Page 1

Data Sheet

Filter drier, shell

Types DCR and DCRE

Danfoss ELIMINATOR® lter drier with replaceable solid core.

Designed for applications requiring high moisture capacity and acid adsorption capacity.

Danfoss ELIMINATOR® lter driers with

replaceable solid core, type DCR, are for use in

liquid and / or suction lines in refrigeration,

freezing and air-conditioning systems.

Besides being able to meet the demanding

requirements of high working pressure levels

when operating with R410A thanks to

replaceable solid cores the DCR programme

oers exibility with respect to dierent

applications.

Available with copper connections. DCRE

programme oers to be used with ammable

refrigerants A2L, Group .

AI222586433727en-001201

Page 2

Filter drier, shell, types DCR and DCRE

Features

DCR / DCRE housing:

• PED approved for PS up to 46 bar for the DCR and up to 50 bar for DCRE

• DCR / DCRE housing (including core holder) are made entirely of steel and are thus compatible with all refrigerants

• DCR / DCRE housings have undergone phosphate pre-treatment and have a corrosion-resistant powder-paint

nish

• DCR / DCRE housings are helium leak tested

Top covers for DCR / DCRE housings:

• Zinc-chromated steel top covers with or without external access connection

Inserts for DCR housings - strainer 48 - F strainer - compatible with all refrigerants:

• Retains dirt particles larger than 15 μm

• For use direct in DCR housings

• Utilised in the suction or liquid line

Inserts for DCR housings - solid cores

48 - DM - 100% molecular sieve solid core suitable for HFC refrigerants:

• Provides high moisture adsorption at low and high condensing temperatures

• Eective protection against impurities

48 - DC - 80% molecular sieve and 20% activated alumina solid core suitable for HCFC refrigerants and compatible

with HFC refrigerants:

• Adsorbs moisture and acid in the system throughout the entire temperature range

48 - DA - 30% molecular sieve and 70% activated alumina solid core suitable after compressor burnout and

compatible with HCFC / HFC refrigerants:

Inserts for DCRE housings - solid cores:

• 48 - DM

• 48 - DC

All solid cores have an optimised uniform grain size ensuring eective dirt removal and low pressure drop. The

robust solid cores withstand pressure surge and vibration.

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 2

Page 3

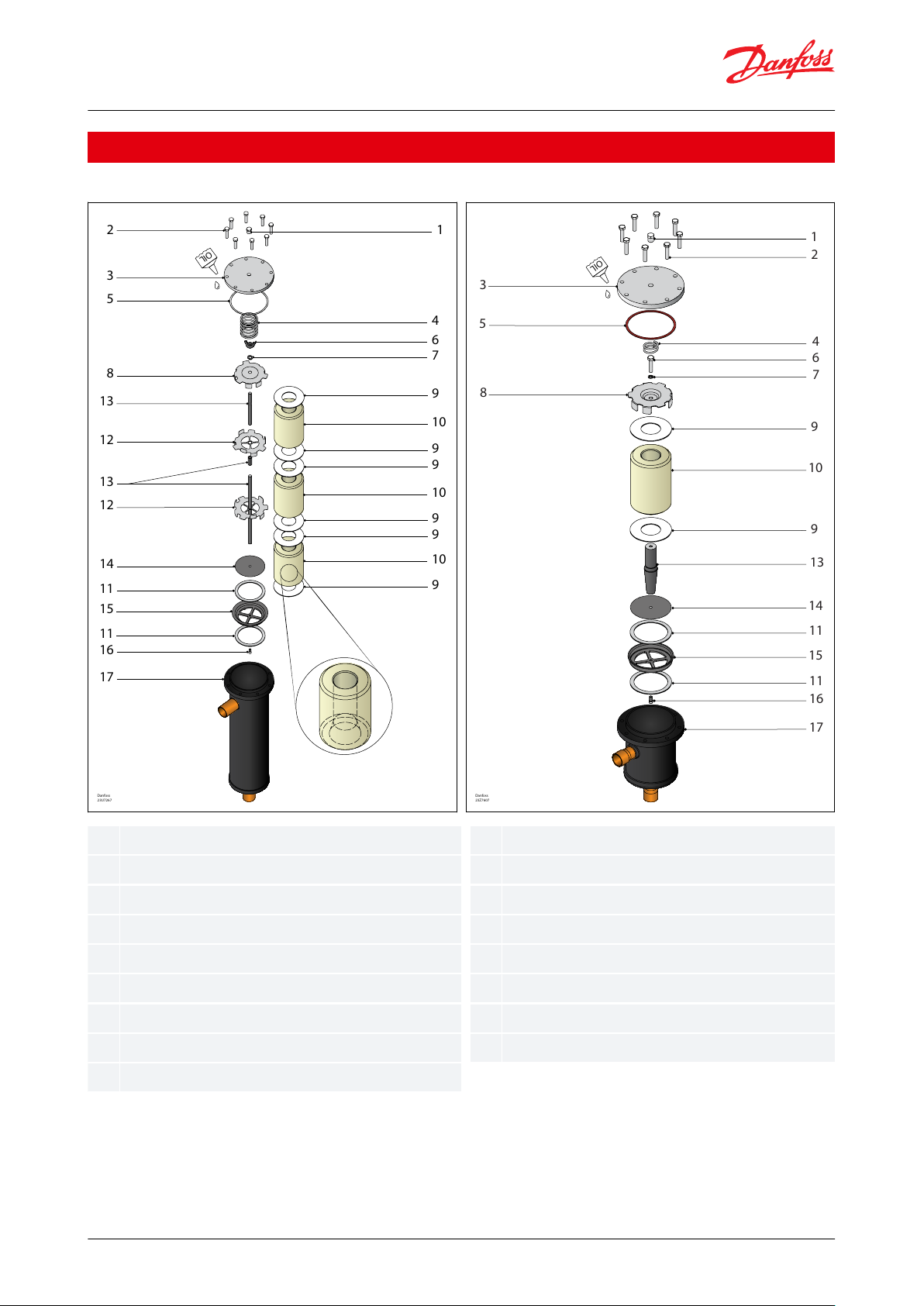

6

7

2

5

3

1

8

12

12

14

11

15

11

16

17

9

9

9

9

9

10

10

13

13

9

10

4

Danfoss

23U7267

OIL

1

2

3

5

4

6

7

8

9

10

9

14

11

15

11

16

13

17

Danfoss

23Z7607

OIL

1234567891011121314151617

Plug for cover

Bolts for cover

Top cover

Spring

Top cover gasket

Wing nut (DCR) / Bolt (DCRE)

Lock washer

Top plate

Core felt gasket

Solid core

Core holder felt gasket

Core plate

Distance rod

Wire mesh

Core holder

Hex socket head screw

Shell

Filter drier, shell, types DCR and DCRE

Functions

Figure 1: DCR

Figure 2: DCRE

Inner taper of core should always face towards lter outlet. This apply for DCR and DCRE components.

