Page 1

CDS Directional

Control Valve

Assembly and Test

Manual

Page 2

2

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

© 2005 Sauer-Danfoss. All rights reserved. Printed in U.S.A.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer-Danfoss reserves the right to alter its products without prior notice. This also applies to products

already ordered provided that such alterations aren’t in conflict with agreed specifications. All trademarks in

this material are properties of their respective owners. Sauer-Danfoss and the Sauer-Danfoss logotype are

trademarks of the Sauer-Danfoss Group. Detroit Diesel®, Cummins®, and Caterpillar® trademarks are properties

of their respective owners.

Front cover illustrations: F101 489, F301 112, P104 394

ORGANIZATION AND

HEADINGS

To help you quickly find information in this manual, the material is divided into sections,

topics, subtopics, and details, with descriptive headings set in red type. Section titles

appear at the top of every page in large red type. Topic headings appear in the left

hand column in BOLD RED CAPITAL LETTERS. Subtopic headings appear in the body

text in bold red type and detail headings in italic red type.

References (example: See Topic xyz, page XX) to sections, headings, or other publications are

also formatted in red italic type. In Portable Document Format (PDF) files, these references

represent clickable hyperlinks that jump to the corresponding document pages.

Tables, illustrations, and graphics in this manual are identified by titles set in

blue italic

type above each item. Complementary information such as notes, captions, and drawing

annotations are also set in blue type.

References (example: See

Illustration abc, page YY) to tables, illustrations, and graphics

are also formatted in blue italic type. In PDF files, these references represent clickable

hyperlinks that jump to the corresponding document pages.

Defined terms and acronyms are set in bold black

type in the text that defines or

introduces them. Thereafter, the terms and acronyms receive no special formatting.

Black italic

type is used in the text to emphasize important information, or to set-off

words and terms used in an unconventional manner or alternative context. Red and blue

italics represent hyperlinked text in the PDF version of this document (see above).

An indented

Table of Contents (TOC) appears on the next page. Tables and illustrations

in the TOC set in blue type. In the PDF version of this document, the TOC entries are

hyperlinked to the pages where they appear.

TABLES, ILLUSTRATIONS,

AND COMPLEMENTARY

INFORMATION

SPECIAL TEXT

FORMATTING

TABLE OF CONTENTS

Using this manual

Page 3

3

520L0924 • October 2005

INTRODUCTION

ASSEMBLY

TESTING

TROUBLESHOOTING

APPENDIX A

CDS Directional Control Valve Assembly and Testing Manual

Contents

Overview ...........................................................................................................................................................4

General instructions ...................................................................................................................................... 4

Safety precautions ......................................................................................................................................... 5

Unintended machine movement ....................................................................................................... 5

Flammable cleaning solvents ...............................................................................................................5

Fluid under pressure ................................................................................................................................ 5

Personal safety ........................................................................................................................................... 5

Symbols used in Sauer-Danfoss literature .............................................................................................6

Required tools .................................................................................................................................................6

Assembly instructions ..................................................................................................................................

7

Centering types ...............................................................................................................................................9

Spring centered assembly (A) ..............................................................................................................9

Three position detent assembly (B) .................................................................................................10

Spring/detent detent assembies (C,D&E) ......................................................................................11

Spring center/float detent assembly (J) .........................................................................................13

Hydraulic kickout (F) ..............................................................................................................................14

Spring center assembly (G, H, I) ..........................................................................................................14

Auxiliary valves ..............................................................................................................................................15

Load check ......................................................................................................................................................16

Handle assembly ..........................................................................................................................................17

Joystick assembly .........................................................................................................................................18

Alternate joystick assembly ......................................................................................................................19

Cable assembly .............................................................................................................................................20

Oil and test conditions ...............................................................................................................................22

Adjusting pressure settings ......................................................................................................................

22

Main relief valve ......................................................................................................................................22

Work port relief valve ............................................................................................................................22

Adjusting main/port relief valves ......................................................................................................22

Leakage testing .............................................................................................................................................23

Work port leakage ..................................................................................................................................23

Load check leakage ................................................................................................................................23

Function testing ............................................................................................................................................24

Spring Center Function .......................................................................................................................24

Detent Functions ....................................................................................................................................24

Float Functions ........................................................................................................................................25

Pneumatic Function ..............................................................................................................................25

Hydraulic Function .................................................................................................................................25

Solenoid Function .................................................................................................................................26

Three Way Spools ....................................................................................................................................26

Backpressure test .........................................................................................................................................26

The valve leaks ...............................................................................................................................................

28

It still leaks .......................................................................................................................................................28

Sticky spool ....................................................................................................................................................29

Relief doesn’t work .......................................................................................................................................29

Cable binds .....................................................................................................................................................29

Appendix A Testing certification form ..................................................................................................

30

Page 4

4

520L0924 • October 2005

Follow these general procedures when assembling CDS stack valves.

e Keep it clean

Cleanliness is a primary means of assuring satisfactory valve life, on either new or

repaired units. Clean the outside of the valve thoroughly before assembly. Take care to

avoid contamination of the system ports. Cleaning parts by using a clean solvent wash

and air drying is usually adequate.

