Danfoss CTM 1, CTM 2 Data sheet

Data Sheet

CTM Liquid valve

Type CTM 1 and CTM 2

Improves COP and lowers swept volume of the MT compressors in all CO2 systems

Liquid Ejector is a part of the CO2 Adaptive

Liquid Management (CALM), Danfoss' solution

to handle liquid in all types of transcritical CO

systems in all climates. Due to higher suction

pressure, Liquid Ejector, together with Adaptive

Liquid Control (ALC), enables lower energy

consumption and better utilization of

evaporators, resulting in operational savings.

Improved system performance results in fewer

or smaller compressors and a minimal suction

accumulator.

2

Liquid Ejector is designed for CO2 transcritical

systems to pump the CO2 liquid from the low

point in the suction accumulator back to the

receiver resulting even in 8 bar pressure lift

after mixing with gas coming from the gas

cooler.

The Liquid Ejector, AK-PC pack controllers, AKCC case controllers, and AK-SM system

manager comprise the Danfoss CALM.

AI283050886671en-000501

Pressure

Danfoss

32F996.12

P

H

P

L

P

S

P

D

P

H

P

D

P

L

P

S

1

2 3

4 5

6

7

12345

67Nozzle

Throat

Exit

Mixing chamber

Diuser

Intake due to pressure dierential

Pressure increase due to reducing ow

velocity

CTM Liquid valve , Type CTM 1 and CTM 2

Features

First Cost savings

• Lower cost compared to standard booster system due to lower swept volume of compressors (i.e. smaller

compressors or less number of compressors).

• Reliable and robust design

• Fully integrated solution not requiring any additional components like check valves or motorized ball valves

• Fully serviceable - wide range of spare parts and accessories

• Easily accessible strainer / lter for fast maintenance

• Brings rst cost savings

• Enables 5 - 10 % savings on compressor swept volume, compared to standard booster systems

Fast Pay Back – Energy saving

• Improved COP and lower swept volume to the MT compressors , resulting in lower energy consumption.

• Savings for end users

• Fast payback – lower energy consumption

• Less compressors and higher eciency on the systems, leads to shorter payback time of less than 2 years on

avarage globally

• The combination of CTM 1 and CTM 2 Liquid valve and the Danfoss CALM controllers ensure an easy setup and

commissioning, robust control of the system that ensures many years of problem free operation

