Page 1

Data Sheet

CTM Liquid valve

Type CTM 1 and CTM 2

Improves COP and lowers swept volume of the MT compressors in all CO2 systems

Liquid Ejector is a part of the CO2 Adaptive

Liquid Management (CALM), Danfoss' solution

to handle liquid in all types of transcritical CO

systems in all climates. Due to higher suction

pressure, Liquid Ejector, together with Adaptive

Liquid Control (ALC), enables lower energy

consumption and better utilization of

evaporators, resulting in operational savings.

Improved system performance results in fewer

or smaller compressors and a minimal suction

accumulator.

2

Liquid Ejector is designed for CO2 transcritical

systems to pump the CO2 liquid from the low

point in the suction accumulator back to the

receiver resulting even in 8 bar pressure lift

after mixing with gas coming from the gas

cooler.

The Liquid Ejector, AK-PC pack controllers, AKCC case controllers, and AK-SM system

manager comprise the Danfoss CALM.

AI283050886671en-000501

Page 2

Pressure

Danfoss

32F996.12

P

H

P

L

P

S

P

D

P

H

P

D

P

L

P

S

1

2 3

4 5

6

7

12345

67Nozzle

Throat

Exit

Mixing chamber

Diuser

Intake due to pressure dierential

Pressure increase due to reducing ow

velocity

CTM Liquid valve , Type CTM 1 and CTM 2

Features

First Cost savings

• Lower cost compared to standard booster system due to lower swept volume of compressors (i.e. smaller

compressors or less number of compressors).

• Reliable and robust design

• Fully integrated solution not requiring any additional components like check valves or motorized ball valves

• Fully serviceable - wide range of spare parts and accessories

• Easily accessible strainer / lter for fast maintenance

• Brings rst cost savings

• Enables 5 - 10 % savings on compressor swept volume, compared to standard booster systems

Fast Pay Back – Energy saving

• Improved COP and lower swept volume to the MT compressors , resulting in lower energy consumption.

• Savings for end users

• Fast payback – lower energy consumption

• Less compressors and higher eciency on the systems, leads to shorter payback time of less than 2 years on

avarage globally

• The combination of CTM 1 and CTM 2 Liquid valve and the Danfoss CALM controllers ensure an easy setup and

commissioning, robust control of the system that ensures many years of problem free operation