As with any precision equipment, all parts must be kept free of foreign materials and

chemicals. Protect all exposed sealing surfaces and open cavities from damage and

foreign material. If left unattended, cover the valve with a protective layer of plastic.

l Lubricate moving parts

During assembly, coat all moving parts with a film of clean hydraulic oil. This assures that

these parts will be lubricated during start-up.

d Lubricate all O-rings and gaskets

Lightly lubricate all O-rings with clean petroleum jelly prior to assembly. If the stack valve

is being repaired, it is recommended that all O-rings be replaced..

GENERAL INSTRUCTIONS

CDS Directional Control Valve Assembly and Testing Manual

Introduction

This manual provides information and procedures for the assembly of a new CDS valve

group using the following guidelines:

The specification sheet (CDS build tool and CDS order form) is compiled by the

distributor and assigned a number provided by Sauer-Danfoss. The order form is then

sent to Sauer Danfoss (preferably electronically [FAX]) and reviewed and approved by

the Sauer-Danfoss Technical Support Team (TST) or customer service (CDS) assigned

personnel. The specification sheet will then be logged into a master file. Once it is

determind that the distributor wants S-D to start providing this assembly, a SauerDanfoss part number will be assigned.

After final testing, the test certification, (Appendix A), is to be completed by the

assembly/testing personnel. A copy of the certification must be sent to the TST at SauerDanfoss, Easley, SC.

Before, during and after the assembly/disassembly of new CDS groups, absolute

cleanliness and care must be observed with regard to internal and external parts of the

units concerned. Use non-volatile, petroleum based solutions for cleaning valves and/or

modules. Replace all parts considered likely to cause malfunction during subsequent

testing and report nonconforming product to Sauer-Danfoss (TST ). Replace all loose

O-rings (without exceptions) with new O-rings. Lubricate all moving parts with hydraulic

oil before assembly. Lubricate all O-rings with petroleum jelly. Lubricate all detent and

spring centered accessories with LUBRIPLATE 730-1 or equvaliant.

Refer to this manual and the CDS Specification sheet for module designations, item

numbers, spare parts numbers, tightening torques, etc., whether assembling new groups

or making repairs.

Refer to Directional Control Valves Technical Information Manual

520L0564 for more

detailed information including order codes and specifications.

OVERVIEW

Page 5

5

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Introduction

Always consider safety precautions before beginning a service procedure. Protect

yourself and others from injury. Take the following general precautions whenever servicing a

hydraulic system.

Unintended machine movement

W Warning

Unintended movement of the machine or mechanism may cause injury to the technician

or bystanders. To protect against unintended movement, secure the machine or disable /

disconnect the mechanism while servicing.

Flammable cleaning solvents

W Warning

Some cleaning solvents are flammable. To avoid possible fire, do not use cleaning

solvents in an area where a source of ignition may be present.

Fluid under pressure

W Warning

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin

causing serious injury and/or infection. This fluid may also be hot enough to cause burns.

Use caution when dealing with hydraulic fluid under pressure. Relieve pressure in the

system before removing hoses, fittings, gauges, or components. Never use your hand

or any other body part to check for leaks in a pressurized line. Seek medical attention

immediately if you are cut by hydraulic fluid.

Personal safety

W Warning

Protect yourself from injury. Use proper safety equipment, including safety glasses, at all

times.

SAFETY PRECAUTIONS

Page 6

6

520L0924 • October 2005

WARNING may result in injury

CAUTION may result in damage to

product or property

Reusable part

Non-reusable part, use a new part

Non-removable item

Option – either part may exist

Superseded – parts are not

interchangeable

Measurement required

Flatness specification

Parallelism specification

External hex head

Internal hex head

Torx head

O-ring boss port

Tip, helpful suggestion

Lubricate with hydraulic fluid

Apply grease/petroleum jelly

Apply locking compound

Inspect for wear or damage

Clean area or part

Be careful not to scratch or damage

Note correct orientation

Mark orientation for reinstallation

Torque specification

Press in – press fit

Pull out with tool – press fit

Cover splines with installation

sleeve

Pressure measurement/gauge

location or specification

SYMBOLS USED IN

SAUER-DANFOSS

LITERATURE

The symbols above appear in the illustrations and text of this manual. They are intended

to communicate helpful information at the point where it is most useful to the reader.

In most instances, the appearance of the symbol itself denotes its meaning. The legend

above defines each symbol and explains its purpose.

CDS Directional Control Valve Assembly and Testing Manual

Introduction

REQUIRED TOOLS The following tools are required to build a CDS control valve :

Hand tools:

Hex head wrench: 3/32, 1/8, 5/32, 1/4

Sockets: 3/8 deep well, 11 mm, 13 mm, 17 mm, 1 inch, 22 mm, 32 mm

Phillips and flat head screw driver

Torque wrench: 3/8 drive 0-68 N•m [0-50 lbf•ft].

Page 7

7

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

ASSEMBLY

INSTRUCTIONS

The valve is to be assembled in accordance with the CDS stack valve order form.

Install inlet section first

The assembly sequence for CDS stack valve groups is as follows :

1. Ensure that all parts required, according to the completed CDS stack valve order

form are present. Unpack and inspect all parts for damage and cleanliness. Ensure

that all parts are free of nicks, burrs, contamination etc.

