Page 1

Data sheet

Thermostat, Differential thermostat

RT

An RT thermostat is fitted with

a single-pole changeover switch.

The position of the contacts depends on the bulb

temperature and the set scale value.

The RT series includes thermostats for general

applications within industrial and marine

refrigeration.

The RT series also includes differential

thermostats, thermostats for neutral zone

regulation and special thermostats with

gold-plated contact surface for PLC applications.

Features • Waterproof versions, enclosure IP66

• Wide regulating range

• Wide range of units for industrial

and marine applications

• Suitable for alternating and direct current

• Interchangeable contact system

• Special versions for PLC applications

• Safety Integrity Level:

SIL 2 according to IEC 61508

© Danfoss | DCS (az) | 2017.09 DKRCC.PD.CB0.A9.02 | 520H12296 | 1

Page 2

Data sheet | Thermostat, Differential thermostat, type RT

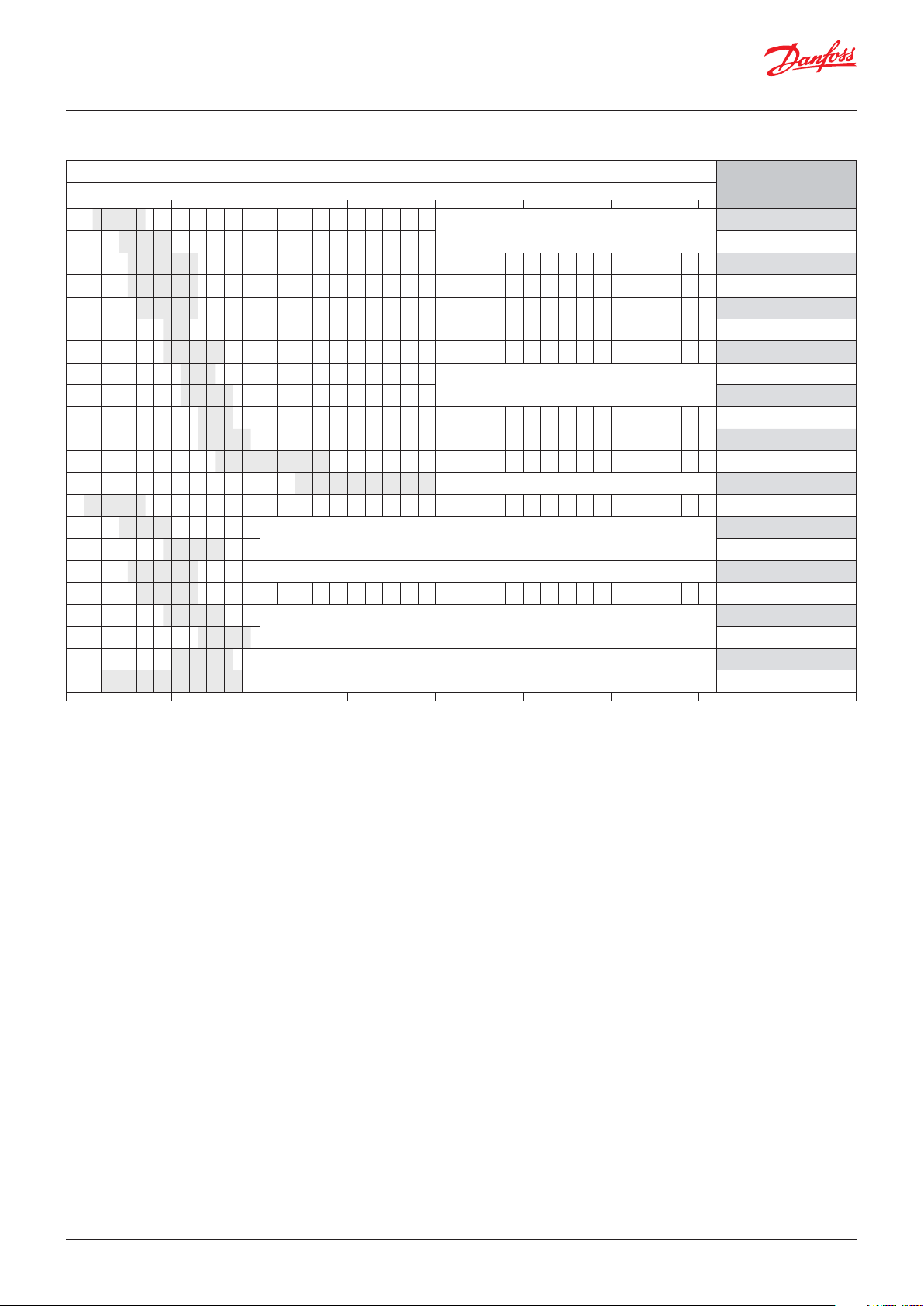

Approvals

RT 2

RT 3

RT 4

RT 7

RT 8

RT 8L

RT 9

RT 11

• • • • • • • • • • • •

• • • • • • • • • • • • • • • • • • • • • • • •

RT 12

RT 13

RT 14

RT 14L

RT 15

RT 16L

RT 17

RT 23

RT 24

RT 34

RT 101

RT 102

RT 107

RT 140

RT 140 L

RT 270

•

• •

•

Lloyd’s Reg. of Shipping, LR

Germanischer Lloyd, GL

Det Norske Veritas, DNV

Bureau Veritas, BV

Russian Maritime Register

of Shipping, RMRS

Technical data

• • • • • • • • • •

•

• • • • • • • • • • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • • • • • • • • • • •

Nippon Kaiji Kyokai, NKK

Korean Register of Shipping, KRS

Conformity with EN 60730-2-1 to 9

CE mark according to EN 60947-4, -5

China Compulsor y Certificate, CCC

Cable connection Pg 13.5. Cable diameter 6 – 14 mm.

Enclosure

Permissible ambient temperature

IP66 acc. to EN 60529 / IEC 60529,

except for versions with ext. reset which are IP54.

-50 – 70 °C for thermostat housing.

Switches See “Ordering switches”

Properties according to EN 60947

Wire dimensions

solid / stranded 0.2 – 2.5 mm

flexible, w / out ferrules 0.2 – 2.5 mm

flexible, with ferrules 0.2 – 1.5 mm

Tightening torque max. 1.5 Nm

Rated impulse voltage 4 kV

Pollution degree 3

Short circuit protection, fuse 10 A

Insulation 400 V

Ingress Protection IP54, IP66

2

2

2

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 2

Page 3

Data sheet | Thermostat, Differential thermostat, type RT

Overview

[°C]

-50 0 50 100 150 200 250 300

Range

[°C]

Typ e

Vapour-charged with remote bulb (bulb coldest)

Adsorption-charged with remote bulb

(bulb warmest or coldest)

Partial charge with remote bulb (bulb warmest) 70 – 150 RT 107

Vapour-charged with coiled capillary tube sensor (room thermostats)

Adsorption-charged with coiled capillary tube sensor (room thermostats) -25 – 15 RT 34

Adsorption-charged dead zone thermostats with remote bulb (bulb warmest or coldest)

Vapour-charged dead zone thermostat (room thermostat) 0 – 38 RT 16L

Adsorption-charged differential thermostats with remote bulb (bulb warmest or coldest) -30 – 40 RT 270

