Page 1

Installation Guide

Danfoss Gas Sensor

080R9333

Type DGS

ENGLISH

Technician use only!

This unit must be installed by a suitably qualified technician who

will install this unit in accordance with these instructions and the

standards set down in their particular industry/country.

Suitably qualified operators of the unit should be aware of the

regulations and standards set down by their industry/country for

the operation of this unit.

These notes are only intended as a guide, and the manufacturer

bears no responsibility for the installation or operation of this unit.

Failure to install and operate the unit in accordance with these

instructions and with industry guidelines may cause serious

injury including death, and the manufacturer will not be held

responsible in this regard.

It is the installer’s responsibility to adequately ensure that the

equipment is installed correctly and set up according to the

environment and the application in which the products are being

used.

Please observe that DGS works as a safety device securing a

reaction to a detected high gas concentration. If a leakage

occurs, the DGS will provide alarm functions, but it will not

solve or take care of the leakage root cause itself.

AN284527372096en-000301

Regular Test:

To maintain product performance and comply with the local

requirements, the DGS must be tested regularly.

DGSs are provided with a test button that may be activated to

validate the alarm reactions.

Additionally, the sensors must be tested by either bump test or

calibration.

Danfoss recommends the following minimum calibration intervals:

DGS-IR: 60 months

DGS-SC: 12 months

DGS-PE: 6 months

With DGS-IR it is recommended to do an annual bump test in years

without calibration.

Check local regulations on calibration or testing requirements.

Do not spray or pour pure refrigerant or other liquids onto the

sensor head to perform a bump test. This may significantly reduce

the lifetime of the sensor head or even destroy it.

For propane: after exposure to a substantial gas leak, the sensor

should be checked by bump test or calibration and replaced if

necessary.

Location:

For all gases heavier than air, Danfoss recommends placing the

sensor head app. 30cm (12") above the floor and, if possible, in the

air flow. All gases measured with these DGS sensors are heavier

than air: HFC grp 1, HFC grp 2, HFC grp 3, CO and Propane.

Dimensions and appearance

For further details on Test and Location please see the Danfoss

Application Guide: "Gas detection in refrigeration systems".

Fig. 1

© Danfoss | Climate Solutions | 2022.01

AN284527372096en-000301 | 1

Page 2

Cable gland opening

Danfoss

1

C

148H126_01-2018

Hole punching for cable gland:

1. Select the location for the safest cable entry

2. Use a sharp screwdriver and a small hammer

3. Place the screwdriver and hammer with precision

while moving the screwdriver within a small area

until the plastic is penetrated.

Fig. 2

Danfoss Gas Sensor DGS

5

GND

4

AO_01

not used

2

DI_01

1

S&H supply

x1

LED

Yellow/Green/Red

Sensor 2

x9

open: 0-20mA

closed: 0-10V

B&L

open: 19200 Baud

closed: 38400 Baud

JP5

x8

x2

JP4

Continue precision punching with small movements

until the round piece can be pulled out with your

fingers.

WARNING: be very careful not to damage

the internal board components with the

screwdriver.

Status LED / B&L:

GREEN is power on.

- flashing if maintenance needed

YELLOW is an indicator of Error.

- the sensor head is disconnected or not the expected type

- AO configured as 0 – 20 mA, but no current is

80Z790.1

running

- flashing when sensor is in special mode (e.g. when

- Supply voltage out of range

RED flashing: is an indication of alarm due to gas

concentration level. The Buzzer & Light behaves identical

to the status LED.

x6

x5

Ackn.-/Test

button

1

2

3

1

2

3

Rel. 3

(critical)

Rel. 1

(warning)

4

3

x4

2

1

Danfoss

BMODBUS

A+

24 V AC/D

+

Ackn. / Test button / DI_01:

TEST: The button must be pressed for 8 sec.

Tool

JP3

x3

JP2

JP1

not used

- Critical and warning alarm is simulated and AO goes to

ACKN: If pressed during critical alarm, as default* the relays

and Buzzer go out of alarm condition and back on after 5

minutes if the alarm situation is still active.

* the duration and whether to include the relay status with this

function or not is user defined.

Sensor 1

DI_01 (terminals 1 and 2) is a dry-contact (potential-free)

behaving identically to the Ackn./Test button.

Remove potential burrs and secure flat surfaces.

Install the cable gland according to the enclosed guide.

changing parameters with the Service Tool)

max. (10 V/20 mA), stops on release.

