DEVIreg™ Hotwater

EN

Installation and User Guide

DEVIreg™ Hotwater

DIN-rail programmable controller for hotwater maintenance

Intelligent solutions

with lasting effect

Visit devi.com

Installation and User Guide DEVIreg™ Hotwater

Table of content

1 Introduction .......................................................................4

2 Safety Instructions .................................................................5

3 Mounting Instructions .............................................................5

4 User Manual .......................................................................6

4.1 General use ...................................................................6

Buttons ..................................................................................6

Display ...................................................................................6

Main Screen view (default) ................................................................7

Heater sub-screen view ...................................................................7

Setup wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

First start-up ..............................................................................9

Sub-menu Alarm ........................................................................10

Sub-menu Service .......................................................................10

Function Setup Wizard ...................................................................11

Sub-menu (H1-H4) .......................................................................12

Sub-menu Disinfection schedule .........................................................14

Alarms view .............................................................................15

Main menu ..............................................................................15

4.2 Language setting ........................................................... 16

4.3 Date and Time settings ......................................................16

4.4 BMS settings ................................................................ 16

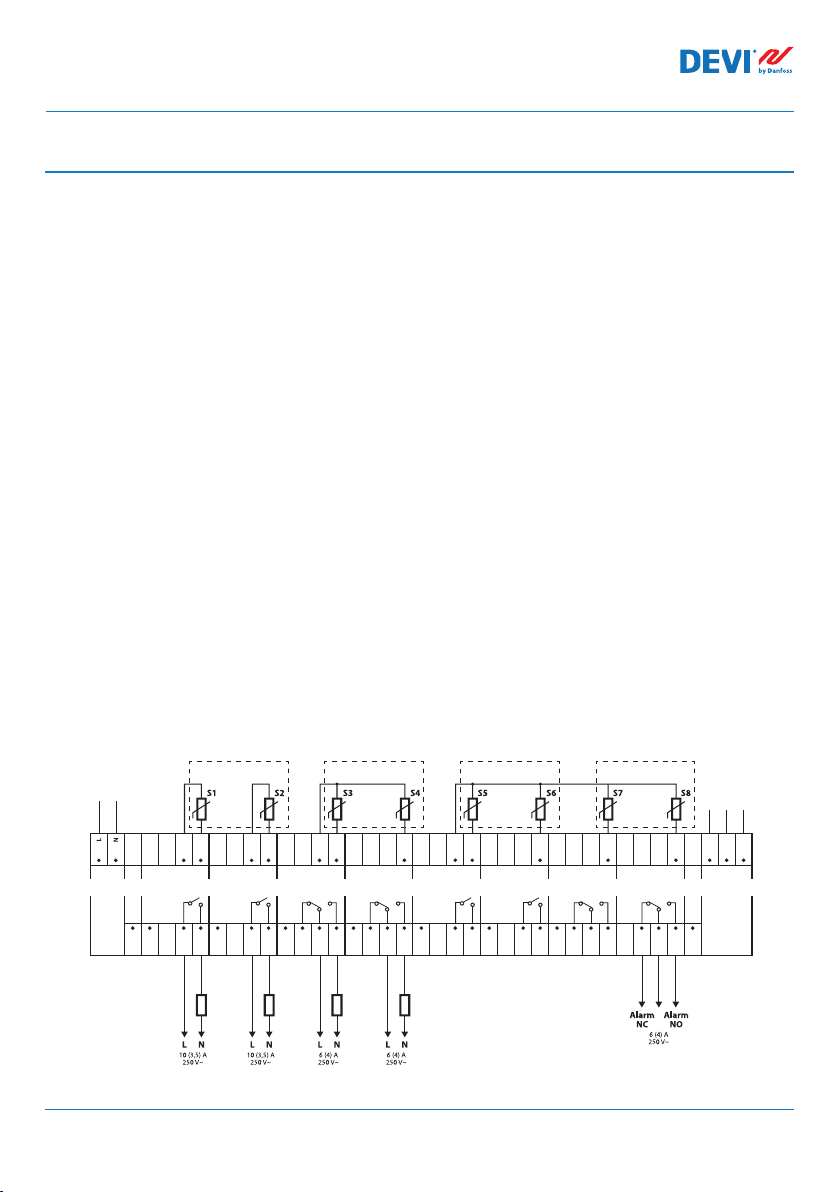

5 Connection diagram ............................................................. 17

Connection scheme DEVIreg™ Hotwater .................................................17

6 Technical Specifications .......................................................... 18

6.1 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Dimensions ................................................................. 19

7 Disposal Instruction .............................................................. 20

FEC | Produced by Danfoss © 3

Installation and User Guide DEVIreg™ Hotwater

1 Introduction

DEVIreg™ Hotwater is a 4 channel electronic programmable controller. 3 additional chan-

cels are not used in this constellation. The device is DIN-rail mountable and is used for

control of Devi Hotwatt cables. Every channel (4) can be individually set up, this will allow

for 4 different temperatures and disinfection schedules.

Universal analog channels’ inputs can be selected via software between 7 types of temperature

sensors including NTC 15 kOhm at 25 °C. The controller has a LCD display, Modbus RS-485

serial interface and 110/230 V AC power supply. Voltage to sensors is SELV.

DEVIreg™ Hotwater has 8 control relays – 2 sets of max. 10 A and 6 sets of max. 6 A; For this

specific application 2, 10A and 2, 6A relays are used. Relay control functions can be set to

Hot-water maintenance and legionella control of a hot-water system by use of applicable

heating cables. Additionally, relay contacts are not connected to a voltage source inside the

controller, and can be used for control systems with any voltage up to 250 V AC.

Hardware of DEVIreg™ Hotwater is based on the Danfoss controller type MCX08M2,

art. no. 080G0307, but is customized with special software.

The product complies with the EN/IEC Standard “Automatic electrical controls for household and similar use”:

• EN/IEC 60730-1 (general)

• EN/IEC 60730-2-9 (thermostat)

More information on this product can also be found at: devi.com

Connection scheme DEVIreg™ Hotwater

Power

110/230 V AC

COM

DI 1-4

DI 1

S - temperature Sensor;

H - Heating element.

