Operating Guide

VLT® Compressor Drive CDS 803

6–30 kW

vlt-drives.danfoss.com

VLT® Compressor Drive CDS 803

Operating Guide

Contents

1

Introduction 6

1.1

Purpose of this Operating Guide 6

Additional Resources 6

1.2

Supplementary Documentation 6

1.2.1

1.2.2

VLT® Motion Control Tool MCT 10 Software Support 6

1.3

Manual and Software Version 6

1.4

Approvals and Certifications 6

1.5

Disposal 7

1.6

CE Declaration 8

Safety 10

2

Safety Symbols 10

2.1

Qualified Personnel 10

2.2

Contents

Safety Precautions 10

2.3

Installation 12

3

3.1

Mechanical Installation 12

3.1.1

Side-by-side Installation 12

3.1.2

Operating Environment 12

3.1.2.1

3.1.2.2

3.2

Electrical Installation 12

3.2.1

Electrical Installation in General 12

3.2.1.1

3.2.2

Fuses and Circuit Breakers 13

3.2.2.1

3.2.3

Electrical Wiring 14

3.2.3.1

3.2.3.2

3.2.3.3

Derating for Ambient Temperature and Switching Frequency 12

Derating for Low Air Pressure and High Altitudes 12

Fastener Torque Ratings 12

Recommendation of Fuses and Circuit Breakers 13

Wiring Schematic 14

Terminal Overview of Enclosure Sizes H3–H5 15

Terminal Overview of Enclosure Size H6 16

3.2.3.4

3.2.3.5

3.2.3.6

3.2.4

Setting Up RS485 Serial Communication 19

3.2.5

EMC-compliant Electrical Installation 20

4

Commissioning 24

4.1

Programming Interfaces 24

Connecting to Mains and Compressor Terminals 16

Relay Terminals 17

Control Terminals 18

AQ321748767627en-000301/130R0570 | 3Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

4.2

Local Control Panel (LCP) 24

4.2.1

Programming via the Quick Menu 25

4.2.2

Programming via the Main Menu 25

4.2.3

Data Transfer from Drive to LCP 26

4.2.4

Data Transfer from LCP to Drive 26

4.2.5

Restoring Factory Default Settings 26

4.2.5.1

4.2.5.2

4.3

Starting Up the Drive for the First Time 27

5

Troubleshooting 28

5.1

Acoustic Noise or Vibration 28

5.2

Warnings and Alarms 28

6

Specifications 32

Recommended Initialization (via Parameter 14-22 Operation Mode) 26

Two-finger Initialization 27

Contents

6.1

Electrical Data 32

6.1.1

Electrical Data 3x200–240 V AC 32

6.1.2

Electrical Data 3x380–480 V AC 32

6.2

Mains Supply (L1, L2, L3) 33

6.3

Compressor Output (U, V, W) 33

6.4

Control Input/Output 34

6.4.1

10 V DC Output 34

6.4.2

24 V DC Output 34

6.4.3

Analog Inputs 34

6.4.4

Analog Outputs 34

6.4.5

Digital Inputs 34

6.4.6

Digital Outputs 35

6.4.7

Relay Outputs, Enclosure Sizes H3–H5 35

6.4.8

Relay Outputs, Enclosure Size H6 35

6.4.9

RS485 Serial Communication 36

6.5

Ambient Conditions 36

6.6

Conforming Standards 37

6.7

Cable Lengths and Cross-sections 37

6.8

Acoustic Noise 37

6.9

Shipping Dimensions 38

6.10

Accessories and Spare Parts 38

7

Appendix 39

7.1

Abbreviations 39

AQ321748767627en-000301/130R05704 | Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

7.2 Conventions 40

Contents

AQ321748767627en-000301/130R0570 | 5Danfoss A/S © 2021.06

Edition

Remarks

Software version

AQ321748767627, version 0301

Various editorial updates.

