Page 1

User manual

DHP-S&DP

VUIFM102

Page 2

If these instructions are not followed during

installation and service, Danfoss A/Sliability

according to the applicable warranty is not

binding. Danfoss A/S retains the right to

make changes to components and specifications without prior notice.

© 2010 Copyright Danfoss A/S.

The Swedish language is used for the original

instructions. Other languages are a translation of original instructions.

(Directive 2006/42/EG)

Page 3

Contents

1 Important information......................................................................................................................... 3

1.1 Safety precautions

................................................................................................................................... 4

1.2 Protection.................................................................................................................................................... 5

2 About your heat pump........................................................................................................................ 6

2.1 Product description................................................................................................................................. 6

2.2 The principles of the heat pump........................................................................................................ 6

2.3 Hot water tank (option).......................................................................................................................... 8

2.4 Room sensor (option)............................................................................................................................. 8

3 Operating instructions......................................................................................................................... 9

3.1 Control panel............................................................................................................................................. 9

3.2 Checking the coolant circuit pressure............................................................................................ 14

3.3 Checking the water level in the heating system........................................................................ 15

3.4 Checking safety valves......................................................................................................................... 15

3.5 In the event of leakage......................................................................................................................... 16

4 Menu information............................................................................................................................... 17

4.1 INFORMATION menu............................................................................................................................ 17

5 Troubleshooting.................................................................................................................................. 25

5.1 Alarm.......................................................................................................................................................... 25

6 Terms and abbreviations.................................................................................................................. 26

7 References............................................................................................................................................. 28

VUIFM102 – 1

Page 4

Page 5

1 Important information

Note! If the installation is not used during the winter, the heating

system must be drained of water, otherwise there is a risk of frost

damage to the installation.

The system can be considered maintenance free but certain checks are

necessary.

Before changing the control computer’s settings, first find out what these

changes mean.

Contact your installer for any service work.

Caution! This apparatus is not intended for persons (including

children) with reduced physical, sensory or psychological

capacity, or who do not have knowledge or experience, unless

supervised or they have received instructions on how the

apparatus functions from a safety qualified person.

Note! Children are not permitted to play with the apparatus.

User manual VUIFM102 – 3

Page 6

1.1 Safety precautions

1.1.1 Installation and maintenance

DANGER! Only authorized installers may install, operate and

carry out maintenance and repair work on the heat pump.

DANGER! Only authorized electricians may modify the electrical

installation.

DANGER! DANGER TO LIFE! Only authorized refrigeration

technicians may work on the refrigerant circuit.

1.1.2 System modifications

Only authorized installers may carry out modifications on the following

components:

•

The heat pump unit

•

The pipes for the refrigerant, brine, water and power

•

The safety valve

Do not carry out construction installations that may affect the operational

safety of the heat pump.

1.1.3 Safety valve

The following safety precautions apply to the hot water circuit’s safety

valve with corresponding overflow pipe:

•

Never block the connection to the safety valve’s overflow pipe.

•

Water expands when it is heated, this means that a small amount of

water is released from the system via the overflow pipe. The water

that exits the overflow pipe can be hot! Therefore, allow it to flow to

a floor drain where there is no risk of burning yourself.

4 – User manual

VUIFM102

Page 7

1.2 Protection

1.2.1 Corrosion Protection

Due to the risk of corrosion, avoid using different types of sprays in the

vicinity of the heat pump. This particularly applies to:

•

Solvents

•

Chlorinated cleaning agents

•

Paints

•

Adhesives

User manual VUIFM102 – 5

Page 8

2 About your heat pump

2.1 Product description

The heat pump is a heating system for heating and hot water if an external

water heater is installed (accessory). It has a compressor developed solely

for heat pumps.

The heat pump is equipped with control equipment which is presented

in a graphical display. The control equipment is also prepared for monitoring via the internet.

Heat enters the house via a water borne heating system. The heat pump

supplies as much of the heat demand as possible before auxiliary heating

is engaged and assists. Additional heater is an accessory.

The heat pump heating system consists of two basic units:

•

Heat pump unit

•

Control equipment

The heat pump unit consists of the following components:

•

Scroll compressor

•

Stainless steel heat exchanger: condenser, evaporator and de-superheater

•

Circulation pumps for collector- and heating system

The control equipment controls the components included in the heating

installation (compressor, circulation pumps and exchange valve) and

determines when to start and stop the pump as well as producing heat

for the house or hot water. If the additional heat (accessory) is installed

the additional heating is controlled by the control equipment. The control

equipment unit consists of the following components:

•

Control computer, as well as operator’s panel with graphical display

•

Temperature sensors (outdoor, supply line, return line and hot water)

•

Room sensor (option)

