Page 1

Danfoss Gas Sensor

Type DGS

Modbus or Service Tool display operation

User Guide

danfoss.com

Page 2

Contents Page

1. Intended use .....................................................................................4

2. Content ..........................................................................................4

3. Operation ........................................................................................4

3.1 Function of the keys and LEDs on the keypad ................................................6

3.2 Setting / changing of parameters and set points .............................................6

3.3 Code Levels.................................................................................7

4. Menu Overview ..................................................................................7

4.1 Error status ............................................................................... 10

4.2 Alarm Status .............................................................................. 10

4.3 Relay Status............................................................................... 10

4.4 Menu Measuring Values ................................................................... 11

4.5 Display Parameters........................................................................ 11

4.5.1 Software Version ........................................................................ 11

4.5.2 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.3 LCD Function Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6. Measuring Point Parameters ..............................................................12

4.6.1 Alarm limits ............................................................................. 12

4.6.2 Alarm delay ............................................................................. 12

4.7 Menu System Parameters..................................................................13

4.7.1 AO function .............................................................................13

4.8 Operating data............................................................................ 14

4.9 Calibration................................................................................ 15

4.9.1 Zero Calibration .........................................................................16

4.9.2 Gain Calibration .........................................................................17

4.9.3 Zero-point calibration of Analog output.................................................. 18

4.10 Addressing .............................................................................. 18

5. Modbus menu survey .......................................................................... 19

6. Technician use only! ............................................................................ 22

6.1 Regular test............................................................................... 22

6.2 Locaton................................................................................... 22

7. Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

2 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

Page 3

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 3

Page 4

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

4 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

1

Intended use

The display of the handheld Service Tool and the

Modbus interface for integration with Building

Management Systems is used as interface for

operation, commissioning and calibration of the

DGS gas detection unit

2

Content

This user guide contains the maximum possible

functionality of concerned display devices.

Depending on the DGS type some features

described here are not possible and therefore the

menu items may be hidden.

Some features are available from Modbus or

handheld Service Tool interface only. Differences

is highlighted in this document.

3

Operation

The configuration and service is made via the

handheld Service Tool or in combination with the

Modbus interface.

Security is provided via password protection

against unauthorized intervention.

Handheld Service Tool:

Operation is done via 6 buttons.

AK-SM 800 Front End:

The configuration is done via the graphical

display and buttons or via the PC tools

StoreView Desktop or AK-ST 500.

Gas D etection Service Tool

Esc

←─

D1 CO2 ppm

Warm-up Time

DGS Service Tool

Page 5

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 5

Operation with the handheld Service Tool is

described in sections 3.1 and 3.2 and chapter 4.

Operation with the Danfoss Front End is

described in chapter 5.

2 functions are configured via jumpers on the

DGS.

Jumper 4, JP 4, located on the bottom left is used

to configure the Modbus baud rate.

As default the baud rate is 38.400 Baud. By

removing the jumper the baud rate is changed to

19.200 Baud. Removing the jumper is required for

integrating with Danfoss System Managers AKSM 720 and AK-SM 350.

Jumper 5, JP5, located on the top left is used to

configure the analogue output type.

As default this is Voltage output. By removing the

jumper this is change to Current output.

Note: the DGS must be power cycled before any

change to JP4 take effect.

JP5

5

4

2

1

not used

GND

AO_01

DI_01

S&H supply

x1

open: 0-20mA

closed: 0-10V

LED

Yellow/Green/Red

1

2

3

1

2

3

x6

x5

Rel. 3

Rel. 1

x4

4

3

2

1

not used

JP3

JP2

JP1

x3

Ackn.-/Test

button

Sensor 1

Sensor 2

Tool

x9

x2

x8

B&L

JP4

Danfoss

80Z790.1

1

open: 19200 Baud

closed: 38400 Baud

BModbus

A+

-

24V ac/dc

+

(critical)

(warning)