Note: For what concern the power supply, please refer to chapter 3.10 Power Con-

ditions and Shielding Conceptions in the User Guide (BC291049702513en-000201).

A Class II power supply is recommended

Fig. 3

2 | AN284527372096en-000301

DC supply for external Strobe&Horn

Whether the DGS is powered by 24 V DC or 24 V AC, a 24

V DC power supply (max. 50 mA) is available between

terminals 1 and 5 on connector x1.

Jumpers

* JP4 open → 19200 Baud

JP4 closed → 38400 Baud (default)

* JP5 open → AO 0 – 20 mA

JP5 closed → AO 0 – 10 V (default)

Note: the DGS must be power cycled before any change to

JP4 takes effect.

Analog Output:

If the analog output AO_01 is used (terminals 4 and 5) then

you need the same ground potential for the AO and the

connected device.

Note: JP1, JP2 and JP3 are not used.

© Danfoss | Climate Solutions | 2022.01

Page 3

DGS installation instructions

The DGS is available with one or two sensors and B&L (Buzzer and

Light) as option (see fig. 1).

For sensors that can be poisoned by e.g. silicones like all

semiconductor and catalytic bead sensors, it is imperative to only

remove the protective cap after all silicones are dry, and then

energize the device.

The sensor protection cap must be removed before taking the

DGS into operation

Mounting and wiring

To wall mount the DGS, unscrew the lid by releasing the four

plastic screws in each corner and remove the lid. Mount the DGS

base to the wall by fitting screws through the holes which the lid

screws were fastened by. Complete the mounting by re-applying

the lid and fastening the screws.

The sensor head must always be mounted so that it points

downwards. The DGS-IR sensor head is sensitive to shock – special

attention should be paid to protect the sensor head from shocks

during installation and operation.

Observe the recommended placing of the sensor head as stated

on page 1.

Extra cable glands are added by following the instruction in fig. 2.

The exact position of the terminals for the sensors, alarm relays,

digital input and analogue output is shown in the connection

diagrams (see fig. 3).

The technical requirements and regulations for wiring,

electrical security, as well as project specific and environmental

requirements and regulations must be met.

Configuration

For convenient commissioning, the DGS is pre-configured and

parameterized with factory-set defaults. See Menu Survey on

page 5.

Jumpers are used to change the analogue output type and the

MODBUS baud rate. See fig. 3.

For DGS with Buzzer & Light, alarm actions are given according to

following table below.

System integration

To integrate the DGS with a Danfoss system manager or general

BMS system, set the MODBUS address using the DGS Service Tool,

using password "1234" when prompted. See the DGS User Guide

for details on operating the DGS Service Tool.

The Baud Rate is adjusted by jumper JP4. As default, the setting

is 38.4k Baud. For integration with AK-SM 720/350 change the

setting to 19.2k Baud.

For more information about data communication see Danfoss

document RC8AC--

Sensor replacement

The sensor is connected to the DGS via a plug connection

enabling simple sensor exchange instead of an on-site calibration.

The internal replacement routine recognizes the exchanging

process and the exchanged sensor and re-starts the measurement

mode automatically.

The internal replacement routine also examines the sensor for

actual type of gas and actual measuring range. If the data does not

match the existing configuration, the built-in status LED indicates

an error. If everything is OK the LED will light up green.

As an alternative, the on-site calibration via the DGS Service Tool

can be performed with the integrated, user friendly calibration

routine.

See the DGS User Guide for details on operating the DGS Service

Tool.

Action Reaction

Loss of power to DGS OFF OFF X (closed)

Gas signal < warning alarm threshold OFF GREEN

Gas signal > warning alarm threshold OFF RED Slow flashing X (closed)

Gas signal > critical alarm threshold ON RED Fast flashing X (closed) X (closed)

Gas signal ≥ critical alarm threshold,

but ackn. button pressed

No alarm, no fault OFF GREEN

No fault, but maintenance due OFF GREEN Slow flashing

Sensor communication error OFF YELLOW

DGS in special mode OFF YELLOW flashing

Alarm thresholds can have the same value, therefore both the relays and the Buzzer

and Light can be triggered simultaneously.

The alarm thresholds have a hysteresis of app. 5%

* whether to include the relay status with the acknowledge function or not is user

defined.

