MAKING MODERN LIVING POSSIBLE

Installation Guide

CF-MC Master Controller

DANFOSS HEATING SOLUTIONS

Installation Guide CF-MC Master Controller

2

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

Content

1. Introduction .................................................................. 4

2. CF2+ System Overview......................................................... 4

3. Functional Overview .......................................................... 4

4. Mounting and Installation Procedure (Sequential)............................... 4

4.1 CF-MC Master Controller......................................................... 4

4.2 24 V Actuators................................................................... 5

4.3 Relays for Pump and Boiler Control............................................... 5

4.4 Input for Away Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.5 Input for Heating and Cooling ................................................... 5

4.6 Wiring .......................................................................... 5

4.7 Power Supply ................................................................... 5

4.8 CF-EA External Antenna ......................................................... 5

4.9 More (2 to 3) CF-MC Master Controllers........................................... 6

4.10 CF-RS, -RP, -RD and -RF Room Thermostats ....................................... 6

4.11 Other System Components ...................................................... 6

4.12 Transmission Test (Link Test) ..................................................... 6

4.13 Mounting of CF-RS, -RP, -RD and -RF Room Thermostats .......................... 7

5. Temperature Settings ......................................................... 7

5.1 CF-RS Room Thermostat ........................................................ 7

5.2 CF-RD and CF-RF Room Thermostat with Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Configuration................................................................. 8

6.1 Actuator Outputs................................................................ 8

6.2 Relays for Pump & Boiler Control ................................................. 9

6.3 Input for Away Function and Heating & Cooling .................................. 9

6.4 Heating/Cooling ................................................................ 9

6.5 Relays on more (2-3) CF-MC Master Controllers................................... 9

6.6 Wireless relay ................................................................... 9

GB

7. Replacing/Resetting the CF-MC Master Controller ............................... 10

7.1 When? .......................................................................... 10

7.2 How? ........................................................................... 10

8. Technical Specifications ....................................................... 11

8.1 CF-MC Master Controller......................................................... 11

8.2 CF-RS, -RP, -RD and -RF Room Thermostats ....................................... 11

9. Troubleshooting .............................................................. 12

9.1 CF-MC Master Controller......................................................... 12

9.2 CF-RS, -RP, -RD and -RF Room Thermostats ....................................... 12

Figures and illustrations

A1 ................................................................................. 14

A2 ................................................................................. 15

B1 ................................................................................. 16

B2 ................................................................................. 17

Danfoss Heating Solutions VIUHK902 01/2016

3

Installation Guide CF-MC Master Controller

1. Introduction

The CF-MC Master Controller is a part of the new trend-setting CF2+ wireless hydronic floor heating

control system from Danfoss. Based on 2-way wireless communication technology CF2+ offers high

transmission safety, easy wireless installation, a high level of individual room temperature control,

and thus optimal comfort and improved energy efficiency.

The system has a variety of beneficial features and easily accessed application functionalities. This

includes a CF-MC Master Controller with short-circuit protected outputs, regulation by Pulse Width

Modulation (PWM) principles, away function, separate relays for both pump and boiler control, selfdiagnostic program and error indication, wireless transmission (link) test possibility on each type of

Room Thermostat, easy wireless system access and extended functionality via the optional CF-RC

Remote Controller, and CF-RU Repeater Unit for extended wireless range.

2. CF2+ System Overview (fig. 1)

1a) CF-MC Master Controller.

1b) CF-RS, -RP, -RD and -RF Room Thermostats.

1c) CF-RC Remote Controller.

1d) CF-RU Repeater Unit.

1e) CF-DS Dew-point Sensor.

1f) CF-WR Wireless Relay.

1g) CF-EA External Antenna.

3. Functional Overview (fig. 2)

Menu selection button.

Menu LEDs.

Output and configuration selection button.

OK button.

Output LEDs.

Output cable fixing.

Relays for pump and boiler.

Input for heating/cooling (external ON/OFF switch).

Input for away function (8 °C) (external ON/OFF switch).

Input for PT1000 pipe sensor.

Front cover release.

External antenna connection.

4. Mounting and Installation Procedure (Sequential)

The wireless systems transmission range is sufficient for most applications; however wireless signals

are weakened on the way from the CF-MC Master Controller to the Room Thermostats and each

building has different obstacles.

Checklist for optimal installation and best wireless signal strength (fig. 3):

• No metal objects between the CF-MC Master Controller and the Room Thermostats.