NOTE:

The DCRE can only be use for A2L when the solid core is placed. DCRE is not allowed to be used as receiver.

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 3

Page 4

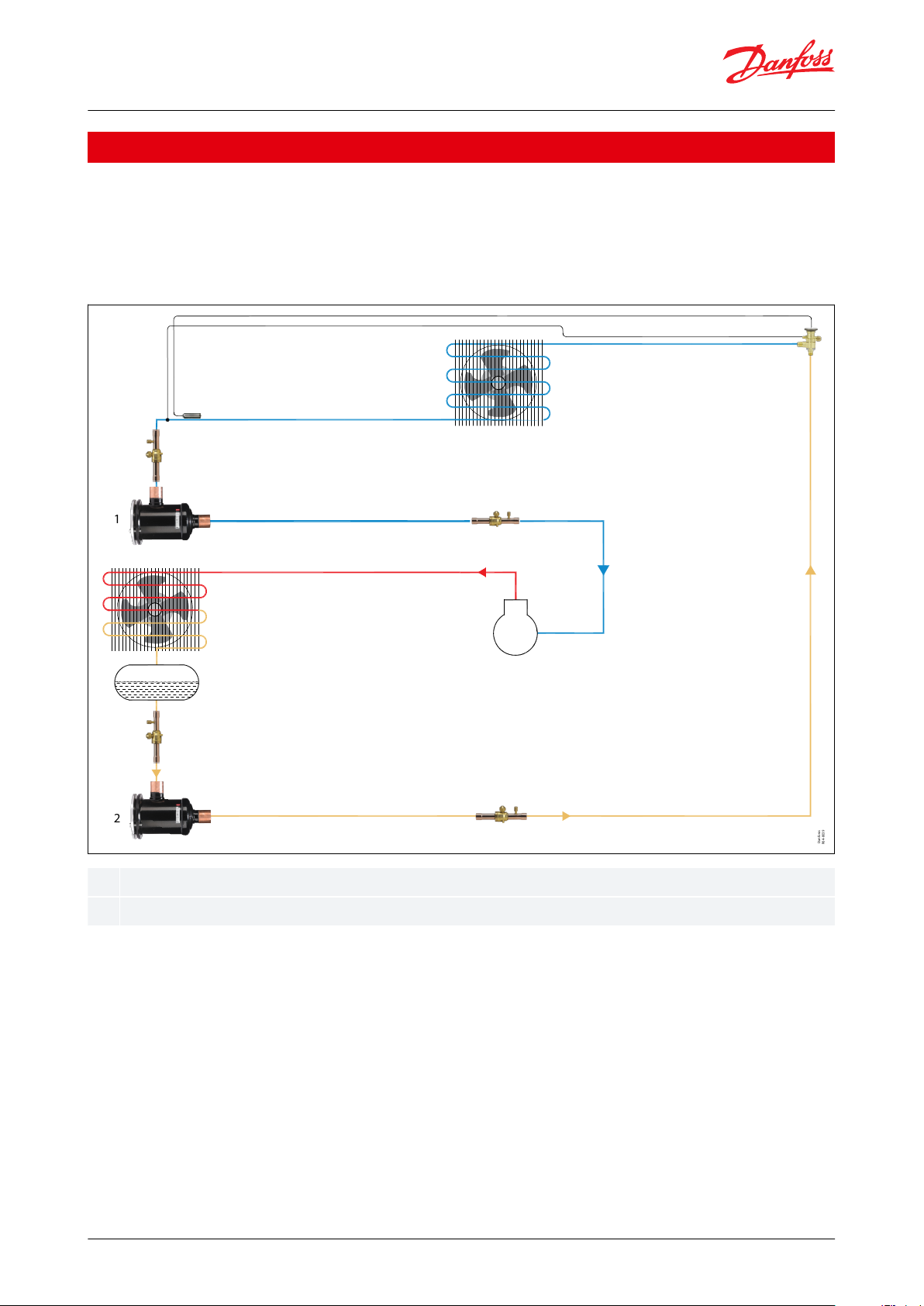

1

2

Danfosss

R64-8039

1

2

DCR, suction line lter drier

DCR / DCRE, liquid line lter drier

Filter drier, shell, types DCR and DCRE

Applications

Danfoss ELIMINATOR® lter driers with replaceable solid core, type DCR / DCRE, protect refrigeration, freezing and

air-conditioning systems from moisture, acids, and solid particles.

With these contaminants eliminated, systems are safer from harmful chemical reactions and from abrasive

impurities.

Figure 3: Applications

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 4

Page 5

Type

Maximum working pressure PS

Temperature range

[bar]

DCR 048

46

- 40 – 70 °C

DCR 096

46

- 40 – 70 °C

DCR 144

35

(1)

/ 46

(2)

- 40 – 70 °C

DCR 192

28

(1)

/ 40

(2)

- 40 – 70 °C

DCRE 048

50

- 40 – 70 °C

Connector

Connector type

Danfoss

23M117

Copper ODF solder connector Copper pipe

Danfoss

23M118

Steel ODF solder connector Copper pipe

Danfoss

23M119

Steel butt weld connector Steel pipe

Solder connector

Recommended soldering material

Copper

Min. 5% Ag

Steel

Silver-o 55 + Easy-ow ux

Type

Code

Description

Filter drier

D

Drier

Solid core

C

Solid core

R

Replaceable

E

Flammable refrigerants

Size (volume)

048

48 in

3

096

96 in

3

144

144 in

3

192

192 in

3

Filter drier, shell, types DCR and DCRE

Product specication

Technical data

Table 1: Technical data

(1)

(1)

For usage with strainer or as a receiver application

For usage with strainer or as a receiver application

(2)

(2)

For “drier” application using all the permissible cores

For “drier” application using all the permissible cores

Connections

Table 2: Type of connector

Table 3: Type of connector and recommended soldering material

Identication

Table 4: Type codes

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 5

Page 6

Type

Code

Description

Connection (lter connection in 1/8 of an inch increments)

5

5

⁄8 in. / 16 mm

7

7

⁄8 in. / 22 mm

9

1

1

⁄8 in. / 28 mm

11

1

3

⁄8 in. / 35 mm

13

1

5

⁄8 in. / 42 mm

17

2

1

⁄8 in. / 54 mm

21

2

5

⁄8 in.

