Page 1

Data Sheet

Pressure switch

Type CS

For air compressors and water boosters

CS pressure switches have a built-in pressure

operated, three-pole switch. The contact

position of which depends on the pressure in

the connector and the range setting and

adjustable dierential.

The pressure switches are tted with a manual

switch that will lock the contact system in the

open position independently of the pressure in

the system. Pressure switches with relief valve is

used in compressed air systems where pressure

relief on the compressor piston before start is

required.

The CS is suited for automatic start and stop of

air compressors and water boosters.

Features:

• Pressure ranges 2 – 20 bar

• Pressure connection G ½ or G ¼

• Contact system 3-pole (TPST) as standard

available also as an accessory

• Adjustable dierential

• Relief valve as accessory

• Manual switch to lock the contact system

• Enclosure IP43 or IP55

• Special versions with pressure connection

made of polyacetal suitable in drinking water

applications

AI239086444789en-000701

Page 2

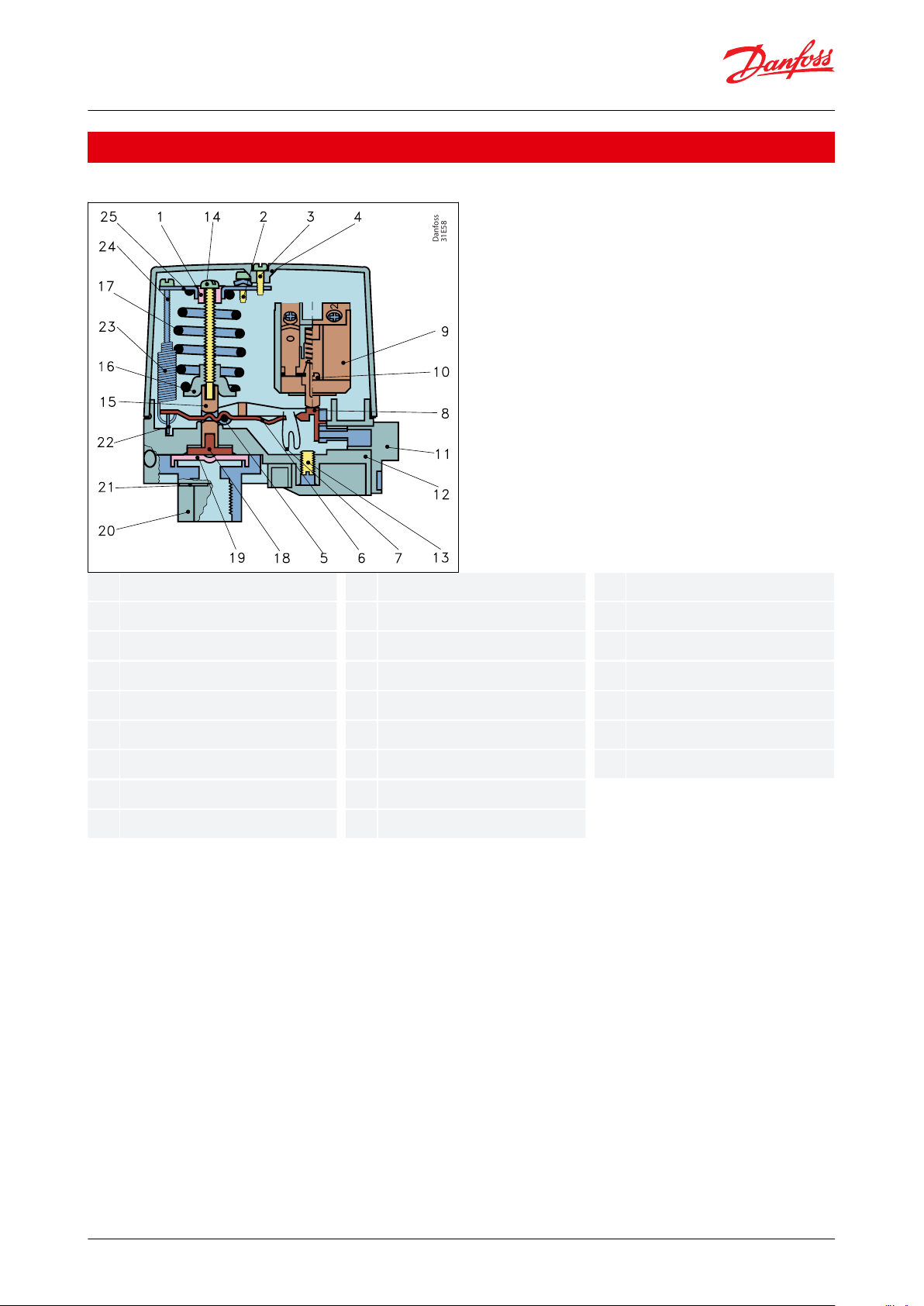

12345678910111213141516171819202122232425

Danfoss

31E58

Slide ring

Earth screw

Cover screw

Cover

Spindle

Toggle arm

Snap spring

Snap arm

Switch housing assy

Self-tapping screw

Manual switch

Base

Grubscrew

Stop pressure screw

Pressure pad

Spring retainer

Compression spring

Pressure shoe

Diaphragm

Flange, G ¼ or G ½

Cap

Dierential arm

Tension spring

Dierential pressure screw

Bracket

Pressure switch, Type CS

Function

Figure 1: Design and function

The pressure switch is built up of the following main elements: connector, diaphragm, snap system, main spring,

