Page 1

Data Sheet

DDC Axial Piston Pumps

with Implement Pump, 20/24 cm³

For more than 40 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off-highway operations around the

world. We have become a preferred supplier by

offering the best of what really matters: The hardware

inside your vehicle application.

Implement pump is an integrated charge pump that

can be used for the lightly-loaded external work

function.

Since implement pump has both external gear pump

and charge pump functions, it allows customers to

apply more compact sizing than existing system using

external gear pump.

The DDC pump with implement pump is a high

quality light duty pump which offers expanded

functionality, great total efficiency, low noise, and

easy installation.

The DDC pump is well suited for turf care

applications, compact utility tractors, harvesters, small

rollers, and agricultural vehicles.

Features

Designed for Durability and Flexibility

•

Compact and light weight aluminum

housing

•

Single piece swash plate

Installation and Packaging Benefits

•

Compact design minimizes installation

space requirements

•

High corner power

Optimized for Direct Displacement

Control

Options

•

Gerotor implement pump

•

Loop bypass valve

•

High Pressure Relief Valve (HPRV) and

Charge Pressure Relief Valve (CPRV)

•

SAE A and SAE B Mounting Flange

Comprehensive technical literature is

online at www.danfoss.com

©

Danfoss | July 2019 L1528780 | AI00000205en-000202 | 1

Page 2

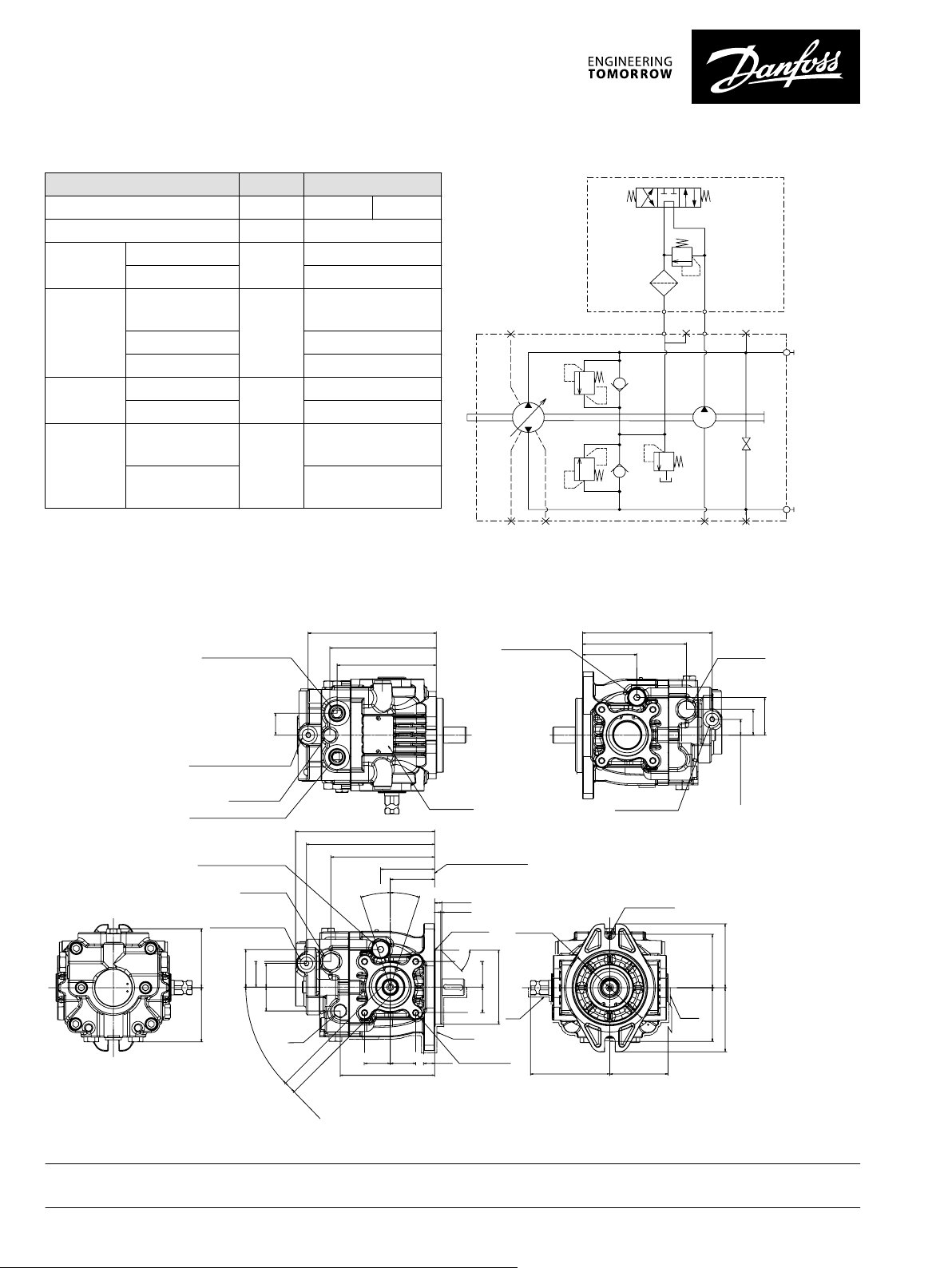

Technical Specifications

A

B

M3 DE

MA

MB

L1L3L2

S

P400052

80.4

±1.5

74.5 ±1.5

System Port “A”

Name Plate

Paint Free

Charge Pressure

Relief Valve

Port ISO 11926-1 -7/8-14

System Port “B”

Port ISO 11926-1 -7/8-14

With Implement Pump

(No Aux-Pad)

