Page 1

Installation instructions

DHP-AQ

VMGFD102

Page 2

If these instructions are not followed during installation and

service, Danfoss A/Sliability according to the applicable warranty

is not binding. Danfoss A/S retains the right to make changes to

components and specifications without prior notice.

© 2010 Copyright Danfoss A/S.

The Swedish language is used for the original instructions. Other

languages are a translation of original instructions.

(Directive 2006/42/EG)

Page 3

Contents

1 About documents and decals ...................................................... 3

1.1

Introduction .................................................................................... 3

1.2 Symbols in documents ................................................................ 3

1.3 Symbols on decals ........................................................................ 3

1.4 Terminology .................................................................................... 5

2 Important information .................................................................... 6

2.1 General safety precautions ........................................................ 6

2.2 Refrigerant ....................................................................................... 6

2.3 Electrical connection .................................................................... 7

2.4 Water quality ................................................................................... 7

2.5 Commissioning .............................................................................. 8

3 Transport, unpacking and positioning ...................................... 9

3.1 Transporting heat pump ............................................................ 9

3.2 Unpacking heat pump ................................................................ 9

3.3 Positioning the heat pump ........................................................ 9

4 The heat pump ................................................................................ 13

4.1 Dimensions and connections ................................................. 13

4.2 Components ................................................................................. 15

4.3 Principle description .................................................................. 17

4.4 Heating ........................................................................................... 17

4.5 Hot water function ..................................................................... 18

4.6 Defrost function .......................................................................... 19

4.7 Cooling function ......................................................................... 20

4.8 Check and safety functions ..................................................... 21

5 System solution ............................................................................... 24

5.1 System solution DHP-AQ Mini ............................................... 24

5.2 System solution DHP-AQ Midi ............................................... 24

5.3 System solution DHP-AQ Maxi ............................................... 25

5.4 System solution intermediate exchanger .......................... 27

6 Piping installation .......................................................................... 29

6.1 Pipe connection .......................................................................... 29

6.2 Connecting cold and hot water lines .................................. 29

6.3 Connecting the heating system supply and

return lines ..................................................................................................... 29

6.4 Noise and vibrations .................................................................. 30

7 Electrical Installation ..................................................................... 32

7.1 Control centre .............................................................................. 32

7.2 Electrical cabinet in heat pump ............................................. 33

7.3 Cable connection ........................................................................ 33

7.4 Position and connect outdoor sensors ............................... 34

7.5 Connecting supply and return pipe sensors ..................... 34

7.6 Connect hot water sensor to external heater ................... 35

7.7 Connecting circulation pump ................................................ 35

7.8 Connect heating cable driptray ............................................. 35

7.9 Connect the communication cable ...................................... 35

7.10 Connecting the power supply ............................................. 36

8 Operator panel ................................................................................ 37

8.1 Manage operator panel ............................................................ 37

8.2 Operating modes ........................................................................ 38

8.3 Symbols .......................................................................................... 38

8.4 Operational information .......................................................... 39

8.5 Important parameters ............................................................... 39

9 Information menu .......................................................................... 47

9.1 Menu overview ............................................................................ 47

9.2 OPERAT. .......................................................................................... 47

9.3 HEATING ......................................................................................... 47

9.4 DISTRIBUTION CIRCUIT 1 - 2 .................................................... 48

9.5 HOT WATER ................................................................................... 49

9.6 COOLING ........................................................................................ 49

9.7 POOL ................................................................................................ 50

9.8 BUFFER TANK ............................................................................... 50

9.9 OP. DATA ........................................................................................ 51

9.10 OPERAT. TIME ............................................................................ 51

9.11 DEFROST ...................................................................................... 52

9.12 CALENDAR .................................................................................. 52

9.13 ALARM .......................................................................................... 53

9.14 LANGUAGE ................................................................................. 53

10 Service menu ................................................................................. 54

10.1 Menu overview ......................................................................... 54

10.2 HOT WATER ................................................................................ 54

10.3 HEATING ...................................................................................... 55

10.4 COOLING ..................................................................................... 56

10.5 AUX. HEATER .............................................................................. 56

10.6 MANUAL TEST ............................................................................ 57

10.7 INSTALLATION ........................................................................... 58

10.8 DEFROST ...................................................................................... 60

10.9 OPTIMUM .................................................................................... 61

10.10 BUFFER TANK .......................................................................... 62

11 Commissioning ............................................................................. 65

11.1 Filling and bleeding the hot water heater

and heating system ..................................................................................... 65

11.2 Checking the pipes and electrical installation ............... 65

11.3 Configuration of control system ......................................... 66

11.4 Manual test ................................................................................. 67

11.5 Start-up and commissioning ................................................ 69

11.6 Installation protocol ................................................................ 70

11.7 Customer information ............................................................ 70

12 Technical data ............................................................................... 71

12.1 Working range compressor operation ............................. 73

VMGFD102 – 1

Page 4

Page 5

www.documentation.heatpump.danfoss.com

1 About documents and decals

1.1

Introduction

The following documents are available for this product:

Installation instructions containing information to install and commission a heat pump installation, and infor-

•

mation about the heat pump’s function, accessories and technical data. Supplied with the heat pump on delivery.

Service instructions that contain information about fault tracing. The service instructions are available for

•

download as below.

The electrical instructions that contain the wiring diagram for the heat pump intended for fault tracing and

•

service. The electrical instructions are available for download as below.

The maintenance instructions must handed over and gone through with the end customer. Supplied with the

•

heat pump on delivery.

Country specific instructions and forms are available where relevant. Supplied with the heat pump on delivery.

•

Sheet with adhesive decals that will be used as translation for the existing English language type plates.

•

The Service instructions and Electrical instructions are available for download here:

1.2 Symbols in documents

The instructions contain different warning symbols, which, together with text, indicate to the user that there are

risks involved with actions to be taken.

The symbols are displayed to the left of the text and three different symbols are used to indicate the degree of

danger:

DANGER! Indicates an immediate danger that leads to fatal or serious injury if necessary measures are not

taken.

Warning! Risk of personal injury! Indicates a possible danger that can lead to fatal or serious injury if

necessary measures are not taken.

Caution! Risk of installation damage. Indicates a possible hazard that can lead to item damage if necessary

measures are not taken.

A fourth symbol is used to give practical information or tips on how to perform a procedure.

Note! Information regarding making the handling of the installation easier or a possible operational

technical disadvantage.

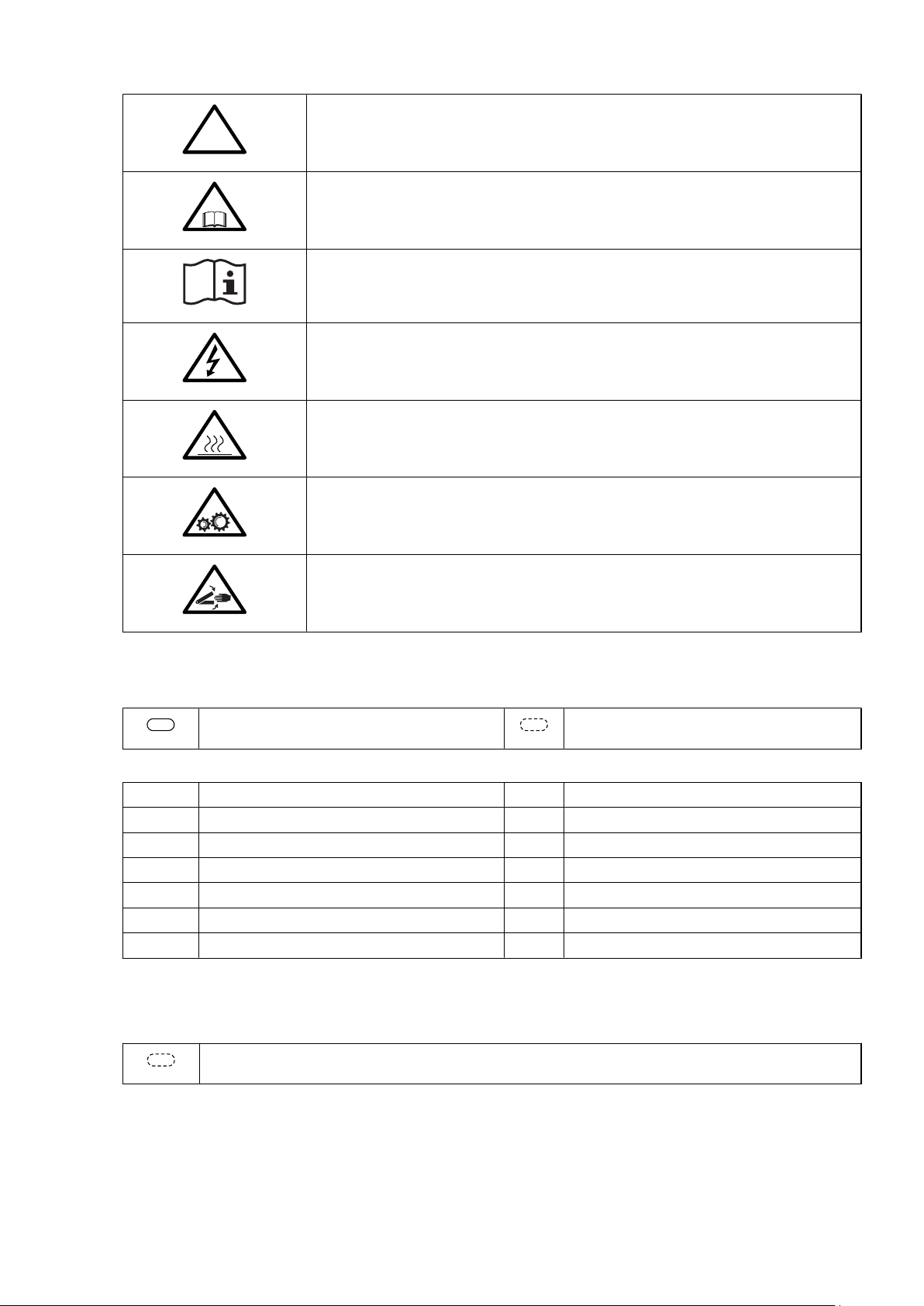

1.3 Symbols on decals

The following symbols can occur on decals on the different parts of the heat pump. Which symbols are used

depends on the heat pump model.

Installation instructions VMGFD102 – 3

Page 6

!

!

406

Warning symbols

Warning, danger!

Read the documentation provided.

Read the documentation provided.

Warning, hazardous electrical voltage!

Warning, hot surfaces!

Warning, moving parts!

Warning, risk of crushing injury!

Electrical components

Component, normal Component, accessory

3 Outdoor unit 362 Shunt valve

50 Outdoor sensor 363 Exchange valve hot water

54 Hot water sensor 365 Supply line sensor

55 Sensor hot-water top 366 Return line sensor

71 Flow sensor 406 Room sensor

304 Circulation pump 408 EVU

353 Drip tray 417 Defrost sensor

Example:

Room sensor

4 – Installation instructions VMGFD102

Page 7

Pipe connections

Bleeding

Defrosting tank

Expansion tank with safety valve, brine

Brine

Temperature and pressure relief valve

1.4 Terminology

Term Meaning

Heating system/Heat transfer fluid

circuit

Supply line The heating system’s supply line with flow direction from the heat pump to radiators/

Return line The heating system’s return line with flow direction from radiators/under floor heating

Circulation pump Circulation pump for heating system.

Refrigerant circuit The energy carrying circuit between the outdoor air and heating system.

Refrigerant The gas/liquid that circulates in the refrigerant circuit.

Tap water

Outdoor unit

Water heater

Heating system

The circuit that generates heat to the property or to the water heater.

under floor heating or water heater.

or water heater to the heat pump.

Installation instructions VMGFD102 – 5

Page 8

2 Important information

2.1

General safety precautions

Warning! Risk of personal injury! Children are not permitted to play with the product.

Caution! The heat pump must be installed by authorised installation engineers and the installation must

follow the applicable local rules and regulations as well as these installation instructions.

Caution! This product is not intended for persons (including children) with reduced physical, sensory or

psychological capacity, or who do not have knowledge or experience, unless supervised or they have

received instructions on how the apparatus functions from a safety qualified person.