Connection type

(blank)

Steel connectors

s

Copper connectors

Type

No. of

cores

Drying capacity [kg refrigerant]

(1)

Liquid capacity [kW]

(2)

Max.

working

pressure

R134a

R404A

R507

R407C

R410A

R134a

R404A

R507

R407C

R410A

[°C]

PS24522452245224522452

[bar]

DCR 0485

1

83.4

76.4

86.9

82.3

91.0

81.9

81.0

74.7

75.5

67.2

67.0

47.1

45.7

68.7

69.746DCR 0487

1

83.4

76.4

86.9

82.3

91.0

81.9

81.0

74.7

75.5

67.2

127.0

89.3

86.6

130.1

132.146DCR 0489

1

83.4

76.4

86.9

82.3

91.0

81.9

81.0

74.7

75.5

67.2

165.0

116.0

112.6

169.1

171.746DCR 04811

1

83.4

76.4

88.7

82.3

91.0

81.9

81.0

74.7

75.5

67.2

205.0

144.2

139.8

210.1

213.346DCR 04813

1

83.4

76.4

86.9

82.3

91.0

81.9

81.0

74.7

75.5

67.2

230.3

162.0

157.1

236.0

239.646DCR 04817

1

83.4

76.4

86.9

82.3

91.0

81.9

81.0

74.7

75.5

67.2

250.1

175.9

170.6

256.3

260.246DCR 04821

1

83.4

76.4

86.9

82.3

91.0

81.9

81.0

74.7

75.5

67.2

255.0

179.3

174.0

261.3

265.446DCR 0967

2

166.8

152.8

173.8

164.6

182.0

163.8

162.0

149.4

151.0

134.4

134

94.3

91.4

137.4

139.546DCR 0969

2

166.8

152.8

173.8

164.6

182.0

163.8

162.0

149.4

151.0

134.4

212.3

149.3

144.8

217.6

220.946DCR 09611

2

166.8

152.8

173.8

164.6

182.0

163.8

162.0

149.4

151.0

134.4

216.9

152.6

148.0

222.3

225.746DCR 09613

2

166.8

152.8

173.8

164.6

182.0

163.8

162.0

149.4

151.0

134.4

294.9

207.4

201.1

302.2

306.846DCR 09617

2

166.8

152.8

173.8

164.6

182.0

163.8

162.0

149.4

151.0

134.4

358

251.8

244.2

366.9

372.546DCR 1449

3

250.2

229.2

260.7

246.9

273.0

245.7

243.0

224.1

226.5

201.6

222.2

156.3

151.6

227.7

231.2

35

(3)

/ 46

(4)

DCR 14411

3

250.2

229.2

260.7

246.9

273.0

245.7

243.0

224.1

226.5

201.6

225.7

158.8

154.0

231.3

234.9

35

(3)

/ 46

(4)

DCR 14413

3

250.2

229.2

260.7

246.9

273.0

245.7

243.0

224.1

226.5

201.6

355.9

250.3

242.8

364.7

370.3

35

(3)

/ 46

(4)

DCR 14417

3

250.2

229.2

260.7

246.9

273.0

245.7

243.0

224.1

226.5

201.6

355.9

250.3

242.8

364.7

370.3

35

(3)

/ 46

(4)

DCR 19211

4

333.6

305.6

347.6

329.2

364.0

327.6

324.0

298.8

302.0

268.8

371.7

261.4

253.6

381

386.8

28

(3)

/ 40

(4)

DCR 19213

4

333.6

305.6

347.6

329.2

364.0

327.6

324.0

298.8

302.0

268.8

459.9

323.5

313.7

471.4

478.6

28

(3)

/ 40

(4)

DCR 19217

4

333.6

305.6

347.6

329.2

364.0

327.6

324.0

298.8

302.0

268.8

459.9

323.5

313.7

471.4

478.6

28

(3)

/ 40

(4)

DCR 19221

4

333.6

305.6

347.6

329.2

364.0

327.6

324.0

298.8

302.0

268.8

459.9

323.5

313.7

471.4

478.6

28

(3)

/ 40

(4)

Filter drier, shell, types DCR and DCRE

Capacity

Table 5: DCR Drying and liquid capacity, type 48-DM

(1)

(1)

Drying capacity is based on following moisture content test standards before and after drying:

Drying capacity is based on following moisture content test standards before and after drying:

• R134a: 1050 – 50 ppm W

• R134a: 1050 – 50 ppm W

• R404A, R507: 1020 – 50 ppm W

• R404A, R507: 1020 – 50 ppm W

• R407C: 1020 – 50 ppm W

• R407C: 1020 – 50 ppm W

• R410A: 1050 – 50 ppm W

• R410A: 1050 – 50 ppm W

• R22: 1050 – 60 ppm.

• R22: 1050 – 60 ppm.

In accordance with ARI 710-2004

In accordance with ARI 710-2004

(2)

(2)

Given in accordance with ARI 710-2004 for:

Given in accordance with ARI 710-2004 for:

• te= -15 °C

• te= -15 °C

• tc= 30 °C

• tc= 30 °C

• Δp = 0.07 bar

• Δp = 0.07 bar

(3)

(3)

For usage with strainer or as a receiver application

For usage with strainer or as a receiver application

(4)

(4)

Refrigerants other than specied in the table please contact Danfoss for the approval.

Refrigerants other than specied in the table please contact Danfoss for the approval.