AI 1

COM

C 1

NO 1

H1 H2 H3 H4

AI 2

COM

DI 2

C 2

NO 2

DI 3

for H2 for H3for H1

AI 3

COM

AI 3-4

NC 3

C 3

NO 3

AI 4

DI 4

NC 4

C 4

NO 4

AI 5

COM

AI 5-8

DI 5

C 5

NO 5

AI 6

DI 6

C 6

NO 6

DI 7

for H4

AI 7

NC 7

C 7

NO 7

NC 8

DI 8

RS485

(Modbus)

D -

D +

AI 8

C 8

NO 8

GND

RS485

COM

DI 5-8

FEC | Produced by Danfoss ©4

Installation and User Guide DEVIreg™ Hotwater

2 Safety Instructions

Make sure the mains supply to the controller is turned off before installation.

Please also note the following:

• The installation of the controller must be done by an authorized and qualified installer

according to local regulations.

• The controller must be connected to a power supply via an all-pole disconnection switch.

• Always connect the controller to continuous power supply.

• Do not expose the controller to moisture, water, dust and excessive heat.

Note: Product is designed for Over Voltage Category II. When used, installation must be

equipped with transient protection.

3 Mounting Instructions

Please observe the following placement guidelines:

Install the thermostat in an electric cabinet with DIN rail attachment or a separate DIN

attachment according to local regulation on IP classes.

Do not place the thermostat in a way that will expose the controller to direct sunlight.

Follow the steps below to mount the thermostat:

1. Click the thermostat on the DIN rail attachment.

2. Connect the thermostat according to the connection diagram, see page 4.

3. The screen of the heating cable must be connected to the earth conductor of the

power supply cable by using a separate connector.

4. Turn on the power supply.

Note: Always install the sensors at assumed hottest and coldest locations on the respective pipe, and in direct contact with the pipe (2 sensors pr. heating circuit)

FEC | Produced by Danfoss © 5

Installation and User Guide DEVIreg™ Hotwater

4 User Manual

4.1 General use

The DEVIreg™ Hotwater is operated via 6 physical buttons to the right of the LCD-display.

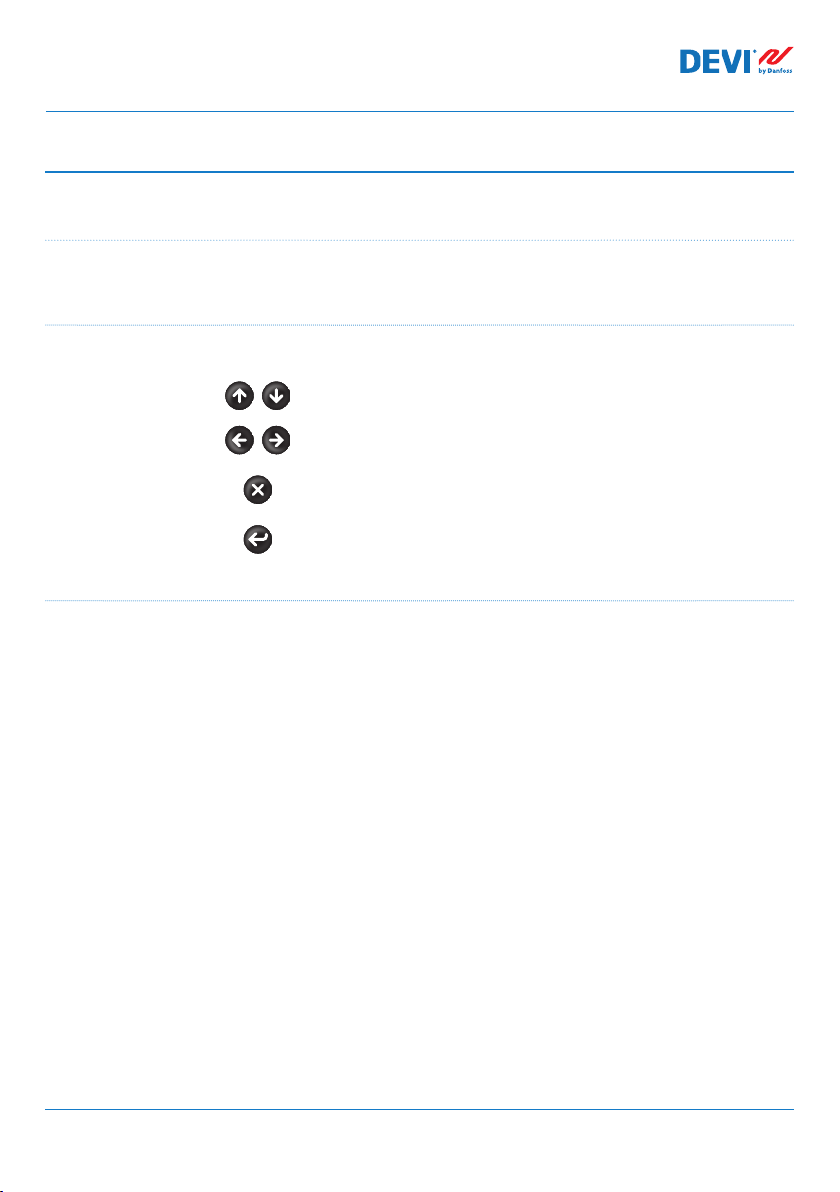

Buttons

The functions of the 4 operated buttons are:

Up, Down

Left, Right

Escape

Enter Confirm / select / go to the Main menu

Display

The DEVIreg™ Hotwater can simultaneously control up to 4 different systems

are referred as H1, H2, H3 and H4 (short for Heater).

The DEVIreg™ Hotwater provides the user with an opportunity to view the current status

of the all systems. This status is allways shown on the main screen.

