Data sheet

Electric 3-way valve

Type CTR 20

The CTR is an electrically operated 3-way valve

designed specically for operation in CO

with heat reclaim. CTR is designed to allow full

proportional control of the surplus heat from

compressor pack into the heat exchanger of

transcritical heat reclaim solutions.

The proportional control of the CTR ensures that

the exact amount of heat required is available at

any time, and the possibility to operate smoothly

in changeover sitiuations allowing for stable

control.

The typical application for the CTR is a Pack/

rack system in food retail application working

with transcritical CO

most attractive energy advantage of transcritical

CO

. Even as transcritical CO2 systems are on

2

par or outperform traditional HFC installations

on energy performance, this also ensures the

possibility to supply high quality heat to be

exploited. Heat reclaim is seeing an increased

deployment and becoming a norm in most

transcritical CO

. Heat reclaim is the current

2

retail installations today.

2

systems

2

Features • Full proportional and on / o control of the

heat reclaim system.

• 2 inlets and 1 outlet or 1 inlet and 2 outlets.

• Applicable to R744 and other common

refrigerants.

• CTR is compatible with oil types PAG and POE

• Full serviceable cartridge design valve.

• Modulating operation to ensure smooth

transition.

• Leak tight, motor integrated in valve.

Application:

Heat reclaim in CO

• Eliminates pressure peaks in heat reclaim

systems.

• Controls transcritical pressure up to 140 bar.

• Available for combo weld or solder/braze.

• Standard M12 connector for easy connection

to the motor driver.

• Internal / external corrosion resistant design.

• Manufactured according to ISO / TS 16943.

systems (transcritical).

2

For more information on the product,

please scan the QR code.