Functions

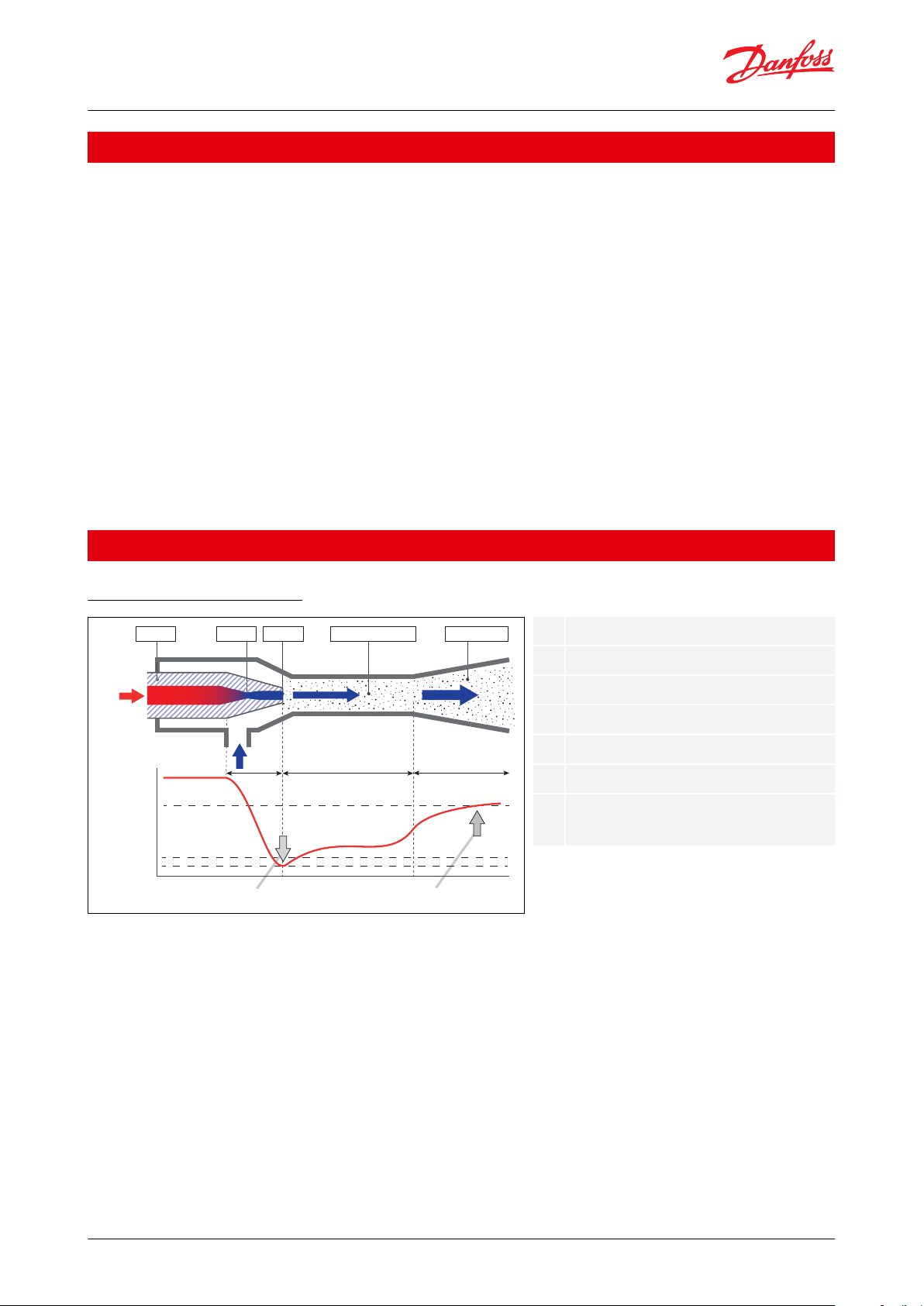

The Multi Ejector function

An ejector is a device that uses expansion energy to compress another uid. In this case with the transcritical system

there is up to 20% of the compressor work that can theoretically be recovered in the expansion.

In this case with the Multi Ejector system the work is coming from the CO2 leaving the gas cooler. The high pressure

CO2 (PH) is entering the nozzle where the expansion is taking place. At the exit of the nozzle the speed is very high

and as a consequence of that the pressure is low.

This low pressure is used to drag liquid from the MT suction accumulator (PL). From there the two ows are mixed in

the mixing chamber where the pressure will be lower than at the drive inlet due to the mixing of vapour from a

higher pressure.

After the mixing the ow enters the diuser where the ow is slowed down. The shape of the diuser enables the

conversion from kinetic energy (velocity) to potential energy (pressure). After the diuser the ow is returned to the

receiver.

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 2

Page 3

Danfoss

R64-2121_30

AK-PC 782A

AKVH

Medium temp. load

MBS 8250

MBS 8250

AKS 4100

AKS 11

AK-CC 550A

AKS 11

FC 103

DGS

CCMT

(ICMTS)

CCMT

(ICMTS)