6.0–10 kW (8–15 hp): Version 2.0

18–30 kW (25–40 hp): Version 61.20

Description

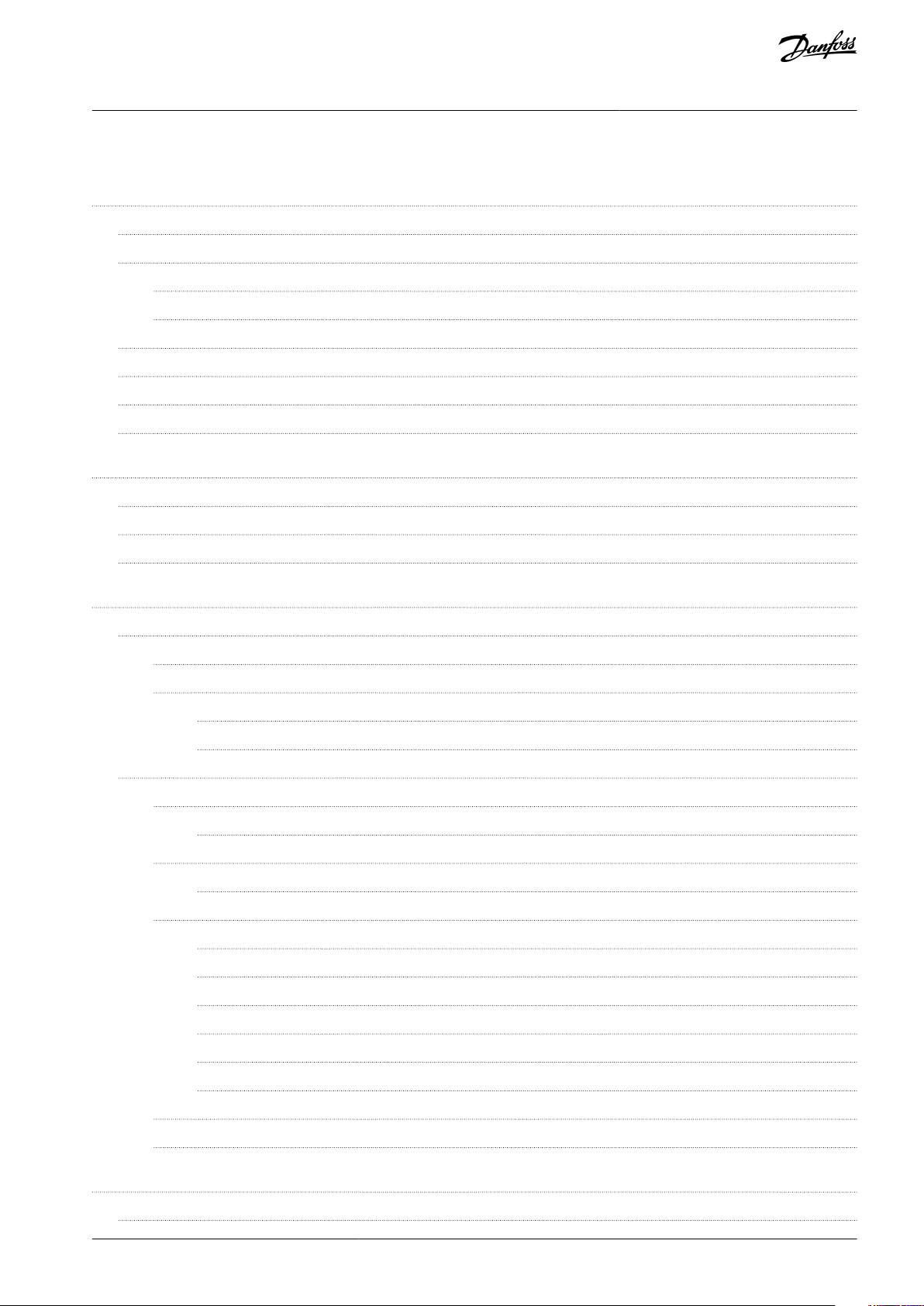

Conformity mark

EU/EC Declaration of Conformity (EC/CE - European Conformity/Conformité Européenne)

Low Voltage Directive/Electromagnetic compatibility (EMC)/Restriction of Hazardous Substances

(RoHS)

Countries of use: Europe

ACMA Declaration of Conformity (RCM - Regulatory Compliance Mark)

Australian Communications Media Authority (ACMA)

Low Voltage Directive/Electromagnetic compatibility (EMC)

Countries of use: Australia and New Zealand

VLT® Compressor Drive CDS 803

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Supplementary Documentation

Other resources are available to understand advanced drive functions and programming.

•

The Programming Guide provides information on how to program and includes complete parameter descriptions.

•

The Design Guide provides detailed information about capabilities and functionality to design motor control systems.

•

The Modbus RTU Operating Instructions explains how to physically establish and configure communication between the Danfoss

FC Series and a controller using the Modbus RTU protocol. Download the Operating Instructions from www.danfoss.com in the

section Service and Support/Documentation.

See

www.danfoss.com for supplementary documentation.

1.2.2 VLT® Motion Control Tool MCT 10 Software Support

Download the software from the Service and Support download page on www.danfoss.com.

During the installation process of the software, enter CD-key 34544400 to activate the CDS 803 functionality. An activation key is not

required for using the CDS 803 functionality.

The latest software does not always contain the latest updates for the drive. Contact the local sales office for the latest drive updates

(in the form of *.upd files), or download the drive updates from the Service and Support download page on www.danfoss.com.

