Page 1

Data sheet

DECS 2.0

Danfoss Energy Control System

Description

DECS 2.0

DECS 2.0

The Danfoss Energy Control System (DECS) is a

web-based SCADA software solution (Supervisory

Control And Data Acquisition) for district heating

systems.

This SCADA solution is typically installed locally

at the heating utility and will automatically

configure its user interface and functionality to

support the application in the controller (for

example Danfoss ECL Comfort 310).

The user of the DECS 2.0 system is able to remote

control and monitor the parameters settings in

the controllers and also monitor actual, reference

and historical values of sensors and meters

connected to the controller.

Danfoss ECL Comfort 310, OPR0010 and OPR0020

controllers are supported by the autoconfiguration features of DECS 2.0, but the ECL

Apex 20 controller can also be supported by

manually adding graphics and programs into

DECS 2.0.

© Danfoss | 2018.05

VD.HX.A5.02 | 1

Page 2

Data sheet DECS 2.0 Danfoss Energy Control System

User benefits The advantages of DECS 2.0 are among others:

Easy installation Easy access

Automatic configuration makes installation easy Access to control and monitor locally and remotely

Advanced techniques are used for simplifying and

automating the installation process. Once the

controller is installed and connected to the

network, the web-based user interface is

generated on the DECS server with just a few

mouse clicks. The DECS server sof tware is installed

at the heating plant and has no special

requirements except for a reliable PC connected

to the internet.

Easy customization Standard

User interface and functionality suits projec t specific

needs

DECS is a visualisation platform based on the

Atvise SCADA system. The user interface and

functionality is easily customized by the system

integrator to project specific requirements using

the Engineering Tool. The scaleability of DECS

ensures an optimized SCADA solution for small,

large and growing district energy networks.