dierential spring and a 3-pole or one-pole contact system. The stop pressure must be set on the main spring and

the dierence between start and stop pressures on the dierential spring.

Pressure from the controlled system is led, via the connector, to the diaphragm. The diaphragm converts this

pressure to a mechanical movement which is transferred by the snap system to the contact system. In this way, the

contact system starts or stops a compressor/pump.

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 2

Page 3

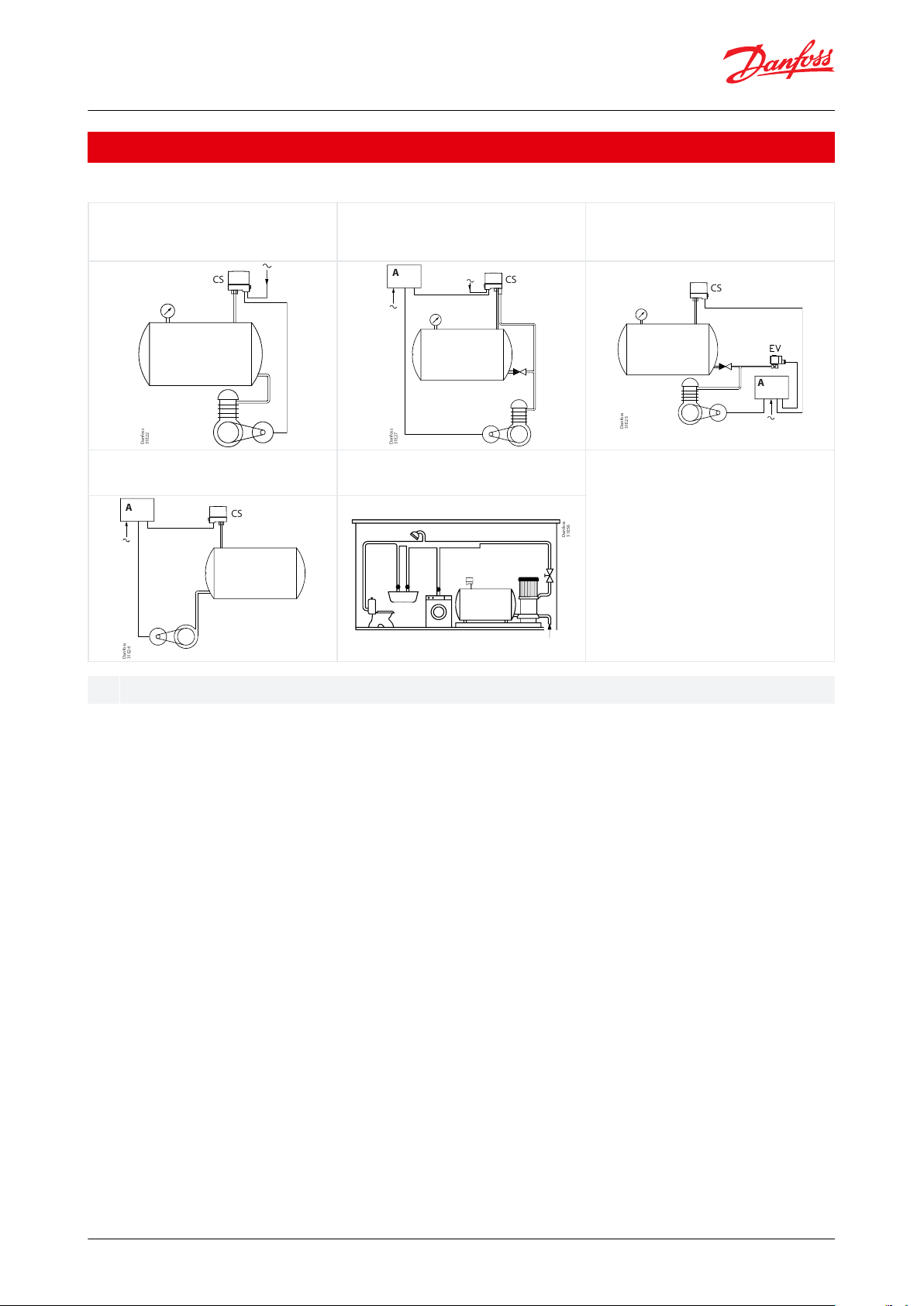

A

Example 1

Control of an air compressor with a CS pressure

switch.

