Technical Information

Digital Displacement® Pump Gen 1

DDP096 and DPC12

www.danfoss.com

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Revision history Table of revisions

Date Changed Rev

June 2021 Added new Gen 1 content; recreated document structure 0201

December 2019 Revised to reflect 420 bar limit and updated software features 0102

October 2019 First edition: 280 bar, industrial 0101

2 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Contents

General information

Overview..............................................................................................................................................................................................5

About the DDP.................................................................................................................................................................................. 5

Theory of operation.........................................................................................................................................................................5

Multi-outlet pump...................................................................................................................................................................... 6

Features and benefits..................................................................................................................................................................... 8

General safety warnings.................................................................................................................................................................8

Fluid under high pressure........................................................................................................................................................8

OEM responsibility......................................................................................................................................................................8

Pressure relief............................................................................................................................................................................... 9

Failure and fault states..............................................................................................................................................................9

Intended use.................................................................................................................................................................................9

Improper use.................................................................................................................................................................................9

Personnel qualifications.........................................................................................................................................................10

Technical specifications

DDP096 pump specifications.................................................................................................................................................... 11

DDP general specifications................................................................................................................................................... 11

DDP fluid specifications......................................................................................................................................................... 11

DDP mechanical specifications........................................................................................................................................... 12

DPC12 controller specifications................................................................................................................................................13

DPC12 input power supply...................................................................................................................................................13

Separate coil and logic power supplies...................................................................................................................... 13

Wiring and fuses.................................................................................................................................................................. 14

Pressure sensors for DPC12............................................................................................................................................. 14

Non-volatile memory write/erase ratings........................................................................................................................14

General ratings.......................................................................................................................................................................... 14

Environmental standards and criteria...............................................................................................................................15

LED messages............................................................................................................................................................................ 16

DPC12 housing..........................................................................................................................................................................16

DDP characteristics

Performance.....................................................................................................................................................................................17

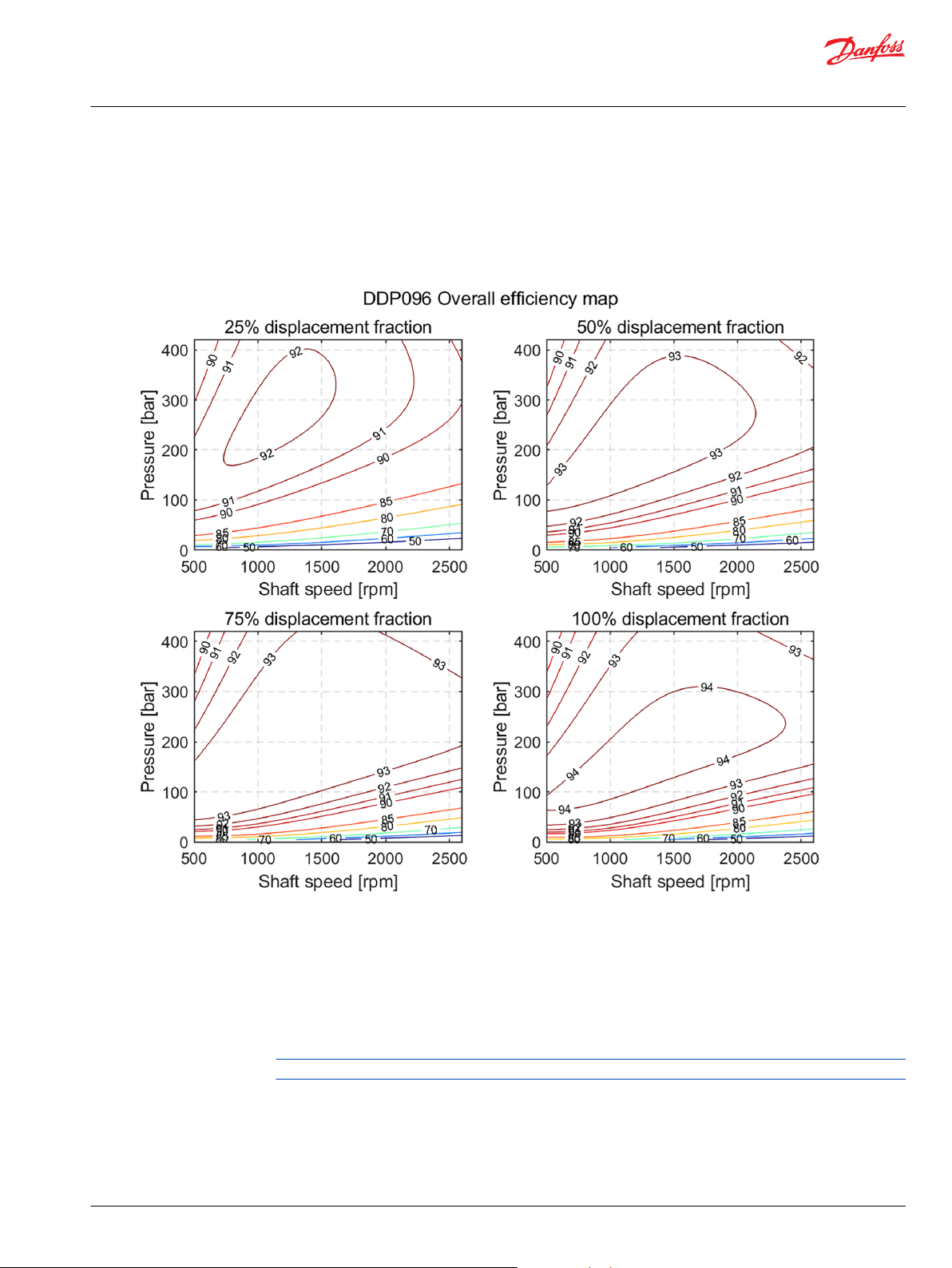

Overall pump efficiency......................................................................................................................................................... 17

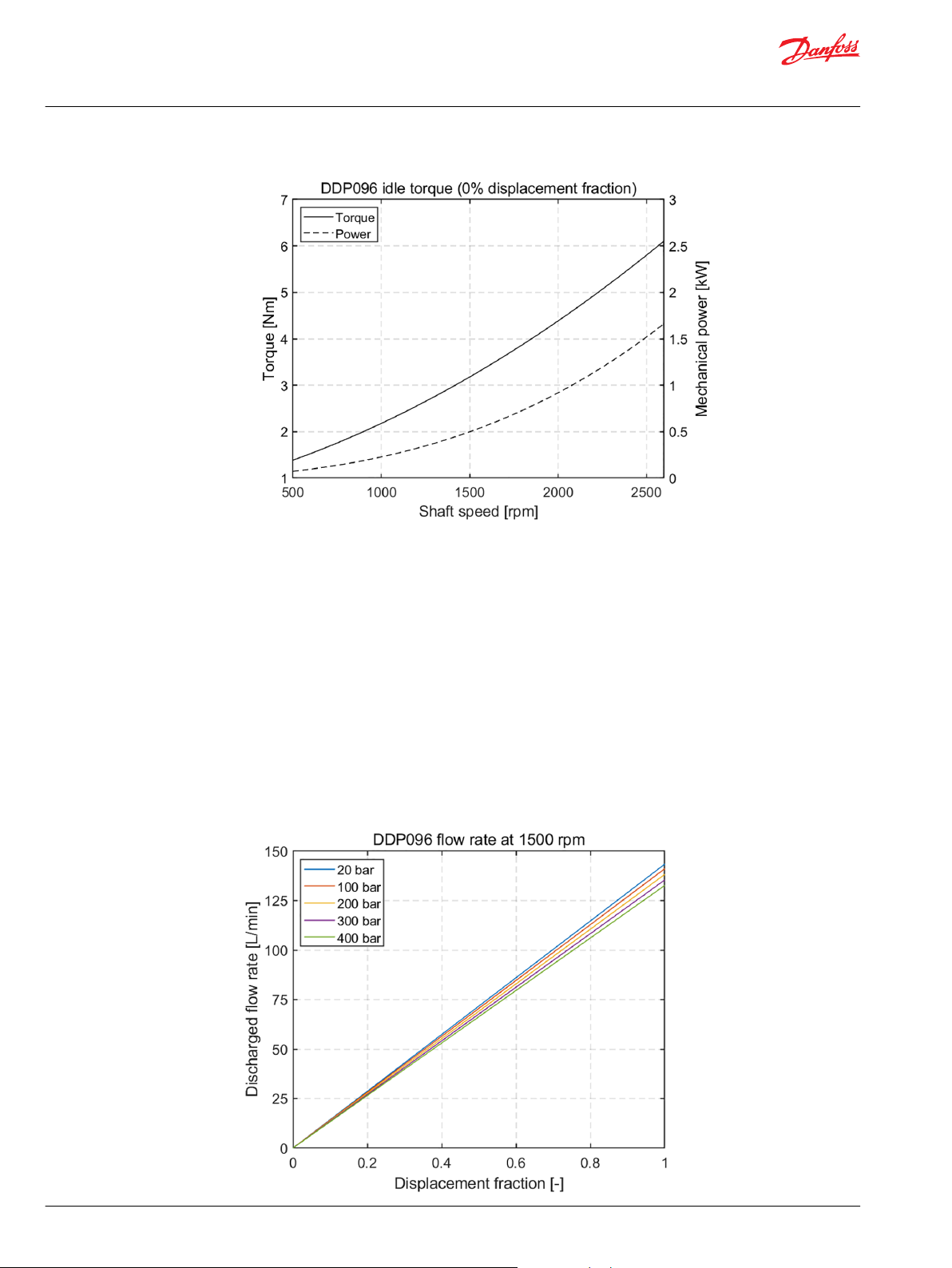

Idle losses.....................................................................................................................................................................................17

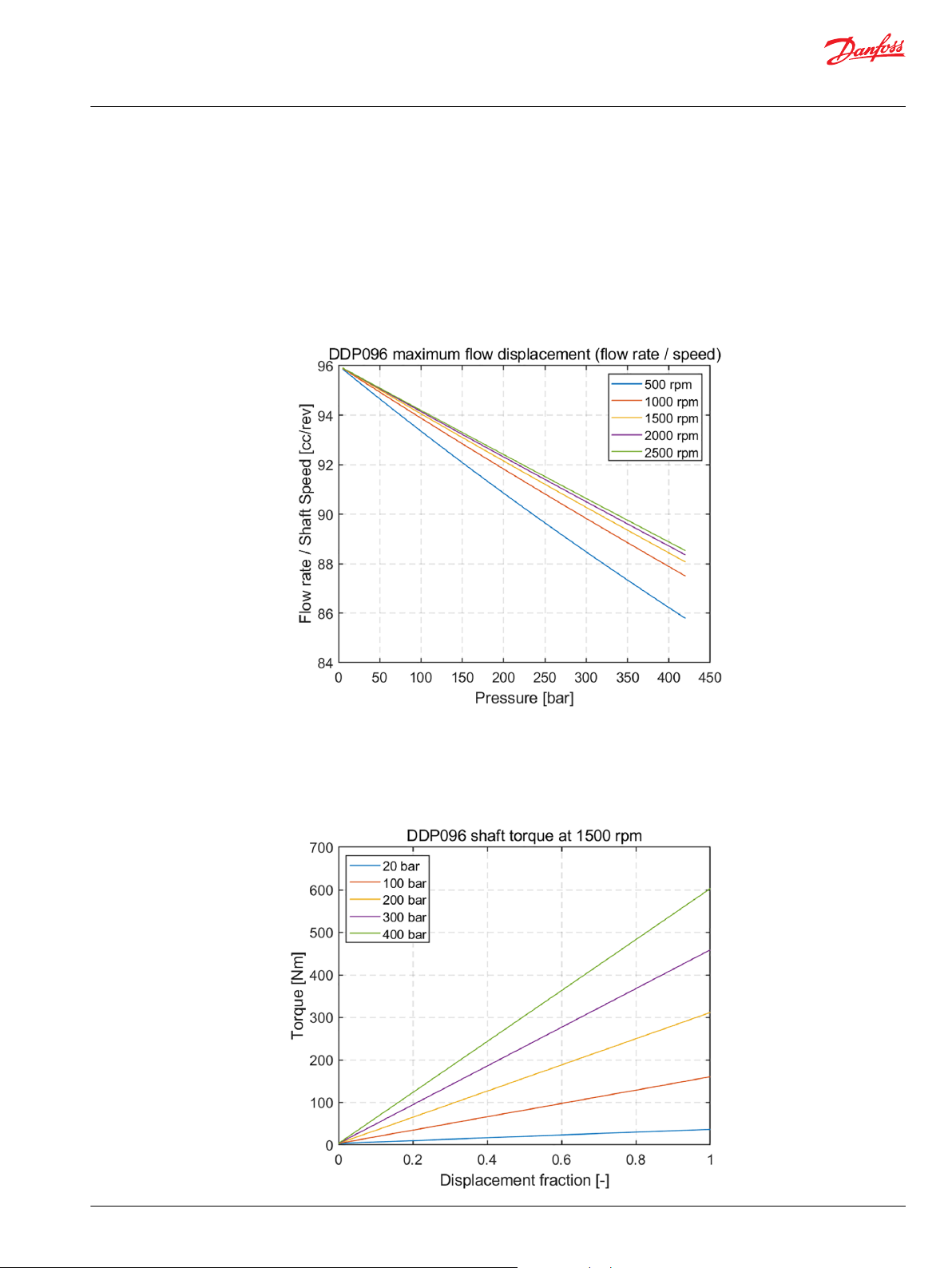

Pump discharged flow and shrinkage.............................................................................................................................. 18