Caution! When cooling it is important to limit the lowest flow line temperature to prevent condensation.

2.2 Refrigerant

2.2.1

2.2.2 Toxicity

2.2.3 Work on the refrigerant circuit

Fire risk

The refrigerant is not combustible or explosive in normal conditions.

In normal use and normal conditions the refrigerant has low toxicity. However, although the toxicity of the refrigerant is low, it can cause injury (or be highly dangerous) in abnormal circumstances or where deliberately abused.

Warning! Risk of personal injury! Spaces in which heavy vapour can collect below the level of the air must

be well ventilated.

Refrigerant vapour is heavier than air and, in enclosed spaces below the level of a door for example, and in the

event of leakage, concentrations can arise with a resultant risk of suffocation due to a lack of oxygen.

Warning! Risk of personal injury! Refrigerant exposed to a naked flame creates a poisonous irritating gas.

This gas can be detected by its odour even at concentrations below its permitted levels. Evacuate the area

until it has been sufficiently ventilated.

Caution! Work on the refrigerant circuit must only be carried out by a certified engineer!

Caution! When repairing the refrigerant circuit, the refrigerant must not be released from the heat pump it must dealt with in the appropriate way.

6 – Installation instructions VMGFD102

Page 9

Refilling must only be carried out using new refrigerant (for the amount and type of refrigerant see manufacturer’s

plate) through the service valves.

Caution! All warranties from Danfoss are void if, when filling with refrigerant other than Danfoss A/S

specified refrigerant, if there has not been written notification that the new refrigerant is an approved

replacement refrigerant together with other remedies.

2.2.4 Scrapping

Caution! When the heat pump is to be scrapped the refrigerant must be extracted for disposal. Local rules

and regulations related to the disposal of refrigerant must be followed.

2.3 Electrical connection

DANGER! Hazardous electrical voltage! The terminal blocks are live and can be highly dangerous due to

the risk of electric shock. All power supplies must be isolated before electrical installation is started. The

heat pump is connected internally at the factory, for this reason electrical installation consists mainly of

the connection of the power supply.

Warning! Electrical installation may only be carried out by an authorised electrician and must follow

applicable local and national regulations.

Warning! The electrical installation must be carried out using permanently routed cables. It must be

possible to isolate the power supply using a multi-pole circuit breaker with a minimum contact gap of 3

mm.

2.4 Water quality

Caution! A normal heating system always contains a certain amount of corrosion particulates (rust) and

sludge products from calcium oxide. This comes from acid that is naturally occurring in the fresh water

that the system is filled with. It is not good practice to have to fill the heating system regularly which is

why any leakage in the heating system should be repaired immediately. Normal filling should occur only

once or twice a year. The water in the heating system should be as clean as possible, always position the

dirt filter on the return line from the heating system to the heat pump, as close to the heat pump as

possible.

Caution! Hard water; Normally it is not a problem installing a heat pump in areas with hard water because

the normal operating temperature for the hot water does not exceed 60°C. In areas where there are

exceptional prevailing conditions with the water one can install a softening filter, which softens the water,

cleans any impurities and prevents the build up of calcification.

Installation instructions VMGFD102 – 7

Page 10

2.5 Commissioning

Caution! The installation may only be commissioned if the heating system is filled and bled. Otherwise the

circulation pump can be damaged.

Caution! If the installation is only to operate using an auxiliary heater during the installation, ensure that

the heating system is filled and bled and that the compressor cannot be started. This is carried out by

setting the operating mode to AUX. HEATER.

8 – Installation instructions VMGFD102

Page 11

3 Transport, unpacking and positioning

3.1

Transporting heat pump

Caution! The heat pump must always be transported and stored standing and in a dry environment. If the

heat pump is laid on the incorrect side it may become seriously damaged as the oil in the compressor can

run out in the pressure pipe and therefore prevent normal function.

Caution! Always secure the heat pump so that it cannot tip over during transportation.

3.2 Unpacking heat pump

3.2.1

Delivery check

1. Check that there is no transport damage.

Remove the packaging and check that the delivery contains the following components.

2.

Table 1. Supplied contents

Quantity Name

1 Heat pump

1 Control unit

1 Document set

1 Package (1 x shut-off valve with filter, 1 x outdoor sensor)

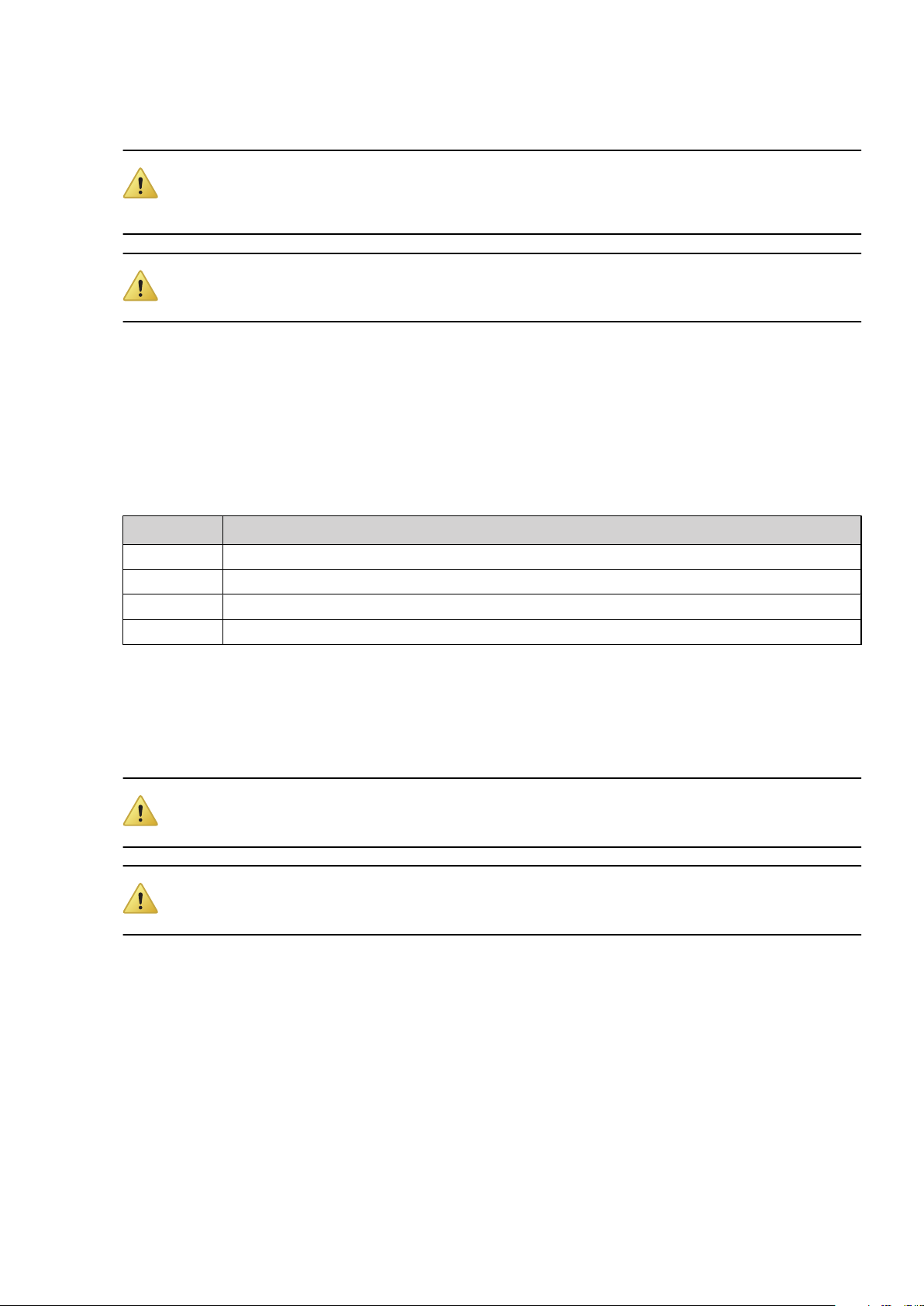

3.3 Positioning the heat pump

3.3.1

Recommended location

When positioning the heat pump, note the following:

Caution! The heat pump must be positioned outdoors on a stable base. The floor must be able to support

the gross weight of the heat pump. (see Technical data)

Caution! The heat pump must be secured on a stable base, for example a cast foundation. All four

mounting points must be secured to the base.

Installation instructions VMGFD102 – 9

Page 12

100 mm

~900 mm

b

c

a

7

5

4

3

6

1

8

2

Position Description

a Drainage hole

b Foundation

c Gravel

Meas-

6-9 kW 11-13 kW 16-18 kW

urements

1 450 mm 470 mm 710 mm

2 424 mm 480 mm 480 mm

3 618 mm 672 mm 857 mm

4 130 mm 190 mm 145 mm

5 61 mm 65 mm 65 mm

6 ~1,000 mm ~1,200 mm ~1300 mm

7 ~650 mm ~720 mm ~720 mm

8 Ø 65 mm Ø 65 mm Ø 65 mm

Bolt size

6-9 kW 11-13 kW 16-18 kW

M10 (4x) M12 (4x) M12 (4x)

10 – Installation instructions VMGFD102

Page 13

Caution! A driptray is installed with the purpose of gathering and draining away melt water during

defrosting. Connect a hose or pipe along with a heat trace cable between the outlet of the drip tray and a

drain or a free draining piece of ground. The heat cable must be connected to the terminal provided and

is necessary to prevent ice blockage.

Caution! Check with a spirit level that the heat pump is installed horizontally.

Caution! Incorrect positioning of the heat pump risks reduction of performance.

Caution! The unit with water heater must be placed indoors, in an area with a floor drain.

Caution! The unit with water heater must be placed indoors, on a stable surface. The floor must be able to

support the gross weight of the unit with filled water tank (see Technical data).

Note! Avoid placing the heat pump near windows or walls to noise sensitive areas.

Note! Ensure that there is sufficient distance to neighbouring properties so that they are not exposed to

noise. Applicable local regulations must be followed.

Note! The heat pump should not be enclosed.

Note! Keep the heat pump and its immediate area free of snow, ice, leaves etc.

Note! Remember that the heat pump must have a certain amount of space in order to function and for

servicing. Otherwise there is a risk that the air will recirculate from exhaust to intake. Avoid this by

following the dimensions given below.

Installation instructions VMGFD102 – 11

Page 14

>

2

0

0

0

m

m

>

2

0

0

0

m

m

>1500

m

m

>

300

m

m

>

2

000

mm

1

3.3.2 Lifting instructions

To lift the heat pump into position, unscrew the side plates by slackening off the screws (1).

Then use the side members behind the side panels to lift and position the heat pump.