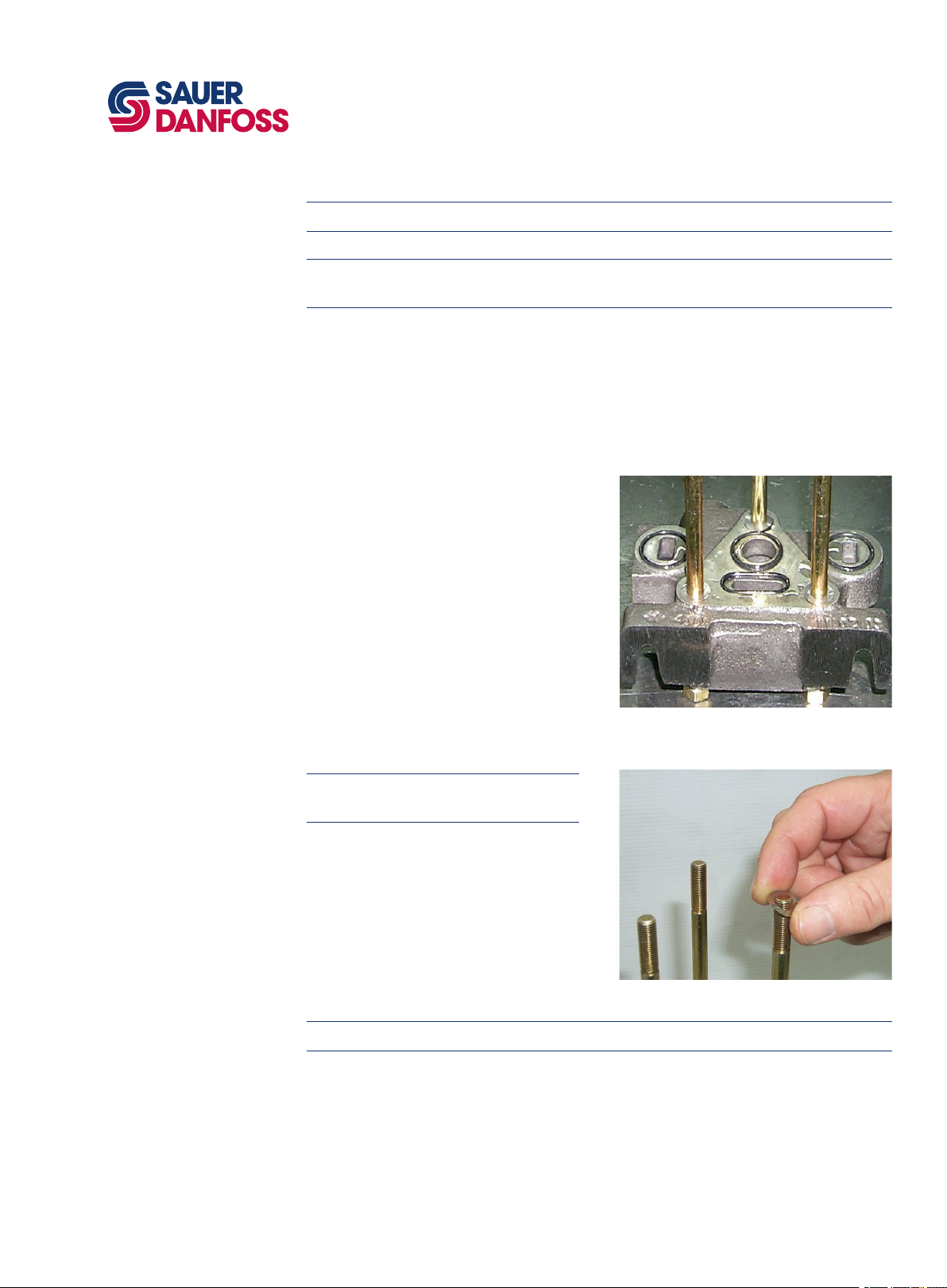

4 Install shims between each section,

one per tie rod.

This will ensure that the O-rings do not fall out during assembly

The first spool listed in model number is closest to the inlet section.

Install shims between each section

Install shims between each section

including Inlet and Outlet sections.

6. Install the basic valve section

module(s) indicated on the order

form against the inlet section.

Ensure that the machined surface

of the next section faces the O-rings

of the previous section.

Following assembly steps include installation of optional relief valves and optional

control components.

2. Install a nut and lock washer on one

end of each tie rod. Guide tie rods

through holes in each section (inlet

section first).

3. Place all lubricated O-rings in their

respective grooves in the different

modules before installing them.

Page 8

8

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

7. Install the outlet section against the

last basic valve section.

8. Install lockwashers and nuts on end

of tie rods.

Install the lock washers and nuts hand

tight so the sections can’t separate and

allow the O-rings to fall out of place.

Install outlet section

11. Check each spool to ensure free movement of all sections. Any binding or sticking

in spools is unacceptable. If binding/sticky spools are present, disassemble the stack

and inspect for cause. Replace parts as required.

Spool movement will have a slight drag from the O-rings. Be careful not to shift the spool

end past the O-rings. Shifting spool end past the O-rings may damage the O-rings.