Input torque................................................................................................................................................................................19

Electronic control losses.........................................................................................................................................................20

Noise characteristics..................................................................................................................................................................... 20

Control operation

Control modes, limits, and features........................................................................................................................................ 21

Control modes and sources..................................................................................................................................................21

Limits.............................................................................................................................................................................................21

Other features............................................................................................................................................................................22

Control diagrams......................................................................................................................................................................23

Example use cases....................................................................................................................................................................25

Controller interaction...................................................................................................................................................................25

Overview......................................................................................................................................................................................25

PLUS+1® CAN/USB gateway..................................................................................................................................................25

Configuration and tuning......................................................................................................................................................25

Commissioning mode.............................................................................................................................................................26

Diagnostics and errors............................................................................................................................................................26

Model code

DDP model code............................................................................................................................................................................ 27

DDP part options............................................................................................................................................................................28

Mechanical installation

Pump transport and handling...................................................................................................................................................30

Storage...............................................................................................................................................................................................31

©

Danfoss | June 2021 BC306384089197en-000201 | 3

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Contents

Installation requirements............................................................................................................................................................31

Pump arrangement..................................................................................................................................................................31

Pump shaft coupling...............................................................................................................................................................31

Understanding and minimizing system noise............................................................................................................... 31

Air removal..................................................................................................................................................................................32

Removing air with gravity................................................................................................................................................32

Removing air with an auxiliary pump..........................................................................................................................33

Removing air through the DDP outlet port...............................................................................................................33

Removing air by submersion.......................................................................................................................................... 34

Flushing........................................................................................................................................................................................34

Filtration.......................................................................................................................................................................................34

Controller mounting................................................................................................................................................................35

Pump dimensions..........................................................................................................................................................................36

Common dimensions..............................................................................................................................................................36

Shaft end view dimensions..............................................................................................................................................37

Side view dimensions........................................................................................................................................................ 38

Top view dimensions.........................................................................................................................................................39

Rear view dimensions........................................................................................................................................................40

Single-outlet pump dimensions......................................................................................................................................... 41

Multi-outlet pump dimensions............................................................................................................................................43

Multi-outlet pump side view dimensions.................................................................................................................. 44

Multi-outlet pump rear view dimensions...................................................................................................................45

Controller dimensions..................................................................................................................................................................46

Electrical installation

Installation requirements............................................................................................................................................................47

Wiring overview........................................................................................................................................................................ 47

Machine wiring guidelines....................................................................................................................................................47

Machine welding guidelines................................................................................................................................................ 48

CAN bus installation................................................................................................................................................................ 48

System diagnostic connector...............................................................................................................................................49

Fuses..............................................................................................................................................................................................49

Grounding...................................................................................................................................................................................49

Hot plugging..............................................................................................................................................................................49

Connectors....................................................................................................................................................................................... 50

Pump connectors..................................................................................................................................................................... 51

Controller connectors............................................................................................................................................................. 54

Commissioning and troubleshooting

Basic commissioning procedure.............................................................................................................................................. 59

Commissioning and troubleshooting with PLUS+1 Service Tool................................................................................ 59

Initial procedure........................................................................................................................................................................59

Commissioning DDP valves and hydraulic installation.............................................................................................. 59

Further system commissioning and validation............................................................................................................. 60

Symptoms and diagnosis............................................................................................................................................................61

Serviceability....................................................................................................................................................................................61

4 | © Danfoss | June 2021 BC306384089197en-000201

E

C

G

B

A D

F

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

General information

Overview

This document contains important information about the safe operation and control of the open circuit

hydraulic Digital Displacement® Pump (DDP096) and its partnered electronic controller (DPC12).

Throughout this document the complete partnered product will be referred to as the Digital

Displacement® Pump or DDP.

Guidance is given on the transportation, commissioning and operation of the pump. For disposal please

contact Danfoss.

All safety guidance provided in this document must be followed. Relevant residual risks and control

measures are outlined.

This document is not a substitute for appropriate professional training and competency dealing with

hydraulic circuits. Only competent persons should install, operate or maintain the pump and controller.

About the DDP

Digital displacement is a new hydraulic pump technology based on a radial piston pump design. An

electronic controller selectively enables each piston by actuating a corresponding on/off valve. In this

way, the pump displacement is digitally variable resulting in fast and accurate flow control. Digital

Displacement® Pumps have high efficiency and very low idle losses because they use only as many

pistons as are needed to meet the demand.

Theory of operation

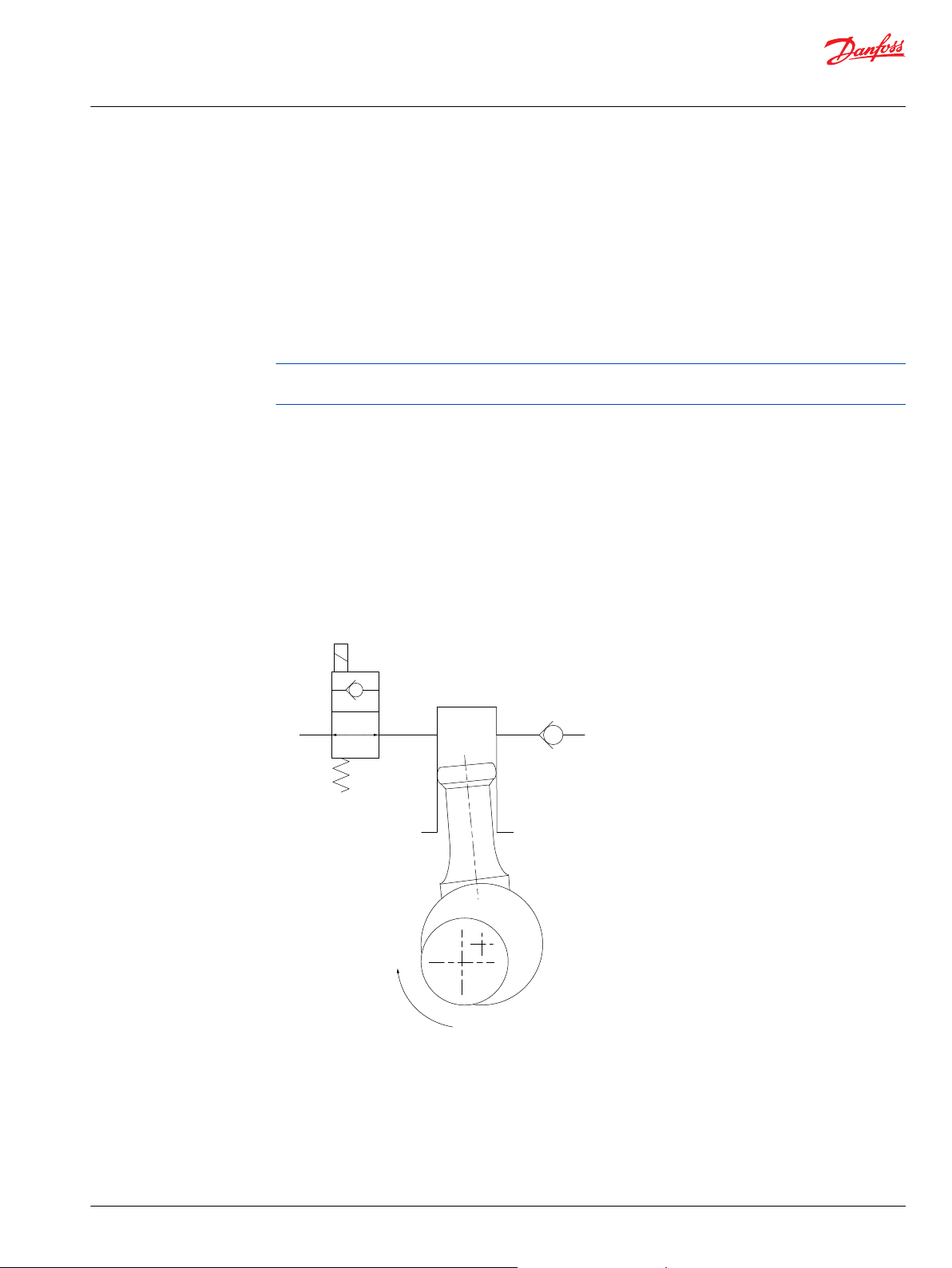

Check valves connect each of the pump’s piston chambers to the inlet and outlet, as shown below.

The outlet check valve is passive. The inlet check valve is actively controlled and is normally open and can

be closed by energizing a solenoid coil. As the pump’s input shaft rotates, it turns an eccentric cam which

pushes the piston up and down in the piston chamber. The controller determines whether or not the

piston will pump fluid to the outlet. If the piston is idling, the inlet check valve is not energized and the

inlet check valve remains in the open position. The fluid displaced by the piston moves freely back and

forth from the inlet. No fluid is discharged to the outlet.

To pump each piston, the controller closes the solenoid valve when the piston is at bottom dead center.

The inlet check valve closes and the piston forces the fluid through the outlet check valve. When the

A Inlet

B Inlet check valve

C Outlet check valve

D Outlet

E Piston

F Cam

G Shaft rotation

©

Danfoss | June 2021 BC306384089197en-000201 | 5

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

General information

piston reaches top dead center, the inlet check valve reopens and fluid is drawn from the inlet into the

piston chamber as the piston moves out to begin another cycle.

The DDP has 12 pistons which each displaces 8cc of fluid per stroke for a total displacement volume of 96

cc/rev. The pump geometry is designed so that the pistons are evenly spaced 30° apart. Every piston is

enabled at full displacement (displacement fraction Fd = 1), and every piston is disabled at Fd = 0. For 0 <

Fd < 1, the controller uses a sequence of enabled and disabled pistons which are represented by ones

and zeros respectively in the following table of examples.