** If the DGS has two sensors and the "Room Mode" is configured to "2 rooms",

then relay 1 ac ts as a critical relay for sensor 1 and relay 3 acts as a critical

relay for sensor 2. Both relays are SPDT NC. The Buzzer and Light operation is

independent of the "Room Mode" setting.

Buzzer

OFF

(ON after delay)

Reaction

Light

RED Fast flashing X (closed)* (open)*

Warning relay 1**

SPDT NO (Normally Open)

Critical relay 3**

SPDT NC (Normally closed)

© Danfoss | Climate Solutions | 2022.01

AN284527372096en-000301 | 3

Page 4

DGS installation test

As DGS is a digital device with self-monitoring, all internal errors

are visible via the LED and MODBUS alarm messages.

All other error sources often have their origins in other parts of the

installation.

For fast and comfortable installation test we recommend

proceeding as follows.

Optical Check

Right cable type used.

Correct mounting height according to definition in the section

about mounting.

LED status – see DGS trouble shooting.

Functional test (for initial operation and maintenance)

Functional test is done by pressing the test button for more than

8 seconds and observing that all connected outputs (Buzzer, LED,

Relay connected devices) are working properly. After deactivation

all outputs must automatically return to their initial position.

Zero-point test (if prescribed by local regulations)

Zero-point test with fresh outdoor air.

A potential zero offset can be read out by use of the Service Tool.

Trip test with reference gas (if prescribed by local regulations)

The sensor is gassed with reference gas (for this you need a gas

bottle with pressure regulator and a calibration adapter).

In doing so, the set alarm thresholds are exceeded, and all output

functions are activated. It is necessary to check if the connected

output functions are working correctly (e.g. the horn sounds, the

fan switches on, devices shut down). By pressing the push-button

on the horn, the horn acknowledgement must be checked. After

removal of the reference gas, all outputs must automatically return

to their initial position.

Other than the trip testing, it is also possible to perform a

functional test by means of calibration. For further information,

please refer to the User Guide.

Comparing sensor gas type with DGS specification

The replacement sensor specification must match the DGS

specification.

The DGS software automatically reads the specification of the

connected sensor and compares with the DGS specification.

This feature increases the user and operating security.

New sensors are always delivered factory-calibrated by Danfoss.

This is documented by the calibration label indicating date

and calibration gas. A re-calibration is not necessary during

commissioning if the device is still in its original packaging

(including air-tight protection by the red protective cap) and if the

calibration certificate has not expired.