Page 6

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

6 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

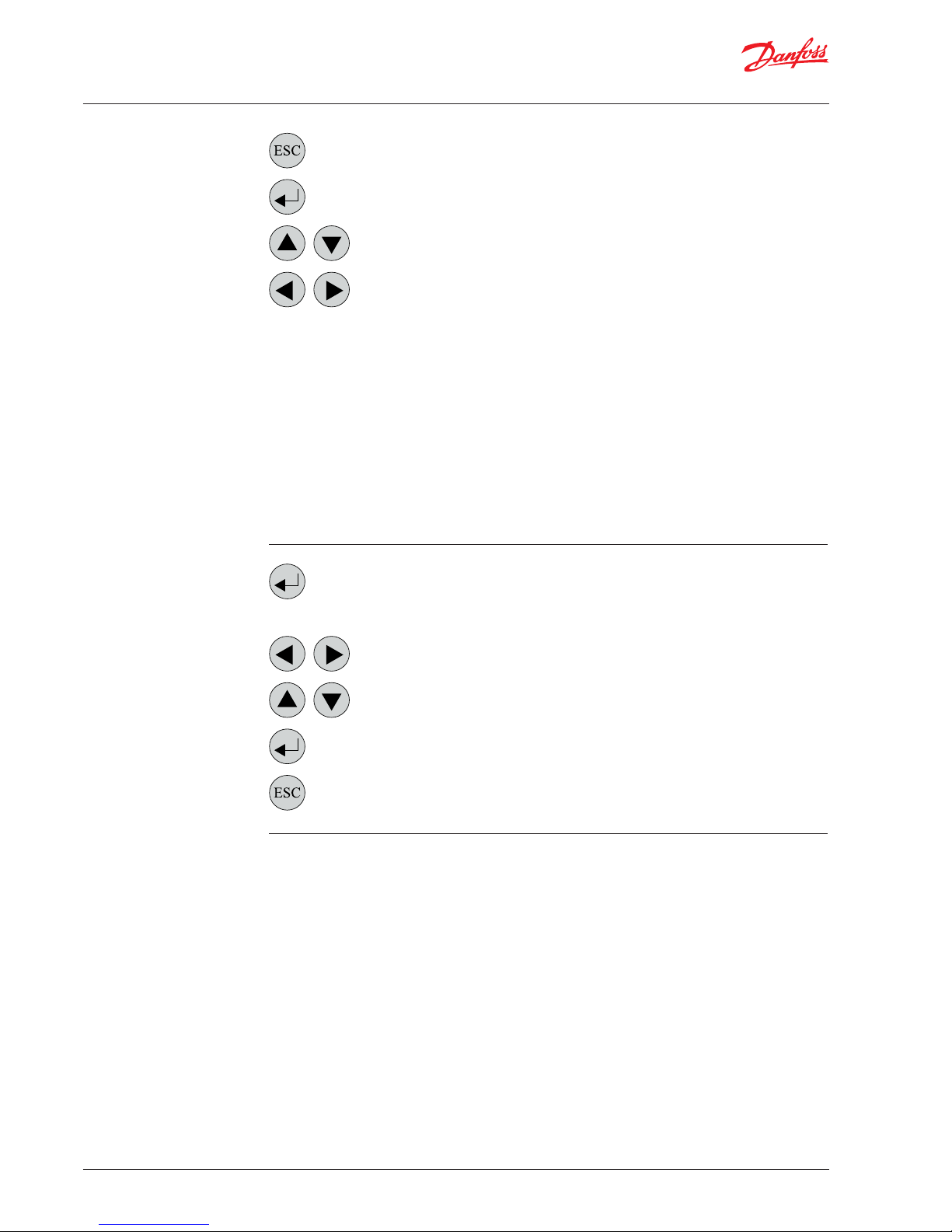

3.1

Function of the keys and LEDs

on the keypad

Exits programming, returns to the previous menu level.

Enters sub menus, and saves parameter settings.

Scrolls up & down within a menu, changes a value.

Change of cursor position.

The status LEDs indicate the operating state.

• Green

Continuous = Operating voltage

Flashing = Maintenance message

• Yellow

Continuous = Failure

Slowly flashing = Warming-up

Fast flashing = Special mode

• Red = Alarm

The backlight of the display changes from green

to red when an alarm is active.

3.2

Setting / changing of

parameters and set points

Open desired menu window.

Code input field opens automatically, if no code is approved.

Set the desired parameter / set point with the keys.

After input of valid code the cursor jumps onto the first position segment to be changed.

Push the cursor onto the position segment, which has to be changed.

Save the changed value, confirm storage (ENTER).

Cancel the save / close editing / return to a higher menu level (ESCAPE function).

Page 7

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 7

3.3

Code Levels

All inputs and changes are protected by a

four-digit numeric code (= password) against

unauthorised intervention according to the

regulations of all national and international

standards for gas warning systems. The menu

windows of status messages and measuring

values are visible without entering a code.

The access to the protected features is cancelled

automatically if no button is pushed within 15

minutes.

The service technician access code to the

protected features is ‘1234’