Next menu entry / next line / next setting parameter

Shows additional information

Escape return to previous level of menu / show Alarm

screen

. These 4 systems

FEC | Produced by Danfoss ©6

Installation and User Guide DEVIreg™ Hotwater

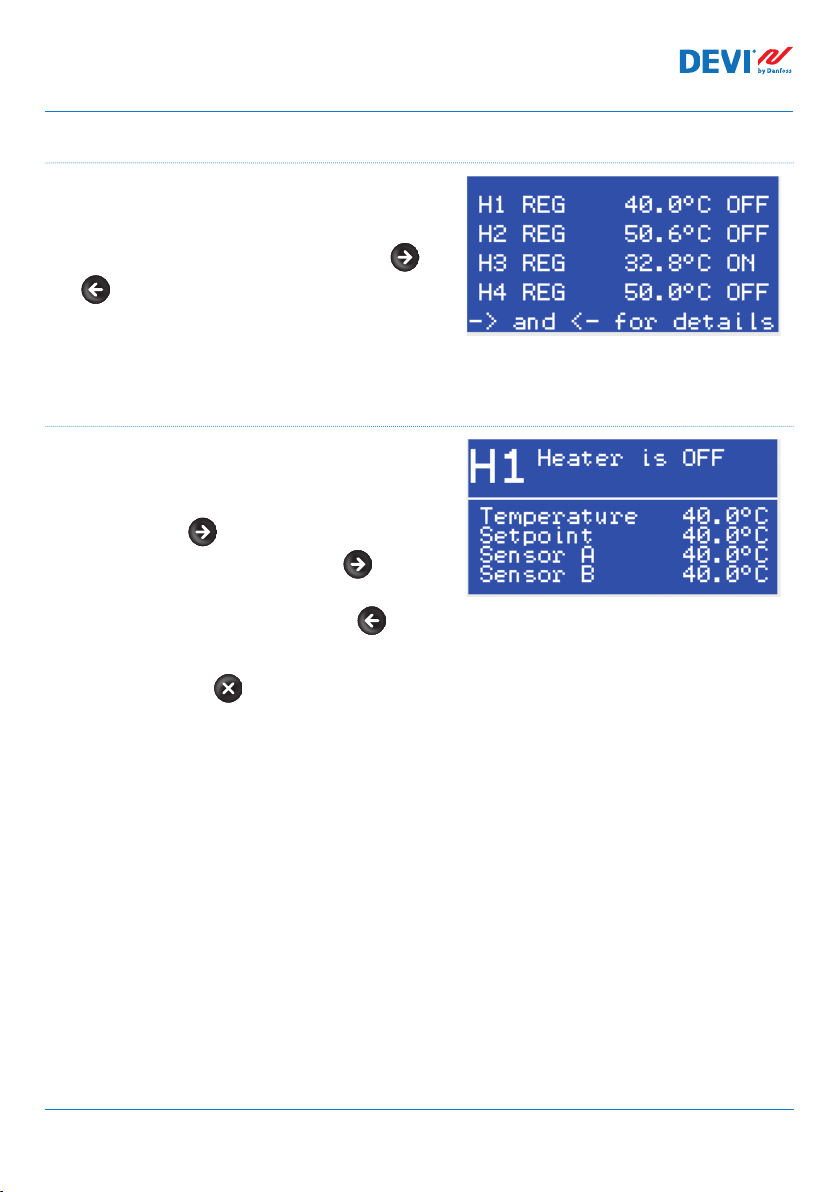

Main Screen view (default)

The Main Screen is the main window

appearing when the controller is powered. This

screen displays an overview of data from the

different heaters. (H1-H4) by pressing the

and more detailed information can be ob-

tained from the respective heaters sub screen.

This view provides the user with an overview of

all systems, however with limited information.

Heater sub-screen view

These screens give to user quick and more

detailed information about settings and status

of each heater.

Just press button on the Main Screen of controller and H1 data will appear, press again

- and you'll see H2 data, and so on. To progress

reversly through this menu please use .

To exit from sub-screens view and return to the

Main Screen - press 1 time.

FEC | Produced by Danfoss © 7

Installation and User Guide DEVIreg™ Hotwater

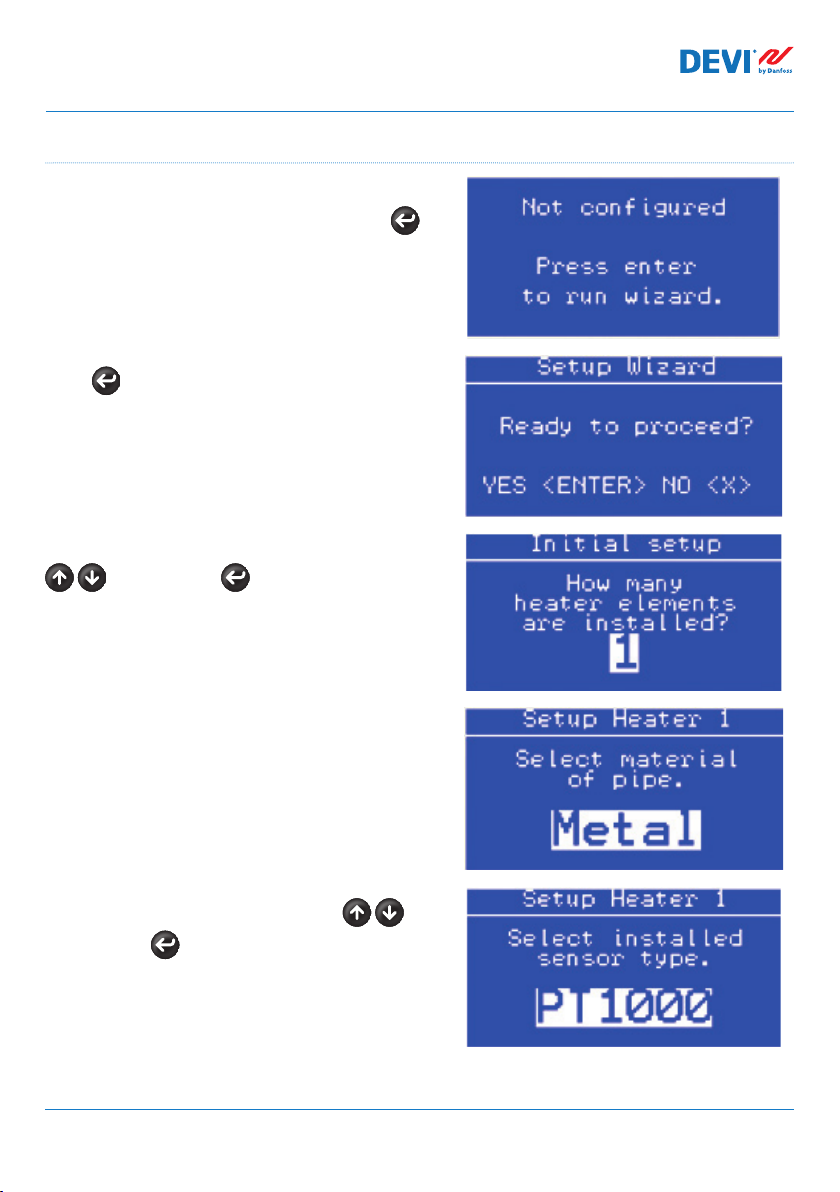

Setup wizard

On the first power on of the device, the device

will ask to run the wizard to do this press

Press once more to proceed into the setup.

