Page 1

User Manual

PLUS+1® Compliant

Digital Displacement (DD) Function

Blocks

www.danfoss.com

Page 2

User Manual

Digital Displacement (DD) Function Blocks

Revision history Table of revisions

Date Changed Rev

September 2021 First edition 0101

2 | © Danfoss | September 2021 BC384074844183en-000101

Page 3

User Manual

Digital Displacement (DD) Function Blocks

Contents

Introduction

DD Application Configuration

Configure the DD Information Function Block......................................................................................................................5

Configure the DD Service Function Block............................................................................................................................... 5

Configure DD Service Rx Service Screens...........................................................................................................................6

Configure the DD Control and Limit Function Block...........................................................................................................7

Configure DD Services...............................................................................................................................................................8

Using Namespaces...........................................................................................................................................................................9

Change Namespace Value.....................................................................................................................................................10

Setup Configuration Parameter Inputs..................................................................................................................................10

DD Information Function Block

DD Information Function Block Inputs.................................................................................................................................. 11

DD Information Function Block Outputs...............................................................................................................................12

DD Information Service Screen.................................................................................................................................................13

DD Service Function Block

DD Service Function Block Inputs............................................................................................................................................15

DD Service Function Block Outputs........................................................................................................................................16

DD Service Rx Service Screen.....................................................................................................................................................17

DD Control and Limit Function Block

DD Control and Limit Function Block Inputs....................................................................................................................... 19

DD Control and Limit Function Block Parameters........................................................................................................20

DD Control and Limit Function Block Outputs....................................................................................................................21

Service Configuration Items.......................................................................................................................................................22

DD Control and Limit Service Screens....................................................................................................................................23

©

Danfoss | September 2021 BC384074844183en-000101 | 3

Page 4

User Manual

Digital Displacement (DD) Function Blocks

Introduction

The Digital Displacement Function Blocks provide configuration parameters for the Digital Displacement

Pump (DDP) as well as gather and report data from the DDP. This document provides instructions for

configuring the DDPDD Function Blocks and descriptions of the parameters and signals used in the

function blocks.

For instructions on configuring a basic application for the DDP, see DD Application Configuration on page

5.

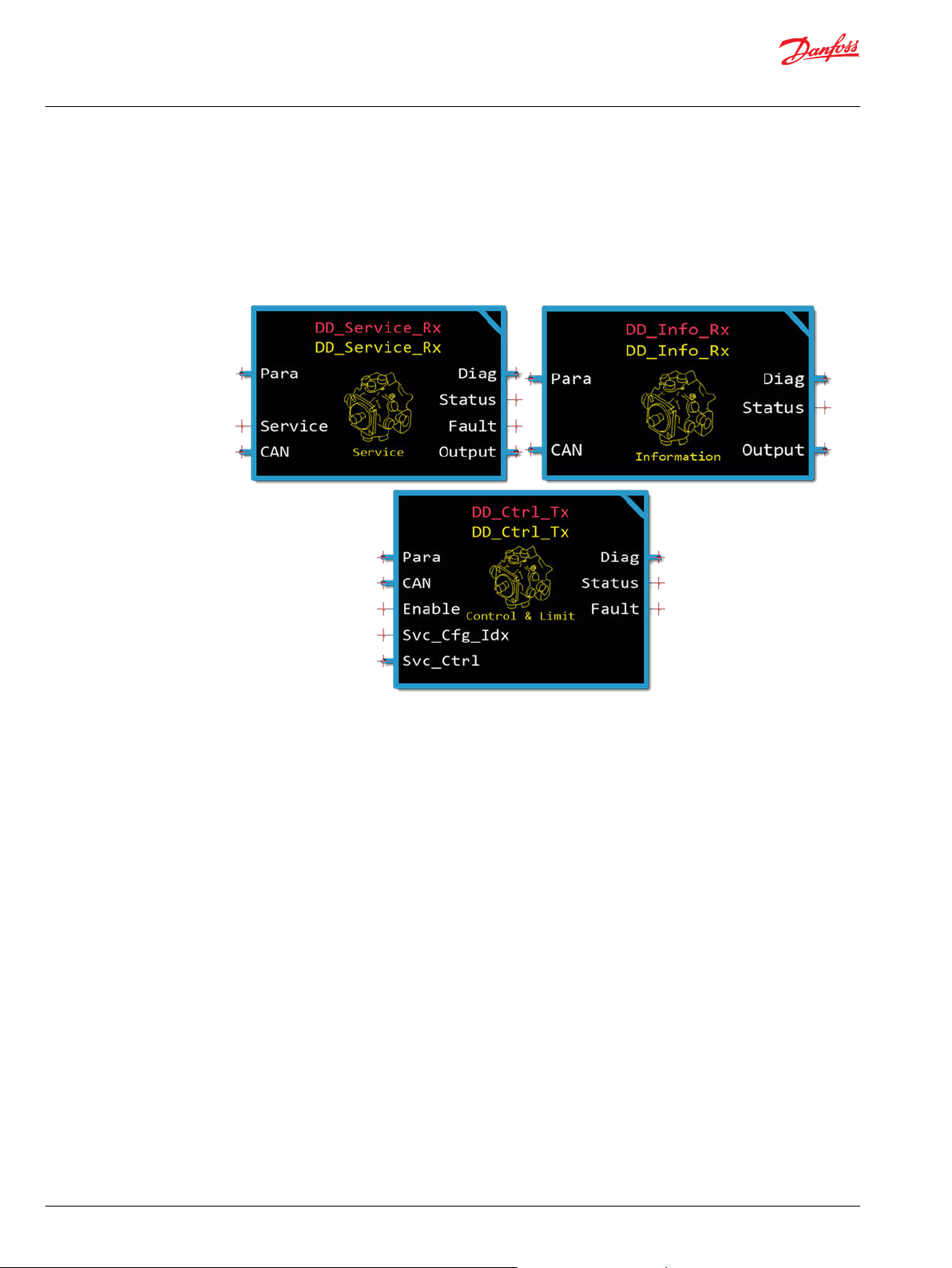

DD Information Function Block:

•

The DD Information Function Block receives data from the DDP. For more information on DD

Information Function Block parameters and settings, see DD Information Function Block on page 11.

DD Service Function Block:

•

The DD Service Function Block receives data from the selected DD service. For more information on

DD Service Function Blocks parameters and settings, see DD Service Function Block on page 15.

DD Control and Limit Function Block:

•

The DD Control and Limit Function Block configures the DDP and DD services. For more information

on DD Control and Limit Function Block parameters and settings, see DD Control and Limit Function

Block on page 19.

4 | © Danfoss | September 2021 BC384074844183en-000101

Page 5

User Manual

Digital Displacement (DD) Function Blocks

DD Application Configuration

This section provides instructions for configuring the DD Function Blocks. The instructions here describe

the basic process for configuring the function blocks for an application. Your application will require

additional configuration steps to customize the DDP for your purposes.