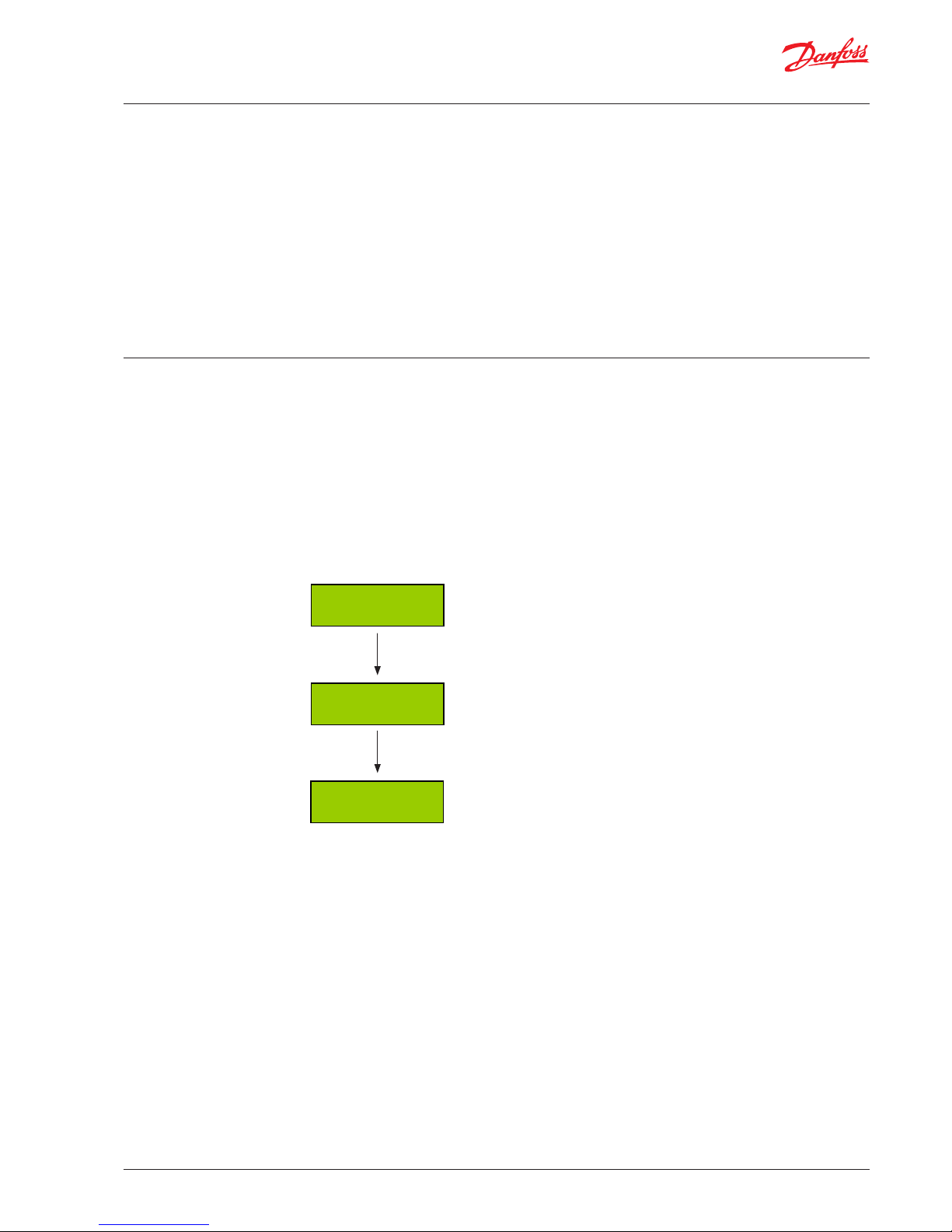

4

Menu Overview

Menu operation is done via a clear, intuitive and

logical menu structure. The operating menu

contains the following levels:

• Starting menu with indication of the device

type if no Measuring Point is registered,

otherwise scrolling display of the gas

concentrations of all registered sensors in

5-second intervals. If alarms are active, only the

values of the sensors currently in alarm status

are displayed.

• Main menu

• 5 sub menus under “Installation and

Calibration”

Power On Time of the basic device

Second counter counts down, when communication display <> basic

device is OK. In case of communication error the count-down will stop.

“Warm-up Time” is displayed. As soon as the sensor warm-up time has

expired, the measured value is displayed = measuring mode.