4 | AN284527372096en-000301

© Danfoss | Climate Solutions | 2022.01

Page 5

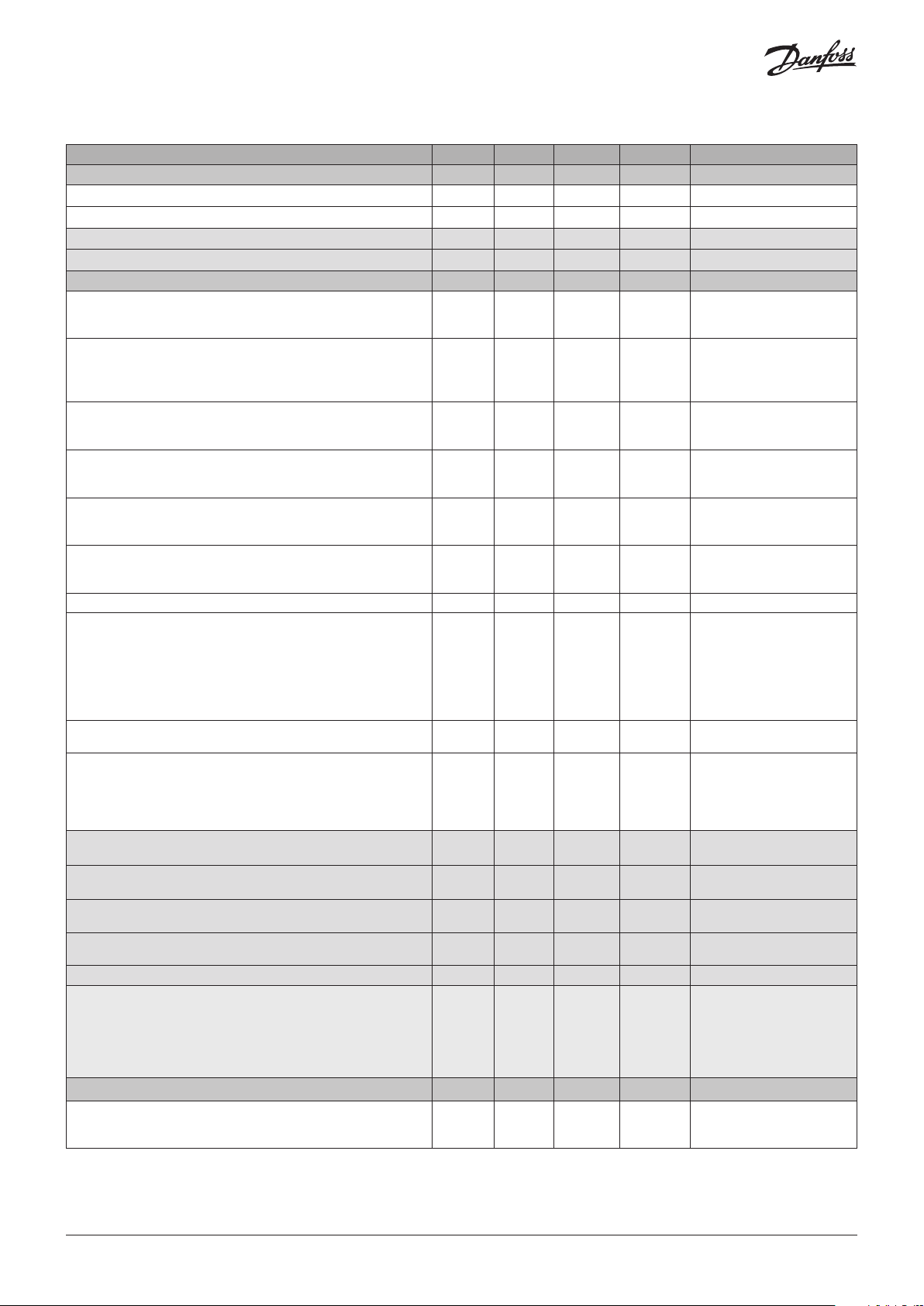

Menu Survey

Function Min. Max. Factory Unit AKM name

Gas level

Sensor 1 Actual gas level in % of range 0.0 100.0 - % Gas level %

Sensor 1 Actual gas level in ppm 0 FS1 - ppm Gas level ppm

Sensor 2 Actual gas level in % of range 0.0 100.0 - % 2: Gas level %

Sensor 2 Actual gas level in ppm 0 FS1 - ppm 2: Gas level ppm

Alarms Alarm settings

Indication of critical alarm (critical alarm of Gas1 or Gas2 active)

0: No active alarm(s)

1: Alarm(s) active

Common indication of both critical and warning alarm as well as

internal and maintenance alarms

0: No active alarm(s), warning(s) or errors

1: Alarm(s) or warning(s)) active

Gas 1 Critical limit in %.

Critical limit in % (0-100)

Gas 1 Critical limit in ppm

Critical limit in ppm; 0: Warning Signal deactivated

Gas 1 Warning limit in % (0-100) 0 100.0 HFC: 25

Gas 1 Warning limit ppm 0: Warning Signal deactivated 0.0 FS1 HFC: 500

High (critical and warning) alarm delay in seconds, if set to 0: no delay 0 600 0 sec. Alarm delay s

When set to 1, the Buzzer is reset (and the relays if defined: Relay rest

enable) to no alarm indication. When the alarm is reset or the

time-out duration is exceeded, the value is reset to 0.

Note: The alarm condition is not reset-only the output indication is

reset.

0: Alarm outputs not reset

1: Alarm outputs reset – Buzzer muted and relays reset if configured

Duration of alarm reset before automatic re-enable of alarm outputs.

A setting of 0 disables the ability to reset alarm.

Relay reset enables:

Relay reset with alarm acknowledge function

1= (default) Relays wil be reset if the alarm acknowledge function is

activated

0: Relays remain active until the alarm condition clears

Gas 2 Critical limit in %.