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 6

Page 7

Type

No. of

cores

Drying capacity [kg refrigerant]

(1)

Liquid capacity [kW]

(2)

Max.

working

pressure

R134a

R404A

R507

R407C

R410A

R134a

R404A

R507

R407C

R410A

[°C]

PS24522452245224522452

[bar]

DCR 0485

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

67.0

47.1

45.7

68.7

69.746DCR 0487

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

127.0

89.3

86.6

130.1

132.146DCR 0489

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

165.0

116.0

112.6

169.1

171.746DCR 04811

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

205.0

144.2

139.8

210.1

213.346DCR 04813

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

230.3

162.0

157.1

236.0

239.646DCR 04817

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

250.1

175.9

170.6

256.3

260.246DCR 04821

1

65.5

59.9

68.2

64.6

71.4

64.3

63.6

58.6

59.3

52.7

255.0

179.3

174.0

261.3

265.446DCR 0967

2

131.0

119.8

136.4

129.2

142.8

128.6

126.6

117.2

118.6

105.4

134.0

94.3

91.4

137.4

139.546DCR 0969

2

131.0

119.8

136.4

129.2

142.8

128.6

126.6

117.2

118.6

105.4

212.3

149.3

144.8

217.6

220.946DCR 09611

2

131.0

119.8

136.4

129.2

142.8

128.6

126.6

117.2

118.6

105.4

216.9

152.6

148.0

222.3

225.746DCR 09613

2

131.0

119.8

136.4

129.2

142.8

128.6

126.6

117.2

118.6

105.4

294.9

207.4

201.1

302.2

306.846DCR 09617

2

131.0

119.8

136.4

129.2

142.8

128.6

126.6

117.2

118.6

105.4

358.0

251.8

244.2

366.9

372.546DCR 1449

3

196.5

179.7

204.6

193.8

214.2

192.9

189.9

175.8

177.9

158.1

222.2

156.3

151.6

227.7

231.2

35

(3)

/ 46

(4)

DCR 14411

3

196.5

179.7

204.6

193.8

214.2

192.9

189.9

175.8

177.9

158.1

225.7

158.8

154.0

231.3

234.9

35

(3)

/ 46

(4)

DCR 14413

3

196.5

179.7

204.6

193.8

214.2

192.9

189.9

175.8

177.9

158.1

355.9

250.3

242.8

364.7

370.3

35

(3)

/ 46

(4)

DCR 14417

3

196.5

179.7

204.6

193.8

214.2

192.9

189.9

175.8

177.9

158.1

355.9

250.3

242.8

364.7

370.3

35

(3)

/ 46

(4)

DCR 19211

4

262.0

239.6

272.8

258.4

285.6

257.2

253.2

234.4

237.2

210.8

371.7

261.4

253.6

381.0

386.8

28

(3)

/ 40

(4)

DCR 19213

4

262.0

239.6

272.8

258.4

285.6

257.2

253.2

234.4

237.2

210.8

459.9

323.5

313.7

471.4

478.6

28

(3)

/ 40

(4)

DCR 19217

4

262.0

239.6

272.8

258.4

285.6

257.2

253.2

234.4

237.2

210.8

459.9

323.5

313.7

471.4

478.6

28

(3)

/ 40

(4)

DCR 19221

4

262.0

239.6

272.8

258.4

285.6

257.2

253.2

234.4

237.2

210.8

459.9

323.5

313.7

471.4

478.6

28

(3)

/ 40

(4)

Type

Recommended plant capacity [kW]

Evaporating temperature te [°C]

-40

-20

4.4

-30

-20

4.4

-40

-20

4.4

-40

-20

4.4

Pressure drop ∆p [bar]

0.04

0.1

0.21

0.04

0.07

0.14

0.04

0.1

0.21

0.04

0.1

0.21

R22 / R407C

R134a

R404A / R507

R410A

DCR 0485

3.1

8.9213

5.4132.4

7.1

17.5

3.1

8.921DCR 0487

5.8

16.1

37.8

5.6

9.9

23.4

4.5

12.9

31.2

5.8

16.1

37.8

DCR 0489

7.8

21.6

50.7

7.5

13.3

31.5617.2

41.8

7.8

21.6

50.7

DCR 04811

10

27.3

63.3

9.6

16.8

39.5

7.7

21.8

51.91027.3

63.3

DCR 04813

10

27.3

63.3

9.6

16.8

39.5

7.7

21.8

51.91027.3

63.3

DCR 04817

10

27.3

63.3

9.6

16.8

39.5

7.7

21.8

51.91027.3

63.3

DCR 04821

10

27.3

63.3

9.6

16.8

39.5

7.7

21.8

51.91027.3

63.3

DCR 0965

3.3

9.1

21.4

3.2

5.7

13.4

2.5

7.4183.3

9.2

21.6

DCR 0967

5.8

16.2

38.1

5.6

9.9

23.6

4.5

12.9

31.4

5.8

16.2

38.1

DCR 0969

8.7

24.6

58.3

8.41535.9

6.8

19.7

48.1

8.7

24.6

58.3

DCR 09611

11.9

33.4

79.3

11.4

20.4

48.9

9.3

26.8

65.4

11.9

33.4

79.3

DCR 09613

14.1

39.9

95.2

13.6

24.3

58.51132

78.7

14.1

39.9

95.2

DCR 09617

14.1

39.9

95.2

13.6

24.3

58.51132

78.7

14.1

39.9

95.2

Filter drier, shell, types DCR and DCRE

Table 6: DCR Drying and liquid capacity , type 48-DC

(1)

(1)

Drying capacity is based on following moisture content test standards before and after drying:

Drying capacity is based on following moisture content test standards before and after drying:

• R134a: 1050 – 50 ppm W

• R134a: 1050 – 50 ppm W

• R404A, R507: 1020 – 50 ppm W

• R404A, R507: 1020 – 50 ppm W

• R407C: 1020 – 50 ppm W

• R407C: 1020 – 50 ppm W

• R410A: 1050 – 50 ppm W

• R410A: 1050 – 50 ppm W

• R22: 1050 – 60 ppm

• R22: 1050 – 60 ppm

In accordance with ARI 710-2004

In accordance with ARI 710-2004

(2)

(2)

Given in accordance with ARI 710-2004 for:

Given in accordance with ARI 710-2004 for:

• te= -15 °C

• te= -15 °C

• tc= 30 °C

• tc= 30 °C

• Δp = 0.07 bar

• Δp = 0.07 bar

(3)

(3)

For usage with strainer or as a receiver application

For usage with strainer or as a receiver application

(4)

(4)

Refrigerants other than specied in the table please contact Danfoss for the approval.