• Wireless signal through walls on shortest possible diagonal distance.

• Optimise the wireless signal by installing a CF-RU Repeater Unit.

Note! Danfoss recommends that an installation plan is made before beginning the actual installation.

4.1 CF-MC Master Controller

Mount the CF-MC Master Controller in an horizontal upright position.

Wall:

• Remove the front cover (fig. 4).

• Mount with screws and wall plugs (fig. 5).

DIN-Rail:

• Mount DIN-rail parts (fig. 6).

• Click on DIN-rail (fig. 7).

• Release from DIN-rail (fig. 8).

Important! Complete all the installations on the CF-MC Master Controller described below, before

connecting to a 230 V power supply!

4

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

LNL

N

4.2 24 V Actuators

• Connect the two actuator wires to an output (fig. 9).

• Fix the cable - round cable (fig. 10), squared/flat cable (fig. 11).

Note! If NC (normally closed) actuators are installed for Pulse Width Modulation (PWM) regulation for

floor heating, no further actuator output configuration is needed (see chapter 6.1).

4.3 Relays for Pump and Boiler Control

• Pump: Connect the live wire (L) across the Pump Relay from an external power supply. Make

sure the power supply is switched off. Then connect the live wire, and complete other connec tions to the pump in accordance with existing law (fig. 12).

• Fix the cable (fig. 13).

• Boiler: Connect the live wire (L) across the Boiler Relay from an external power supply. Make

sure the power supply is switched off. Then connect the live wire, and complete other

connections to the boiler in accordance with existing law.

Note! The relays for pump and boiler are potential free contacts and can therefore NOT be used as direct

power supply. Max. load is 230 V and 8 A/2 A (inductive)!

4.4 Input for Away Function

• Connect the two wires from an external switch (ON/OFF) to the two terminals for the Away Func tion input (fig. 14).

When this switch is closed (ON) the system will override the current set point for all the room

thermostats and change it to 8 °C.

• Fix the cable (fig. 15).

GB

Note! The Away Function ensures a set room temperature fixed at 8 °C for all Room Thermostats, but it

can be changed with the CF-RC Remote Controller.

If the system is configured for cooling, a dew-point sensor can be connected instead of an external switch.

4.5 Input for Heating and Cooling

• Connect both wires from an external switch (ON/OFF) to the terminals for heating and cooling

input (fig. 16).

With the switch closed (ON), the system will switch from heating to cooling mode.

• Fix the cable (fig. 17).

Note! With the system in cooling mode, the actuator output will be activated (ON for NC actuators/OFF

for NO actuators), when the temperature in a room exceeds the set point +2 °.

When the system is in cooling mode a dew-point sensor should be installed, connected to the Away Function input and placed on the primary supply side.

