Page 1

Data Sheet

Solenoid valve and coil

Type CSV 2 - CSV 22

Normally Closed (NC)

CSV is a direct or servo-operated solenoid valve

for liquid, suction, and hot gas lines with

common uorinated refrigerants.

CSV valves are for refrigeration, freezing, and air

conditioning plants.

CSV valves and coils are sold separately.

Features

• Designed for media temperatures up to 105

°C / 221 °F

• Supplied as normally closed (NC) with deenergized coil

• Wide choice of coils for AC and DC

• Suitable for listed refrigerants, including

ammable refrigerants

• Available in are and solder connection

3

⁄8 in

1

⁄2 in

versions Flare connections up to

• Solder connections up to 1

• Small encapsulated coils with long life time

under extreme conditions.

• Compact construction with small dimensions,

low weight for both valve and coil

• Simple and fast mounting of coil - clip-ON /

OFF

AI153586441354en-000801

Page 2

Features

Description

Refrigerant

R22, R134a, R404A, R507, R407C, R513A, R452A, R1234ze, R600, R600a and R290.

Temperature of medium

-40 – 105 °C / -40 – 221°F (Maximum 130 °C / 265 °F during defrosting)

Maximum working pressure

35 bar / 508 psig

Solenoid valve and coil, Type CSV 2 - CSV 22

Media

Table 1: Media features

For a complete list of approved refrigerants, visit store.danfoss.com and search for individual code numbers, where

refrigerants are listed as part of technical data.

NOTE:

Special note for R1234ze(E), R290, R600 and R600a: Ignition risk is evaluated in accordance to ISO 5149 and IEC

60335. EX range Zone 2(category 3 IIA).

For countries where safety standards are not an indispensable part of the safety system Danfoss recommends the

installer gets a third party approval of any system containing ammable refrigerant.

NOTE:

• Please follow specic selection criteria stated in the data sheet for these particular refrigerants.

• CSV is not suitable for oil free application. For detailed informations please contact Danfoss

• Flare connections are only approved for A1 and A2L refrigerants.