12 – Installation instructions VMGFD102

Page 15

33

5

4

6

1

2

600

380

204

1

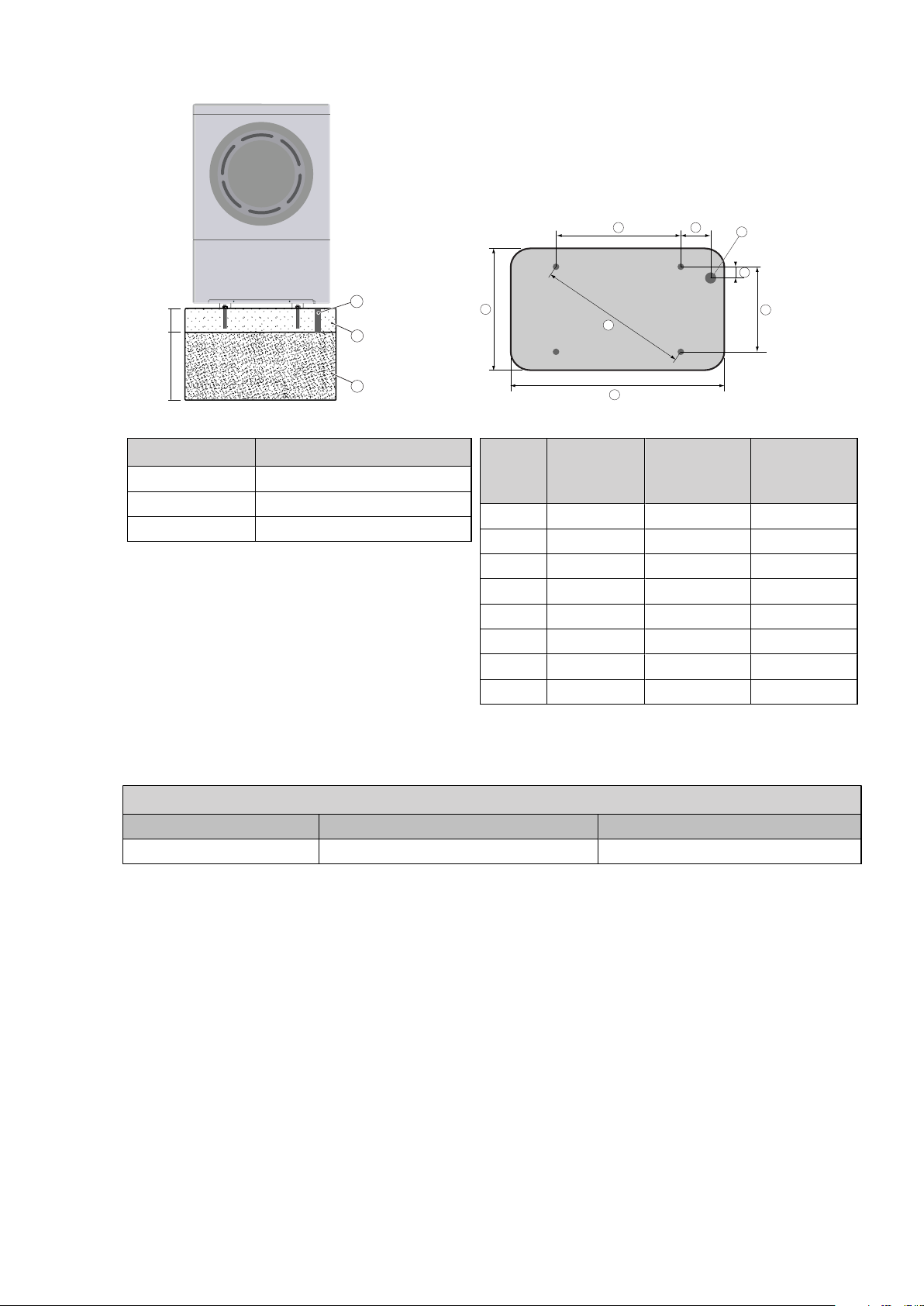

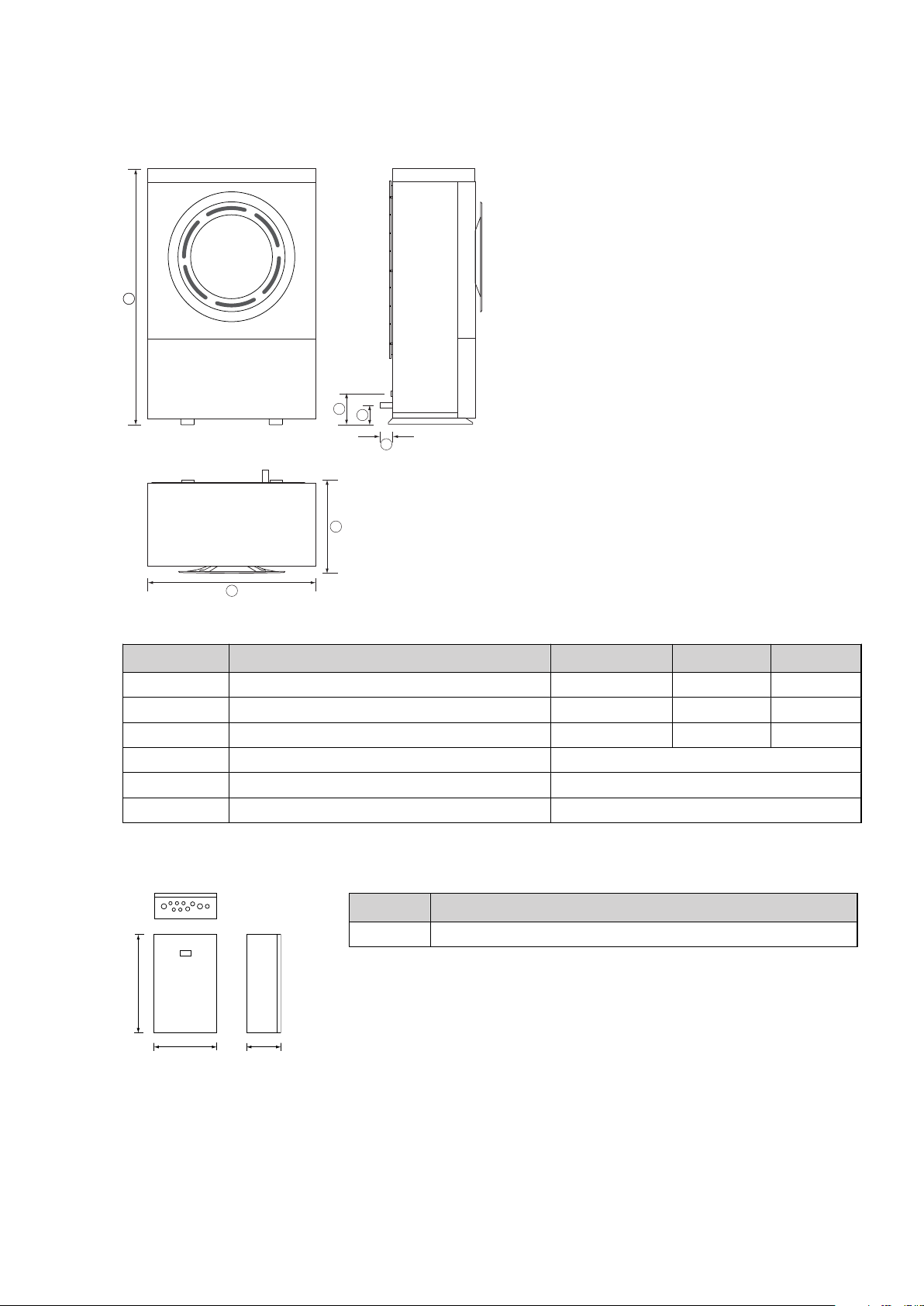

4 The heat pump

4.1

Dimensions and connections

Position Description 6-9 kW 11-13 kW 16-18 kW

1 Width 856 mm 1,016 mm 1,166 mm

2 Depth 510 mm 564 mm 570 mm

3 Height 1,272 mm 1,477 mm 1,557 mm

4 Height to supply line pipe, 28 mm Cu 155.5 mm

5 Height to return line pipe, 28 mm Cu 96.5 mm

6 Length max protruding pipe 30 mm

Control unit DHP-AQ Mini

Position Description

1 Lead-in for supply, sensor and communication cables

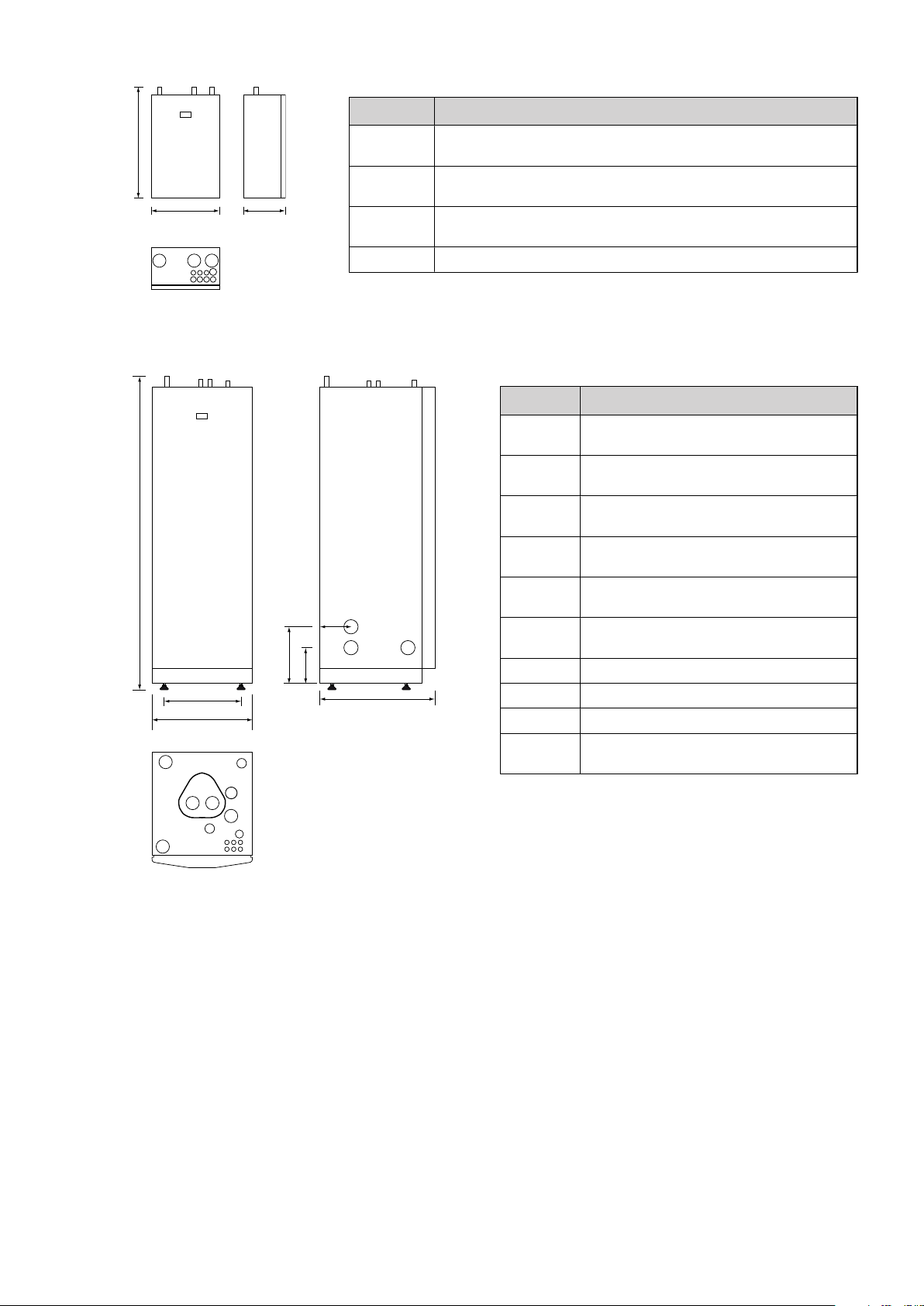

Control unit DHP-AQ Midi

Installation instructions VMGFD102 – 13

Page 16

675

420

255

1

2

3

4

1845 ±10

596

455

690

1

2

3

4

5

125

210

330

6

7

8

9

10

Control unitDHP-AQ Maxi

Position Description

1 Supply line for heating system,

28 mm Cu

2 Supply line to water heater,

28 mm Cu

3 Supply line from heat pump,

28 mm Cu

4 Lead-in for supply, sensor and communication cables

Position Description

1 Supply line heating system,

28 mm Cu

2 Return line heating system,

28 mm Cu

3 Connection for bleed valve,

22 mm Cu

4 Hot water line,

22 mm Cu

5 Cold water line,

22 mm Cu

6 Lead-in for supply, sensor and communica-

tion cables

7 Supply or return line heat pump

8 Supply or return line heat pump

9 Extra knock-out

10 Safety valve for temperature and pressure

(only applies to certain models)

14 – Installation instructions VMGFD102

Position 7 and 8 can be connected to either the left or righthand side or bottom of the control unit.