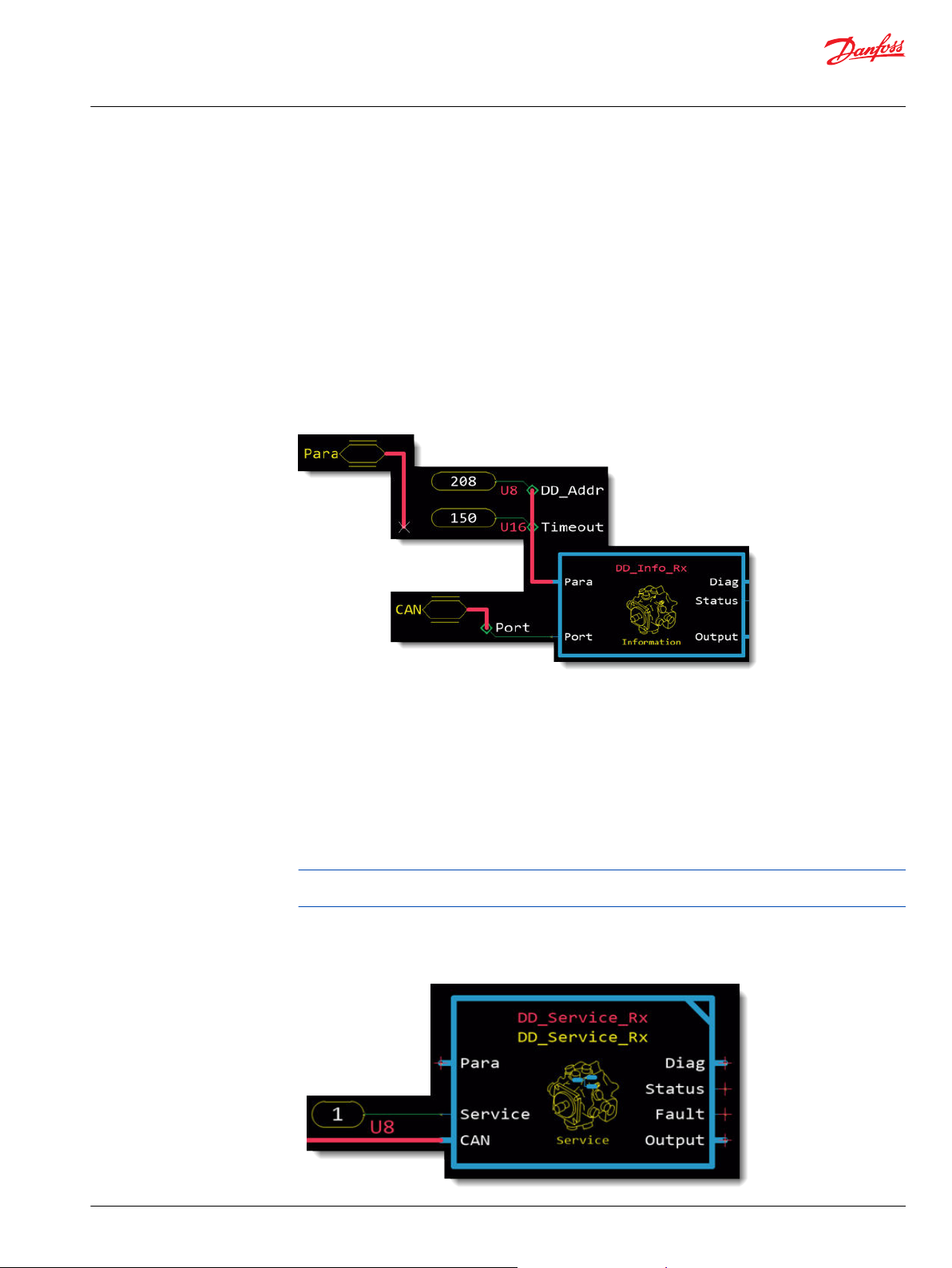

Configure the DD Information Function Block

The DD Information Function Block gathers information from the DDP. Follow these steps to configure

the DD Information Function Block. This task describes a basic configuration process. Your application

might require additional configuration steps.

1. Add the DD Information Function Block to the application.

2. Route the CAN bus on the function block to the CAN input BUS that contains CAN communication

from the DDP.

3. Enter the DDP CAN address in the value for DD_Addr if the CAN address of the DDP is different from

the default.

4. Save the project.

Configure the DD Service Function Block

The DD Service Function Block gathers and reports information from a DD service. Follow these steps to

configure the function block. This task describes a basic configuration process. Your application might

require additional configuration steps.

1. Add a DD Service Function Block to your application for each DD service you intend to use.

2. Modify the namespace of each function block to a unique name that indicates which DD service it

monitors.

Identical namespace values will result in errors when compiling the application. For more information

on changing the namespace, see Using Namespaces on page 9.

3. Route the CAN input BUS on the function block to the CAN input BUS that contains CAN

communication from the DDP.

4. Set a DD service number on the Service input of the function block.

©

Danfoss | September 2021 BC384074844183en-000101 | 5

Page 6

User Manual

Digital Displacement (DD) Function Blocks

DD Application Configuration

a) Add a 3 Character Typed Constant component and route it to the Service input.

b) Set the value to the number of the service configured in the DD Control and Limit Function Block.

c) Set the Type to U8.

5. Save the project.

6. Configure the service screens. For instructions, refer to Configure DD Service Rx Service Screens on page

6.