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 2

Page 3

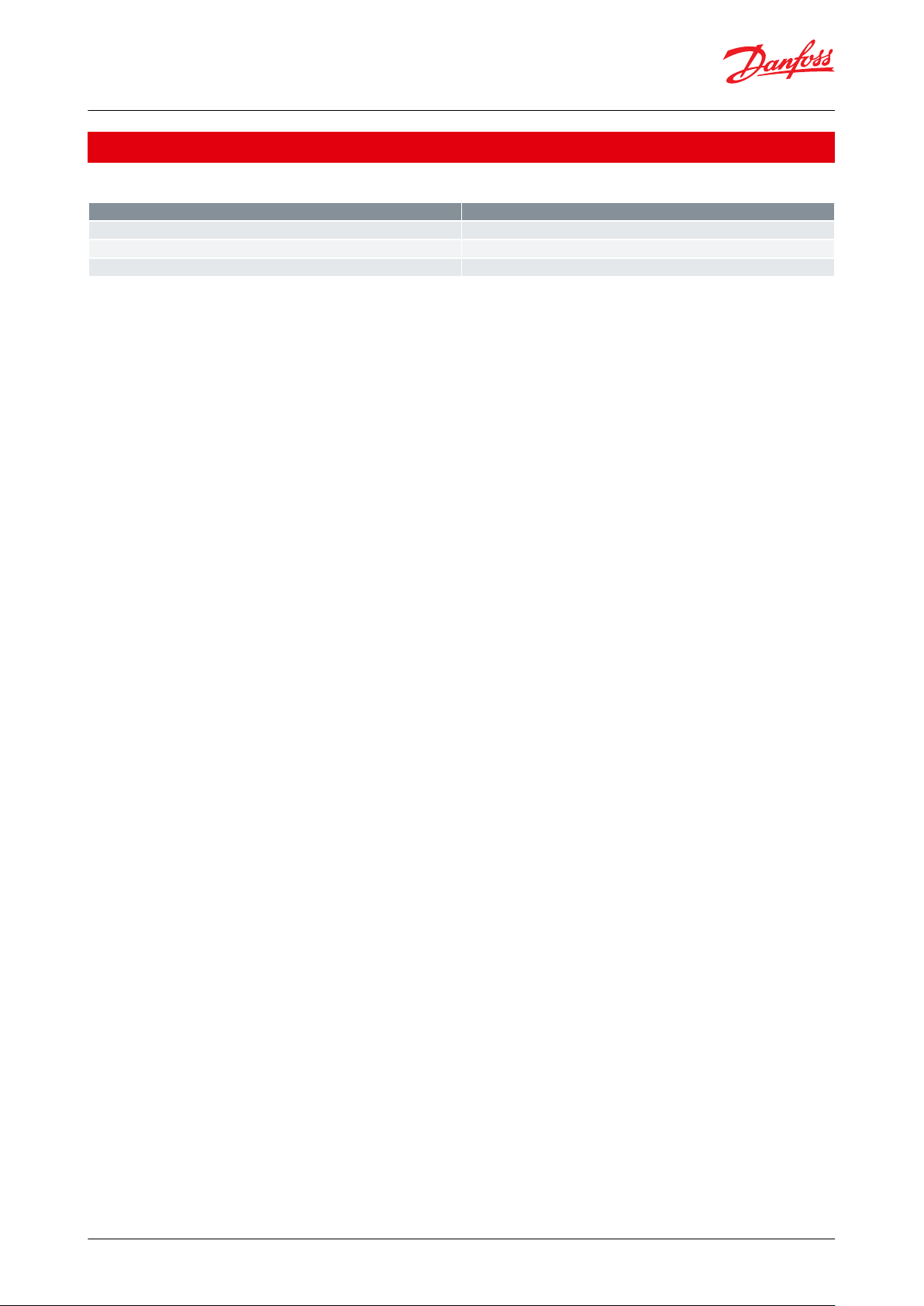

Type

Kv (m3/h)

R22/R407C

R134a

R404A/R507

R290

R513A

R452A

R600

R600a

R1234ze(E)

CSV 2

0.1

2.01

1.86

1.36

2.24

1.66

1.38

2.53

2.25

1.66

CSV 3

0.3

6.03

5.58

4.09

6.72

4.97

4.15

7.6

6.76

4.99

CSV 6

0.54

10.86

10.05

7.35

12.09

8.95

7.48

13.69

12.18

8.98

CSV 10

1.5

30.17

27.91

20.43

33.59

24.85

20.76

38.02

33.82

24.93

CSV 15

2.6

52.3

48.38

35.41

58.22

43.07

35.99

65.89

58.62

43.22

CSV 20

5

100.57

93.04

68.1

111.96

82.83

69.22

126.72

112.74

83.12

CSV 22

6

120.68

111.65

81.72NA99.39

83.06NANA

NA

Type

Kv (m3/h)

R22/R407C

R134a

R404A/R507

R290

R513A

R452A

R600

R600a

R1234ze(E)

CSV 2

0.1

0.22

0.16

0.19

0.27

0.16

0.19

0.13

0.15

0.13

CSV 3

0.3

0.67

0.48

0.58

0.82

0.47

0.56

0.38

0.45

0.39

CSV 6

0.54

1.2

0.87

1.05

1.47

0.8410.68

0.82

0.7

CSV 10

1.5

3.33

2.42

2.91

4.08

2.35

2.78

1.89

2.27

1.95

CSV 15

2.6

5.77

4.2

5.04

7.07

4.07

4.81

3.27

3.93

3.38

CSV 20511.1

8.08

9.69

13.6

7.82

9.26

6.3

7.56

6.49

CSV 22613.32

9.69

11.61NA9.38

11.11NANA

NA

Type

K

v

(m3/h)

R22/R407C

R134a

R404A/R507

R290

R513A

R452A

R600

R600a

R1234ze(E)