Seconds indicator = 0

After about 2 seconds

Power On Time

19s

Danfoss

DGS

D1 CO2 ppm

Warm-up Time

Page 8

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

8 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

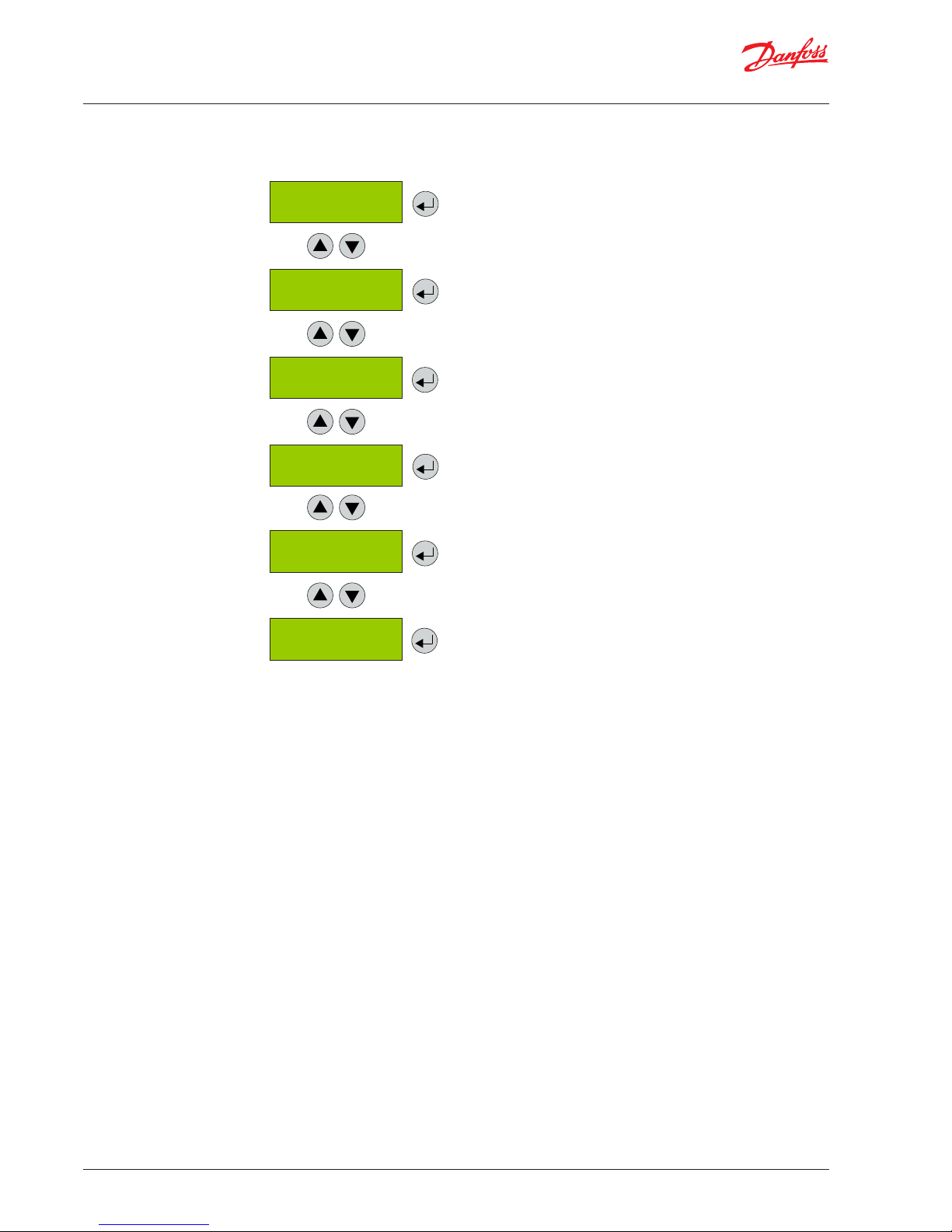

4

Menu Overview

(Continued)

Starting menu

Main menu

Error Status

Alarm Status

Relay

Status

Measuring Values

Display

Parameters

Installation &

Calibration

Reading and acknowledgement of errors

See chapter 4.1

Display of the status of active alarms

See chapter 4.2

Display of the relay status. Protected by password.

See chapter 4.3

Display of measuring values

See chapter 4.4

Read-out of handheld tool version, language and set-up of language.

Partly protected by password

See chapter 4.5

Reading and change of the relay, measuring point and

system parameters as well as test and calibration functions

Chapter #

Page 9

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 9

Service

OFF

MP Parameters

System Parameters

See chapter 4.6

See chapter 4.7

The following menu items are only accessible

with Service ON (password protected)

!! Service ON = Special mode = Fault message is

active!!

4

Menu Overview

(Continued)

Starting menu

Main menu Chapter #

Operating Data

See chapter 4.8

MP Parameters

See chapter 4.9

Calibration

Addressing

See chapter 4.10

Page 10

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

10 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

4.1

Error status

A pending fault activates the yellow LED (Fault).

The integrated fault management records the

first 99 occurred faults with time stamps in the

menu „System Errors“.

4.2

Alarm Status

Display of the currently pending alarms in plain

text in the order of their arrival. Only those

measuring points are displayed, where at least

one alarm is active.

Alarms in latching mode (latching mode is only

valid for certain DGS types, DGS-PE) can be

acknowledged in this menu (only possible if the

alarm isn’t active).

Alarm Status DP 1

“A1

DP 1

Acknowledge?

Symbol Description Function

DP 1 Measuring Point No.

1 = Relays 1 = Warning relay

2 = Buzzer

3 = Relay 3 = Critical relay

‘A1

‘‘A1

Alarm status

‘A1 = Alarm 1 active

‘‘A1 = Alarm 1 in latching mode, can be acknowledged

4.3

Relay Status

Reading of the current status of alarm relays.

The actual relay status is displayed, depending on

the relay mode (energized <> de-energized).

Selection of the alarm relay 1 – X

Alarm Relay

Status

Alarm Relay 1

Status OFF

Symbol Description Function

1 Alarm Relay Alarm relay = 1 - X

OFF Relay Status Relay OFF = coil de-energised

ON Relay Status Relay ON = coil energised

Selection of the next alarm relay

A number of error messages may be displayed

related to the sensor; Out of Range, Wrong type,

Removed, Calibration due, Voltage Error

“Voltage Error” refers to the supply voltage. In

this case the product will not go into normal

operation until the supply voltage is within the

specified range.

Note:

Relay 3 is Normally Closed with a fail-safe function at

power loss, i.e. in normal operation without any errors

or alarms, the coil is energised (Relay ON)

Page 11

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 11

4.4

Menu Measuring Values

In this menu, the display shows the measuring

value with gas type and unit.

Measuring Values D 1 CO2 ppm

A ! 450

Symbol Description Function

D1 Actual Modbus address D1: Modbus address = 1

CO2 Gas type Display of gas type (must comply with gas type of sensor head)

ppm Gas unit Unit

51.0 C Measured value Current measured value (current value) of the gas concentration

A! Alarm indication At least one alarm has been released at this Measuring Point

# Maint. info Sensor head: maintenance due (maintenance date exceeded)

? ConfigError Gas type or meas. range doesn’t agree with sensor head.

Comm. err. Fault Measuring Point Communication error, sensor head <> I/O board

Underrange

Overrange

Meas. range monitoring

Meas. signal < admissible range (< zero point – 6 %)

Meas. signal > admissible range (> full scale value + 6 %)

Locked Measuring Point locked Measuring Point was temporarily locked by the operator.

Warm-up Warm-up time Warm-up time of the sensor active

Selection of the next measuring point

4.5

Display Parameters

In the menu Display Parameters you can find the

general parameters of the display.

