required by current control mode configuration

and was not received within the timeout window.

Check configuration, message content and

sending frequency.

WARNING ERR_AE_520981_09_TL_PMREF ERR_OC_520981_09_TL_PMREF

520982 9 CAN bus power limit timeout J1939 power limit message is required by current

limit configuration and was not received within

the timeout window. Check configuration,

message content and sendin g frequency.

WARNING ERR_AE_520982_09_TL_PWRLIM ERR_OC_520982_09_TL_PWRLIM

520983 9 CAN bus pump

enable/service index timeout

J1939 pump setup message is required by

current configuration and was not received within

the timeout window. Check configuration,

message content and sendin g frequency.

WARNING ERR_AE_520983_09_TL_PMPEN ERR_OC_520983_09_TL_PMPEN

520984 9 CAN bus flow limit timeout J1939 flow limit message is required by current

limit configuration and was not received within

the timeout window. Check configuration,

message content and sendin g frequency.

WARNING ERR_AE_520984_09_TL_FLLIM ERR_OC_520984_09_TL_FLLIM

520987 16 Service 1 broken valves above

maximum

Too many valves are not functioning properly.

Check other error codes to see which valves are

not functioning. For further help, contact Danfoss.

CRITICAL ERR_AE_520987_16_LM_BROKENVL

VMAX_S1

ERR_OC_520987_16_LM_BROKENV

LVMAX_S1

520988 16 Service 2 broken valves above

maximum

Too many valves are not functioning properly.

Check other error codes to see which valves are

not functioning. For further help, contact Danfoss.

CRITICAL ERR_AE_520988_16_LM_BROKENVL

VMAX_S2

ERR_OC_520988_16_LM_BROKENV

LVMAX_S2

520995 1 Service 1 unbroken valves

below limping minumum S1

Not implemented in this version SEVERE ERR_AE_520995_01_LM_LIMPVLVM

IN_S1

ERR_OC_520995_01_LM_LIMPVLV

MIN_S1

520996 1 Service 2 unbroken valves

below limping minimum

Not implemented in this version SEVERE ERR_AE_520996_01_LM_LIMPVLVM

IN_S2

ERR_OC_520996_01_LM_LIMPVLV

MIN_S2

521003 2 Internal 3.3V out of range Internal 3.3V power supply is out of range. If error

persists, contact Danfoss for help.

SEVERE ERR_AE_521003_02_LM_OUT3V3 ERR_OC_521003_02_LM_OUT3V3

521005 2 Invalid data in J1939 message Data in at least one J1939 CAN message is outside

range limits. CAN message is ignored. Ensure that

J1939 CAN messages are implemented correctly