Installation guide

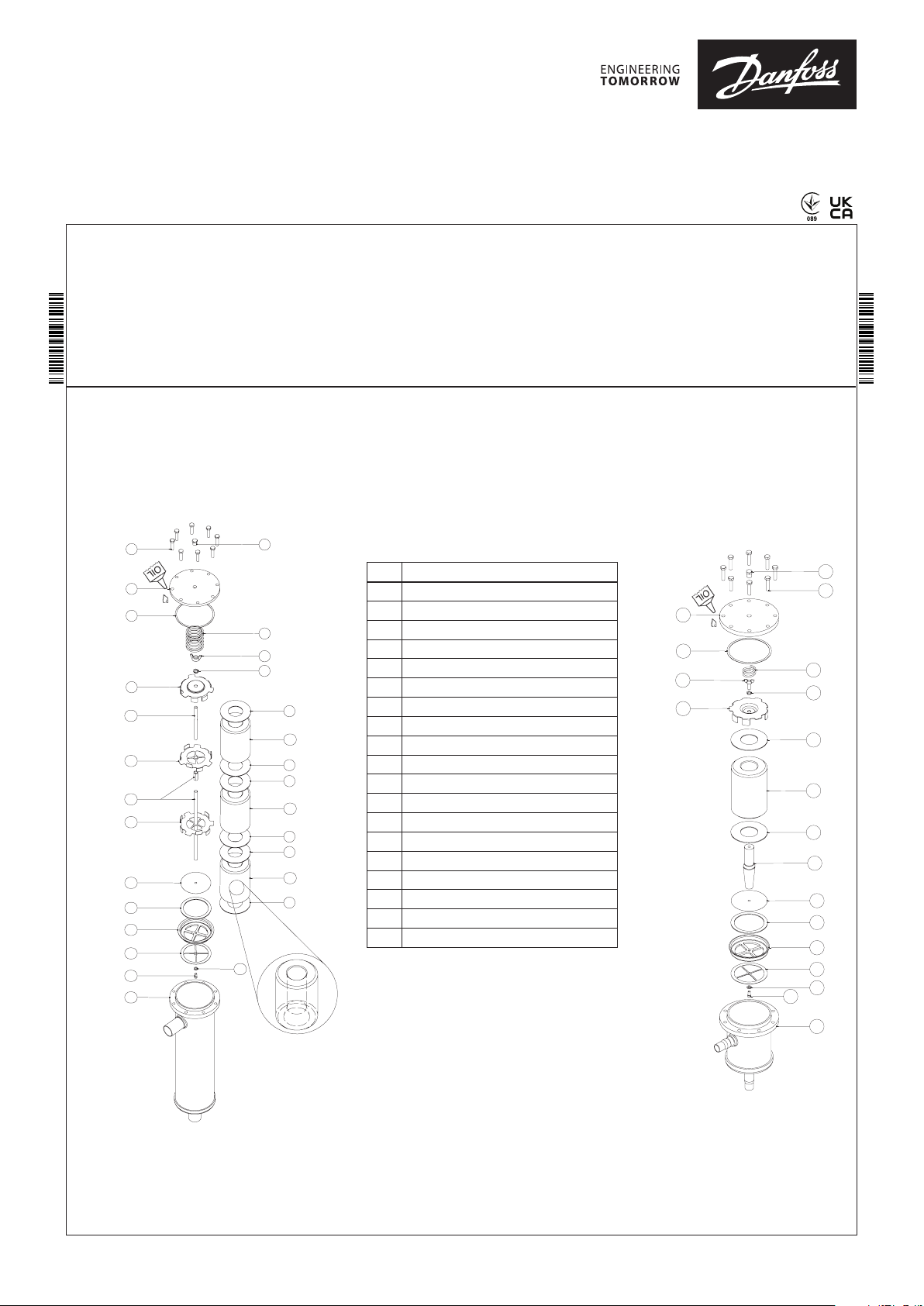

Filter drier, shell with cross gasket

Type DCR / DCR E

Refrigerants:

DCR Standard (A1, Group 2)

R22, R23, R113, R125, R134a R404A, R407A, R407C, R407F, R410A,

023R9543

R438A, R448A, R449A, R449B, R450A, R452A, R507A, R513A, R1233zd,

R1234ze, etc.