Refrigerants other than specied in the table please contact Danfoss for the approval.

Table 7: Recommended plant capacity in suction line - burn-out, type 48-DA

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 7

Page 8

Type

Recommended plant capacity [kW]

Evaporating temperature te [°C]

-40

-20

4.4

-30

-20

4.4

-40

-20

4.4

-40

-20

4.4

Pressure drop ∆p [bar]

0.04

0.1

0.21

0.04

0.07

0.14

0.04

0.1

0.21

0.04

0.1

0.21

R22 / R407C

R134a

R404A / R507

R410A

DCR 09621

14.1

39.9

95.2

13.6

24.3

58.51132

78.7

14.1

39.9

95.2

DCR 1445

3.51022.8

3.4614

2.7

7.7

18.9

3.51022.8

DCR 1447

6.6

18.9

42.9

6.3

11.2

26.4

5.1

14.5

35.6

6.6

18.9

42.9

DCR 1449

8.8

25.1

57.2

8.41535.2

6.8

19.4

47.5

8.8

25.1

57.2

DCR 14411

13.2

38.1

92.2

12.72356.2

10.3

30.7

76.6

13.2

38.1

92.2

DCR 14413

13.2

38.1

92.2

12.72356.2

10.3

30.7

76.6

13.2

38.1

92.2

DCR 14417

13.2

38.1

92.2

12.72356.2

10.3

30.7

76.6

13.2

38.1

92.2

DCR 14421

13.2

38.1

92.2

12.72356.2

10.3

30.7

76.6

13.2

38.1

92.2

DCR 1925

4.2

11.5

27.347.1

16.8

3.2

9.2

22.7

4.2

11.5

27.3

DCR 1927

7.9

21.6

51.4

7.6

13.4

31.6

6.1

17.4

42.7

7.9

21.6

51.4

DCR 1929

10.6

28.9

68.9

10.21842.1

8.2

23.3

57.2

10.6

28.9

68.9

DCR 19211

14.8

41.8

99.4

14.3

25.5

61.2

11.6

33.6

82.2

14.8

41.8

99.4

DCR 19213

18

51.1

122.1

17.4

31.17514.1

41.1

1011851.1

122.1

DCR 19217

18

51.1

122.1

17.4

31.17514.1

41.1

1011851.1

122.1

DCR 19221

18

51.1

122.1

17.4

31.17514.1

41.1

1011851.1

122.1

Type

No. of

cores

Drying capacity [g of water]

(1)

Acid ca‐

pacity

(2)

Evaporating temperature te [°C]

-40

-20

4.4

-30

-20

4.4

-40

-20

4.4

-40

-20

4.4

R22 / R407C

R134a

R404A / R507

R410A

[g]

DCR 048128191245382747301942352526.6

DCR 096256372490775494603784705053.3

DCR 1443845636

135

115811429056

126

1057579.9

DCR 19241127448

180

153

108

189

12075168

140

100

106.5

Danfoss

23M86

Refrigerant

R22 / R407C

R134a

R404A / R507

R410A

Evaporating temperature [°C]

-40

-20

4.4

-30

-20

4.4

-40

-20

4.4

-40

-20

4.4

Pressure drop ∆p [bar]

0.04

0.1

0.21

0.04

0.07

0.14

0.04

0.1

0.21

0.04

0.1

0.21

Recommended system capacity [kW]

15471131528691238931547

113

Filter drier, shell, types DCR and DCRE

NOTE:

Data given in accordance with ARI-Standard 710-2004 for te = 4.4 °C and tc = 32.2 °C

Table 8: DCR Drying and acid capacity , type 48-DA

(1)

(1)

Drying capacity is expressed during drying in:

Drying capacity is expressed during drying in:

• R22: EPD = 10 ppm W, corresponding to a dew point temperature = -50 °C

• R22: EPD = 10 ppm W, corresponding to a dew point temperature = -50 °C

• R134a: EPD = 50 ppm W, corresponding to a dew point temperature = -37 °C

• R134a: EPD = 50 ppm W, corresponding to a dew point temperature = -37 °C

• R404A: EPD = 10 ppm W, corresponding to a dew point temperature = -40 °C

• R404A: EPD = 10 ppm W, corresponding to a dew point temperature = -40 °C

• R407C: EPD = 10 ppm W, corresponding to a dew point temperature = -40 °C

• R407C: EPD = 10 ppm W, corresponding to a dew point temperature = -40 °C

(2)

(2)

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number)

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number)

Figure 4: Strainer

Table 9: Strainer mounted in suction line, type 48-F

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 8

Page 9

Refrigerant

R22 / R407C

R134a

R404A / R507

R410A

Recommended system capacity [kW]

(1)

390

350

260

390

Type

No of

cores

Drying capacity [kg refrigerant]

Liquid capacity [kW]

Max.

working

pressure

R32

R444B

R452B

R454B

R1234yf

R32

R444B

R452B

R454B

R1234yf

[°C]

PS24522452245224522452

[bar]

DCRE 0485s

1

70.2

64.6

83.0

74.3

80.4

71.6

82.6

76.5

155.9

143.9

102.1

77.9

85.1

69.0

48.550DCRE 0487s

1

70.2

64.6

83.0

74.3

80.4

71.6

82.6

76.5

155.9

143.9

221.4

138.9

184.5

149.5

105.250DCRE 0489s

1

70.2

64.6

83.0

74.3

80.4

71.6

82.6

76.5

155.9

143.9

245.9

154.3

204.9

166.0

116.9

50

DCRE 04811s

1

70.2

64.6

83.0

74.3

80.4

71.6

82.6

76.5

155.9

143.9

312.4

196.0

260.4

266.6

148.5

50

DCRE 04813s

1

70.2

64.6

83.0

74.3

80.4

71.6

82.6

76.5

155.9

143.9

351.0

267.5

292.5

299.5

166.8

50

Type

No of

cores

Drying capacity [kg refrigerant]

Liquid capacity [kW]

Max.

working

pressure

R32

R444B

R452B

R454B

R1234yf

R32

R444B

R452B

R454B

R1234yf

[°C]

PS24522452245224522452

[bar]