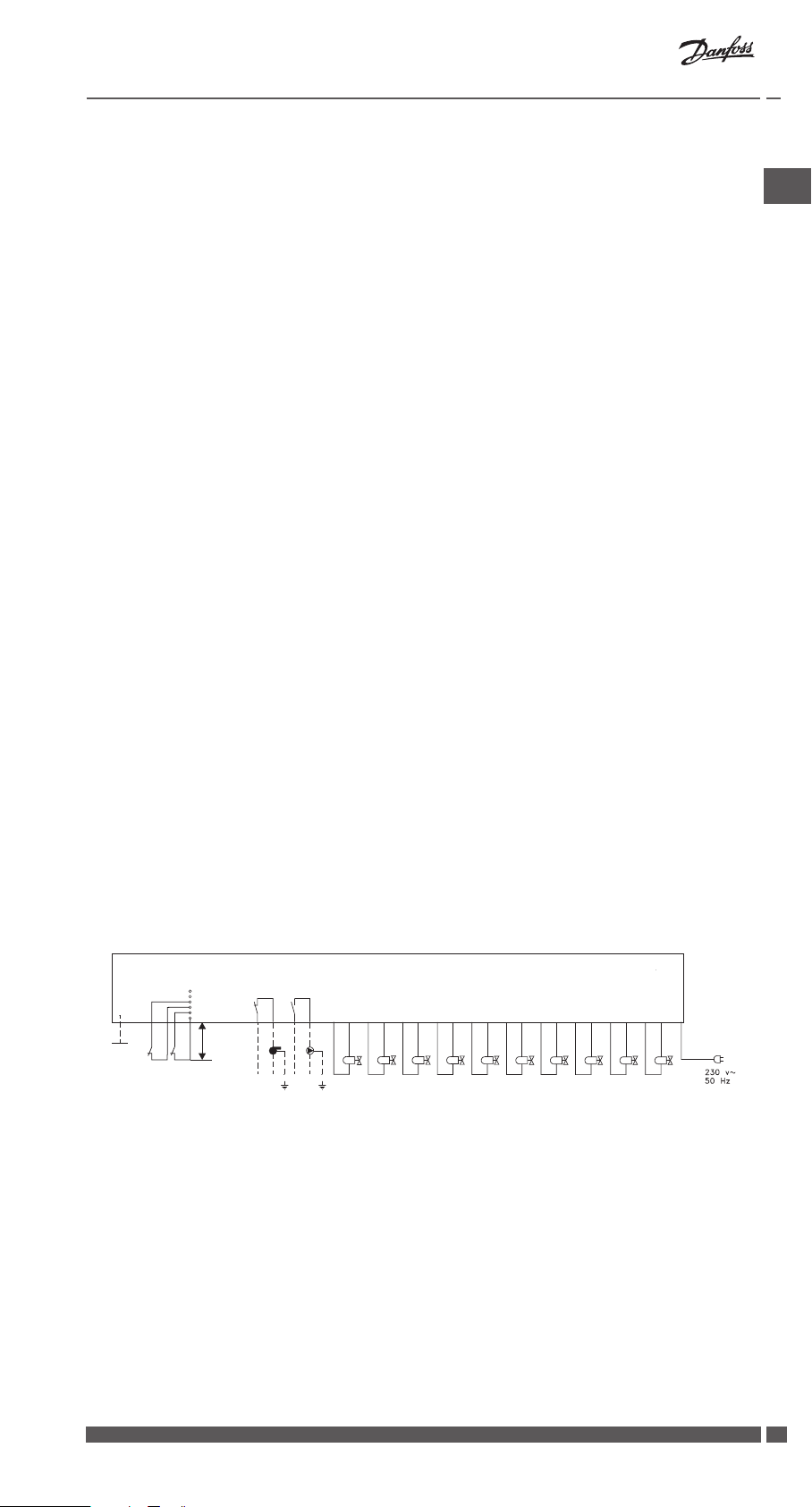

4.6 Wiring

Input Relays Actuator outputs

PT1000

Away Function

External

antenna

Heating/Cooling

Max. 3 m

910876 54321

4.7 Power Supply

Connect the CF-MC Master Controller power supply plug to a 230 V power supply, when all actuators, pump and boiler controls and other inputs are installed.

Note! If the power supply plug is removed from the power supply cable during installation, ensure that the

connection is made according to existing law/legislation.

4.8 CF-EA External Antenna

The CF-EA External Antenna is installed as diverter when there is no transmission possible through a

large building, heavy construction or metal barrier, e.g. if the CF-MC Master Controller is located in a

metal cabinet/box.

• Remove the plastic cover from the antenna connection on the CF-MC Master Controller (fig. 18).

• Connect the CF-EA External Antenna (fig. 19).

• Place the CF-EA External Antenna on the other side of the transmission barrier away from the

CF-MC Master Controller.

Danfoss Heating Solutions VIUHK902 01/2016

5

Installation Guide CF-MC Master Controller

4.9 More (2 to 3) CF-MC Master Controllers

Note! To have a troublefree installation of the CF-MC Master Controller 2 and/or 3, it is recommended to

complete installation of the CF-MC Master Controller 1.

CF-MC Master Controller 1 should be the one connected to the local supply pump.

• Up to 3 CF-MC Master Controllers can be connected in one system.

• If there are 2 or 3 CF-MC Master Controllers, connect them to a 230 V power supply within a

distance (max. 1.5 m) from CF-MC Master Controller 1, allowing simultaneous handling of all the

CF-MC Master Controllers.

Activate Install mode on CF-MC Master Controller 1 (fig. 20):

• Use the menu selection button to select the Install mode. Install LED flashes.

• Activate Install mode by pressing OK . Install LED goes ON.

Initiate installation on CF-MC Master Controller 2 or 3 (fig. 20):

• Activate installation to CF-MC Master Controller 1 by pressing OK .

• Install LED flickers during communication and goes OFF when installation is complete.

• Relocate CF-MC Master Controller 2 and/or 3 if necessary. Link test will be initiated automati-

cally on reconnection to 230 V power supply.

