Page 1

Installation guide

Electric 3-way valve

Type CTR 20

Main application:

Heat reclaim

027R9972

Stepper motor type:

Bipolar

Phase Current:

100 mA RMS / 141 mA Peak

Refrigerant: R74 4

for other refrigerants

contact Danfoss

Ambient temperature:

Min. -40 °C / -40 °F

Max. 60 °C / 140 °F

Max working pressure:

140 Bar / 2030 psig

Coil resistance:

52 Ohm ±10% (25 °C)

ENGINEERING

TOMORROW

Fluid temperature:

Min. 0 °C / 32 °F

Max. 150 °C / 302 °F

Total full steps:

6600

Step rate:

75 stp./sec.

027R9972

Note!

Valves are delivered in approximately half

opened position and is ready for brazing.

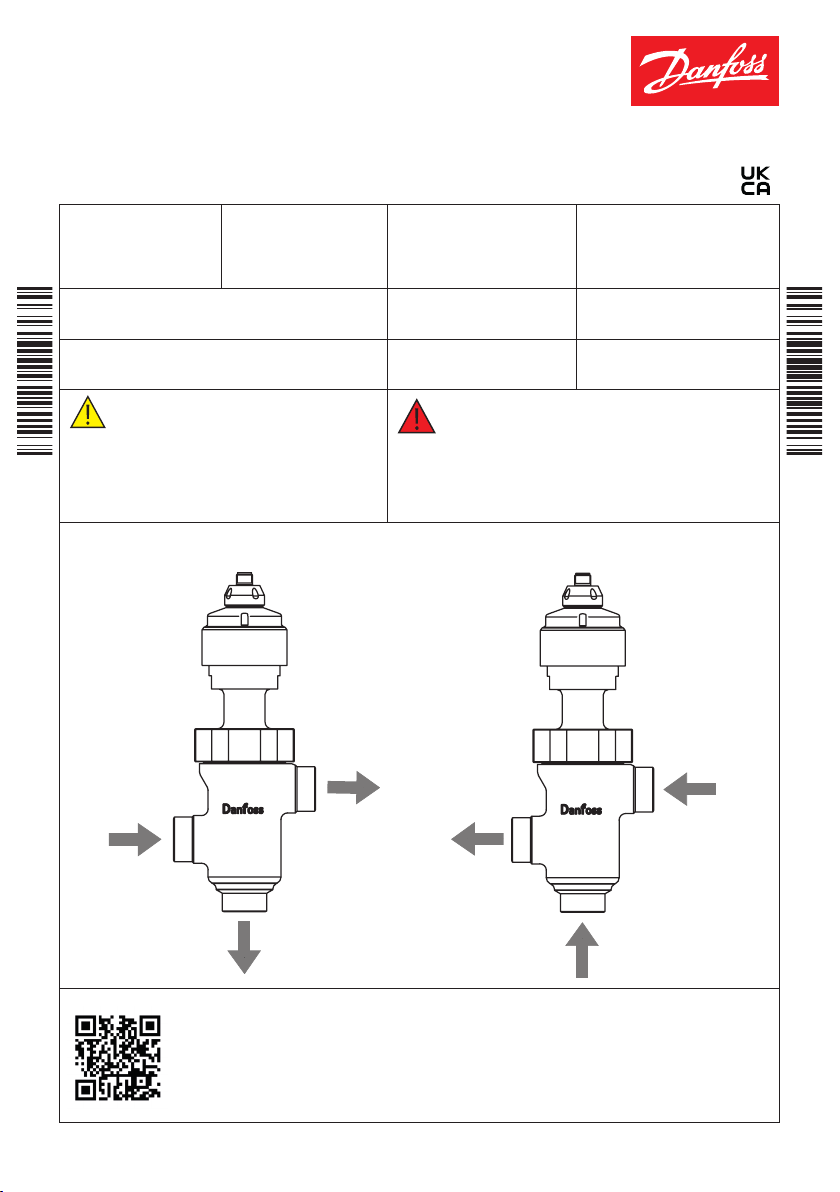

Flow direction

A.

1 in 2 outs

Common

3

1

2

Warning!

Do not connect directly to AC / DC power source.

Connect valve to appropriate controller/driver only.

Do not operate valve while assembling or

disassembling.

B.

2 in 1 out

Common

3

1

2

For more information on the product,

please scan the QR code.