Functions

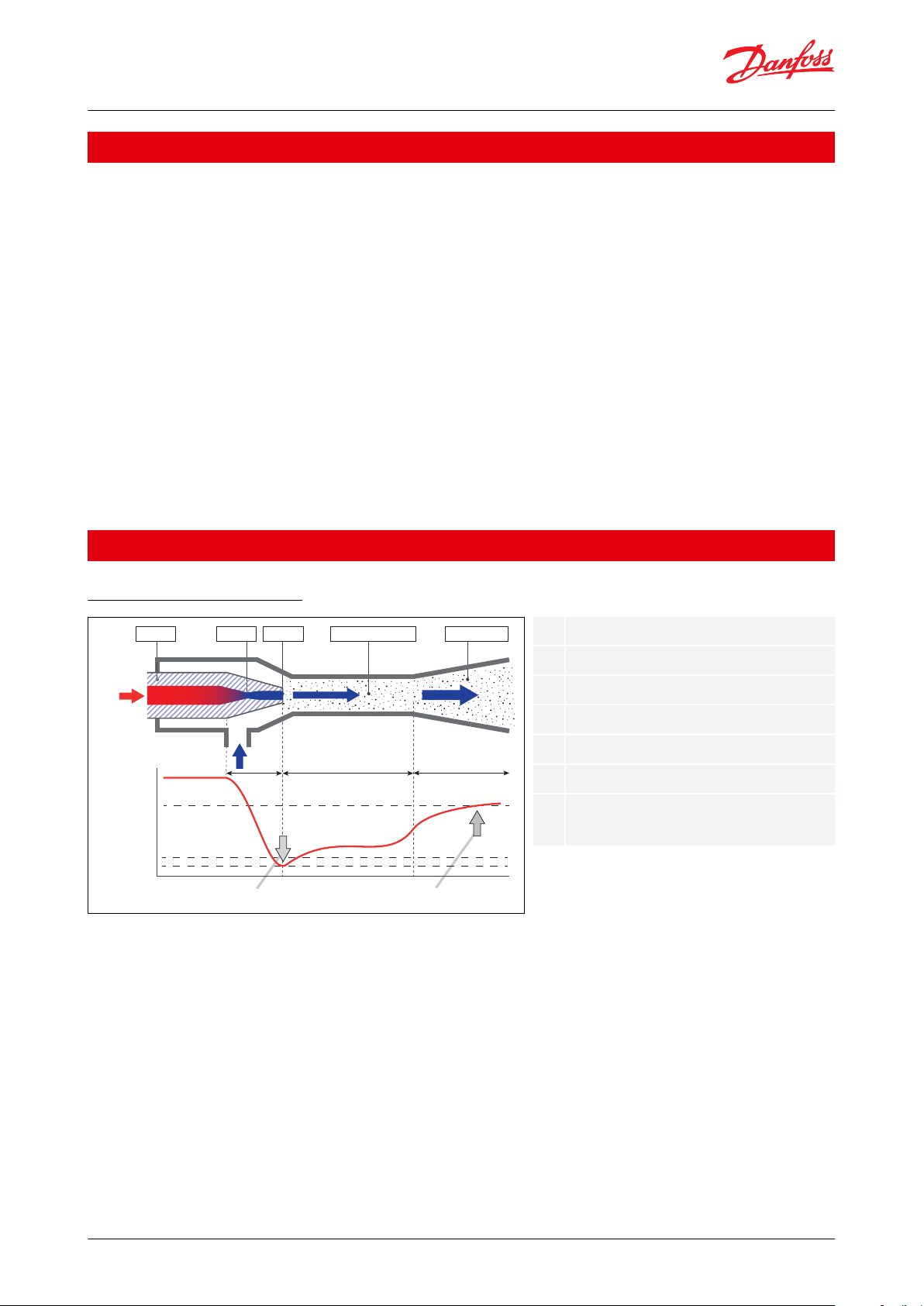

The Multi Ejector function

An ejector is a device that uses expansion energy to compress another uid. In this case with the transcritical system

there is up to 20% of the compressor work that can theoretically be recovered in the expansion.

In this case with the Multi Ejector system the work is coming from the CO2 leaving the gas cooler. The high pressure

CO2 (PH) is entering the nozzle where the expansion is taking place. At the exit of the nozzle the speed is very high

and as a consequence of that the pressure is low.

This low pressure is used to drag liquid from the MT suction accumulator (PL). From there the two ows are mixed in

the mixing chamber where the pressure will be lower than at the drive inlet due to the mixing of vapour from a

higher pressure.

After the mixing the ow enters the diuser where the ow is slowed down. The shape of the diuser enables the

conversion from kinetic energy (velocity) to potential energy (pressure). After the diuser the ow is returned to the

receiver.

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 2

Danfoss

R64-2121_30

AK-PC 782A

AKVH

Medium temp. load

MBS 8250

MBS 8250

AKS 4100

AKS 11

AK-CC 550A

AKS 11

FC 103

DGS

CCMT

(ICMTS)

CCMT

(ICMTS)