1.3 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

Table 1: Manual and Software Version

1.4 Approvals and Certifications

AQ321748767627en-000301 / 130R05706 | Danfoss A/S © 2021.06

Description

Conformity mark

VIT-SEPRO Declaration of Conformity (VIT - All-Union Institute of Transformer Engineering)

Low Voltage Directive/Electromagnetic compatibility (EMC)

Country of use: Ukraine

089

Moroccan Declaration of Conformity (CMIM - Moroccan Conformity Mark)

Low Voltage Directive/Electromagnetic compatibility (EMC)

Country of use: Morocco

Eurasian Economic Union Declaration of Conformity (EAC - Eurasian Conformity Mark)

Customs Union Technical Regulations (CU TR)

Low voltage Directive/Electromagnetic compatibility (EMC)/Restriction of Hazardous Substances Direc-

tive (RoHS)

Countries of use: Eurasian Economic Union (Russia, Belarus, Kazakhstan, Armenia, and Kirghizstan)

Certification of Compliance UL listed (UL - Underwriters Laboratories)

Safety organization

Countries of use: USA and Canada

Certification of Compliance UL recognized (UL - Underwriters Laboratories)

Safety organization

Countries of use: USA and Canada

Do not dispose of equipment containing electrical components together with domestic waste.

Collect it separately in accordance with local and currently valid legislation.

VLT® Compressor Drive CDS 803

Operating Guide

Introduction

N O T I C E

The VLT® Compressor Drive CDS 803 with SXXX in the type code is certified against UL 508C. Example:

CDS803P7K5T4E20H4XXCXXXSXXXXAXBXCXXXXDX

The VLT® Compressor Drive CDS 803 with S096 in the type code is certified against UL/EN/IEC 60730-1. Example:

CDS803P30KT4E20H2XXXXXXS096XAXBXCXXXXDX

1.5 Disposal

AQ321748767627en-000301 / 130R0570 | 7Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