For other refrigerants, please contact Danfoss representative.

Media Temperature: -40 - 70 °C / -40 - 160 °F

Design

DCR

2

3

5

8

13

12

13

12

14

11

15

16

18

19

1

Pos. Description

1 Plug for cover

2 Bolts for cover

4

6

7

3 Top cover

4 Spring

5 Top cover gasket

6 Wing nut (DCR) / Bolt (DCRE)

9

10

9

9

10

9

9

10

9

7 Lock washer

8 Top pla te

9 Core felt gasket

10 Solid core

11 Core holder felt gasket

12 Core plate

13 Distance rod

14 Wire Mesh

15 Core holder

16 Cross gasket

17 Washer

18 Hex socket head screw

19 Shell

17

Inner taper of core always facing towards

filter outlet. This apply for DCR and DCRE

components.

DCR E Flammables (A2L, Group 1)

R32, R444A, R444B, R445A, R446A, R447A, R451A, R452B,

R454B, R455A, R1234yf, etc.

DCR E

3

5

6

8

4

7

9

10

9

13

14

11

15

16

17

18

19

023R9543

1

2

Імпортер:ТОВ з іі "Данфосс ТОВ" 04080, Київ 80, п/с 168, Україна

© Danfoss | Climate Solutions | 2021.07

Info for UK customers only: Danfoss Ltd., 22 Wycombe End, HP9 1NB, GB

AN162686432084en-000901 | 1

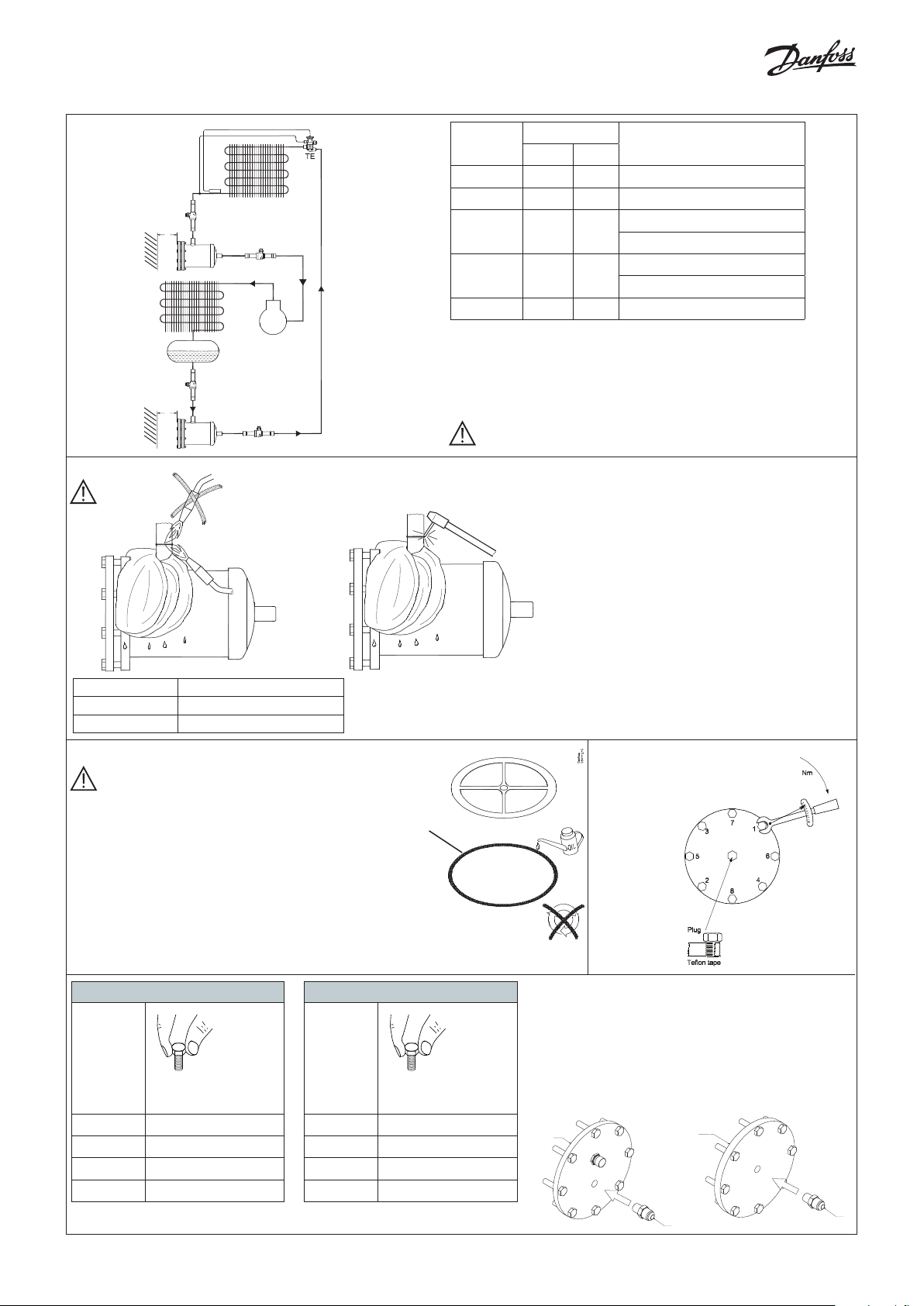

Installation

Danfoss

Danfoss

Danfoss

23Z84.10

L

DCR

Suction line filter

Liquid line filter drier

L

DCR/DCRE

Typ e

L minimum

[mm] [in]

Maximum working pressure

PS / MWP [bar] / [psig]

DCR 048 170 7 46 / 667 *

DCR 096 310 13 46 / 667 *

DCR 144 310 13

DCR 192 310 13

35 / 507

46 / 667

28 / 406

40 / 580

1

)

2

)

1

)

2

)

DCRE 048 170 7 50 / 725

1)

For usage with strainer or as a receiver application

2)

For “drier” application using all the permissible cores

3)

* For either 1* or 2*

MWP shall not be less than the pressure outlined in sect 9.2 of ANSI/

ASHRAE 15 for the refrigerant used in the system. After charging, the