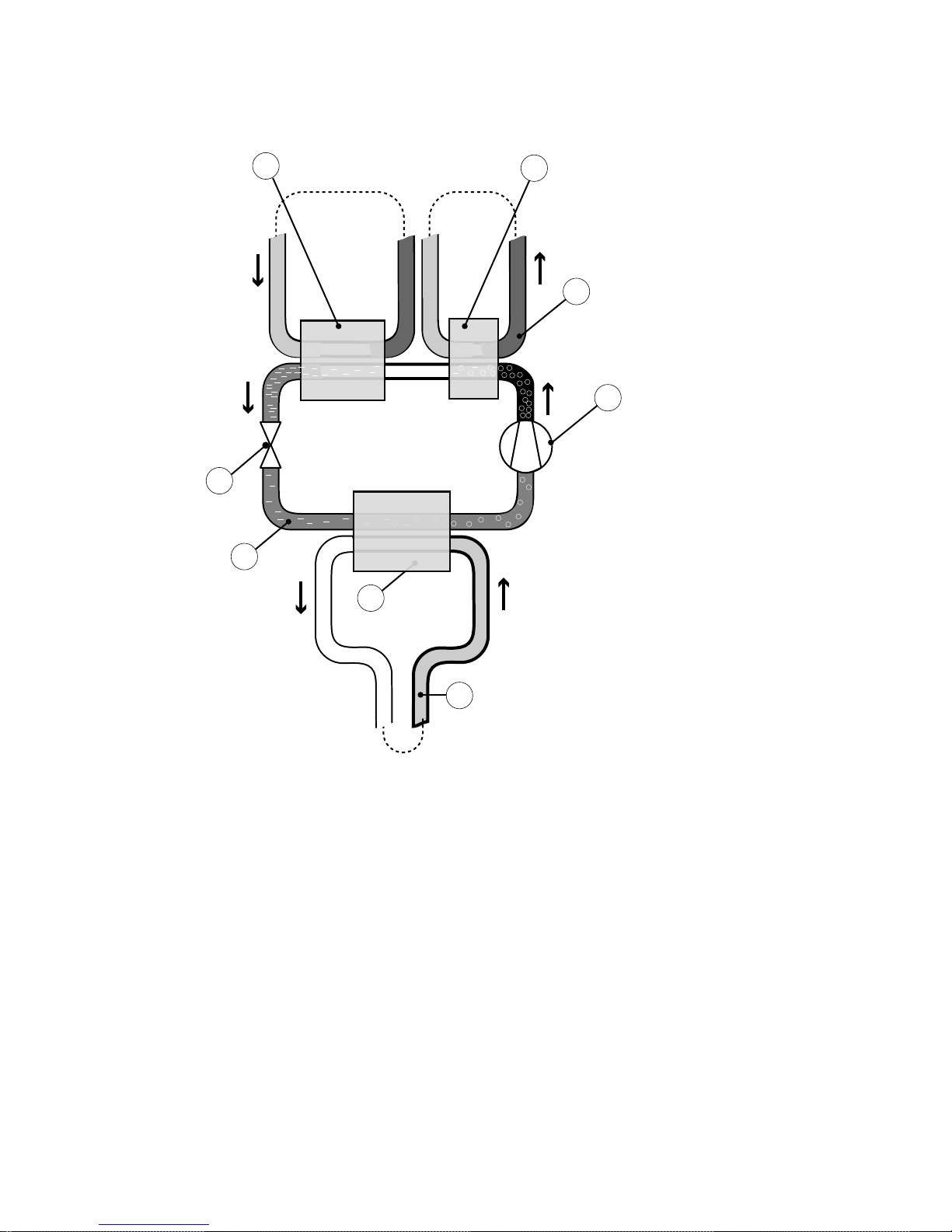

2.2 The principles of the heat pump

A heat pump utilises the energy found in a natural heat source. Simply

put, it obtains energy in the form of heat from a heat source.

6 – User manual VUIFM102

Page 9

The heat pump is, therefore, a very environmentally friendly and economical way of heating a house.

5

4

7

1

2

3

6

8

Figure 1. The principles of the heat pump

The heat pump has four separate fluid circuits

•

Brine circuit (1) – is a fluid (brine) filled hose lowered into a lake, buried

in the ground or lowered into bedrock. The brine obtains energy from

the surroundings by the fluid temperature in the hose being heated

a few degrees.

•

Refrigerant circuit (7) – is a circuit in the heat pump that through

evaporation, compression and condensation takes energy from the

brine circuit and supplies it to the heat transfer fluid circuit. The refrigerant is chlorine free.

User manual VUIFM102 – 7

Page 10

•

Heat transfer fluid circuit (8) – is the water that transports the heat/

energy to the heating system and the hot water tank.

•

Hot gas circuit – is a high temperature circuit for the hot water circuit’s

final heater. If the heat pump is not connected to any water heaters,

the hot gas circuit does not need to be connected.

1. The brine circuit (1) evaporates the refrigerant in the evaporator

(2), using heat from lake, ground or rock. The refrigerant is turned

to gas.

2. The refrigerant passes the compressor (3) where the pressure and

temperature are raised.

3. The refrigerant then continues to the de-superheater (4). Here a

small high temperature output is used, for example, to top up the

hot water temperature.

4. The heat transfer fluid circuit (hot gas circuit) condenses refrigerant

to liquid form in the condensor (5), by giving off heat to the house

and hot water.

5. The refrigerant then passes through the expansion valve (6) where

the pressure and temperature drop and converts the refrigerant

from liquid to liquid and gas. The process then starts again.

2.3

Hot water tank (option)

The heat pump can also produce hot water for an external water heater.

The water temperature of the hot water tank is controlled by the control

switch and cannot be adjusted.

Hot water production stops when the control switch reaches its maximum

operating pressure.

2.4 Room sensor (option)

The heat pump system can be equipped with a room sensor as an option.

Only authorised electricians may carry out the installation.

See wiring diagram for connections.

8 – User manual

VUIFM102

Page 11

3 Operating instructions

3.1 Control panel

3.1.1 Function description

The heat pump has an integrated control system which automatically calculates the heat demand in the house to ensure that the correct amount

of heat is produced and emitted where necessary. There are many different values (parameters), which are required in order to do the calculation

of the heat demand.