Example 2

Control of a compressor with a CS pressure switch

tted with pressure relief valve. Note the check valve

between pressure relief line and reservoir.

Example 3

Control of an air compressor with a CS. An EV210B 3B

solenoid valve is recommended where there is need

for especially fast pressure relief.

CS

Danfoss

31E22

CS

A

Danfoss

31E27

CS

A

Example 4

Control of a centrifugal pump with a CS, via an

automatic star-delta switch, motor starter, or similar.

Example 5

Pressure boosting system for domestic circuits. A type

CS switch is used to start/stop the pump.

CS

A

Danfoss

31E56

Motor starter or automatic start-delta switch

Pressure switch, Type CS

Application

Table 1: Application examples

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 3

Page 4

Electrical life on rated load

100.000 operations

Mechanical life

1.000.000 operations

Ambient temperature

-20 – 70 °C

Temperature of medium

(1)

Water

0 – 70 °C

Air

-20 – 70 °C

Vibration-proof

0 – 1000 Hz at 4g

Resonance frequency,

see Figure 2

Direction A-B

341 Hz

Direction C-D

332 Hz

Direction E-F

488 Hz

Diaphragm material

Hytrel

Pressure connector

Special

Polyacetal, G ½

Others

Silumin, G ¼ or G ½

Pressure relief valve (capacity)

2000 cm3 from 10 – 1 bar in 18.8 sec.

Grade of enclosure to IEC 529

IP43 or IP55

Danfoss

U31E34

Contact load

IeU

e

AC-3

12 A

220 – 415 V

AC-3

9 A

600 V

DC-13/14

2 A

220 V (3 contacts in series)

Wire dimension

solid / stranded

0.7 – 2.5 mm

2

exible,

with / without ferrules

0.75 – 2.5 mm

2

exible,

with ferrules

0.5 – 1.5 mm

2

Tightening torque

max. 1.2 Nm

Rated impulse voltage

4 kV

Pollution degree

3

Short circuit protection, fuse

25 A

Insulation

600 V

IP-index

IP43 or IP55

Pressure switch, Type CS

Product specication

Technical data

Table 2: Specications

(1)

(1)

For water and seawater, max. 80 °C

For water and seawater, max. 80 °C

Figure 2: Resonance frequency

Table 3: Contact load

Table 4: Properties according to EN 60947

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 4

Page 5

Danfoss

31E43

12Stop pressure screw

Dierential screw

Danfoss

31E47

Turns of

screw

Pressure switch, Type CS

Setting

Figure 3: Adjustment

All standard versions of CS pressure switches are preset and supplied with springs under minimum compression.

1.

Turn the stop pressure screw (1) the given number of times towards + (high stop pressure), see Figure 4: Stop

pressure graph.

2.

Turn the dierential screw (2) the given number of times towards + (max. dierential), see Dierential pressure

nomograms.

3.

Start the plant and let it run until the required stop pressure is reached.

4.

Turn the stop pressure screw (1) towards minus (lower stop pressure) until the plant stops.

5.

Reduce the pressure to the required start pressure.

6.

Turn the dierential screw (2) towards minus (smaller dierential) until the plant starts.

7.

Check that the plant stops and starts at the required pressures.

NOTE:

If the dierential is set at a value greater than the stop pressure the plant cannot start. If this is the case, set the

dierential at a smaller value (towards minus).

Figure 4: Stop pressure graph

Example:

A compressor is to be regulated by a CS pressure switch. The start pressure is 3.5 bar, and the stop pressure 5 bar.

The choice should be a CS with a range of 2 – 6 bar.

1.

Turn the stop pressure screw (1) about 12 times. See Figure 3: Adjustment.

2.

Turn the dierential screw (2) about 4.5 times. See Figure 8: CS 2–6 [bar]. Take a straight line from 5 bar stop

pressure on the nomogram to the dierential, 1.5 bar and read o the number of turns, i.e. 4.5.

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 5

Page 6

Danfoss

31E52

Danfoss

31E51

d > 8.5 mm – 1

d ≤ 8.5 mm – 2

031E0293

Danfoss

31E73

Pressure switch, Type CS

Take a straight line from 5 bar stop pressure on the nomogram to the dierential, 1.5 bar and read o the number of

turns, i.e. 4.5.

Installation

Recommended orientation

The pressure switches will operate regardless of their orientation. However, to meet the enclosure requirements of

IP43 and IP55, they must be mounted vertically with the connection downwards. The CS pressure switches are selfsupporting (on the connection).

Fitting a pressure relief valve:

1.

Remove the blanking plug

2.

Fit the pressure relief valve

3.