Page 17

11

10

12

13

14

16

15

17

1

2

3

4

5

6

7

8

9

19

18

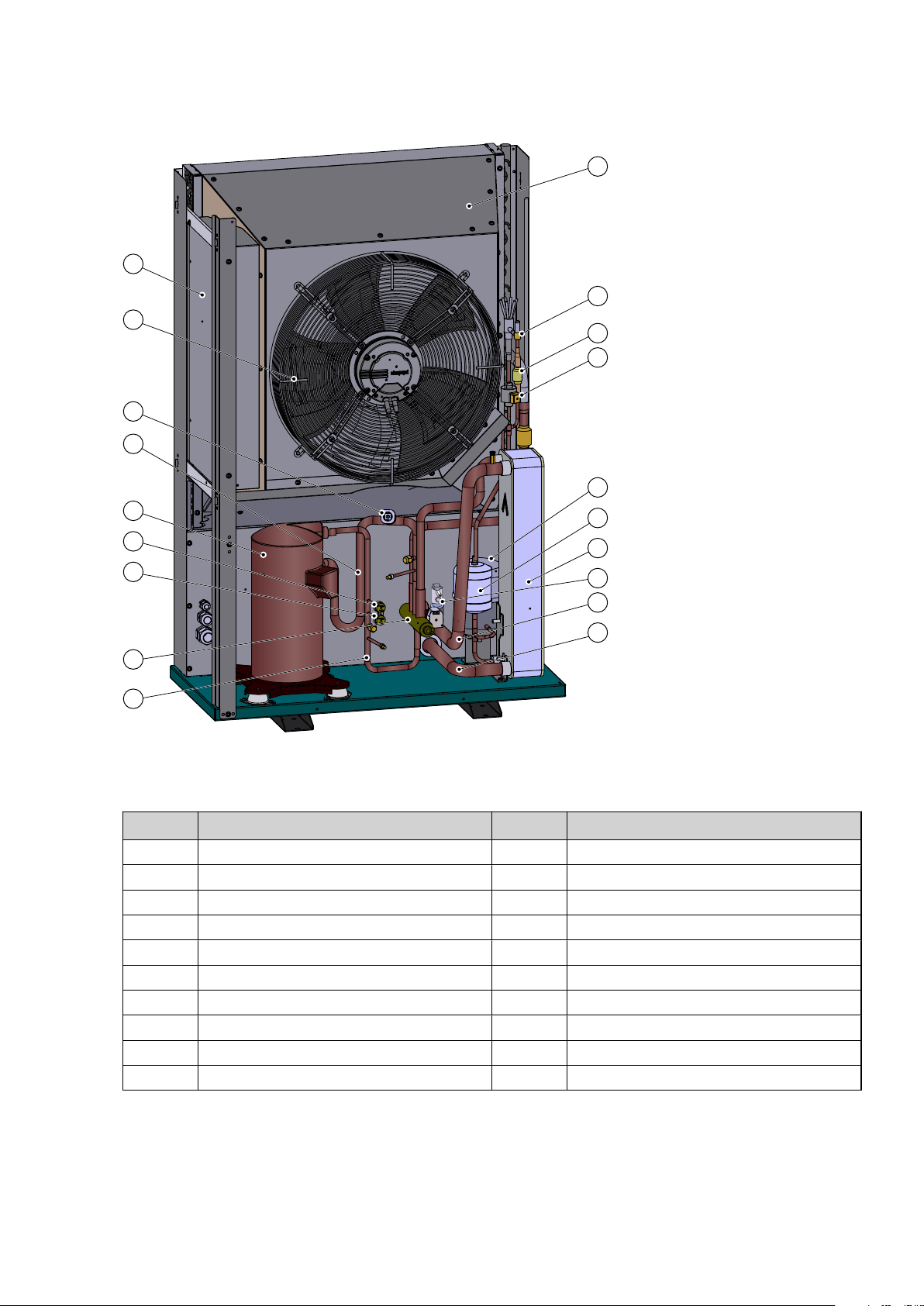

4.2 Components

4.2.1

Outdoor unit

Position Name Position Name

1 Electrical cabinet 11 Electronic expansion valve

2 Fan 12 Receiver

3 Pressure transmitter 13 Drying filter

4 Suction line 14 Heat exchanger

5 Compressor 15 Flow sensor

6 High pressure switch 16 Heating system supply line

7 Operating pressure switch 17 Return line heating system

8 Four-way valve 18 Solenoid

9 Discharge pipe 19 Non-return valve

10 Air heat exchanger

Installation instructions VMGFD102 – 15

Page 18

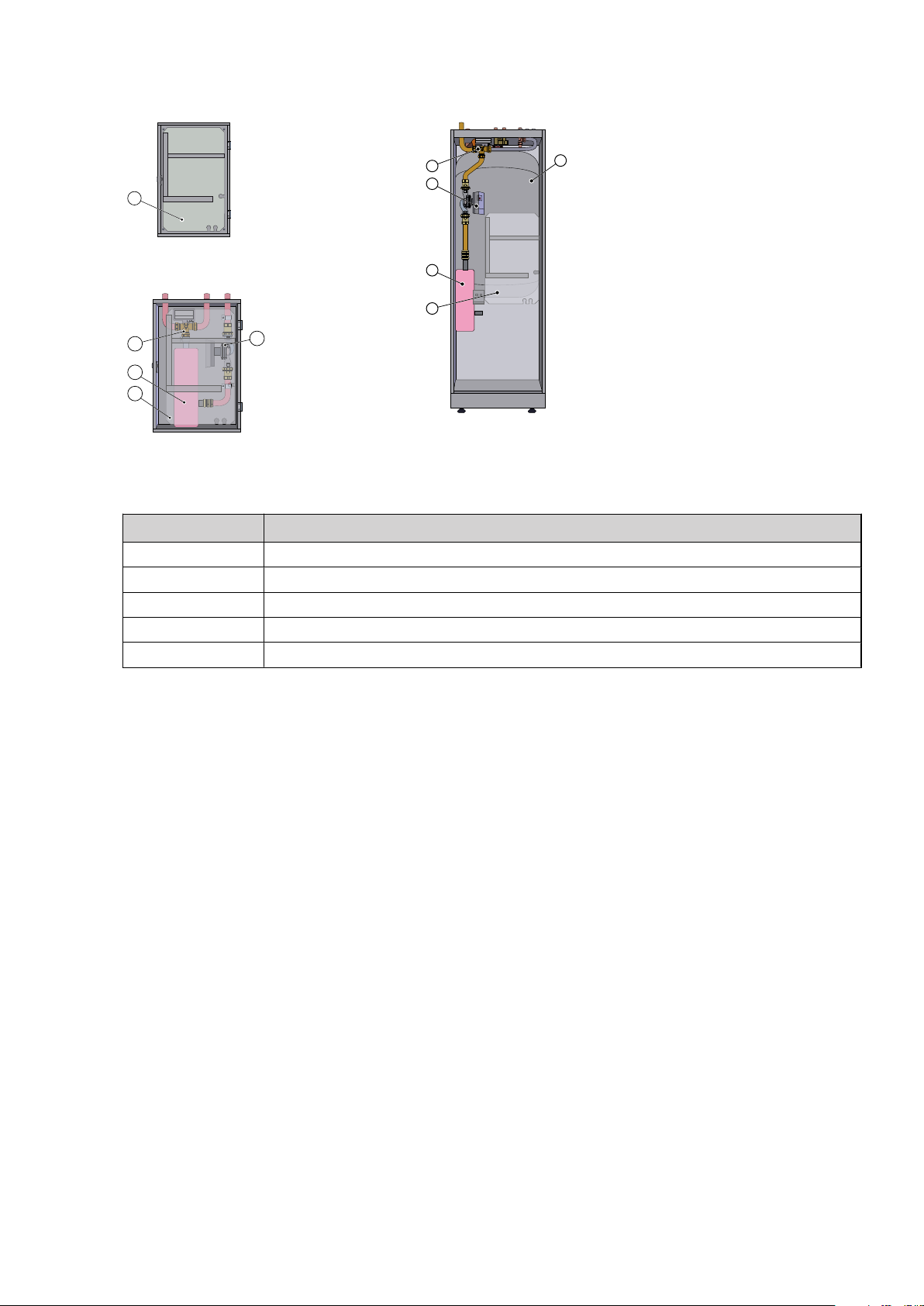

4.2.2 Indoor unit

1

1

2

4

3

5

1

2

3

4

DHP-AQ Mini

DHP-AQ Midi

DHP-AQ Maxi

Position Description

1 Control module (transparent in image)

2 Immersion heater

3 Reversing valve

4 Circulation pump

5 Water heater

4.2.3 Speed controlled fan

The fan is operated by a permanent solenoid motor with great efficiency. The fan starts at a nominal speed, which

differs depending on the size of output. The fan speed is adjusted up or down as required which is determined by

the temperatures in the refrigerant circuit.

4.2.4 Electronic expansion valve

When the refrigerant passes the expansion valve the pressure and temperature of the refrigerant are reduced. In

this way the energy in the outdoor air is available to the refrigerant circuit. By regulating the opening degree of

the expansion valve one can optimise the flow in the refrigerant circuit in different operating conditions. Control

of the electronic expansion valve is based on the measurements of temperatures and pressures in the refrigerant

circuit and outside air.

4.2.5 Auxiliary heat

An auxiliary heater is included in DHP-AQ Midi and DHP-AQ Maxi and consists of an immersion heater, which is

located on the supply line ahead of the reversing valve. An immersion heater is available for DHP-AQ Mini as an

accessory. Also see System solution, Page 24, pos 114.

Immersion heaters in the DHP-AQ series intended for 400V supply voltage have three heating elements and can be

controlled in five power stages. Products for 230V have two heating elements and are controlled in three power

stages.

The parameter MAX STEP determines the number of power stages the immersion heater can be controlled to. The

two stages 4 and 5 cannot be engaged when the compressor is in operation as opposed to stages +4 and +5

where it is possible.

With an internal immersion heater which is controlled by several power stages an external auxiliary heater, for

example an electric boiler, can be controlled using the potential free output 101.8 – 101.16.

If an immersion heater of a different type is used that requires a start signal in DHP-AQ Mini (placed before the hot

water reversing valve) the auxiliary heater is controlled from the potential free output 101.8 – 101.16. The parameter MAX STEP is set to ”P”.

16 – Installation instructions VMGFD102

Page 19

In the event of power cuts longer than three minutes, only a 6 kW output will be connected immediately after

power has returned, the remaining output is delayed two hours.

4.2.6 Compressor heater

The compressor heater runs in intervals when the outdoor temperature falls below 10°C. The compressor heater

does not run at the same time as the compressor.

4.3 Principle description

A heat pump utilises the renewable energy from the sun and that is also found in a natural heat source, such as

rock, ground, lakes, ground water or air. The heat pump can be compared to a reversed refrigerator; in a refrigerator heat is transferred from the inside of the refrigerator to the outside, whereas in a heat pump, the solar energy

that is stored in a heat source is transferred to the inside of the house. In both a refrigerator and heat pump the

process is driven by an electrically powered compressor. The heat pump uses the solar energy in the heat source

and gives off two to three times more heat energy than it uses in electrical energy. The heat pump is, therefore, a

very environmentally friendly and economical way of heating a house.