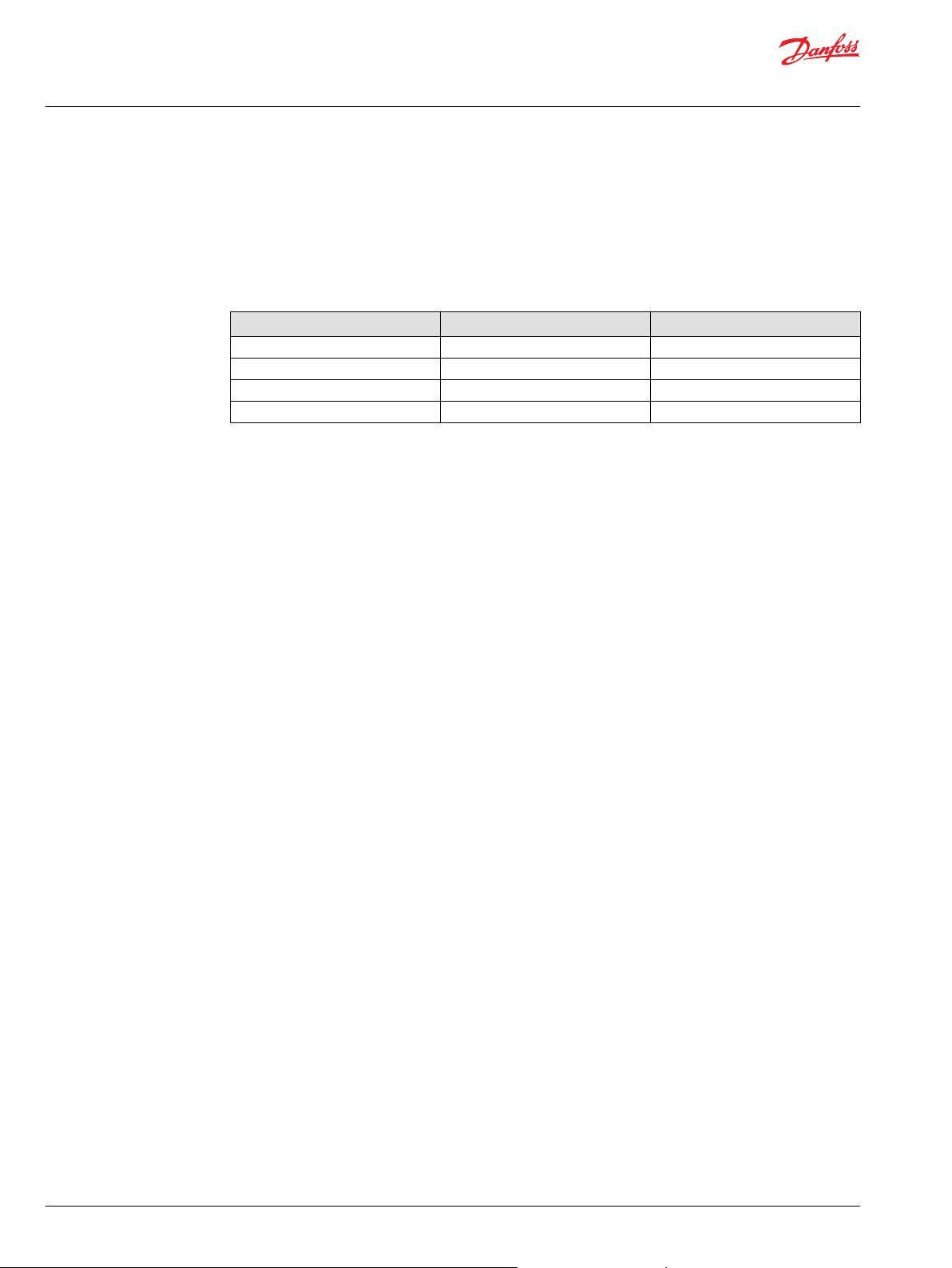

Displacement Fraction Piston Sequence Sequence Length

0.5 01… 2

0.25 0001… 4

7/12 = 0.583 010101101011… 12

19/24 = 0.792 111101111011 110111101110… 24

The desired displacement fraction is achieved as an average over time. Some displacement fractions can

be achieved with short sequences like 01… or 001… Other displacement fractions are achieved with

longer sequences. For example, Fd = 0.792 = 19/24 has 10 active pistons during the first revolution and 9

active pistons during the second revolution. Fd = 0.51 requires a repeating sequence of length 100 with

51 ones and 49 zeros. Any value of Fd can be achieved with a sufficiently long binary sequence.

The controller does not use fixed or pre-programmed sequences of on and off pistons. At every 30

degrees of shaft rotation, the controller determines whether to enable the next piston based on the

current Fd command and the history of pistons enabled. In the preceding table, the commanded

displacement is constant, so the piston sequence is periodic. The same pistons are not necessarily

enabled or disabled, but can change with each shaft rotation.

The DDP can operate in various control modes including pressure control, load sensing, flow control,

displacement control, torque or power control and combinations of these. The control modes are

monitored by the DPC12 pump controller based on sensor inputs and configured with parameters and

limits at a software level. For instance, to regulate the pump pressure in pressure control mode, the

controller compares the measured pressure to the desired pressure and calculates a displacement

command with a proportional-integral control algorithm.

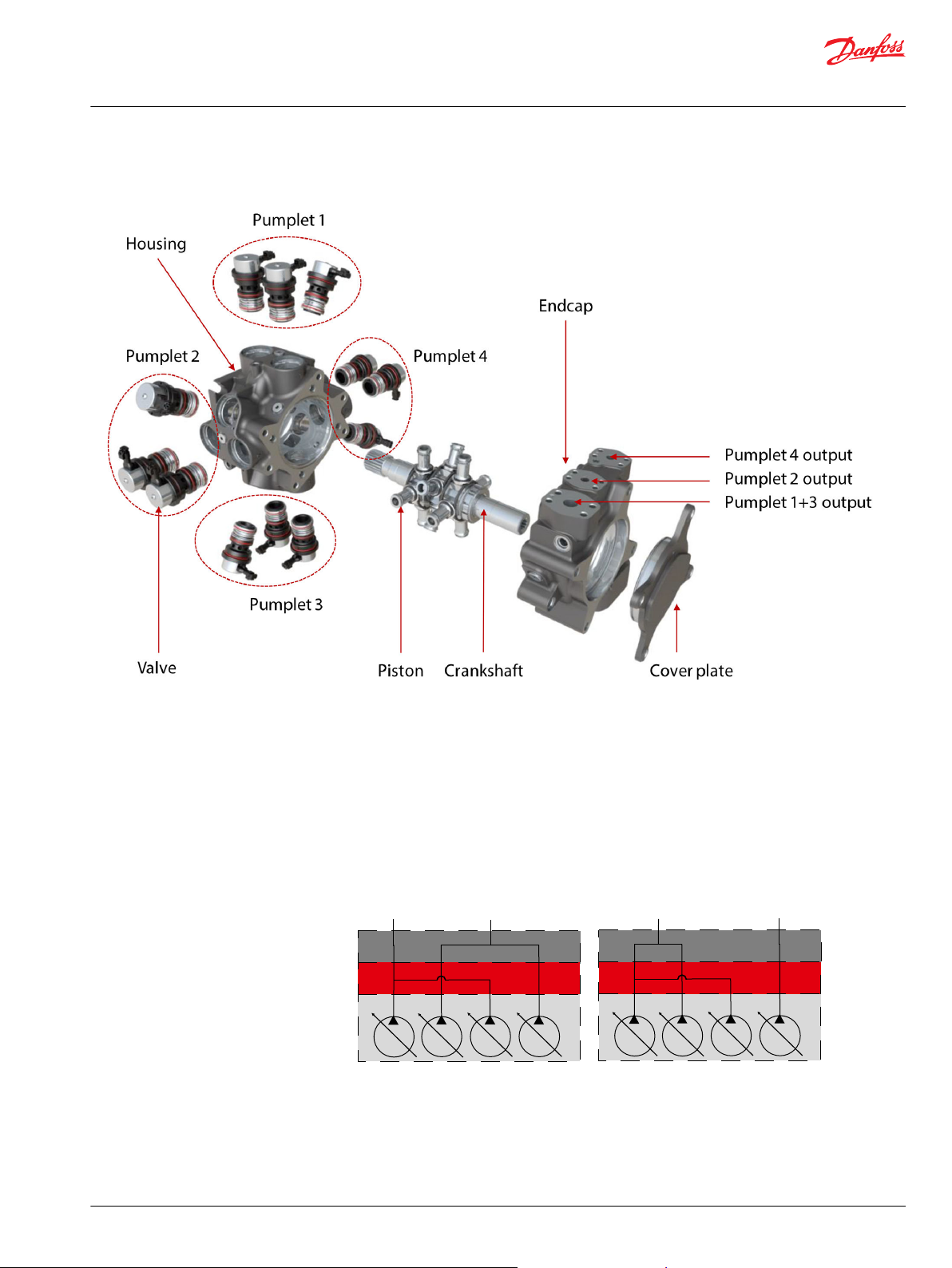

Multi-outlet pump

The DDP096 is composed of 12 pistons and valves (i.e. 12 pumping units). These pumping units are

divided into four groups called pumplets. The DDP can be perceived as a combination of four

independent pumplets producing each up to 24cc/rev, given its unique radial design and digital control.

The DDP096 is available either as a single-outlet endcap or a multi-outlet endcap. The single-outlet DDP

has one inlet and one outlet like other conventional hydraulic pumps. However, the multi-outlet DDP

leverages the four pumplets to offer multiple outputs from a single pump with independent flows,

pressures, and control modes.

6 | © Danfoss | June 2021 BC306384089197en-000201

2 services 2 services

Ganging

manifold

48-24-24 cc/rev

endplate

Pumplets

48 cc/rev

48 cc/rev

P1 P2

P4

24 cc/rev

24 cc/rev24 cc/rev

24 cc/rev

1

2 3

4

72 cc/rev

24 cc/rev

P1 P2

P4

24 cc/rev

24 cc/rev 24 cc/rev

24 cc/rev

1

2 3

4

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

General information

Three-outlet DDP096 exploded view

The current multi-outlet endcap provides three outlets to the DDP:

•

2 outlets producing up to 24 cc/rev each

•

1 outlet producing up to 48 cc/rev

With this multi-outlet endcap, different displacements are achievable with a ganging manifold to suit an

application using two services. A service is one level higher than the pump outlet and represents the

number of fluid consumers of the DDP. A service is essential to control the DDP096 with the DPC12.

Services diagram

©

Danfoss | June 2021 BC306384089197en-000201 | 7

Currently, only 2-service operation (Service 1 and Service 2) is available. There are two settings possible

for 2-service operation:

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

General information

•

P1 / (P2 + P4) [48 / 48 cc/rev]

•

(P1 + P2) / P4 [72 / 24 cc/rev]

P1, P2, and P4 represent the outlet ports of the multi-outlet DDP096 endcap. (P2+P4) means that the P2

and P4 ports must be connected with a ganging manifold. Refer to Pump dimensions for more

information on ports.

Service 1 (S1) and Service 2 (S2) must be selected at the software level and configured accordingly. Refer

to Software manual for more information.

Features and benefits

Features and benefits of the DDP are as follows.

•

High efficiency radial piston pump with exceptional part-load performance

•

Low idle losses even when pressurized

•

Near-silent operation for pressure-holding applications

•

Fast response, low displacement hysteresis

•

CAN bus interface with performance and diagnostic information, sensored outputs, tunable

parameters, PLUS+1® Compliant

•

Virtually no leakage at zero flow output

•

Zero to full displacement (or the reverse) in half a revolution

•

Options for multiple independent outlets from a single pump, through-shaft capability and auxiliary

mounting

*

General safety warnings

The DDP has been manufactured according to the generally accepted rules of hydraulic machine design

and uses the latest advanced valve concepts to maximize operating efficiency and user controllability.

Fluid under high pressure

Escaping hydraulic fluid under pressure can have sufficient force to penetrate skin causing serious injury

and/or infection.

Additionally, the fluid may cause burns.

Use caution when dealing with hydraulic fluid under pressure.

Always relieve pressure in the system before removing hoses, fittings, gauges, or other components.

Never use hands or any other body parts to check for leaks in a pressurized component; seek medical

attention immediately if you are cut by hydraulic fluid.

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

*

Half a revolution plus 8.5 ms for communication and processing time. For example, at 1800 rpm, processing time is 16.2 ms + 8.5

ms = 24.7 ms.

8 | © Danfoss | June 2021 BC306384089197en-000201

W

W

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

General information

•

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

equipment.

•

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

system being programmed in a manner that jeopardizes safety.

•

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

•

The hydraulic system must also be designed to withstand an emergency shutdown where hydraulic

flow will stop, and pressure may drop significantly.

Warning

There is the potential to cause personal injury or damage to equipment if the following instructions and

warning are not followed.

•

Please read these instructions thoroughly before commissioning the pump.

•

Keep these instructions in an accessible location and always pass them on to the end user of the

pump.

•

Consult with Danfoss if there are any questions about the intended use of the pump or safety

implications from operating the pump.

•

Operating conditions and technical data given in the data sheet must be followed at all times.

Pressure relief

The pump is not supplied with any mechanical pressure limiting device as standard. Pressure transducers

present on the pump are for pressure compensation and can not substitute as a safety device.