The device will ask for the amount heaters use

to select and to accept.

The device will now ask for the details of each

heater in the following pattern

- Pipe material

- Sensor type

- Temperature setpoint

- Enable disinfection

All mentioned can be selected with and

accepted by .

FEC | Produced by Danfoss ©8

Installation and User Guide DEVIreg™ Hotwater

If multiple heaters are entered, this exact procedure will repeat till all information is filled for

all heaters.

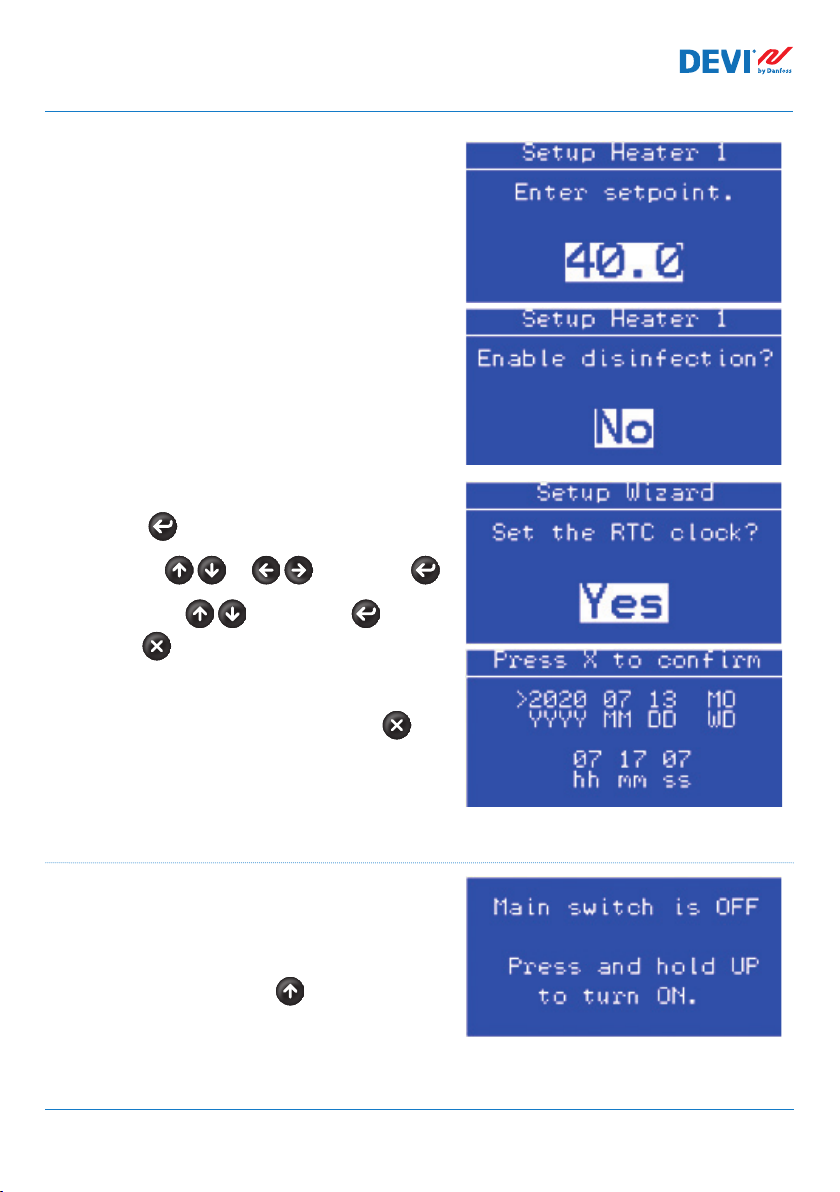

The final step in the wizard is the RTC (Real Time

Clock) press

Navigate with or select with

Manipulate with accept with or

return with

Once time and date are set confirm with

First start-up

Ensure everything is correctly connected and

securely fixed.

Please check this now.

Once verified press and hold (approx. 3-5 sec.)

to turn on the device.

T

he device will now commence normal operation.

FEC | Produced by Danfoss © 9

Installation and User Guide DEVIreg™ Hotwater

Sub-menu Alarm

The structure in this Sub-menu is navigated like

the main menu.

Active alarms: display of the currently active

alarms and is to navigate like Alarm view.

Having an active alarm will activate alarm

relay. Alarms will be retained till reset has been

performed.

Reset Alarms: Reset all alarms by pressing

Log history: display previous alarms in a list

with date and timestamp. This is navigated like

Alarm view.

Clear log history: clears the log history permanently by pressing

Sub-menu Service

The structure in this Sub-menu is navigated like

the main menu.

System: contains a system submenu for professional users containing (Yxx) parameters.

Additionally this menu should under normal

circumstances not be used.

This menu will change according to the user

level password entered in Login.

Relay counters:

Displays the number of relay ON/OFF switching’s performed by each relay.

Software info:

Displays the installed software version.

Device info:

Displays serial number, product code and BIOS version

FEC | Produced by Danfoss ©10

Installation and User Guide DEVIreg™ Hotwater

RTC setup:

Setup of the real time clock, this is to navigate like explained in setup wizard step RTC.

Login:

Enables a password to be input and is to be navigated with and select

with

Configuration:

Contains buzzer activation time, delay for alarm activation and alarm state when device

is OFF.

Serial settings:

Contains Modbus/CAN serial address, Modbus serial baudrate and Modbus serial settings

Language:

The structure in this Sub-menu is navigated like the main menu.

Contains the different language variants.

Function Setup Wizard

This function will reset the device into the Setup

Wizard.

Yes with or NO with

FEC | Produced by Danfoss © 11

Installation and User Guide DEVIreg™ Hotwater

Sub-menu (H1-H4)

The structure in this Sub-menu is navigated like the main menu.

Sensor type:

to select correct type and to confirm.

Be aware that 2 sensors must be used for each heater circuit (H1-H4) and that these must

be the same type.

-PT1000

-NTC16K (NTC16.8K)

-NTC100 (NTC100K)

-NTC2K

-NTC5K

-NTC10K

-NTC15K (Std. DEVI sensor)

Has no default value as this must be set in setup wizard. Please refer to the sensors maximum

and minimum temperatures to ensure safe operation of the system.