-45 – -15 RT 9

-30 – 0 RT 13

-25 – 15 RT 3

-25 – 15 RT 2, RT 7

-20 – 12 RT 8

-5 – 10 RT 12

-5 – 30 RT 14

5 – 22 RT 23

8 – 32 RT 15

15 – 34 RT 24

15 – 45 R T 140

25 – 90 RT 101, RT 102

-50 – -15 RT 17

-30 – 0 RT 11

-5 – 30 RT 4

-20 – 12 RT 8L

-5 – 30 RT 14L

15 – 45 RT 140L

-50 0 50 100 150 200 250 300

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 3

Page 4

Data sheet | Thermostat, Differential thermostat, type RT

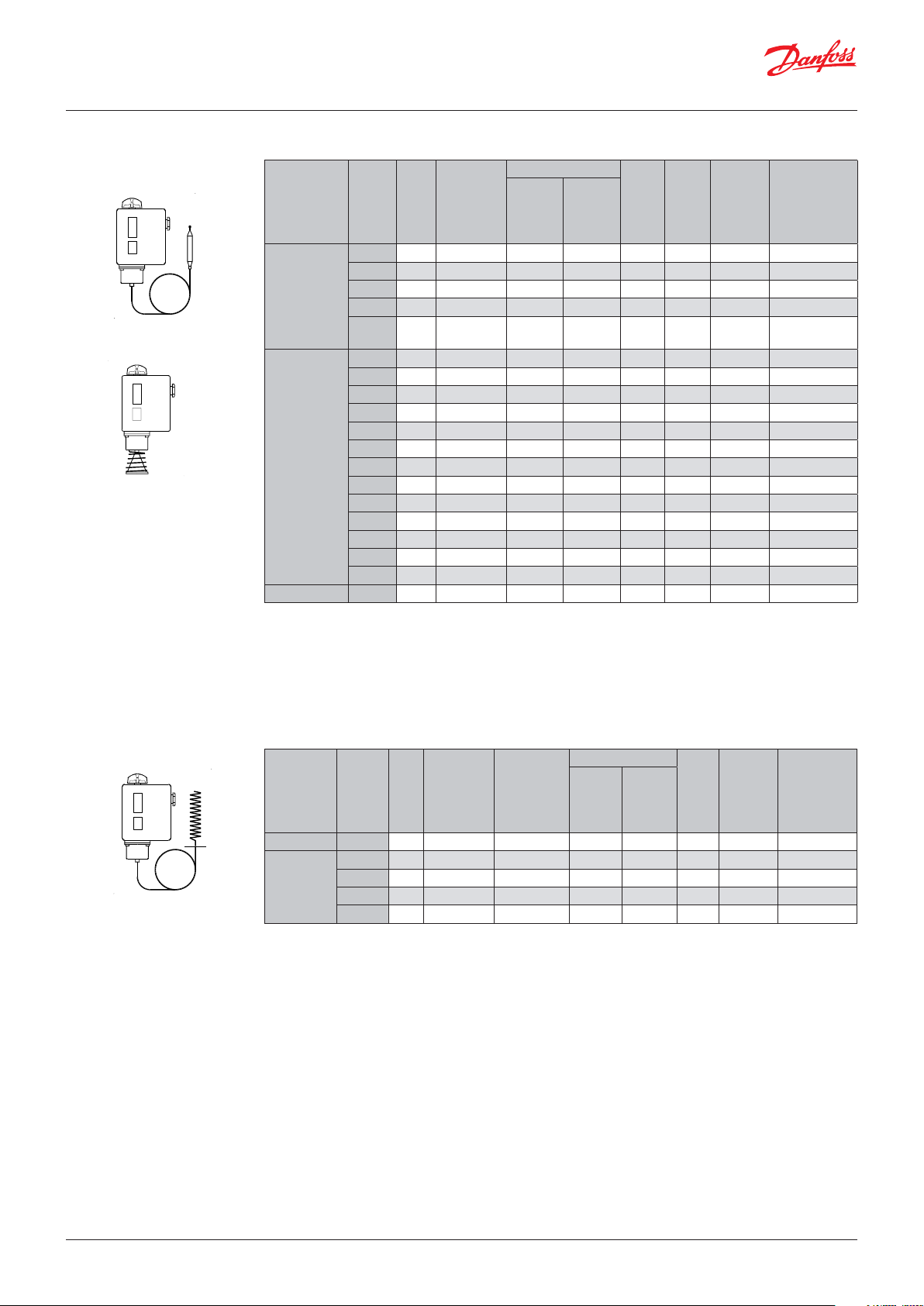

Ordering

Thermostats

Differential ∆t

Charge Type

Bulb

type

Regulation

range

At min.

range

setting

At max.

range

setting

Reset

[°C] [K] [K] [°C] [m]

RT 9 A -45 – 15 2.2 – 10.0 1.0 – 4.5 auto 150 2 017-506666

RT 3 A -25 – 15 2.8 – 10.0 1.0 – 4.0 auto 150 2 017-501466

Vapour 1)

RT 17 B -50 – -15 2.2 – 7.0 1.5 – 5.0 auto 100 – 017-511766

RT 11 B -30 – 0 1.5 – 6.0 1.0 – 3.0 auto 66 – 017- 50836 6

RT 4 B -5 – 30 1.5 – 7.0 1.2 – 4.0 auto 75 –

RT 13 A -30 – 0 1.5 – 6.0 1.0 – 3.0 auto 150 2 017-509766

RT 2 A -25 – 15 5.0 – 18.0 6.0 – 20.0 auto 150 2 017-500866

RT 8 A -20 – 12 1.5 – 7.0 1.5 – 7.0 auto 145 2 017- 506 366

RT 12 A -5 – 10 1.0 – 3.5 1.0 – 3.0 auto 65 2 017-5089 66

RT 23 A 5 – 22 1.1 – 3.5 1.0 – 3.0 auto 85 2 017-52786 6

RT 15 A 8 – 32 1.6 – 8.0 1.6 – 8.0 auto 150 2 017 -5115 66

Adsorption 2)

RT 24 A 15 – 34 1.4 – 4.0 1.4 – 3.5 auto 105 2 017-528566

RT 140 C 15 – 45 1.8 – 8.0 2.5 – 11.0 auto 240 2 017-523666

RT 102 D 25 – 90 2.4 – 10.0 3.5 – 20.0 auto 300 2 017-514766

RT 34 B -25 – 15 2.0 – 10.0 2.0 – 12.0 auto 100 – 017-511866

RT 7 A -25 – 15 2.0 – 10.0 2.5 – 14.0 auto 150 2 017-5 05366

RT 14 A -5 – 30 2.0 – 8.0 2.0 – 10.0 auto 150 2 017-509966

RT 101 A 25 – 90 2.4 – 10.0 3.5 – 20.0 auto 300 2 017- 50036 6

Partial 3) RT 107 A 70 – 150 6.0 – 25.0 1.8 – 8.0 auto 215 2 017- 51356 6

1

The sensor must be located colder than thermostat housing and capillary tube.

2

The sensor can be located warmer or colder than thermostat housing.

3

The sensor must be located warmer than thermostat housing and capillary tube.

4

With built-in heating coil − reduces the thermal differential

.

Max.

bulb

temp.

Capillary

tube

length

Code no.