Critical limit in % (0-100)

Gas 2 Critical limit in ppm

Critical limit in ppm; 0: Warning Signal deactivated

Gas 2. Warning limit in % (0-100) 0 100.0 CO2: 25 % 2: Warn. limit %

0 1 - - GD alarm

0 1 - - Common errors

0.0 100.0 HFC: 25

CO2: 25

R290: 16

0 FS1 HFC: 500

CO2: 5000

R290: 800

CO2: 25

R290: 16

CO2: 5000

R290: 800

0 1 0 - Reset alarm

0 9999 300 sec. Reset alarm time

0 1 1 - Relay rst enable

0.0 100.0 CO2: 25 % 2: Crit. limit %

0 FS1 CO2: 5000 ppm 2: Crit. limit ppm

% Crit. limit %

ppm Crit. limit ppm

% Warn. limit %

ppm Warn. limit ppm

SW 1.1x

Gas 2. Warning limit ppm 0: Warning Signal deactivated 0.0 FS1 CO2: 5000 ppm 2: Warn. limit ppm

High (critical and warning) alarm delay in seconds, if set to 0: no delay 0 600 0 sec. 2: Alarm delay s

Configuration of relays for one or two rooms’ application mode.

1: One room with two sensors sharing the same warning relay and

critical relay

2: Two rooms with one sensor in each, and each sensor having a

critical alarm relay. In this mode, warning alarms activate as normal

on the LED indicator, hand-held Service Tool and on MODBUS.

Service

Status of the sensor's warm-up period:

0: Ready

1: Warming up one or more sensors

1

The max. alarm limit for CO2 is 16000 ppm / 80% of full scale. All other values equal the full scale range of the specific product.

© Danfoss | Climate Solutions | 2022.01

1 2 1 - 1:1 room (default)