12. The spools are pre-installed into the spool bores of each valve section at the factory.

Each spool is matched to its housing. Do not interchange spools. Inter-changing

a spool from one section to another, may cause spool to bind and/or create high

internal spool leakage.

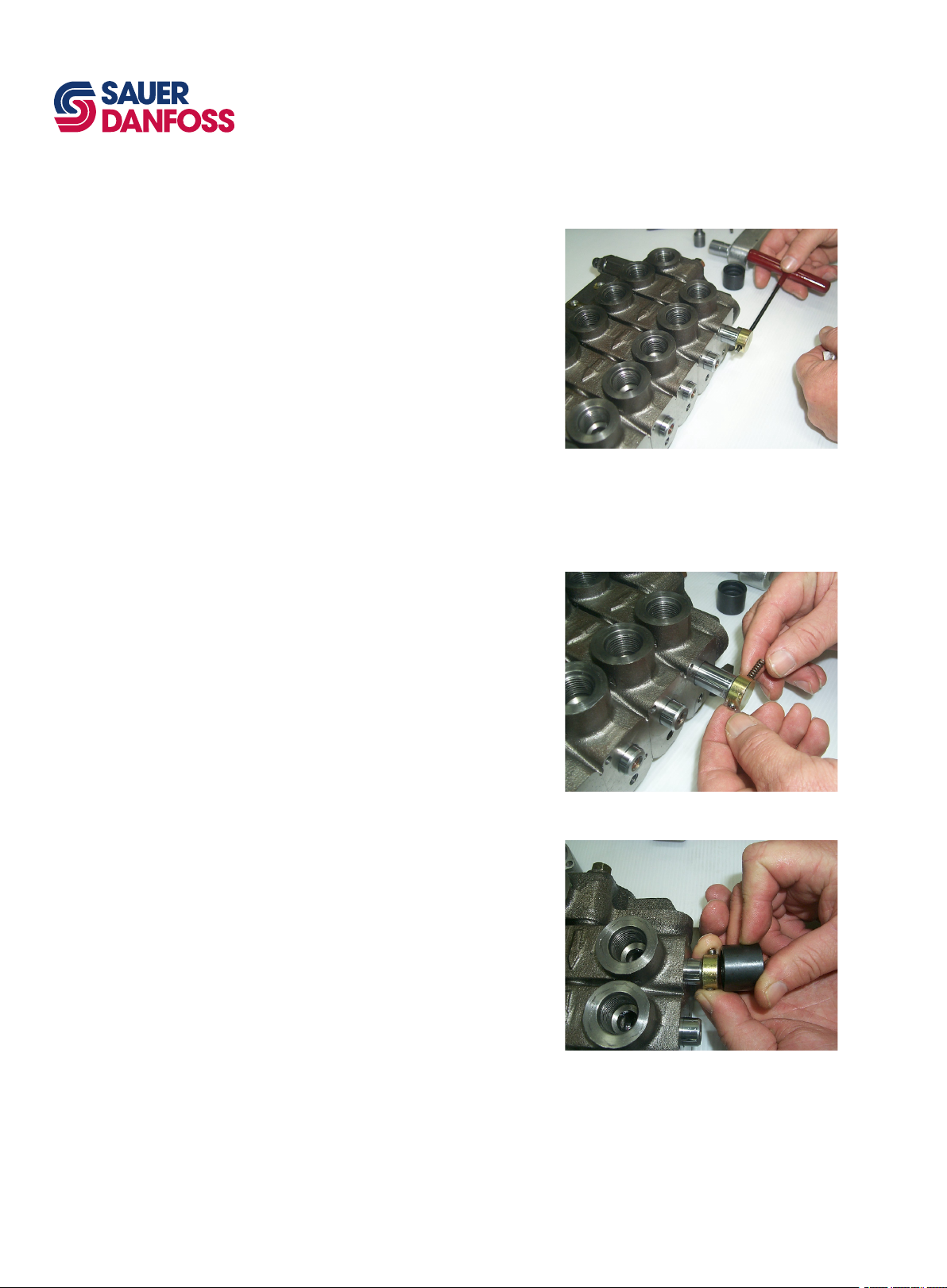

13. Install the specified option (plug

or relief valve) to the inlet section.

Torque to 27-39 N•m [20-25 lbf•ft]

Install plug/relief valve in inlet section

9. Lay the stack down on its mounting

feet. Adjust washers and nuts so

tie rods stick out equal distance on

either side of valve.

10. Tighten tie rod nuts incrementaly in

staggered order.

Tie rod nut torque:

• CDS 60 is 16-18 N•m [13-15 lbf•ft] ,

• CDS 100 is 25-27 N•m 18-20 [lbf•ft]

using a 1/2 inch socket.

Torque tie rods

Page 9

9

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

CENTERING TYPES Assemble the spring/detent assemblies to the valve as specified in the order form. The

stem(s) for each assembly must have Liquid Lock ThreadsTM or equivalent applied. For

CDS 60 tighten the stem(s) to a torque of 2.7-4.0 N•m [2-3 lbf•ft] using a 11mm socket.