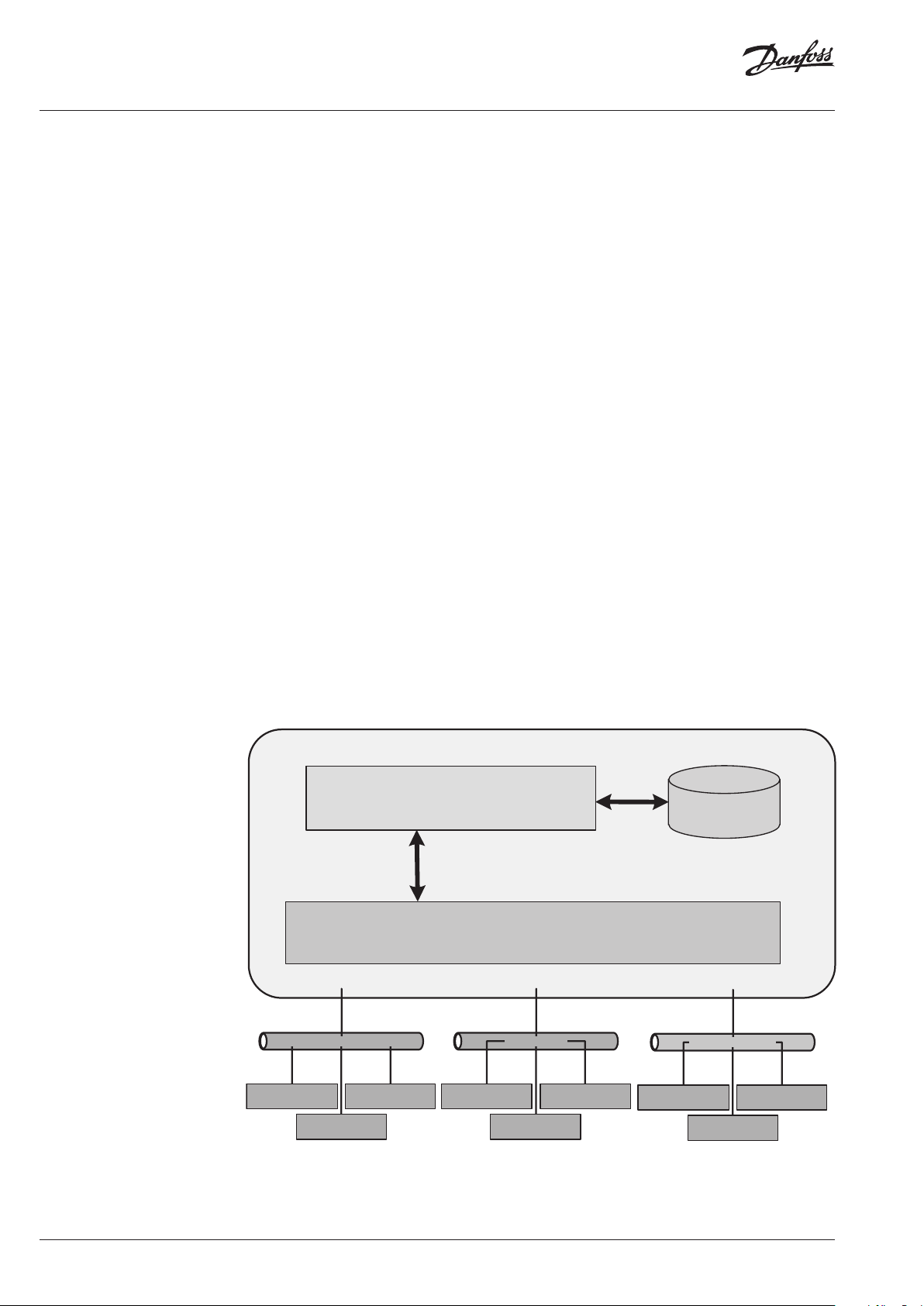

System architecture The architecture of DECS 2.0 is shown below.

The central building blocks of the DECS 2.0 s ystem

are the HMI (Human Machine Inter face) using the

Atvise SCADA Client software from Certec, the

database for storing all logged data from the

controllers and the OPC UA Server software

handling the data communication with the

controllers.

Data is constantly exchanged between the

controllers and the DECS Server. The server

provides an intuitive user interface, which is

accessible from any standard browser on a PC,

laptop or smartphone connected to the internet.

You can control and monitor your heating station

and substation installations from everywhere.

System is built on standardized software and

interfaces

Standardized DECS Server software increases

reliability, lowers hardware complexity and allows

integration of other building automation systems

into the heating system. The communication

interfaces are based on the well-known ModbusRTU or Modbus-TCP protocols, which provide a

reliable, low complexity network.

DECS 2.0 suppor ts data communication between

the server and controllers using Modbus-TCP

(Ethernet), LON bus and Modbus-RS485.

Ethernet (MODBUS-TCP)

Bioma ss

Controller

Bioma ss

Controller

CENTRAL SYSTEM

HMI (atvise)

(Web-Browser / SCADA-System)

OPC UA Server

Bioma ss

Controller

Biomass

Controller

LON network

Biomass

Controller

Bioma ss

Controller

MODBUS (RS485)

Biomass

Controller

Databa se

Bioma ss

Controller

Biomass

Controller

2 | © Danfoss | 2018.05

VD.HX.A5.02

Page 3

Data sheet DECS 2.0 Danfoss Energy Control System

Application DECS 2.0 software automatically adapts its user

interface to fit the application in the controller.

The following controller applications are

supported:

• ECL Comfort 310 controller

* Please see ‘List of app lication keys

supported by DECS 2.0’

Go to http://heating.danfoss.com. In the

‘Documentation’ menu select ‘Electronic

Controllers & PI Controllers > SCADA

Solutions > Data sheet’.

• OPR0020 Controller

* Firmware R4 and newer

• OPR0010 Controller

* Firmware v3.

