Page 1

Technical Information

PLUS+1® Connect

CS100 IoT Gateway

www.danfoss.com

Page 2

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Revision history Table of revisions

Date Changed Rev

April 2021 Removed GNSS verbiage 0103

January 2021 Added output warning 0102

October 2020 First edition 0101

2 | © Danfoss | April 2021 BC299456869228en-000103

Page 3

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Contents

About this Manual

About this manual............................................................................................................................................................................5

Device elements

Device Information.......................................................................................................................................................................... 6

Indicator elements........................................................................................................................................................................... 6

Type label............................................................................................................................................................................................ 7

Intended use...................................................................................................................................................................................... 7

Service and support.........................................................................................................................................................................8

Product Conformity

CS100.................................................................................................................................................................................................... 9

Compliance with CE................................................................................................................................................................... 9

Compliance with ECE R-10.......................................................................................................................................................9

PTCRB.............................................................................................................................................................................................. 9

PLUS+1® Compliance.................................................................................................................................................................9

Safety information

General information......................................................................................................................................................................10

Safety advice....................................................................................................................................................................................10

Avoid property damage.............................................................................................................................................................. 11

Connecting the supply voltage...........................................................................................................................................12

Polarity reversal.........................................................................................................................................................................12

IP protection rating..................................................................................................................................................................12

Welding guidelines.................................................................................................................................................................. 12

Warranty and liability....................................................................................................................................................................12

Servicing the CS100.................................................................................................................................................................12

Ordering information

Part number.....................................................................................................................................................................................13

Related products............................................................................................................................................................................13

Device Functions

Available variants & functions...................................................................................................................................................14

Operating modes...........................................................................................................................................................................14

GNSS (Global Navigation Satellite System)...........................................................................................................................14

Wireless Solution............................................................................................................................................................................14

SIM card.............................................................................................................................................................................................14

Input/output functions (I/O)......................................................................................................................................................14

CAN interfaces.................................................................................................................................................................................15

Device configuration.................................................................................................................................................................... 15

CS100 firmware update............................................................................................................................................................... 15

Secure connection to the PLUS+1 Connect portal............................................................................................................15

Connector

Main connector...............................................................................................................................................................................16

CS100 Technical Data

Electrical Data..................................................................................................................................................................................17

Mechanical Data.............................................................................................................................................................................17

Interface/Protocol/Certification................................................................................................................................................17

Multifunction inputs..................................................................................................................................................................... 18

Outputs..............................................................................................................................................................................................19

PLUS+1® Connect portal

Problem with connection to PLUS+1® Connect portal.................................................................................................... 20

Packaging and Transport

IP protection rating....................................................................................................................................................................... 21

Disposal............................................................................................................................................................................................. 21

CS100 Technical Drawings

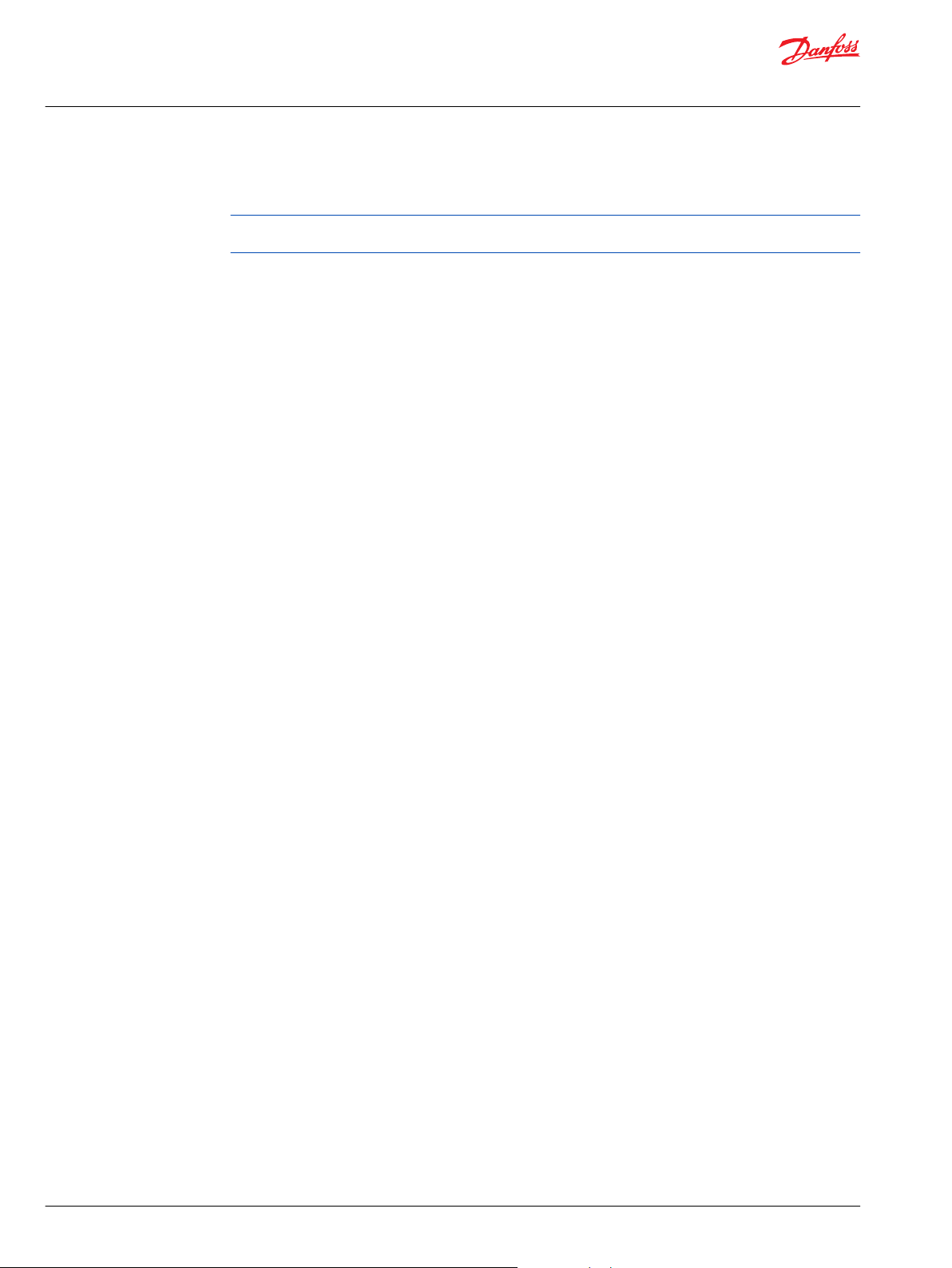

CS100 Dimensions.........................................................................................................................................................................22

CS100 Cable..................................................................................................................................................................................... 22