system shall be marked with the refrigerant and oil used.

“The DCRE can only be use for A2L when the solid core is

placed. DCRE is not allowed to be used as receiver.”

Brazing

Keep flames

away from body

23M71.12

Connector type Brazing material

Copper Min. 5 % Ag

Steel Silver-flo 55 + Easy-flow flux

Do not install DCR / DCRE insert before

soldering

Note: Confirm correct top cover gasket is selected for DCR or DCRE

Welding

23M115.10

Gasket

Customer best practice will still be needed:

• Use wet wrap when installing.

• Braze the joints.

• Let them cool down.

• Clean the brazing /welding area after the installation (remove remaining flux with a brush).

• This is an important operation and needs to be

done with great care to remove all remaining flux.

• Paint / Anti-corrosive needs to cover all open

steel parts, areas where the black original paint

has been burnt due to brazing and at least 3 cm

approx of the copper.

• Paint the joints twice.

How to tighten the bolts

Pos 5

Note: Do not reuse the gasket

Danfoss

23M73.11

DCRE - Bolts M10 x 1.5

DCR - Bolts M8 x 1.25

Optional Fuse and/or Plug, recommended tightening

torques:

Fuse: 1/4”NPT - 3/8” Flare: 20 Nm / 14.75 ft-lb applying

2 to 3 wraps of teflon tape.

Step 1

Fingertighten all

bolts

Step 2 5 Nm / 3.69 ft lb

Step 3 20 Nm / 14.75 ft lb

Step 4 35 Nm / 25.81 ft lb

Step 5* 50 Nm / 36.88 ft lb

* Repeat until complete tightness has been reached.

© Danfoss | Climate Solutions | 2021.07

Step 1

Fingertighten all

bolts

Step 2 3 Nm / 2.21 ft lb

Step 3 10 Nm / 7.37 ft lb

Step 4 20 Nm / 14.75 ft lb

Step 5* 28 Nm / 20.65 ft lb

Plug: 1/4” NPT: 50 Nm / 36.87 ft-lb applying 2 to 3

wraps of teflon tape.

Reference

Cover

Cover

Fuse

AN162686432084en-000901 | 2

Fuse

Loading...

Loading...