Display

Parameters

4.5.1

Software Version

Software Version

XXXXX - YYYYY

Software version of the handheld Service Tool

and of DGS.

Symbol Description Function

XXXXX Software Version of the Service Tool XXXXX Software Version

YYYYY Software Version of the DGS YYYYY Software Version

Page 12

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

12 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

4.5.2

Language

Language

English

Selection of the menu language (password

protected)

Symbol Description Default Function

English Language English

English

USA English

German

French

Spanish

4.5.3

LCD Function Check

Function for testing the LCD function (password protected)

All LEDs light up for about two seconds. The backlight is

yellow. (Green and red are activated at the same time). All

points are displayed on the LCD

LCD Function

check ?

4.6

Measuring Point Parameters

Reading and changing of the parameters for each

measuring point.

MP Parameters MP 1

Active

Selection of measuring point (1 – X)

Symbol Description Default Function

0 sec. Delay Alarm 0 sec

Gas concentration > alarm threshold + set time = Alarm ON

Gas concentration < alarm threshold – hysteresis = Alarm OFF

Warning limit

C 5000 ppm

4.6.1

Alarm limits

For each measuring point two alarm thresholds

are available for free definition. If the gas

concentration is higher than the set alarm

threshold, the associated alarm is activated. If the

gas concentration falls below the alarm threshold

inclusive hysteresis the alarm is reset again.

The hysteresis of both alarm is 5% of the default

alarm threshold (e.g. with 5000pmm this

corresponds to 250ppm)

Critical limit

C 5000 ppm

4.6.2

Alarm delay

Delay Alarm ON

0 s

For setting the alarm delay for Critical and

Warning alarms

Page 13

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 13

4.7

Menu System Parameters

System Parameters

Symbol Description Default Function

Analog Output 1 Selection of channel Selection of the analog output 1 - X

50%

100 %

Selection of input range

for maximum output signal

50 %

50% = at a concentration of 50% of the measuring point range the

output will be set to 10V (20mA without JP5 mounted)

100% = at a concentration of 100% of the measuring point range

the output will be set to 10V (20mA without JP5 mounted)

- DANFOSS ONLY SETTING

--

Do not change – If doing so a small “noise signal” (step form) on

top of the measured ppm-value with a duty-cycle of app. 180s is

activated.

0V

2V

Selection of minimum

output signal

0 V.

0V = at the minimum measuring signal of the sensor, the output will

be set to 0V (0mA without JP5 mounted)

2V = at the minimum measuring signal of the sensor, the output will

be set to 2V (4mA without JP5 mounted)

4.7.1

AO Function

The configuration of the analog outputs.

The analog output checks the current signal for

validity. Signal deviations of more than 5% from

the nominal value will entail an error message

(causes: short circuit or interruption of cable,

actuator not connected).

If more than one measuring points is present,

the maximum value of the two measurement is

assigned to the output.

Using this function, it is possible to configure the

output signal.

The CO2 sensor with a range of 0-20.000ppm

has an output signal of 0-10V corresponding to

0-10.000ppm as default

In example this may be changed to say 2-10V for

0-20.000ppm by changing settings to “100%” and

“2V”.

AO Function

Analog Output 1

50 % -- min=0V.

Page 14

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 14

4.8

Operating Data

Operating Data

Software version

XXXX

Software version of the measuring point

Operating Data

SC X

Operating days

expected XXX

This menu is for retrieving relevant operational data of the sensor head.

No changes or modifications are possible.

Operating Data

SC

Expected lifetime (in days) of a new

measuring point

Days of Operation

X Days

Current days of operation

Min. Temperature

25 °C

Display of the lowest temperature

detected at the device

Max. Temperature

25 °C

Display of the highest temperature

detected at the device

Maintenance Days

remaining XXXX

Days until the next calibration is due

Operating Days last

XXX

Days of operation when the last

calibration happened

If more than one sensor head is connected to

the DGS, the selection is done at X.

Number of Calib.

X

How many times the measuring point

has been calibrated

Sensivity

XXX%

Remaining sensitivity of the sensor. Must

be replaced when at 35%

Page 15

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

15 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

4.9

Calibration

Zero DP 1

Zero calibration

DP 1

Sxxx CO2 450ppm

Calibration gas

XXXX ppm

This section gives an overview of the calibration menu.

The calibration description can be found on the following pages.

For HFC, remember to use the specified calibration gas.

(HFC grp1 = R1234yf, grp.2 = R134a, grp.3 = R407c)

Calibrate

Set the test gas concentraion

Gain DP 1

Gain calibration

Burn clean

Selection of the

measuring point

to be calibrated

Calibration AO 1

Only available for combustible gases

(Propane)

See section 4.9.1

See section 4.9.2

See section 4.9.3

Page 16

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 16

4.9.1

Zero Calibration

Zero DP 1

100 ppm

The stepwise calibration process is described below.

Note: The specified warm-up times etc. must be strictly observed before starting the calibration

process.

Zero DP 1

Apply test gas according to instructions.

Zero DP 1

90 ppm

Step 2: Calculation of the new zero point

During calculation an underscore in line 2 runs from left to right

and the current value drops to zero.

Zero DP 1

SAVE

Step 3: Save the newly calculated zero point

„SAVE“ is displayed, as long as the function is executed.