For CDS 100 tighten the stem(s) to a torque of 4.0-5.4 N•m [3-4 lbf•ft] using a 13mm

socket.

Spring/detent assemblies1. Install the stem and spring assembly

on the spool using Liquid Lock

ThreadsTM or equivalent. For CDS

60 tighten the stem(s) to a torque

of 2.7-4.0 N•m [2-3 lbf•ft] using a

11mm socket. For CDS 100 tighten

the stem(s) to a torque of 4.0-5.4 N•m

[3-4 lbf•ft] using a 13mm socket.

2. Lubricate the spring assembly with

Lubriplate 730-1TM or equivalent.

3. Install the end cap over the spring

package. Apply Liquid Lock Threads

TM

or equivalent and install the two

(2) screws and washers using the

appropriate screw driver.

Screw torque:

• CDS 60 and CDS 100 2.7-4.0 N•m [2-3

lbf•ft].

Lubricate spring assembly

Install endcap over spring assembly

For loose sections,

complete assembly with

section clamped in a

protective jawed vice

before adding to stack..

Spring centered assembly (A)

Page 10

10

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

1. Install stem on spool using using

Liquid Lock ThreadsTM or equivalent.

For CDS 60 tighten the stem(s) to

a torque of 2.7-4.0 N•m [2-3 lbf•ft]

using a 11mm socket. For CDS 100

tighten the stem(s) to a torque of

4.0-5.4 N•m [3-4 lbf•ft] using a 13mm

socket.

2. Fasten cap to spool with two screws

and washers. Using a 5/32 hex driver,

torque screws to 5.5-8.2 N•m [4-6

lbf•ft].

Install detent assembly

Install spring in detent assembly

Install cover in detent assembly

3 Lubricate the steel balls and

spring with LUBRIPLATE 730-1TM or

equivalent.

4. Install one ball and the spring into

the holes of the end cap.

5. Install second ball on other end of

spring.

6 Compress the balls against the

spring evenly and slip the sleeve

over the end.

Three position detent assembly (B)CENTERING TYPES

(continued)

Page 11

11

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

Install cover over detent assembly7. Install the end cap.

8. Apply

Liquid Lock Threads

TM

or

equivalent and install screws and

washers. Tighten to a torque of

2.7-4.1 N•m [2-3 lbf•ft] using the

appropriate screw driver.

CENTERING TYPES

(continued)

Spring/detent detent assembies (C,D&E) Spring/detent assemblies

2. Install detent spring and larger steel

ball.

3. Lubricate the crossholes with

LUBRIPLATE 730-1

TM

or equivalent.

4. Install smaller steel bals in crossholes.

5. Press in larger steel ball using a

punch or allen wrench.

Do not press the steel ball in too far

or the smaller steel balls may fall inside

stem.

1. Install the stem and spring assembly

on the spool using

Liquid Lock

ThreadsTM or equivalent. For CDS 60

tighten the stem(s) to a torque of

2.7-4.0 N•m [2-3 lbf•ft] using a 11mm

socket. For CDS 100 tighten the

stem(s) to a torque of 4.0-5.4 N•m

[3-4 lbf•ft] using a 13mm socket.

Spring and ball

Page 12

12

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

Install endcap

3. Install backup washer. ?

Install detent5. Install detent sleeve.

6. Slide the end cap spacer over the

detent.

CENTERING TYPES

(continued)

Cover extension7. Slide endcap spacer over spool.

8. Install endcap using two screws and

washers.

9. Apply

Liquid Lock Threads

TM

or

equivalent.

10. Torque screws to 2.7-4.1 N•m [2-3

lbf•ft] using the appropriate screw

driver.

Page 13

13

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

Install spring assembly and spool end

1. Install spring assembly and spool

end. Use LocktiteTM on spool end.

For CDS 60 tighten the stem(s) to

a torque of 2.7-4.0 N•m [2-3 lbf•ft]

using a 11mm socket. For CDS 100

tighten the stem(s) to a torque of

4.0-5.4 N•m [3-4 lbf•ft] using a 13mm

socket.

Spring center/float detent assembly (J)

Spring and ball

Spacer

6. Slide end cap spacer over spool. Slide

detent sleeve over spool.

CENTERING TYPES

(continued)

2. Install detent spring and larger steel

ball.

3. Lubricate the crossholes with

LUBRIPLATE 730-1

TM

or equivalent.

4. Install smaller steel bals in crossholes.

5. Press in larger steel ball using a

punch or allen wrench.

Do not press the steel ball in too far

or the smaller steel balls may fall inside

stem.

Page 14

14

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

5. Screw cap on endcap.

Torque screws

Screw on endcap

4. Install the two (2) screws and

washers. Apply Liquid Lock Threads

TM

or equivalent and torque screws

to 2.7-4.1 N•m [2-3 lbf•ft] using the

appropriate screw driver.

CENTERING TYPES

(continued)

Sauer-Danfoss recommends purchasing a complete assembly..

Hydraulic kickout (F)

Install spring assembly (G, H, I) using process similar to (A), page 9.

Spring center assembly (G, H, I)

Page 15

15

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

AUXILIARY VALVES 1. Assemble the main relief valve into

the inlet. Ensure that the O-rings are

lubricated. The torque for the relief

valve assembly is 41-48 N•m [20-25

lbf•ft], using a 1 inch wrench. For

inlet section without the relief valve

option, go to next step.