017-503666

017-503766 4)

Thermostats with adjustable dead zone

Neutral zone NZ

Charge Type

Bulb

type

Regulation

range

Mechanical

differential

At min.

range

setting

At max.

range

setting

[°C] [K] [K] [K] [°C] [m]

Vapour RT 16L B 0 – 38 1.5 – 0.7 1.5 – 5.0 0.7 – 1.9 10 0 – 017L0 02466

RT 8L A -20 – 12 1.5 1.5 – 4.4 1.5 – 4.9 145 2 017L00 306 6

Adsorption

RT 14L A -5 – 30 1. 5 1.5 – 5.0 1.5 – 5.0 15 0 2 017L00346 6

RT 140 L C 15 – 45 1.8 – 2.0 1.8 – 4.5 2.0 – 5.0 24 0 2 017L003166

RT 101L A 25 – 90 2.5 – 3.5 2.5 – 7.0 3.5 – 12.5 300 2 017L00 6266

Max.

bulb

temp.

Capillary

tube

length

Code no.

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 4

Page 5

Data sheet | Thermostat, Differential thermostat, type RT

Ordering

Continued

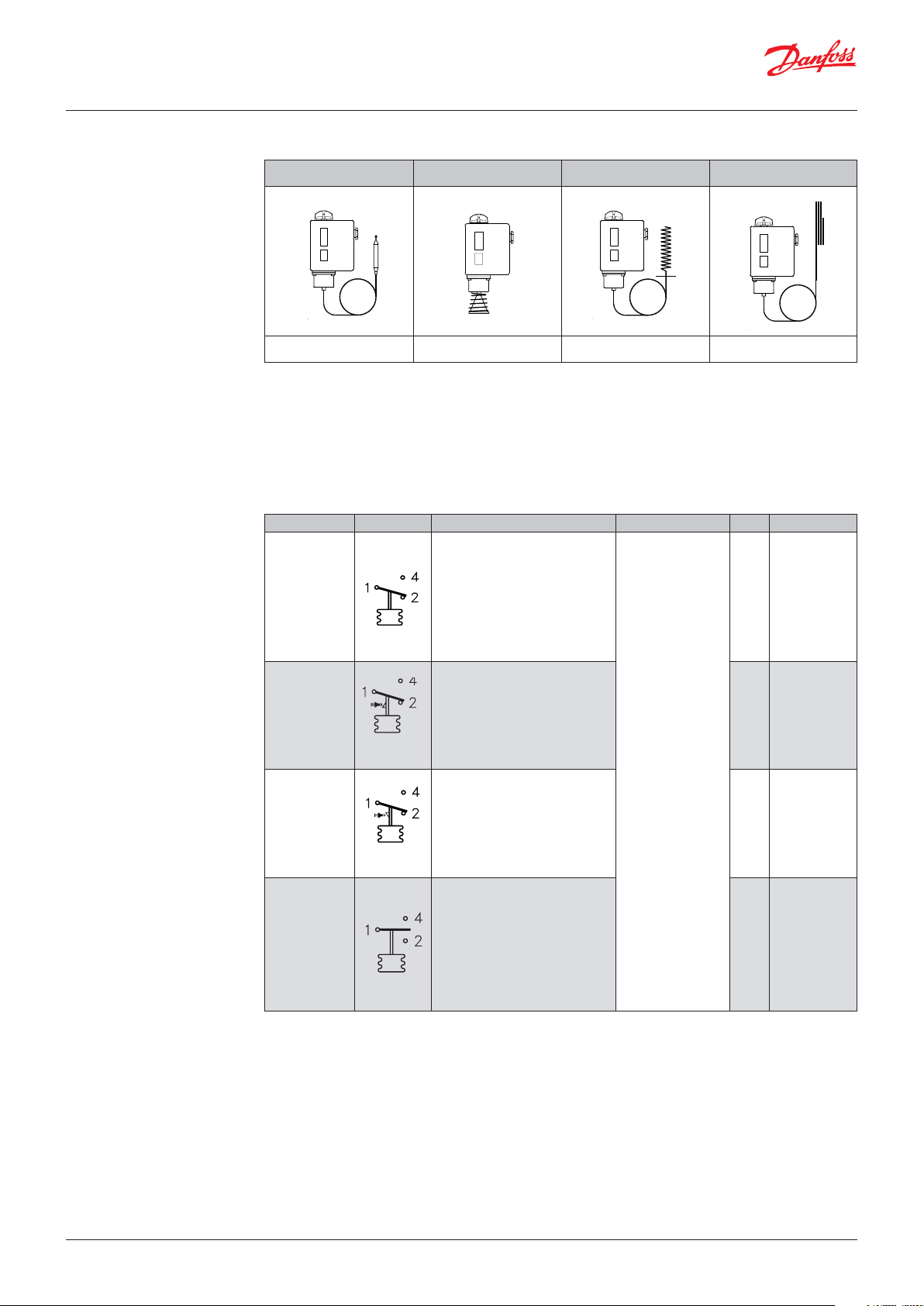

Type of bulb / sensor

A B C D

Cylindrical remote sensor Room sensor Duct sensor Capillary tube sensor

Special versions

RT can be supplied with special switches.