A pressure relief valve rated for full flow in the hydraulic circuit is important in protecting the product and

personnel.

The OEM is responsible for designing the system to mitigate potential unsafe situations, such as

providing adequate pressure relief.

Failure and fault states

If electrical power to the DPC12 controller is lost, the DDP096 pump will output zero flow. Some software

faults also cause the DDP096 to stop providing flow. If zero output flow is an undesirable failure/fault

mode in the application, means of providing backup flow must be designed into the system.

Intended use

Digital Displacement® pumps are components in terms of the EU machinery directive 98/37/EC. Hydraulic

pumps are not ready to use machines as described in the EU machine directive. Digital Displacement

pumps are produced with the sole intention of being incorporated within a machine or further assembly

to form a machine or system. The product may only be fully commissioned after it has been installed in

the machine or system for which it is intended.

The Digital Displacement® pump produces and controls the flow of hydraulic fluid most commonly with

the function of regulating the output pressure. It is assumed that a flow control device, such as a closed

center proportional valve, is present in the system between the pump and the controlled load. Other

applications may be acceptable but should be discussed with Danfoss first.

®

Improper use

Warning

Digital Displacement® pumps may not be used in explosive environments. Digital Displacement® pumps

may not be used in life critical applications.

Please contact Danfoss for further information on use in specific applications.

©

Danfoss | June 2021 BC306384089197en-000201 | 9

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

General information

Personnel qualifications

The system operates with high pressure fluid. Assembly and disassembly of the pump for maintenance

purposes is only to be carried out by Danfoss or a qualified service technician authorized by Danfoss.

Installation of the pump and electrical equipment must be carried out by suitably qualified personnel

with experience and knowledge of working with hydraulic and electrical systems.

10 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Technical specifications

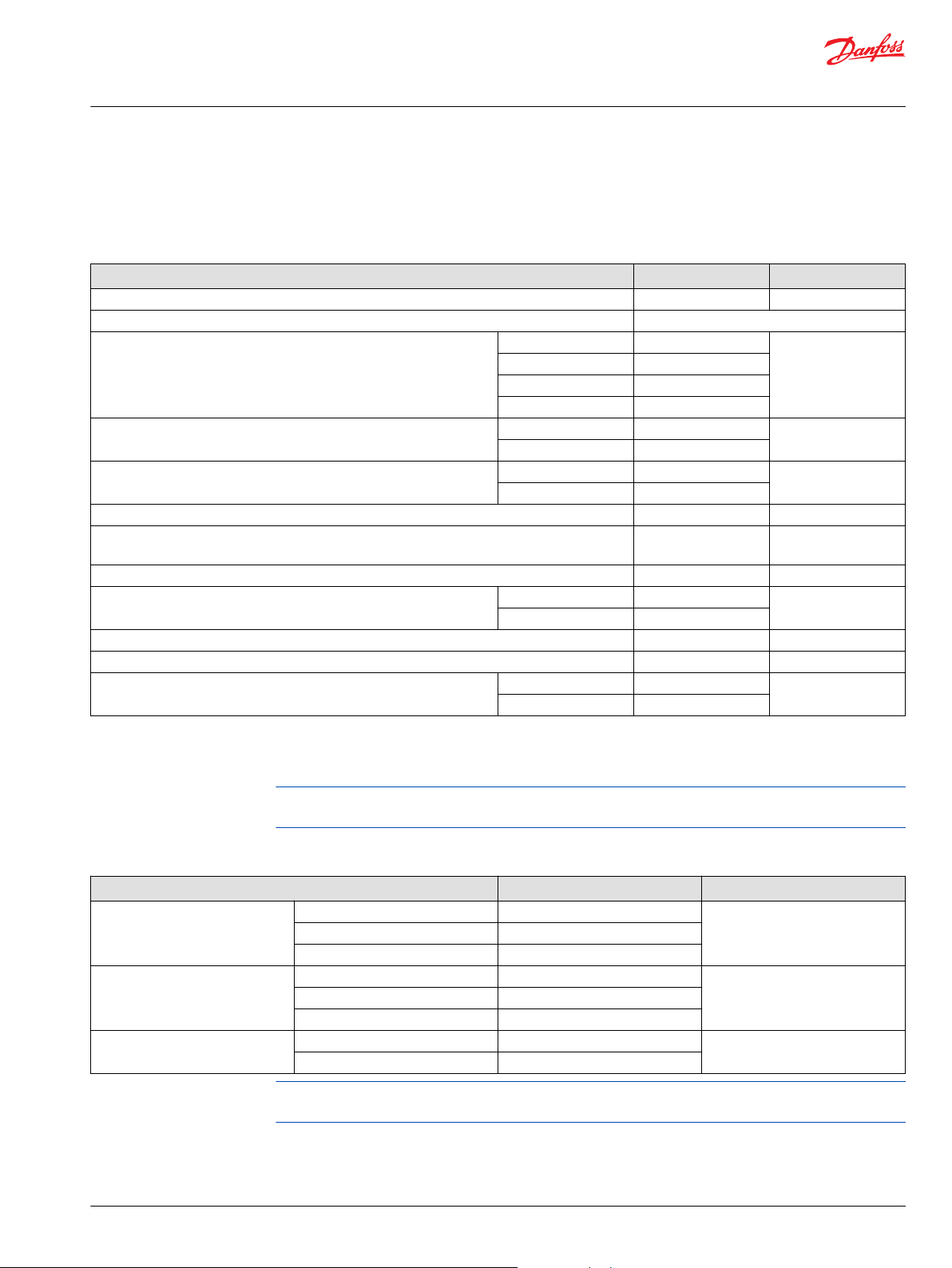

DDP096 pump specifications

DDP general specifications

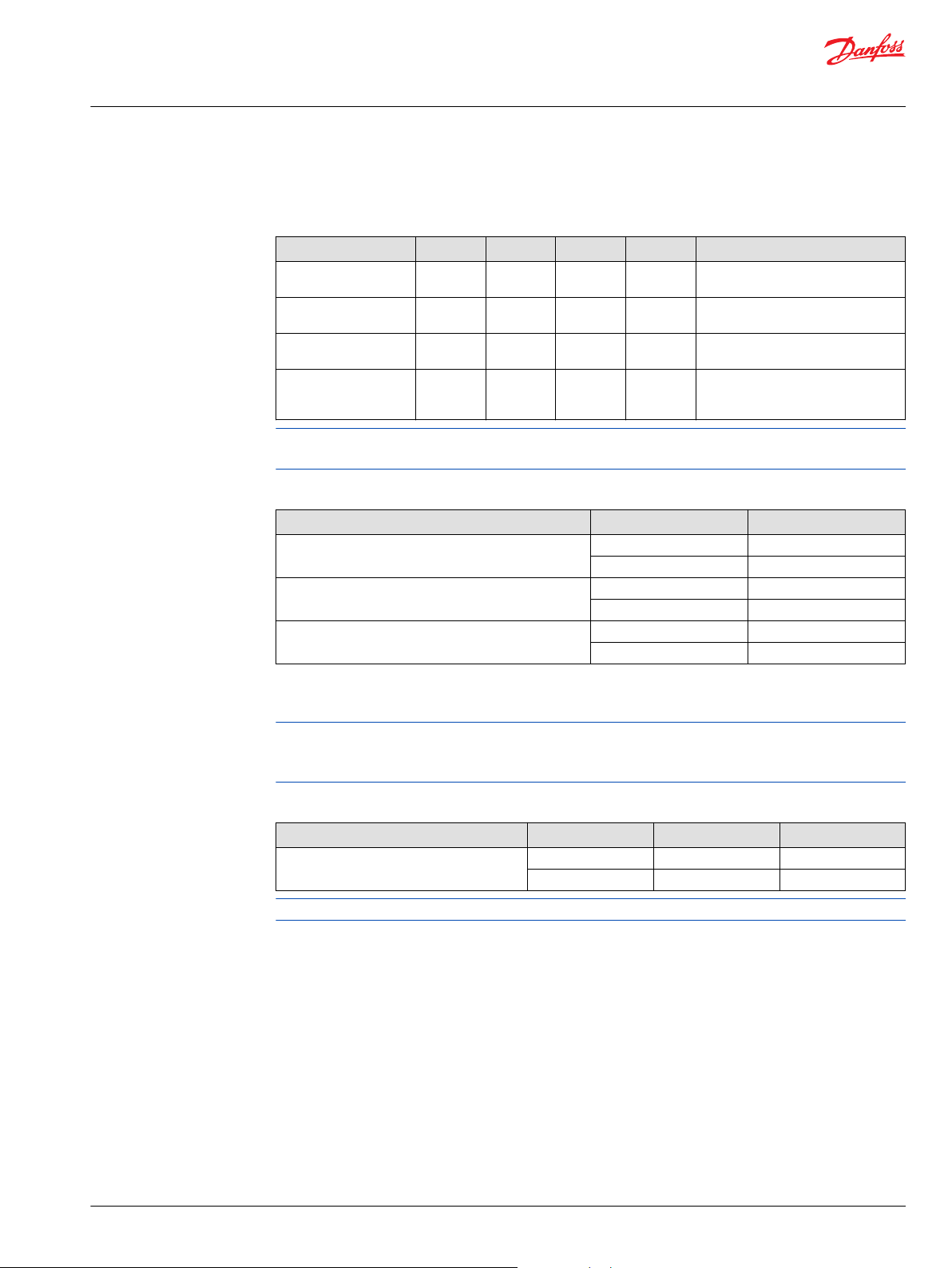

The below table contains information for displacement, pressure, torque, and temperature.

Description Value Units

Maximum displacement 96 [5.86] cm3/rev [in3/rev]

Available rotation (viewed from shaft end of the pump) Clockwise (CW) [R]

Outlet pressure Maximum peak 450 [6530] bar [psi]

Maximum continuous 420 [6090]

Minimum continuous 20 [290]

Minimum intermittent11 [15]

Inlet pressure (absolute)

Input speed Minimum 1450 min-1 (rpm)

Maximum power 45 [60] kW [hp]

Flow at rated speed and maximum displacement (theoretical)

Torque at full displacement, 1500 rpm & ∆p=400 bar

Mass Single outlet 51.6 [114] kg [lb]

Approximate filling capacity 2.3 [0.61] L [US gal]

Mass moment of inertia of internal rotating components (single pump without through shaft) 0.001037 [0.00076] kg·m2 [slug·ft2]

Ambient temperature Minimum 0 [32] °C [°F]

1

Performance degradation expected.

2

Size hoses or piping appropriately to ensure the minimum pressure condition is satisfied.

3

For more information, refer to Input torque on page 19.

2

3

Minimum 0.8 [12] bar [psi]

Maximum 3.5 [50]

Maximum 1850

144 [38] @1500 rpm

173 [45.6] @1800 rpm

600 [5310] N·m [lbf·in]

Multi outlet 53.9 [119]

Maximum 70 [158]

L/min [US gal/min]

Maximum power and speed specifications represent the current qualification. Wider speed operation

and/or higher power limit may be possible. Check with your Danfoss representative.

DDP fluid specifications

Description Value Units

Viscosity Minimum continuous 10 cSt

Recommended range 16 - 40

Maximum for cold start 1000

Temperature Minimum for cold start 0 [32] °C [°F]

Maximum continuous 60 [140]

Maximum intermittent 70 [158]

Cleanliness per ISO4406:1999 Recommended 17/15/12

Minimum 18/16/13

Viscosity and temperature specifications represent the current qualification. Wider temperature and/or

viscosity operation may be possible. Check with your Danfoss representative.