©

Danfoss | April 2021 BC299456869228en-000103 | 3

Page 4

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Contents

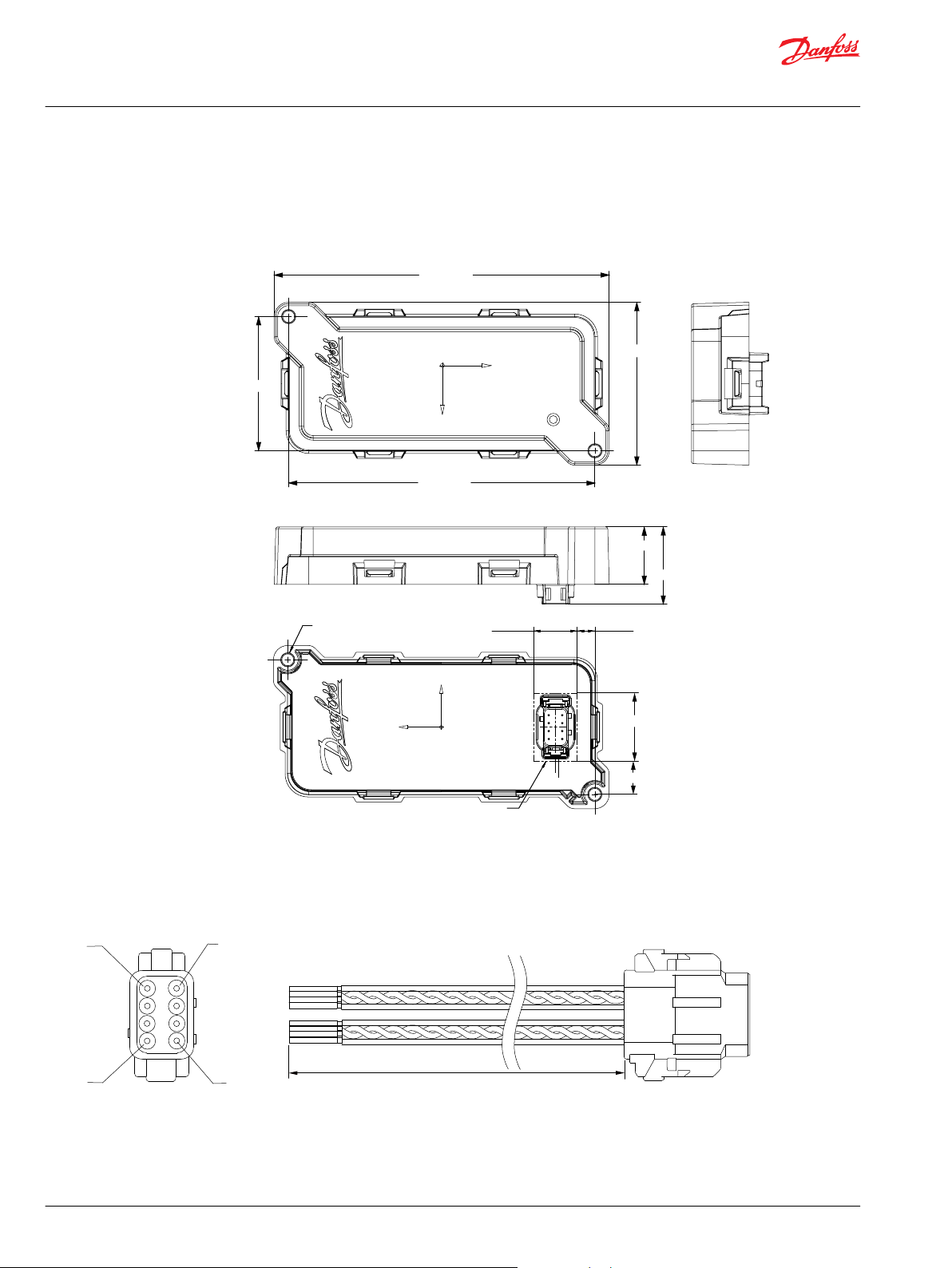

Mounting

Inside mount....................................................................................................................................................................................23

Top Mount........................................................................................................................................................................................23

4 | © Danfoss | April 2021 BC299456869228en-000103

Page 5

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

About this Manual

About this manual

This document is part of the product and provides important information on the intended use, safety,

installation and operation of the device(s) described below. The manual is intended for qualified

technicians and electricians with advanced knowledge in electrical engineering and fieldbus systems,

allowing them to estimate the risks and hazards of operating the device and to integrate it into systems

with components of other manufacturers.

The qualified personnel must know the contents of this manual and have access to it at all times.