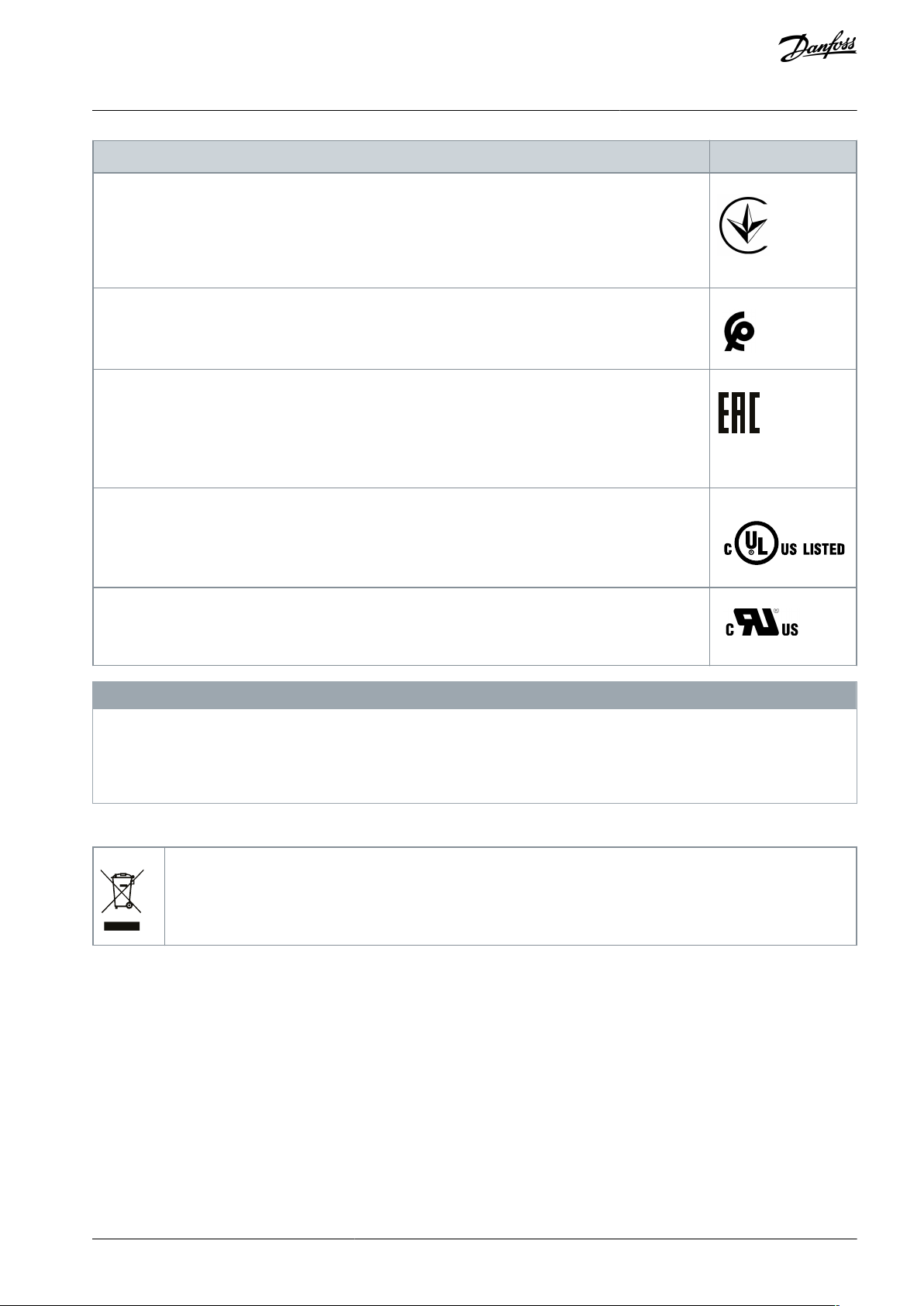

1.6 CE Declaration

Introduction

AQ321748767627en-000301 / 130R05708 | Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

Introduction

AQ321748767627en-000301 / 130R0570 | 9Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AQ321748767627en-000301 / 130R057010 | Danfoss A/S © 2021.06

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x200

6.0–10 (8.0–15)

15

3x400

6.0–7.5 (8.0–10)

4

3x400

10–30 (15–40)

15

VLT® Compressor Drive CDS 803

Operating Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

AQ321748767627en-000301 / 130R0570 | 11Danfoss A/S © 2021.06

Power [kW (hp)]

Clearance above/below [mm (in)]

Size

IP protection rating

3x200–240 V

3x380–480 V

H3

IP20–6.0–7.5 (8.0–10)

100 (4)

H4

IP20

6.0–7.5 (8.0–10)

10 (15)

100 (4)

H5

IP20

10 (15)

18.5–22 (25–30)

100 (4)

H6

IP20–30(40)

200 (7.9)

Power [kW (hp)]

Torque [Nm (in-lb)]

Enclosure size

IP protection rating

3x200–240 V

3x380–480 V

Mains

Motor

DC connection

Control terminals

Ground

Relay

H3

IP20–6.0–7.5 (8.0–10)

0.8 (7)

0.8 (7)

0.8 (7)

0.5 (4)

0.8 (7)

0.5 (4)

VLT® Compressor Drive CDS 803

Operating Guide

3 Installation

3.1 Mechanical Installation

3.1.1 Side-by-side Installation

The drive can be mounted side by side but requires the clearance specified in Table 3 above and below for cooling.

Table 3: Clearance Required for Cooling

N O T I C E

With IP21/NEMA Type1 option kit mounted, a distance of 50 mm (2 in) between the units is required.

Installation

3.1.2 Operating Environment

3.1.2.1 Derating for Ambient Temperature and Switching Frequency

Ensure that the ambient temperature measured over 24 hours is at least 5 °C (9 °F) lower than the maximum ambient temperature

that is specified for the drive. If the drive is operated at a high ambient temperature, decrease the constant output current. For

derating specifications, see the VLT® Compressor Drive CDS 803 Design Guide listed in

1.2 Additional Resources.

3.1.2.2 Derating for Low Air Pressure and High Altitudes

The cooling capability of air is decreased at low air pressure. For altitudes above 2000 m (6562 ft), contact Danfoss regarding PELV.

Below 1000 m (3281 ft) altitude, derating is not necessary. For altitudes above 1000 m (3281 ft), decrease the ambient temperature

or the maximum output current. Decrease the output by 1% per 100 m (328 ft) altitude above 1000 m (3281 ft) or reduce the maximum ambient cooling air temperature by 1 °C (1.8 °F) per 200 m (656 ft).

3.2 Electrical Installation

3.2.1 Electrical Installation in General

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper conductors

are required. 75 °C (167 °F) is recommended.