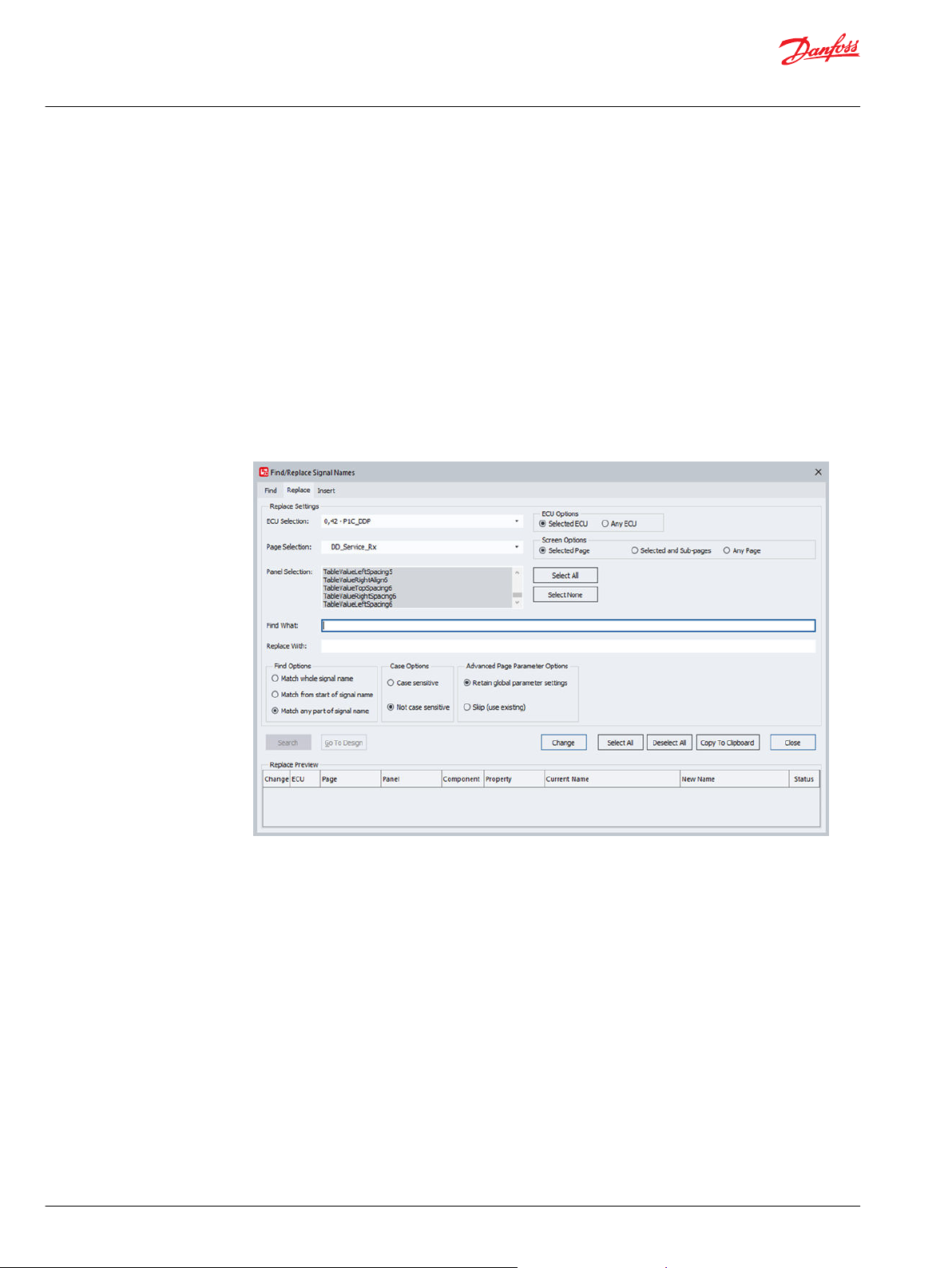

Configure DD Service Rx Service Screens

After changing the namespace for DD Service Function Blocks, you must configure the DD Service RX

Service Screens to communicate with the function blocks using the new namespace. This is not necessary

if the DDP uses only one service and the DD Service Function Block uses the default namespace.

1. Open the PLUS+1 Service Tool.

2. Add a DD Service Rx Service Screen for each DD Service Function Block.

3. Select Edit > Find/Replace Signal Names.

4. Select the Replace tab.

5. From the ECU Selection list, select the ECU for the function block.

6. From the Page Selection list, select the service screen to modify.

7. Next to the Panel Selection area, click Select All.

8. In the Find What field, enter the former function block namespace value .

9. In the Replace With field, enter the new function block namespace value.

10. Select Match any part of signal name.

11. Click Search. The PLUS+1 Service Tool finds all instances of the searched text.

12. Click Change. The PLUS+1 Service Tool replaces the former namespace with the new namespace.

13. Save the system.

14. Repeat these steps for any additional function blocks that have changed namespaces.

6 | © Danfoss | September 2021 BC384074844183en-000101

Page 7

User Manual

Digital Displacement (DD) Function Blocks

DD Application Configuration

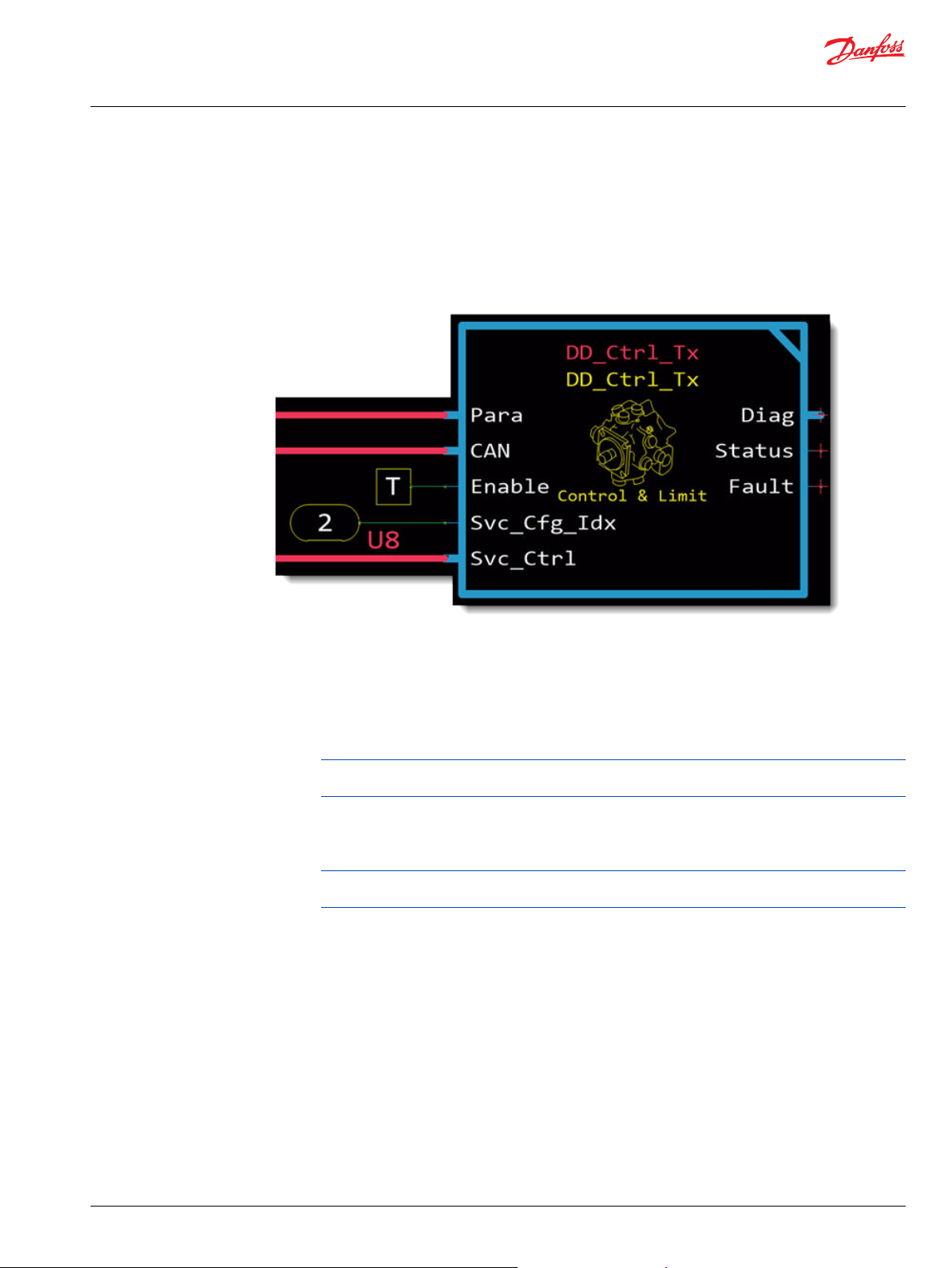

Configure the DD Control and Limit Function Block

The DD Control and Limit Function Block configures the operation of the DDP. Follow these steps to

configure the function block. This task describes a basic configuration process. Your application might

require additional configuration steps.