See next page.

When ordering, please state:

1. Ty pe

2. Code no. of standard unit

3. Code no. of special switch

Switches

Version Symbol Description Contact rating Reset Code no.

Single-pole changeover switch

with terminal board proof against

Standard

SPDT

leakage current.

Fitted in all standard

versions of type RT.

Snap action changeover contacts.

Auto 017-403066

Man.

reset

Man.

reset

Neutral

zone

SPDT

SPDT

SPDT

For manual reset of unit after

contact changeover on rising

temperature.

For units with reset facility.

For manual reset of unit after

contact changeover on falling

temperature.

For units with reset facility.

Single-pole changeover

switch with dead zone

and terminal board proof

against leakage current.

Alternating current

Ohmic:

AC 1 = 10 A, 400 V

Inductive:

AC 3 = 4 A, 400 V

AC 15 = 3 A, 400 V

Dir. current:

DC 13 = 12 W, 220 V

Max. 017-404266

Min. 017-404166

Available only

as a component

part of RT

–

controls with

adjustable

neutral zone

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 5

Page 6

Data sheet | Thermostat, Differential thermostat, type RT

Ordering

(continued)

Switches

Version Symbol Description Contact rating Reset Code no.

Single-pole changeover switch

with gold plated (oxide-free)

contact surfaces.

Standard

SPDT

Man.

reset

SPDT

Neutral

zone

SPDT

Man.

reset

SPDT

Increases cut-in reliability on alarm

and monitoring systems, etc.

Snap action changeover contacts.

Terminal board proof against

leakage current.

Single-pole changeover switch

with gold plated (oxide-free)

contact surfaces.

Increases cut-in reliability on alarm

and monitoring systems, etc.

Snap action changeover contacts.

Terminal board proof against

leakage current.

Single-pole changeover switch

with dead zone and gold plated

(oxide-free) contact surfaces.

Increase cut-in reliability on alarm

and monitoring systems, etc.

Snap action changeover contacts.

Terminal board proof against

leakage current.

Single-pole changeover switch

with gold plated (oxide-free)

contact surfaces.

Increases cut-in reliability on alarm

and monitoring systems, etc.

Snap action changeover contacts.

Terminal board proof against

leakage current.

Alternating

current

Ohmic:

AC 1 = 10 A, 400 V

Inductive:

AC 3 = 2 A, 400 V

AC 15 = 1 A, 400 V

Dir. current:

DC 13 = 12 W, 220 V

Auto 017-424066

Max. 017-404866

Available

only as a

component

–

part of RT

controls with

adjustable

neutral zone

Min. 017-40 4766

Alternating current

Single-pole changeover

Cuts in two

circuits

simultaneously

SPST

With

non-snap

action

change- over

contacts

1

) If current is led through contacts 2 – 4, i.e. terminals 2 – 4 connected but not 1, max. permissible load is increased

to 90 W, 220 V.

SPDT

The switches are shown in the position they

assume on falling temperature, i.e. after

downward movement of the RT main spindle.

The setting pointer of the control shows the scale

switch that cuts in two circuits

simultaneously on rising

temperature. Snap action

changeover contacts. Terminal

board proof against leakage

current.

Single-pole changeover switch

with non-snap action changeover

contacts.

An exception is RT with switch, code no.

017-404266, with max. reset where the setting

pointer shows the scale value at which contact

changeover occurs on rising temperature.

Ohmic:

AC 1 = 10 A, 400 V

Inductive:

AC 3 = 3 A, 400 V

AC 15 = 2 A, 400 V

Dir. current:

DC 13 = 12 W, 220 V

Alternating

or direct current

25 VA, 24 V

Max. 017-403466

1)

– 017-018166

value at which contact changeover occurs on

falling temperature.

Spare parts and accessories,

see separate spare parts catalogue.

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 6

Page 7

17-372.1

Data sheet | Thermostat, Differential thermostat, type RT

Design / Function

5. Setting knob

9. Regulation range scale

10. Loop terminal

11. Pg 13.5 screwed cable

entry

12. Main spring

14. Terminals

15. Main spindle

16. Switch

17. Upper guide bush

18. Contact arm

19. Differential temperature

setting nut

23. Bellows element

25. Fixing hole

26. Sensor (bulb) clip

28. Capillary tube

29. Sensor (bulb)

30. Sensor (bulb) pocket

31. Capillary tube gland

38. Earth terminal

44. Temperature setting

spindle

Key sketch of RT thermostat

5

44

12

17

15

19

23

28

29

RT thermostat

5

38

25

10

11

14

17

16

18

19

25

9

44

Danfoss

17-156.14

4

1

2

16

18

12

15

26 29

1

Danfoss

23

28

31

30

The thermostatic element consists of a sensor

(29) capillary tube (28) and bellows element (23).