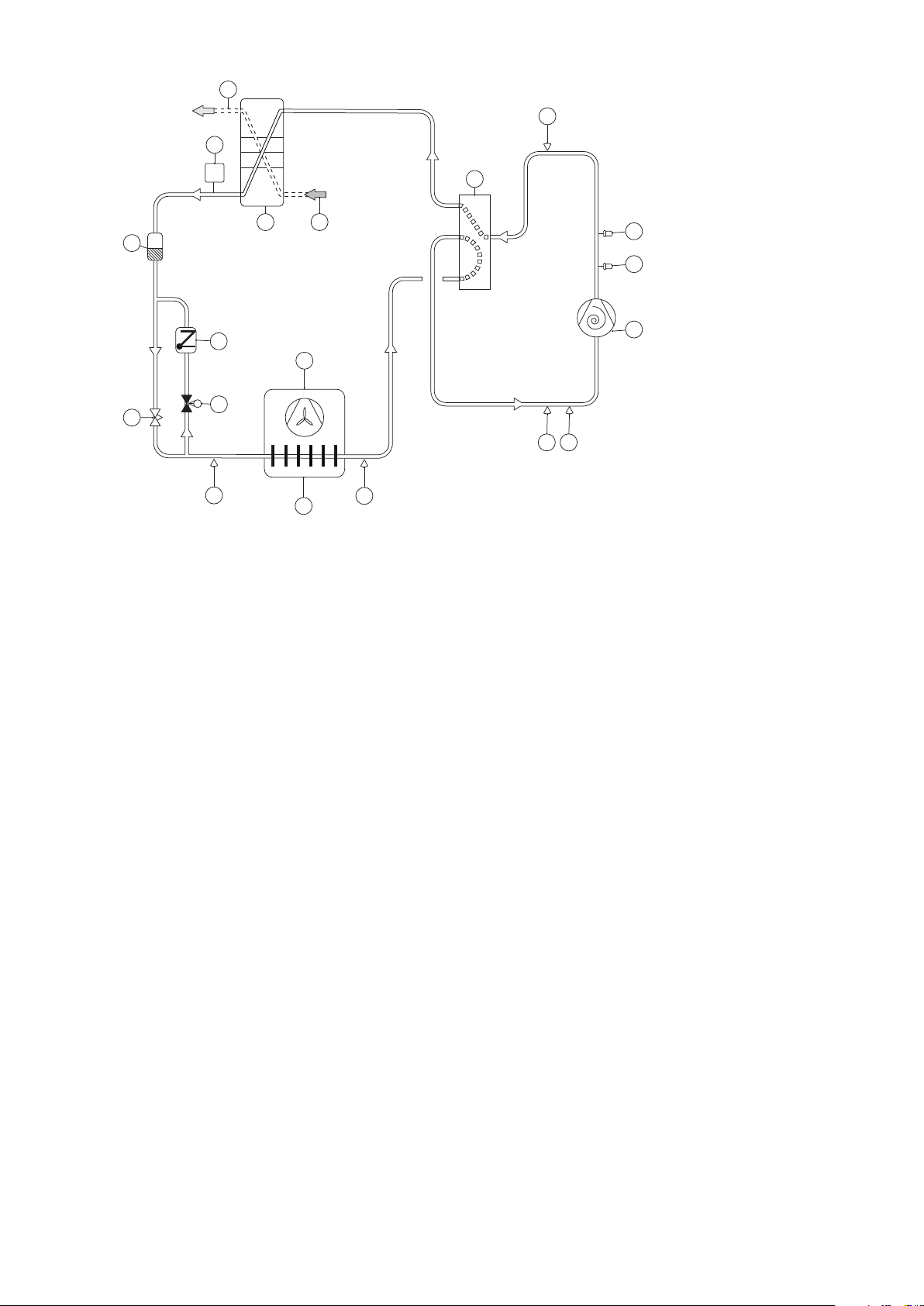

4.4 Heating

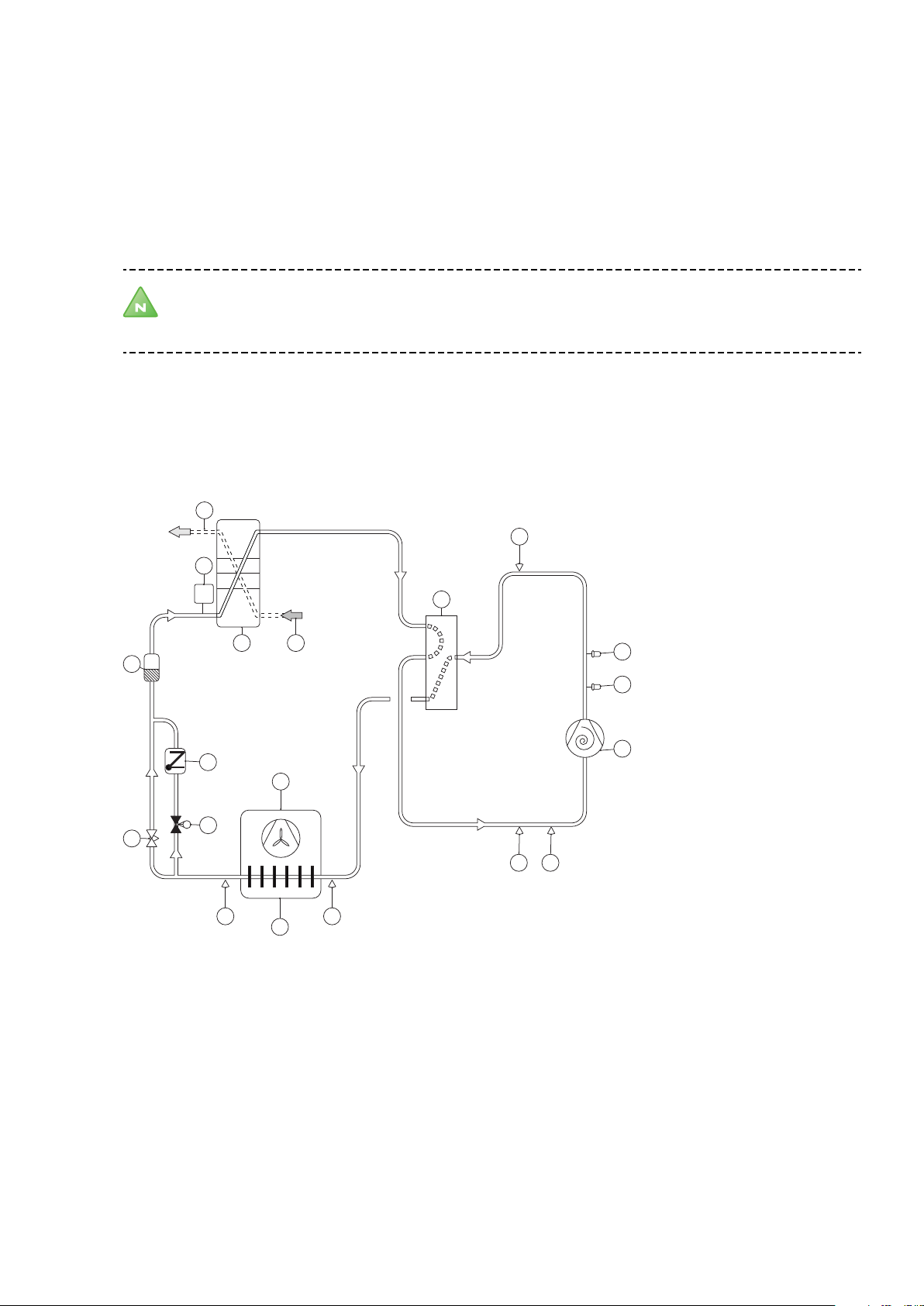

The heat pump produces heating (see figure below).

When the compressor (1) receives a start signal the refrigerant is compressed in gas form via the 4 way valve (5) to

the plate heat exchanger (7). The hot refrigerant gives off heat through the plate heat exchanger (7) to the heating

system (8) and transfers to liquid phase. The refrigerant continues through the drying filter (10) and the electronic

expansion valve (11) to the air exchanger (15). In the air exchanger (15) the refrigerant is heated to gas form by the

hotter outdoor air. The gas continues via the 4 way valve (5) back to the compressor (1).

Installation instructions VMGFD102 – 17

Page 20

3

2

1

1918

17

15

14

16

11

13

12

10

9

8

7 6

5

4

Position Description Position Description

1 Compressor 11 Electronic expansion valve

2 Operating pressure switch 12 Non-return valve

3 High pressure switch 13 Solenoid

4 Discharge pipe sensor 14 Refrigerant sensor 2

5 Four-way valve 15 Air exchanger (evaporator)

6 Heating system (cold return line) 16 Fan

7 Plate heat exchanger (condenser) 17 Refrigerant sensor 1

8 Heating system ( hot supply line) 18 Pressure transmitter

9 Receiver 19 Temperature transmitter

10 Drying filter

The heat pump can produce heat for heating (house, pool), hot water and cooling. The hot water requirement is

prioritised before the heating requirement and cooling requirement. The heating requirement is calculated from

outdoor temperature and set heat curve.

For a fuller description of heat curves etc., seeImportant parameters, Page 39.

4.5 Hot water function

The water heater is equipped with a TWS coil (Tap Water Stratificator). The hot water is led from the heat pump

through the water heater in the TWS coil from the top down. In this way the upper section of the water heater,

where the hot water is tapped from, is always heated first.

Heating the hot water in the water heater is not stopped by the temperature but via the pressure in the refrigerant

circuit of the heat pump unit. The operating pressure switch on the pressure pipe breaks at 28.5 bar. This means

that heat pumps in different output classes may have slightly different peak temperatures for hot water. As a rule

the peak temperature is between 54 – 58°C in a 180-litre water heater. Thanks to the design of the water heater

and the TWS coil the hot water layers itself so that the hottest water is always at the top of the water heater and

the cooler water at the bottom.

Two sensors indicate the present temperature of the hot water to the heat pump controls. A top water sensor that

is located in the top of the water heater, and a hot water sensor located approx 50 cm up from the bottom of the

water heater. Both the sensor values are ”weighted” where the hot water sensor influence is 65 % (factory setting,

18 – Installation instructions VMGFD102

Page 21

3

2

1

1918

17

15

14

16

11

13

12

10

9

8

7 6

5

4

can be changed if necessary). This means that if the start value for hot water production is set to 40°C the heat

pump need not necessarily start hot water production when the hot water sensor displays 40°C but also makes

reference to what temperature the peak water sensor displays. If it is still very hot at the top of the water heater

the start of hot water production will be delayed.

With anti-legionella operation, when the immersion heater heats the water heater to 60°C to prevent growth of

legionella bacteria, the peak water sensor temperature has no impact, only the hot water sensor has control. Antilegionella is factory set as top heating interval every 7th day.

4.6 Defrost function

The heat pump defrosts (see figure below).

Note! The designations for condenser and evaporator are switched during the defrost function (like the

cooling function) compared to the heating function, because the designations follow the cooling

technical function that respective units have (evaporation respectively condensing).

When the compressor (1) receives a start signal the refrigerant is compressed in gas form via the 4 way valve (5) to

the air exchanger (15). The hot refrigerant gives off heat to the air exchanger (15), shifts to liquid phase and continues to the plate heat exchanger (7). In the plate heat exchanger (7) the refrigerant is heated to gas form by the

hotter heating system (6). The heating system is cooled. The refrigerant continues via the 4 way valve (5) back to

the compressor (1).

Position Description Position Description

1 Compressor 11 Electronic expansion valve

2 Operating pressure switch 12 Non-return valve

3 High pressure switch 13 Solenoid

4 Discharge pipe sensor 14 Refrigerant sensor 2

5 Four-way valve 15 Air exchanger (condenser)

6 Heating system (hot return line) 16 Fan

7 Plate heat exchanger (evaporator) 17 Refrigerant sensor 1

8 Heating system ( cold supply line) 18 Pressure transmitter

Installation instructions VMGFD102 – 19

Page 22

3

2

1

1918

17

15

14

16

11

13

12

10

9

8

7 6

5

4

Position Description Position Description

9 Receiver 19 Temperature transmitter

10 Drying filter

Defrosting is initiated by low temperature in the refrigerant circuit after the air exchanger and, among other

things, is dependent on outdoor temperature, humidity and operating time. The length of defrosting varies

depending on the extent of freezing of the air exchanger. Defrost continues until the air heat exchanger is free of

ice and the temperature after the air exchanger has risen to the desired temperature. After completed defrosting

the heat pump returns to the operating mode before defrosting.

During defrosting the heat pump retrieves energy from the house's heating system. The water volume in the heating system can be increased by installing a buffer tank. The buffer tank can also act as a surge tank.

4.7 Cooling function

The heat pump produces cooling (see figure below).

The refrigerant process is similar to that at the defrosting function.

Note! The designations for condenser and evaporator are switched during the cooling function (like the

defrosting function) compared to the heating function, because the designations follow the cooling

technical function that respective units have (evaporation respectively condensing).

When the compressor (1) receives a start signal the refrigerant is compressed in gas form via the 4 way valve (5) to

the air exchanger (15). The hot refrigerant gives off heat to the air exchanger (15), shifts to liquid phase and continues to the plate heat exchanger (7). In the plate heat exchanger (7) the refrigerant is heated to gas form by the

hotter heating system (6). The heating system is cooled. The refrigerant continues via the 4 way valve (5) back to

the compressor (1).