©

Danfoss | April 2021 BC299456869228en-000103 | 5

Page 6

1

2

3

4

5

C

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

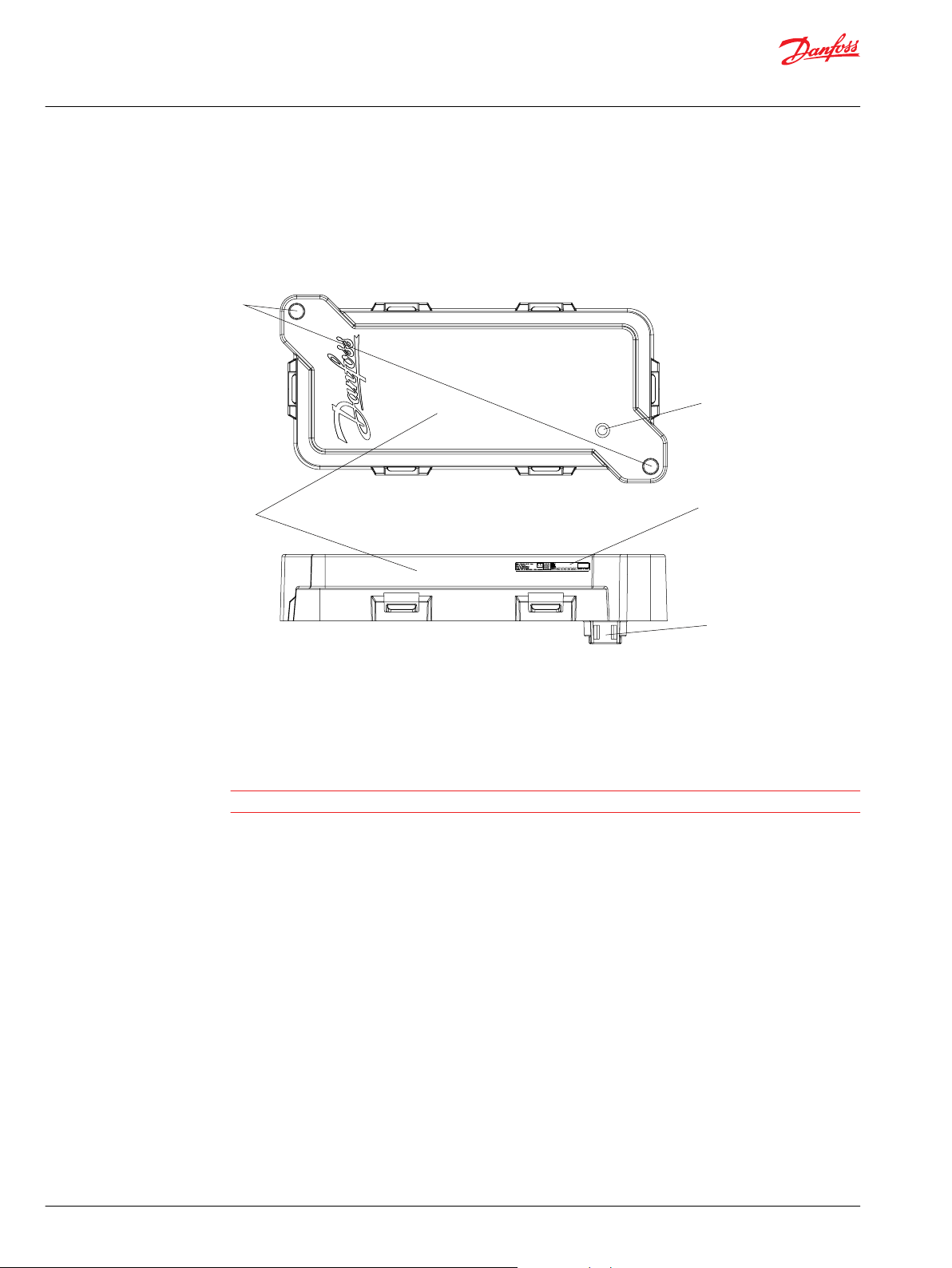

Device elements

This chapter gives an overview of the device elements, functions and describes the intended use. It

further lists the available device variants and the product certifications.

Device Information

The device elements for the CS100

Indicator elements

1. Mounting holes

2. Housing

3. Status LED

4. Type label

5. 8 Pin DEUTSCH connector

Caution

This device is not field serviceable. Opening the housing will void the warranty.

The device is equipped with the indicator element: 1x Device State multicolor LED.

6 | © Danfoss | April 2021 BC299456869228en-000103

Page 7

C

W

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Device elements

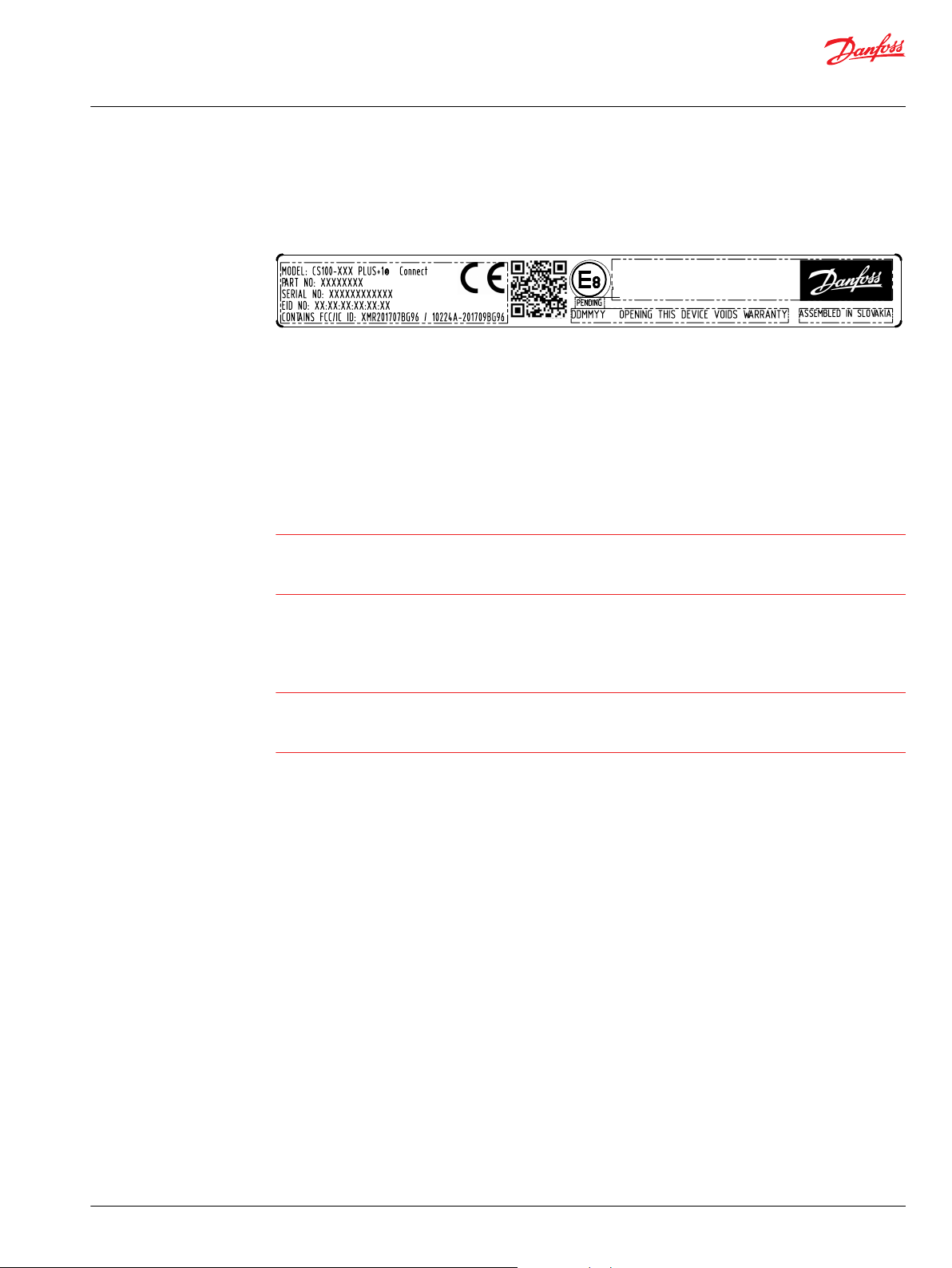

Type label

The CS100 type label is located on the side of the enclosure.

CS100 type label information

•

Model

•

Part number

•

Serial number

•

E-mark certification number

•

CE Mark

•

Country of Origin

•

Traceability code in data matrix code

Caution

Intended use

The device type label contains important information and should not be removed. Solvents can destroy

the label imprint.

Do not contact the type label with any solvent-containing substance.

Warning

Danger due to possibility of deficient data transmissions. This device operates using radio signals and

cellular networks.

Do not us this device for safety-related applications.

Insufficient mobile radio network availability, interference, failure or malfunction of the device may lead

to faulty data transmission. Because of this, data transmission cannot be guaranteed always and under all

conditions.