MBS

8250

MBS

8250

LT

AKS 11

FC 103

Multi

Ejector

Gas cooler

AKS 11

AKS 11

Low temp. load

MBS 8250

AKS 11

AKS 32R

AKS 32R

AK-CC 550A

AKVH

AKS 11

MT

AK-SM 8xx

AKS 21A

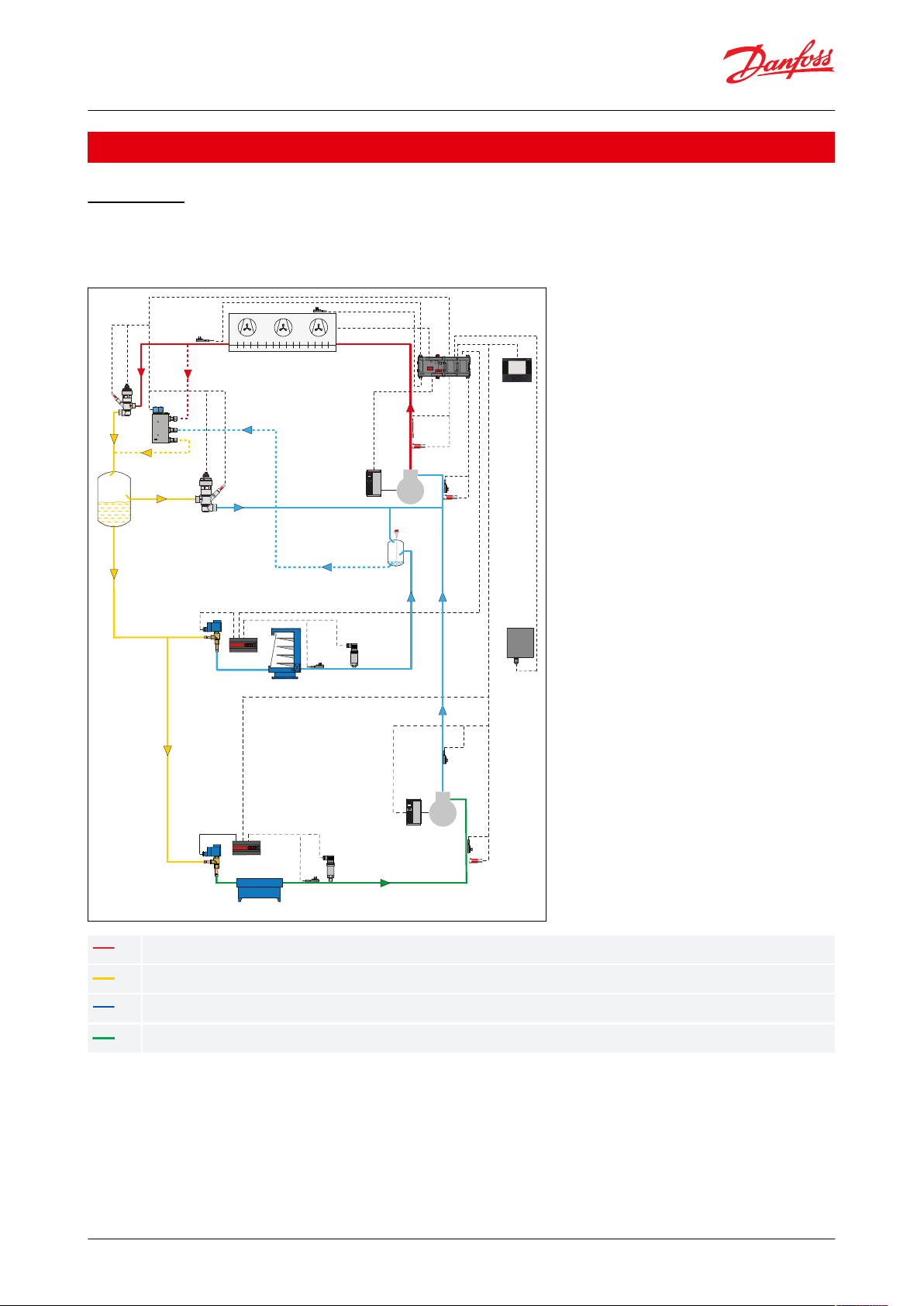

HP High Pressure (120-140 bar Max working pressure)

HP Receiver Pressure (60-90 bar Max working pressure)

LP Suction Pressure MT (35-55 bar Max working pressure)

LP Suction Pressure LT (25-30 bar Max working pressure)

CTM Liquid valve , Type CTM 1 and CTM 2

Applications

Application

The Multi Ejector is designed to lift a part of the liquid from MT suction and mix it with the gas coming from the gas

cooler at medium pressure level.

Figure 1: Application

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 3

Page 4

Refrigerant

R744 with oil

Maximum working pressure

140 bar / 2031 psi

Max. test pressure

1.43 x 140 bar / 1.43 x 2031 psi

Max. OPD

90 bar / 1305 psi (for single-voltage coil, 50 Hz)

Min. OPD

< 0.1 bar / 1.45 psi

Max. pres. dif. E and C connections

20 bar / 290 psi

Media temp. range

-10 °C – +50 °C / +14 °F – 122 °F

Ambient temp. range

-10 °C – +50 °C / +14 °F – 122 °F

Humidity

0 − 100% R.H. (0-97% R.H. non-condensation condition if IP level is below IPX5)