MBS

8250

MBS

8250

LT

AKS 11

FC 103

Multi

Ejector

Gas cooler

AKS 11

AKS 11

Low temp. load

MBS 8250

AKS 11

AKS 32R

AKS 32R

AK-CC 550A

AKVH

AKS 11

MT

AK-SM 8xx

AKS 21A

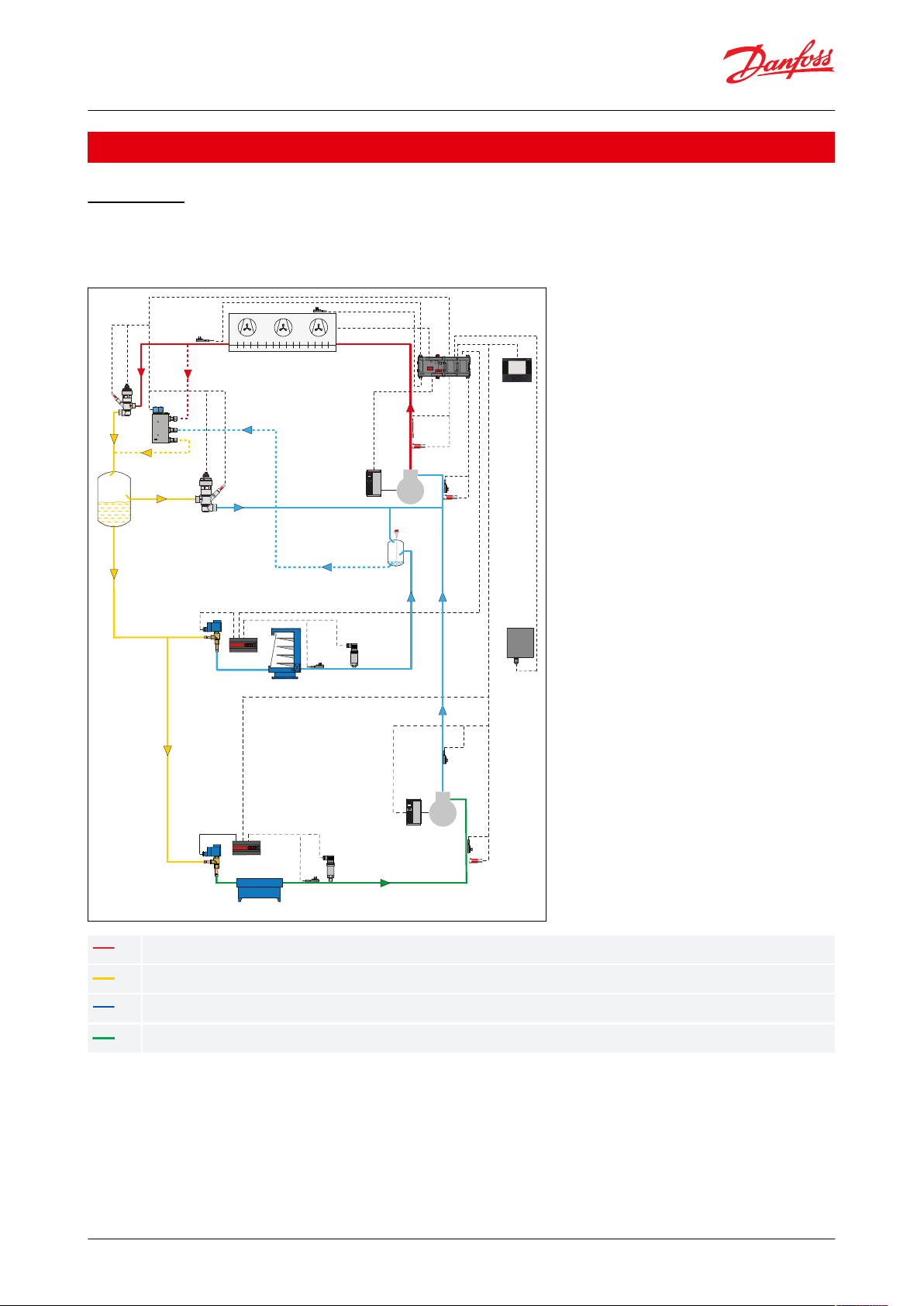

HP High Pressure (120-140 bar Max working pressure)

HP Receiver Pressure (60-90 bar Max working pressure)

LP Suction Pressure MT (35-55 bar Max working pressure)

LP Suction Pressure LT (25-30 bar Max working pressure)

CTM Liquid valve , Type CTM 1 and CTM 2

Applications

Application

The Multi Ejector is designed to lift a part of the liquid from MT suction and mix it with the gas coming from the gas

cooler at medium pressure level.

Figure 1: Application

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 3

Refrigerant

R744 with oil

Maximum working pressure

140 bar / 2031 psi

Max. test pressure

1.43 x 140 bar / 1.43 x 2031 psi

Max. OPD

90 bar / 1305 psi (for single-voltage coil, 50 Hz)

Min. OPD

< 0.1 bar / 1.45 psi

Max. pres. dif. E and C connections

20 bar / 290 psi

Media temp. range

-10 °C – +50 °C / +14 °F – 122 °F

Ambient temp. range

-10 °C – +50 °C / +14 °F – 122 °F

Humidity

0 − 100% R.H. (0-97% R.H. non-condensation condition if IP level is below IPX5)