• If CF-MC Master Controller 2 and/or 3 has it’s own pump, the relays for pump and boiler must

be configured accordingly (see chapter 6.5).

Note! Later removal of CF-MC Master Controller 2 or 3 from CF-MC Master Controller 1 can only be done

by resetting CF-MC Master Controller 1 (see chapter 7.2).

4.10 CF-RS, -RP, -RD and -RF Room Thermostats

Note!

Assignment of Room Thermostats to CF-MC Master Controller should be within a distance of 1.5 m.

Activate Install mode on CF-MC Master Controller (fig. 20):

• Use the menu selection button to select the Install mode. Install LED flashes.

• Activate Install mode by pressing OK . Install LED goes ON.

Activate Install mode on CF-RD and -RF Room Thermostats (fig. 20/21):

• Press the push button . LED and flicker during communication.

Activate Install mode on CF-RS and -RP Room Thermostats (fig. 20/21):

• Press the push button / . LED and flicker during communication.

Select output on CF-MC Master Controller (fig. 20/22):

• All available output LEDs on CF-MC Master Controller light up, and the first one flashes.

• Press output selection button to select desired output (flashes). Accept with OK .

• All output LEDs go OFF. Selected output stays ON shortly.

Room Thermostat installation status (fig. 21):

• Satisfactory: LED goes OFF.

• Not satisfactory: LED flashes 5 times.

Note!

A Room Thermostat can be assigned to several outputs if needed by repeating the installation process.

4.11 Other System Components

The installation procedure of other system components to the CF-MC Master Controller (CF-RC Remote Controller, and CF-RU Repeater Unit) is described in the enclosed instructions for these system

components.

4.12 Transmission Test (Link Test)

The transmission test (link test) between the CF-MC Master Controller and other system components,

is initiated from the other system components like CF-RU Repeater Unit, CF-RC Remote Controller,

etc. See the enclosed instruction for these components for transmission test (link test) procedures.

Room Thermostats

When the transmission test (link test) from a Room Thermostat is received by the CF-MC Master

Controller, the assigned output(s) will flash. This makes it possible to identify the outputs to which a

Room Thermostat has been assigned (fig. 22 - ).

6

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

Initiate transmission test on Room Thermostat (fig. 27):

• Press the push button , LED goes ON.

• Satisfactory: LED goes OFF.

• Not satisfactory: LED flashes 5 times.

No Link connection to Room Thermostat:

• Try to relocate the Room Thermostat in the room.

• Or install the CF-RU Repeater Unit and locate between the CF-MC Master Controller and the Room

Thermostat.

Note! CF-MC Master Controller output LED(s) connected to the Room Thermostat, flash(es) during Link

test.

4.13 Mounting of CF-RS, -RP, -RD and -RF Room Thermostats

Mount the CF-RS, -RP, -RD and -RF Room Thermostat sheltered from the sunlight and other sources

of heat (fig. 23).

Mount with screws (fig. 24):

Back plate.

Turning knob release (only available for CF-RS and -RD).

Back plate lock/unlock (turn 90°).

Screw hole for wall mounting.

Battery placement.

Screw and wall plug.

GB

Note! Remove enclosed strips from batteries to activate.

A Room Thermostat can be assigned to several outputs if needed by repeating the installation process.

5. Temperature Settings

5.1 CF-RS and -RP Room Thermostat

Turning knob/cover (fig. 25):

Turning knob/cover release

CF-RS Room temperature limitation (fig. 26):

Minimum limitation (blue) (from 10 °C)

Maximum limitation (red) (up to 30 °C)

5.2 CF-RD and CF-RF Room Thermostat with Digital Display (fig. 21)

SET Set value adjustment

MIN Minimum temperature limitation

MAX Maximum temperature limitation

Transmission link icon

Low battery indicator

Alarm icon

Room temperature icon*

Floor temperature icon*

* Only valid for CF-RF Room Thermostat

Settings only available from CF-RC Remote Controller:

Lock icon

Timer icon

Cooling icon**

AUTO

** Only valid for CF-RD Room Thermostat. One of the standard CF-RD Room Thermostats can be defined

as a master thermostat for sequential control of heating and cooling stages, according to the room

temperature. This function is only available via CF-RC Remote Controller (see instruction for CF-RC).