2:2 rooms

0 1 - - DGS Warm-up

AN284527372096en-000301 | 5

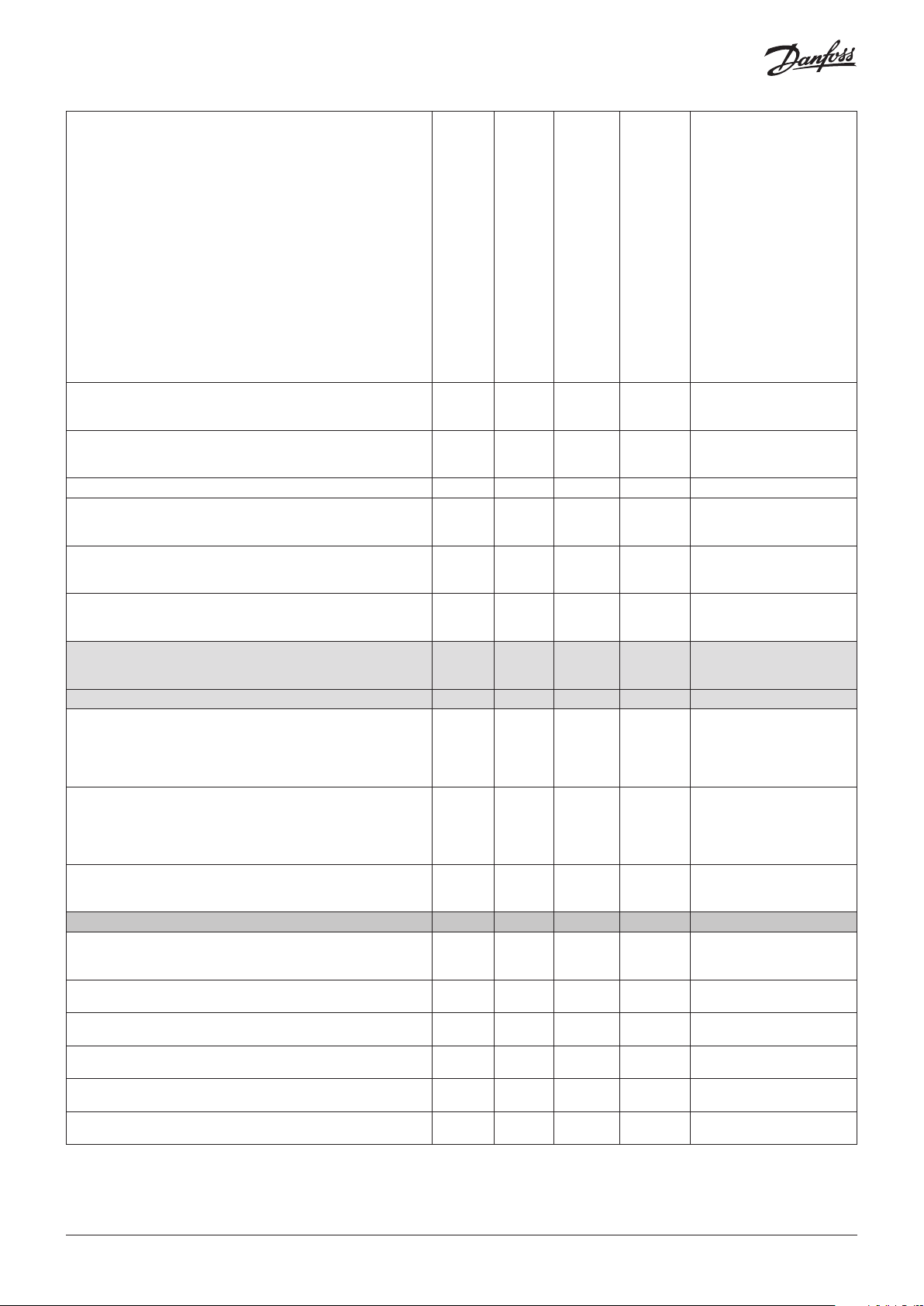

Page 6

Readout the attached gas sensor type.

1 5 N - Sensor type

1: HFC grp 1

R1234ze, R454C, R1234yf

R1234yf, R454A, R455A, R452A

R454B, R513A

2: HFC grp 2

R407F, R416A, R417A

R407A, R422A, R427A

R449A, R437A, R134A

R438A, R422D

3: HFC grp 3

R448A, R125

R404A, R32

R507A, R434A

R410A, R452B

R407C, R143b

2

4: CO

5: Propane (R290)

Full scale range 0 32000 HFC: 2000

ppm Full scale ppm

CO2: 20000

R290: 5000

Gas 1 Days until next calibration 0 32000 HFC: 365

days Days till calib

CO2: 1825

R290: 182

Gas 1 Estimates how many days remaining for sensor 1 0 32000 - days Rem.life time

Status of the Critical Alarm Relay

0 1 - - Critical Relay

1: ON = no alarm signal, coil under power - normal

0: OFF = alarm signal, coil depowered, alarm situation

Status of the Warning Relay:

0 1 - - Warning Relay

0: OFF= inactive, no warning active

1: ON = active warning, coil under power

Status of the Buzzer:

0 1 - - Buzzer

0: inactive

1: active

Gas 2 Days until next calibration 0 32000 HFC: 365

days 2: Days til calib

CO2: 1825

R290: 182

Gas 2 Estimates how many days remaining for sensor 2 0 32000 - days 2: Rem.life time

Activates a mode which simulates an alarm. Buzzer, LED and relays all

0 1 0 - Test Mode

activate.

1:-> Test function - no alarm generation possible now

Automatically falls back to Off after 15 min.

0: back to normal mode

Analogue output max. scaling

0: zero to full scale (e.g sensor 0-2000 ppm) 0-2000 ppm will give

0-10 V)

0 1 HFC: 1

CO: 1

R290: 0

- AOmax = half FS

1: zero to half scale (e.g sensor 0-2000 ppm) 0-1000 ppm will give

0-10 V)