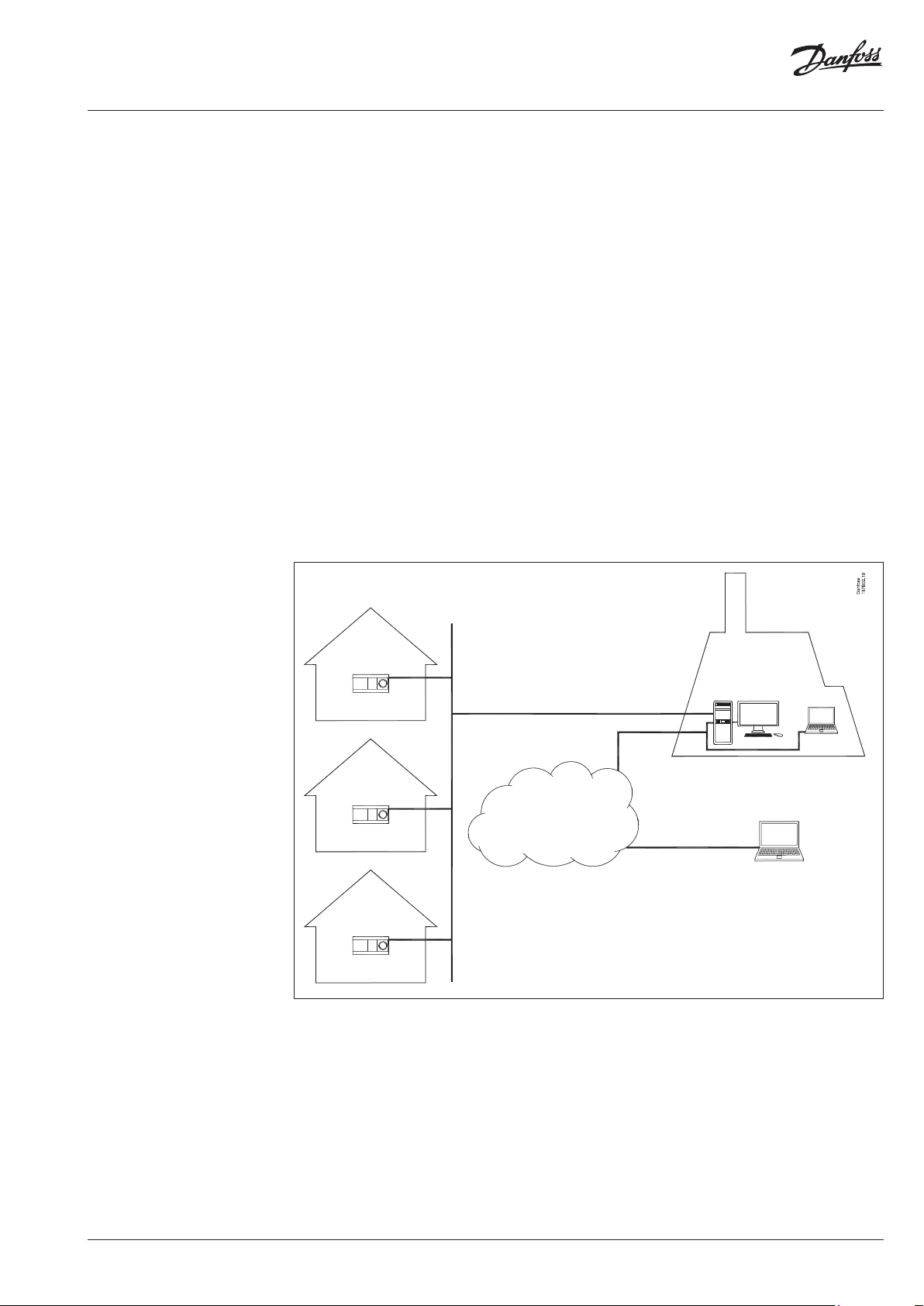

Below is an application example of DECS 2.0 in a

biomass district heating network using

Modbus-RS485 for data communication. The

server, which has DECS 2.0 installed, is located in

the district heating utility and a central laptop is

used for operating the DECS 2.0 system.

j

l

As an option the ECL Apex 20 controller can be

integrated into DECS 2.0 to remote control and

monitor the district heating utility or boiler house.

This requires a system integrator to develop a

customized application for the ECL Apex 20

controller as well as a customized HMI for the

DECS 2.0 system using the OPC server software

for ECL Apex 20.

An external ser vice provider also has access to the

DECS 2.0 system using his laptop connected to

the internet. The server and the ECL Comfort 310

controllers are communicating via an RS485 serial

link using the Modbus protocol.

k

n

p

j

m

j

q

j Private house

k Boiler house for biomass

l Modbus-RS485 network

m Internet

n DECS 2.0 server

o DECS 2.0 client (external service provider)

p DESC 2.0 client (central administration)