Setpoint:

Settable with to select and to confirm.

Settable temperature setpoint (desired maintained temperature) between 20.0-80.0°C

(20-60.0°C on plastic pipe).

Has no default value as this must be set in setup wizard.

Hysteresis:

Settable with to select and to confirm.

Settable between 1.0-10.0K

Defaults to 2.0K

High temperature:

Settable with to select and to confirm.

Settable between 20.0-90.0K

Defaults to Setpoint+Hysteresis+5K

Not settable below setpoint

FEC | Produced by Danfoss ©12

Installation and User Guide DEVIreg™ Hotwater

Alarm delay:

Settable with to select and to confirm.

Temperature alarm delay

Settable between 10-240s

Defaults to 10s

Sensor weighting:

Settable with to select and to confirm.

Weighting the impact of the 2 sensors on the heater regulation.

0% means that the regulation is made on basis of sensor A only 100% meaning sensor B only,

thus 50% is the mean between sensor A and B.

Settable between 0-100%

Defaults to 50%

Disinfection temp:

Settable with to select and to confirm.

Settable between 55-80.0°C

Defaults to 55°C

Pipe material:

Settable with to select and to confirm.

This parameter will have impact on the maximum settable temperatures.

Can be set to metal or plastic.

Has no default value as this must be set in setup wizard

Disinfection alarm temperature:

Settable with to select and to confirm.

This parameter will have impact on the alarm temperature for disinfection temperatures.

Defaults to 65°C

FEC | Produced by Danfoss © 13

Installation and User Guide DEVIreg™ Hotwater

Maximum rising time:

Settable with to select and to confirm.

This parameter will have impact on when the alarm will be triggered due to, too low

temperature (setpoint not reached).

Defaults to 120 minutes.

Sub-menu Disinfection schedule

The structure in this Sub-menu is navigated like

the main menu.

(H1-H4) Schedule:

Press to go to next parameter and to

cancel.

Settable with to select and to

confirm.

Defaults to Sunday at 02:00.

(H1-H4) Manual start:

Starts the Disinfection procedure manually by

pressing

FEC | Produced by Danfoss ©14

Installation and User Guide DEVIreg™ Hotwater

Temperature time table:

Temperature of

disinfection [C°]

55 2h 00 minutes

56 1h 20 minutes

57 1h 00 minutes

58 0h 50 minutes

59 0h 45minutes

60 0h 40 minutes

61 0h 35 minutes

62 0h 30minutes

63 0h 28 minutes

64 0h 27 minutes

65 0h 26minutes

Disinfection time

Temperature of

disinfection [C°]

66 0h 25 minutes

67 0h 25 minutes

68 0h 22 minutes

69 0h 21 minutes

70 0h 20 minutes

71 0h 18minutes

72 0h 14 minutes

73 0h 12 minutes

74 0h 10 minutes

75 0h 10 minutes

Alarms view

By pressing button from Main Screen –

screen(-s) with Alarm appears.

If more than 1 Alarm is happened – use naviga-

tion by going . Pressing button again

leads from Alarm to Main Screen. Having an

active alarm will activate alarm relay. Alarms will

be retained till reset has been performed.

Main menu

Disinfection time

By pressing from the Main Screen– screen

Main Menu appears.

The menu system is navigated from Main

Screen by the following sequence:

The main menu is navigated by and .

Pressing the the selected sub-menu will be

shown. Pressing button you will be taken

back to the previous menu step.

FEC | Produced by Danfoss © 15

Installation and User Guide DEVIreg™ Hotwater

4.2 Language setting

DEVIreg™ Hotwater controller has different programmed languages located in Sub-menu

Service under languages.

4.3 Date and Time settings

DEVIreg™ Hotwater controller has RTC (Real Time Clock) for fixing time of data logging

information, for example Alarms.

NB: Battery back-up time is min. 48 hours.

4.4 BMS(Building Management System) settings

DEVIreg™ Hotwater controller has Modbus RS-485 opto-insulated serial interface.

Modbus RS-485 settings can be done by the following menu sequence:

EN: Main Screen – Enter to Main Menu – Enter to Service – Enter to

Serial settings

EN: Main Screen – Enter to Main Menu – Device settings – BMS settings – { Enter –

Serial address – Down – Serial baud rate – Down – Serial settings }

More detailed information is contained in the Appendix A.

FEC | Produced by Danfoss ©16

Installation and User Guide DEVIreg™ Hotwater

110/230 V AC

5 Connection diagram

Connection scheme DEVIreg™ Hotwater

Power

DI 1

COM

DI 1-4

S - temperature Sensor;

H - Heating element.

for H2 for H3for H1

AI 1

COM

C 1

NO 1

AI 2

COM

DI 2

C 2

NO 2

AI 3

COM

AI 3-4

DI 3

NC 3

C 3

NO 3

DI 4

H1 H2 H3 H4

for H4

RS485

(Modbus)

D -

AI 4

AI 5

COM

AI 5-8

AI 6

AI 7

D +

AI 8

GND

RS485

NC 4

C 4

NO 4

DI 5

C 5

NO 5

DI 6

C 6

NO 6

DI 7

NC 7

C 7

NO 7

NC 8

DI 8

C 8

NO 8

COM

DI 5-8

FEC | Produced by Danfoss © 17

Installation and User Guide DEVIreg™ Hotwater

6 Technical Specifications

6.1 Technical data

Type Value

Nominal voltage 110/230 V~ AC, 50–60 Hz

Power consumption, max. 20 V A

Relay load:

Resistive (inductive, cos(phi sign) = 0,6)

Total current load limit

C1-NO1, C2-NO2

C3-NO3-NC3, C4-NO4-NC4

C8-NO8-NC8

Sensor inputs Analog inputs AI1-AI8

Compatible sensors NTC15k (15 kOhm @ 25 °C) (standard) (max 90 °C)

Digital inputs DI1-DI8, voltage free contacts, on/off inputs

Connection specification Grouped screws plug-in connectors

Cable specification for connectors terminals 0,2-2,5 mm²

Battery back-up time, min. 48 hours

Ball pressure test 125 °C

Pollution degree 2 (domestic use)

Controller type 1 C

Operating temperatures and conditions CE: -20T60 / UL: 0T55, 90% RH non-condensing

Storage temperature and conditions -30Т85, 90% RH non-condensing

IP class IP40 only on the front cover

Protection class Class II Immunity against voltage surges Over Voltage Category II