Analogue output min. value

0 1 0 - AOmin = 2V/4 mA

0: select 0-10 V or 0-20 mA output signal

1: select 2-10 V or 4-20 mA output signal

Alarms

Critical Limit alarm

0 1 - - Critical limit

0: OK

1: Alarm. Gas limit exceeded and delay expired

0: OK

0 1 - - Out of range

1: Fault. Out of range under test – over range or under range

0: OK

0 1 - - Wrong SensorType

1: Fault. Sensor and head failures

0: OK

0 1 - - Sensor removed

1: Fault. Sensor out or removed, or wrong sensor connected

0: OK

0 1 - - Calibrate sensor

1: Warning. Due for calibration

0: OK

0 1 - - Warning limit

1: Warning. Gas level above warning level and delay expired

6 | AN284527372096en-000301

© Danfoss | Climate Solutions | 2022.01

Page 7

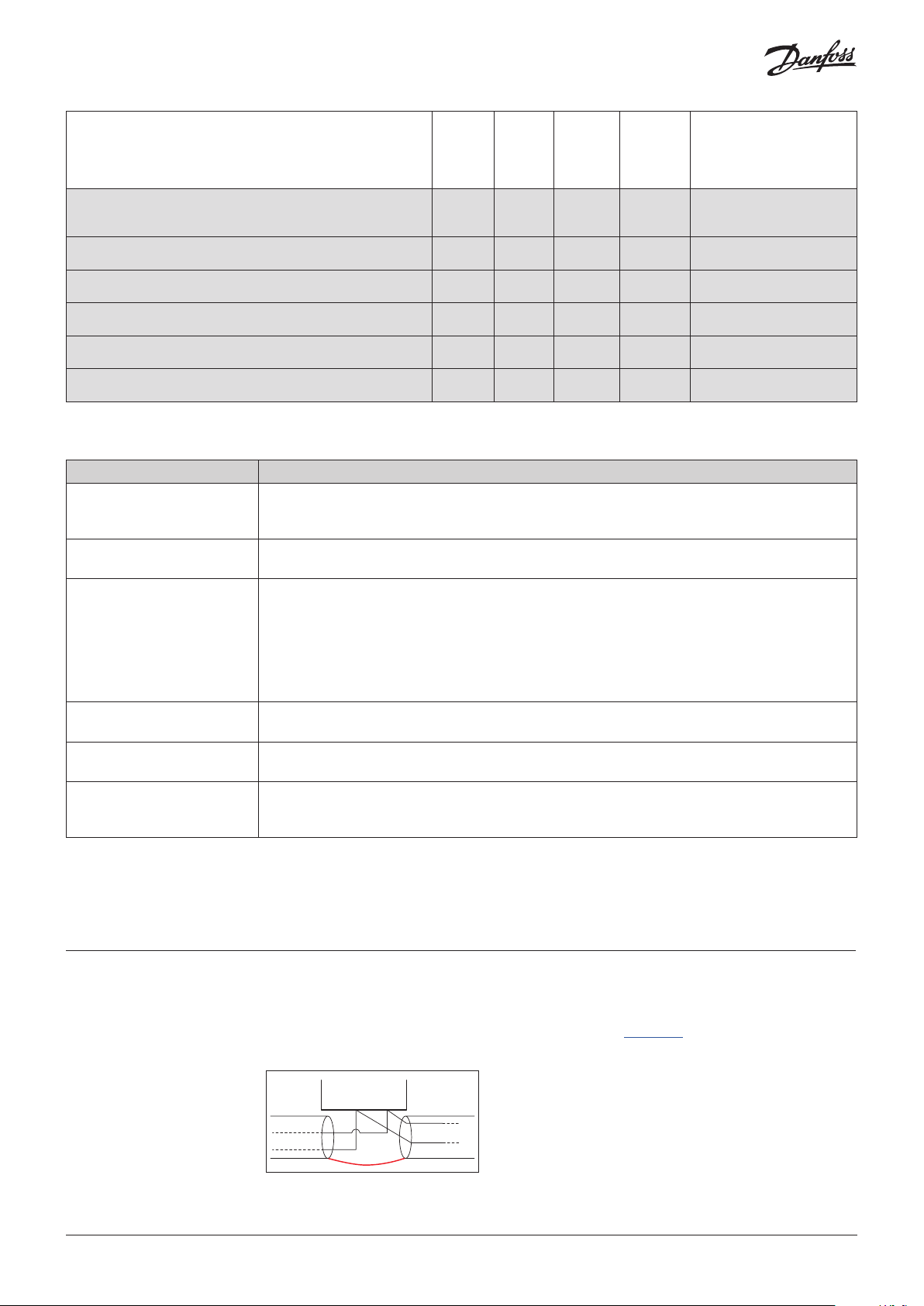

Indication if the normal alarm function is inhibited or in normal

oss

80Z875

operation

0: Normal operation, i.e. alarms are created and cleared

1: Alarms inhibited, i.e. alarm status is not updated, e.g. due to DGS in

test mode

Critical Limit alarm

0: OK

1: Alarm. Gas limit exceeded and delay expired

0: OK

1: Fault. Out of range under test – over range or under range

0: OK

1: Fault. Sensor and Head failures

0: OK

1: Fault. Sensor out or removed, or wrong sensor connected

0: OK. Sensor not due for calibration

1: Warning. Due for calibration

0: OK

1: Warning. Gas level above warning level and delay expired

0 1 - - Alarm inhibited

0 1 - - 2: Criti. limit

0 1 - - 2: Out of range

0 1 - - 2: Wrong SensType

0 1 - - 2: Sens.removed

0 1 - - 2: Calibrate sens

0 1 - - 2: Warning limit

DGS troubleshooting

Symptom: Possible cause(s):

LED off • Check power supply. Check wiring.

• DGS MODBUS was possibly damaged in transit. Check by installing another DGS to confirm the

fault.