For more information on DD Control and Limit Function Block parameters and settings, see DD Control

and Limit Function Block on page 19.

1. Add the DD Control and Limit Function Block to the application.

2. Route the CAN input on the function block to the CAN input BUS that carries CAN communication

from the DDP.

3. Configure the Src_Addr parameter with the J1939 address of the controller.

Add a 3-Character Typed Constant component and set the address of the local controller.

•

Route it to an external input to allow an external control.

•

To prevent conflicts with other addresses, use the Address output of the AddrClaim_Tx_Rx

function block in the J1939 Function Block Library.

4. Enable the function block with the Enable input.

Add a True or False component.

•

Route it to an external input to enable or disable the function block from an external control.

•

To prevent conflicts with other addresses, use the Claimed output of the AddrClaim_Tx_Rx

function block in the J1939 Function Block Library.

5. Configure the Svc_Cfg_Idx (service configuration index) input.

Route it to an external input to allow an external input to set the service configuration index.

•

Add a 3-Character Typed Constant component and set service configuration index.

•

6. Route the Svc_Ctrl (service control) BUS to the input BUS.

7. Save the project.

8. Configure the services. For instructions, see Configure DD Services on page 8.

©

Danfoss | September 2021 BC384074844183en-000101 | 7

Page 8

User Manual

Digital Displacement (DD) Function Blocks

DD Application Configuration

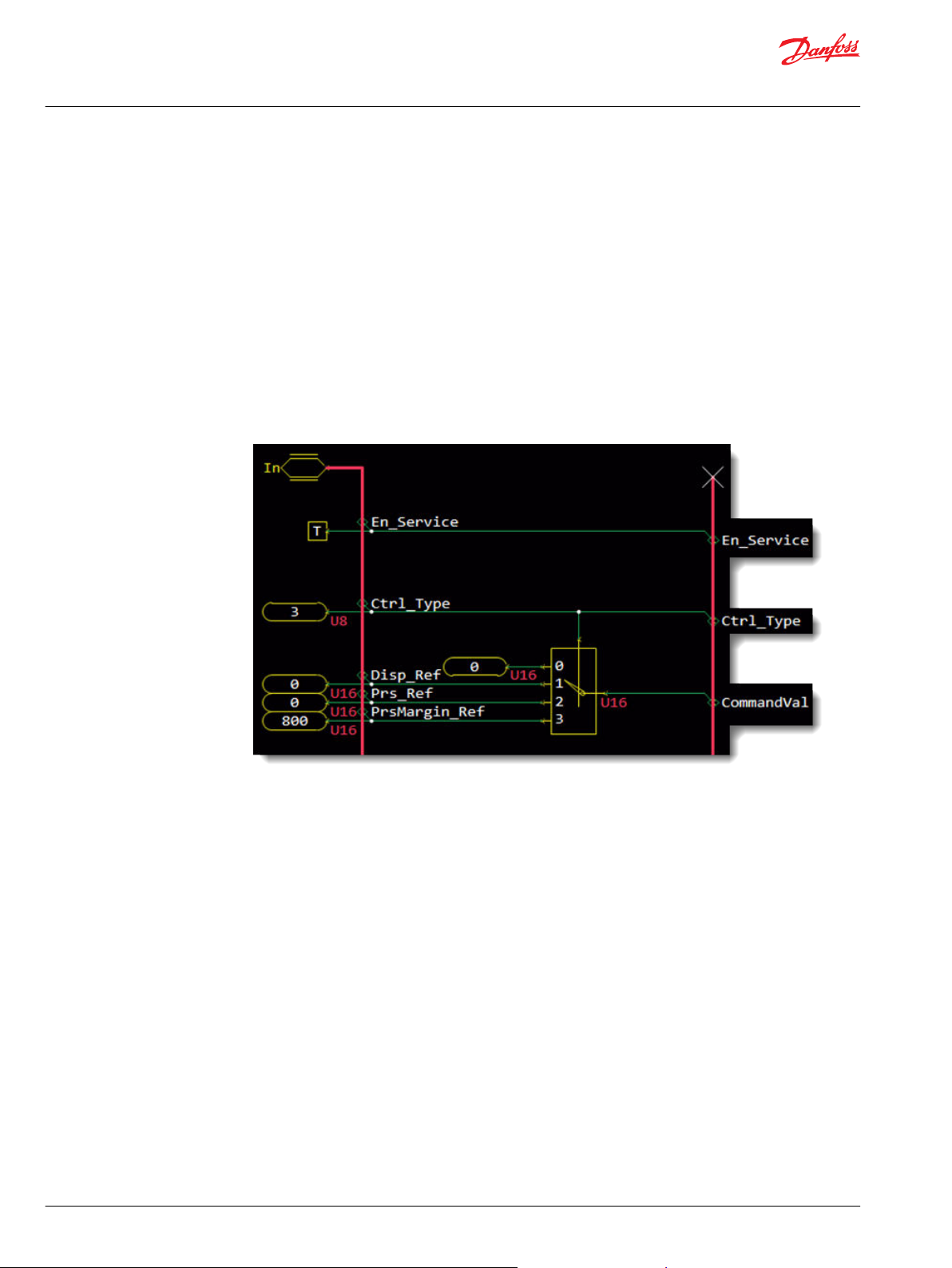

Configure DD Services

The DDP can provide flow to two different hydraulic circuits. Services in the DD Control and Limit

Function Block control the functionality of the DDP for each hydraulic circuit. Follow these steps to

configure DD services.

•

Danfoss supports specific combinations of service configuration parameters. For more information on

the supported use cases, see the Digital Displacement Pump Software Manual.

•

For more information on DD service configuration items, see Service Configuration Items on page 22.

1. In the DD Control and Limit Function Block, break the link between the service pages you want to

modify.

a) Select Edit > Break Reference Link to Page.

b) Click on the service page. A confirmation dialog box opens.

c) Click Yes.

2. Enter a service page.

3. Enable the service.

Query the False constant to the En_Service signal then change the modifier to True.

•

Or, delete the False constant component to En_Service to allow an external signal to enable and

•

disable the service.

4. Set the Ctrl_Type (control type) for the service.

a) Query the typed constant component connected to the Ctrl_Type.

b) Enter a value that corresponds to the control type.