During installation and service, the control panel is used to set and change

values that have to be adapted according to the house demand. The control panel is integrated into the front of the heat pump and consists of a

display, a keypad and an indicator. In the display, a simple menu system

is used to navigate the desired settings and values. During operation, the

User manual VUIFM102

– 9

Page 12

display always shows the set ROOM value, the operating mode and the

status of the heat pump.

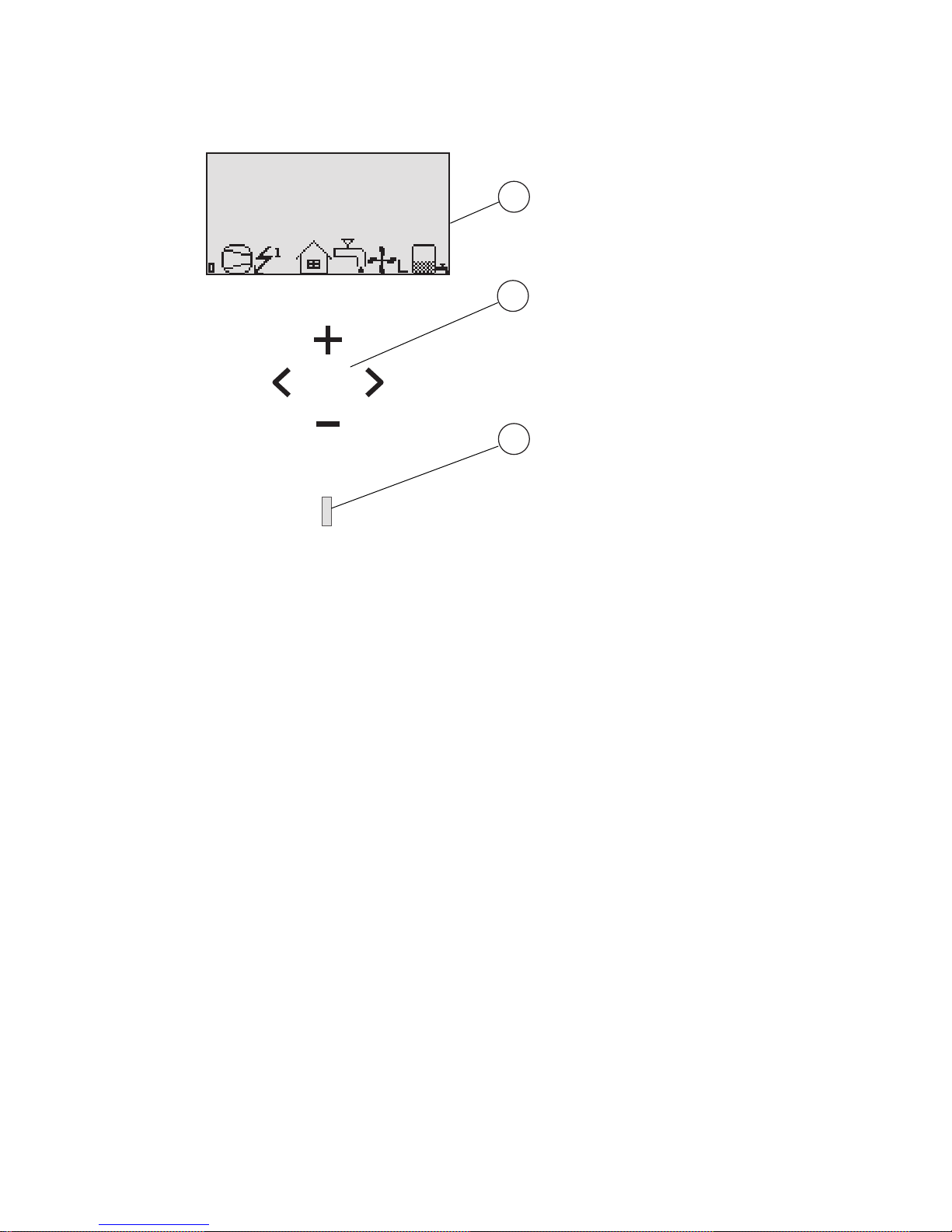

3

2

1

ROOM

NO HEAT DEMAND

OPERAT. AUTO

20°C

(20°C)

Figure 2. Display, keypad and indicator.

Position Description

1 The display text and symbols are only shown as examples. Certain

symbols cannot be displayed at the same time.

2 Keypad:

+ Plus sign used to scroll up a menu or increase the values.

- Minus sign used to scroll down a menu or reduce the values.

> Right arrow used to select a value or open a menu.

< Left arrow to cancel selection or exit a menu.

3 Indicator

The control system is operated via a user-friendly menu system, which is

shown in the display. Use the keypad’s four navigation symbols to navigate the menus and increase or reduce the set values.

The INFORMATION menu is opened by pressing the left or right buttons.

The INFORMATION menu has a number of sub menus, see Menyinformation.

10 – User manual VUIFM102

Page 13

For installation and service, the SERVICE menu is used, which is opened

by pressing the left button for five seconds. The SERVICE menu has a

number of sub menus, see Menu information.

The INFORMATION and SERVICE menus are intended for two categories

of user, customers and installers. Customers may only open the INFORMATION menu with a limited number of settings. Installers have to be able

to change many settings in the control settings. The SERVICE menu is

therefore hidden from the customers.