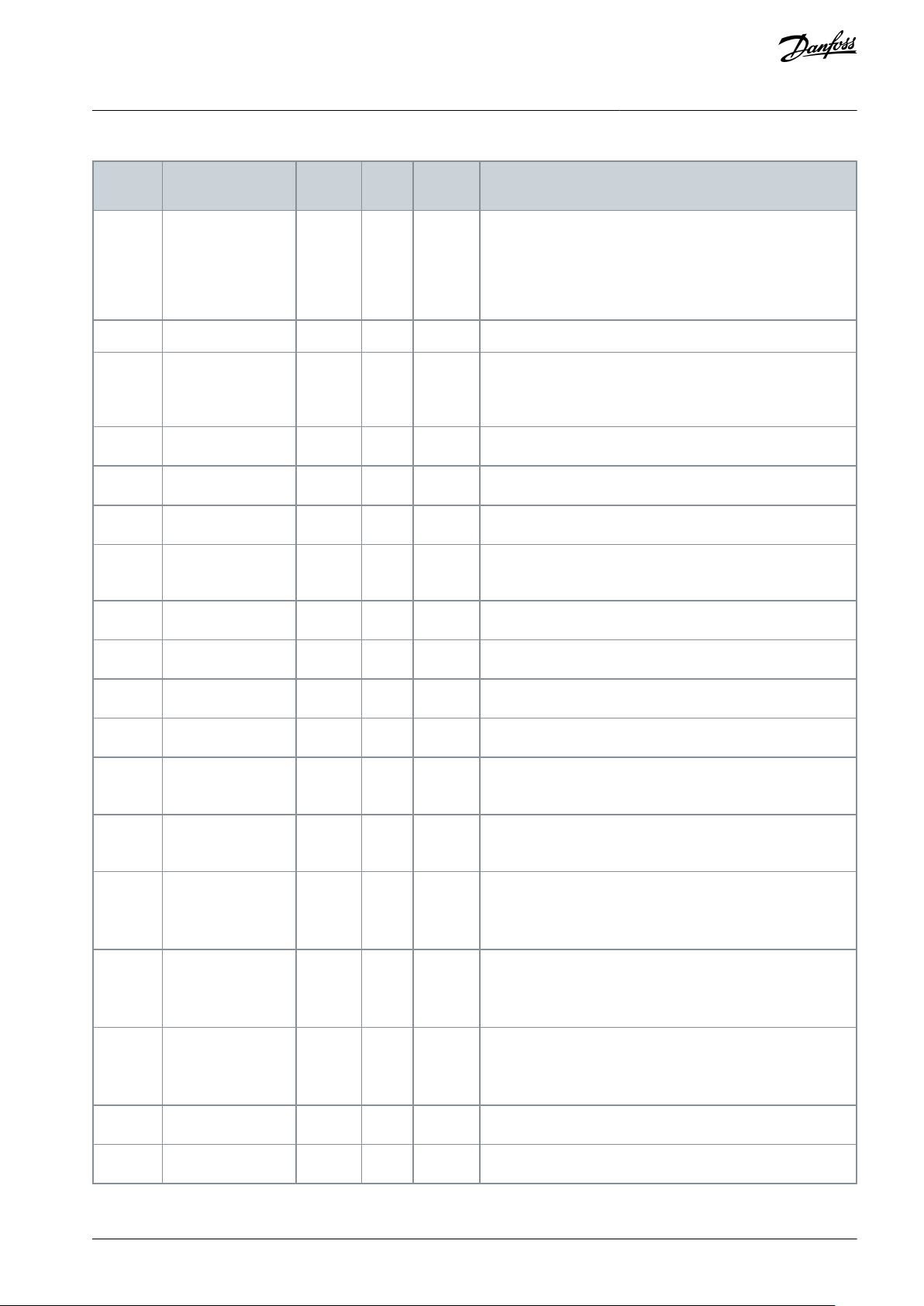

3.2.1.1 Fastener Torque Ratings

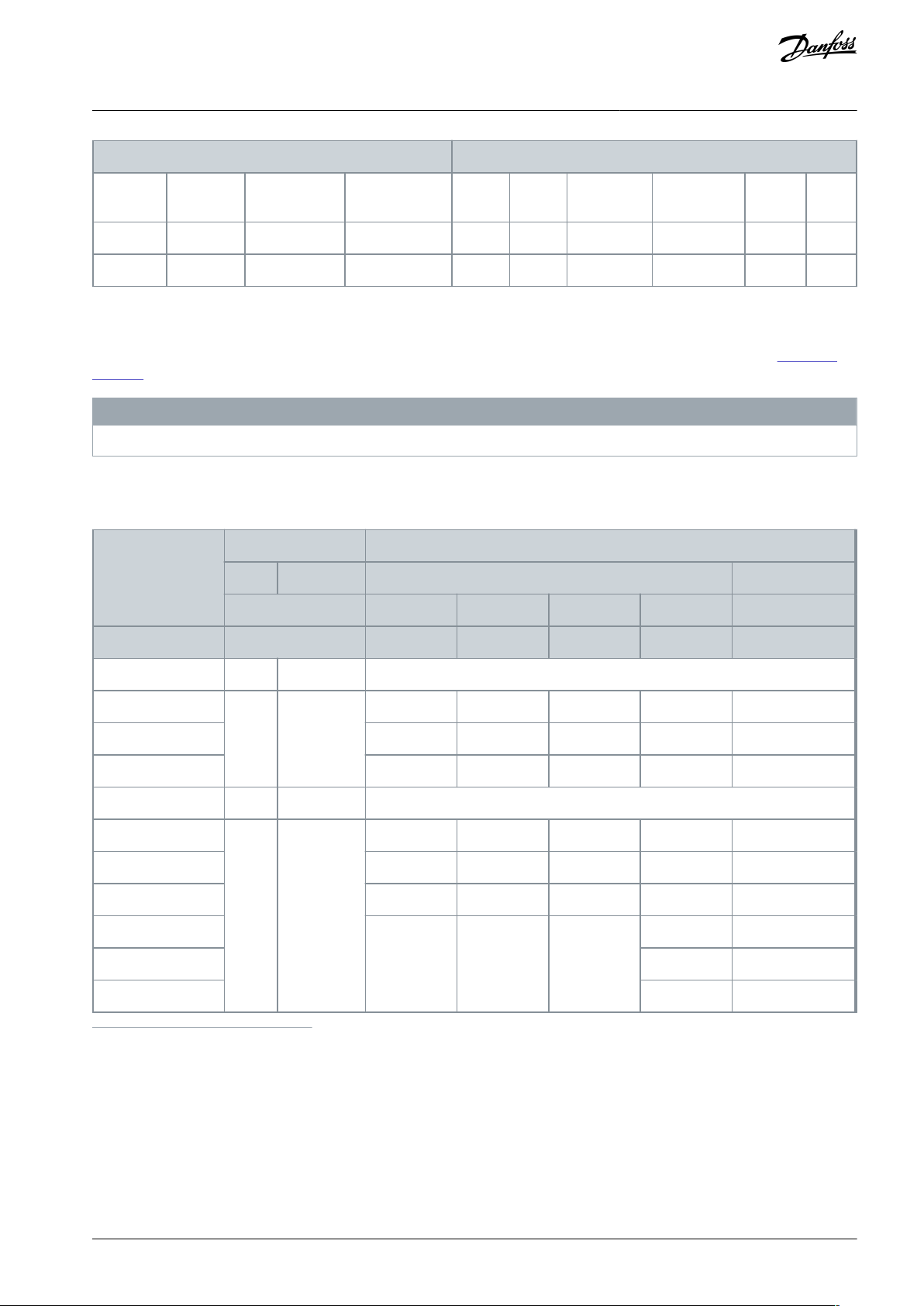

Table 4: Tightening Torques for Enclosure Sizes H3–H6, 3x200–240 V & 3x380–480 V

AQ321748767627en-000301 / 130R057012 | Danfoss A/S © 2021.06

Power [kW (hp)]

Torque [Nm (in-lb)]

H4

IP20

6.0–7.5 (8.0–

10)

10–15 (15–20)

1.2 (11)

1.2 (11)

1.2 (11)

0.5 (4)

0.8 (7)

0.5 (4)

H5

IP20

10 (15)

18.5–22 (25–30)

1.2 (11)

1.2 (11)

1.2 (11)

0.5 (4)

0.8 (7)

0.5 (4)

H6

IP20–30 (40)

4.5 (40)

4.5 (40)

–

0.5 (4)

3 (27)

0.5 (4)

Circuit breakers

(1)

Fuse

UL

Non-ULULNon-UL

Bussmann

Bussmann

Bussmann

Bussmann

Maximum fuse

Power [kW (hp)]

Type RK5

Type RK1

Type J

Type T

Type gG

3x200–240 V

6.0 (8.0)

–

–

FRS-R-50

KTN-R50

JKS-50

JJN-50

gG-50

7.5 (10)

FRS-R-50

KTN-R50

JKS-50

JJN-50

gG-50

10 (15)

FRS-R-80

KTN-R80

JKS-80

JJN-80

gG-63

3x380–480 V

6.0 (8.0)

–

–

FRS-R-25

KTS-R25

JKS-25

JJS-25

gG-25

7.5 (10)

FRS-R-25

KTS-R25

JKS-25

JJS-25

gG-25

10 (15)

FRS-R-50

KTS-R50

JKS-50

JJS-50

gG-50

18.5 (25)

–––

JJS-80

gG-63

22 (30)

JJS-80

gG-63

30 (40)

JJS-125

gG-80

VLT® Compressor Drive CDS 803

Operating Guide

Installation

3.2.2 Fuses and Circuit Breakers

Fuses and circuit breakers ensure that possible damage to the drive is limited to damage inside the unit. Danfoss recommends fuses

on the supply side as protection. For further information, see the application note Fuses and Circuit Breakers found on www.dan-

foss.com under Service and support/Documentation/Manuals & guides.