Position Description Position Description

1 Compressor 11 Electronic expansion valve

2 Operating pressure switch 12 Non-return valve

3 High pressure switch 13 Solenoid

20 – Installation instructions VMGFD102

Page 23

1

3

6

5

7

8

4

9

2

10

Position Description Position Description

4 Discharge pipe sensor 14 Refrigerant sensor 2

5 Four-way valve 15 Air exchanger (condenser)

6 Heating system (hot return line) 16 Fan

7 Plate heat exchanger (evaporator) 17 Refrigerant sensor 1

8 Heating system ( cold supply line) 18 Pressure transmitter

9 Receiver 19 Temperature transmitter

10 Drying filter

Cooling function is started by the heat pump control unit and is primarily temperature controlled. If the hot water

heater is installed the control unit will alternate between cooling and hot water production with prioritisation for

the hot water requirement.

4.8 Check and safety functions

The heat pump has a number of check and safety functions to protect the installation against damage during

abnormal operating conditions.

The diagram below shows the heat pump's circuits with respective safety functions.

Symbol explanation

1 Heat transfer fluid circuit

2 Flow sensor

3 Safety valve, heat transfer fluid circuit, externally mounted

4 Refrigerant circuit

5 Operating pressure switch

6 High pressure switch

7 Pressure transmitter

8 Compressor

9 Fan

10 Discharge pipe sensor

Heat transfer fluid circuit (1)

If the flow in the heat transfer fluid circuit is below the permitted value at heat pump start and before the defrosting blocks the flow sensor (2) heat pump's normal operation, an alarm indicator on the control unit control panel

flashes and a warning text appears in the display of the control panel. The alarm resets itself when the flow

returns.

If the pressure in this circuit exceeds the opening pressure for the safety valve (3), the valve opens, releases the

overpressure and closes again. The safety valve overflow pipe must have an open connection to the drain and

visibly flow into this in a frost-free environment.

Refrigerant circuit (4)

The refrigerant circuit's high pressure side is equipped with a high pressure switch (6) and an operating pressure

switch (5).The operating pressure switch stops the compressor when the operating pressure is reached.

If the operating pressure switch does not work and the pressure continues to increase in the circuit, the high pressure switch activates when its break pressure is reached, whereupon the compressor stops and the heat pump's

normal operation is blocked.

If the high pressure switch is activated an alarm indicator flashes on the control unit's control panel and a warning

text appears in the display of the control panel. The blocked heat pump is reset by setting the operating mode to

OFF and then back to the previously selected mode.

Installation instructions VMGFD102 – 21

Page 24

If the pressure transmitter (7) registers too low pressure in the refrigerant circuit, the heat pump's normal operation is blocked, an alarm indicator on the heat pump's control panel flashes and a warning text appears in the

display of the control panel. The blocked heat pump is reset by setting the operating mode to OFF and then back

to the previously selected mode. The pressure transmitter is also used to monitor temperature and pressure at

compressor start. Deviations are handled in the same way as low pressure.

Compressor (8)

The compressor is equipped with a thermal over current relay to protect the compressor against over current.

If the over current relay (see figure below) is activated, the heat pump's normal operation is blocked, an alarm

indicator on the control unit's control panel flashes and a warning text appears in the display of the control panel.

The blocked heat pump is reset by setting the operating mode to OFF and then back to the previously selected

mode.

The compressor is also equipped with an internal protector that stops the compressor if it risks becoming overhea-

ted. The internal protector cannot be reset manually, the compressor must cool before it can be restarted. No

alarm connected to this protector.

The discharge pipe sensor (10) stops the compressor at too high pressurised gas temperature. This is indicated in

the display by a square. The stop is ceased when the temperature becomes normal.

Fan (9)

The fan motor is equipped with motor protection. If this is activated, the heat pump's normal operation is blocked,

an alarm indicator on the control unit's control panel flashes and a warning text appears in the display of the control panel.

Alarms can be caused by objects sticking in the fan or the fan having frozen solid. Rectify the cause of the alarm

and reset the heat pump by setting the operating mode to OFF and then back to the previously selected mode.

Speed (rpm) controlled circulation pump

The circulation pump has an internal overload protector, which is reset automatically after cooling.

The overload protector also activates the alarm for the circulation pump and blocks the heat pump's normal oper-

ation. Indication occurs by the alarm indicator flashing on the control unit's control panel and a warning text

appears in the display of the control panel. The circulation pump will attempt to start for 45 seconds every 5

minutes to try to acknowledge the alarm automatically. If the function is not normal after 5 start attempts the heat

pump is constantly blocked and must be reset by setting the operating mode to OFF and then back to the previously selected mode.

Alarm mode

If an alarm that affects the heat pump's normal operation is activated this will be indicated in the control panel's

display window. In order to further attract attention, the heat pump will not produce hot water.

The heat pump will initially try to meet the heat demand using the compressor. If this is not possible, the built-in

electric heating element engages.

Immersion heater

The auxiliary heater consists of an electric heating element mounted on the heating system supply line. It has an

overheat protector that switches off the electric heating element if it is at risk of becoming overheated. The overheat protector's control panel is located in the control unit (see the image below).

If the overheat protector is activated an alarm indicator flashes on the heat pump's control panel and a warning

text appears.

The overheat protector is reset by pushing the reset button, which is on the overheat protector.

Electrical system

22 – Installation instructions VMGFD102

Page 25

4

1

2

3

2

3

2

A

B C D

The heat pump control and control unit are fused with fuses F1 and F2 (see figures below).

Symbol explanation

A Heat pump

B Control unit DHP-AQ Mini

C Control unit DHP-AQ Midi

D Control unit DHP-AQ Maxi

1 Fuse F1

2 Fuse F2

3 Overheating protection

4 Overcurrent protection

Installation instructions VMGFD102 – 23

Page 26

5

71

96

91

52

114

100

36

51

50

40

112

80

62

21

80

63

64

33

10

11

10

11

5 System solution

Explanations for the positions are given after the images of the system solution.

5.1 System solution DHP-AQ Mini

DHP-AQ Mini includes the control module with supply and return line sensors. The heat pump produces only heat

or cooling. Two heating circuits can be connected, one using a shunt. The shunt is controlled by the heat pump

control system. The flow line temperature is controlled with reference to the outside temperature following a set

heat curve. The additional heater starts automatically on demand.

Buffer tank is installed for equalisation of the temperature for the heating system and to guarantee sufficient

energy when defrosting. The buffer tank volume must be 20 l/kW heat pump output (for systems without water

heaters). DHP-AQ Mini does not contain a water heater. Water heater is available as an accessory for DHP-AQ Midi

and is included in DHP-AQ Maxi.

5.2 System solution DHP-AQ Midi

DHP-AQ Midi includes the control module with supply and return pipe sensors, circulation pump, 3-way valve and

electric auxiliary heater. The heat pump produces heat, cooling and hot water. Production of heating and hot

water cannot occur at the same time because the exchange valve for heating and hot water is positioned after the

heat pump and the auxiliary heater. Hot water production is prioritised ahead of heat and cooling. Two heating

circuits can be connected, one using a shunt. The shunt is controlled by the heat pump control system. The flow

line temperature is controlled with reference to the outside temperature following a set heat curve. The additional

24 – Installation instructions VMGFD102

Page 27

91

52

114

100

36

51

50

112

80

62

21

80

63

64

33

10

11

10

11

53

55

77

85

87

83 80

13

12

18

40

5

71

96

heater starts automatically on demand. The auxiliary heater carries out peak heating charging (anti-legionella

function) in those operating modes that permit auxiliary heat.

Buffer tank is installed for equalisation of the temperature for the heating system and to guarantee sufficient

energy when defrosting. The buffer tank volume must be 10 l/kW heat pump output (for systems with water heaters). Water heater is available as an accessory.

5.3 System solution DHP-AQ Maxi

DHP-AQ Maxi includes the control module with supply and return pipe sensors, circulation pump, 3-way valve,

electric auxiliary heater and water heater. The heat pump produces heat, cooling and hot water. Production of

heating and hot water cannot occur at the same time because the exchange valve for heating and hot water is

positioned after the heat pump and the auxiliary heater. Hot water production is prioritised ahead of heat and

trol system. The flow line temperature is controlled with reference to the outside temperature following a set heat

curve. The additional heater starts automatically on demand. The auxiliary heater carries out peak heating charg-

cooling. Two heating circuits can be connected, one using a shunt. The shunt is controlled by the heat pump con-

ing (anti-legionella function) in those operating modes that permit auxiliary heat.

Buffer tank is installed for equalisation of the temperature for the heating system and to guarantee sufficient

energy when defrosting. The buffer tank volume must be 10 l/kW heat pump output (for systems with water heaters).

Installation instructions VMGFD102 – 25

Page 28

5

71

96

91

52

114

100

36

51

50

40

112

80

62

21

80

63

64

33

10

11

10

11

53

55

77

87

83 80

13

12

18

Position Name Position Name

5 Heat pump unit 62 Room sensor

10 Supply line 63 Shunt valve

11 Return line 64 Supply line sensor shunt group

12 Cold water 71 Flow sensor

13 Hot water 77 Switching valve for hot water

18 Water heater 80 Shut-off valve

33 Circulation pump shunt group 85 Bleed valve

21 Buffer tank 83 Non-return valve

36 Circulation pump 87 Safety valve (9 bar)

40 Control unit 91 Strainer

50 Outdoor sensor 96 Flexible hose

51 Supply line sensor 100 Safety valve (1.5 bar)

52 Return line sensor 112 Expansion vessel, closed

26 – Installation instructions VMGFD102

Page 29

Position Name Position Name

53 Hot water sensor 114 Auxiliary heat

55 Peak temperature sensor

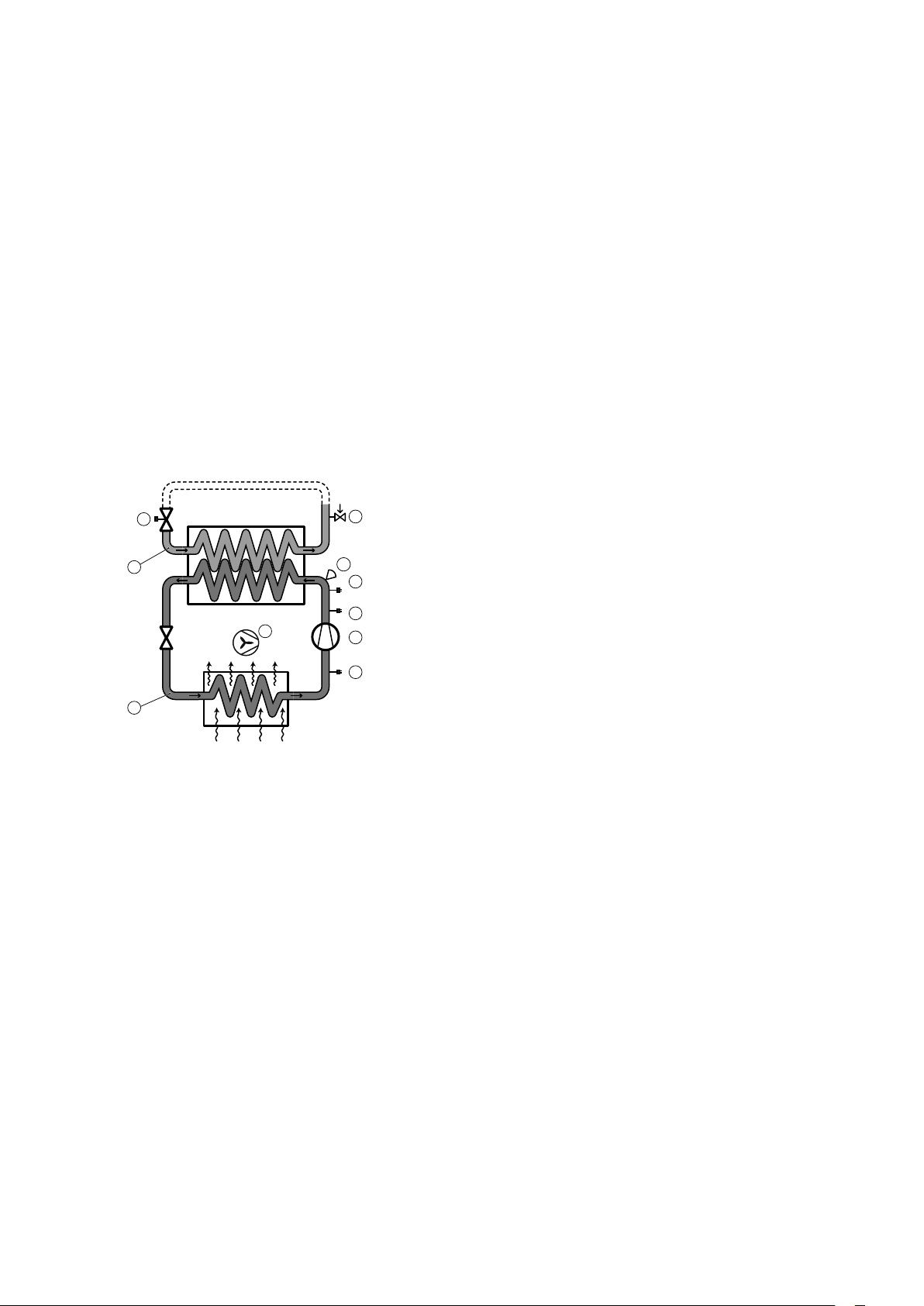

5.4 System solution intermediate exchanger

To safeguard against the pipes freezing an intermediate exchanger can be installed indoors. In such cases one

must use glycol intended for refrigerant applications in the circuit to the heat pump unit and an extra circulation

pump. Follow the supplier's instructions for mixing, but if none is given 35% is the lowest concentration recommended. To order and for more information about the intermediate exchanger and the circulation pump, contact

Danfoss.