The element contains a charge that reacts to

temperature variations at the sensor so that the

pressure on the moving bellows rises when

temperature rises.

By turning the setting knob (5) the main spring

(12) can be set to balance the pressure

in the element.

A rise in temperature at the sensor compresses

the bellows and moves the main spindle (15)

upwards until spring force and element pressure

are in equilibrium.

The main spindle (15) is fitted with a guide bush

(17) and a differential setting nut (19) that

together transfer the main spindle movement

to the switch (16).

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 7

Page 8

17-331.15

Data sheet | Thermostat, Differential thermostat, type RT

Design / Function

(continued)

5. Setting knob

9. Regulation range scale

12. Main spring

15. Main spindle

16. Switch

17. Upper guide bush

18a and 18b. Contact arm

20. Lower guide bush

23. Bellows element

25. Fixing hole

28. Capillary tube

29. Sensor (bulb)

40. Neutral zone setting nut

44. Temperature setting

spindle

Key sketch RT L thermostat with neutral zone

44

12

15

17

20

40

23

28

29

4

1

2

18a

16

18b

Danfoss

RT L thermostat with neutral zone

Danfoss

17-428.19

25

44

17

20

5

9

18a

16

18b

25

40

RT L thermostats are fitted with a switch with an

adjustable neutral zone. This enables the units to

be used for floating control.

The neutral zone switch contact arms (18a) and

(18b) are operated by the spindle guide bushes

(17) and (20).

temperature

Neutral zone

4

1

2

4

1

4

1

2

2

NZ

Set temperature

The upper guide bush (17) is fixed while the

lower guide bush (20) can be moved up or down

by the setting nut (40). In this way the neutral

zone can be varied between a minimum value

(equal to the mechanical differential of the unit)

and a maximum value (depending on the type of

RT unit).

4

1

4

1

2

2

Danfoss

Differential

Mechanical

differential

~NZ minimum

Differential

time

17-429.13

Terminology Floating control

A form of delayed control where the correcting

element (e.g. valve, damper, or similar) moves

towards one extreme position at a rate

independent of the magnitude of the error when

the error exceeds a definite positive value, and

towards the opposite extreme position when the

error exceeds a definite negative value.

© Danfoss | DCS (az) | 2017.09

Hunting

Periodic variations of the controlled variable

from the fixed reference.

Neutral zone

The interval between the make points

of the two contacts.

DKRCC.PD.CB0.A9.02 | 520H12296 | 8

Page 9

17-676.16

-1

-2

-3

-4

[z]

Data sheet | Thermostat, Differential thermostat, type RT

Charges 1. Vapour charge

[p]

Pressure

t t t t

Here the interdependence between the pressure

and temperature of saturated vapour is utilized,

i.e. the element is charged with saturated vapour

plus a small amount of liquid.

The charge is pressure-limited; a further increase

in pressure after evaporation of all the liquid in

the bulb, will only result in a small pressure

increase in the element.

Temperature

Danfoss

[t]

This principle can be utilized in thermostats for

low temperature, etc., where evaporation must

be able to take place from the free liquid surface

in the bulb (within the operation range of the

17-301.12

thermostat), and where at the same time, the

bellows must be protected against deformation

when kept at normal ambient temperatures.

Since the pressure in the element depends on

the temperature at the free liquid surface, the

thermostat must always be placed so that the

bulb is colder than the rest of the thermostatic

element.

The evaporated liquid will recondense at the

coldest point, i.e. the bulb. Thus, as intended, the

bulb becomes the temperature-controlling

element in the system.

Note:

When the bulb is coldest, the ambient

temperature has no effect on regulating

accuracy.

2. Adsorption charge

Scale deviation factor

[p]

Pressure

Danfoss

Temperature

t t

v

[t]

t

In this case the charge consists partly of a

superheated gas and partly of a solid having a

large adsorption surface.

17-303.12

4

o

C

30

10

-10

-30

70

o

C

50

o

C

o

20

C

100%50%

o

C

o

C

o

C

3

2

1

0

Danfoss

Relative

scale

setting

(%)

The solid is concentrated in the bulb and it is

therefore always the bulb that is the

temperature-controlling part of the thermostatic

element.

Curves for different ambient temperatures.

The bulb can thus be placed warmer or colder

than the rest of the thermostatic element.

Such a charge is however to some extent

0% ~ lowest scale setting temperature,

100% ~ highest scale setting temperature.

sensitive to changes in the temperature of the

bellows element and capillary tube.

Under normal conditions this is not important,

but if the thermostat is used in extreme

conditions, scale deviation will occur.

The scale can be corrected by using the graph

and the table.

Scale correction = Z × a.

Z can be found in the graph and "a" in the table.