DCRE 0485s

1

55.1

50.7

65.1

58.3

63.1

56.2

64.8

60.0

122.3

112.9

102.1

77.9

85.1

69.0

48.550DCRE 0487s

1

55.1

50.7

65.1

58.3

63.1

56.2

64.8

60.0

122.3

112.9

221.4

138.9

184.5

149.5

105.250DCRE 0489s

1

55.1

50.7

65.1

58.3

63.1

56.2

64.8

60.0

122.3

112.9

245.9

154.3

204.9

166.0

116.9

50

DCRE 04811s

1

55.1

50.7

65.1

58.3

63.1

56.2

64.8

60.0

122.3

112.9

312.4

196.0

260.4

266.6

148.5

50

DCRE 04813s

1

55.1

50.7

65.1

58.3

63.1

56.2

64.8

60.0

122.3

112.9

351.0

267.5

292.5

299.5

166.8

50

Refrigerant and oil types

DCDMDA

Refrigerant

HFC (R134a, R404A, R507, R407C and

R410A)

Recommended

Recommended

Recommended

HFO (R1234ze, R407F, R407A, R454C)

Recommended

Recommended

Recommended

HCFC (R22)

Recommended

Recommended

Recommended

R32, R444A, R444B, R445A, R446A,

R447A, R451A, R452B, R454B, R455A,

R1234yf

Recommended

Recommended

NA

Oil

Mineral or AB

Recommended

Recommended

Recommended

POE or PAG, pure

Recommended

Recommended

Recommended

POE or PAG, with additives

Not recommended

(1)

Recommended

Recommended

Filter drier, shell, types DCR and DCRE

Table 10: Strainer mounted in liquid line

(1)

(1)

The data given apply to DCR 04811 with 48-F core.

The data given apply to DCR 04811 with 48-F core.

Liquid capacity is given in accordance with ARI 710-2004 for: te= -15 °C, tc= 30 °C, Δp = 0.07 bar

Liquid capacity is given in accordance with ARI 710-2004 for: te= -15 °C, tc= 30 °C, Δp = 0.07 bar

Table 11: DCRE Drying and liquid capacity, type 48-DM

Table 12: DCRE Drying and liquid capacity, type 48-DC

Core selection

Table 13: Core selection

(1)

(1)

DC

DC

lter driers cores contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also polar substances

lter driers cores contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also polar substances

and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity, though this is not harmful to the

and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity, though this is not harmful to the

system.

system.

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 9

Page 10

Danfoss

23M93.13

H1

L1

L4

L3

H5

121

128

157

L2 L

P

Danfoss

23M92.11

P

157

Plug 1/4 in. NPT

Danfoss

23M8040

165

138.4

Ø

52

Ø

42.9

Ø

93.5

Ø

123.5

48-DM, 48-DC and 48-DA 100-DM and 100-DC

Type

No. of

cores

DCR with steel connectors

DCR with copper connectors

Net weight

(1)

LL1L2L3L4H1H5LL1L2L3L4H1H5[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCR 0485(s)

1

242.9

162.7

1701212

96.821259.9

179.7

1701212

112.8195.2

DCR 0487(s)

1

237

156.8

1701717

90.327259.5

179.3

1701717

112.8255.2

DCR 0489(s)

1

240.4

160.2

1702222

94.334261.9

181.7

1702020

115.8325.2

DCR 0489(s)

1

240.4

160.2

1702222

94.334261.9

181.7

1702020

115.8325.2

DCR 04811(s)

1

242.8

162.6

1702525

97.342264.3

184.1

1702525

118.8395.2

DCR 04813(s)

1

248

167.8

1702929

103.348265.5

185.3

1702929

120.8465.2

DCR 04813(s)

1

248

167.8

1702929

103.348265.5

185.3

1702929

120.8465.2

DCR 04817(s)

1

253.7

173.5

1703333

110.860267.7

187.5

1703434

124.8585.2

DCR 04821(s)

1

256.5

176.3

1703838

115.873269.5

189.3

1703434

128.8715.2

DCR 0965(s)

2

381.9

301.7

3101212

96.821398.9

318.7

3101212

112.8196.6

DCR 0967(s)

2

376

295.8

3101717

90.327398.5

318.3

3101717

112.8256.6

DCR 0969(s)

2

379.4

299.2

3102222

94.334400.9

320.7

3102020

115.8326.6

DCR 0969(s)

2

379.4

299.2

3102222

94.334400.9

320.7

3102020

115.8326.6

DCR 09611(s)

2

381.8

301.6

3102525

97.342403.3

323.1

3102525

118.8396.6

DCR 09613(s)

2

387

306.8

3102929

103.348404.5

324.3

3102929

120.8466.6

DCR 09613(s)

2

387

306.8

3102929

103.348404.5

324.3

3102929

120.8466.6

DCR 09617(s)

2

392.7

312.5

3103333

110.860406.7

326.5

3103434

124.8586.6

DCR 09621(s)

2

395.5

315.3

3103838

115.873408.5

328.3

3103434

128.8716.6

DCR 1445(s)

3

523.9

443.7

3101212

96.821540.9

460.7

3101212

112.8197.8

DCR 1447(s)

3

518

437.8

3101717

90.327540.5

460.3

3101717

112.8257.8

DCR 1449(s)

3

521.4

441.2

3102222

94.334542.9

462.7

3102020

115.8327.8

DCR 1449(s)

3

521.4

441.2

3102222

94.334542.9

462.7

3102020

115.8327.8

DCR 14411(s)

3

523.8

443.6

3102525

97.342545.3

465.1

3102525

118.8397.8

Filter drier, shell, types DCR and DCRE

Dimensions and weights

Figure 5: DCR housing

Figure 7: DCR solid core

Figure 6: DCR top cover

Table 14: Dimensions and weights for DCR

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 10

Page 11

Danfoss

23M94

H1

L1

L4

L3

H2

114.3

123.7

153.6

L2 L

P

Danfoss

23M95

153.6

P

Plug 1/4 in. NPT

Type

No. of

cores

DCR with steel connectors

DCR with copper connectors

Net weight

(1)

LL1L2L3L4H1H5LL1L2L3L4H1H5[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCR 14413(s)

3

529

448.8

3102929

103.348546.5

466.3

3102929

120.8467.8

DCR 14413(s)

3

529

448.8

3102929

103.348546.5

466.3

3102929

120.8467.8

DCR 14417(s)

3

534.7

454.5

3103333

110.860548.7

468.5

3103434

124.8587.8

DCR 14421(s)