•

Do not operate the device in machines and applications where life depends on the proper (fault-free)

operation of this device.

•

Never rely solely on wireless device for essential communications, the CS100 is not designed for

safety related applications.

•

This device is designed to be used in systems which must be checked for conformity with legal

requirements prior to placing into operation.

•

Only qualified technicians and electricians with advanced knowledge of electrical engineering and

fieldbus systems should put this device into operation. The integrator of this device is responsible to

check and comply with regional directives and requirements.

•

The device can be used in environments that require protection class IP69k.

•

IP69k protection is only ensured if all connectors are plugged in or covered with suitable protection

caps.

•

Before exposing the device to dust and water, plug in all connectors.

•

Do not immerse the device in water or other liquids.

The OEM of a machine or vehicle in which PLUS+1® or others electronic controls are installed has the full

responsibility for all consequences that may occur.

©

Danfoss | April 2021 BC299456869228en-000103 | 7

Page 8

C

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Device elements

•

Danfoss has no responsibility for any consequences (direct or indirect) caused by failures or

malfunctions.

•

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

equipment.

•

Danfoss does not assume any responsibility for PLUS+1® products being incorrectly applied or the

system being programmed in a manner that jeopardizes safety.

•

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

•

A system FMEA should be performed on all applications.

CS100 interfaces are designed for transmitting data that is available within a CAN network via LTE 4G

Cat.M1, additionally via GSM/GPRS/EDGE.

The interfaces are suitable for use in mobile and stationary systems for industry, small business area, and

in agricultural and forestry machinery. Featured is an easy-to-install plastic enclosure which can be bolted

to a panel.

The devices have integrated antennas and must be installed properly to the machine to avoid bolt

interference and to ensure the recommended line of sight to the sky.

Service and support

Contact PLUS+1® Support and Services:

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1support-and-services/#tab-overview

The most recent driver, firmware, tools and documentation versions are available for download from

https://www.danfoss.com/en/products/software/?sort=default_sort

Caution

Warranty will be voided if device is opened.

Device is not field serviceable. Do not open the device.

8 | © Danfoss | April 2021 BC299456869228en-000103

Page 9

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Product Conformity

CS100

Compliance with CE

This device complies with the directives, standards, and normative documents. Directive

2014/53/EU on Radio equipment and telecommunications terminal equipment

Directive 2004/108/EC on Electromagnetic compatibility

Immunity standard for industrial environments (EN 61000-6-2 (2006)

Emission standard for industrial environments (EN 61000-6-3 (2007)

Compliance with ECE R-10

This device has been approved to comply with Regulation No. 10. ECE Regulation No. 10

(Revision 3, 14/08/2008) Approval No.: 10 R-XXXXXX

PTCRB

PLUS+1® Compliance

Danfoss CS100 is compliant with PLUS+1® System Control Platform.

Danfoss Telematics features are added in the Remote Interface (Machine information, signal

strength, geographical position linked to Google Maps, CAN Status).

This device has been certified for use on PTCRB Mobile

Network Operator networks.

For more information, see the certified device section

http//ptcrb.com

©

Danfoss | April 2021 BC299456869228en-000103 | 9

Page 10

W

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Safety information

In this chapter, you will find important information on how to avoid life-threatening situations and

injuries and how to prevent product damage.

General information

These instructions are part of the device.

They contain text and illustrations for the correct handling of the module and must be read before

installation or use.

Before deploying the device described in this document, read the entire Technical Information and the

User Manual document, including all safety information.

Non-observance of the notes, operation that is not in accordance with use as prescribed below, wrong

installation or handling can result in serious harm concerning the safety of people and plant.

Keep this manual for future use and make all information available to anyone deploying the device, even

after installation.

Tampering with the device can lead to considerable risks for the safety of people and plant. It is not

permitted and leads to an exclusion of any liability and warranty claims.

The device must be installed, connected and put into operation by a qualified electrician.

In the event of malfunctions or uncertainties, please contact the manufacturer.

This device is designed to be used in systems which must be checked for conformity with legal

requirements prior to placing into operation. The integrator of this device is responsible to check and

comply with regional directives and requirements.

Safety advice

Warning

Danfoss strongly recommends that initialization and provisioning of CS100 IoT Gateways be completed

outside of machine production processes. It is best practice to de-couple this initialization and

provisioning from machine production processes.

General

Danger due to possibly deficient data transmission.

CS100 unit operates using radio signals and cellular networks and is not authorized for use in safety-

related applications.

Deficient network coverage, failure or malfunction of the device may lead to deficient data transmission.

Because of this, connection cannot be guaranteed at all times under all conditions.

•

Do not operate the device in machines and applications where life depends on the proper operation

of this piece of equipment.

•

Never rely solely upon any wireless device for essential communications.

Health care

Danger of interference caused by RF energy.

Medical equipment may be sensitive to RF energy.

10 | © Danfoss | April 2021 BC299456869228en-000103

Page 11

W

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Safety information

•

When in a hospital or other health care facility, observe the restrictions on the use of cellular

communication equipment. Switch CS100 unit off, if instructed to do so by the guidelines posted in

sensitive areas.

The operation of cardiac pacemakers, other implanted medical device and hearing aids can be affected

by interference from CS100 unit's antennas placed close to the device.

•

If in doubt about potential danger, contact a physician or the manufacturer of the implanted medical

device to verify that it is properly shielded. Pacemaker patients are advised to keep CS100 unit and its

antennas away from the pacemaker while it is on.

Air traffic

Danger of interference caused by RF energy.

The operation of wireless appliances in an aircraft is forbidden to prevent interference with

communications systems. Failure to observe these instructions may lead to the suspension or denial of

cellular services to the offender, legal action, or both.

•

Switch the unit off before boarding an aircraft.

•

Make sure it cannot be switched on inadvertently.

Explosives

Danger of explosion.

Operation of any electrical equipment in potentially explosive atmospheres can constitute a safety

hazard.

•

Observe the applicable regulations and precautions when you are near explosive areas (i.e. petrol

stations, fuel depots, chemical plants or where blasting operations are in progress).

•

Do not mount the antenna in the close environment of fuel tanks, vessels with explosives and

insufficiently shielded electronic devices.

Antennas

Danger due to absorption of RF energy.

Mobile communication devices may pose a health risk when operated in the close proximity of persons.

•

Install the device with integrated antenna(s) used for the CS100 to provide a separation distance of at

least 20 cm / 8 inches from all persons.

•

Do not operate them in conjunction or co-locate them with any other antenna or transmitter.

Electronic equipment

Danger of interference caused by RF energy

The unit receives and transmits radio frequency energy while switched on. Interference may occur if it is

used close to TV sets, radios, computers or inadequately shielded equipment.

Follow any special regulations and always switch off the unit wherever use is forbidden, or when you

suspect that it may cause interference or danger.