©

Danfoss | June 2021 BC306384089197en-000201 | 11

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Technical specifications

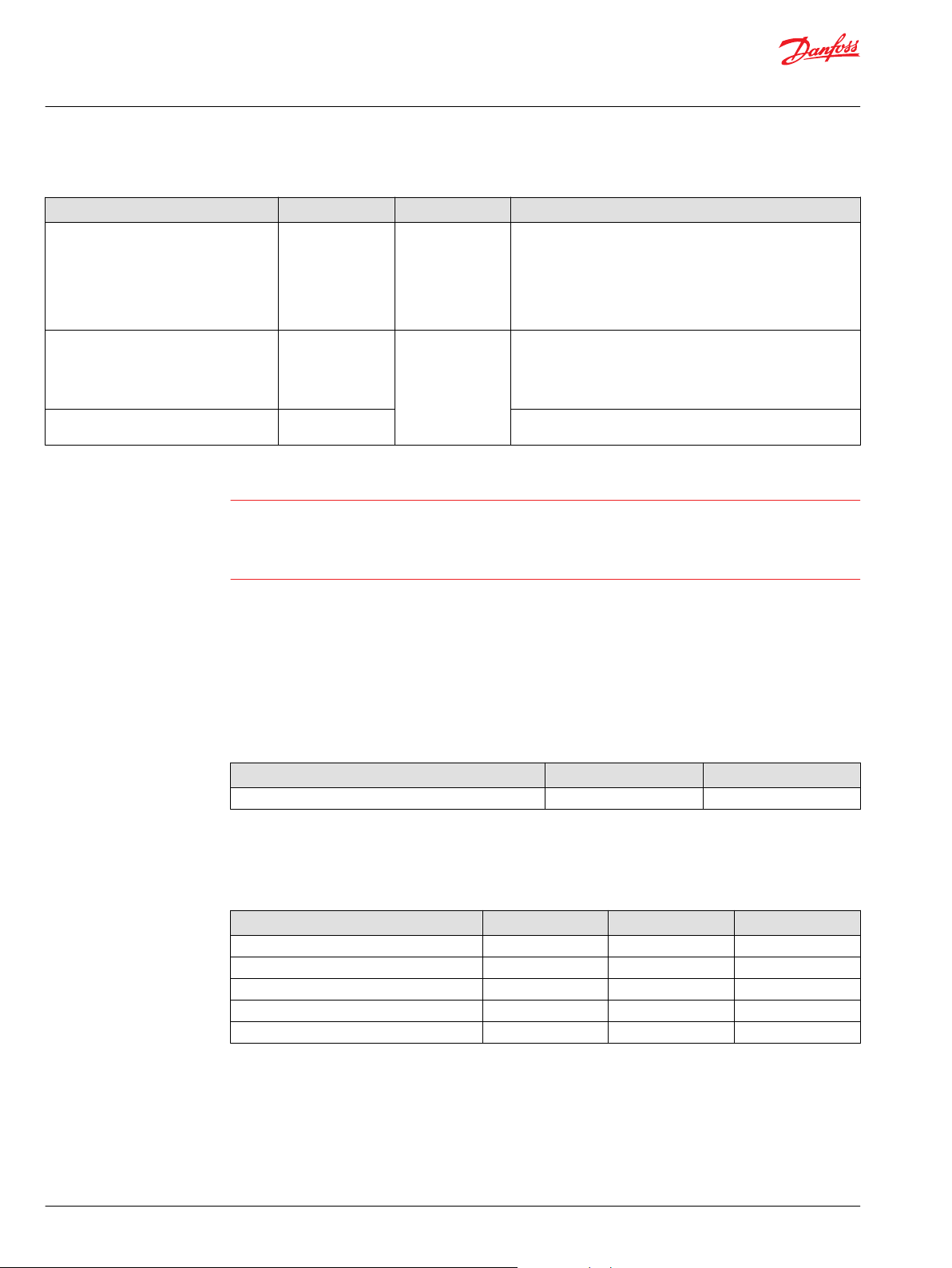

DDP mechanical specifications

Description Value Notes

Front mounting flange SAE C 4-bolt Flange 127-4 adhering to ISO 3019-1 (SAE

Front input shaft 23 tooth 16/32 pitch Spline per ANSI B92.1b-1996 class 6e

Inlet/Suction port S DN 51 (Ø 51 mm) Shipped with steel cover. For more information,

Outlet/Pressure port(s) Single outlet P DN 25 (Ø 25 mm)

Multi outlet P1 DN 19 (Ø 19 mm)

P2 DN 13 (Ø 13 mm)

P4 DN 13 (Ø 13 mm)

Bleed port plugs M14 x 1.5 per ISO 6149-1 Steel plugs

Lifting brackets Two brackets on endcap bolts, and another

Pump wiring harness connectors

Sensors included in DDP

aligned with outlet port(s)

DTM04-12PC (green) – C3

DTM04-12PA (grey) – C4

DTM04-12PB (green) – C5

1 speed and temperature sensor

1 (to 3) pressure sensor(s)

J744:1996)

see pump dimensions.

Only intended for lifting pump and Danfoss

supplied sensors/wiring

C3 is for the sensor harness

C4 is for the coil harness “A”

C5 is for the coil harness “B”

The DDP has a pressure sensor (0-600 bar) on

each service.

Substituting the factory supplied speed/temperature or pressure sensors will void the warranty. Only

replace sensors with genuine Danfoss replacements parts. Contact your Danfoss representative for more

details.

12 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Technical specifications

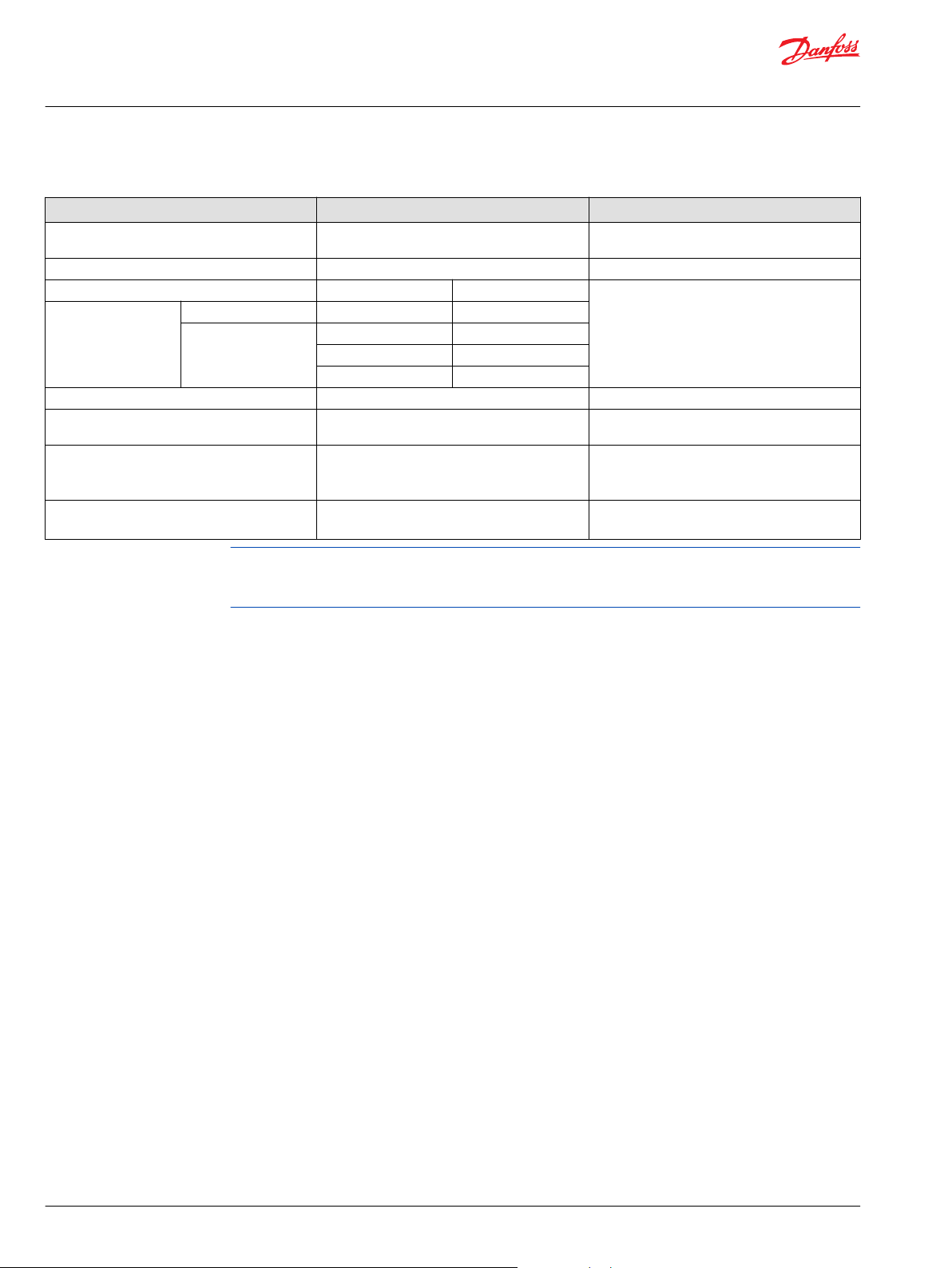

DPC12 controller specifications

DPC12 input power supply

Description Minimum Typical Maximum Unit Notes

Supply voltage 21.6 24 26.4 VDC For both coil and logic power

Cranking voltage 6 VDC Minimum voltage before the logic

Voltage disabling coil

outputs

DPC12 power-on time 1.5 s Time from power-on to completing

Supply voltage range represents the current qualification. Wider supply voltage range may be possible.

Check with your Danfoss representative.

Coil power consumption

Description Typical Unit

Approximate coil power vs theoretical flow, full

displacement

Full displacement @ 1500 rpm

Full displacement @ 1800 rpm

*

Tests performed at full displacement Fd=1 (most power consuming condition); 24 VDC power supply; 34 mΩ for

each pump-to-controller coil cable @ 20°C (2 meter cable with a 1 mm2 CSA). Refer to Wiring and fuses on page 14

for recommendations.

*

*

*

9 VDC Minimum voltage before coil outputs

supplies

resets

turn off

address claim procedure, ready to

pump

51 mA/(L/min)

1.2 W/(L/min)

8.0 A

192 W

8.8 A

211 W

Power consumption values are reported as mean values. The DPC12 draws a variable pulsed load from

the coil power supply, so the power supply must be able to handle higher peak currents. If operating

from a switch-mode converter, consult Danfoss on recommended parts.

Logic power consumption

Description Typical Maximum Unit

Logic power consumption (with 24 VDC

power supply)

100 220 mA

2 5 W

The maximum logic power consumption is with 6 pressure sensors (4-20 mA).

Separate coil and logic power supplies

The controller coil and logic supply inputs (i.e. power) are internally separated, while the supply returns

(i.e. ground) are internally connected (see Grounding on page 49). This means that supply inputs and

returns must be supplied to both to produce flow. The separation allows the coil circuitry to be deenergized while the logic remains powered, thus providing communication with the controller while the

coils can no longer cause pumping. Any switching device used must be on the supply inputs. The coil

and logic supply returns must always be connected to system ground and all supply return pins must be

used in order to provide the appropriate current sinking. Due to higher power requirements of the coil

circuitry compared to the logic circuitry, different gauges of wire may be needed.