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A2.02 | 1

Data sheet | Electric 3-way valve type CTR 20

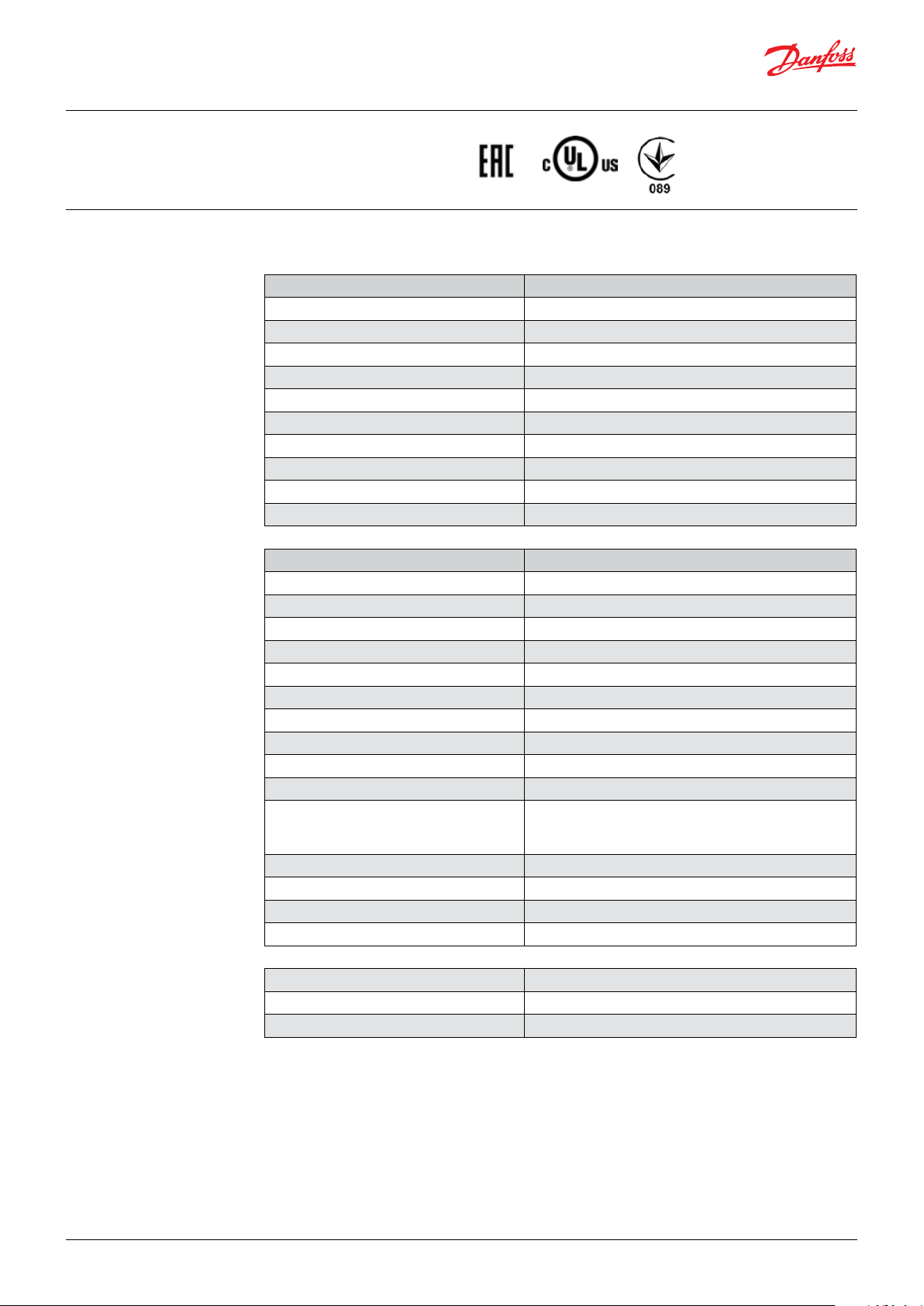

Approval (in progress)

Technical data

Valve specication

Electrical specication

UL, EAC, CRN, cUL

Feature CTR 20 (DN25)

Flow 1 inlet -2 outlets or 2 inlets - 1 outlet

Refrigerant R744 (For other refrigerants please contact Danfoss)

Oil Types PAG / POE

MWP/ Refrigerant 140 bar / 2030 psig

MOPD 3 bar / 43 psi

Allowed ambient temperature range -40 – +60 °C / -40 – +140 °F

Allowed refrigerant temperature range 0 – +150 °C / +32 – +302 °F

Environment temp (Transport/Warehouse) -40 – +70 °C / -40 – +158 °F

Lifetime / endurance 10 years / 50.000 cycles in CO

Serviceable Yes

Stepper motor type Bipolar permanent motor

IP rating of electric connection 67

Step mode Microstepping (recommended), 2 phase full step

Phase resistance 52.4 ohm ±10% per coil

Inductance 85.7 mH ±20%

Current per coil 100 mA RMS / 142 mA Peak

Holding current 20% holding current (recommended)

Duty cycle 100% duty cycle is allowed

Max. total power Current driver: 1.2 Watt

Number of full steps 6600

Closing / opening time 88 sec @ 75 PPS

Step rate

Electric connector type M12

Reference position Over drive against the full close position (both top & bottom)

Overdriving in closing direction Recommended 3% of total step ie. 180 full steps

Recommended controller/driver AK-XM 208C, EKD 316, EKD 316C

Current control

75 PPS for top and bottom 10% opening / closing degree and

remaining at 250 pps

≤ 75 step /sec. (recommended)

system with 3 bar di. pressure

2

© Danfoss | DCS (sw) | 2018.07

Material of construction (Housing) Stainless Steel

Installation orientation Vertical / Horizontal (Inverted not allowed)