3

537.5

457.3

3103838

115.873550.5

470.3

3103434

128.8717.8

DCR 1925(s)

4

663.9

583.7

3101212

96.821680.9

600.7

3101212

112.8199.1

DCR 1927(s)

4

658

577.8

3101717

90.327680.5

600.3

3101717

112.8259.1

DCR 1929(s)

4

661.4

581.2

3102222

94.334682.9

602.7

3102020

115.8329.1

DCR 1929(s)

4

661.4

581.2

3102222

94.334682.9

602.7

3102020

115.8329.1

DCR 19211(s)

4

663.8

583.6

3102525

97.342685.3

605.1

3102525

118.8399.1

DCR 19213(s)

4

669

588.8

3102929

103.348686.5

606.3

3102929

120.8469.1

DCR 19213(s)

4

669

588.8

3102929

103.348686.5

606.3

3102929

120.8469.1

DCR 19217(s)

4

674.7

594.5

3103333

110.860688.7

608.5

3103434

124.8589.1

DCR 19221(s)

4

677.5

597.3

3103838

115.873690.5

610.3

3103434

128.8719.1

Type

No. of cores

DCRE with copper connectors

Net weight

(2)

LL1L2L3L4H1H2

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCRE 0485(s)

1

219.93

152.13

1701818

99.85164.4

DCRE 0487(s)

1

221.42

153.62

1701919

101.85

22.22

4.6

DCRE 0489(s)

1

228.15

160.35

170

22.5

22.5

108.85284.8

DCRE 04811(s)

1

233.15

165.35

170

23.5

23.5

113.85355.0

DCRE 04813(s)

1

236.15

168.35

170

27.5

27.5

116.85

41.28

5.2

Filter drier, shell, types DCR and DCRE

(1)

(1)

Without core. For total weight add 0.7 kg per core for 48-DM and 48-DC, 0.8 kg per core for 48-DA or 0.4 kg per strainer 48-F

Without core. For total weight add 0.7 kg per core for 48-DM and 48-DC, 0.8 kg per core for 48-DA or 0.4 kg per strainer 48-F

Figure 8: DCRE housing

Table 15: Dimensions and weights for DCRE

Figure 9: DCRE top cover

(2)

(2)

Without core. For total weight add 0.7 kg per core for 48-DM and 48-DC, 0.8 kg per core for 48-DA or 0.4 kg per strainer 48-F

Without core. For total weight add 0.7 kg per core for 48-DM and 48-DC, 0.8 kg per core for 48-DA or 0.4 kg per strainer 48-F

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 11

Page 12

Danfoss

23M77

Type

Number of cores

Copper connectors

Cover type

Max. working pres‐

sure PS

Code number

Solder ODF

[in.]

[mm]

[bar]

DCR 0485s

1

5

⁄8

16

Plug

46

023U7250

DCR 0487s

1

7

⁄8

22

Plug

46

023U7251

DCR 0487s

1

7

⁄8

22–46

023U7571

DCR 0489s1–28Plug

46

023U7252

DCR 0489s

1

1

1

⁄8

–

Plug

46

023U7253

DCR 0489s1–28–46023U7268

DCR 04811s

1

1

3

⁄8

35

Plug

46

023U7254

DCR 04813s

1

1

5

⁄8

–

Plug

46

023U7255

DCR 04813s1–42Plug

46

023U7256

DCR 04813s1–42–46023U7303

DCR 04817s

1

2

1

⁄8

54

Plug

46

023U7257

DCR 04821s

1

2

5

⁄8

–

Plug

46

023U7276

DCR 0967s

2

7

⁄8

22

Plug

46

023U7258

DCR 0969s2–28Plug

46

023U7259

DCR 0969s

2

1

1

⁄8

–

Plug

46

023U7260

DCR 0969s

2

1

1

⁄8

––46

023U7278

DCR 09611s

2

1

3

⁄8

35

Plug

46

023U7261

DCR 09613s

2

1

5

⁄8

–

Plug

46

023U7262

DCR 09613s2–42Plug

46

023U7263

DCR 09613s2–42–46023U7463

DCR 09617s

2

2

1

⁄8

54

Plug

46

023U7264

DCR 09617s

2

2

1

⁄8

54–46

023U7290

DCR 09621s

2

2

5

⁄8

–

Plug

46

023U7281

DCR 1449s3–28Plug

35

(1)

/ 46

(2)

023U7265

DCR 14411s

3

1

3

⁄8

35

Plug

35

(1)

/ 46

(2)

023U7267

DCR 14411s

3

1

3

⁄8

––35

(1)

/ 46

(2)

023U7275

DCR 14413s

3

1

5

⁄8

–

Plug

35

(1)

/ 46

(2)

023U7282

DCR 14413s3–42Plug

35

(1)

/ 46

(2)

023U7269

DCR 14413s

3

1

5

⁄8

42–35

(1)

/ 46

(2)

023U7297

DCR 14417s

3

2

1

⁄8

54

Plug

35

(1)

/ 46

(2)

023U7270

DCR 19211s

4

1

3

⁄8

––28

(1)

/ 40

(2)

023U7083

DCR 19213s

4

1

5

⁄8

–

Plug

28

(1)

/ 40

(2)

023U7272

DCR 19213s4–42Plug

28

(1)

/ 40

(2)

023U7273

DCR 19213s

4

1

5

⁄8

––28

(1)

/ 40

(2)

023U7082

DCR 19217s

4

2

1

⁄8

54

Plug

28

(1)

/ 40

(2)

023U7274

Filter drier, shell, types DCR and DCRE

Ordering

DCR/DCRE housing and insert are ordered separately. Select housing and top cover with all internal parts assembled

from table 1,2 or 3 and required number of inserts from table 4.

Figure 10: DCR

Table 16: DCR Housing with copper connectors + top cover

(1)

(1)

For usage with strainer or as a receiver application

For usage with strainer or as a receiver application

(2)

(2)

For “drier” application using all the permissible cores

For “drier” application using all the permissible cores

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 12

Page 13

Danfoss

23M77

Type

Number of cores

Steel connectors

Cover type

Max. working

pressure PS

Code number

Solder ODF

Butt weld

[in.]

[mm]

[in.]