CSV 2

0.1

0.9

0.69

0.74

1.02

0.64

0.76

0.56

0.63

0.56

CSV 3

0.3

2.69

2.08

2.22

3.07

1.93

2.29

1.68

1.89

1.67

CSV 6

0.54

4.85

3.75

3.99

5.53

3.48

4.12

3.03

3.4

3.01

CSV 10

1.5

13.46

10.38

11.05

15.35

9.66

11.44

8.42

9.45

8.37

CSV 15

2.6

23.34

17.99

19.15

26.61

16.75

19.83

14.6

16.38

14.51

CSV 20544.88

34.59

36.83

51.18

32.21

38.13

28.07

31.5

27.91

CSV 22653.86

41.51

44.2NA38.65

45.76NANA

NA

Solenoid valve and coil, Type CSV 2 - CSV 22

Product specication

Rated capacity [KW]

Table 2: Rated capacity [KW] for Liquid

Table 3: Rated capacity [KW] for Suction

Rated liquid and suction vapour capacity is based on:

• evaporating temperature te = -10 °C

• liquid temperature ahead of valve tl = 25 °C

• pressure drop in valve ∆p = 0.15 bar

Table 4: Rated capacity [KW] for Hot-gas

Rated hot gas capacity is based on:

• condensing temperature tc = 40 °C

• pressure drop across valve ∆p = 0.8 bar

• hot gas temperature th = 65 °C

• subcooling of refrigerant ∆t

sub

= 4 K

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 3

Page 4

L2

B

L

H

A

L2

B

L

A

H

L1

45

L2

B

H

L1

L

A

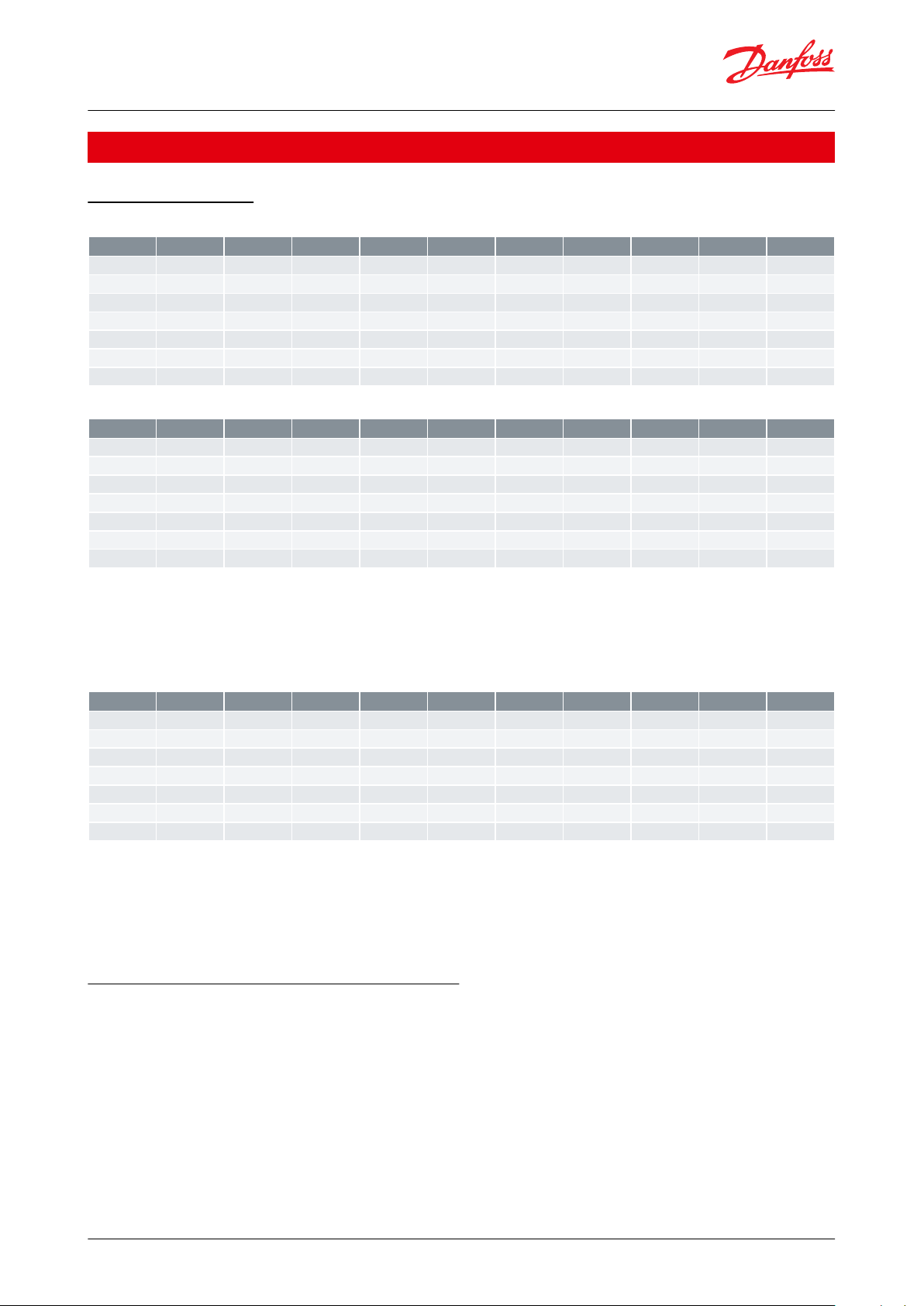

Type

A Connection (ODF)

BHLL1L2

Weight

[in]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

CSV 2

1

⁄4

6195682–340.1

CSV 3

1

⁄4

6196592–340.1

3

⁄8

10196596–340.1

CSV 6

3

⁄8

10196596–340.1

1

⁄2

121965

112–34

0.1

CSV 10

1

⁄2

124673

1425034

0.2

5

⁄8

164673

1425034

0.2

CSV 15

5

⁄8

164674

1676234

0.4

7

⁄8

224676

1676234

0.4

CSV 20

7

⁄8

225382

1776434

0.6

1

1

⁄8

285384

1967434

0.6

CSV 22

1

1

⁄8

286287

2409134

0.9

1

3

⁄8

356289

2409134

0.9

Coil–––––––0.1

Solenoid valve and coil, Type CSV 2 - CSV 22

Dimensions and weights - solder connection