5. Configure the reference value for the selected control type.

a) Query a typed constant component connected to Disp_Ref, Prs_Ref, or PrsMargin_Ref.

b) Enter a reference value for the control type.

8 | © Danfoss | September 2021 BC384074844183en-000101

Page 9

User Manual

Digital Displacement (DD) Function Blocks

DD Application Configuration

6. Follow these steps to set a torque limit on the service.

Using Namespaces

a) Set the True/False constant component connected to En_Torq_Limit to True.

b) Query the typed constant component connected to Torq_Limit and enter a torque limit value.

7. Follow these steps to set a flow limit on the service.

a) Set the True/False constant component connected to En_Flow_Limit to True.

b) Query the typed constant component connected to Flow_Limit and enter a flow limit value.

8. Follow these steps to set a power limit on the service.

a) Set the True/False constant component connected to En_Pwr_Limit to True.

b) Query the typed constant component connected to Pwr_Limit and enter a power limit value.

9. Save the project.

Namespaces can help you successfully compile an application that uses the same function block more

than once.

Change each function block's namespace by setting its Namespace value to something unique. If you do

not change the Namespace value, you cannot compile the application.

The Namespace value adds a unique prefix to each component name.

Also, if you want to use these function blocks' companion Service Tool screens, you must include the

function block's advanced checkpoint with namespace in the application's compiled .lhx file. Use the

function block's Checkpoints page to include the checkpoint.

©

Danfoss | September 2021 BC384074844183en-000101 | 9

Page 10

User Manual

Digital Displacement (DD) Function Blocks

DD Application Configuration

Change Namespace Value

To successfully compile your application, change the namespace value for function blocks that are used

more than once in an application.

1. In the PLUS+1® GUIDE menu bar, click the Query/Change button.

2. Click on the function block whose namespace you want to set to a unique value.

The Edit Page window opens.

3. In the Edit Page window, enter a meaningful Namespace value.

Namespace values are case-sensitive.

•

To save controller memory, use a short namespace value.

•

4. Press Enter.

5. Repeat these steps to enter unique namespace values for other identical function blocks.

Setup Configuration Parameter Inputs

Use the parameter (Para) input to apply a common set of configuration parameters to multiple function

blocks. Follow these steps to setup configuration parameter inputs for the application.

1. Create a Parameters page to hold the configuration parameters the function blocks will share.

2. Connect the Parameters page to the Para input of the DD Function Block.

3. Add the configuration parameters and their values to the Parameters page.

a) Copy the configuration parameters from the function block.

b) Paste the configuration parameters into the Parameters page.

c) Route the parameters to the Para output of the Parameters page.

d) Modify the configuration parameters as needed.

4. In the function block, route each configuration parameter to the Para input bus and connect it to the

corresponding input signal.

To avoid compiler errors, ensure that the Namespace value for each function block is unique.

10 | © Danfoss | September 2021 BC384074844183en-000101

Page 11

User Manual

Digital Displacement (DD) Function Blocks

DD Information Function Block

The DD Information Function Block receives data from the DDP. This chapter provides information on

inputs, outputs, and parameters used to configure the function block for your application.

DD Information Function Block Inputs

The table below describes the inputs to the DD Information Function Block.

Item Type Range Description [Unit]

Para BUS ––

CAN BUS ––

DD_Addr U8 0–238

Timeout U16 10–1000

Port Port ––

Holds configuration values for the function block. Route

signals from the application to control the configuration

values from the application.

For information on configuring parameters for external

control, refer to Setup Configuration Parameter Inputs on

page 10.

The CAN address of the DD controller. The default value

is 208.

The time in milliseconds between messages after which a

fault is triggered. The default value is 150.

[ms]

BUS containing the port sub-signal and CAN messages.

Sets the physical CAN port on the DDP that receives data.

This variable can be found in the CAN sub-BUS if using

the Main Template.

©

Danfoss | September 2021 BC384074844183en-000101 | 11

Page 12

User Manual

Digital Displacement (DD) Function Blocks

DD Information Function Block

DD Information Function Block Outputs

The table below describes the output signals from the DD Information Function Block.

Item Type Description

Diag BUS

Status U16 Reports the status of the function block.

Output BUS Contains all of the output values for the function block.

The following table includes descriptions for sub-signals contained in the Output bus.

Output Sub-Signals

Item Type Range Description [Unit]

Act_Shaft_Spd S16 -3500–3500

Act_Pump_Temp S16 -40–150

Device_State U8 0–13

Device_Mode U8 0–13

Sig_Status BUS ––

Act_Shaft_Spd_NA

Act_Pump_Temp_NA

Device_State_NA

Device_Mode_NA

Sig_Fault BUS T/F

Act_Shaft_Spd_Flt

Act_Pump_Temp_Flt

Device_State_Flt

Device_Mode_Flt

Updated BOOL T/F

Provides diagnostic data for troubleshooting as well as all parameters and

output signals.

0x0000: Status OK.

0x8008: At least one parameter is out of range.

This output uses a bitwise-reporting scheme where multiple items can be

reported at a time.

BOOL T/F

BOOL T/F

The speed of the shaft in the DDP. Positive values

indicate clockwise rotation of the shaft. Negative values

indicate counter-clockwise rotation of the shaft.

[rpm]

The temperature of the DDP.

[°C]

The current state of the DD controller.

0: Initializing

1: Disabled

2: Active

3: Error

4: Error Hold

5–13: Reserved

The current mode of the DD controller. Options include

Normal, Limp, and Commissioning.

0: Normal

1: Limp

2: Commissioning

3–13: Reserved

Bus containing signals that indicate the availability of the

output signals from the DDP.

Indicates the availability of the specified output signal.

T: The signal is unavailable

F: The signal is available

Bus containing signals that indicate the fault status of the

output signals.

Indicates the fault status of the specified output signal.

T: The signal has a fault

F: The signal is OK and does not have a fault

Indicates that the function block received new data in the

current cycle.

T: Received new data

F: Did not receive new data

12 | © Danfoss | September 2021 BC384074844183en-000101

Page 13

User Manual

Digital Displacement (DD) Function Blocks

DD Information Function Block

Output Sub-Signals (continued)

Item Type Range Description [Unit]

NoMsgReceived BOOL T/F

MsgTimedOut BOOL T/F

DD Information Service Screen

The DD Information service screen presents information on the Digital Displacement Pump from the DD

Information Function Block. The following table describes the data provided by the DD Information

service screen.

Indicates that a message has not been received from the

device since powering it on.

T: The function block has not received a message

F: The function block received a message

Indicates that the time between messages from the

device has exceeded the Timeout value. If the timeout

has been exceeded, the function block retains the last

received values for the output signals.

T: The message timed out

F: No error

Item Description

Parameter

DD_Addr

Timeout

Outputs

Status

No Messages Received

©

Danfoss | September 2021 BC384074844183en-000101 | 13

The CAN address of the DD controller. The default value is 208.