Housing

Aluminium AW-6082 T6

Connections

Stainless steel AISI 304

Ejectors

Brass

Screws

Stainless steel A2-70

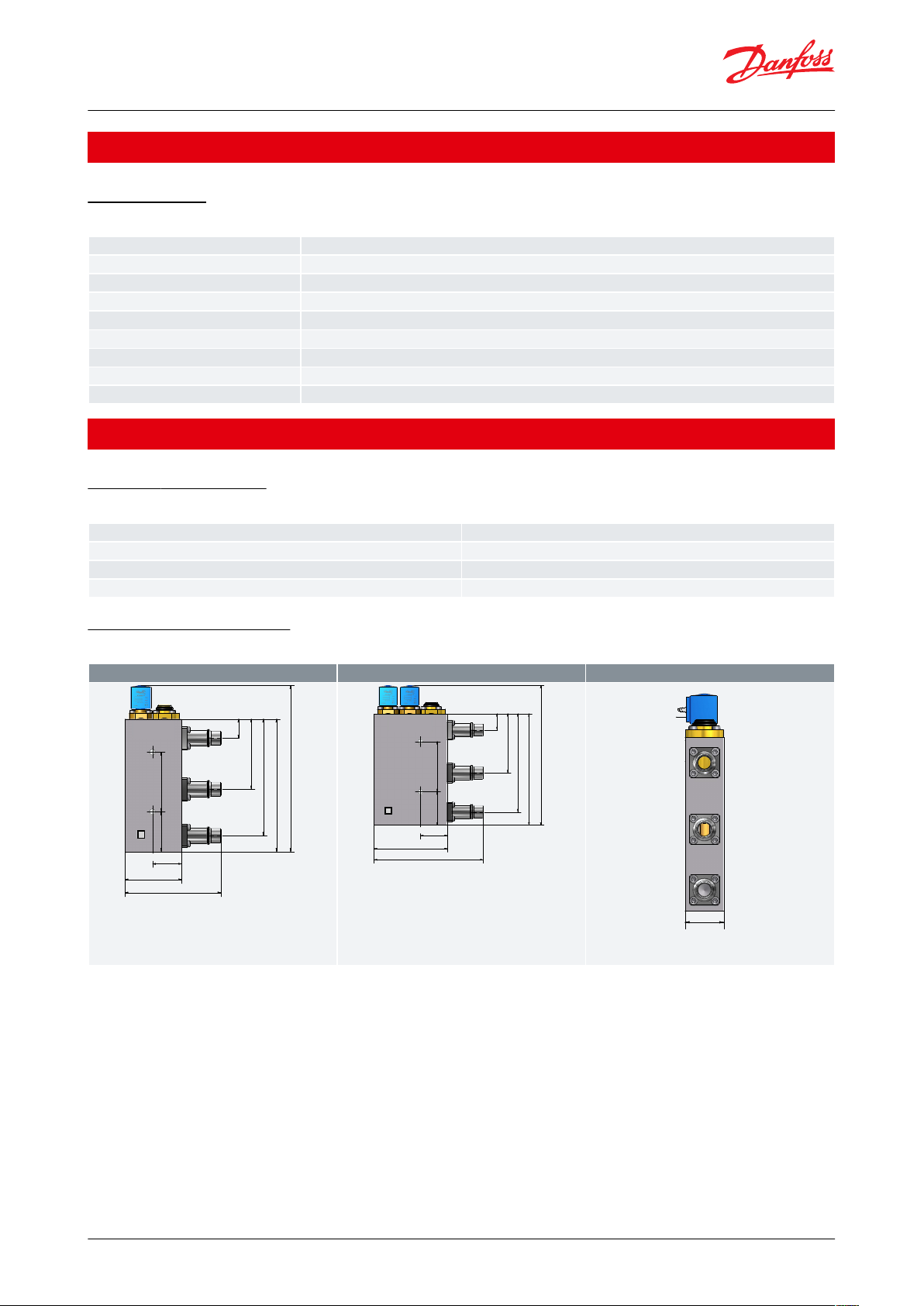

CTM 1 [Weight: 2.6 Kg / 5.7 lb]

CTM 2 [Weight: 3.6 Kg / 7.9 lb]

250.7 mm / 9.9 inch

200 mm / 7.9 inch

176 mm / 6.9 inch

106 mm / 4.2 inch

47.3 mm / 1.86 inch

92.5 mm / 3.6 inch

156.5 mm / 6.16 inch

60

90

29 mm / 1.14 inch

Danfoss

32F889.10

250.7 mm / 9.9 inch

200 mm / 7.9 inch

176 mm / 6.9 inch

106 mm / 4.2 inch

29 mm / 1.14 inch

131 mm / 5.16 inch

195 mm / 7.7 inch

47.25 mm / 1.86 inch

60

90

Danfoss

32F890.10

Danfoss

32F888.10

45 mm /

1.77 inch

CTM Liquid valve , Type CTM 1 and CTM 2

Media

Technical data

Table 1: Technical data

Product specication

Material specication

Table 2: Material specication

Dimensions and weights

Table 3: Dimensions and weights

© Danfoss | Climate Solutions | 2021.03 AI283050886671en-000501 | 4

Loading...

Loading...