q ECL Comfort 310 controller

o

VD.HX.A5.02

© Danfoss | 2018.05 | 3

Page 4

Data sheet DECS 2.0 Danfoss Energy Control System

Application

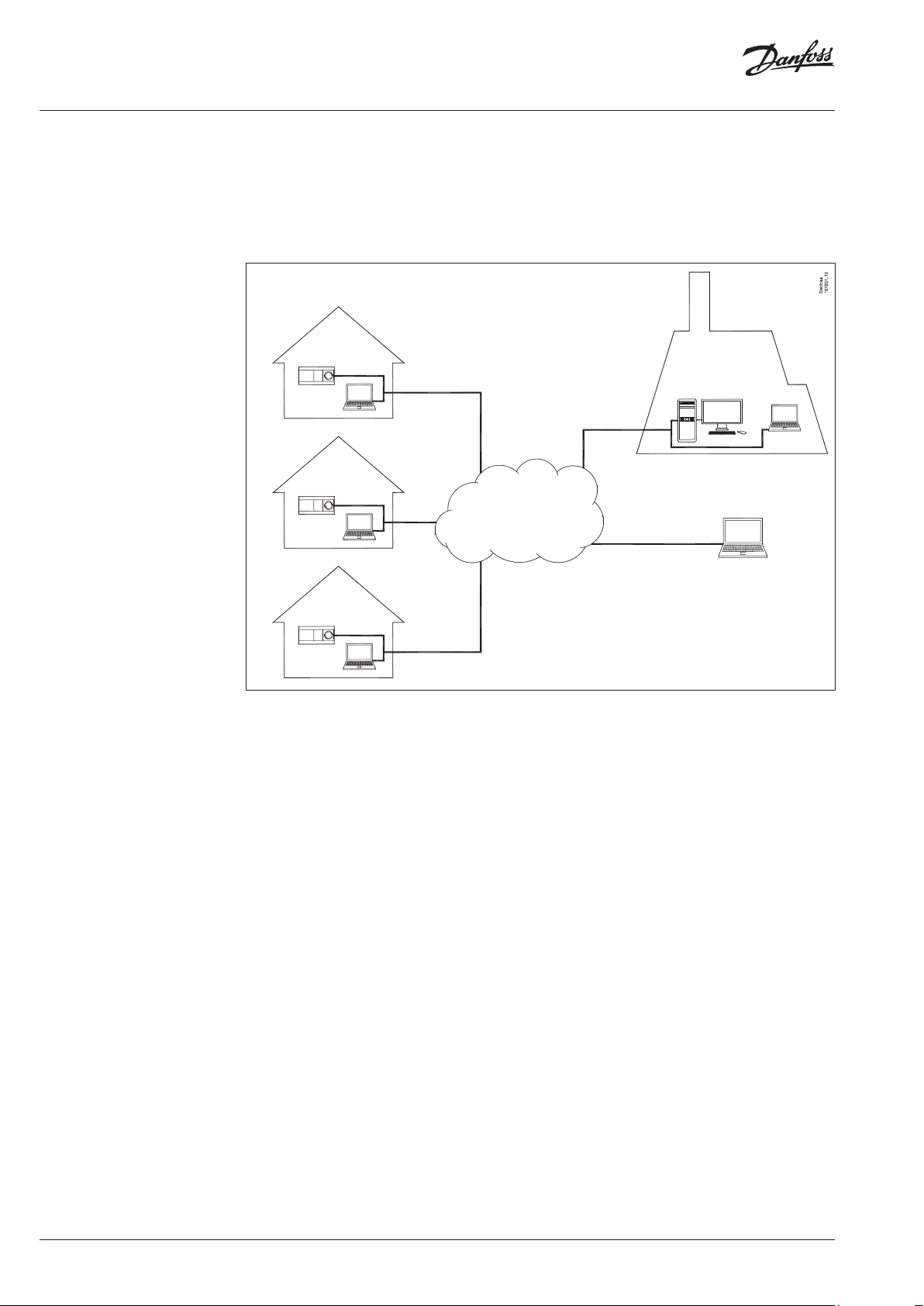

Below is an application example of DECS 2.0 in

biomass district heating network using ModbusTCP (ethernet) for data communication. It is similar

to the previous example except that the ECL

Comfort 310 controllers are communicating with

the server via standard internet connections using

the Modbus protocol.

j

l

j

l

m

j

These internet connections may be used also by

laptops in the houses for browsing the internet

and also to access the DECS 2.0 system.

k

n

p

o

Languages

l

q

j Private house

k Boiler house for biomass

l Modbus-TPC network (internet)

m Internet

n DECS 2.0 server

o DECS 2.0 client (external service provider)

p DESC 2.0 client (central administration)

q ECL Comfort 310 controller

The following languages are supported by the

graphical user interface of DECS 2.0:

• English

• German

• Italian

4 | © Danfoss | 2018.05

VD.HX.A5.02

Page 5

Data sheet DECS 2.0 Danfoss Energy Control System

Data communication

Selection matrix for existing

and new DECS networks

The options for data communication between

controllers and server are listed below. See also

the selection matrix in the next section for

information on selecting the correct data

communication type.