Typ e Range [°C]

RT 2 -25 – 15 2.3

RT 7 -25 – 15 2.9

RT 8, RT 8L -20 – 12 1.7

RT 12 -5 – 10 1.2

RT 14, RT 14L -5 – 30 2.4

RT 15 8 – 32 1.2

RT 23 5 – 22 0.6

© Danfoss | DCS (az) | 2017.09

RT 24 15 – 34 0.8

RT 101, RT 102 25 – 90 5.0

RT 140, RT 140L 15 – 45 3.1

DKRCC.PD.CB0.A9.02 | 520H12296 | 9

Correction

factor “a”

Page 10

Data sheet | Thermostat, Differential thermostat, type RT

Charges

(continued)

Example

Scale correction on an RT 14 (range -5 – 30 °C)

at activating temperature 12 °C and ambient

temperature -10 °C.

The scale temperature, 12 °C, lies approximately

in the middle of the scale range, i.e. relative scale

setting of 50%.

The factor Z can be found in the graph from 50%

and the curve for -10 °C, i.e. approx. -1.2.

3. Partial charge

[p]

Pressure

Danfoss

17-302.12

Temperature

t tt

[t]

Partial charge is used in RT units having a range

lying higher than ambient temperature.

As with the vapour charge, the partial charge

utilizes the interdependence between the

pressure and temperature of saturated vapour.

The correction factor “a” can be found in the table

for an RT 14, i.e. 2.4.

The scale correction = Z×a=-1.2×2.4=-2.88.

If activation at 12 °C for the same conditions is

required, the thermostat must be set at

12×2.88=9.12≈9.1.

The partial charge is of such a volume that the

bellows housing, capillary tube and a small part

of the bulb are filled when the thermostat is in

operation. The bulb is thus the warmest part of

the system.

The liquid will condense in the remaining,

coldest, part of the system but because of the

volume of the charge the free liquid surface will

always be in the bulb. In this way, the bulb

becomes the temperature-controlling part of the

system.

Note:

When the bulb is placed warmest, the ambient

temperature has no effect on regulating

accuracy.

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 10

Page 11

Data sheet | Thermostat, Differential thermostat, type RT

Design / Function RT differential thermostat

Danfoss

17-378.12

1. LT sensor (bulb)

2. Capillary tube

4. LT bellows element

5. Setting disc

9. Regulation range scale

10. Loop terminal

11. Pg 13.5 screwed cable

entry

12. Main spring

14. Terminals

15. Main spindle

16. Switch

17. Upper guide bush

18. Contact arm

20. Lower guide bush

24. HT bellows element

25. Fixing hole

28. Capillary tube

32. HT sensor (bulb)

38. Earth terminal

39. Blow-out disc

1

25

32

An RT differential thermostat contains a singlepole changeover switch that makes or breaks

depending on the temperature difference

between the two sensors of the unit.

The RT 270 017D003166 is for use in process

plant, ventilation plant, and refrigeration and

heating plant where there is need to maintain

a certain temperature differential, 0 – 15 °C,

between two media. One sensor is used as a

reference and the other as a control sensor. The

temperature differential is the direct controlled

variable.

2

4

5

9

10

11

12

14

15

16

17

18

20

25

38

39

24

28

Within the operating range the RT 270 can be

set for different temperature differentials by the

setting disc (5).

When the differential between LT and HT sensor

temperature falls, the main spindle (15) moves

downwards.

The contact arm (18) is moved downwards by

the guide (17) so that contacts (1-4) break and

contacts (1-2) make when the set temperature

differential is reached.

The contacts changeover again when the

temperature differential rises to the set value plus

the fixed contact differential of approx. 2 °C.

© Danfoss | DCS (az) | 2017.09

The figure shows a cross-section of the RT 270.

The differential thermostat contains two bellows

elements: the LT element whose sensor must be

placed in the medium having the lowest

temperature, and the HT element whose sensor

must be placed in the medium having the

highest temperature.

The main spring has a rectilinear characteristic.

Example

Set differential =4 °C.

Switch breaks at 4 °C differential and remakes at

4+2= 6 °C.

DKRCC.PD.CB0.A9.02 | 520H12296 | 11

Page 12

Data sheet | Thermostat, Differential thermostat, type RT

Terminology Regulation range

The temperature differential between LT and

HT sensors within which the unit can be set to

operate. Indicated on the thermostat scale.

Scale indication

The difference between the temperature on LT

and HT sensors at the moment when the switch

contacts change over as a result of the downward

movement of the spindle.

Operating range

The temperature range of the LT sensor, within

which the differential thermostat can operate.

Setting of differential The knob can be used to make a setting on the

range scale for the lowest temperature at which

the contact system must be activated

(cut-out or cut-in).

Contact differential

The temperature rise on the HT sensor over the

set temperature differential which causes the

switch contacts to make or break.

Reference sensor

The sensor that is placed in the medium whose

temperature is not affected by the function of the

thermostat (HT or LT sensor).

Control sensor

The sensor that is placed in the medium whose

temperature must be controlled

(LT or HT sensor).