Zero DP 1

0 ppm

After the value has been successfully stored, a square appears

on the right for a short time = Zero point calibration is finished

and new zero offset has been stored with success.

Step 1: Display of the current value

Start calibration process.

When the current value is stable, press for finishing the calculation of the new

value.

Zero DP 1

0 ppm

The display automatically goes to step 1: Display of new zero

point.

Message Description

Current value too high Wrong gas for zero point calibration

Current value unstable

Appears when the sensor signal does not reach the zero point within the target time. Disappears

automatically when the sensor signal is stable.

Time too short

The message “value unstable” starts an internal timer. Once the timer has run out and the current

value is still unstable, the text is displayed. The process starts over again. If the value is stable,

the current value is displayed and the calibration procedure is continued. If the cycle is repeated

several times, an internal error has occurred. Stop the calibration process and replace the sensor

head.

During the calculation phase, the following messages may occur:

If aborting the zero-offset calibration, the offset value there will not be updated. The sensor head

continues to use the “old” zero offset. A full calibration routine must be conducted to save any

calibration change.

Page 17

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

17 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

4.9.2

Gain Calibration

Gain DP 1

100 ppm 100%

The stepwise calibration process is described below.

Note: The specified warm-up times etc. must be strictly observed before starting the calibration

process.

Gain DP 1

Apply test gas according to instructions.

Gain DP 1

_90 ppm

Step 2: Calculation of the new gain

During calculation an underscore in line 2 runs from left to

right and the current value converges to the set test gas

concentration. The sesitivity is recalucated, too.

Gain DP 1

SAVE

Step 3: Save the newly calculated gain

‚SAVE‘ is displayed as long as the function is executed.

Gain DP 1

0.0 ppm

After the value has been successfully stored, a square appears

on the right for a short time.= Gain calibration is finished and

new gain offset has been stored with success.

Step 1: Display of the current value and of the sensitivity

from the last calibration

Start calibration process.

When the current value is stable, press for finishing the calculation of the new

value.

Gain DP 1

0.0 ppm

The display automatically goes to step 1: Display

Message Description

Current value too high

Test gas concentration > than set value

Internal error → Replace sensor head

Current value too low No test gas or wrong test gas applied to the sensor

Test gas too high

Test gas too low

The set test gas concentration must be between 30% and 90% of the measuring range.

Current value unstable

Appears when the sensor signal does not reach the calibration point within the target time.

Disappears automatically when the sensor signal is stable.

Time too short

The message “value unstable” starts an internal timer. Once the timer has run out and the current

value is still unstable, the text is displayed. The process starts over again. If the value is stable,

the current value is displayed and the calibration procedure is continued. If the cycle is repeated

several times, an internal error has occurred. Stop the calibration process and replace the sensor

head.

Sensitivity < Sensitivity of the sensor head < 30 %, calibration no longer possible → Replace sensor head.

Internal error Internal , unrecoverable error → Replace sensor head.

During the calculation phase, the following messages may occur:

Test Gas

XX.X ppm

Enter concentration of the test gas used.

This value isn’t cleared when exiting the menu, therefore before calibrating

always check the value if correct.

Page 18

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 18

4.9.3

Zero-point Calibration of Analog

Output

Calibration AO 1

320 0

With this menu item you can adjust the zero-point of the analog output (4mA). The zero-point

correction is only possible when the minimum output is 2V or 4mA, i.e. not possible when minimum

output is 0V or 0mA”.

The error message of the output monitoring is suppressed as long as the menu Calibration AO is open.

Therefore, connect the amperemeter (measuring range 20 mA DC) to the analog output only after

having opened the menu.

Calibration AO 1

Connect amperemeter to the analog output.

Calibration AO 1

320 323

Adjust the zero offset on the right by changing the offset value

slowly, until the amperemeter shows the desired value.

Display of the current zero offset on the left.

Calibration AO 1

SAVE

Save the adjusted zero offset.

Calibration AO 1

323 323

Return to the display of the current zero offset.

4.10

Addressing

Set Address

4

Addressing

Assignment of the modbus address of the device for system integration, e.g. with Danfoss

front end type AK-SM 800

Define the modbus address

Symbol Description Default Function

4 modbus Address 0 0 = Device is not addressed, bus not used. Max value is 96

Page 19

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

19 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

5

Modbus menu survey

Function Min Max Factory Unit AKM name

Gas level

Sensor 1 Actual gas level in % of range 0.0 100.0 - % Gas level %

Sensor 1 Actual gas level in ppm 0 FS2 - ppm Gas level ppm

Sensor 2 Actual gas level in % of range 0.0 100.0 - % 2: Gas level %

Sensor 2 Actual gas level in ppm 0 FS2 - ppm 2: Gas level ppm

Alarms Alarm settings

Indication of critical alarm (critical alarm of Gas1 or Gas2 active)

0: No active alarm(s)

1: Alarm(s) active

0 1 0 - GD alarm

Common indication of both critical and warning alarm as well as

internal and maintenance alarms

0: No active alarm(s), warning(s) or errors

1: Alarm(s) or warning(s)) active

0 1 0 - Common errors

Gas 1 Alarm limit in %.