Dimensions (H/W/D), DIN dimension : 110(122) х 138 х 70 mm, 8 DIN modules

Mounting method DIN rail, complying with EN 60715

Weight, net 511 g

Menu languages: EN

Base controller Danfoss MCX08M2, item no. 080G0307

Software class A

10 (3,5) A (100 000 cycles), cos(phi) = 0.5

6 (4) A (100 000 cycles), cos(phi) = 0.6

6 (4) A (100 000 cycles), cos(phi) = 0.6

NTC10k (10 kOhm @ 25 °C)

NTC5k (5 kOhm @ 25 °C)

NTC2k (2 kOhm @ 25 °C)

NTC100 (100 kOhm @ 25 °C)

NTC16k (16,7 kOhm @ 100 °C)

PT1000 (1000 Ohm @ 0 °C)

32 A

FEC | Produced by Danfoss ©18

Installation and User Guide DEVIreg™ Hotwater

110

6.2 Dimensions

140 6063

FEC | Produced by Danfoss © 19

Installation and User Guide DEVIreg™ Hotwater

7 Disposal Instruction

FEC | Produced by Danfoss ©20

Installation and User Guide DEVIreg™ Hotwater

Appendix A. BMS and RS-485 interface

The controller has a built-in Modbus data transmission system and can be connected to

the BMS central unit.

A1. Communication settings

Default communication settings:

• Serial address: 1.

• Serial baud rate (Transmission speed): 19200.

• Serial setting: 8N1.

A2. RS-485 specifications

MCX hardware network specifications (wiring, topology, etc.) can be found in Danfoss document:

User manual. Meet any HVAC requirement with the reliability of MCX network.

This document provides general indications for the setup of RS-485 networks.

A3. Modbus parameters and variables

Modbus parameters and variables for DEVIreg™ Hotwater controller.

LABEL DESCRIPTION MIN MAX.