Avoid property damage

Warning

Property damage may occur and unintended movement of machine or mechanism may cause injury to

the technician or bystanders.

Before any installation of the Control system, turn ignition lock off and disconnect the battery. Before

handling the device disconnect externally. Also, disconnect independently supplied output load circuits.

©

Danfoss | April 2021 BC299456869228en-000103 | 11

Page 12

W

W

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Safety information

Connecting the supply voltage

The supply voltage must be within the operating range. Connect the supply voltage to power supply.

Protect the module by using a fuse with requisite fuse level: 2 amps. To avoid damage, switch off power

to the device when connecting/disconnecting the main connector to the device.

The CS100 and control system must be connected to the same power supply and ground connection to

ensure trouble free communication.

Polarity reversal

Polarity reversal can damage the unit. Protect the CS100 module against power supply polarity reversal

by using an external fuse, maximum 2 amps.

IP protection rating

IP 67 rating is ensured only with the following guidelines:

•

Do not expose the device to dust and water if the connectors are not plugged in.

•

Do not immerse the device in water or other liquids.

•

Do not operate the device unless temperature is between -40 °C and +75 °C (-40 °F and +167 °F).

•

Do not store and/or transport the device unless it is kept at a temperature between -40 °C and +85 °C

(-40 °F and +185 °F).

Warranty and liability

Welding guidelines

Welding should be done before the installation of the control system.

The following is recommended when welding on a machine equipped with electronic components:

•

Turn the engine off.

•

Remove electronic components from the machine before any arc welding.

•

Disconnect the negative battery cable from the battery.

•

Do not use electrical components to ground the welder.

•

Clamp the ground cable for the welder to the component that will be welded as close as possible to

the weld.

We assume no liability for defects caused by normal wear, external influences, and errors of installation,

operating or maintenance. This also applies if the customer itself or third parties without our approval

modify the components of our products (e.g. devices, elements or additional hardware facilities;

programs or program elements of the software).

Servicing the CS100

Warning

The device can only be repaired by the manufacturer, it is not field serviceable. Opening the device

housing will void the Warranty.

Warning

To prevent misuse, immediately inform Danfoss in case of loss or theft of the device or the related SIM

card that is factory pre-installed on it.

12 | © Danfoss | April 2021 BC299456869228en-000103

Page 13

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Ordering information

Part number

Device and part number

CS100 IoT Gateway

Related products

Related product and part numbers

DEUTSCH mating connector bag assembly

11230826

K29620

(16-20 AWG)

©

Danfoss | April 2021 BC299456869228en-000103 | 13

Page 14

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Device Functions

Available variants & functions

Variant GNSS CAN Bus

CS100 Yes 2 2 Yes Yes Yes

Operating modes

CS100 devices operate in Data Logging mode.

Data logging

In this operation mode the CS100 unit logs specific CAN messages, GNSS position data and internal

variables according to its configuration and sends them to the Danfoss PLUS+1® Connect portal.

CS100 devices have an internal non-volatile memory which allow CS100 to store the logged data in case

of a cellular outage. When the cellular connection is recovered the logged data are sent to the Danfoss

PLUS+1® Connect portal automatically.

GNSS (Global Navigation Satellite System)

The GNSS enables the devices to determine their position using the Global Positioning System (GPS). The

position data can then be transmitted via the cellular connection to the Danfoss PLUS+1® Connect portal.

The device includes a GNSS receiver for determining position data: the receiver can process signals from

GPS, GLONASS, and BeiDou satellites. It can process data from multiple navigation systems

simultaneously: this increases the accuracy.

The CS100 uses GNSS as a time source. When GNSS sync is not available, the local timing accuracy is ±2

seconds per day.

Interface

Local MFIO RTC Data Logging Power

Management

Wireless Solution

CS100 interfaces transmit data available on a CAN bus via LTE Cat.M1 and 2G telecommunication

services.

Beyond the LTE Cat.M1/GSM functionality, these services allow for communication with web servers at

higher data rates. The communication is based on the TCP/IP protocol, the communication is encrypted

and secure (TLS). Using these services requires a connection to a Danfoss PLUS+1 Connect portal.

SIM card

Factory installed into the device there is a network operator SIM card.

Inserting generic SIM card is not possible because the housing cannot be opened.

The functionality depending on the ambient temperature can be assured for the maximum transfer rate

only between -38 °C to 55 °C (36.4 °F to 131 °F).

Input/output functions (I/O)

CS100 feature two multifunction input/output (2 DIN/AIN/ResIN/FreqIN/CrntIN/DOut) configurable with

several options like the same type of pins available on PLUS+1 ECUs. You can use the input function, for

instance, to read and log status information from devices or machines as well as to directly determine

and monitor switch and key states. You can send the data from the input/output function via the CAN

bus or via the mobile radio network.

14 | © Danfoss | April 2021 BC299456869228en-000103

Page 15

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Device Functions

CAN interfaces

The device features 2 CAN Bus interfaces. The CAN interfaces meet the specifications CAN 2.0 A/B

protocol and the physical layer according to ISO 11898-2 high-speed up to 1 Mbit / s. The CAN interfaces

are operational only when existing power supply is energized. A support for CAN-FD is not possible.

Device configuration

The CS100 can be remotely configured from the Danfoss PLUS+1® Connect portal to monitor the

machine state, performance, and position. Both position and machine data are periodically transmitted

and stored to the Danfoss Data Portal.

CS100 firmware update

You can load a firmware update to the CS100 via the Danfoss PLUS+1® Connect portal. The firmware

update may reset the saved configuration to default. After the firmware update, load your configuration

to the device through the PLUS+1® Connect portal.

Secure connection to the PLUS+1 Connect portal

CS100 always establishes a secure encrypted TLS connection to the PLUS+1 Connect portal. If, for specific

reasons, the encryption is a problem, please contact your Danfoss representative for possible solutions.

©

Danfoss | April 2021 BC299456869228en-000103 | 15

Page 16

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Connector

CS100 is equipped with: 1x Main connector (CAN Bus, I/O, Power).

Main connector

The connector functions:

•

Connecting the device to the CAN bus network

•

Supplying the device with power

•

Local multifunction Inputs/Outputs

To avoid damage to the device, connect/disconnect the main connector only if the power supply to the

device is switched off.

To maximize the performance of the GPS receiver, mount the GPS antenna in a place where it is level with

the local geographic horizon and has full view of the sky above.