Danfoss Heating Solutions VIUHK902 01/2016

Automatic change-over icon**

Heating icon**

7

Installation Guide CF-MC Master Controller

Changing default display temperature:

• The actual room temperature is shown in the display as default.

• To change default display from actual room temperature to actual floor surface temperature,

press and hold the push button until SET MAX is shown in the display.

• Press the button shortly and repeatedly until or is flashing in the display.

• Press the up/down selector to select the new default display temperature:

Room temperature Floor surface temperature.

Setting of room temperature:

• Make sure actual room temperature is shown in the display.

• Press the up/down selector to set the desired room temperature value. SET is shown in the

display.

• When releasing the up/down selector the display returns to actual temperature.

Note! The thermostat regulates the floor heating system according to room temperature set point, within

the maximum and minimum limitations defined for the floor surface temperature.

Room temperature limitation:

• Make sure actual room temperature is shown in the display.

• Press the push button until SET MAX is shown in the display.

• Press the up/down selector to set the maximum room temperature limitation.

• Press the push button shortly, SET MIN is shown in the display.

• Press the up/down selector to set the minimum room temperature limitation.

• Press the push button shortly and the actual floor surface temperature is shown in the

display.

Floor surface temperature limitation (only valid for CF-RF):

• Ensure actual floor surface temperature is shown in the display illustrated by .

• Press and hold the push button until SET MAX is also shown in the display.

• Press the up/down selector to set the maximum floor surface temperature limitation.

• Press the push button shortly, SET MIN is also shown in the display.

• Press the up/down selector to set the minimum floor surface temperature limitation.

IMPORTANT!

As heat emission from the floor may vary slightly depending on floor covering - and thereby cause inaccurate temperature measurement - it may be necessary to adjust the setting of max. and min. floor surface

temperatures accordingly. It is important always to follow recommendations from the floor manufacturer

regarding max. floor surface temperature. It is recommended to include mixing shunt for floor heating

circuits in order to ensure optimal flow temperature. - In addition to minimised energy consumption, correct setting of the flow temperature will eliminate the risk of excessive heat transfer to the floor.

6. Configuration

6.1 Actuator Outputs

Activate Output mode on CF-MC Master Controller (fig. 20/22):

• Use the menu selection button to select the Output mode. Output LED flashes.

• Activate Output mode by pressing OK . Output LED goes ON.

Select the output configuration:

• Press the output selection button and toggle between the possible output configurations

- the output LEDs will be ON – indicated below:

• 1 LED: The outputs are configured to NC actuators with ON/OFF regulation.

• 2 LEDs: The outputs are configured to NO actuators with ON/OFF regulation.

• 3 LEDs: The outputs are configured to NC actuators with Pulse Width Modulation (PWM)

regulation for floor heating (default).

• 4 LEDs: The outputs are configured to NO actuators with Pulse Width Modulation (PWM)

regulation for floor heating.

• 5 LEDs: A Remote Controller is installed, and it is not possible to change settings from the

CF-MC Master Controller.

• Activate selected output configuration by pressing OK .

Note! During periods with no output activations the CF-MC Master Controller will run a valve motion

program every 2 weeks and it will last for up to 12 minutes. Individual output configuration is possible with

the CF-RC Remote Controller, see separate instruction.

8

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

6.2 Relays for Pump and Boiler Control

Activate Relay mode on CF-MC Master Controller (fig. 20):

• Use the menu selection button to select the Relay mode. Relay LED flashes.

• Activate Relay mode by pressing OK . Relay LED goes ON.

Select the Relay configuration (fig. 20/22):

• Press the output selection button and toggle between the possible Relay configurations -

the output LEDs will be ON – indicated below:

• NO LEDs: The relays are not used.

• 1 LED: Pump control.

• 2 LEDs: Boiler control.

• 3 LEDs: Pump and boiler control.

• 4 LEDs: Pump control with 2 min. start/stop delay.

• 5 LEDs: Pump and boiler control, with 2 min. start/stop delay on pump (default).

• Activate selected relay configuration by pressing OK .

Note! If the pump relay is active, the CF-MC Master Controller will run a pump motion program every 3rd

day and it will last for one minute.

More relay configurations can be made via the CF-RC Remote Controller (see separate instruction).

6.3 Input for Away Function and Heating and Cooling

Activate Input mode on CF-MC Master Controller (fig. 20):

• Use the menu selection button to select the Input mode. Input LED flashes.

• Activate Input mode by pressing OK . Input LED goes ON.