Typ e Description Remarks

Modbus-RS485 Modbus communication via RS485 serial link

is supported by ECL Comfort 310 controllers.

Additional network components may be

needed, i.e. repeaters and gateways.

Modbus-TCP

LON bus

This matrix shows which controllers, data

communication network and SCADA software

are to be used in existing DH networks in case of

warranty or expansion projects.

Modbus communication via ethernet over

internet is supported by OPR0020 and ECL

Comfort 310 controllers.

Additional network components may be

needed, i.e. router and firewall.

LON bus communication via twisted pair serial

link is supported by O PR0020 and ECL Comfort

310 controllers.

The ECL Comfort 310 controller must be

equipped with the ECA34 LON module.

Licenses for components using LON bus are

needed.

For new DH networks the ECL Comfort 310

controller must be used with a Modbus or

Ethernet data network with DECS 2.0.

LON networks should not be

offered in new DECS 2.0 projects.

Modbus is recommended instead.

Existing DH networks New DH networks

Project type Warranty Expansion

Controller

(in substation)

Controller

(in DH utility)

Data network LON (or Ethernet) Modbus-RS485 or Modbus-TCP

Software DECS 1.0

OPR0010 OPR0020 ECL Comfort 310

(incl. LON module)

ECL Apex 20 ECL Apex 20

DECS 2.0 DECS 2.0 OPC Server

(E3)

ECL Comfort 310

(ECL Apex 20)

VD.HX.A5.02

© Danfoss | 2018.05 | 5

Page 6

Data sheet DECS 2.0 Danfoss Energy Control System

Ordering

To use the DECS 2.0 system a server must have

the Atvise SCADA client software and DECS 2.0

software installed. A combined license for Atvise

SCADA Client software and DECS 2.0 software is

If a LON network is used the ECL Comfort 310

controller must be equipped with an ECA34 LON

module and the DECS 2.0 s erver must be equipped

with the Loytec LON NIC.

ordered using the code no. for “DECS 2.0 Software

li cens e”.

In order to use ECL Comfort 310 controllers in a

DECS 2.0 system, each ECL Comfort 310 controller

Additionally a “DECS 2.0 Controller license” must

must have a supported application key installed.

be ordered for each controller registered to the

DECS 2.0 system.

If the DECS 2.0 system is customized to include

also remote control and monitoring of the district

Miscellaneous data communication components

and software drivers may also be needed to

heating utility an ECL Apex 20 controller and ECL

Apex 20 OPC Server software are needed.

establish a DECS 2.0 system. The components

needed depend on the size of the data

communication network and type of network, i.e.

Modbus or LON.

Typ e Designation Code no.

Software DECS 2.0 Software license

DECS 2.0 Controller license

Data

communication

ECA34 LON module for ECL Comfort 310

Loytec LON NIC (PCI/Parallel/USB)

1)

187B1500

187B1501

087H3204

004F9067

Application Please see ‘List of application keys supported by DECS

2.0’

Go to http://heating.danfoss.com. In the

Documentation’ menu select ‘Electronic Controllers &

PI Controllers > SCADA Solutions > Data sheet’.

Controller

3)

ECL Comfort 310 Controller

OPR0020 Controller

ECL Apex 20 Controller

2)

2)

087H3040

00 4F9021

087B2506

Other accessory hardware and soft ware for DECS

2.0 projects are to be purchased locally or

outsourced to local partners/suppliers.

1)

No separate data sheet exists for this product.

To be used only when expanding existing OPR0020/LON

bus based DH networks with ECL310 controllers

2)

See separate data sheet for this component for ordering

details

3)

Max. 1200 controller

6 | © Danfoss | 2018.05

VD.HX.A5.02

Page 7

Data sheet DECS 2.0 Danfoss Energy Control System

Technical data Modbus-RS485 data communication:

Data format • 1 start bit

Communication protocol Modbus RTU

Electrical interface RS485

Cable type Twisted pair + Modbus reference (signal ground)

Max. bus cable length 1200 m (dependent on cable type and

Communication speed • 38.4 Kbit/s half duplex (default)

Network According to the standard Modbus Serial Line

Max. number of Modbus masters 30

Max. number of controllers per Modbus master 247

Modbus-TCP data communication:

Communication protocol Modbus TCP

Electrical interface Ethernet, RJ45 connector

Cable type Standard Ethernet cable (CAT 5)