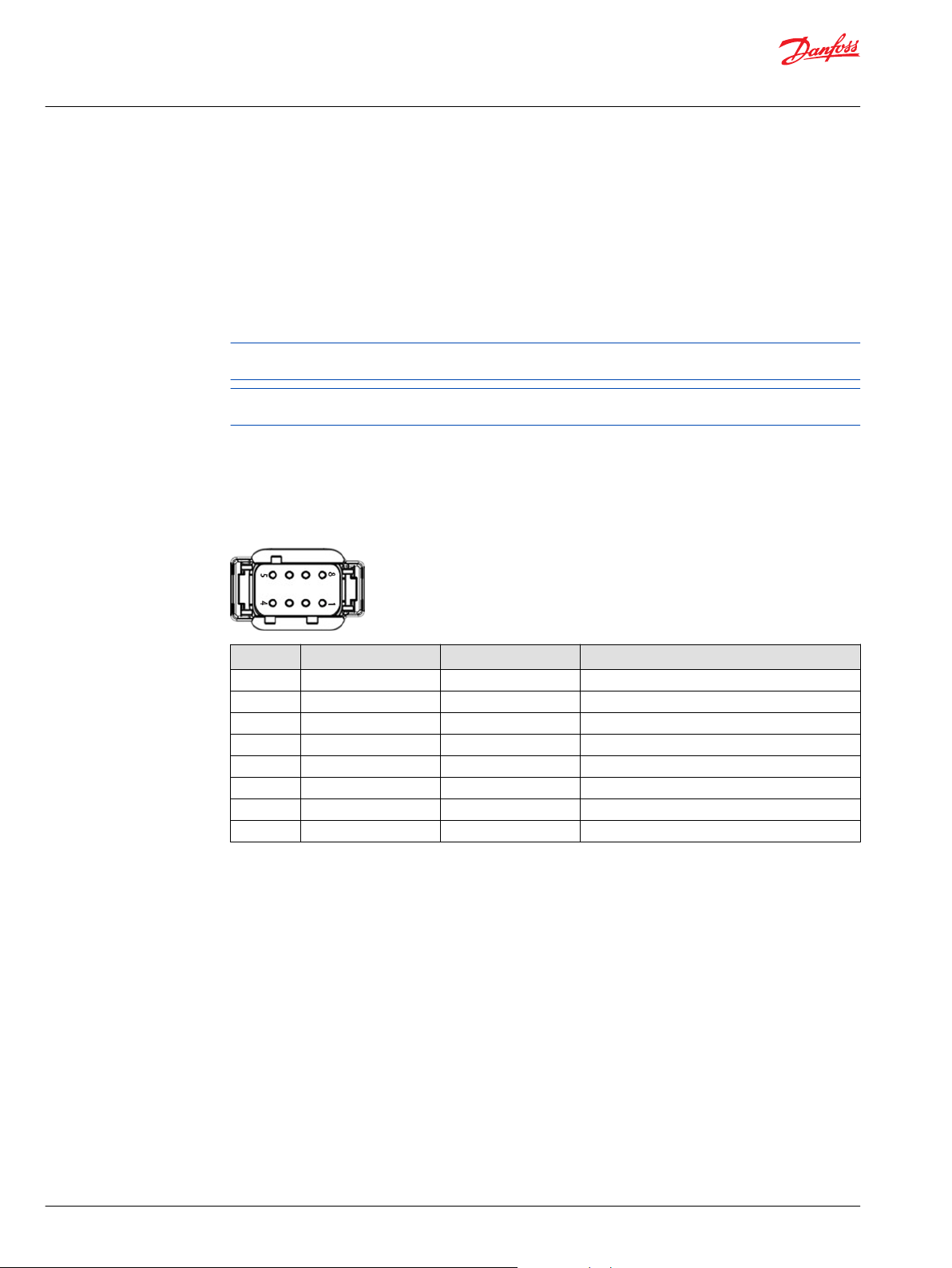

8-pin DEUTSCH CAN/power supply/local MFIO

The table and drawing below show the pin assignment and conductor colors of the connector. The colors

stated in the table below are the conductor colors of the cable listed.