Housing

Aluminium AW-6082 T6

Connections

Stainless steel AISI 304

Ejectors

Brass

Screws

Stainless steel A2-70

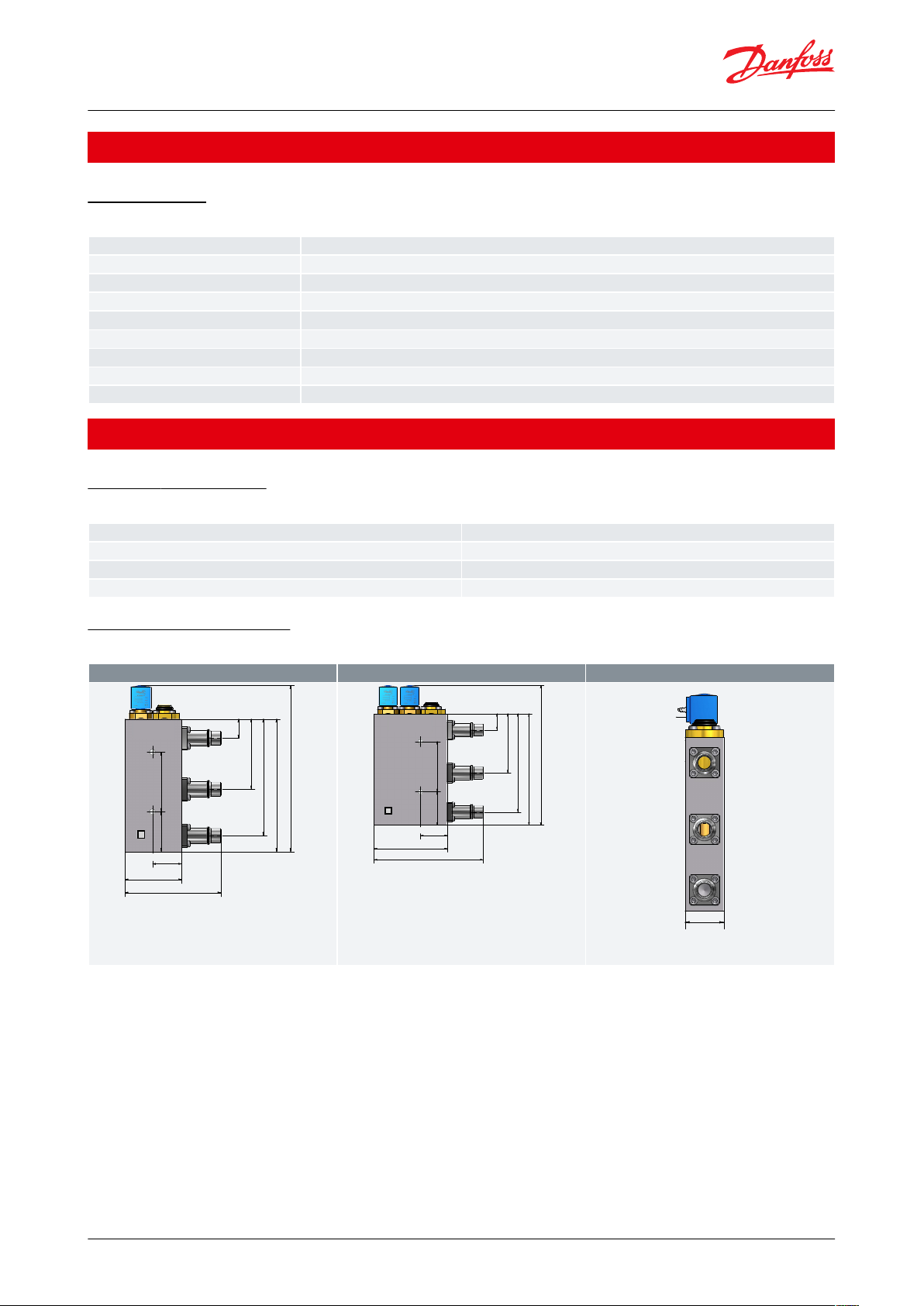

CTM 1 [Weight: 2.6 Kg / 5.7 lb]

CTM 2 [Weight: 3.6 Kg / 7.9 lb]