©

Danfoss | June 2021 BC306384089197en-000201 | 13

W

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Technical specifications

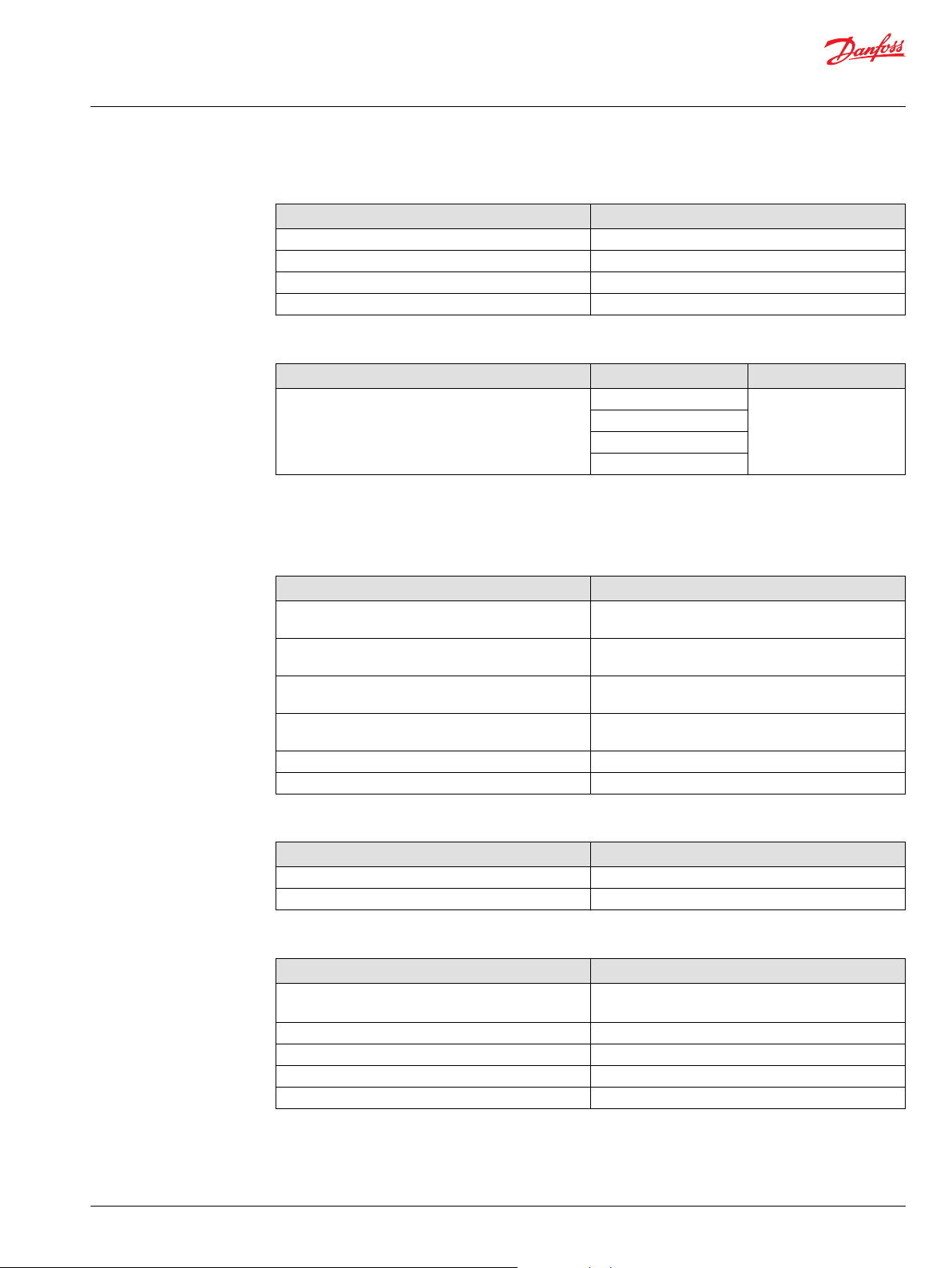

Wiring and fuses

Description Value Unit Notes

Pump-to-controller coil cable resistance 25 - 55 @ 20 °C mΩ One-way resistance of pump-to-controller cable (from pump

Coil supply fuse requirements (24V

system)

Logic supply fuse recommendations 3 Fuse recommended for system protection. Fuse not required for

30 A Use fast acting fuses of I2t ≤ 3500 A2s. A fused coil power supply

connector C4/C5 to controller connector C4/C5, excluding pins

and crimps). Any additional connections between the pump

connector and controller connector should be included in the

resistance calculation. Contact your Danfoss representative if

your application requires pump-to-controller cables that cannot

satisfy this rule.

is essential to protect the DPC12 against reverse polarity

conditions. Without a fuse, the DPC12 can be damaged.

Multiple or sustained reverse polarity events can also damage

the DPC12.

reverse polarity protection.

Warning

When powering the DPC12 from a current limited power supply, use special consideration to ensure

power supply has enough margin to blow the chosen fuse. For example, pairing a 40A fuse with a current

limited power supply of 40A is potentially dangerous. The fuse current must be exceeded by a large

margin to guarantee the fuse blows before hardware damage.

Pressure sensors for DPC12

While the DDP096 pump is already equipped with pressure sensor(s), additional pressure sensor(s) may

be required for load sensing operation. The DPC12 is only compatible with 4-20 mA pressure sensors. The

controller supplies a minimum supply voltage of 12V to pressure sensors. The receiver has a maximum

load resistance of 160 Ω. A 4-20 mA sensor that accepts a minimum supply voltage of 8V or less is

recommended. Contact your Danfoss representative for recommended pressure sensors.

Non-volatile memory write/erase ratings

Description Value Unit

EEPROM write/erase cycles

*

Minimum valid cycles over entire operating temperature range

*

4 x 10

6

General ratings

Environmental

Description Minimum Maximum Unit

Ambient operating temperature -40 [-40] 70 [158] °C [°F]

Electronics temperature shut down

Storage temperature -55 [-67] 85 [185] °C [°F]

Humidity 80 %

Ingress Protection (IP) ratings

1

Internal electronics temperature monitoring will error in extreme temperatures.

2

Documented IP ratings are valid only when the mating connectors are in place and unused connector pin positions

have sealing plugs installed.

1

2

-40 [-40] 105 [221] °C [°F]

IP69K

14 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Technical specifications

Product compliance

Description EU Directive

CE rating -

EMC 2014/30/EU

RoHS 2011/65/EU

REACH (EC) No 1907/2006

CAN port

Description Value Unit

Available baud rates 125 kbps

*

Default value; see the DPC12 software manual for more information.

Environmental standards and criteria

250

500

1000

*

Climate environmental standards

Description Applicable standard

Storage operating IEC 60068-2-1, test Ab

Operating temperature IEC 60068-2-1, test Ab

Thermal cycle IEC 60068-2-2, test Na

Humidity IEC 60068-2-78,

Solar radiation (UV exposure) ASTM G154

Degree of protection (IP) IEC 60529

IEC 60068-2-2 test Bb

IEC 60068-2-2, test Bd

IEC 60068-2-38 (partial)

IEC 60068-2-30, test Db

Chemical standards

Criteria Applicable standard

Ice water shock ISO 16750-4

Chemical resistance ISO 16750-5

Mechanical and electrical connection standards

Criteria Applicable standard

Random vibration (Level 2)

Bump IEC 60068-2-29, test Eb

Shock IEC 60068-2-27, test Ea

Free fall IEC 60068-2-32, test Ed

Wire force IEC 60730-1 section 11.7

IEC 60068-2-6, test Fc

IEC 6008-2-64, test Fh

©

Danfoss | June 2021 BC306384089197en-000201 | 15

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Technical specifications

Electrical and electromagnetic standards

Criteria Applicable standard Additional information

EMC emissions ISO 13766 Electromagnetic compatibility for earth moving

EMC immunity ISO 13766 Electromagnetic compatibility for earth moving

Electrostatic discharge

Auto electrical transients

For more information about criteria and standards please contact your Danfoss representative.

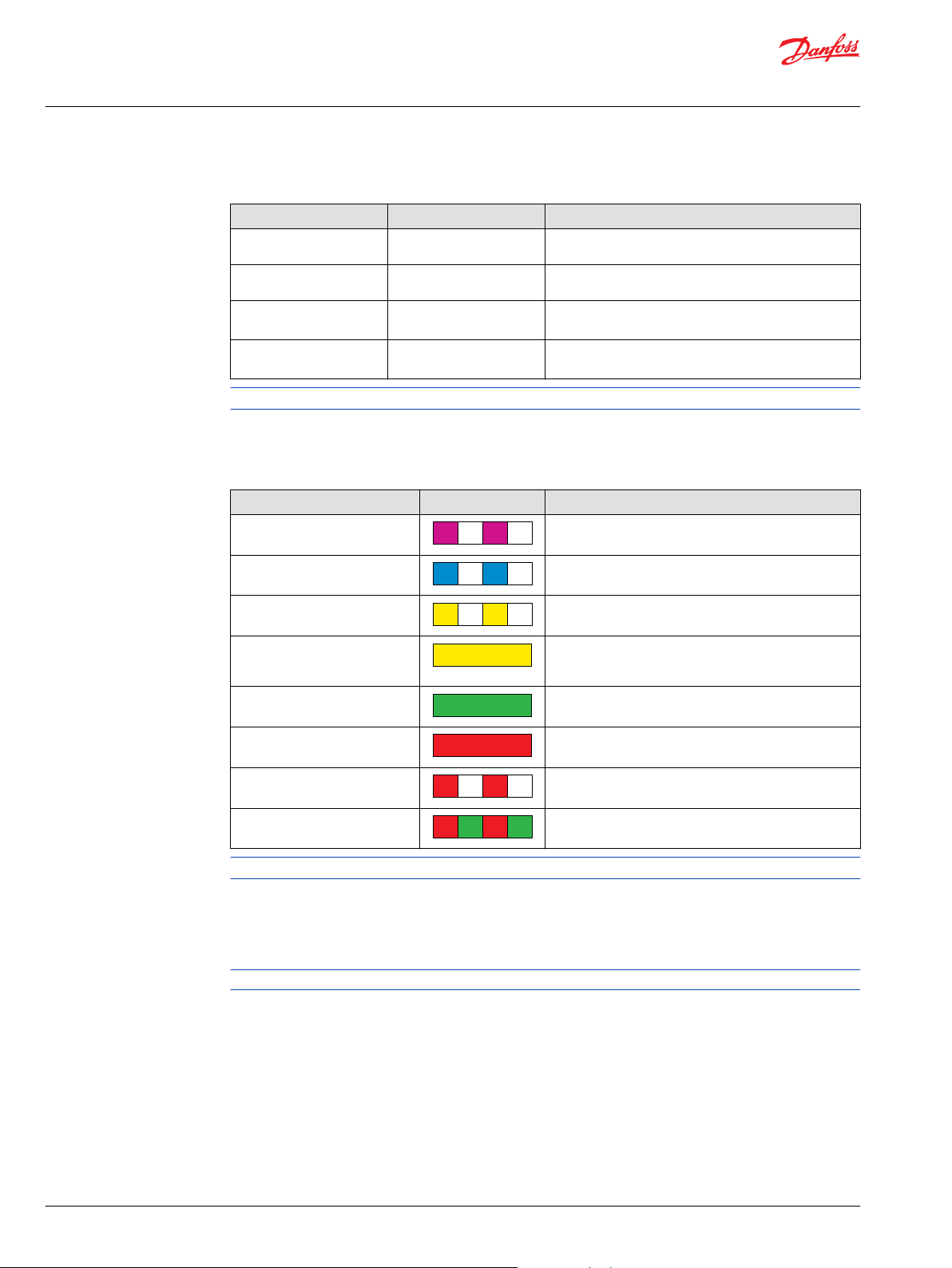

LED messages

LED characteristics meaning

Characteristic LED Indication

Magenta; blink rate 1.5 Hz Device is in BOOT-LOADER mode

EN 61000-4-2

SAE J1113-13

ISO 7637-2

ISO 7637-3

machinery

machinery

Electrostatic discharge immunity test

Road vehicles — Electrical disturbances from conduction

and coupling

Blue; fast irregular blinking Device is downloading application software

Yellow; blink rate 1.5 Hz Device is in COMMISSIONING mode

Yellow; continuous Device is either waiting for DM13 message to enable the

Green; continuous Device is in ACTIVE state

Red; continuous Device is in ERROR or ERROR_HOLD state

Red; blinking J1939 address claim fault

Alternating red/green Device is in LIMP mode and there is no severe error

pump, in INIT state directly after power up, or in

DISABLED state

Refer to the DPC12 Software manual for details on operation modes.

DPC12 housing

The DPC12 housing features a snap together assembly. The controller weighs 2.8 kg [6.2 lbs]. Once

assembled at the factory, the housing cannot be opened for service.

The DPC12 controller is not field serviceable. Opening the DPC12 housing voids the factory warranty.

16 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

DDP characteristics

Performance

Overall pump efficiency

The overall pump efficiency is the ratio of the hydraulic output power to the mechanical input power.

Inlet pressure 1.0 bar abs – inlet temperature 49°C with ISO VG46 oil.

Idle losses

In a Digital Displacement® pump each piston chamber is isolated from the outlet line by a high-pressure

valve, acting as a check valve. As a result, the idle losses of the DDP096 are independent from the outlet

pressure.

While in idling mode, the discharge flow of the pump is exactly 0 L/min.

See Theory of operation on page 5 for more information.