GB

Select the Input configuration (fig. 20/21/22):

• Press the output selection button and toggle between the possible Input configurations

- the output LEDs will be ON – indicated below:

• 1 LED: The input ports are not used.

• 2 LEDs: The CF-MC Master Controller will switch to cooling mode when the input for heating/

cooling is activated (fig. 2 - ).

• 3 LEDs: The CF-MC Master Controller will switch to a fixed set room temperature at 8 °C for

all Room Thermostats when the input for away function is activated (fig. 2 - ).

• 4 LEDs: The CF-MC Master Controller will switch to cooling mode when the input for

heating/cooling is activated (fig. 2 - ). In heating mode the CF-MC Master Controller will

switch to a fixed set room temperature at 8 °C for all Room Thermostats when the input for

away unction is activated (fig. 2 - ) (default).

• Activate selected input configuration by pressing OK .

6.4 Heating/Cooling

A 2-pipe system can be configured for automatic heating/cooling change-over.

• A PT-1000 pipe sensor must be connected to the PT-1000 input (fig. 2 - ).

• Configuration is only possible via CF-RC Remote Controller (see separate instruction).

6.5 Relays on more (2 to 3) CF-MC Master Controllers

If more CF-MC Master Controllers are connected to CF-MC Master Controller 1 in one system, their

relays for pump and boiler control should be configured separately!

Activate Relay mode on CF-MC Master Controller 2/3 (fig. 20):

• Use the menu selection button to select the Relay mode. Relay LED flashes.

• Activate Relay mode by pressing OK . Relay LED goes ON.

Select the Relay configuration (fig. 20/22):

• Press the output selection button and toggle between the possible Relay configurations the output LEDs will be ON – indicated below:

Uses pump and boiler connected to CF-MC Master Controller 1:

• NO LEDs: The relays are not used (default).

If local manifold and pump are separate:

• 1 LED: Pump control.

• 4 LEDs: Pump control with 2 min. start/stop delay.

• Activate selected relay configuration by pressing OK .

6.6 Wireless relay

CF-WR Wireless Relay can be connected to the CF-MC Master Controller and configured by the CF-RC

Remote Controller (see separate instruction).

Danfoss Heating Solutions VIUHK902 01/2016

9

Installation Guide CF-MC Master Controller

7. Replacing/Resetting the CF-MC Master Controller

7.1 When?

If the CF-MC Master Controller in an existing CF2+ system is reset to factory settings or replaced with

another CF-MC Master Controller, it is necessary to reset all the other CF2+ system components also,

in order to be able to re-install them to the reset or replaced CF-MC Master Controller.

7.2 How?

Note! Only “Reset” the CF-MC Master Controller to factory settings if the normal in- and uninstallation

procedures can not be followed!

Resetting the CF-MC Master Controller (fig. 20/22):

• Disconnect the 230 V power supply to CF-MC Master Controller until the power LED is OFF.

• Press and hold at the same time menu selection button , OK button , and output selection

button .

• Reconnect the 230 V power supply to CF-MC Master Controller and release the three buttons

when the power LED and all the output LEDs are ON.

• The CF-MC Master Controller is reset when all output LEDs goes OFF.

Resetting the CF-RS, -RP, -RD and -RF Room Thermostats (fig. 27):

• Remove the Room Thermostat from the back plate and disconnect one of the batteries .

• Press and hold the push button (Link test) and reconnect the battery .

• Release the push button when the red LED has been On and Off again.

• The Room Thermostat is now reset and ready for installation to a CF-MC Master Controller.

Resetting the CF-RC Remote Controller (fig. 28):

• At the same time, activate soft key 1 , soft key 2 and the down selector .

• The CF-RC Remote Controller requests confirmation before resetting.

• Confirmation with “yes” Resets the CF-RC Remote Controller and it is now ready for installation to

a CF-MC Master Controller.

Resetting the CF-RU Repeater Unit (fig. 29):

• Disconnect the CF-RU Repeater Unit from the 230 V power supply.

• Press and hold the push button (Link test) and reconnect the 230 V power supply.

• Release the push button when the red LED has been On and Off again.

• The CF-RU Repeater Unit is now reset and ready for installation to a CF-MC Master Controller.