© Danfoss | DCS (sw) | 2021.01

AN187286434604en- 000201

Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

Page 2

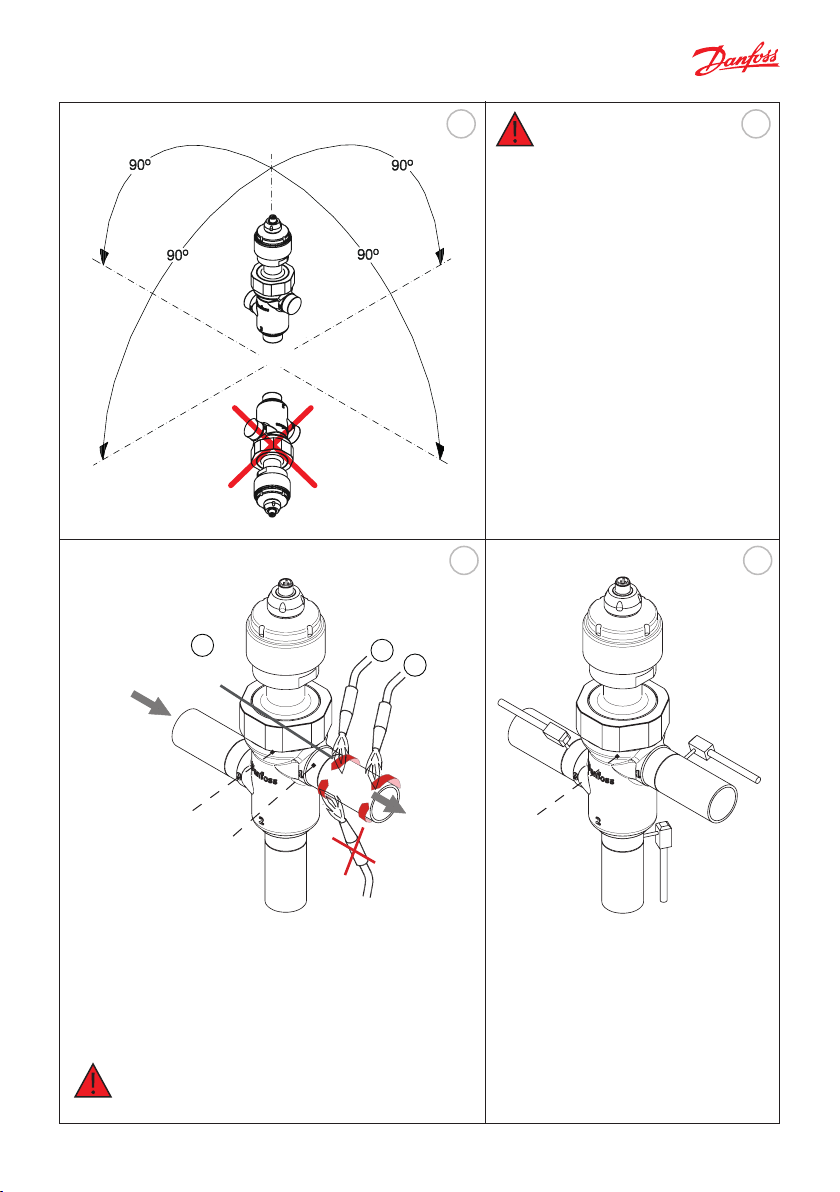

Mounting direction

27H401.10

1

• Do not disassemble the valve

before brazing or welding.

• the valve must be in middle position

Danfoss

by brazing and welding (as it is

delivered).

2

Brazing

3

Material

for brazing

N

2

max.

75 °C /

max.

167 °F

700 °C /

1300 °F

Recommendation: Solder nozzle 4 - 6 mm N (5/32 in - 15/64 in)

Materials used for brazing:

• Flus: Metalli tenacity No. 5 Powder or Braze Tec special h paste.

• Filler: Silver-Flo 55 (BS:AG 14/ DIN L-Ag55 Sn) or

Silver-Flo 56 (AWS B Ag-7).

Filler metals containing Phosphor i.e. BS: CP 1/

DIN L-Ag 15P or BS: CP 3/ DIN L-Ag P7 must not be used.

© Danfoss | DCS (sw) | 2021.01

Danfoss

27H402.10

2

1

Welding

3a

max.

75 °C /

167 °F

Recommendation for TIG welding

• Power approximately 60A.

• Use Shield gas charge - Argon.

• Material for welding - approximately

2 mm thick stainless steel alloy.

AN187286434604en- 000201

3b

Danfoss

027H7244

Page 3

Electrical connections

A1

27H405.10

4

Danfoss

27H435.10

Danfoss

34G166.10

Warning /

For your own notes

A1 and A2 = coil I

B1 and B2 = coil II

B1

A2

M12 connection

on CTR valve

B2

Danfoss

© Danfoss | DCS (sw) | 2021.01

AN187286434604en- 000201

Page 4

Danfoss

Service only

Danfoss

Danfoss

27H403.10

Spanner : 72 mm / 2.8 in

Unskrew th e big nut with 5 rotations

Danfoss

27H403.10

5 X

1

Lift the motor with a s crewdriver untill it is l oose

Service kit with 3 O-rings

Code no. 027H7248

27H407.10

1 Green dot

2 Red dot

2

Danfoss

27H408.10

43

Unscrew the big nut full y

The “fixi ng” pin must be place d in the gap

© Danfoss | DCS (sw) | 2021.01

27H409.10

Align

3 No color

5

Danfoss

27H404.10

Max. torque:130 Nm/ 95.9 ft-lbf

AN187286434604en- 000201

6

Loading...

Loading...