The time in milliseconds between messages after which a fault is triggered. The default

value is 150.

Reports the status of the function block.

Indicates that a message has not been received from the device since powering it on.

Page 14

User Manual

Digital Displacement (DD) Function Blocks

DD Information Function Block

Item Description

Reception Timeout

Actual Shaft Speed

Actual Pump

Temperature

Device State

Device Mode

Output Signal Availability and Fault Statuses

Not Available

Fault

Indicates that the time between messages from the device has exceeded the Timeout

value. If the timeout has been exceeded, the function block retains the last received

values for the output signals.

The speed of the shaft in the DDP. Positive values indicate clockwise rotation of the

shaft. Negative values indicate counter-clockwise rotation of the shaft.

The temperature of the DDP.

The current state of the DD controller.

The current mode of the DD controller. Options include Normal, Limp, and

Commissioning.

Indicates the availability of the specified output signal.

Indicates the fault status of the specified output signal.

14 | © Danfoss | September 2021 BC384074844183en-000101

Page 15

User Manual

Digital Displacement (DD) Function Blocks

DD Service Function Block

The DD Service Function Block receives data from the selected DD service. This chapter provides

information on input, output, and parameter signals.

DD Service Function Block Inputs

The table below describes input signals for the DD Service Function Block.

Item Type Range Description [Unit]

Para BUS ––

CAN BUS ––

Service U8 1–8

DD_Addr U8 0–238

Timeout U16 10–1000

Port Port ––

Holds configuration values DD_Addr and Timeout.

For information on configuring parameters for external

control, refer to Setup Configuration Parameter Inputs on

page 10.

The CAN address of the DD controller. The default value

is 208.

The time in milliseconds between messages after which a

fault is triggered. The default value is 150.

[ms]

BUS containing the port sub-signal and CAN messages.

Sets which physical CAN port of the hardware to receive

data from. This variable can be found in the CAN sub-BUS

if using the Main Template.

Sets the DD service from which the function block

receives data. A DD Service Function Block can receive

data from only one DD service. To receive data from

multiple DD services, add a DD Service Function Block to

the application for each DD service.

©

Danfoss | September 2021 BC384074844183en-000101 | 15

Page 16

User Manual

Digital Displacement (DD) Function Blocks

DD Service Function Block

DD Service Function Block Outputs

The following table describes output signals for the DD Service Function Block.

Item Type Description [Unit]

Diag BUS

Status U16

Fault U16

Output BUS

Provides diagnostic data for troubleshooting as well as all

parameters and output signals.

Reports the status of the function block.

0x0000: Status OK.

0x8008: At least one parameter is out of range.

This output uses a bitwise-reporting scheme where

multiple items can be reported at a time.

Reports fault statuses for the function block.

0x0000: No fault

0x8001: Input value is too low

0x8002: Input value is too high

This output uses a bitwise-reporting scheme where

multiple items can be reported at a time.

Contains all of the output signals for the function block.

For more information on the signals contained within

Output, see Output Sub-Signals on page 16.

The following table includes descriptions for sub-signals contained in the Output bus.

Output Sub-Signals

Item Type Range Description [Unit]

Displacement U16

Prs U16

Load_Prs U32

Sig_Status BUS ––

Displacement_NA

Prs_NA

Load_Prs_NA

Sig_Fault BUS T/F

Displacement_Flt

Prs_Flt

Load_Prs_Flt

Updated BOOL T/F

BOOL T/F

BOOL T/F

0–10000 The displacement reading from the DDP.

[0.01%]

0–60000 The pressure reading from the DDP.

Displayed at a resolution of 2 kPa.

[0.01 bar/1 kPa]

0–100000 The load pressure reading from the DDP.

Displayed at a resolution of 2 kPa.

[0.01 bar/1 kPa]

Bus containing signals that indicate the

availability of the output signals from the

DDP.

Indicates the availability of the specified

output signal.

T: The signal is unavailable

F: The signal is available

Bus containing signals that indicate the

fault status of the output signals.

Indicates the fault status of the specified

output signal.

T: The signal has a fault

F: The signal is OK and does not have a

fault

Indicates that the function block received

new data in the current cycle.

T: Received new data

F: Did not receive new data

16 | © Danfoss | September 2021 BC384074844183en-000101

Page 17

User Manual

Digital Displacement (DD) Function Blocks

DD Service Function Block

Output Sub-Signals (continued)

Item Type Range Description [Unit]

NoMsgReceived BOOL T/F

MsgTimedOut BOOL T/F

DD Service Rx Service Screen

The DD Service Rx service screen displays information on the Digital Displacement PumpDD Service

Function Block. The following table describes the data provided by the DD Service Rx service screen.

Indicates that a message has not been

received from the device since powering it

on.

T: The function block has not received a

message

F: The function block received a message

Indicates that the time between messages

from the device has exceeded the

Timeout value. If the timeout has been

exceeded, the function block retains the

last received values for the output signals.

T: The message timed out

F: No error

Item Description

Input

Service #

Parameter

DD Address

Timeout

Outputs

©

Danfoss | September 2021 BC384074844183en-000101 | 17

The number of the service set on the function block.

The CAN address of the DD controller. The default value is 208.

The time in milliseconds between messages after which a fault is triggered. The default

value is 150.

Page 18

User Manual

Digital Displacement (DD) Function Blocks

DD Service Function Block

Item Description

Displacement

Pressure

Load Pressure

NoMsgReceived

MsgTimeOut

Status

Fault

Output Signal Availability and Fault Statuses

Not Available

Fault

The displacement reading from the DDP.

The pressure reading from the DDP. Displayed at a resolution of 2 kPa.

The load pressure reading from the DDP. Displayed at a resolution of 2 kPa.

Indicates that a message has not been received from the device since powering it on.

Indicates that the time between messages from the device has exceeded the Timeout

value. If the timeout has been exceeded, the function block retains the last received

values for the output signals.

Reports the status of the function block.

Reports fault statuses for the function block.

Indicates the availability of the specified output signal.

Indicates the fault status of the specified output signal.

18 | © Danfoss | September 2021 BC384074844183en-000101

Page 19

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

The DD Control and Limit Function Block configures the DDP and DD services. This chapter provides

information used to configure the function block.

DD Control and Limit Function Block Inputs

The following table describes input signals for the DD Control and Limit Function Block.

Item Type Range Description [Unit]

Para BUS ––

Loop_Tm U16 0–65535

CAN BUS ––

Port Port ––

Enable BOOL T/F

Svc_Cfg_Idx U8 0–15

Holds configuration values for the function block. Route

signals from the application to control the configuration

values from the application.

For more information, see DD Control and Limit Function

Block Parameters on page 20.

Sets the processing time of one program loop.

[ms]

BUS containing the port sub-signal and CAN messages.

Sets which physical CAN port of the hardware to receive

data from. This variable can be found in the CAN sub-BUS

if using the Main Template.

Enables and disables the function block.