©

Danfoss | June 2021 BC306384089197en-000201 | 17

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

DDP characteristics

Pump discharged flow and shrinkage

Pump shrinkage

The DDP096 output flow rate is proportional to the displacement fraction as the number of valves being

enabled increases linearly with the displacement fraction. The discharged flow rate will also decrease as

the pressure increases. In conventional machines, such a decrease in flow is normally associated with

volumetric efficiency, as the energy is lost as leakage. With Digital Displacement® pumps, this decrease is

due to pump shrinkage and is mostly caused by the compression of oil. Most of the energy stored in the

compressed oil is then transferred back to the crankshaft when the piston chamber is depressurized after

top dead center.

The conventional definition of volumetric efficiency (defined by ISO4409:2019) is therefore inappropriate

for Digital Displacement® pumps. For a more accurate definition of the DDP’s volumetric efficiency, please

refer to A More Accurate Definition of Mechanical and Volumetric Efficiencies for Digital Displacement Pumps

from Christopher Williamson and Noah Manring.

18 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

DDP characteristics

Discharged flow

To estimate the actual DDP096 discharged flow rate at a given pressure and shaft speed, the shaft speed

should be multiplied by the “Flow rate / Shaft Speed” (i.e. pump displacement) presented in the graph

below. For example, at 400 bar and 2500 rpm the DDP096 pump displaces a maximum of 88.5 cc/rev,

equivalent to 177 L/min.

As each valve actuation is done independently, the pump shrinkage ratio is independent of the pump

displacement demand. Therefore, when requesting 25% of pump output flow, the pump will displace

exactly 25% of maximum flow in the same condition of pressure speed and viscosity.

Input torque

Due to internal compressed energy recovery, the torque and input power follow the same rule as the

pump discharge flow; the input torque and power increases less with pressure than would be expected

from the theoretical value.

©

Danfoss | June 2021 BC306384089197en-000201 | 19

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

DDP characteristics

Noise characteristics

Electronic control losses

The DDP does not have hydraulic control losses. Controller electrical losses are directly linked to pump

output flow (i.e. displacement and speed) as this translates into more valve actuations. Refer to DPC12

input power supply on page 13 for more information.

Conventional hydraulic machines have predominant tonal content caused by the rapid discharge of

pressurized oil at the end of each pumping cycle. The frequency content of this tone is directly linked to

the shaft speed and the number of pumping chambers. The sound power level is correlated to system

pressure and shaft speed, but marginally to displacement – and therefore not necessarily correlated to

output power.

The DDP sound pressure level is typically lower than comparable variable displacement swashplate type

pumps. But more importantly, due to its fundamental operating principle, DDP sound characteristics are

very different from conventional hydraulic pumps.

With Digital displacement, audible sound is generated during individual pumping events (influenced by

pressure and shaft speed). At idle, a DDP is therefore silent. Sound power level will increase with output

flow and system pressure. In other terms, the DDP sound power level is correlated to output power.

There is no predominant tone in the noise output when DDP idles as compressed oil is not discharged

but reused; the frequency content is low. A DDP sound will typically not be noticeable when used in

combination with internal combustion applications.

The lack of tonal content in DDP improves the noise characteristic in variable-speed applications. Human

ears can detect variation of tone frequency which is considered disturbing. DDP is expected to be

beneficial in electrified applications, where noise emission of the hydraulic system becomes

predominant.

Although air-borne noise from the pump will be low, DDP can create additional fluid-borne noise and

structure-borne noise which can generate system level noise. It is important to mitigate such vibrations

by adequately isolating the pump from the rest of the system. See the Understanding and minimizing

system noise on page 31 for more information on pressure pulsation mitigation.

20 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Control operation

Together with a Digital Displacement® Pump, the DPC12 controller is an integral part of the product; the

pump cannot function without its controller.

The DPC12 offers different modes for controlling the pump and to aid in system startup. Parameters are

used to set the behavior of the DPC12 and are selected through use of the Danfoss PLUS+1® Service Tool

and diagnostic file (P1D). Whichever control modes or limits are applied, the same pump and controller

hardware (DDP096 and DPC12) are used.

For multi-service pumps, the control mode is selected for each service. The control loop for each service is

independent of all other control loops. For example, one service may be in Displacement control while

another is in Load-sense control. The specific valid combinations depend on the software version. Refer

to the Software Manual for details.

Software control of the DDP provides many benefits including the following:

Flexibility Change control modes of the pump or services to allow the same pump to work for

multiple applications

Ease of tuning Tune response and recovery behavior with parameters rather than changing hardware

CAN control Send variable control mode setpoints via CAN to create more versatile or precise

applications

Diagnostics Receive real-time feedback of DDP performance as well as errors codes to aid in

troubleshooting

Control modes, limits, and features

Control modes and sources

The DDP096 operates in three principle modes:

Displacement control The service is commanded to provide a fraction of its maximum displacement

Pressure control The service is commanded to maintain a certain pressure at its output

Load sense control The service is commanded to maintain a pressure at its output that is a certain

Each control mode has a reference (displacement reference, pressure reference, pressure margin

reference) that must be provided by a source. Each control reference is converted into a target

displacement (Fd) to meet the demand.

Control references can be sourced from either a parameter in the DPC12 on-board memory (configured

with the PLUS+1® Service Tool) or another controller in the system using CAN messages. To avoid

overloading the J1939 CAN bus, only the needed parameters should be actively transmitted.

Flow control is a common control request and can be handled by setting the control mode to pressure

control with a flow limit over J1939 (refer to Limits on page 21).

Limits

On top of the target displacement, the DPC12 controller can apply limits. The following limits are

available for configuration:

Flow limit

•

Torque limit

•

Power limit

•

Pressure limit

•

margin pressure greater than the pressure at the load-sense pressure sensor

If a limit is reached, then the displacement is capped to the maximum displacement within the limit.

Limits may also be set to the unlimited source, which means the limit will not be applied. Setting a limit to

zero will limit the displacement to zero, preventing the service from producing flow.

©

Danfoss | June 2021 BC306384089197en-000201 | 21

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Control operation

Multiple limits can be active at once depending on the valid configurations available in the software

version.

Not all limits can be applied together or with the principle control modes. The specific valid combinations

depend on the software version. Refer to the Software Manual for details or contact your Danfoss

representative for available combinations.

Other features

Given its digital nature, DDP has some unique features:

Minimum speed

for pumping

Startup ramp

time

Pressure fault

limit

Enable/disable

service

DM11 A J1939 standard Diagnostic Message (DM) used to transition the DPC12 controller

DM13 A J1939 standard Diagnostic Message (DM) used to prevent the DPC12 controller

See the Software Manual or contact your Danfoss representative for more details on these features.

The DDP will not pump when below a set speed threshold. This feature allows the

prime mover to come up to speed with very little torque from the DDP.

This feature can be enabled so that a displacement limit is ramped from 0 to 100%

over a set time, allowing control modes to load the prime mover more slowly.

The pump will go to an error state and stop pumping when the pressure exceeds

this limit.

Each service can be enabled or disabled via CAN or a Service Tool parameter

depending on the valid configurations.

out of ERROR_HOLD status without needing to power cycle the controller.

from raising low severity errors until the message is received, allowing time for other

controllers to boot and send required signals.

22 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Control operation

Control diagrams

Service control algorithm diagram

©

Danfoss | June 2021 BC306384089197en-000201 | 23

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Control operation

Only specific combinations of control modes and limits are available. Refer to Software manual or contact

your Danfoss representative for details.

The service control algorithm diagram represents the signals and parameters used to control each service

of a DDP.

Note that Fd stands for displacement fraction and represents a normalized displacement from 0 to 1 for a

given service.

The +∞ symbol is used to represent that demand/limit is unlimited, but when the signal has been

converted to Fd and saturated, only a value of 1 will be passed along.

The MIN block signifies that multiple demands/limits may be active at once, but the lowest Fd (i.e.

minimum) is given priority and passed to the pumping algorithm. Since the lowest value is given priority,

unlimited demands/limits use values of 1. A value of 0 is not used to turn off a demand/limit since this

would be passed to the flow algorithm resulting in no flow from the pump.

Flow, Torque and Power Limits can also be considered “demands” if the primary control mode (e.g.

pressure control) is commanding a higher Fd than the limit. In this situation, the limit is being used as the

active command. This allows the DPC12 to be used in a flow control setup, for example, even though

there is no apparent primary control mode for this.

It may not be desirable to operate on a Torque, Power or Pressure Limit for significant periods of time

since these have high gains and can cause system instability. They can however be useful in avoiding

excess load on the prime mover and stall conditions.

Control loop diagram

The control loop diagram represents the pressure control loop which is part of the service control

algorithm diagram. The pressure control loop requires the signal from the pressure sensor mounted at

the outlet of the service. A load-sense pressure signal is required from a pressure sensor in the load-sense

resolving network of the service if Load-Sense Mode is used. The proportional gains and integration time

are tuned via non-volatile parameters. Contact your Danfoss representative for details on tuning these

parameters.

24 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Control operation

Example use cases

Here are some example combinations of control modes and limits:

Single Service Displacement control by PLUS+1®: Entire pump displacement used for one service,

•

controlled by a displacement command that is saved in a parameter in non-volatile memory. The

service is enabled/disabled by another parameter in memory.

Single Service Displacement control by J1939 with Torque Limit: Entire pump displacement used for

•

one service, controlled by a displacement command that is sent to the DPC12 via J1939 CAN

message. A Torque Limit is sent via CAN to limit the maximum torque applied to prime mover from

the service. A Pressure Limit is set via two parameters saved in memory. The service is enabled/

disabled via CAN message.

Single Service Pressure control by J1939 with Flow Limit: Entire pump displacement used for one

•

service, controlled by a pressure command that is sent to the DPC12 via J1939 CAN message. A Flow

Limit is sent via CAN to limit the maximum flow produced by the service. A Power Limit is set via one

parameter saved in memory. The service is enabled/disabled via CAN message.

Two Service Mixed Displacement/Load Sense control by J1939: Pump displacement used for 2

•

services. Service 1 has displacement control, torque limit, and enable/disable by CAN messages, as

well as pressure limit from a parameter saved in memory. Service 2 has Load Sense control, torque

limit, and enable/disable by CAN messages, as well as pressure limit from a parameter saved in

memory.

The combinations above are all available in software version v2.7.1.

Controller interaction

Overview

Interaction with the DPC12 for configuration, tuning commissioning and diagnostics is achieved with the

PLUS+1® Service Tool and the PLUS+1® Diagnostic (P1D) file that matches the controller software version.

Communication occurs over the CAN bus and a CAN gateway such as the Danfoss CG150 is required. The

diagnostic file allows parameter changes which select the control mode, limits, tuning gains, and other

features. These parameters are saved in non-volatile memory. There are also pages to interact with

Commissioning Mode and to see past and active Errors.

PLUS+1® CAN/USB gateway

Communication between the DPC12 and a personal computer (PC) on software uploads, downloads,

Service Tool, and Diagnostic Page interaction is accomplished using the system´s CAN bus.

The PLUS+1® CG150-2 CAN/USB gateway provides the communication interface between the system

CAN bus and a PC USB port. When connected to a PC, the gateway acts as a USB slave. In this

configuration, all required electrical power is supplied to the gateway by the upstream PC host. No other

power source is required.

Refer to the PLUS+1® Guide Software User Manual (document number AQ152886483724) for gateway setup information. Refer to the CG150-2 CAN/USB Gateway Data Sheet (document number AI152986480800)

for electrical specifications and connector pin details.

Other CAN gateways can be used. Please contact your Danfoss representative for more information.

Configuration and tuning

Configuring the DPC12 involves selecting the desired CAN Node Address, control mode, and limits using

the diagnostic file associated with the software version.

Tuning is required for pressure and load sensing control modes. Gain parameters are set to achieve

different pump response behavior in the application system. These parameters are typically set by system

engineers during pump commissioning in the system. For further information and help with tuning,

contact your Danfoss representative.

©

Danfoss | June 2021 BC306384089197en-000201 | 25

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Control operation

Identical application systems, such as machines of the same make and model, can use the same

configuration and tuning parameters. Use the DPC12 All Params page in the diagnostic file to export

parameters from one controller and import them to another.

Commissioning mode

Commissioning mode is used during initial DDP installation to incrementally test the functionality of the

solenoids and valves, help with air removal, and to aid in troubleshooting of the system. In this mode,

some limits and errors are ignored to enable these activities.