2. Assemble the port relief valve(s)

(with and with out anti-cavitation)

into the valve stack section(s). Ensure

that the O-rings are lubricated.

The torque for the port relief valve

assembly is 41-48 N•m [20-25 lbf•ft],

using a 1 inch wrench.

3. Assemble the plug for the port relief

into the valve stack section(s). Ensure

that the O-rings are lubricated. The

torque for the assembly is 20-27

N•m [15-20 lbf•ft], using a 1 inch hex

driver.

4. Assemble pilot operated check

valves and flow control valves using

the same process used for reliefs.

For sections used without auxiliary

valves, check to ensure the correctness of

body for function desired.

Auxiliary valve

Flow control piston option

Pilot operated check piston option

Page 16

16

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

LOAD CHECK Assemble the load check sections as specified in the order form.

Assemble the load check valves into the valve stack section(s). Ensure that the O-rings

are lubricated. Install the check with spring into the valve section, then install the plug.

The torque for the plug is 20-27 N•m [15-20 lbf•ft], using a 22 mm wrench (CDS 60), 32

mm wrench (CDS 100).

For assemblies with motor spools in the section, the cavity for a load check will receive a

plug. Ensure that the O-rings are lubricated. The torque for the plug is 20-27 N•m [15-20

lbf•ft], using a 22 mm wrench (CDS 60), 32 mm wrench (CDS 100).

Stamp the part number, date code, relief valve setting, build center number on the name

plate in the proper locations. Attach the name plate to the inlet section using two (2)

drive screws.

Page 17

17

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

HANDLE ASSEMBLY 1. Install upper and lower pivot

assemblies using LocktiteTM. Ensure

pivot assemblies are installed equal

distance (use a straight edge) . The

torque for the relief valve assembly

is 40-48 N•m [30-35 lbf•ft], using a 1

inch wrench.

Install pivot assemblies

Assemble handle linkage2. Assemble handle linkage using pins

and cotter pins supplied.

Page 18

18

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

JOYSTICK ASSEMBLY

Joystick assembly

Joystick assembly attached to sections

2. Assemble joystick pivot assembly.

Use LocktiteTM. The torque for the

nuts is 40-48 N•m [30-35 lbf•ft], using

a 7/16 inch wrench.

3. Bolt joystick assembly to sections

using hardware supplied.

Attach joystick handle

Joystick pivot1. Assemble joystick pivot. Use

LocktiteTM. The torque for the pivot is

40-48 N•m [30-35 lbf•ft], using a 7/16

in wrench.

4. Attach joystick handle.

Page 19

19

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

Joystick pivot

Add bushing

1. Assemble joystick pivot using

LocktiteTM. Use a straight edge to

ensure pivots are equal distance. The

torque for the pivot is 40-48 N•m [3035 lbf•ft], using a 7/16 inch wrench.

2. Add a bushing when installing the

bearing. Install washer and nut.

Torque nut to 40-48 N•m [30-35

lbf•ft].

Install third bearing

ALTERNATE JOYSTICK

ASSEMBLY

Connect pivot plate

3. Install third bearing using long bolt.

Install washer and nut. Torque nut to

40-48 N•m [30-35 lbf•ft].

4. Attach pivot plate using washers and

nuts provided. Torque nuts to 40-48

N•m [30-35 lbf•ft].

Page 20

20

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

CABLE ASSEMBLY 1. Install cable connector. Use

LocktiteTM. The torque for the cable

connector is 40-48 N•m [30-35 lbf•ft],

using a 1 inch wrench.

Install pivot assemblies

Install locknut

Cable end

2. Install locknut on cable.

3. Install cable end.

Page 21

21

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Assembly

Connect cable end

Tighten locknut

1. Connect cable to section using pin

provided.

2. Tighten locknut. Torque to 40-48 N•m

[30-35 lbf•ft].

Slide can

Attach bracket to section

CABLE ASSEMBLY

(continued)

3. Slide can over cable end.

4. Attach bracket to section using

screws and washers. Torque screws

to 40-48 N•m [30-35 lbf•ft].

Page 22

22

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Testing

OIL AND TEST

CONDITIONS

ADJUSTING PRESSURE

SETTINGS

• Pressure required: Up to 207 bar [3000 psi] on a regulated line

• Flow required: Minimum of 80 liters/min [10-15 USgal/min] or stack flow and pressure

requirements

• Oil type: Mobil DTE 24 or equvilant

• Oil temperature: 43°C +/- 3°C [110°F +/- 5°F]

• Oil cleanliness level: ISO 19/16 (10 micron or better; suction and return)

• 12/24 Volt DC power supply and digital volt meter

• Remote joystick

Main relief valve

Test the main inlet pressure relief valve by applying oil pressure on the pressure port of

the inlet section.

1. Install a 69 bar [1000 psi] gauge in the pressure port of the inlet section.

2. Connect the tank port to the tank.

3. Shift one of the spools in a section to block free flow through the valve.

4. Set the main Inlet relief of the valve assembly to customer required specification.

Refer to Sauer-Danfoss publication CDS stack valve assembly order form 520Lxxx for

relief settings.