Max. bus cable length According to Ethernet standard

Communication speed • 10 Mbit/s

TCP Port number 502 (default for Modbus TCP protocol)

Network Star network according to the standard Ethernet

• 8 data bits

• even parity

• 1 stop bit

installation)

• 19.2 Kbit/s half duplex

• 9.6 Kbit/s half duplex

Implementation Guide V1.0

• 100 Mbit/s

implementation guidelines

LON data communication:

Communication protocol LonWorks

Electrical interface RS485

Cable type Twisted pair with shield

Max. bus cable length 500 m (dependent on cable type, termination

and installation)

Communication speed • 78.1 Kbit/s

Network Serial line, star or loop network according to the

LonWorks implementation guidelines by

Echelon

Max. number of controllers per NIC-interface 500

VD.HX.A5.02

© Danfoss | 2018.05 | 7

Page 8

Data sheet DECS 2.0 Danfoss Energy Control System

DECS 2.0 system

requirements

DECS 2.0 server:

Operating system • Microsoft® Windows XP (SP3 with latest

updates installed) (32-bit)

• Microsoft® Windows 7 (SP1 with latest

updates installed) (32-bit)

CPU Intel® or AMD® processor (>= 1,6 GHz)

RAM Minimum: 4 GB RAM

Free disc space 500 GB

(depending on the number of controllers

connected to DECS 2.0 and archieving

frequency)

Video A windows certified graphics card and driver.

Minimum resolution is 1280*1024 pixel

3rd party software • Atvise server V2.1.18 (Certec)

• Loytec network interface software 4.1.x for

LON networks

• Microsoft® .NET Framework 3.5 and

compatible versions

Web browser SVG capable internet browser:

• Mozilla Firefox

• Internet Explorer

• Google Chrome

Web browser must comply with requirements of

Atvise SCADA Client software.

For details about specific browser versions

compatible with Atvise please visit http://www.

atvise.com/en/resources/system-requirements

Backup recommendations RAID Level 1 or RAID Level 5

Data communication interface on DECS 2.0

server:

Modbus-RS485 RS485 port compatible with

• MOXA UPort 1130

• MOXA NPort 5150

• Phoenix Contact FL COM SERVER RS485

Modbus-TCP Ethernet compatible interface

LON bus Loytec LON NIC (LonWorks/EIA 709) using PCI,

Parallel or USB for LON networks

DECS 2.0 client:

Operating system • Microsoft® Windows XP (SP3 with latest

updates installed)

• Microsoft® Windows 7 (SP1 with latest

updates installed)

CPU Intel® or AMD® processor (>= 1,6 GHz)

RAM Minimum: 2 GB RAM

Free disk space 1 GB

Video A windows certified graphics card and driver.

Minimum resolution is 1280*1024 pixel

Web browser SVG capable internet browser:

• Mozilla Firefox

• Internet Explorer

• Google Chrome

Web browser must comply with requirements of

Atvise SCADA Client software.

For details about specific browser versions

compatible with Atvise please visit http://www.

atvise.com/en/resources/system-requirements

8 | © Danfoss | 2018.05

VD.HX.A5.02

Page 9

Data sheet DECS 2.0 Danfoss Energy Control System

Technical literature and

additional information

Typ e Description Literature no.

Operating

guide, DECS

2.0

Operating

guide,

DECS 2.0

User guide,

DECS 2.0

For further information on supported application

keys please visit http://heating.danfoss.com.

In the ‘Documentation’ menu select ‘Electronic

Controllers & PI Controllers > SCADA Solutions.

Operating guide for DECS 2.0 software on

servers incl. Atvise SCADA client, HMI and

database including instructions on how to

configure DECS 2.0

Operating guide on how to use the features

of DECS 2.0 at district heating networks

User guide on how to use the features of DECS

2.0 in homes

VI.HX.C

VI.HX.A

VI.HX.B

VD.HX.A5.02

© Danfoss | 2018.05 | 9

Page 10

Data sheet DECS 2.0 Danfoss Energy Control System

10 | © Danfoss | 2018.05

VD.HX.A5.02

Page 11

Data sheet DECS 2.0 Danfoss Energy Control System

VD.HX.A5.02

© Danfoss | 2018.05 | 11

Page 12

Data sheet DECS 2.0 Danfoss Energy Control System

12 | © Danfoss | DHS-SMT/DK | 2018.05

VD.HX.A5.02

Loading...

Loading...