250.7 mm / 9.9 inch

200 mm / 7.9 inch

176 mm / 6.9 inch

106 mm / 4.2 inch

47.3 mm / 1.86 inch

92.5 mm / 3.6 inch

156.5 mm / 6.16 inch

60

90

29 mm / 1.14 inch

Danfoss

32F889.10

250.7 mm / 9.9 inch

200 mm / 7.9 inch

176 mm / 6.9 inch

106 mm / 4.2 inch

29 mm / 1.14 inch

131 mm / 5.16 inch

195 mm / 7.7 inch

47.25 mm / 1.86 inch

60

90

Danfoss

32F890.10

Danfoss

32F888.10

45 mm /

1.77 inch

CTM Liquid valve , Type CTM 1 and CTM 2

Media

Technical data

Table 1: Technical data

Product specication

Material specication

Table 2: Material specication

Dimensions and weights

Table 3: Dimensions and weights

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 4

Page 5

ACE

1234567

1

2

3

4

5

E

A

C

3

4

5

E

A

C

2

1

6

7

Gas cooler outlet - Ball valve - inlet connector

Combi brazing 1/2 inch ODF - weld 5/8 inch

(EN10220)

Suction connector. MT evaporator outlet - Ball

valve - suction connector.

Combi brazing 1/2 inch ODF - weld 5/8 inch

(EN10220)

Common outlet connector - Ball valve - Receiver

Combi brazing 1/2 inch ODF - weld 5/8 inch

(EN10220)

Label

Strainer

High pressure inlet

Suction inlet

Receiver

Ejector 1

Ejector 2

CTM Liquid valve , Type CTM 1 and CTM 2

Connector positions

Figure 2: Connector positions

Mounting order of ejectors for CTM 2:

Ejectors with the highest capacities (longest ejectors) must be placed closest to the suction connector C.

Any blank ejector should be placed after the ejectors.

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 5

Page 6

Danfoss

32F1019.10

E E

S

ESEjector

Strainer

1.2.1.

2.

Type

Code no.

Product name

Ejector 1

Ejector 2

CTM 1

032F5683

CTM Multi Ejector LE 200

CTM ELE 200

-

CTM 1

032F5684

CTM Multi Ejector LE 400

CTM ELE 400

-

CTM 2

032F5694

CTM Multi Ejector LE 400

CTM ELE 200

CTM ELE 200

CTM 2

032F5685

CTM Multi Ejector LE 600

CTM ELE 200

CTM ELE 400

CTM 2

032F5695

CTM Multi Ejector LE 800

CTM ELE 400

CTM ELE 400

Image

Part

Type

Capacity - HP Mass

ow

Description

Code no. Single

pack

[kg/h]

[lb/h]

Ejectors

CTM ELE 200

200

441

1. Completely assembled ejector with O-rings

already mounted

032F9110

CTM ELE 400

400

882

1. Completely assembled ejector with O-rings

already mounted

032F9111

Image

Part

Type

Description

Code no. Single pack

X 1

X 2

X 2

X 6

Strainer

CTM strainer

Mesh only

2 sets of 2 O-rings

032F9113

O-rings

CTM O-rings

2 sets of 2 O-rings for strainer

6 sets of 3 O-rings for ejectors

032F9114

Connectors

DN 15

Connector + O-ring

032F9115

CTM Liquid valve , Type CTM 1 and CTM 2

Ordering

Valve conguration

Figure 3: Valve conguration

Accessories

Spare parts

Table 4: Ejectors

Table 5: Strainer, O-rings and Connectors

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 6

Page 7

Image

Type

Voltage

Frequency / Power consumption

Code no. Single

pack

[V]

[Hz]

[W]

[Hz]

[W]

with DIN plug

(1)

AS230CS

230508607

042N7601

AZ120CS

110 - 120508.5607

042N4202

Image

Type

Voltage [V]

Frequency

Code no. Single pack

DIN plug (LED)

230

50 / 60

042N0265

(1)

DIN plug

Max. 250

50 / 60

042N0156

Type

Capacity - Mass

ow

(1)

Capacity - Mass

ow

(2)

Code no. Single pack

[kg/h]

[lb/h]

CTM 1 LE 200

200

441

032F5683

CTM 1 LE 400

400

882

032F5684

CTM Liquid valve , Type CTM 1 and CTM 2

DIN spade connection

Table 6: DIN spade connection

(1)

(1)

The three pins on the coil can be tted with spade tabs, 6.3 mm wide (to DIN 46247). The two current carrying pins can also be tted with

The three pins on the coil can be tted with spade tabs, 6.3 mm wide (to DIN 46247). The two current carrying pins can also be tted with

spade tabs, 4.8. mm wide. Max. lead cross section: 1.5 mm2.

spade tabs, 4.8. mm wide. Max. lead cross section: 1.5 mm2.

Voltage variation: V AC -15% - 10%, If DIN plug is used (DIN 43650) the leads must be connected in the socket. The

socket is tted with a Pg 11 screwed entry for 6 – 12 mm.