Work port relief valve

Test the work port pressure relief valves by applying oil pressure on the work port.

1. Install a 69 bar [1000 psi] gauge in the work port of the selected section.

2. Connect the tank port to the tank.

3. Block all other ports off with steel plugs.

4. Set the port relief of the valve assembly according to Sauer-Danfoss publication CDS

stack valve assembly order form 520Lxxx.

Adjusting main/port relief valves

Adjust the main/port relief valves by loosening the lock nut (17 mm) and turning the

adjusting screw (11 mm). Turning the adjusitng screw clockwise raises the relief pressure

and turning counterclockwise lowers the relief pressure. Retest the relief pressure.

Continue to turn the adjusting screw, lock the locknut, and retest until the desired setting

is reached.

Non-Adjustable relief’s are adjusted by adding shim or shims of various thickness until

the desired setting is obtained.

Connect the valve to a test stand consisting of a hydraulic pump, appropriate hoses and

fittings, appropriate gauges, temperature control, power supply, and an adequate filter

and tank. The minimum specifications for the test stand are listed below.

Page 23

23

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Testing

Load check leakage

See note on oil and test conditions page

22.

Apply 69 bar [1000 psi] to the work port

opposite handle assembly. Plug all ports

except work port and Pressure port. Shift

spool slightly to prime the passage way

before starting leakage test.

Shift the spool in the full out position

(towards operator) to check for leakage.

Maximum leakage allowed out the outlet

port is 80 cc [5 cubic inches] per minute

(22 cc [1.4 cubic inches] in 10 seconds).

Leakage testing apparatus

Work port leakage

Plug all ports except work port to be tested and tank port. Apply 69 bar [1000 psi] to

the work port of each section. Shift spool slightly to prime the passage way before

starting the test. Check for leakage out by using goose neck style tubing (shown below)

in the outlet port. With the spool in the neutral position,pressurize the work port and

check leakage rate for 10 seconds. Check a minimum of twice per port. Rotate spool 180

degrees befor to checking the second time. Maximum leakage allowed out the outlet

port is 16 cc [1 cubic inch] per minute (2.6 cc [0.16 cubic inch] for 10 seconds).

Leakage testing

LEAKAGE TESTING

Page 24

24

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Testing

FUNCTION TESTING Function testing insures the correct dynamic manual operation of the CDS stack valve

assembly. Perform this test after completing the pressure adjustments. Test each section

of the assembly. Connect each section to a hydraulic cylinder to perform the test. Install a

gauge (69 bar [1000 psi]) in the cylinder extension and retraction lines.

1. Connect the valve to pressure and tank. Plug all work ports except the ports from the

section to be tested.

2. Connect the

A port of the valve to the rod end of the cylinder and the B port to the

base end of the cylinder.

3. Shift the control lever of the section in (towards the valve) and observe cylinder

retraction. Shift the same control lever out (away from the valve) and observe

cylinder extension. Repeat several times.

On valve groups with lever(s) on the B side, the cylinder movement will be opposite.

4. Check the spool travel smoothness in both directions. Sticky spools indicate

problems with the O-rings. Replace the section if spool travel is not smooth.

5. Check the metering of the spool in both directions. The speed of cylinder extension/

retraction is controllable by metering the spool.

6. Check each work port for the ability to build full system pressure, as limited by the

port relief if present. Hold the lever at full stroke after the cylinder reaches the end of

the stroke. Line pressure should not go above relief setting.

Spring Center Function

1. Shift the spool manually in one direction and let go of the control lever. The valve

should center itself, with no hesitation. If the control lever sticks in any position,

check for binding of the spool.

2. Check spool return in both directions. If the spool sticks, replace the section.

Detent Functions

1. Shift the spool in one direction manually. Let go of the control lever. The spool

should remain in shifted position.

2. Check detent function in both directions. If the control lever moves back in neutral

position, check for cause of the spool movement. Repair or replace detent function.

Page 25

25

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Testing

Float Functions

Spools with the detent float option have four postions. Spring center for three positions

and detent for the fourth. The fourth position (float) may be detented in the extreme in

or out position of the spool travel.

The difference between the spring center function and this fourth postion (float) ,is that

the work port and inlet flow dumps to tank once shifted into detent.

1. Shift the spool to detent position.

The spool must remain in detent when the handle

is released.

2. If the control lever goes back to neutral after being moved to detent, check for the

cause of the spool movement. Rebuild or replace the detent function.

Pneumatic Function

1. Apply air pressure to actuator. The spool will shift with 4-12 bar [58-174 psi] air

pressure applied for each direction. Shifting pressure will vary pending size of valve

(CDS 60/100), valve flow, and pressure requirements.

2. Remove air pressure. The spool should return to neutral. Check function in both

directions. If the spool does not return to neutral, check for cause of spool bind.

Replace actuator. Replace section if necessary.

Hydraulic Function

1. Apply hydraulic pressure to actuator. The spool will shift with at 35-100 bar [1161450 psi] pilot pressure applied for each direction. Shifting pressure will vary

pending size of valve (CDS 60/100) and valve flow and pressure requirements.