Valve opening characteristic Linear

DKRCC.PD.VL0.A.02 | 2

Data sheet | Electric 3-way valve type CTR 20

Ordering

Spareparts

Related products

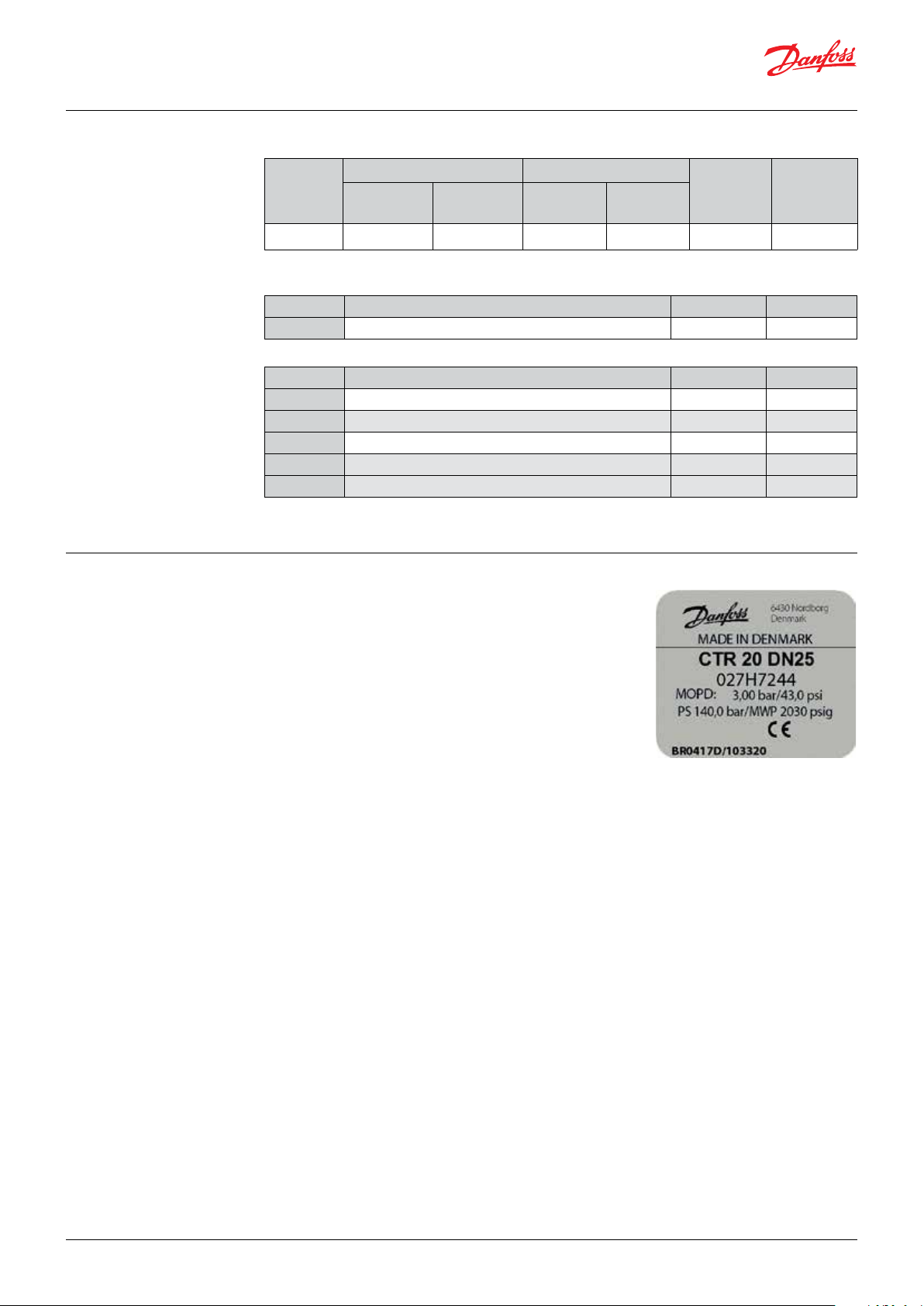

Identication, product label

Valve including actuator

Type Connection Flow rate

1

Weld

)

[inch]

CTR 20

1

) OD according to EN 10220

Type Description

Gasket O-ring spare part kit for CTR 20 (3 O-rings)

Type Description Single pack Code no.

AK-XM 208C Stepper output module 1 080Z0023

EKD 316C Superheat controller / driver (prefered EKD) 1 084B8045

EKD 316 Superheat controller / driver 1 084B8040

EKA 164A Optional display for EKD 316 1 084B8563

AST-G Manual service driver 1 034G0013

1

[inch]

1 1/

8

Solder ODF

k

[m

value

v

3

/h]

value

C

v

[gpm]

20 23.1 1

Single pack Code no

027H7244

Single pack Code no.

1 027H7248

MADE IN DENMARK : Country of origin

CTR 20 DN25 : Valve type

027H7244 : Code number

MOPD: 3,00 bar / 43.0 psi : Max. operation pressure

PS 140,0 bar / MWP 2030 psig : Max. working pressure

CE : Approval

BR0417D/103320 : (Manufactoring no.)