Fit the plastoform screw

Figure 5: Installation

Figure 6: Installation

Fitting screwed cable entries

The accessory bag contains two sets of metal gaskets each with dierent internal diameters. These will give a

sucient cord relief if used correctly with the cable diameter concerned.

Drain hole

If because of large temperature variations there is a risk of condensate forming in the pressure switch, a screwdriver

can be used to make a drain hole in the enclosure.

Figure 7: Drain hole

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 6

Page 7

Danfoss

31E53

Stop pressure

No. of turns

on Δp screw

CS 2–6 [bar]

Differential

Danfoss

31E54

Stop pressure

CS 4–12 [bar]

Differential

No. of turns

on Δp screw

Danfoss

31E55

Stop pressure

CS 7–20 [bar]

Differential

No. of turns

on Δp screw

Danfoss

31E61

Danfoss

31E62

Danfoss

31E63

Danfoss

31E49

IeU

e

AC-3

12 A

220 V – 415 V

9 A

600 V

DC-13 / 14

2 A

220 V (3 contacts in series)

Pressure switch, Type CS

Dierential pressure nomograms

Figure 8: CS 2–6 [bar]

Figure 9: CS 4–12 [bar]

Dimensions [mm] and weights [kg]

Figure 11: Dimensions [mm]

Figure 10: CS 7–20 [bar]

Weight approx. 0.5 kg

Mains connection

Figure 12: 3-pole AC load

Table 5: Contact load

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 7

Figure 13: 1-pole AC load

Figure 14: 1-pole DC load

Page 8

Stop pressure p

e

[bar]

Min. dierential

Δp [bar]

Max. dierential

Δp [bar]

Max. test

pressure p

e

[bar]

Grade of

enclosure

Pressure

connection

Code no.

Type

2 – 6

0.72 – 1.0

1.0 – 2.010IP43

G ¼

031E020266

1-pole

2 – 6

0.72 – 1.0

1.0 – 2.010IP43

G ¼

031E020066

3-pole

2 – 6

0.72 – 1.0

1.0 – 2.010IP55

G ¼

031E020566

3-pole

2 – 6

0.72 – 1.0

1.0 – 2.010IP43

G ½

031E021066

3-pole

2 – 6

0.72 – 1.0

1.0 – 2.010IP55

G ½

031E021566

(1)

3-pole

4 – 12

1 – 1.5

2.0 – 4.020IP43

G ¼

031E022066

3-pole

4 – 12

1 – 1.5

2.0 – 4.020IP55

G ¼

031E022566

(1)

3-pole

4 – 12

1 – 1.5

2.0 – 4.020IP43

G ½

031E023066

3-pole

4 – 12

1 – 1.5

2.0 – 4.020IP55

G ½

031E023566

(1)

3-pole

7 – 20

2 – 3.5

3.5 – 7.032IP43

G ¼

031E024066

3-pole

7 – 20

2 – 3.5

3.5 – 7.032IP55

G ¼

031E024566

3-pole

7 – 20

2 – 3.5

3.5 – 7.032IP43

G ½

031E025066

3-pole

7 – 20

2 – 3.5

3.5 – 7.032IP55

G ½

031E025566

(1)

3–pole

Stop pressure p

e

[bar]

Min. dierential

Δp [bar]

Max. dierential

Δp [bar]

Max. test

pressure p

e

[bar]

Grade of

enclosure

Pressure

connection

Code no.

Type

2 – 6

0.72 – 1.0

1.0 – 2.010IP43

G ½

031E101066

3-pole

4 – 12

1 – 1.5

2.0 – 4.020IP43

G ½

031E101266

3-pole

7 – 20

2 – 3.5

3.5 – 7.032IP43

G ½

031E101466

3–pole

Description

Code no.

Three pole contact system (TPST)

031E029166

Pressure relief valve, incl.

xing screw (for 6 mm pipe/hose)

031E029866

Pressure relief valve, incl.

xing screw (for 1/4 in. pipe/hose)

031E029766

Two Pg 16 screwed cable entries with gaskets (cable diam. 6.5 – 15 mm)

031E029366

Nipple with 7/16-20 UNF and M10 x 1 int.

031E029666

File name

Document type

Document topic

Approval authority

BK_W_0862_01_2108

Food and Health - Performance

Certicate

-

PZH

RU C-DK.БЛ08.В.00063_18

Electrical - Safety

Certicate

EMC/LVE

EAC

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

060-9650.AC

EU Declaration

LVD/RoHS

Danfoss

Pressure switch, Type CS

Ordering

Table 6: Standard pressure switch type CS

(1)

(1)

Preferred versions

Preferred versions

Table 7: Special versions with Polyacetal pressure connection - suitable for drinking water

Accessories and spare parts

Table 8: Accessories and spare parts

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 9: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI239086444789en-000701 | 9

Loading...

Loading...