2. Remove pilot pressure. The spool should return to neutral. Check function in both

directions. If the spool does not return to neutral, check for cause of spool bind.

Replace actuator. Replace section if necessary.

FUNCTION TESTING

(continued)

Page 26

26

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Testing

BACKPRESSURE TEST 1. Plug all ports except the outlet port with steel plugs.

2. Apply 39 bar [570 psi] pressure to the outlet port.

3. Inspect all areas for external leakage. Any leakage is unacceptable. Replace the Orings between any sections that leak.

4. Remove all steel plugs, fittings and hoses. Drain the oil from the valve. Install plastic

plugs in all ports.

Solenoid Function

Testing electrical sections requires a power supply (12-24 volt) and appropriate electrical

connections. Install a gauge (69 bar [1000 psi]) in the working port of the spool being

tested.

Before testing, be sure a pressure build up valve has been specified in the outlet section.

Pressure to shift the spool will depend on the number of sections and a given flow to

create required standby pressure for each section. 6-8 Bar PSI needed to shift CDS 60 and

? for 100

1.

Apply voltage to one solenoid. The spool should shift to its working position with the

appropriate pressure being generated in the working port. Disconnect the voltage.

The spool should shift to its neutral position.

2. Apply voltage to the second solenoid. The spool should shift to its working position

with the appropriate pressure being generated in the working port. Disconnect the

voltage. The spool should shift to its neutral position.

3. If the spool does not return to neutral, check for cause of spool bind. If the spool has

not returned to neutral, the inlet pressure will remain at a higher than standby level.

If numerous valves will be tested, it is recommended to build a working coil into the

test stand (for example:12 volt coil with flying lead). This ciol can be used to check the

function of the valves. After proper valve function has been determined, a production

coil can be installed on the valve.

Three Way Spools

For valve groups with 3-way spools, the test procedure will be the same as a single port

from a 4-way spool.

After all sections have been tested, verify that all relief valve settings are still correct.

Refer to Adjusting pressure settings section page 22.

FUNCTION TESTING

(continued)

Page 27

27

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Notes

Page 28

28

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Troubleshooting

Item Description Action

THE VALVE LEAKS

Disconnect......

Item Description Action

IT STILL LEAKS

Page 29

29

520L0924 • October 2005

CDS Directional Control Valve Assembly and Testing Manual

Troubleshooting

Item Description Action

RELIEF DOESN’T WORK

Item Description Action

STICKY SPOOL

Item Description Action

CABLE BINDS

Page 30

30

BLN-10263 • 520L0924 • October 2005

CDS Stack Valve Assembly and Testing Manual

Appendix

APPENDIX A

TESTING CERTIFICATION

FORM

The following page contains the CDS stack valve test certification form.

A copy of the certification must be sent to the TST at Sauer-Danfoss, Easley, SC.

Fax number 864-XXX-XXXX.

Page 31

S015 01/99

Sauer-Danfoss

CDS Stack Valve Test Certification

SYSTEM #: DATE CODE: BUILD CENTER #: QUANTITY:

INLET: WITH RELIEFS W/O RELIEFS RELIEF SETTING GPM SETTING:

WORK SECTIONS OPTIONS ACTUATORS FUNCTION

SECTION SPOOL

TYPE

Port

Leakage

PILOT

CHECK

PORT

RELIEFS

LOAD

CHECK

MANUAL HYD. PNEU ELECT OTHER

1.

2.

3.

4.

5.

6.

7.

8.

ASSEMBLER: DATE: TESTER: DATE:

NOTES:

Page 32

Sauer-Danfoss Mobile Power and Control Systems

– Market Leaders Worldwide

Sauer-Danfoss is a comprehensive supplier providing complete

systems to the global mobile market.

Sauer-Danfoss serves markets such as agriculture, construction, road

building, material handling, municipal, forestry, turf care, and many

others.

We offer our customers optimum solutions for their needs and

develop new products and systems in close cooperation and

partnership with them.

Sauer-Danfoss specializes in integrating a full range of system

components to provide vehicle designers with the most advanced

total system design.

Sauer-Danfoss provides comprehensive worldwide service for its

products through an extensive network of Authorized Service

Centers strategically located in all parts of the world.

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000, Fax: +1 515 239 6618

Sauer-Danfoss GmbH & Co. OHG

Postfach 2460, D-24531 Neumünster

Krokamp 35, D-24539 Neumünster, Germany

Phone: +49 4321 871-0, Fax: +49 4321 871 122

Sauer-Danfoss ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444, Fax: +45 7488 4400

www.sauer-danfoss.com

OUR PRODUCTS

Hydrostatic transmissions

Hydraulic power steering

Electric power steering

Electrohydraulic power steering

Closed and open circuit axial piston

pumps and motors

Gear pumps and motors

Bent axis motors

Orbital motors

Transit mixer drives

Planetary compact gears

Proportional valves

Directional spool valves

Cartridge valves

Hydraulic integrated circuits

Hydrostatic transaxles

Integrated systems

Fan drive systems

Electrohydraulics

Microcontrollers and software

Electric motors and inverters

Joysticks and control handles

Displays

Sensors

520L0924 • October 2005

Loading...

Loading...