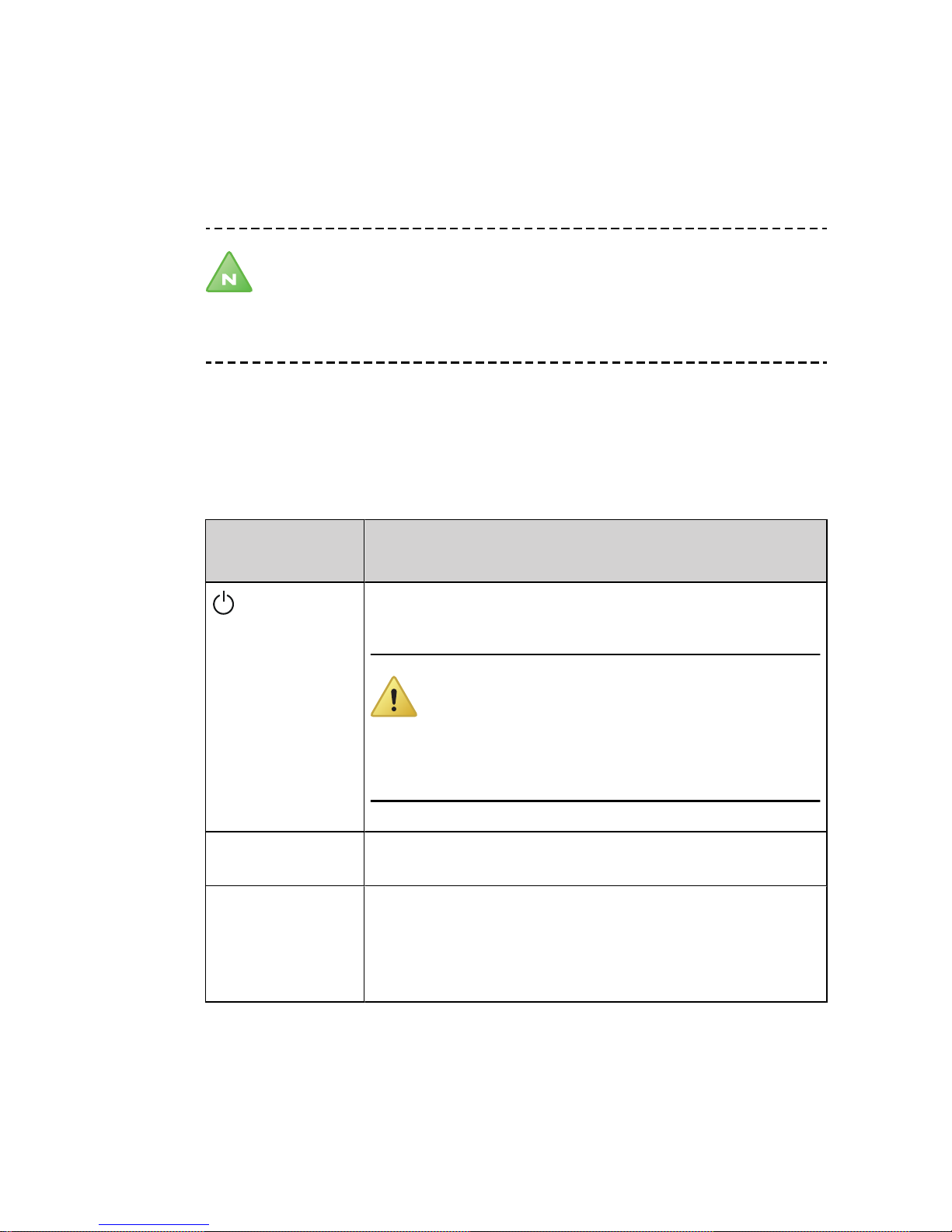

1

2

Figure 3. The menus are reached by pressing different buttons.

Position Description

1 Information menu

Press the left or right buttons.

2 Service menu

Press and hold the left button for at least five seconds

The indicator at the bottom of the control panel has three modes:

•

Not lit, means that the heat pump is not powered.

•

When the light shines continuously, the heat pump has power and is

ready to produce heat or hot water.

•

Flashing, means an active alarm

Caution! During a service that consists of replacing the display

card, all heat pump settings are reset to factory settings.

Therefore note current settings before replacement.