Power supply/ CAN bus/ I/O connector

Pin Designation Color Description

1 Ground Black Power Supply

2 9 to 36 Vdc Red Power Supply

3 CAN 1 high Yellow CAN bus 1

4 CAN 1 low Green CAN bus 1

5 MFIO1/CL15 Brown Multifunction IO/Ignition

6 MFIO2 Orange Multifunction IO

7 CAN 2 high Yellow/White CAN bus 2

8 CAN 2 low Green/White CAN bus 2

16 | © Danfoss | April 2021 BC299456869228en-000103

Page 17

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

CS100 Technical Data

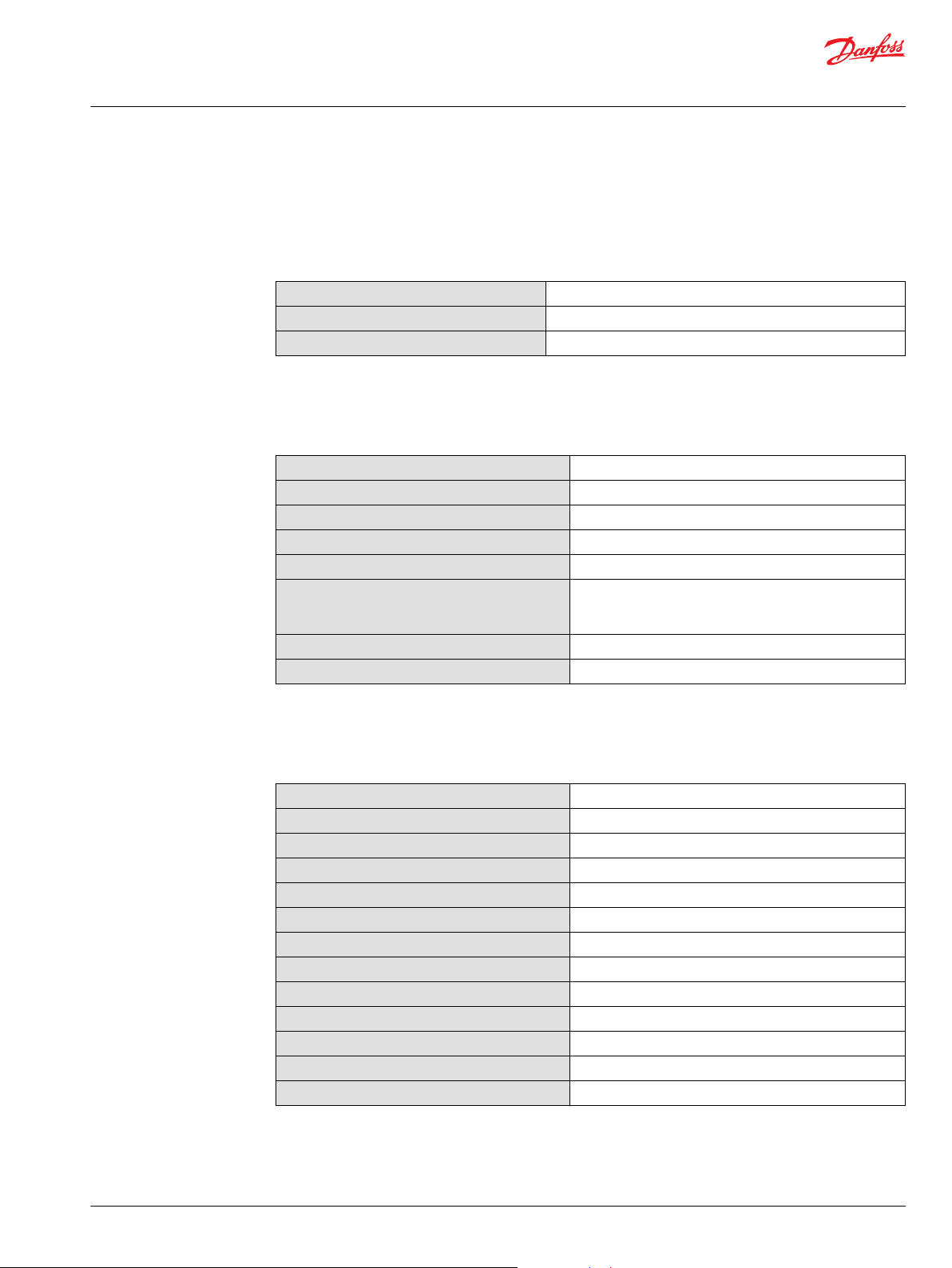

Electrical Data

Electrical data

DC supply voltage

Memory buffering capacity

EMI/RFI rating

Mechanical Data

Mechanical data

Dimension L x W x D

Housing

Color

Operating temperature

Storage temperature

IP rating

Weight

Status LED

9 to 36 Vdc

16 MB

100 V/m

177 x 86 x 41 mm

Tamper resistant

Black

-40 to 75°C [-40 to 167°F]

-40 to 85°C [-40 to 185°F]

IP67 (with connector mated)

IP69k (when top mounted and with connector plugged in or

suitably capped)

250 grams

1 Multi-color

Interface/Protocol/Certification

Interface/Protocol/Certification

CAN bus network

Multifunction Input/Output

Radio Module

Cat M1 Throughput (UL/DL)

2G-EGPRS Throughput (UL/DL)

Cat M1 LTE FDD Bands

2G – EGPRS Bands

GNSS Constellations

Antennas

SIM Card

Certifications

Vibrations

Shock

2 (ISO 11898-2 High Speed, 2.0A/B)

2 (DIN/AIN/ResIN/FreqIN/CrntIN/CL15/DOUT)

LTE Cat M1 and 2G cellular

Max 375 kbps / Max 375 kbps

Max 236.8 kbps / Max 296 kbps

B1/B2/B3/B4/B5/B8/B12/B13/B18/B19/B20/B26/B28

850/900/1800/1900 MHz

GPS, GLONASS, BeiDou, Galileo

Cellular and GNSS (Internal)