T: Enables the function block

F: Disables the function block

Sets the Service Configuration Index or the index for

cylinder combination for service outlet. This sets the

combination of pumplets assigned to DD services.

0: Service 1 uses pumplet 1+3. Service 2 uses pumplets

•

2 and 4.

1: Service 1 uses pumplet 1+3. Service 2 uses pumplet

•

4.

2: Service 1 uses pumplet 1+3 and 2. Service 2 uses

•

pumplet 4.

3–15: Reserved

•

©

Danfoss | September 2021 BC384074844183en-000101 | 19

Page 20

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

Item Type Range Description [Unit]

Svc_Ctrl BUS ––

Chkpt BOOL T/F

DD Control and Limit Function Block Parameters

The following table describes parameters for the DD Control and Limit Function Block.

For information on configuring parameters for external control, refer to Setup Configuration Parameter

Inputs on page 10.

Contains controls for DD services. Default signals are

present but, by default, will not send commands. Enter

the page corresponding to the service to customize it for

your application.

For instructions, see Configure DD Services on page 8.

Enables advanced checkpoints using Namespace for

each diagnostic signal.

T: Enables advanced checkpoints.

F: Disables advanced checkpoints.

Item Type Range Description

Priority U8

TxRate_CtrlMsgs U8

0-7 Sets the priority of CAN messages from the DD controller

to the DDP.

0 is the highest priority and 7 is the lowest priority. 3 is

the default priority.

0-5 Sets the rate at which the DD controller sends control

messages to the DDP.

0: 10 ms

1: 20 ms

2: 50 ms

3: 100 ms

4: 200 ms

5: 300 ms

If this rate is less than the twice Loop_Tm, the DD

Control and Limit Function Block increases the rate to

twice Loop_Tm.

20 | © Danfoss | September 2021 BC384074844183en-000101

Page 21

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

Item Type Range Description

TxRate_CfgMsgs U8

DD_Addr U8

Src_Addr U8

En_SetupCmdMsg BOOL

Send_LimpCmdMsg BOOL

En_LimpMode BOOL

NotAvailable_UseZero BOOL T/F

0-5 Sets the rate at which the DD controller sends

configuration messages to the DDP.

0: 10 ms

1: 20 ms

2: 50 ms

3: 100 ms

4: 200 ms

5: 300 ms

If this rate is less than the twice Loop_Tm, the DD

Control and Limit Function Block increases the rate to

twice Loop_Tm.

0-238 The CAN address of the DD controller. The default value

is 208.

0-253 The CAN address of the device sending the

communication.

T/F Enables or disables setup command messages.

T: Enables message transmission

F: Disables message transmission

T/F Enables or disables transmission of Limp Mode

commands from the DD controller.

T: Enables command transmission

F: Disables command transmission

T/F Enables or disables Limp Mode. Used in the event of a

mechanical error, Limp Mode limits the functionality of

the DDP to prevent further damage to the DDP.

T: Enables Limp Mode

F: Disables Limp Mode

Sets how the DDP sends signal values when the signals

are unavailable.

T: Sets unavailable signals to send a value that is

functionally 0. Scaled and offset values also result in 0

values.

F: Sets unavailable signal values to 1.

DD Control and Limit Function Block Outputs

The table below describes the outputs signals for the DD Control and Limit Function Block.

Item Type Description

Diag BUS

Status U16 Reports the status of the function block.

Fault U16

©

Danfoss | September 2021 BC384074844183en-000101 | 21

Provides diagnostic data for troubleshooting as well as all parameters and

output signals.

0x0000: Status OK.

0x8008: At least one parameter is out of range.

This output uses a bitwise-reporting scheme where multiple items can be

reported at a time.

Reports fault statuses for the function block.

0x0000: No fault

0x8002: Input value is too high, transmission is interrupted

This output uses a bitwise-reporting scheme where multiple items can be

reported at a time.

Page 22

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

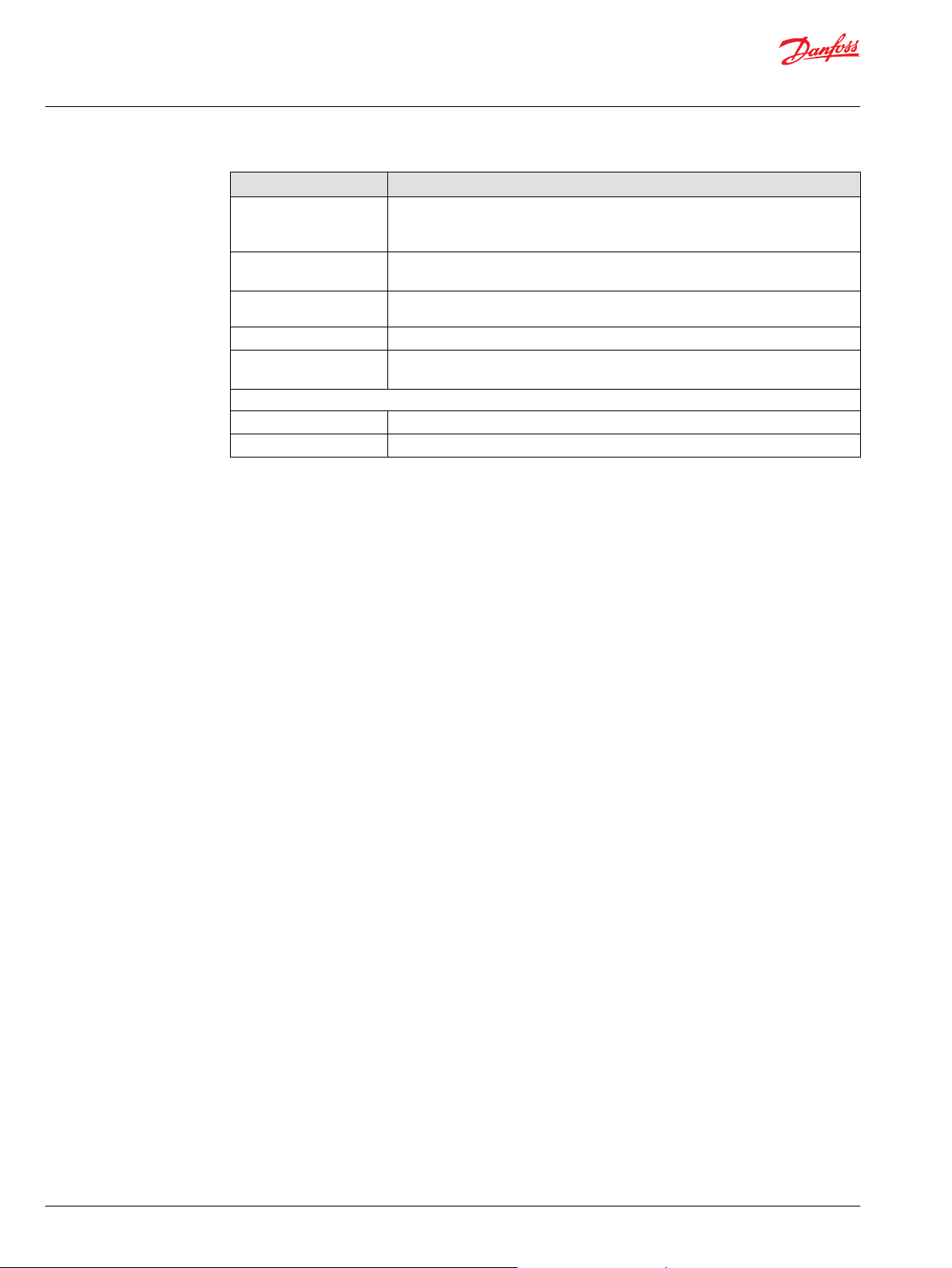

Service Configuration Items

The following table describes the items in the Service pages used to configure a DPP service.