User manual VUIFM102 – 11

Page 14

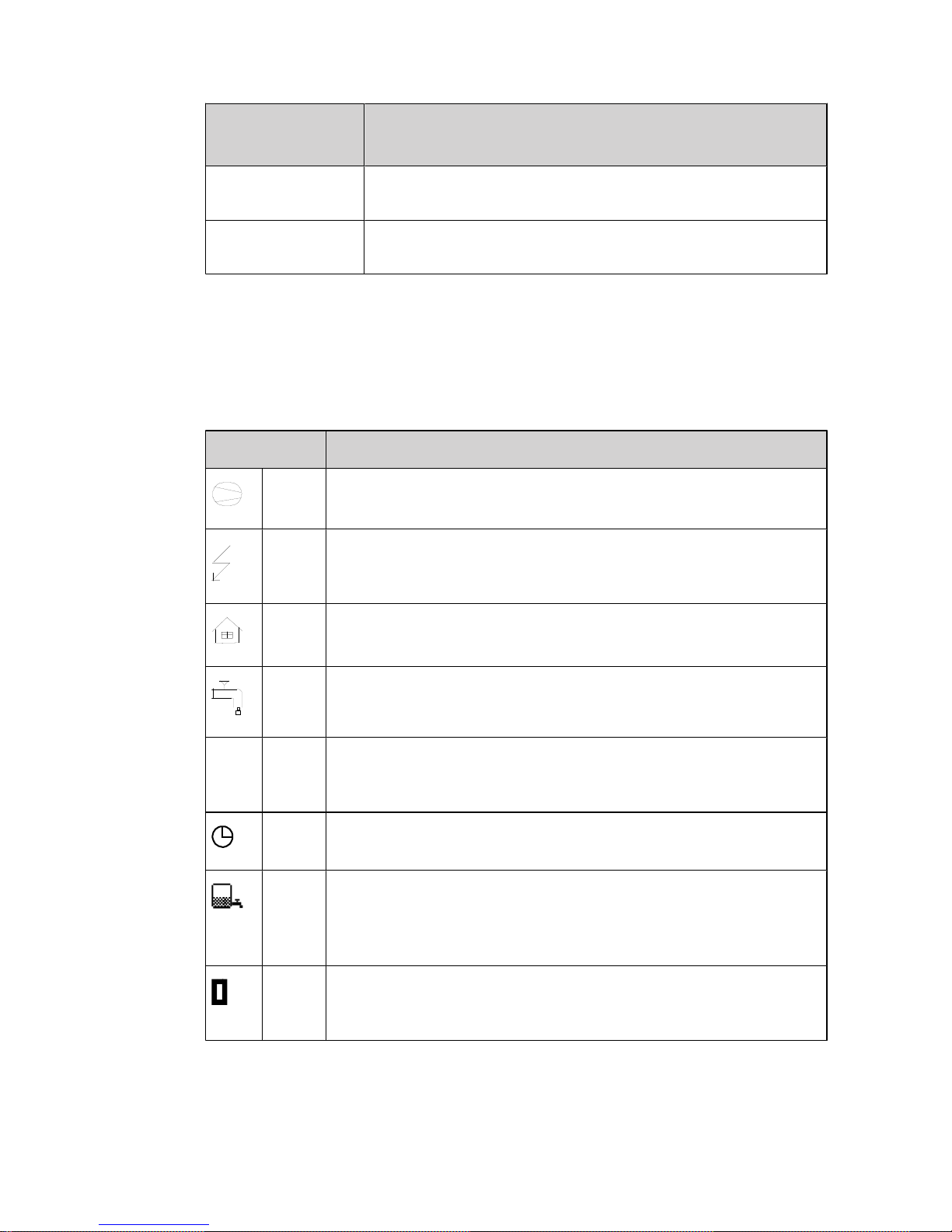

3.1.2 Display

The display shows information about the heat pump’s operation, status

and any alarms, in text form. Operating mode and status, indicated by

symbols, are also shown in the lower part which shows the heat pump’s

active processes.

Note! To change the display language, press the following

sequence of buttons: right arrow, arrow down to bottom menu,

arrow right, scroll between languages using + or -. Then select

language using right arrow.

3.1.2.1 Operating modes

Table 1. Shows the set operating mode of the heat pump.

Operating

mode

Meaning

(OFF)

The installation is fully switched off. This mode is also used

to acknowledge certain alarms.

Caution! If the operating mode OFF is to be

used for long periods during the winter, the

water in the heating system in the heating

system must be drained, otherwise there is a

risk of frost damage.

AUTO The heat pump and the auxiliary heater are automatically

controlled by the control system.

HEAT PUMP The control system is controlled so that only the heat pump

unit (compressor) is allowed to operate. In this operating

mode peak heating charging (anti-legionella function) of

the hot water will not run because the auxiliary heater is not

used.

12 – User manual VUIFM102

Page 15

Operating

mode

Meaning

AUX. HEATER The control system only permits the auxiliary heater to be

in operation.

HOT WATER In this mode the heat pump only produces hot water, no

heat goes to the heating system.

3.1.2.2 Symbols

Table 2. Symbols shown in the display.

Symbol Meaning

HP Indicates that the compressor is in operation.

1

LIGHT

NING

Indicates that the auxiliary heater is in operation. The number

indicates what additional step is activated.

HOUSEIndicates that the heat pump produces heat for the heating sys-

tem.

TAP Indicates that the heat pump produces heat for the water heater.

F FLOW

SENSOR

An F indicates that a flow sensor is installed.

CLOCKIndicates that tariff control is active.

TANK Indicates the level of hot water in the water heater. When hot

water is produced for the water heater, this is indicated by a

flashing icon for the tank. A lightning symbol by the symbol

indicates peak heating charging (anti-legionella function).

SQUAREEither indicates that the operating pressure switch has deployed,

or that the pressure pipe temperature has reached its maximum

temperature.

User manual VUIFM102 – 13

Page 16

3.1.2.3 Operational information

Table 3. Shows information about the heat pump.

Message Meaning

ROOM Shows the set ROOM value. Standard value: 20°C.

If the accessory room sensor is installed it shows the

actual temperature and the desired indoor temperature

is shown within brackets.

START Indicates that there is a need for heat production and that

the heat pump will start.

EVU STOP Indicates that the additional function EVU is active. This

means that the heat pump is off as long as EVU is active.

NO HEAT DEMAND Indicates that there is no heating production demand.