Alarm limit in % (0-100), not lower 1: Warn Limit allowed

0.0 100.0 HFC: 25

CO2: 25

R290: 16

% Crit. limit %

Gas 1 Alarm limit in ppm

Alarm limit in ppm; 0: Warning Signal deactivated

0 FS2 HFC: 500

CO2: 5000

R290: 800

ppm Crit. limit ppm

Gas 1. Warning limit in % (0-100) 0 100.0 HFC: 25

CO2: 25

R290: 16

% Warn. limit %

Gas 1

Warning limit ppm 0: Warning Signal deactivated

0.0 FS

2

HFC: 500

CO2: 5000

R290: 800

ppm Warn. limit ppm

High (critical and warning) alarm delay in seconds, if set to 0: no delay 0 600 0 sec Alarm delay s

When set to 1, the audible sounder are reset (and the relays if

defined: Relay rest enable) to no alarm indication. When the alarm is

reset or the time out duration is exceeded, the value is reset to 0.

Note: The alarm condition is not reset only the output indication is

reset.

0: Alarm outputs not reset

1: Alarm outputs reset –buzzer muted and relays reset if configured

0 1 0 - Reset alarm

Duration of alarm reset before automatic re-enable of alarm outputs.

A setting of 0 disables the ability to reset alarm.

0 9999 300 sec Reset alarm time

1

Relay reset enable:

Relay reset with alarm acknowledge function

1: (default) Relays wil be reset if the alarm acknowledge function is

activated

0: Relays remains active until the alarm condition clears

0 1 1 - Relay rst enable

1

Gas 2 Alarm limit in %.

Alarm limit in % (0-100), not lower 1: Warn Limit allowed

0.0 100.0 CO2: 25 % 2:Crit. limit %

Gas 2 Alarm limit in ppm

Alarm limit in ppm; 0: Warning Signal deactivated

0 FS2 CO2: 5000 ppm 2:Crit. limit ppm

Gas 2. Warning limit in % (0-100) 0 100.0 CO2: 25 % 2:Warn. limit %

Gas 2. Warning limit ppm 0: Warning Signal deactivated 0.0 FS

2

CO2: 5000 ppm 2:Warn. limit ppm

High (critical and warning) alarm delay in seconds, if set to 0: no delay 0 600 0 sec 2:Alarm delay s

Service

Status of the sensors warm up period

0: Ready

1: Warming Up 1 or more sensors

0 1 0 - DGS Warm-up

Page 20

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

20 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

Read out the attached Gas sensor type.

1: HFC gr.1

R1234ze, R454c, R1234yf

R1234yf, R454a, R452A

R454b, R513a

2: HFC gr.2

R407F, R416a, R417a

R407A, R422a, R427a

R449A, R437a, R134A

R438a, R422D

3: HFC gr.3

R448A, R125

R404A, R32

R507A, R434a

R410A, R452b

R407C, R143b

4: CO2

5: Propane (R290)

1 5 N - Sensor type

Full scale range 0 32000 HFC: 2000

CO2: 20000

R290: 5000

ppm Full scale ppm

Gas 1 Days until next calibration 0 32000 HFC: 365

CO2: 1825

R290: 182

days Days till calib

Gas 1 Shows how many % of Sensitivity remaining

Note: Value only updated after calibration

0 100 100 % Rem.sensivity

Status of the critical alarm relay

1: ON = No alarm signal, Coil under Power - normal

0: OFF = alarm signal, Coil depowered, Alarm Situation

0 1 0 - Critical Relay

Status of the Warning Relay

0: OFF= inactive, no Warning active

1: ON = active Warning, Coil under Power

0 1 0 - Warning Relay

Status of the buzzer

0: inactive

1: active

0 1 0 - Buzzer

Gas 2 Days until next calibration 0 32000 HFC: 365

CO2: 1825

R290: 182

days 2:Days til calib

Gas 2 Shows how many % of Sensitivity remaining

Note: Value only updated after calibration

0 100 100 % 2:Rem.sensivity

Activates a mode which simulates an alarm. Buzzer, LED and relays all

activate

1:-> Test function - no alarm generation possible now

Automatically falls back to Off after 15 min.

0: back to Normal mode

0 1 0 - Test Mode

Analog Output Selction Sensivity

0: zero to full Scale (e.g (Sensor 0-2000ppm) 0-2000ppm will give

0-10V)

1: zero to Half Scale (e.g (Sensor 0-2000ppm) 0-1000ppm will give

0-10V)