PARAMETERS & STATUS VARIABLES

SYS Main Menu > System variables

S1 MaxH1_0dec 0 100 80 RW 3001

S2 MaxH1_1dec 0.0 100.0 80.0 RW 3002

S3 MaxH2_0dec 0 100 80 RW 3003

S4 MaxH2_1dec 0.0 100.0 80.0 RW 3004

S5 MaxH3_0dec 0 100 80 RW 3005

S6 MaxH3_1dec 0.0 100.0 80.0 RW 3006

S7 MaxH4_0dec 0 100 80 RW 3007

S8 MaxH4_1dec 0.0 100.0 80.0 RW 3008

S9 AlarmH1 0.0 90.0 90.0 RW 3009

S10 AlarmH2 0.0 90.0 90.0 RW 3010

S11 AlarmH3 0.0 90.0 90.0 RW 3011

S12 AlarmH4 0.0 90.0 90.0 RW 3012

S13 InitConfigured 0 1 0 RW 3013

S14 Dis_warn 0 1 0 RW 3014

StU Service > System

FEC | Produced by Danfoss © 21

VALUE/

TYPE

UNIT RW ADU

Installation and User Guide DEVIreg™ Hotwater

y01 Main switch 0 1 0 - OFF Enum 1 RW 3015

y02 Heaters used 0 4 0 RW 3016

y03 Maximum plastic temp 0.0 80.0 60.0 °C RW 3017

y04 Reset counters 0 4 0 - NO Enum 7 RW 3018

y07 Restore default parameters 0 1 0 - NO Enum 2 RW 3019

ALA Service > Configuration

BUZ Buzzer activation time 0 15 1 min RW 3023

AdL Alarm relay activation delay 0 999 0 s RW 3024

AOF Alarm relay active if unit in OFF 0 1 1 - YES Enum 2 RW 3025

SEr Service > Serial settings

SEr Serial address (Modbus and CAN) 1 100 1 RW 3026

bAU Serial baudrate (Modbus) 0 7 5 - 192 Enum 3 RW 3027

COM Serial settings (Modbus) 0 2 0 - 8N1 Enum 4 RW 3028

HE1 Main Menu > H1 Settings

H00 Sensor type 0 6 6 - PT1000 Enum 5 RW 3029

H01 Setpoint 20.0 S2 40.0 °C RW 3030

H02 Hysteresis 1.0 10.0 2.0 K RW 3031

H03 High temperature H01 S9 55.0 °C RW 3032

H04 Alarm delay 10 240 10 s RW 3033

H05 Sensor weighting (0 = 100% sensor A) 0 100 50 % RW 3034

H06 Disinfection temp 55 S1 55 °C RW 3035

H07 Pipe material 0 1 0 - Metal Enum 6 RW 3036

H08 Disinfection alarm temp H06 90.0 65.0 °C RW 3037

H09 Max rising time 1 240 120 min RW 3038

HE2 Main Menu > H2 Settings

H10 Sensor type 0 6 6 - PT1000 Enum 5 RW 3039

H11

Setpoint

H12 Hysteresis 1.0 10.0 2.0 K RW 3041

H13 High temperature H11 S10 55.0 °C RW 3042

H14 Alarm delay 10 240 10 s RW 3043

H15 Sensor weighting (0 = 100% sensor A) 0 100 50 % RW 3044

H16 Disinfection temp 55 S3 55 °C RW 3045

H17 Pipe material 0 1 0 - Metal Enum 6 RW 3046

H18 Disinfection alarm temp H16 90.0 65.0 °C RW 3047

H19 Max rising time 1 240 120 min RW 3048

HE3 Main Menu > H3 Settings

H20 Sensor type 0 6 6 - PT1000 Enum 5 RW 3049

H21 Setpoint 20.0 S6 40.0 °C RW 3050

H22 Hysteresis 1.0 10.0 2.0 K RW 3051

H23 High temperature H21 S11 55.0 °C RW 3052

H24 Alarm delay 10 240 10 s RW 3053

H25 Sensor weighting (0 = 100% sensor A) 0 100 50 % RW 3054

H26 Disinfection temp 55 S5 55 °C RW 3055

H27 Pipe material 0 1 0 - Metal Enum 6 RW 3056

20.0 S4 40.0 °C RW 3040

FEC | Produced by Danfoss ©22

Installation and User Guide DEVIreg™ Hotwater

H28 Disinfection alarm temp H26 90.0 65.0 °C RW 3057

H29 Max rising time 1 240 120 min RW 3058

HE4 Main Menu > H4 Settings

H30 Sensor type 0 6 6 - PT1000 Enum 5 RW 3059

H31 Setpoint 20.0 S8 40.0 °C RW 3060

H32 Hysteresis 1.0 10.0 2.0 K RW 3061

H33 High temperature H31 S12 55.0 °C RW 3062

H34 Alarm delay 10 240 10 s RW 3063

H35 Sensor weighting (0 = 100% sensor A) 0 100 50 % RW 3064

H36 Disinfection temp 55 S7 55 °C RW 3065

H37 Pipe material 0 1 0 - Metal Enum 6 RW 3066

H38

Disinfection alarm temp

H39 Max rising time 1 240 120 min RW 3068

LOG Status var > MCX Design Hotspots

V01 SystemOnOff 0 1 0 - OFF Enum 1 Read 8101

C01 Reset Alarms 0 2 RW 1859

V11 H1_highTemp 0 1 0 - NO Enum 2 Read 8102

V09 H1_controlTemp -50.0 120.0 0.0 °C Read 8103

V11 H1_reference 0.0 100.0 0.0 °C Read 8104

V12 H1 pullDown 0 1 0 - NO Enum 2 Read 8105

V13 H1 manualDis 0 1 0 RW 9901

V14 H2 manualDis 0 1 0 RW 9902

V15 H3 manualDis 0 1 0 RW 9903

V16 H4 manualDis 0 1 0 RW 9904

V16 H1 sensorA error 0 1 0 - NO Enum 2 Read 8106

V17 H1 sensorB error 0 1 0 - NO Enum 2 Read 8107

V16 H1_sensorA -50.0 120.0 0.0 °C Read 8108

V17 H1_sensorB -50.0 120.0 0.0 °C Read 8109

V15 H1_heater 0 1 0 - OFF Enum 1 Read 8110

V16 H1_state 0 6 0 Read 8111

V17 H1_DisinfectionTimer 0 50000 0 s Read 8112

V18 H2 sensorA -50.0 120.0 0.0 °C Read 8113

V19 H2 sensorB -50.0 120.0 0.0 °C Read 8114

V20 H2 sensorA error 0 1 0 - NO Enum 2 Read 8115

V21 H2 sensorB error 0 1 0 - NO Enum 2 Read 8116

V22 H2 controlTemp -50.0 120.0 0.0 °C Read 8117

V23 H2 reference -50.0 120.0 0.0 °C Read 8118

V24 H2 heater 0 1 0 - NO Enum 2 Read 8119

V25 H2 pullDown 0 1 0 - NO Enum 2 Read 8120

V26 H2 highTemp 0 1 0 - NO Enum 2 Read 8121

V27

H2 DisinfectionTimer

V28 H2 state 0 6 0 Read 8123

V29 H3_sensorA -50.0 120.0 0.0 °C Read 8124

V30 H3_sensorB -50.0 120.0 0.0 °C Read 8125

H36 90.0 65.0 °C RW 3067

0 50000 0 s Read 8122

FEC | Produced by Danfoss © 23

Installation and User Guide DEVIreg™ Hotwater

V31 H3_controlTemp -50.0 120.0 0.0 °C Read 8126

V32 H3_reference -50.0 120.0 0.0 °C Read 8127

V33 H3 heater 0 1 0 - NO Enum 2 Read 8128

V34 H3 state 0 6 0 Read 8129

V35 H3 sensorA error 0 1 0 - NO Enum 2 Read 8130

V36 H3 sensorB error 0 1 0 - NO Enum 2 Read 8131

V37 H3 DisinfectionTimer 0 50000 0 s Read 8132

V38 H3 highTemp 0 1 0 - NO Enum 2 Read 8133

V39 H3 pullDown 0 1 0 - NO Enum 2 Read 8134

V40 H4 sensorA -50.0 120.0 0.0 °C Read 8135

V41 H4 sensorB -50.0 120.0 0.0 °C Read 8136

V42 H4 sensorA error 0 1 0 - NO Enum 2 Read 8137

V43 H4 sensorB error 0 1 0 - NO Enum 2 Read 8138

V44 H4 controlTemp -50.0 120.0 0.0 °C Read 8139

V45 H4 reference -50.0 120.0 0.0 °C Read 8140

V46 H4 heater 0 1 0 - NO Enum 2 Read 8141

V47 H4 state 0 6 0 Read 8142

V48 H4 DisinfectionTimer 0 50000 0 s Read 8143

V49 H4 highTemp 0 1 0 - NO Enum 2 Read 8144

V50 H4 pullDown 0 1 0 - NO Enum 2 Read 8145

V51 H1 Duty 0 100 0 % Read 8146

V52 H2 Duty 0 100 0 % Read 8147

V53 H3 Duty 0 100 0 % Read 8148

V54 H4 Duty 0 100 0 % Read 8149

V56 H1 counter 0 2147483647 0 Read 8150

V57

H2 counter

V58 H3 counter 0 2147483647 0 Read 8154

V59 H4 counter 0 2147483647 0 Read 8156

ALARMS

LABEL DESCRIPTION MIN MAX RESET IN OFF

E01 Sensor1 A error 0 1 AUTO ACTIVE Read 1901 .08

E02 Sensor1 B error 0 1 AUTO ACTIVE Read 1901 .09

E03 Sensor2 A error 0 1 AUTO ACTIVE Read 1901 .10

E04 Sensor2 B error 0 1 AUTO ACTIVE Read 1901 .11

E05 Sensor3 A error 0 1 AUTO ACTIVE Read 1901 .12

E06 Sensor3 B error 0 1 AUTO ACTIVE Read 1901 .13