HEAT PUMP START --XXIndicates that there is a heating production demand and

will start in XX number of minutes.

HEAT PUMP+AUX.

HEAT

Indicates that heat production is active with both compressor and auxiliary heater.

AUX. HEATER Indicates that there is an auxiliary heater demand.

3.2 Checking the coolant circuit pressure

The brine circuit must be filled with the correct amount of fluid otherwise

the installation may become damaged.

Ensure that system has the necessary pressure, however, not above maximum pressure of 6 bar.

14 – User manual VUIFM102

Page 17

See the installation instructions when filling brine.

1

2

Figure 4. Filling the brine

system

Symbol explanation

1 Used when filling

2 Connected to brine circuit

3.3 Checking the water level in the heating system

The line pressure of the installation must be checked once a month. Ensure

that heating system has the necessary pressure, however, not above maximum pressure of 6 bar.

You can use normal tap water when topping up the heating system. In

certain exceptional cases the water quality may be so poor (for example

very hard water) that it is not suitable for filling the heating system. If

unsure, contact your installer.

Do not use any additives for water treatment in the heating system’s water!

3.4 Checking safety valves

Both the safety valves for the heating system must be checked at least

four times a year to prevent lime deposits clogging the mechanism.

The safety valve of the water tank protects the enclosed heater against

over pressure in the water tank. It is mounted on the cold water inlet line,

its outlet opening facing downwards. If the safety valve is not checked

User manual VUIFM102 – 15

Page 18

regularly, the water tank might be damaged. It is quite normal that the

safety valve lets out small amounts of water when the water tank is being

charged, especially if a lot of hot water was used previously.

Both safety valves can be checked by turning the cap a quarter of a turn

clockwise until the valve lets out some water through the overflow pipe.

If a safety valve does not work properly, it must be replaced. Contact your

installer.

The opening pressure of the safety valves is not adjustable.

3.5 In the event of leakage

In the event of leakage in the hot water pipes between the unit and water

taps, close the shut-off valve on the cold water inlet immediately. Contact

your installer, see References, Page 28.

In the event of leakage in the brine circuit, turn off the heat pump and call

your installer immediately, see References, Page 28.

16 – User manual VUIFM102

Page 19

4 Menu information

4.1 INFORMATION menu

Open the menu by pressing the left or right button. The menu also shows

history and operating times.

Menus in italics are only visible if the expansion card (accessory) is installed.

Table 4. Used to change the heat pump's operating modes and to adjust

the heat curve.

Menu Sub menu Sub menu Sub menu

INFORMATION

OPERAT.

Ø CANCEL

Ø

AUTO

HEAT PUMP

AUX. HEATER (must

be activated)

HOT WATER (must be

activated)

MANUAL TEST

HEAT CURVE

CURVE

MIN

MAX

CURVE 5

CURVE 0

CURVE -5

HEAT STOP

REDUCTION

TANK TEMP (if buffer tank is activated)

OVERCHARGE (if buffer tank is activated)

ROOM FACTOR (if a room sensor is installed)

POOL (expansion card)

POOL HYSTERESIS (expansion card)

HEAT CURVE 2 (if shunt group is activated)

User manual VUIFM102 – 17

Page 20

Menu Sub menu Sub menu Sub menu

CURVE

MIN

MAX

TEMPERATURE

OUTDOOR

ROOM (if a room sensor is installed)

SYSTEM SUPPLY (if buffer tank is activated)

SUPPLY LINE

RETURN LINE

BUFFER TANK (must be activated)

HOT WATER (must be activated)

INTEGRAL

BRINE IN

BRINE OUT

POOL (expansion card)

COOLING

SHUNT GROUP (must be activated)

2ND HEAT CIR.

CURRENT (expansion card)

OPERAT. TIME

HEAT PUMP

AUX. HEAT 1

AUX. HEAT 2

AUX. HEAT 3

HOT WATER (must be activated)

COOLING

ACT COOLING

LANGUAGE

SVENSKA

ENGLISH

DEUTSCH

NEDERLANDS

FRANÇIS

ESPAÑOL

ITALIANO

NORSK

DANSK

SUOMI

EESTI

POLSKI

ČEŠTINA

18 – User manual VUIFM102

Page 21

4.1.1 Sub-menu OPERAT.

Table 5. Used to select operating mode.

Menu

selection

Meaning Factory

setting

(OFF)

The installation is fully switched off. This mode is

also used to acknowledge certain alarms.

CANCEL = starting point, no changes made.

To select OFF as operating mode, press the minus

sign once to scroll down one step and press the

right arrow once.

-

AUTO

Automatic operation with both heat pump and

auxiliary heater permitted. If the number of power

stages for auxiliary heating are set to zero (SERVICE

-> AUX. HEATER -> MAX STEP) only AUTO or OFF

can be selected as operating mode.

-

HEAT PUMP

Operation with only heat pump permitted.

Note! No peak heating charging

(anti-legionella function) with only

heat pump operation.

-

AUX.

HEATER

Operation with only auxiliary heater permitted. -

HOT WATER

Operation with heat pump for hot water production and auxiliary heater during peak heating

charging (anti-legionella function).

-

MANUAL

TEST

Only displayed when the value for MANUAL TEST

is set to 2 in

The SERVICE menu. Outputs that control components are activated manually.

-

User manual VUIFM102– 19

Page 22

4.1.2 Sub-menu HEAT CURVE

Table 6. Used to change settings for the heat curve.