Caution! No glycol mixtures may be used in systems with hot zinc dipped pipes or components.

Installation instructions VMGFD102 – 27

Page 30

5

71

96

100

112

82 38

65

Position Name Position Name

5 Heat pump unit 82 Adjustment valve

38 Circulation pump 96 Flexible hose

65 Intermediate exchanger 100 Safety valve (1.5 bar)

71 Flow sensor 112 Expansion vessel, closed

28 – Installation instructions VMGFD102

Page 31

6 Piping installation

6.1

Pipe connection

Caution! Piping installation must be carried out in accordance with applicable local rules and regulations.

The hot water tank must be equipped with an approved safety valve.

Caution! There is a risk of the pipes to the heat pump freezing when water circulation through the heat

pump stops when outdoor temperatures fall below freezing. Normally the integrated flow sensor gives an

alarm if there is low flow (assumes that there is current to the heat pump), for example when the radiator

pump has stopped. In the event of longer flow stops, for example in case of power failure or if the plant is

OFF, there is however an obvious risk of freezing . By installing a stop cock on the inside of the house wall

it is possible to drain the part of the system that goes out to the heat pump if necessary. Another way of

ensuring against freezing is to install an intermediate exchanger indoors. In such cases one must use

glycol intended for refrigerant applications in the circuit to the heat pump unit and an extra circulation

pump, see System solution intermediate exchanger. Another option is to fill the heating system with antifreeze.

Caution! To prevent leaks, ensure that there are no stresses in the connecting pipes!

Caution! It is important that the heating system is bled after installation. Bleed valves must be installed

where necessary.

Caution! Heating systems with closed expansion tanks must also be supplied with approved pressure

gauges and safety valves.

Caution! Cold and hot water pipes and overflow pipes from safety valves must be made of heat resistant

and corrosion-resistant material, e.g. copper. The safety valve overflow pipes must have an open

connection to the drain and visibly flow into this in a frost-free environment.

Caution! The connecting pipe between the expansion tank and the safety valve must slope continuously

upwards. A continuous upwards slope means that the pipe must not slope downwards from the

horizontal at any point.

Note! Ensure that the pipe installation is carried out in accordance with the dimensions and connection

diagrams.

6.2 Connecting cold and hot water lines

If necessary, connect the cold water and hot water pipes with all the necessary components, see System solution,

Page 24.

6.3 Connecting the heating system supply and return lines

Connecting the heating system supply and return lines, see System solution, Page 24.

For information on how flexible hoses should be installed, see Flexible hoses, Page 30.

Installation instructions VMGFD102 – 29

Page 32

1

2

1. Connect the supply pipe with a flexible hose connection and with all the necessary components.

2.

Connect the return pipe with a flexible hose connection and with all the necessary components including a

filter.

3. Insulate the supply and return lines all the way to the heat pump.

Position Description

1 Supply line 28 mm copper pipe

2 Return line 28 mm copper pipe

6.4 Noise and vibrations

6.4.1 Installation of the heat pump

To prevent disturbing noise from the heat pump the following recommendations should be observed:

In the event the heat pump is positioned on a vibration sensitive base, vibration dampers should be used. The

•

vibration dampers must be correctly dimensioned with regard to the heat pump's weight so that static spring

depression of at least 2 mm is obtained in all mounting components. Vibration dampers are available to purchase as accessories.

Connection of the heat transfer fluid to the heat pump must be made using a flexible hose to prevent trans-

•

mission of vibration to building construction and the pipe system, see Flexible hoses, Page 30.

Ensure that pipes at lead-ins are not lying against the walls.

•

Ensure that the electrical supply cable does not provide a path for vibration because it is overstretched.

•

6.4.2 Flexible hoses

All pipes should be routed in such a way that vibrations cannot be transmitted from the heat pump through the

piping and out into the building. This also applies to the expansion pipe. We recommend that flexible hoses are

30 – Installation instructions VMGFD102

Page 33

used for all pipe connections to avoid the transmission of vibrations. Flexible hoses are available to purchase as

accessories. The figures below show how appropriate and inappropriate installations look using this type of hose.

Installation instructions VMGFD102 – 31

Page 34

4

3

1

5

6

3

4

5

6

2

1

7

7 Electrical Installation

DANGER! Hazardous electrical voltage! The terminal blocks are live and can be highly dangerous due to

the risk of electric shock. All power supplies must be isolated before electrical installation is started. The

heat pump is connected internally at the factory, for this reason electrical installation consists mainly of

the connection of the power supply.

Warning! Electrical installation may only be carried out by an authorised electrician and must follow

applicable local and national regulations.

Warning! The electrical installation must be carried out using permanently routed cables. It must be

possible to isolate the power supply using a multi-pole circuit breaker with a minimum contact gap of 3

mm.

7.1 Control centre

7.1.1

Installation

Caution! The control centre must be installed in a frost-free environment.

The control centre contains the necessary components for voltage supply, control systems and operation.

7.1.2 DHP-AQ Mini electrical components in the control centre

Symbol explanation

1 Terminal block

3 Hub card

4 Space for expansion card (accessory)

5 Space for communications card (accessory)

6 Space for terminal block for expansion card (accessory)

7.1.3 DHP-AQ Midi electrical components in the control centre

Symbol explanation

1 Terminal block

2 Terminal block for internal electrical auxiliary heater (IH)

3 Hub card

4 Space for expansion card (accessory)

5 Space for communications card (accessory)

6 Space for terminal block for expansion card (accessory)

32 – Installation instructions VMGFD102

7 Overheating protection

Page 35

2

3

4

1

5

6

7

3

4

5

2

1

6

1

2

3

5 O K!

4

7.1.4 DHP-AQ Maxi electrical components in the control centre

Symbol explanation

1 Terminal block

2 Terminal block for internal electrical auxiliary heater (IH)

3 Hub card

4 Space for expansion card (accessory)

5 Space for communications card (accessory)

6 Space for terminal block for expansion card (accessory)

7 Overheating protection

7.2 Electrical cabinet in heat pump

Symbol explanation

1 Heat pump card

2 Expansion valve card

3 Soft starter

4 Overcurrent protection

5 Terminal block

6 Capacitor (only for 230V 1N)

7.3 Cable connection

Note! Laying electrical wiring can also cause noise so this installation must be carried out appropriately.

An appropriate installation is where there is approximately 300 mm free cable between the heat pump

and the building. It is inappropriate to bolt trunking between the heat pump and the wall. This is because

vibrations can then be transmitted from the heat pump through the trunking to the walls of the house.

UV resistant cable must be used for outdoor power cables. Cable choice must follow applicable local and national

regulations.

UV resistant, twinned pair date/telephone cable must be used for outdoor communication cables. The cable must

be screened with the one end of the screening (it does not matter which end) earthed in a ground block. The cable

section area must be a minimum of 0.25 mm2.

When the power cable is connected to the terminal block a screwdriver is used to open the terminal block.

1. Insert the screwdriver.

2. Straighten the screwdriver.

3. Push the screwdriver down to release the cable lock.

Installation instructions VMGFD102 – 33

Page 36

H

2/3 x H

com

305

-B25

118.5

com

-B25

com

110

-B8

com

111

-B9

1

2

4. Insert the cable and hold it in place.

5.

Pull the screwdriver out.

6. Check that the cable is secured by carefully pulling on the cable.

7.4 Position and connect outdoor sensors

Position the outdoor sensor on the north or north west side of the house.

•

For higher buildings, the sensor should be positioned between the second and third storeys. Its location must

•

not be completely protected from the wind but not in a direct draft. The outdoor sensor should not be placed

on reflective panel walls.

The sensor must be positioned at least 1 m from openings in the walls that emit hot air.

•

If the sensor cable is connected through a pipe, the pipe must be sealed so that the sensor is not affected by

•

outgoing air.

Recommended location

Unsuitable location

The outdoor sensor is connected by a two core cable. A maximum cable length of 50 m applies for a cross section

of 0.75 mm2. For greater lengths a cross section of 1.5 mm2 is used, up to a maximum of 120 m.

Then connect the sensor to the heat pump (outdoors) or the heat pump's control centre (indoors).

7.5 Connecting supply and return pipe sensors

DHP-AQ Mini - no sensors connected upon delivery.

DHP-AQ Midi - supply line sensor connected upon delivery.

DHP-AQ Maxi - both sensors connected upon delivery.

Control unit

1. Supply line sensor

2.

Return line sensor

34 – Installation instructions VMGFD102

Page 37

com

113

-B20

-B21

com

114

1

2

PE

101.1

N

M

-M4

116.1

com

116.2

com

0 - 10 V

-2

-4

-1

-3

-M4

N

L1.1

PE

R4

BUS_B

com

BUS_A

com

BUS_B

BUS_A

7.6 Connect hot water sensor to external heater

Control unit

1. Toph sensor

2.

7.7 Connecting circulation pump

Connecting circulation pump for DHP-AQ Mini When installing further circulation pumps, see electrical instructions.

Control unit

Hot water sensor

Control unit

7.8 Connect heating cable driptray

Heat pump

7.9 Connect the communication cable

Heat pump Control unit

Installation instructions VMGFD102 – 35

Page 38

3

1

5

2

4

6

L1

L2

L3

N

PE

L1

SPARE

SP1

N

PE

1 2

3

1

5

2

4

6

L1

L2

L3

N

PE

7.10 Connecting the power supply

Connect power cable to heat pump unit and to terminal block in control centre as below.

DANGER! Electrical current! The power cable may only be connected to the terminal block intended for

this purpose. No other terminal blocks may be used!

7.10.1 Connection heat pump 400 V, 3-N

Circuit-breaker Terminal block heat pump

Incoming cable

7.10.2 Connection heat pump 230 V, 1-N

Circuit-breaker Terminal block heat pump

Incoming cable

7.10.3 Connection control centre 400 V, 3-N (DHP-AQ Midi and DHP-AQ Maxi)

Circuit-breaker Terminal block control centre

Incoming cable

36 – Installation instructions VMGFD102

Page 39

2

1

3

ROOM

NO HEAT DEMAND

OPERAT. AUTO

20°C

8 Operator panel

8.1

Manage operator panel

The heat pump has an integrated control system which automatically calculates the heat demand in the house to

ensure that the correct amount of heat is produced and emitted where necessary.

The control panel is operated using a keypad and information is shown in a display and by an indicator.

Note! The information in the display and menus will vary depending on the heat pump model and

connected accessories.

1. Keypad

Indicator

2.

3. Display

+ Plus sign used to scroll up a menu and increase the values.

- Minus sign used to scroll down a menu and reduce the values.

> Right arrow used to select a value or open a menu.

< Left arrow to cancel selection or exit a menu.

The indicator at the bottom of the control panel has three modes:

Not lit, means that the heat pump is not powered.

•

When the green light shines continuously, the heat pump has power and is ready to produce heat or hot

•

water.

Flashing green, means an active alarm.