0 1 1 - AOmax = half FS

Analog Output Selection Zero start

0: select 0-10V or 0-20mA Output signal

1: select 2-10V or 4-20mA Output signal

0 1 0 - AOmin = 2V/4mA

Alarms

Critical Limit alarm

0: Alarm not active

1: Alarm, gas limit exceeded and delay expired

0 1 0 - Critical limit

0: OK

1: Fault. Out of range under test –Overrange or Underrange

0 1 0 - Out of range

0: OK, sensor no errors

1: Fault, Sensor and Head failures

0 1 0 - Wrong SensorType

Page 21

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 21

0: OK, sensor in place

1: Fault, Sensor out or removed, or wrong sensor placed in

0 1 0 - Sensor removed

0: OK, Sensor not due for calibration

1: Warning, Due for calibration

0 1 0 - Calibrate sensor

0: OK, Gas level below warning level

1: Warning, Gas level above warning level and delay expired

0 1 0 - Warning limit

Indication if the normal alarm function is inhibited or in normal

operation

0: Normal operation, i.e. alarms are created and cleared

1: Alarms inhibited, i.e. alarm status is not updated, e.g. due to DGS in

test mode

0 1 0 - Alarm inhibited

Critical Limit alarm

0: Alarm not active

1: Alarm, gas limit exceeded and delay expired

0 1 0 - 2:Criti. limit

0: OK

1: Fault. Out of range under test –Overrange or Underrange

0 1 0 - 2:Out of range

0: OK, sensor no errors

1: Fault, Sensor and Head failures

0 1 0 - 2:Wrong SensType

0: OK, sensor in place

1: Fault, Sensor out or removed, or wrong sensor placed in

0 1 0 - 2:Sens.removed

0: OK, Sensor not due for calibration

1: Warning, Due for calibration

0 1 0 - 2:Calibrate sens

0: OK, Gas level below warning level

1: Warning, Gas level above warning level and delay expired

0 1 0 - 2:Warning limit

1

“Reset alarm time” and “Relay rst enable”: These two parameters related to the alarm reset/acknowledge function are not accessible with the hand-

held tool.

2

The max alarm limit for CO2 is 16.000ppm / 80% of full scale. All other values equal the fullscale range of specific product

Page 22

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

22 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

6

Technician use only!

This unit must be installed by a suitably qualified

technician who will install this unit in accordance

with these instructions and the standards set

down in their particular industry/country.

Suitably qualified operators of the unit should be

aware of the regulations and standards set down

by their industry/country for the operation of this

unit.

These notes are only intended as a guide and

the manufacturer bears no responsibility for the

installation or operation of this unit.

Failure to install and operate the unit in

accordance with these instructions and with

industry guidelines may cause serious injury

including death and the manufacturer will not be

held responsible in this regard.

It is the installer’s responsibility to adequately

ensure that the equipment is installed

correctly and set up accordingly based on the

environment and the application in which the

products are being used.

6.1

Regular Test

Please observe that DGS works as a safety

device securing a reaction to a detected high

gas concentration. If a leakage occurs, the

DGS will provide alarm functions, but it will

not solve or take care of the leakage root

cause itself.

6.2

Location

For all gas’ heavier than air, Danfoss recommends

locating the sensor head app. 30cm (12”) above

the floor and if possible in the air flow. All gas’

measured with these DGS-sensors are heavier

than air: HFC grp 1, HFC grp 2, HFC grp 3, CO2

and Propane.

For further details on Test and Location please

see the Danfoss Gas Detection application guide,

DKRCI.PA.S00.A-.02

To maintain product performance and comply

with the local requirements the DGS must be

tested regularly.

DGS’s are provided with a test button that may

be activated to validate the alarm reactions.

Additionally the sensors must be tested by either

bump test or calibration.

Danfoss recommends the following minimum

calibration intervals:

DGS-IR: 60 months

DGS-SC: 12 months

DGS-PE: 6 months

With DGS-IR it is recommended to do an annual

bump test in years without calibration.

Check local regulations on calibration or testing

requirements.

After exposure to a substantial gas leak, the

sensor should be checked by bump test or

calibration and replaced if necessary.

Page 23

User Guide | Danfoss Gas sensor. Type DGS. Modbus or Service Tool display operation

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RS8KD102 | 23

7

Ordering

DGS Sensors

Spares and accessories

Product Description Code no. Product Description Code no.

DGS-SC H FC gr. 1* 080Z2803 Spare se nsor HFC gr.1* Spare 080Z2815

DGS-SC H FC gr. 2* 080Z2804 Spare se nsor HFC gr.2* Spare 080Z2816

DGS-SC H FC gr. 3* 080Z2805 Spare se nsor HFC gr.3* Spare 080Z2817

DGS-PE Propane 080Z2806 Spare sensor Propane Spare 080Z2818

DGS- IR-CO2 080Z2800 Spare sensor CO2 Spare 080Z2813

DGS- IR-CO2 5 m 080Z2801 Spar e sensor CO2 - 5 m Spare 080Z2814

DGS- IR 2 * CO2 - 5 m 080Z2802 Hand He ld Service Tool Accessory 080Z2820

DGS-SC H FC gr.1* + B&L 080Z2809 Strob e & Horn Accessory 080Z2819

DGS-SC H FC gr.2* + B& L 080Z2810 Splash guard Accessory 148H 6226

DGS-SC H FC gr.3* + B&L 080Z2811 Duct se t Accessory 148H 6236

DGS- PE Propane + B&L 080Z2812 Calibraton adaptor for SC2 Accessor y 148 H623 2

DGS- IR CO2 + B&L 080Z2807 Remote kit Accessory 148H6238

DGS- IR-CO2 5 m + B&L 080Z2808 Power Supply AK- PS075 Accessory 080Z0053

*HFC gr.1:: R1234ze, R454c, R1234yf, R45 4a, R452A, R454b, R513a

HFC gr.2: R407F, R416a, R417a, R407A, R422a, R427a, R449A, R437a, R134A, R438a, R422D

HFC gr.3: R44 8A, R125, R404A, R 32, R507A, R434a, R410A, R452b, R407C, R143b

Page 24

24 | RS8KD102

© Danfoss | DCS (ADAP-KOOL®) | 2018.12

Loading...

Loading...