BR = Kolding

04 = week

17 = 2017

D = Thursday

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A.02 | 3

34G211.10

Pr

C

Data sheet | Electric 3-way valve type CTR 20

Accessories:

M12 angle cable

M12 angle female connector is intended for use with a standard M12 male connector,

available on stepper motor valves.

This cable is designed to oer high exibility and small outer diameters with tensile strength.

The angle way M12 cable consist of paired, twisted wires, which decreases mutual inuence between

signals transmitted along the cable and reduces inuence of external sources of interference. The

cables thus provides a higher degree of protection against lost steps compared to other cables.

Approvals

Specication

Ordering

Identication

RoHS

Jacket PVC - black

Cable outer sheath Oil resistant

Water proof rating IP 67

Operating temperature range -40 – +80 °C / -40 - +176 °F

Wire type Twisted pair, cross section 20 AWG / 0.5 mm

Cable outer diameter 7.0 mm / 0.28 inch

Minimum bending radius 10 x cable diameter

Cable combustibility / test Flame retardant / VW-1 / CSA FT - 1

M12 standard EN 61076-2-101

Reference standard UL style 2464 and DIN VDE 0812

LVD directive 73/23/EEC and 93/68/EEC

Cable Cable length (L) Insulation Packing format Code no.

PVC - black

2 m / 6.6 ft SR-PVC Single pack 034G7073

8 m / 26.2 ft SR-PVC Single pack 034G7074

oduct type

ode no

2

Connections

Dimensions

A2 black

A1 white

B1 red

B2 green

34G210.10

8 meters / 26.2 feet

Manufacturing date

Meters / Feets

Country

34G209.10

Ø 63 mm / 1/4 inch

35 mm / 1.4 inch2 meters / 6.6 feet

49 mm / 1.9 inch

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A.02 | 4

Danfoss

027H325.10

D

a

n

f

o

ss

027H325.10

Data sheet | Electric 3-way valve type CTR 20

Valve design

1. M12 connector

2. Actuator

3. Spindle

4. Valve housing

5. Connection 1

6. Connection 3

7. Connection 2

8. Valve cone

1

2

3

4

5

8

6

7

Flow direction

1 inlet 2 outlets

Connection 3 is always

common inlet

2 inlets 1 outlet

Connection 3 is always

common outlet

CTR Valve can be used in following ways

as shown in the drawings.

Danfoss

R64-3023.10

Danfoss

R64-3022.10

Danfoss

xxxx.10

Danfoss

27H002.10

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A.02 | 5

MT Evaporator

Data sheet | Electric 3-way valve type CTR 20

Coolselector®2

is a Danfoss calculation and selection software, designed to make selection processes for all

refrigerationprojects easier and less time consuming.

For fast and precise selection of valve, use Danfoss’ CoolSelector2® software.

You can download it from http://coolselector.danfoss.com

Application example

MT/IT

Heat Recovery

o

55

C

LT Evaporator

Danfoss

R64-3024.10

AKS

AKS

AKVH

AKS

CCMT

AKS

HP High Pressure

Receiver Pressure

MT Suction Pressure

LT Suction Pressure

40oC

MM

CTR

CTR

CCMT

© Danfoss | DCS (sw) | 2018.07

In CO2 systems, the higher pressure and

temperature make it possible to recover heat

for tap water and heating. The excess heat is

removed using a gas cooler.

Regulation is carried out during transcritical and

subcritical states and the controller will control

the gas pressure/condensing pressure so that

the system achieves the optimum COP when the

recovered heat is taken into account.

The regulation of the heat recovery circuits is

done with regard to the cooling system. In the

event of conict, the safety situation is that the

cooling system has higher priority than the

recovery circuits.

The two heat recovery circuits can be considered

as independent circuits - also with regard to the

cooling system.

First, the circuit for hot tap water will take the

energy it needs to use. The remaining energy is

then available for use by the next circuit. This also

takes what is available. If there is then any excess

energy, this is removed via the gas cooler. There

must be a cooling requirement in order to supply

for heat recovery.

DKRCC.PD.VL0.A.02 | 6

Data sheet | Electric 3-way valve type CTR 20

Application example

Hot water Heat reclaim

AKS

Pump

CTR

CTR Valve provides Modulating operation to ensure smooth transition avoiding too many Compressor

on/o when going from Heat reclaim mode to full through Gas Cooler.