Plug for DIN spade connection

Table 7: Plug for DIN spade connection

(1)

(1)

Only for AS230CS

Only for AS230CS

Multi Ejector

Figure 4: CTM 1

Table 8: Multi Ejector CTM 1

(1)

(1)

R744 at 40 bar / 5 °C

R744 at 40 bar / 5 °C

(2)

(2)

R744 at 580 psi / 40 °F

R744 at 580 psi / 40 °F

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 7

Page 8

Type

Capacity - Mass ow

(3)

Capacity - Mass ow

(4)

Code no. Single pack

[kg/h]

[lb/h]

CTM 2 LE 400

400

882

032F5694

CTM 2 LE 600

600

1323

032F5685

CTM 2 LE 800

800

1764

032F5695

CTM Liquid valve , Type CTM 1 and CTM 2

Figure 5: CTM 2

Table 9: Multi Ejector CTM 2

(3)

(3)

R744 at 40 bar / 5 °C

R744 at 40 bar / 5 °C

(4)

(4)

R744 at 580 psi / 40 °F

R744 at 580 psi / 40 °F

(LE = Liquid ejector)

(The above code numbers are without coils which should be ordered separately – see coil ordering below).

Danfoss CALM controllers

Pack controller AK-PC 782A

Danfoss oers a wide range of market leading Pack Controllers.

Being the ag ship and best in class controller for transcritical CO2 packs controls, the AK-PC 782A oers the highest

possible eciency with the Multi Ejector, CTM.

The complete application control features:

• Complete booster pack control of up to 3 suction groups (max. 12 compressors) and high pressure system

• Signicant savings with heat recovery for tap water and heat reclaim

•

Extensive control of oil ow and pressurization

• Best in class safety monitoring and fail-safe functions

• Minimal energy consumption while ensuring optimal food quality

• Auto-congured, easy-to-use graphical representation with Danfoss System Manager

• Independent, customised control and monitoring of auxiliary function

Case controllers AK-CC 550A and AK-CC 750A

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 8

Page 9

CTM Liquid valve , Type CTM 1 and CTM 2

Danfoss AK-CC 550A and AK-CC 750A case controllers manage refrigerated display cases, cold rooms, or

refrigeration cabinets. Controlling Electronic Expansion Valves (EEV), they optimize evaporator utilization and

energy consumption using the Minimum Stable Superheat (MSS) or new Adaptive Liquid Control (ALC) algorithm,

giving you the best possible refrigeration capacity from the energy consumed and ensuring food safety.

AK-SM 8xx system manager

The Danfoss AK-System Manager (AK-SM) is a modern solution for the food retail markets. The AK-SM uses the latest

technology to provide the maximum benet to the end user, both in terms of energy saving optimization, control

options and user friendly access.

AK-SM ensures a shift mode of operation in AK-CC case controllers: Minimum Stable Superheat (MSS) or Adaptive

Liquid Control (ALC) based on feedback from pack controller AK-PC.

Disclaimer

WARNING:

The CTM Multi Ejector valve is approved for use only with Danfoss pack controller type AK-PC 78x, AK-CC 550A or

AK-CC 750A and system manager AK-SM 8xx.

Danfoss expressly disclaims, and any responsibility or liability, whether based on contract, breach of warranty, tort,

statute or otherwise, shall be excluded, if the CTM Multi Ejector valve is used with any controller other than a

Danfoss controller type AK-PC 78x, AKCC 550A or AK-CC 750A and AK-SM 8xx.

For further information on AK-PC, AK-CC and AK-SM, please see separate document.

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 9

Page 10

File name

Document type

Document topic

Approval authority

Danfoss 032F9627.AA

Manufacturers Declaration

PED

Danfoss

UL SA45046

Mechanical - Safety C

erticate

-

UL

CTM Liquid valve , Type CTM 1 and CTM 2

Certicates, declar

ations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Certicates, declarations, and approvals

Table 10: C

AS230CS: LLC CDC TYSK; The Low Voltage Directive 2014/35/EU (LVD);

Electromagnetic Compatibility Directive 2014/30/EU (EMC)

AZ120CS: C UR US; LLC CDC TYSK; The Low Voltage Directive 2014/35/EU

(LVD); Electromagnetic Compatibility Directive 2014/30/EU (EMC)

erticates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 11

Loading...

Loading...