•

Caution! During a service that consists of replacing the display card, all heat pump settings are reset to

factory settings. Therefore note current settings before replacement.

The control system is divided into the following two main menus:

INFORMATION

•

SERVICE

•

The INFORMATION menu is opened by pressing the left or right buttons.

For installation and service, the SERVICE menu is used, which is opened by pressing the left button for five sec-

onds.

Installation instructions VMGFD102 – 37

Page 40

8.2 Operating modes

Table 2. Shows the set operating mode of the heat pump.

Operating mode Meaning

(OFF)

AUTO The heat pump regulates automatic compressor operation and auxiliary heater.

COMPRESSOR The control system is controlled so that only the heat pump unit (compressor) is allowed to

AUX. HEATER The control system only permits the auxiliary heater to be in operation.

HOT WATER In this mode the heat pump only produces hot water, no heat goes to the heating system.

MANUAL TEST Operating mode MANUAL TEST is selected. Used to test different functions, for example circu-

The installation is fully switched off. This mode is also used to acknowledge certain alarms.

Caution!If the operating mode OFF or HOT WATER is to be used for long

periods during the winter, the water in the heating system in the heating

system must be drained, otherwise there is a risk of frost damage.

Alternatively the system solution with intermediate exchanger should be

used.

operate. In this operating mode peak heating charging (anti-legionella function) of the hot

water will not run because the auxiliary heater is not used.

lation pump.

8.3 Symbols

Table 3. Symbols shown in the display.

Symbol Meaning

F FLOW SENSOR Indicates that the flow sensor is active (there is flow).

COMPRESSOR Indicates that the compressor is in operation.

LIGHTNING Indicates that the auxiliary heater is in operation. The number indicates what additional

step is activated.

HOUSE Indicates that the heat pump produces heat for the heating system.

TAP Indicates that the heat pump produces heat for the water heater.

CLOCK Indicates that tariff control is active.

TANK Indicates the level of hot water in the water heater. When hot water is produced for the

water heater, this is indicated by a flashing icon for the tank. A lightning symbol by the

symbol indicates peak heating charging (anti-legionella function).

SQUARE Either indicates that the operating pressure switch has deployed, or that the pressure

pipe temperature has reached its maximum temperature.

DEFROST Displayed when defrosting is active.

FAN Displayed when the fan is active.

COOLING Displayed if cooling is produced.

38 – Installation instructions VMGFD102

A = Active cooling.

Page 41

8.4 Operational information

The following operating information may also appear:

Message Meaning

ROOM Shows the set ROOM value. Standard value: 20°C.

START Indicates that there is a need for heat production or hot water and that the heat pump will

EVU STOP Indicates that the additional function EVU is active. EVU is used to switch off the heat

NO HEAT DEMAND Indicates that there is no heating or hot water production demand.

NO COOLING DEMAND Indicates that there is no cooling demand.

COMPRESSOR START --XX Indicates that there is a need for heat, hot water or cooling and that the heat pump will

COMPRESSOR+IMM.HEAT Indicates that heat production is active with both compressor and auxiliary heater.

START_MIN Indicates that there is a demand for heating or hot water production but that a start delay

AUX. HEATER Indicates that there is an auxiliary heater demand.

ACT COOLING Displayed if cooling is active.

DEFROST X(Y) Displayed when defrosting is active. X shows the actual reached temperature. Y shows at

If the accessory room sensor is installed it shows the actual temperature and the desired

indoor temperature is shown within brackets.

start.

pump during high energy tariffs.

start in XX minutes.

is active.

what temperature defrost is complete.

8.5 Important parameters

8.5.1

8.5.2 CURVE

Heat production - calculating

The indoor temperature is adjusted by changing the heat pump’s heat curve, which is the control system’s tool for

calculating what the supply temperature should be for water that is sent out in the heating system. The heat curve

calculates the supply temperature depending on the outdoor temperature. The lower the outdoor temperature,

the higher the supply temperature. The difference between the desired and actual supply temperature is the basis

for calculation of the heating requirement.

The heat curve will be adjusted in connection with installation. It must be adapted later on, however, to obtain a

pleasant indoor temperature in any weather conditions. A correctly set heat curve reduces maintenance and gives

energy efficient operation.

The control computer shows the value for CURVE by means of a graph in the display. The heat curve can be

changed by adjusting the CURVE value. The value for the CURVE indicates which value on the supply temperature

is required in relation to the outdoor temperature.

Installation instructions VMGFD102 – 39

Page 42

4

2 0 0 - 2 0

2 4

4 0

5 6

2

3

1

5

2 0 0 -2 0

2 4

4 0

5 6

2

3

1

Figure 1. Graph showing the set value 40 for CURVE.

Position Description

1 Supply temperature (°C)

2 Maximum supply temperature

3 Outdoor temperature (°C)

4 0°C

5 Value for CURVE is 40°C

In the event of outdoor temperatures below 0°C, a higher setpoint value is calculated and in the event of outdoor

temperatures greater than 0°C, a lower setpoint value is calculated.

Figure 2. Increasing or reducing the CURVE changes the slope of the curve.

Position Description

1 Supply temperature (°C)

2 Maximum supply temperature

3 Outdoor temperature (°C)

If the CURVE value is increased, the heat curve will become steeper and if the value is reduced, it will become flatter.

40 – Installation instructions VMGFD102

The most energy efficient and cost effective setting is achieved by changing the CURVE value to adjust the temperature in the house to an even and constant temperature. For a temporary increase or reduction, adjust the

ROOM value instead.

Page 43

2 0 0 - 2 0

2 4

4 0

5 6

2

3

1

8.5.3 ROOM

If you wish to increase or reduce the indoor temperature, change the ROOM value. The difference between changing the ROOM value and the CURVE value is as follows:

When changing the ROOM value, the angle of the curve on the system's heat curve does not change, instead

•

the entire heat curve is moved by 3°C for every degree change of the ROOM value. The reason that the curve is

adjusted 3°C is that an approximate 3°C increase in supply temperature is usually needed to increase the

indoor temperature 1°C.

When changing the CURVE value, the angle of the curve on the system's heat curve changes.

•

Figure 3. Changing the ROOM value changes the heat curve upwards or downwards.

Position Description

1 Supply temperature (°C)

2 Desired supply temperature

3 Outdoor temperature (°C)

The relationship of the supply temperature to the outdoor temperature will not be affected. The supply temperature will be increased or reduced by the same number of degrees all along the heat curve. I.E. The entire heat curve

rises or drops instead of the curve gradient changing.

This method of adjusting the indoor temperatures can be used for a temporary raise or drop. For long term increases or reductions of the indoor temperature, the heat curve should be adjusted.

8.5.4 Adjusting the heat curve at -5°C, 0°C and 5°C

Sometimes, at outdoor temperatures between -5°C and +5°C, part of the heat curve may need adjusting if the

indoor temperature is not constant. For this reason, the control system includes a function which only adjusts the

heat curve at three outdoor temperatures: -5°C, 0°C and +5°C. This function will allow one to increase or reduce

the setpoint value for the supply line temperature, without affecting the rest of the heat curve, at three specific

outdoor temperatures. If, for example, the outdoor temperature is -5°C, the supply temperature will change gradually between 0°C and -10°C, maximum adjustment being reached at -5°C. The figure below shows the adjusted

CURVE -5. The adjustment can be seen in the graph in the form of a bump.

Choose to adjust the heat curve individually at three specified outdoor temperatures: -5°C, 0°C and +5°C. The supply temperature can be changed by plus/minus 5°C.

Installation instructions VMGFD102 – 41

Page 44

2 0 0 -2 0

2 4

4 0

5 6

-5

2

1

3

Figure 4. The adjusted curve at -5°C

Position Description

1 Supply temperature (°C)

2 Outdoor temperature (°C)

3 Local higher supply temperature at -5°C

8.5.5 HEAT STOP

The HEAT STOP function automatically stops all production of radiator heat when the outdoor temperature is

equal to, or higher than, the value entered for heat stop.

When the heat stop function is activated, the circulation pump will be turned off - except when hot water is being

produced. The circulation pump will be "exercised" for one minute per day. The factory set value for activating

heat stop is an outdoor temperature of 17°C. If the heat stop function is active, the outdoor temperature must

drop 3°C when setting, before the heat stop stops.

8.5.6 MIN and MAX

The MIN and MAX values are the lowest, respectively highest set point values that are allowed for the supply temperature.

Adjusting the minimum and maximum supply temperatures is particularly important if under floor heating is used.

Note! MIN and MAX temperatures do not limit the actual temperature on the supply line.

Caution! For under floor heating under a parquet floor or stone floor, too high a supply temperature can

damage the floor.

If your house has a basement, the MIN value should be adjusted to a suitable temperature for the basement in

summer. A condition for maintaining the heat in the basement in the summer is that all radiators have thermostat

valves that switch off the heat in the rest of the house. It is extremely important that the heating system and the

radiator valves are trimmed correctly. As it is usually the end customers themselves who have to carry out trimming, remember to inform them how to carry it out correctly. Also remember that the value for HEAT STOP needs

adjusting upwards for summer heating.

8.5.7 TEMPERATURES

The heat pump can show a graph of the history of the temperatures of the different sensors. The graph shows how

the temperature has changed during the last 60 measurement points. The time interval between the measurement points can be adjusted between one minute and one hour, factory setting is one minute.

History is available for all sensors, but only the set value is shown in the display for the room sensor. The integral

value that may appear is the heating system’s energy balance.

42 – Installation instructions VMGFD102

Page 45

1 5

7

3

4

1 4

11

1 3

1 2

3

4

6

1 2

11

88

2

5

2

1 0

9

1

5

1 0

9

15

15

16

8.5.8 INTEGRAL

The heat demand in the house depends on the season and weather conditions and is not constant. The heat

demand can be expressed as temperature difference over time and can be calculated giving an integral value as a

result (heat demand). To calculate the integral value, the control system uses several parameters.

A heat deficit is needed to start the heat pump, and there are two integral values, A1 (default value = -60), which

starts the compressor and A2, (factory set = -600), which starts the auxiliary heater and A3 (user-defined value),

which starts the external auxiliary heater. External auxiliary heater operation is activated when the integral passes

the value for INTEGRAL A3. During heat production, the deficit reduces and when the heat pump stops, the inertia

in the system causes a surplus of heat.

The integral value is a measurement of the area under the time axis and is expressed in degree minutes. The figure

below shows the factory settings for the integral values that the heat pump has. When the integral value has

reached the set value for INTEGRAL A1, the compressor starts and if the integral value does not drop but continues

to rise, the auxiliary heater starts when the integral value has reached the set value for INTEGRAL A2.

Position Description

1 Integral

2 Heat surplus

3 INTEGRAL A1

4 INTEGRAL A2

5 Heating deficit

6 Time

7 Heat pump operation

8 No operation

9 Compressor

10 Aux. heat. + ext. aux. heater

11 Compressor start (A1)

12 Auxiliary heater start (A2)

13 Aux. heater stop (latest by A1)

14 Compressor stop (=0)

Installation instructions VMGFD102 – 43

Page 46

Position Description

1

5

2

8

9

3

4

6

7

15 INTEGRAL A3

16 External auxiliary heater (INTEGRAL A3 < INTEGRAL A2)

The calculation of the integral value does not stop during hot water production or when pool heating is produced.

8.5.9 HYSTERESIS

In order to start the heat in advance during sudden changes of the heat demand, there is a value, HYSTERESIS,

which controls the difference between the actual supply temperature, t1 and the calculated supply temperature,

t2. If the difference is equal to or greater than the set HYSTERESIS value (x), i.e. there is a heat demand, or the heat

demand disappears, quicker than the usual integral calculation, the integral value is forced to either the start value

(-60) INTEGRAL A1 or to the stop value (0).

Figure 5. Conditions for HYSTERESIS to force the integral value to change.

Position Description

1 Integral

2 Supply temperature

3 t

4 t

5 Time

6 Compressor stop (0)

7 Compressor start (-60)

8 Hysteresis (Δt) ≥ x

9 Hysteresis (Δt) ≥ x

8.5.10 DEFR CURVE

During operation the air heat exchanger is cooled by the energy exchange, at the same time the humidity causes it

to become covered in frost at low outdoor temperatures. DHP-AQ has an automatic function to defrost the air heat