In the above example, the 3-way valve switches

to enable ow of hot gas to enter heat reclaim

heat exchanger. Here heat is transitioned to the

water loop hence the Hot Gas is cooled. On the

diagram, rst heat is used for Hot Tap water and

then with a second 3-way valve heat used for

55 °C 40 °C

AKS

Pump

CTR

CTR

Danfoss

27H432.10

the heating loop for the building, nally a third

3-way valve is mounted to enable by-pass of the

gas cooler if that is needed. E.g. in a very cold

season, where the pressure would drop too much

after recovering all the heat in the plate heat

exchangers.

Warning

If the pressure drop in the heat exchanger and

connecting pipes are less than 3 bar, the valve

can be installed in any way the users likes based

on the application. However, if there for some

reason is a larger pressure drop than the MOPD

of the valve then the right connection of the

valve, as shown on the following diagram, is

important for safety reasons.

Heat recovery

Danfoss

R64-3029.10

If the connections is done as shown in the

diagram, then the valve will always be able to

go out of heat recovery mode and will always

be able to let the gas cooler into operation

no matter what pressure drop is in the heat

exchanger and piping. Therefore, Danfoss advises

that the valve is always installed according to the

diagram.

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A.02 | 7

B1

A1

A2

Flow direcon 3 - > 2

K

v

Vs % Opening

Data sheet | Electric 3-way valve type CTR 20

Flow characteristics

30

25

20

15

Value

v

K

10

5

0

Danfoss

27H440.11

5

0

10

20

15

25

35

30

40

50

45

60

55

65

75

70

80

85

Flow direcon 1 - > 3

Flow direcon 3 - > 1

Flow direcon 2 - > 3

95

90

100

Driving CTR valve CTR valve uses a bipolar, 2-phase, permanent magnet stepper motor.

CTR valve can be driven using various electronic control techniques i.e: Full step excitation mode, half

step excitation mode, micro stepping mode (recommended).

On selecting controller from other manufacturer than Danfoss, it is necessary to set the correct

valve data into the controller setting. The wrong settings may impair the performance of the valve.

a. Total no. of step

b. Step rate

c. Phase current

d. Overdriving against closing position

Note:

If the controller driving the CTR valve is from another manufacturer than Danfoss or a custom design,

the following points must be considered in order to overcome potential step loss.

To ensure total closing of the valve, and to compensate the lost steps after a dened number of

changes in opening degree, the controller should have a function to overdrive the valve in the closing

direction. It is recommended to overdrive the valve at appropriate intervals.

Cable length

Depending on the type of controller or driver, there will be limitations in cable length between the

controller / driver and the valve.

Both the actual cable length, the level of EMC emission on the location and the driver circuit have an

impact on the actual distortion of the current to the motor.

Warning

At power failure the CTR valve will remain in the actual opening position it has at the moment of

power failure, unless a device in the form of a battery backup to the controller is installed.

The following table shows the full step excitation switching

Stepper motor

switch sequence

sequence

Coil I (B) Coil II (A)

STEP

Red Green White Black

1 + - + -

CLOSING

2 + - - +

3 - + - +

4 - + + 1 + - + -

Color code is only valid for Danfoss M12 cable

OPENING

Danfoss cable connections

Pin Wire color

A1 White

A2 Black

B1 Red

B2 Green

Danfoss

B2

34G177.10

CTR valve

1

4

2

3

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A.02 | 8

71 mm / 2.8 in

027H324.10

Dimensions and weight

360 mm / 14.2 in

Danfoss

027H323.10

/ 10.1 in

m

256 m

Related products

Electronic driver, type EKD 316 /

EKD 316C

in

/ 3.6 in

m

92.5 m

54.5 mm / 2.1

53.5 mm / 2.1 in 53.5 mm / 2.1 in

Electronic controller, type EKC 326a

and EKC 313

Electronic driver

type AK-XM 208C

Danfoss

Weight: Approx. 3.2 kg / 7.05 lbs

AKS 11 / AKS 12 temperature sensor

AKS pressure transmitter

© Danfoss | DCS (sw) | 2018.07

DKRCC.PD.VL0.A2.06 | 9

Loading...

Loading...