Menu

selection

Meaning Factory

setting

CURVE

Calculated supply temperature at 0°C outdoor

temperature. Shown as a graphic curve. The curve

will be limited by the set values of MIN and MAX.

40°C

(for under

floor heating

30°C)

(range:

22°C / 56°C)

MIN

Minimum permitted supply temperature, if the

temperature for heat stop has been reached and

the heat pump has stopped.

10°C

(range:

10°C / 50°C)

MAX

Maximum calculated setpoint value of the supply

temperature.

55°C

(for under

floor heating

45°C)

(range:

40°C / 85°C)

CURVE 5

Local increase or reduction of CURVE at an outdoor

temperature of +5°C. Shown in the graph for

CURVE.

0°C

(range: -5°C /

5°C)

CURVE 0

Local increase or reduction of CURVE at an outdoor

temperature of 0°C. Shown in the graph for CURVE.

0°C

(range: -5°C /

5°C)

CURVE -5

Local increase or reduction of CURVE at an outdoor

temperature of -5°C. Shown in the graph for

CURVE.

0°C (range:

-5°C / 5°C)

HEAT STOP

Maximum outdoor temperature when heat production is permitted.

If the heat stop has been activated the outdoor

temperature must drop 3°C below this setting

before the heat pump resumes the heating cycle.

17°C

(range: 0°C /

40°C)

REDUCTION

Only appears if the tariff control function has been

activated. Lowering set room temperature. Active

when a 10 kΩ connection is placed across the EVU

input connections.

2°C

(range: 1°C /

10°C)

20 – User manual VUIFM102

Page 23

Menu

selection

Meaning Factory

setting

TANK TEMP

Displayed if buffer tank is active. Charges the buffer tank to the set temperature. AUTO setting

charges the tank to the supply line setpoint value.

AUTO

(range:

30°C / 55°C)

OVERCHARGE

Displayed if the buffer tank is active and TANK

TEMP is set to AUTO. Charges the buffer tank to

supply line setpoint value + the value of OVERCHARGE.

0°C

(range: 0°C /

5°C)

ROOM FACTOR

Only displayed if an accessory Room temperature

sensor is installed.

Determines how great an impact the room temperature is to have when calculating the supply

temperature. For under floor heating it is recommended that ROOM FACTOR is set to 1, 2 or 3. For

radiator heating it is recommended that ROOM

FACTOR is set to 2, 3 or 4.

2

(range: 0 / 4)

(0 = no

impact,

4 = very large

impact)

POOL

(Expansion

card)

Only appears if POOL is selected. The temperature

in the pool is controlled by a separate sensor

regardless of the heating and hot water system.

20°C

(range: 5°C /

40°C)

POOL HYSTERESIS (Expansion card)

Only appears if POOL is selected. The difference

between the desired charge value (adjustable) and

actual value to the pool sensor. Pool hysteresis

does not affect the integral value.

0°C

(range: 5°C /

40°C)

User manual VUIFM102 – 21

Page 24

4.1.3 Sub menu HEAT CURVE 2

Only appears if shunt group sensor is connected and activated in menu

SERVICE -> INSTALLATION -> SYSTEM -> SHUNT GROUP.

Table 7. Used to change settings for heat curve 2.

Menu

selection

Meaning Factory

setting

CURVE 2

Calculated shunt group temperature at 0°C outdoor temperature. Shown as a graphic curve. The

curve will be limited by the set values of MIN and

MAX.

40°C

(range:

22°C / 56°C)

MIN

Minimum permitted shunt group temperature, if

the temperature for heat stop has not been

reached.

10°C

(range:

10°C / 50°C)

MAX

Maximum permitted shunt group temperature. 55°C

(range:

15°C / 70°C)

4.1.4 Sub-menu TEMPERATURE

The history of different temperature measurements can be viewed by

pressing the right arrow key. The graph shows the last 60 measurement

points for the set time interval (SERVICE -> INSTALLATION -> LOG TIME).

In the event of an alarm, history stops being logged until the alarm is reset

by changing the operating mode to OFF.

Table 8. Used to indicate the prevailing temperatures, history and set/calculated values.

Menu

selection

Meaning Factory set-

ting

OUTD

Shows the actual outdoor temperature. -

ROOM

Shows the actual set temperature. -

SYSTEM

SUPPLY

Displays system supply temperature at the buffer

tank system.

-

22 – User manual VUIFM102

Page 25

Menu

selection

Meaning Factory set-

ting

SUPPLY

LINE

Shows the actual supply temperature. The calculated supply temperature to the heating system

group is within brackets.

During hot water production in operating mode

AUX. HEATER the value for HOT WATER STOP + 10°

is shown within brackets.

-

RETURN

LINE

Shows the actual return temperature. The stop

temperature, MAX RETURN is within brackets.

-

BUFFER

TANK

Indicates the buffer tank temperature. -

HOT WATER

Shows the actual hot water temperature. -

INTEGRAL

Shows the actual calculated value for integral. -

REFR 1

Shows the actual temperature of refrigerant sensor 1.

-

REFR 2

Shows the actual temperature of refrigerant sensor 2.

-

POOL

(Expansion

card)

Only appears if POOL is selected. Shows the actual

pool temperature.

The set pool temperature is shown in brackets.

-

SHUNT

GROUP

Only appears if SHUNT GROUP is selected. Shows

the actual supply temperature. The calculated

supply temperature to the shunt group is within

brackets.