To enter commissioning mode and access system functions, follow these steps:

1. Go to the DPC12 Commissioning page of the diagnostic file and press the Enter Commissioning

Mode button.

The device is now in commissioning mode.

2. Choose the appropriate commissioning action types from the Commissioning Action Type

parameter dialog.

Available parameters are as follows:

Fire

Pump

Raw

Displacement

After the action type is chosen, action type specific interfaces will be available on screen.

To exit Commissioning mode, press the Exit Commissioning Mode button, then follow the prompts. For

more information on Commissioning Mode parameters and interaction, contact your Danfoss

representative.

Diagnostics and errors

The DPC12 logs active and previously active errors. These errors are broadcast over CAN using standard

Diagnostic Messages such as DM1 and DM2. Errors can also be accessed through the DPC12 Errors page

of the diagnostic file.

There are four error severity levels: INFO, WARNING, CRITICAL and SEVERE. INFO level errors will not cause

the DPC12 to transition to ERROR or ERROR_HOLD states. WARNING and CRITICAL level errors will cause

the DPC12 to transition to ERROR state when active, but once they are all inactive, the DPC12 will

transition to ERROR_HOLD. Once SEVERE level errors are active, they cause the DPC12 to transition to

ERROR state, but will not cause it to change to ERROR_HOLD even if they become inactive. SEVERE level

errors require the DPC12 to be power cycled.

For more information on error code meanings and CAN message descriptions, see the Software Manual

or contact your Danfoss representative.

Actuates the specified coil as soon as possible. Use when the shaft is not

spinning to verify wiring.

Actuates the specified coil at the correct shaft position to enable the pumping

unit (one piston and its valve) to pump a full stroke 1 or 100 times depending on

the Action Type chosen. Use while shaft is spinning to verify pumping or create

small amounts of flow for leak testing.

Actuates coils as necessary to achieve the desired percentage of displacement.

Use to check that correct flow rate is produced or to allow limited functionality

of open center hydraulic circuits.

26 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Model code

DDP model code

The example model code below and the following section describes how to identify parts of the model

code and availability of certain part options.

Model code sections

A B C D E F G H I J K L M

DD P 096 SMNN R C ANA CP 1AAA AA A N NNN (continued

N O P Q R S T U V W X Y

NN NNNN NN A NNN A1 NN A1 A1 AA 02071 00004

Model code breakdown

A Series

B Pump

C Displacement

below)

D Product type

E Rotation

F Mounting flange

G Input shaft spline and auxiliary shaft spline

H Auxiliary mounting flange (through-drive flange)

I Endcap

J Sensors and harness

K Common parts

L Tandem pump mounting flange

M Tandem pump input shaft spline and auxiliary shaft spline

N Tandem pump auxiliary mounting flange

O Tandem pump endcap

P Tandem pump sensors and harness

Q Tandem pump common parts

R Accessory block

S Paint and nametag

T Special hardware or features

U Electronic hardware

V Electronic hardware nametag

W Software build

X Software version

Y Software parameter set

©

Danfoss | June 2021 BC306384089197en-000201 | 27

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Model code

DDP part options

Below is a list of the available configuration options for the DDP. Note that not all combinations are

possible.

The tandem pump and through-drive options are not available yet; part options that use the tandem

section of the model code have been removed.

The stand-alone letter in the title corresponds with model code location. Please refer to DDP model code

on page 27 for entire model code breakdown.

C; Displacement

Code Description

096 96 cm3/rev [5.86 in3/rev maximum displacement

D; Product type

SMNN Single pump for medium-power applications (Gen 1)

E; Rotation

R Clockwise rotation [CW]

F; Mounting flange

C SAE C 4-bolt

G; Input shaft spline and auxiliary shaft spline

ANN 23T; no auxiliary shaft

H; Auxiliary mounting flange (through-drive shaft)

CP Cover plate (no auxiliary flange)

I; Endcap (inlet and outlet ports)

1AAA

3BAA

Inlet port S: DN 51 ISO 6162-1 ; M12 x 1.75

Outlet port P: DN 25 ISO 6162-2; M12 x 1.75

Inlet port S: DN 51 ISO 6162-1; M12 x 1.75

Outlet port P1: DN 19 ISO 6162-2; M10 x 1.5

Outlet port P2: DN 13 ISO 6162-2; M8 x 1.25

Outlet port P4: DN 13 ISO 6162-2; M8 x 1.25

J; Sensors and harness

AA For a 1-service pump (speed/temperature sensor W; pressure sensor M)

AG For a 2-service pump (speed/temperature sensor W; pressure sensors M1 & M4)

K; Common parts

A

R; Accessory block

NNN None

28 | © Danfoss | June 2021 BC306384089197en-000201

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Model code

S; Paint and pump nametag

Code Description

A1 Black paint; Danfoss standard tag

T; Special hardware

NN None

U; Electronic hardware

A1 DPC12 pump controller

V; Electronic hardware nametag

A1 Danfoss standard tag

W; Software build

AA For 1-service operation with DDP096 single

AB For 2-service operation with DDP096 single

X; Software version

02071 v2.7.1 software version

Y; Software parameter set

00004 Unconfigured parameter set (1-service operation and v2.7.1)

00005 Unconfigured parameter set (2-service operation and v2.7.1)

©

Danfoss | June 2021 BC306384089197en-000201 | 29

Lifting

Lifting

Orientation

C

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Mechanical installation

Pump transport and handling

Due to the electrically actuated nature of each valve in the pump and the presence of multiple sensors,

there are wires attached to the outside of the pump body and to each coil, making the pump susceptible

to mechanical impacts.

Any damage to the wires, connectors, sensors, or coils may cause the pump not to function correctly.

Avoid all impacts while transporting the pump. Contact your Danfoss representative if there is any

damage to any of the wires, sensors, or coils on the pump.

Do not directly or indirectly strike the coupling or driveshaft of the pump as this may cause internal

damage.

Do not drop the pump. If dropped, do not use the pump and contact your Danfoss representative.

There are three lifting brackets on DDP096 pumps. One bracket is on one side of the housing (pumplet 1)

and the two other brackets are opposite of each other on the endcap at the rear of the pump. For each

lifting bracket the weight limit is 70 kg.

It is recommended to lift a single pump by attaching hooks to the two lifting brackets on the endcap and

using the bracket on the housing for orientation. It is also possible to lift a single pump by attaching a

hook on the housing lifting bracket and using the endcap brackets for orientation.

Lifting brackets and orientation

Lifting brackets are not aligned with the center of gravity. Some swiveling should be expected when

handling.

Alternatively, the M12 x 16 mm bolt holes (non-standard depth) in the pump housing can be used for

lifting with eyebolts (torqued to 105 N·m ± 10%). There are four bolt holes in total around the pump –

one for each pumplet (located adjacent to the coils of bank A and C and opposite to the bleed port). For

30 | © Danfoss | June 2021 BC306384089197en-000201

more information, see Common dimensions on page 36.

Make certain all lifting gear is rated for the load to be applied and that standard precautions and best

practices are used while lifting the pump.

Caution

The lifting brackets are not rated for any duty other than lifting the pump and the factory supplied wires

and sensors. The brackets are not rated to lift any hoses or pipes that may be attached to the pump

during installation. Lifting brackets on the endcap must not be removed under any circumstance.

If the pump needs to be temporarily stored outside the application or the provided packaging, we

recommend resting the pump vertically (shaft pointing downwards) on the SAE C flange. Stable spacers

are required to avoid contact with the input shaft. It is also possible to rest the pump horizontally, using

cast features of the pump as supports. Suitable spacers must be used to avoid any contact with the coils,

sensors and wiring harnesses of the pump.

C

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Mechanical installation

Caution

Ensure no load is applied to coils, sensors, or wiring when placing the pump on a surface for storage as

these may become damaged.

Storage

The packaging supplied with the pump provides a stable storage method with the shaft pointing

downwards and held in place by the box’s lid to avoid any movement during transport. The controller

and other accessories provided will be in a different compartment of the box. All elements will be

protected against corrosion and reasonable handling shocks. This packaging is suitable for storage.

The storage area must be free from corrosive materials and gasses. The storage area must be dry (5-60%

relative humidity, non-condensing). The ideal temperature for storage is between 5°C and 30°C.

After removing a pump from storage, check over the unit for visible damage to any of the wiring or

sensors.

If the pump must be stored for long periods or in a humid environment (relative humidity > 60%), seal

the parts in airtight bags with desiccant sachets and use VCI materials to protect the hydraulic items.

Store the controller in an antistatic bag.

Installation requirements

The installation locations and position of the pump must be as described in this document. Adhere to all

limits specified in the DDP096 pump specifications section regarding pressure, temperature, viscosity

and cleanliness of the hydraulic fluid. Other configurations are possible; please contact your Danfoss

representative for direction.

Pump arrangement

It is recommended to install the pump in a below-oil level and horizontal or near-horizontal shaft

position. This is the location the pump is installed outside of the tank and below the minimum level of

fluid in the tank or inside the tank with sufficient fluid above. Other arrangements are possible, for which

care must be taken to bleed the pump case.

Pump shaft coupling

At low displacement (Fd < 0.2), Digital Displacement® pumps create torque oscillations with torque

reversals increasing the risk of fretting corrosion at the input shaft interface. It is required to take great

care in shaft coupling interface to increase operating life.

Flooded input shaft installation provides good corrosion protection. For dry shaft installation, a clamped

coupling is recommended. If clamped coupling is not possible, care must be taken to reduce the risk of

shaft interface damage. Application of specific anti-corrosion grease is required in this case and regular

maintenance is highly recommended. For information on lubrication of spline shafts, refer to Lubrication

of Spline Shafts – Technical Specifications.

Excessive misalignment can cause premature wear. Refer to coupling manufacturer specifications for

allowable misalignment. Hardness of the mating spline must be at least 55 Rc and have full spline depth.

Understanding and minimizing system noise

By providing discrete pulses of flow of 8cc per actuation, the control principle of DDP can create fluidborne pulsation at low frequencies. The frequency content of the discharge flow is defined by the

pumping frequency required to meet the requested output flow. For example, at 1000 rpm and

requesting 1/12th of the pump displacement (~8 L/min), only one piston would be used each revolution

generating a pumping frequency of 16.7 Hz. To generate lower flows, it is possible to pump at less than

once per revolution. For example, at 1000 rpm to produce 1 L/min, the DDP would be pumping roughly

one cylinder every 8 revolutions generating a pumping frequency of ~2.1 Hz.

©

Danfoss | June 2021 BC306384089197en-000201 | 31

Technical Information

Digital Displacement® Pump Gen 1 DDP096 and DPC12

Mechanical installation

The resulting flow and torque pulsations generated by a DDP can translate into a range of undesirable

behaviors and can be transmitted to the rest of the system.

•

Air-borne noise is often caused by excitation of resonating mechanical structures, mechanical impact

of loose structures, or system valves clicking or chattering.

•

Structure-borne noise or mechanical vibrations can be perceived by the operator through direct

mechanical coupling of the DDP to the chassis or excitation of natural frequencies by transmission of

fluid-borne noise. It is also possible to feel vibration through hydraulic actuator interfaces such as

steering wheels or mechanical levers.

•

Pressure pulsations can lead to difficulties maintaining stable and accurate pressure or load sense

margin control by a DDP. This can lead to unstable behavior requiring less aggressive gains slowing

the response time of the pump.

A range of countermeasures has been developed over time to manage these impacts. Standard best

practices such as increasing hydraulic compliance or decoupling the hydraulic circuit from the

application chassis can have a big impact.

The following suggestions can help minimize noise and vibration in applications:

•

Increase system compliance by installing longer or larger hoses, thermoplastic hoses, accumulators,

or more oil volume.

•

Use flexible hoses instead of steel plumbing.

•

Limit system line length.

•

If possible, optimize system line position to minimize noise.

•

If steel plumbing is necessary, clamp the lines.

•

If adding additional support, use rubber mounts.

•

Test for resonances in the operating range; if possible, avoid these operating conditions.

Some applications or actuators are more susceptible to vibration than others. Systems with physical

characteristics such as low actuator inertia or very high hydraulic stiffness at low flow rates will need to be

considered more carefully. Contact your Danfoss representative for more support.

Air removal

Air within the pump must be removed to ensure proper operation.