Figure 1: CSV 2 – CSV 6

Figure 2: CSV 10 – CSV 15

Table 5: Dimensions and weights - solder connection

Figure 3: CSV 20 – CSV 22

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 4

Page 5

C

ØB

H3

L

Ø5.2

H1

H2

Type

Connection (are)

BHLCH1H2H3

Weight

[in]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

CSV 2

1

⁄4

6196358134912

7.5

0.085

CSV 3

1

⁄4

6196958135512

7.5

0.096

3

⁄8

10196976155413

8.5

0.128

CSV 6

3

⁄8

10197076155513

8.5

0.128

1

⁄2

12197076155513

8.5

0.137

Solenoid valve and coil, Type CSV 2 - CSV 22

Dimensions and weights - are connection

Figure 4: are connection

Table 6: Dimensions and weights - are connection

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 5

Page 6

Danfoss

32B026

Danfoss

32B04a

Danfoss

32B027

Type

Connection (ODF)

Opening dierential pressure with standard coil ∆P [bar]

K

v

Code no.

[in.]

[mm]

Min.

Max.(=MOPD liquid

(1)

)

m3/h

AC

DC

CSV 2

1

⁄4

−026260.1

032B2040−6026260.1

032B2000

CSV 3

1

⁄4

−

0.052624

0.3

032B2041−6

0.052624

0.3

032B2001

3

⁄8

−

0.052624

0.3

032B2042−10

0.052624

0.3

032B2002

CSV 6

3

⁄8

−

0.052626

0.54

032B2043−10

0.052626

0.54

032B2003

1

⁄2

−

0.052626

0.54

032B2044−12

0.052626

0.54

032B2004

CSV 10

1

⁄2

−

0.052626

1.5

032B2045−12

0.052626

1.5

032B2005

5

⁄8

16

0.052626

1.5

032B2006

CSV 15

5

⁄8

16

0.052626

2.6

032B2007

7

⁄8

22

0.052626

2.6

032B2008

CSV 20

7

⁄8

22

0.052626

5.0

032B2009

1

1

⁄8

−

0.052626

5.0

032B2050−28

0.052626

5.0

032B2010

CSV 22

1

1

⁄8

−

0.052626

6.0

032B2051−28

0.052626

6.0

032B2011

1

3

⁄8

35

0.052626

6.0

032B2012

Danfoss

32B01

Type

Connection (are)

Opening

dierential pressure with standard coil

Δp [bar]

K

v

Code no.