Item Type Range Description [Unit]

En_Service BOOL T/F

Ctrl_Type U8 0-3

CommandVal U16 --

Disp_Ref U16 0-10000

Prs_Ref U16 0-42000

PrsMargin_Ref U16 0-10000

En_Torq_Limit BOOL T/F

Torq_Limit U16 0-15000

En_Flow_Limit BOOL T/F

Flow_Limit U16 0-30000

En_Pwr_Limit BOOL T/F

Pwr_Limit U16 0-50000

Enables or disables the DD service.

T: Enables the DD service

F: Disables the DD service

Sets the control type on the DD service. The control type

controls how pump operates. The following list describes

the control types.

0: No active control

1: Displacement Reference Control: The DDP maintains

a set displacement percentage during operation.

2: Pressure Reference Control: The DDP maintains a set

pressure level at its output during operation.

3: Pressure Margin Reference Control: The DDP

maintains a pressure at its output that is a set margin

greater than the pressure at the input.

Toggles between the control reference values for the

different control types.

Displacement reference for Displacement Control

Reference.

[0.01%]

Pressure reference for Pressure Reference Control.

[0.01 bar / 1 kPa]

Resolution: 2 kPa

The pressure margin reference for Pressure Margin

Reference Control.

[0.01 bar / 1 kPa]

Resolution: 2 kPa

Enables a torque limit for the DD service. After enabling,

set the torque limit using Torq_Limit.

T: Enables the torque limit

F: Disables the torque limit

Sets the torque limit after enabling En_Torq_Limit.

[0.1 Nm]

Resolution: 0.2 Nm

Enables a flow limit for the DD service. After enabling, set

the flow limit using Flow_Limit.

T: Enables the flow limit

F: Disables the flow limit

Sets the flow limit after enabling En_Flow_Limit.

[0.01 liters/min]

Resolution: 0.05 liters/min

Enables a power limit for the DD service. After enabling,

set the power limit using Pwr_Limit.

T: Enables the power limit

F: Disables the power limit

Sets the power limit after enabling En_Pwr_Limit.

[0.01 kW]

Resolution: 0.05 kW

22 | © Danfoss | September 2021 BC384074844183en-000101

Page 23

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

DD Control and Limit Service Screens

DD Control and Limit Function Block service screens display information provided by the function block.

DD Control Tx

The following table describes data displayed in the DD Control Tx service screen.

Item Description

Inputs

Enable Indicates that the function block is disabled or enabled.

Service Config Index

Service 1

Enable Service

Ctrl Type

Command

Enable Torque Limit

Torque Limit

Enable Flow Limit

Flow Limit

Enable Power Limit

Power Limit

All Services Click to view data from all DD services. After clicking, the PLUS=1 Service Tool loads the

Parameters

Priority

Tx Rate - Ctrl

Indicates the service configuration index that sets the cylinder combination for service

outlet from the DDP.

Indicates that the service is enabled or disabled.

The control type set on the DD service. The control type controls how service operates.

The following list describes the three control types.

Displacement Reference Control: The DDP maintains a set displacement percentage

during operation.

Pressure Reference Control: The DDP maintains a set pressure level at its output

during operation.

Pressure Margin Reference Control: The DDP maintains a pressure at its output that

is a set margin greater than the pressure at the input pressure sensor.

The control reference value type for the different control types.

Indicates that the torque limit is enabled or disabled for the service.

The torque limit value in Newton meters.

Indicates that the flow limit is enabled or disabled for the service.

The flow limit value in liters per minute.

Indicates that the power limit is enabled for the service.

The power limit value in kilowatts.

DD Control Tx - Services service screen.

Sets the priority of CAN messages from the DD controller to the DDP.

0 is the highest priority and 7 is the lowest priority. 3 is the default priority.

Sets the rate at which the DD controller sends control messages to the DDP.

©

Danfoss | September 2021 BC384074844183en-000101 | 23

Page 24

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

Item Description

Tx Rate - Cfg

DD Address

Src Address

Enable Setup Cmd Msg

Send Limp Cmd Msg

Enable Limp Mode

NotAvailable_UseZero

Outputs

Status

Fault

DD Control Tx - Services

The table below describes the items on the DD Control Tx - Services service screen panels.

Sets the rate at which the DD controller sends configuration messages to the DDP.

The CAN address of the DD controller. The default value is 208.

The CAN address of the device sending the communication.

Enables or disables setup command messages.

Enables or disables transmission of Limp Mode commands from the DD controller.

Enables or disables Limp Mode. Used in the event of a mechanical error, Limp Mode

limits the functionality of the DDP to prevent further damage to the DDP.

Sets how the DDP sends signal values when the signals are unavailable.

T: Sets unavailable signals to send a value that is functionally 0. Scaled and offset values

also result in 0 values.

F: Sets unavailable signal values to 1.

Reports the status of the function block.

Indicates the fault status of the specified output signal.

Item Description

Enable Service

Ctrl Type

Command

Enable Torque Limit

Torque Limit

Enable Flow Limit

Indicates that the service is enabled or disabled.

The control type set on the DD service. The control type controls how service operates.

The following list describes the three control types.

Displacement Reference Control: The DDP maintains a set displacement percentage

during operation.

Pressure Reference Control: The DDP maintains a set pressure level at its output

during operation.

Pressure Margin Reference Control: The DDP maintains a pressure at its output that

is a set margin greater than the pressure at the input pressure sensor.

The control reference value type for the different control types.

Indicates that the torque limit is enabled or disabled for the service.

The torque limit value in Newton meters.

Indicates that the flow limit is enabled or disabled for the service.

24 | © Danfoss | September 2021 BC384074844183en-000101

Page 25

User Manual

Digital Displacement (DD) Function Blocks

DD Control and Limit Function Block

Item Description

Flow Limit

Enable Power Limit

Power Limit

The flow limit value in liters per minute.

Indicates that the power limit is enabled for the service.

The power limit value in kilowatts.

©

Danfoss | September 2021 BC384074844183en-000101 | 25

Page 26

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | September 2021 BC384074844183en-000101

Loading...

Loading...