10

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

8. Technical Specifications

8.1 CF-MC Master Controller

Transmission frequency 868.42 MHz

Transmission range in normal constructions (up to) 30 m

Transmission power < 1 mW

Supply voltage 230 V AC

Actuator outputs 10 x 24 V DC

Max. continued output load (total) 35 VA

Relays 230 V AC/8 (2) A

Ambient temperature 0 - 50 °C

IP class 30

8.2 CF-RS, -RP, -RD and -RF Room Thermostats

Temperature setting range 5 - 35 °C

Transmission frequency 868.42 MHz

Transmission range in normal constructions

(up to)

Transmission power < 1 mW

Battery Alkaline 2 x AA, 1.5 V

Battery lifetime (up to) 1 to 3 years

Ambient temperature 0 - 50 °C

IP class 21

Floor sensor accuracy* +/- 1 °C

Floor sensor emission coefficient* 0.9

30 m

GB

* Only valid for CF-RF Room Thermostat

Note! See separate instructions for other components.

Danfoss Heating Solutions VIUHK902 01/2016

11

Installation Guide CF-MC Master Controller

9. Troubleshooting

9.1 CF-MC Master Controller

Error indication Possible Causes

Output LED(s), alarm LED and output menu

LED flash. Buzzer is ON*

Output LED(s), alarm LED and input menu

LED flash. Buzzer ON after 12 hours**

Output LEDs 1-4, alarm LED and input LED

flash

Output LEDs 1-5, alarm LED and input menu

LED flash

CF-MC Master controller 1:

Alarm and Install LED’s flashes for approx.

20 sec.

CF-MC Master Controller 2:

Alarm LED lights up for approx. 1 sec.

* Buzzer is shut off by pressing OK. The error indication continues until the error is fixed.

** If the room thermostat signal is lost, the CF-MC Master Controller output will be activated 15 minutes

every hour for frost protection until the error is fixed

9.2 CF-RS, -RP, -RD and -RF Room Thermostats

Error indication Possible Causes

The LED ( and *) flashes every 5th

minute

The LED ( and *) flashes every 30 sec.

The LED, , and flashes*

The LED ( and *) flashes 5 times

E03 and *

E05 and *

Output or actuator is short-circuited or the actuator is disconnected

No wireless signal from room thermostat connected to this or these outputs or the temperature

in the according room is below 5 °C. (Try to verify

the function of the room thermostat by making a

link test)

No signal from the CF-RC Remote Controller

No signal from CF-MC Master Controller 2 or 3

CF-MC Master Controller 2 has an older version of

software, which is not compatible with the newer

software in CF-MC Master Controller 1

Low battery

Critical low battery

Critical low battery

- transmission has stopped

Installation/Link Test is unsatisfactory

Actuator error on output (CF-MC)

Room temperature below 5 °C

* Only valid for CF-RD and -RF Room Thermostats

12

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

GB

Danfoss Heating Solutions VIUHK902 01/2016

13

Installation Guide CF-MC Master Controller

A1

Fig. 1a/CF-MC

Fig. 1b CF-RS CF-RP CF-RD CF-RF

Fig. 1c/CF-RC Fig. 1d/CF-RU Fig. 1e/CF-DS Fig. 1f/CF-WR

Fig. 1g/CF-EA

Fig. 2

14

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

A2

Fig. 3

CF-MC

CF-RU

CF-RS/-RP/-RD/-RF

CF-RS/-RP/-RD/-RF

Fig. 4 Fig. 5

Fig. 6 Fig. 7

Click!

GB

CF-MC

!

Click!

Fig. 8 Fig. 9

Fig. 10 Fig. 11

Danfoss Heating Solutions VIUHK902 01/2016

15

Installation Guide CF-MC Master Controller

B1

Fig. 12 Fig. 13

Fig. 14 Fig. 15

Fig. 16 Fig. 17

Fig. 18 Fig. 19

Fig. 20 Fig. 21

16

01/2016 VIUHK902 Danfoss Heating Solutions

Installation Guide CF-MC Master Controller

B2

Fig. 22

Fig. 20

Fig. 23 Fig. 24

1,5 m.

0,5 m.

0,25 m.

Fig. 25

Fig. 26

CF-RS

GB

CF-RP

Fig. 27

Fig. 28 Fig. 29

Danfoss Heating Solutions VIUHK902 01/2016

17

Danfoss A/S

Indoor Climate Solutions

Ulvehavevej 61

7100 Ve jle

Denmark

Phone: +45 748 8 8500

Fax: +45 7488 8501

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

VIUHK902

Loading...

Loading...