[bar]

DCR 0485

1

5

⁄8

16

1

⁄2

Plug

46

023U7050

DCR 0487

1

7

⁄8

22

3

⁄4

Plug

46

023U7051

DCR 0487

1

7

⁄8

22

3

⁄4

–46023U7151

DCR 04891–281

Plug

46

023U7052

DCR 048911

1

⁄8

–1Plug

46

023U7053

DCR 04811

1

1

3

⁄8

35

1

1

⁄4

Plug

46

023U7054

DCR 04813

1

1

5

⁄8

–

1

1

⁄2

Plug

46

023U7055

DCR 048131–421

1

⁄2

Plug

46

023U7056

DCR 04817

1

2

1

⁄8

542Plug

46

023U7057

DCR 04821

1

2

5

⁄8

–

2

1

⁄2

Plug

46

023U7076

DCR 0967

2

7

⁄8

22

3

⁄4

Plug

46

023U7058

DCR 09692–281

Plug

46

023U7059

DCR 096921

1

⁄8

–1Plug

46

023U7060

DCR 09611

2

1

3

⁄8

35

1

1

⁄4

Plug

46

023U7061

DCR 09611

2

1

3

⁄8

35

1

1

⁄4

–46023U7161

DCR 09613

2

1

5

⁄8

–

1

1

⁄2

Plug

46

023U7062

DCR 096132–421

1

⁄2

Plug

46

023U7063

DCR 09617

2

2

1

⁄8

542Plug

46

023U7064

DCR 14493–281

Plug

35

(1)

/ 46

(2)

023U7065

DCR 144931

1

⁄8

–1Plug

35

(1)

/ 46

(2)

023U7066

DCR 14411

3

1

3

⁄8

35

1

1

⁄4

Plug

35

(1)

/ 46

(2)

023U7067

DCR 14413

3

1

5

⁄8

–

1

1

⁄2

Plug

35

(1)

/ 46

(2)

023U7068

DCR 144133–421

1

⁄2

Plug

35

(1)

/ 46

(2)

023U7069

DCR 14417

3

2

1

⁄8

542Plug

35

(1)

/ 46

(2)

023U7070

DCR 19211

4

1

3

⁄8

35

1

1

⁄4

Plug

28

(1)

/ 40

(2)

023U7071

DCR 19213

4

1

5

⁄8

–

1

1

⁄2

Plug

28

(1)

/ 40

(2)

023U7072

DCR 192134–421

1

⁄2

Plug

28

(1)

/ 40

(2)

023U7073

DCR 19217

4

2

1

⁄8

542Plug

28

(1)

/ 40

(2)

023U7074

DCR 19221

4

2

5

⁄8

–

2

1

⁄2

Plug

28

(1)

/ 40

(2)

023U7086

Filter drier, shell, types DCR and DCRE

Figure 11: DCR

Table 17: DCR Housing with steel connectors + top cover

(1)

(1)

For usage with strainer or as a receiver application

For usage with strainer or as a receiver application

(2)

(2)

For “drier” application using all the permissible cores

For “drier” application using all the permissible cores

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 13

Page 14

Danfoss

23M85

Danfoss

23M86

Danfoss

23M77

Type

Number of cores

Copper connectors solder

Cover

Maximum working

pressure PS

Code number

[in]

[mm]

[bar]

DCRE 0485s

1

5

⁄8

16

plug

50

023U7608

DCRE 0487s

1

7

⁄8

22

plug

50

023U7606

DCRE 0489s11

1

⁄8

–

plug

50

023U7607

DCRE 0489s1–28plug

50

023U7609

DCRE 04811s11

3

⁄8

35

plug

50

023U7610

DCRE 04813s11

5

⁄8

41

plug

50

023U7611

Type

Material

Code number for DCR

Code number for

DCRE

Industrial pack

Multi pack

Multi pack

(8 pcs.)

(3 pcs.)

(3 pcs.)

with gasket

(2)

without gasket

with gasket

(2)

with gasket

(2)

48-DM solid core

(1)

100% molecular sieve

023U1392

023U1393

023U1391

023U1399

48-DC solid core

(1)

80% molecular sieve & 20% Al3 O

2

023U4381

023U4382

023U4380

023U4388

48-DA solid core

(1)

30% molecular sieve & 70% Al3 O

2

023U5381

023U5382

023U5380

–

48-F strainer

(1)

Felt-gasket, 15 µm

023U1921––

–

100-DM solid core

(1)

100% molecular sieve

023U7562––

–

100-DC solid core

(1)

80% molecular sieve & 20% Al3 O

2

023U7563––

–

Core

surface

volume

[cm2]

[cm3]

DM 048, DC 048 and DA 048

612

727

DM 096, DC 096 and DA 096

1225

1454

DM 144, DC 144 and DA 144

1837

2181

DM 192, DC 192 and DA 192

2450

2908

48-F

405

-

Filter drier, shell, types DCR and DCRE

Figure 12: DCRE

Table 18: DCRE Housing with copper connectors + top cover

Figure 13: DCR insert

Figure 14: DCRE insert

Table 19: Type DCR/DCRE, inserts

(1)

(1)

Only use for DCR 048 - 192 housing

Only use for DCR 048 - 192 housing

(2)

(2)

Top cover gasket

Top cover gasket

Table 20: Core surface and volume

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 14

Page 15

Document name

Document type

Document topic

Approval authority

PV 6-238699.19

Pressure - Safety Certicate

NSW

PV 6-238700.19

Pressure - Safety Certicate

NSW

PV 6-238701.19

Pressure - Safety Certicate

NSW

PV 6-238702.19

Pressure - Safety Certicate

NSW

SA6398

Mechanical - Safety Certicate

cULuslisting

UL

023U9601

Manufacturers Declaration

China RoHS

Danfoss

023U9611

Manufacturers Declaration

RoHS

Danfoss

023U9612

EU Declaration

PED

Danfoss

023U9613

Manufacturers Declaration

ATEX/PED/RoHS

Danfoss

023U9631

Manufacturers Declaration

PED/RoHS

Danfoss

RU Д-DK.РА01.B.32851_20

EAC Declaration

PED

EAC

RU Д-DK.БЛ08.B.00828_19

EAC Declaration

Machinery & Equipment

EAC

Filter drier, shell, types DCR and DCRE

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 21: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 15

Page 16

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.02 AI222586433727en-001201 | 16

Loading...

Loading...