-

2ND HEAT

CIR.

Shows the temperature of the second heating circuit if installed by the buffer tank system.

CURRENT

(Expansion

card)

Only appears if CURRENT LIMITER is selected.

Shows the actual current consumption. The set

value for MAX CURRENT is shown between brackets.

-

User manual VUIFM102 – 23

Page 26

4.1.5 Sub-menu OPERAT.TIME

Table 9. Used to show the operating time for each component. Time given

in hours.

Menu

selection

Meaning Factory

setting

HEAT PUMP

Compressor operating time for both heating and

hot water production.

-

AUX. HEATER Operating time of auxiliary heater. -

HOT WATER Operating time for hot water with compressor. -

4.1.6 Sub-menu LANGUAGE

Table 10. Used to set the language of the menu system.

Menu selection

SVENSKA

ENGLISH

DEUTSCH

NEDERLANDS

FRANÇAIS

ESPAÑOL

ITALIANO

NORSK

DANSK

SUOMI

EESTI

POLSKI

ČEŠTINA

24 – User manual VUIFM102

Page 27

5 Troubleshooting

5.1 Alarm

In event of alarm this is indicated in the display with the text ALARM and

an alarm message, see following table. For alarms that are not reset automatically acknowledgement is required. Acknowledge the alarm by setting the heat pump to operating mode OFF.

Message Meaning

HIGH PRESSURE

ERROR

Tripped high pressure switch. Compressor stopped.

LOW PRESSURE

ERROR

Tripped low pressure switch. Compressor stopped.

MOTOR P ERROR Deployed overload relay (Overcurrent relay compressor),

or deployed overload relay for outdoor unit fan. Compressor stopped.

OUTDOOR SENSOR Fault in outside sensor. When the control system calcu-

lates the heat demand, zero degrees is used.

SUPPLY LINE SENSOR

Supply line sensor error. Everything stops except the

heating system’s circulation pump.

RETURN LINE SENSOR

Return sensor fault. Return temperature = Supply line – 5

is used. Calculated supply temperature limited to maximum 45°C.

HOT WATER SENSOR Fault on sensor for start temperature. No hot water pro-

duction.

ERR PHASE SEQ. Alarm that indicates that there is an incorrect phase

sequence to the compressor. Only display and only the

first 10 minutes.

HIGH RETURN Alarm that indicates that high return temperature pre-

vents the compressor’s operation.

BRINEFLOW LOW The flow sensor produces an alarm when the ambient

temperature of the brine circuit becomes too low.

In event of alarm the heat pump will if possible supply heating to the

house, primarily with the compressor, secondarily with the additional

heater. Hot water will stop to indicate that something noteworthy has

occurred.

User manual VUIFM102 – 25

Page 28

6 Terms and abbreviations

Table 11. Terms and abbreviations

Term Explanation

Evaporator In the evaporator, energy is retreived from the heat source

and the refrigerant passing through the evaporator turns

to gas.

De-superheater In the de-superheater part of the total heating output is

released (approx. 15%). A higher temperature than the

normal condensation temperature can found here.

Integral INTEGRAL is the heating system’s energy balance. Heat

generation is controlled by a calculated requirement. This

value is determined by comparing the actual supply temperature with its calculated supply temperature. The difference between the temperatures is added over time.

The resulting value is referred to as the integral. The integral is calculated automatically. The value of the integral

can be viewed in the display under the sub-menu TEMPERATURE.

Compressor The compressor raises the temperature and pressure of

the refrigerant.

Condenser In the condenser, the refrigerant supplies its heat energy

to the heat transfer fluid circuit.

Curve The CURVE value is set via the display. The set value is the

calculated set point value of the flow line at outdoor temperature of 0°C.

Brine Is a water based mixture that transports energy from the

heat source to the heat pump.

Brine circuit The fluid circuit transports energy from the heat source to

the heat pump.

Refrigerant circuit Is the circuit in the heat pump that through evaporation,

compression and condensation takes energy from the

brine circuit and supplies it to the heat transfer fluid circuit.

Refrigerant Is the fluid that transports heat from the brine circuit and

supplies it to the heat transfer fluid circuit.

Radiator Heater element, element.

26 – User manual VUIFM102

Page 29

Term Explanation

Control computer The control computer controls the entire heating instal-

lation. All settings are stored and the history of the installation is registered here. The control computer’s settings

can be changed via the display.

Room If ROOM shows 20°C the heat curve is unaffected. If ROOM

shows higher or lower, this indicates that the heat curve

has been adjusted up or down to change the indoor temperature.

Heat transfer fluid

circuit

The heat transfer fluid circuit obtains heat/energy from

the refrigerant circuit, which it then transports to the

water tank or heating system.

Heat curve The control computer determines the correct tempera-

ture of the water to be distributed to the heating system

based on the heat curve. The indoor temperature is adjusted by changing the gradient of the heating system’s

CURVE.

User manual VUIFM102 – 27

Page 30

7 References

Piping installation

Date ........................................................

Company ........................................................

Name ........................................................

Tel. No. ........................................................

Electrical Installation

Date ........................................................

Company ........................................................

Name ........................................................

Tel. No. ........................................................

System adjustment

Date ........................................................

Company ........................................................

Name ........................................................

28 – User manual VUIFM102

Page 31

System adjustment

Tel. No. ........................................................

User manual VUIFM102 – 29

Page 32

VUIFM102

Loading...

Loading...