Factory Installed

PTCRB, RED, CE, E-Mark

IEC 60068-2-64

IEC 60068-2-27 test Ea

©

Danfoss | April 2021 BC299456869228en-000103 | 17

Page 18

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

CS100 Technical Data

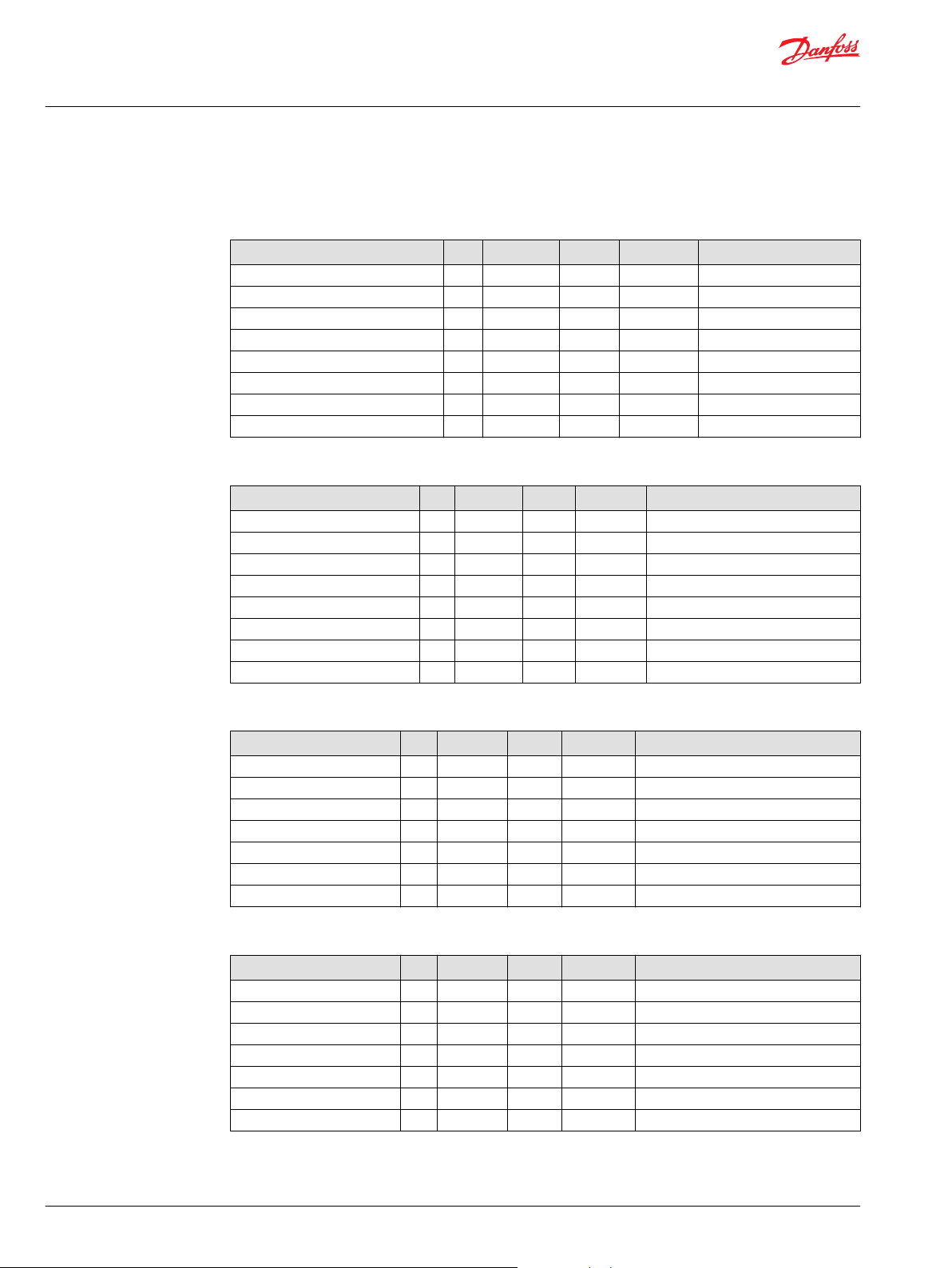

Multifunction inputs

Middle range analog

Description Unit Minimum Typical Maximum Comment

Minimum discernible voltage mV — — 20 —

Maximum discernible voltage V 5.18 5.26 5.33 —

Resolution mV — 1.3 — —

Worst case offset and gain error mV — — 71 VMeasure = 5.26 V

Non-linearity mV — — ±7.8 —

Input impedance kΩ 232 233 234 No pull up or pull down

Input impedance (5V/GND) kΩ 13.9 14.1 14.3 Pull up or pull down

Input impedance (2.5V) kΩ 7.1 7.3 7.4 Pull up and pull down

High range analog

Description Unit Minimum Typical Maximum Comment

Minimum discernible voltage mV — — 145 —

Maximum discernible voltage V 34.5 35.3 36.1 —

Resolution mV — 8.6 — —

Worst case offset and gain error V — — .79 VMeasure = 35.5 V

Non-linearity mV — — ±53 —

Input impedance kΩ 109.1 109.3 109.5 No pull up or pull down (Vin < 5.7 V)

Input impedance (5V/GND) kΩ 13.0 13.2 13.4 Pull up or pull down (Vin < 5.7 V)

Input impedance (2.5V) kΩ 6.9 7.0 7.1 Pull up and pull down (Vin < 5.7 V)

Frequency input middle range

Description Unit Minimum Typical Maximum Comment

Range Hz 0 — 10000 In steps of 1 Hz

Range (phase and quad) Hz 0 — 5000 In steps of 1 Hz

Rising voltage threshold V — — 3.89 Voltage required for frequency input

Falling voltage threshold V 0.85 — — Voltage required for frequency input

Input impedance kΩ 232 233 234 No pull up or pull down

Input impedance (5V/GND) kΩ 13.9 14.1 14.3 Pull up or pull down

Input impedance (2.5V) kΩ 7.1 7.3 7.4 Pull up and pull down

Frequency (PPU) High Range

Description Unit Minimum Typical Maximum Comment

Range Hz 0 — 10000 In steps of 1 Hz

Range (phase and quad) Hz 0 — 5000 In steps of 1 Hz

Rising voltage threshold V — — 23.6 Voltage required for frequency input

Falling voltage threshold V 5.6 — — Voltage required for frequency input

Input impedance kΩ 109.1 109.3 109.5 No pull up or pull down

Input impedance (5V/GND) kΩ 13 13.2 13.4 Pull up or pull down

Input impedance (2.5V) kΩ 6.9 7.0 7.1 Pull up and pull down

18 | © Danfoss | April 2021 BC299456869228en-000103

Page 19

W

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

CS100 Technical Data

Resistance input

Description Unit Minimum Typical Maximum Comment

Range Ω 5.2 — 10000 In steps of 1 Ω

Measurement error % — — 6.4 100Ω

— — 1.9 1kΩ

— — 4.9 10kΩ

Input impedance kΩ 1.32 1.32 1.33 Input impedance to 5V

Outputs

Digital output

Description Unit Minimum Typical Maximum Comment

Output Voltage range V 0

Current mA 0 — 500 Each output pin capable of driving 500mA. No

-10.3

-22.3

@Vin=12v & 500ma

@Vin= 24V & 500ma

current limiting; damage may be done if the load

pulls more than 500mA.

Warning

DOUT pins have short circuit protection but are NOT current limited. Exceeding 500mA per pin could

damage the CS100.

©

Danfoss | April 2021 BC299456869228en-000103 | 19

Page 20

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

PLUS+1® Connect portal

The CS100 is produced with a pre-installed SIM card and with a default configuration that allows the

direct connection of the device to the PLUS+1® Connect portal.

The visibility of the device on the PLUS+1® Connect portal is linked to the activation of the device, if not

activated with a specific data plan the device is not visible on the portal.

Connect the device and ensure the device turns on.

The LED light correct sequence:

The LED lights up green constantly during the first second.

•

The LED starts to flash.

•

Problem with connection to PLUS+1® Connect portal

After connecting to power supply, the LED should then follow the correct sequence. If the LED lights up

green and becomes red or stops during one of the steps, there is a problem. Contact the helpdesk or your

CS PAE. EID number is required in order to help you.

20 | © Danfoss | April 2021 BC299456869228en-000103

Page 21

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Packaging and Transport

IP protection rating

IP 67 rating is ensured only with the following guidelines:

•

Do not expose the device to dust and water if the connectors are not plugged in.

•

Do not immerse the device in water or other liquids.

•

Do not operate the device unless temperature is between -40 °C and +75 °C (-40 °F and +167 °F).

•

Do not store and/or transport the device unless it is kept at a temperature between -40 °C and +85 °C

(-40 °F and +185 °F).

Disposal

Observe national regulations when disposing the device, accessories and its package.

©

Danfoss | April 2021 BC299456869228en-000103 | 21

Page 22

177.70 [7.00]

162.00 [6.38]

86.10 [3.40]

71.00 [2.80]

30.42 [1.20]

40.90 [1.61]

2 X Ø 6.3 THRU

9.30 [0.37]

36.0 [1.42]

17.5 [0.69]

23.0 [0.1]

A

Pin 1

Pin 8

Pin 5 Pin 4

5 Meter ± 10 mm

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

CS100 Technical Drawings

CS100 Dimensions

CS100 dimensions in mm [in]

CS100 Cable

A Minimal panel cutout

22 | © Danfoss | April 2021 BC299456869228en-000103

Page 23

C

Technical Information

PLUS+1 Connect CS100 IoT Gateway — Professional Install Only

Mounting

The device can be directly bolted into spaced drill holes, see CS100 Technical Drawings on page 22. The

device can be mounted in any position, Top Mount on page 23 is recommended.

The devices have integrated antennas and must be installed properly to the machine to avoid bolt

interference and to ensure the recommended line of sight to the sky.

Excessively long bolts, or metallic elements in general, may interfere with radio signal.

Care must be taken to insure that the module connector is positioned so that moisture drains away from

the connector. Provide a drip loop in the harness. Provide strain relief for mating connector wires.

Caution

Module damage may occur.

Use caution when installing modules. It's possible to damage the module if excessive pressure is applied

during the installation of harness strain relief.

Fasteners

Recommended outer diameter (OD) Recommended torque

6.0 mm (0.25 in) 2.26 N•m (20 in•lbs)

Inside mount

Top Mount

Simple mounting option

The connector is facing inward through mounting surface, which allows for mounting on top of the

machine for best antenna exposure.

Recommended mounting option

Raises to IP69k rating, when top mounted and connector is plugged in (or suitably capped for

protection).

©

Danfoss | April 2021 BC299456869228en-000103 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | April 2021 BC299456869228en-000103

Loading...

Loading...