Green flashing • The sensor calibration interval has been exceeded or the sensor has reached the end of life. Carry

out calibration routine or replace with a new factory calibrated sensor.

Yellow • AO configured but not connected (only 0 – 20 mA output). Check wiring.

• Sensor type does not match DGS specification. Check gas type and measuring range.

• Sensor may be disconnected from printed circuit board. Check to see if the sensor is properly

connected.

• The sensor has been damaged and needs to be exchanged. Order replacement sensor from

Danfoss.

• Supply voltage out of range. Check power supply.

Yellow flashing • The DGS is set to service mode from the hand-held Service Tool. Change setting or await time-out

within 15 minutes.

Alarms in the absence of a leak • If you experience alarms in the absence of a leak, try setting an alarm delay.

• Perform a bump test to ensure proper operation.

The zero-measurement drifts The DGS-SC sensor technology is sensitive to the environment (temperature, moist, cleaning agents,

gases from trucks, etc). All ppm measurements below 75 ppm should be disregarded, i.e. no zeroadjustment made.

Power Conditions and Shielding Conceptions

Standalone DGS without

Modbus network

communication

DGS with Modbus

network communication

in combination with other

devices powered by the

same power supply

© Danfoss | Climate Solutions | 2022.01

Shield/screen is not required for standalone DGS with no connection to a RS-485 communication line.

However, it can be done as described in the next paragraph (Fig. 4).

It is strongly recommended to use direct current power supply when:

• more than 5 DGS units are powered by the same power supply

• the bus cable length is longer than 50 m for those powered units

It is moreover recommended to use class 2 power supply (see AK-PS 075)

Make sure to not interrupt the shield when connecting A and B to the DGS (see Fig. 4).

–

A+B

Fig. 4: Loop trough

Danf

AN284527372096en-000301 | 7

Page 8

Shield

Busmaster

Busmaster

Danfoss

Modbus

device

Shld

A

B

DGS 1

#adr 10

A

B Gnd

+

DGS 2

#adr 11

A

B Gnd

+

1 KΩ

DGS n

#adr xx

A

B Gnd

+

AK-PS 075 power supply

+

–

Input 230 V

L

230 V

N

Fig. 5: Wiring diagram for system with one power supply

Ground potential difference between nodes of the RS485 network might affect the communication.

It is advised to connect a 1 KΩ 5% ¼ W resistor between the shield and the ground (X4.2) of any unit o

r group of units connected to the same power supply (Fig. 5).

Please refer to Literature No. AP363940176099.

Danfoss

80Z876

DGS with Modbus

network communication

in combination with other

devices powered by more

than one power supply

It is strongly recommended to use direct current power supply when:

• more than 5 DGS units are powered by the same power supply

• the bus cable length is longer than 50 m for those powered units

It is moreover recommended to use class 2 power supply (see AK-PS 075)

Make sure to not interrupt the shield when connecting A and B to the DGS (see Fig. 4).

1 KΩ

1 KΩ

Shield

DGS 1

#adr n1

A

B Gnd

Shield

DGS 1

#adr n11

A

B Gnd

AK-PS 075 power supply

+

+

+

DGS 2

#adr n2

A

B Gnd

DGS 2

#adr n12

A

B Gnd

+

+

DGS n

#adr nx

A

B Gnd

DGS n

#adr ny

A

B Gnd

+

–

AK-PS 075 power supply

+

+

–

L

230 V

N

L

230 V

N

L

230 V

N

Danfoss

Modbus

device

AK-SM

A

B

Shld

Busslave

L

230 V

N

Danfoss

Modbus

device

AK-CC

A

B

Shld

Fig. 6: Wiring diagram for system with multiple power supplies

Ground potential difference between nodes of the RS485 network might affect the communication.

It is advised to connect a 1 KΩ 5% ¼ W resistor between the shield and the ground (X4.2) of any unit

or group of units connected to the same power supply (Fig. 6).

Please refer to Literature No. AP363940176099.

Danfoss

80Z878

© Danfoss | Climate Solutions | 2022.01

Power supply and voltage alarm

The DGS device goes into voltage alarm when voltage exceeds certain limits.

The lower limit is 16 V.

The upper limit is 28 V, if DGS software version is lower than 1.2 or 33.3 V in all other cases.

When in the DGS the voltage alarm is active, in the System Manager the “Alarm inhibited” is raised.

AN284527372096en-000301 | 8

Loading...

Loading...