N O T I C E

Use of fuses on the supply side is mandatory for IEC 60364 (CE) and NEC 2009 (UL) compliant installations.

3.2.2.1 Recommendation of Fuses and Circuit Breakers

Table 5: Fuses and Circuit Breakers

1

Circuit breakers have not been evaluated by Danfoss as part of the certification process.

AQ321748767627en-000301 / 130R0570 | 13Danfoss A/S © 2021.06

L1

L2

L3

3-phase

power

input

PE

PE

+10 V DC

0-10 V DC-

0-10 V DC-

50 (+10 V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20 mA A OUT / D OUT

45 0/4-20 mA A OUT / D OUT

18 (D IN)

19 (D IN)

27 (D IN)

29 (

D IN)

12 (+24 V OUT)

24 V (NPN)

20 (COM D IN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

Bus ter.

RS485

Interface

RS485

(N RS485) 69

(P RS485) 68

(Com RS485 ) 61

(PNP)-Source

(NPN)-Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240 V AC 3 A

Not present on all power sizes

Do not connect shield to 61

01

02

03

relay 1

relay 2

UDC+

UDC-

Motor

U

V

W

e30bj246.10

06

05

04

240 V AC 3 A

VLT® Compressor Drive CDS 803

Operating Guide

3.2.3 Electrical Wiring

3.2.3.1 Wiring Schematic

Installation

Illustration 1: Basic Wiring Schematic Drawing

There is no access to UDC- and UDC+ on the following units:

IP20, 380–480 V, 30 kW (40 hp).