E07 Sensor4 A error 0 1 AUTO ACTIVE Read 1901 .14

E08 Sensor4 B error 0 1 AUTO ACTIVE Read 1901 .15

A01 Heater1 high temp 0 1 AUTO INACTIVE Read 1901 .00

A02 Heater2 high temp 0 1 AUTO INACTIVE Read 1901 .01

A03 Heater3 high temp 0 1 AUTO INACTIVE Read 1901 .02

A04 Heater4 high temp 0 1 AUTO INACTIVE Read 1901 .03

A05 Heater1 disinfection fail 0 1 MANUAL INACTIVE Read 1901 .04

A06 Heater2 disinfection fail 0 1 MANUAL INACTIVE Read 1901 .05

0 2147483647 0 Read 8152

FEC | Produced by Danfoss ©24

Installation and User Guide DEVIreg™ Hotwater

A07 Heater3 disinfection fail 0 1 MANUAL INACTIVE Read 1901 .06

A08 Heater4 disinfection fail 0 1 MANUAL INACTIVE Read 1901 .07

A09 Heater1 rising fail 0 1 MANUAL INACTIVE Read 1902 .08

A10 Heater2 rising fail 0 1 MANUAL INACTIVE Read 1902 .09

A11 Heater3 rising fail 0 1 MANUAL INACTIVE Read 1902 .10

A12 Heater4 rising fail 0 1 MANUAL INACTIVE Read 1902 .11

A13 Heater1 high disinfection 0 1 MANUAL INACTIVE Read 1902 .12

A14 Heater2 high disinfection 0 1 MANUAL INACTIVE Read 1902 .13

A15 Heater3 high disinfection 0 1 MANUAL INACTIVE Read 1902 .14

A16 Heater4 high disinfection 0 1 MANUAL INACTIVE Read 1902 .15

AI ANALOG INPUTS

1 Sensor 1A -30.0 170.0 PT1000 Read 18502

2 Sensor 1B -30.0 170.0 PT1000 Read 18503

3 Sensor 2A -30.0 170.0 PT1000 Read 18504

4 Sensor 2B -30.0 170.0 PT1000 Read 18505

5 Sensor 3A -30.0 170.0 PT1000 Read 18506

6 Sensor 3B -30.0 170.0 PT1000 Read 18507

7 Sensor 4A -30.0 170.0 PT1000 Read 18508

8 Sensor 4B -30.0 170.0 PT1000 Read 18509

DI DIGITAL INPUTS

AO ANALOG OUTPUTS

DO DIGITAL OUTPUTS

1 Heater 1 0 1 N.O. Read 18003

2 Heater 2 0 1 N.O. Read 18004

3 Heater 3 0 1 N.O. Read 18005

4 Heater 4 0 1 N.O. Read 18006

8 Alarm 0 1 N.O. Read 18002

I/O CONFIGURATION

FEC | Produced by Danfoss © 25

Installation and User Guide DEVIreg™ Hotwater

Warranty

At DEVI, we find it of great importance to deliver high quality products with long lasting effects.

DEVIwarranty™ is a series of 4 individual, best-in-market warranties to give you full peace of mind while using DEVI products in

electric heating systems. For all DEVI products, we maintain the following warranties:

A 20-year full service warranty is valid for:

• heating cables incl. DEVIflex™ / DEVIsafe™ / DEVIsnow™ / DEVIasphalt™ / DEVIaqua™/ DEVIbasic™ / DEVIcomfort™ /

DEVIsport™ (DSM3) / DEVImulti™ / DEVIinline™;

• heating mats incl. DEVImat™ / DEVIcomfort™ / DEVIheat™ / DEVIsnow™ / DEVIasphalt™ / DTCE;

Not only does this warranty include costs of reparation or replacement, but also installation and floor materials, such as damage

to brickwork and tiles. For more details, read DEVIwarranty™ terms and conditions below.

A 10-year product warranty is valid for:

• DEVIcell™ plates, DEVIpipeguard™ LSZH self-limiting heating cables;

A 5-year product warranty is valid for DEVI thermostats, floor heating systems, self-limiting heating cables, and

accessories:

• DEVIreg™ Smart thermostat;

• DEVIreg™ Touch thermostat;

• DEVIdry™ floor heating element under carpet, laminate and wooden floor (not including the DEVIdry™ thermostats and

control sets);

• DEVIiceguard™, DEVIpipeheat™, DEVIpipeguard™ and DEVIhotwatt™ self-limiting heating cables;

• All related accessories;

A 2-year product warranty is valid for:

• DEVIreg™ 130–132 / 233 / 316 /330 / 527 / 528 / 530–535 / 610 thermostats;

• DEVIreg™ Hotwater, DEVIreg™ 850 controllers;

• DEVIlink™ wireless control system;

• DEVIdry™ thermostats and control sets;

• DEVIreg™ Therm Control;

• DEVIfoil™ heating foils;

• DEVIrail™ towel heaters;

• DEVItemp™ industrial heaters;

• DEVItronic™ anti-condensation heaters;

• Radiant heaters;

• Power supply units for thermostats;

• All related accessories, including heating cables, and heating mats accessories.

Should you, against all expectations, experience a problem

the date of purchase on the following conditions:

During the warranty period DEVI shall offer a new comparable product or repair the product in case the product is found to be

faulty by reason of defective design, materials or workmanship. The repair or replacement shall be carried out free of charge

providing that the warranty claim is valid. The decision to either repair or replace will be solely at the discretion of DEVI. DEVI

shall not be liable for any consequential or incidental damages including, but not limited to, damages to property or extra utility

expenses.

An extension of the warranty period following repairs undertaken cannot be granted.

The warranty shall be valid only if the WARRANTY CERTIFICATE is completed correctly and in accordance with the instructions, and

provided the fault is submitted to the installer or the seller without undue delay and proof of purchase is provided. Please note that

the WARRANTY CERTIFICATE must be completed in English or local language.

DEVIwarranty™ shall not cover any damage caused by incorrect conditions of use, incorrect installation or if installation has been

carried out by non-authorized electricians. All work will be invoiced in full if DEVI is required to inspect or repair faults that have

arisen as a result of any of the above.

The DEVIwarranty™ shall not extend to products which have not been paid in full.

DEVI will, at all times, provide a rapid and effective response to all complaints and inquiries from our customers.

The warranty explicitly excludes all claims exceeding the above conditions.

Attention: The Warranty Certificate must be completed correctly for the Warranty to be valid.

with your DEVI product, you will find that DEVI offers DEVIwarranty™ from

FEC | Produced by Danfoss ©26

Installation and User Guide DEVIreg™ Hotwater

Warranty Certificate

The DEVIwarranty™ is granted to:

Name:

Address:

Postal code: Phone:

Please observe!

In order to obtain the DEVIwarranty™, the following must be

carefully filled in. See other conditions on previous page.

Electrical Installation by:

Installation date:

Type of thermostat:

Production code:

Suppliers Stamp:

FEC | Produced by Danfoss © 27

Installation and User Guide DEVIreg™ Hotwater

Danfoss A/S

Nordborgvej 81

6430 Nordborg, Syddanmark

Denmark

08097137 & AN377831097153en-000101 Produced by Danfoss © 06/2021

Loading...

Loading...