The differential roller 19 must then be used

to set the differential. The highest activating

temperature at the sensor is equal to the

activating temperature + the set differential.

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 12

Page 13

AB

AB

AB

AB

AB

AB

AB

AB

AB

Data sheet | Thermostat, Differential thermostat, type RT

Nomograms for

obtained differentials

RT 2 RT 3 RT 4

[°C] [°C]

15

10

5

0

-5

-10

-15

-20

-25

RT 7

[°C] [°C]

15

10

5

0

-5

-10

-15

-20

-25

10 9

C

5

6

1

Danfoss

17-435.14

7

8

9

10

4 3 2

11

5

12

13

14

7 6

15

16

17

18

10 9 8

19

C

20

[°C] [°C]

-25

-20

-15

-10

-5

0

5

10

15

RT 9

1

Danfoss

17-436.17

2

1

2

3

3

4

4

5

6

7

5

8

10 9

C

6

7

8

9

10

10

15

20

25

30

RT 10

[°C] [°C]

Danfoss

17-780.13

-60

-55

-50

-45

-40

-35

-30

-25

2

1

3

2

4

3

5

4

6

7

6 5

7

8

9

8

10

11

Danfoss

17-791.13

-45

-35

-25

6

7

8

9

10

C

12

13

14

-15

1

1

2

2

3

3

4

5

4

5

6

7

8

9

10

[°C] [°C]

-5

0

5

1

2

3

4

5

6

7

8

9

10

C

[°C] [°C]

1

2

3

4

5

6

7

8

9

10

C

1

1.2

2

3

4

5

6

7

Danfoss

17-790.13

1

Danfoss

17-781.13

2

3

4

5

6

7

A = Range setting

B = Obtained differential

C = Differential setting

RT 11, RT 13

[°C] [°C]

-30

2

-25

-20

-15

-10

-5

0

3

4

5

6

7

8

9

10

C

RT 12

[°C] [°C]

17-240.19

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

10

1

1

Danfoss

2

3

4

5

6

1

1

1,5

5 4 3 2

2

6

2,5

9 8 7

3

10

C

3,5

Danfoss

17-792.13

RT 24

[°C] [°C]

15

20

25

30

10 9

35

1

1,4

Danfoss

17-779.13

1,5

2 1

3

2

4

5

2,5

6

7

3

8

3,5

C

4

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 13

Page 14

AB

AB

AB

AB

AB

AB

AB

Data sheet | Thermostat, Differential thermostat, type RT

Nomograms for

obtained differentials

(continued)

RT 14

[°C] [°C]

30

25

20

15

10

5

0

8 7

9

10

C

-5

RT 34

[°C] [°C]

15

10

5

0

-5

-10

-15

-20

-25

9

10

C

RT 17

1

2

3

3 2

4

5

6

Danfoss

4

5

6

7

8

9

10

[°C] [°C]

-50

17-793.13

-40

-30

-20

-15

1.5

2

1

2

3

3

4

5

6

4

7

8

5

9

10

C

6

7

RT 101

1

2

Danfoss

4

5 4 3 2

6

6

7

8

8

10

12

[°C] [°C]

90

17-795.14

80

70

60

50

40

30

25

2

1

4

2

3

6

4

5

8

6

7

8

9

10

C

10

12

14

16

18

20

Danfoss

17-471.18

Danfoss

17-452.18

RT 23

[°C] [°C]

5

10

15

20

8 7

9

10

C

22

RT 107

[°C] [°C]

70

80

90

100

110

120

130

140

150

1

2

3

4

5

6

7

8

9

10

C

1

Danfoss

1,5

2

17-794.13

3 2 1

4

5

6

2,5

3

3,5

1,8

Danfoss

17-796.12

5

10

15

20

25

A = Range setting

B = Obtained differential

C = Differential setting

RT 140

[°C] [°C]

45

40

35

30

25

20

15

5

6

7

8

9

10

C

1

2

1

Danfoss

2

3

4

17-319.18

3

4

5

6

7

8

9

10

11

© Danfoss | DCS (az) | 2017.09

DKRCC.PD.CB0.A9.02 | 520H12296 | 14

Page 15

Data sheet | Thermostat, Differential thermostat, type RT

Dimensions [mm]

and weights [kg]

RT thermostat housing

RT 4, RT 11, RT 16L, RT 17, RT 34 RT thermostat housing RT 140, RT 140L

© Danfoss | DCS (az) | 2017.09

RT 2, RT 3, RT 7, RT 9,

RT 13, RT 101

RT 14L, RT 15, RT 107,

RT 270

RT 12, RT 23, RT 24RT 8, RT 8L, RT 14,

DKRCC.PD.CB0.A9.02 | 520H12296 | 15

RT 102

Net weight approx. 1 kg

Page 16

© Danfoss | DCS (az) | 2017.09 DKRCC.PD.CB0.A9.02 | 520H12296 | 16

Loading...

Loading...