Port ISO 11926-1 -9/16-18

Charge Gage Port “M3” Or

Implement return Port “E”

51.5

±0.8

35±0.8

32.5±0.8

32.5±0.8

190.5±1.2

175.5±1.2

142±1.8

74±0.8

60.94±0.8

CCW

CW

18°

Max Disp

18°

Max Disp

1.5

±0.5

9.7

0

-0.5

Mounting Flange

Flange 101-2

Per ISO 3019-1 (SAE B)

Paint

Free

8x M8x 1.25

13 Full Thread

Depth

R0.75 Max

6

.

1

0

1

Ø

0

5

0

.

0

-

2x35±0.82x35±0.8

45°±5°

15

±1

129.5±1.2

2x 35±0.8

2x 35

±0.8

Bypass

Valve

2x17

+0.06

-0.04

4x45°

±3°

Paint

Free

Paint

Free

73±0.3

73

±0.3

87

±1.5

87±1.5

Ø120

2x Ø14.3

±1.5

108

±0.8

79.2

±1.5

+0.3

-0.1

P400138

175.5±1.2

146

±1.2

2x 136

±1.2

2x 30±0.5

Case Drain Port “L1”

Port ISO 11926-1 3/4-16

High Pressure

Relief Valve

Implement Return

Port “E”Or Charge Gage

Port “M3”

Port ISO

11926-1 -9/16-18

177

±1.2

142±1.2

74±0.8

21.5

±0.8

35

±0.8

51.5±0.8

Case Drain Port “L2”

Port ISO 11926-1

3/4-16

High Pressure

Relief Valve

Implement

Discharge Port “D”

Port ISO

11926-1 -9/16-18

Features Unit Value

Displacement cm3 [in3] 20 [1.22] 24 [1.46]

Weight (w/charge pump) kg [lb] 11 [24.3]

Input Speed Rated min

Maximum 4500

System

Pressure

Max. Working

*

Pressure

-1

4000

(rpm)

bar [psi] 300 [4350]

Max. pressure 345 [5004]

Min. Low Loop 4 [58]

Case

Pressure

Implement

Pressure

Rated bar [psi] 1.5 [21.7]

Maximum 3 [43.5]

Maximum Working

**

Pressure

Maximum Pressure

bar [psi] 70 [1015]

85 [1230]

(absolute)

*

Applied pressures above maximum working pressure requires Danfoss

application approval.

**

Continuous operation at absolute implement pump relief pressure =

Short term t < 30sec

Dimensions

Schematic

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | July 2019 L1528780 | AI00000205en-000202

Loading...

Loading...