[in.]

[mm]

Min.

Max.(=MOPD liquid

(1)

)

m

3

/h

CSV 2

1

⁄4

–026

0.1

032B2030

CSV 3

1

⁄4

–

0.05260.3

032B2031

3

⁄8

–

0.05260.3

032B2032

CSV 6

3

⁄8

–

0.05260.54

032B2033

1

⁄2

–

0.05260.54

032B2034

Solenoid valve and coil, Type CSV 2 - CSV 22

Ordering

Ordering solder connection

Figure 5: CSV2,3,6

Figure 6: CSV 10,15

Table 7: Ordering - solder connection

Figure 7: CSV 20, 22

(1)

(1)

For detailed MOPD, for media in gas form, please contact Danfoss.

For detailed MOPD, for media in gas form, please contact Danfoss.

Ordering are connection

Figure 8: are connection

Table 8: Ordering - are connection

(1)

(1)

For detailed MOPD, for media in gas form, please contact Danfoss.

For detailed MOPD, for media in gas form, please contact Danfoss.

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 6

Page 7

Danfoss

42N9040.10

Type

Power consumption

Frequency

Voltage[V]

Code no.

[W]

[Hz]

[AC]

CSV 2 – CSV 22

650220

034Z2014

(1)

Danfoss

42N9042

Type

Voltage[V]

Frequency

Power consumption

Code No.

[AC]

[Hz]

Industrial Pack

single pack

CSV2-22

24

50/60

Holding: 6W 12VA Inrush:

26VA

−

042N7608

230

50/60

−

042N7601

240

50/60

−

042N760212DC

14W

042N8686−24DC14W

042N8687

042N7687

Solenoid valve and coil, Type CSV 2 - CSV 22

Ordering solenoid coil with DIN Terminal box IP65

NOTE:

For use with R290, the Coil with DIN Plug (code 034Z2014) is validated in accordance to ISO 5149, IEC 60335 (ref.

IEC/EN 60079-15). Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335 ( ref. IEC/EN 60079-15).

• Please make sure that there is no spark, arc on the spade connection during the application.

• If coils are below IPx5, they must be protected against ultraviolet, moisture and major impact, especially the

connection of coils.

• Always install a fuse ahead of the coil to avoid short circuit.

• The coil should be used in area of not more than pollution degree 2.

• Use of socket cable with suitable mechanical lock function to connect with coils.

• Follow the installation guide to mount the coil correctly.

NOTE:

Please follow specic selection criteria stated in the data sheet for this particular refrigerants.

Ordering coil with DIN Plug

Figure 9: Coil with DIN Plug

Table 9: Ordering - Coil with DIN Plug

(1)

(1)

The 034Z2014 is exclusively for China market, coil and din plug are included, IP65. Spare parts of the coil for other region and DIN plug are

The 034Z2014 is exclusively for China market, coil and din plug are included, IP65. Spare parts of the coil for other region and DIN plug are

available on request.

available on request.

Ordering coil with DIN spade connection

Figure 10: Coil with DIN spade connection

Table 10: Ordering Coil - DIN spade connection

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 7

Page 8

Danfoss

42N9041

Type

Voltage[V]

Frequency

Power consumption

Code No.

[AC]

[Hz]

Industrial Pack

single pack

CSV2-22

115

50/60

Holding: 6W 12VA Inrush:

26VA

−

042N7662

230

50/60

042N8651

042N7651

240

50/60

042N8652

−

Danfoss

42N9043

Description

Code no.

DIN Plug (EN175301-803 type A)

042N0156

Solenoid valve and coil, Type CSV 2 - CSV 22

Ordering coil cable connection

Figure 11: Coil cable connection

Table 11: Coil cable connection

Accessories

Figure 12: DIN Plug with sealing ring

Table 12: Accessories

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 8

Page 9

Certicates, declarations, and approvals

Document name

Document type

Document topic

Approval authority

032B9610

Manufacturers Declaration

PED/RoHS

Danfoss

033F4006

Manufacturers Declaration

China RoHS

Danfoss

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 13: Certicates, declarations, and approvals

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI153586441354en-000801 | 9

Loading...

Loading...