-

N O T I C E

AQ321748767627en-000301 / 130R057014 | Danfoss A/S © 2021.06

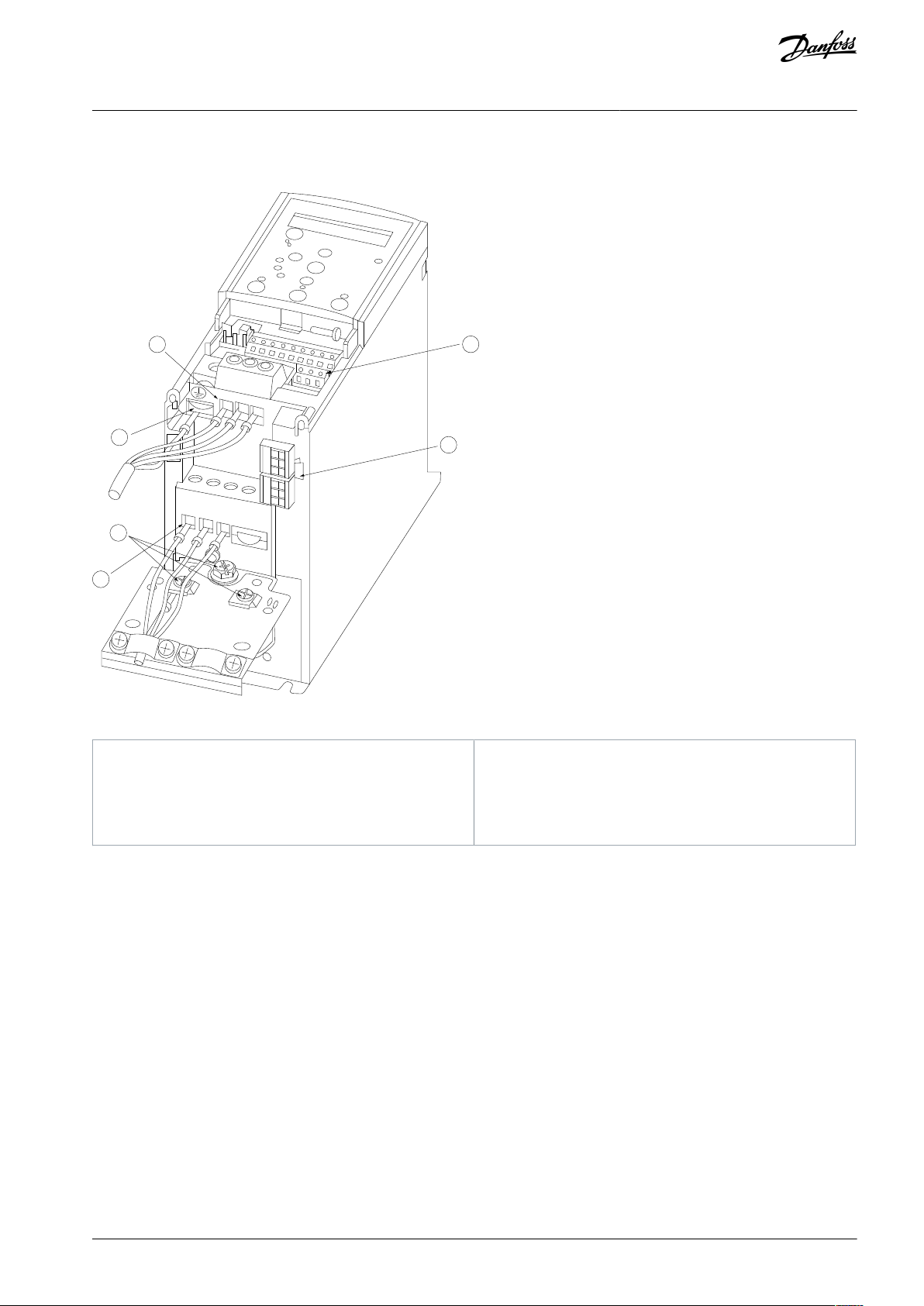

1

2

2

3

4

U

V

W

-DC

+DC

e30bb634.11

5

MAINS

MOTOR

1

Mains

2

Ground

3

Compressor

4

Relays

5

Control terminals

VLT® Compressor Drive CDS 803

Operating Guide

3.2.3.2 Terminal Overview of Enclosure Sizes H3–H5

Installation

Illustration 2: Enclosure Sizes H3–H5

AQ321748767627en-000301 / 130R0570 | 15Danfoss A/S © 2021.06

1

95

99

L1 91 / L2 92 / L3 93

U 96 /

V 97 /

W 98

03 02 01

06 05 04

2

3

4

e30bb762.12

1

Mains

2

Ground

3

Compressor

4

Relays

e30bi968.10

VLT® Compressor Drive CDS 803

Operating Guide

3.2.3.3 Terminal Overview of Enclosure Size H6

Installation

Illustration 3: Enclosure Size H6

3.2.3.4 Connecting to Mains and Compressor Terminals

•

Tighten all terminals in accordance with the information provided in 3.2.1.1 Fastener Torque Ratings.

•

Keep the compressor cable as short as possible to reduce the noise level and leakage currents.

•

Use a shielded/armored compressor cable to comply with the EMC emission specifications and connect this cable to both the

decoupling plate and the compressor. Also see 3.2.5 EMC-compliant Electrical Installation.

1.

Connect the ground cable to the ground terminal, then connect the mains supply to terminals L1, L2, and L3.

AQ321748767627en-000301 / 130R057016 | Danfoss A/S © 2021.06

e30bi967.10

Drive terminals

Compressor

UT1VT2W

T3

VLT® Compressor Drive CDS 803

Operating Guide

2.

Connect the ground cable to the ground terminal, then connect the compressor to terminals U, V, and W.

Table 6: Connection of Compressor to Terminals

Installation

3.2.3.5 Relay Terminals

Relay 1

•

Terminal 01: Common.

•

Terminal 02: Normally open.

•

Terminal 03: Normally closed.

Relay 2

•

Terminal 04: Common.

•

Terminal 05: Normally open.

•

Terminal 06: Normally closed.

AQ321748767627en-000301 / 130R0570 | 17Danfoss A/S © 2021.06

Relay1

Relay2

03

02

01

06

05

04

e30bi798.10

e30bd331.11

VLT® Compressor Drive CDS 803

Operating Guide

Installation

Illustration 4: Relay Outputs 1 and 2

3.2.3.6 Control Terminals

Remove the terminal cover to access the control terminals.

Use a flat-edged screwdriver to push down the lock lever of the terminal cover under the LCP, then remove the terminal cover as

shown in the following illustration.

Illustration 5: Removing the Terminal Cover

The following illustration shows all the drive control terminals. Applying start (terminal 18), connection between terminals 12-27,

and an analog reference (terminal 53 or 54, and 55) make the drive run.

The digital input mode of terminal 18, 19, 27, and 29 is set in parameter 5-00 Digital Input Mode (PNP is default value).

AQ321748767627en-000301 / 130R057018 | Danfoss A/S © 2021.06

e30bf892.10

12 20 55

181927 29 42 54

45 50 53

DIGI IN

61 68 69

N

P

COMM. GND

+24 V

GND

GND

10 V OUT

10 V/20 mA IN

0/4-20 mA A OUT/DIG OUT

BUS TER.

OFF ON

DIGI IN

DIGI IN

DIGI IN

0/4-20 mA A OUT/DIG OUT

10 V/20 mA IN

VLT® Compressor Drive CDS 803

Operating Guide

Illustration 6: Control Terminals

Installation

3.2.4 Setting Up RS485 Serial Communication

3.2.4.1 RS485 Features

RS485 is a 2-wire bus interface compatible with multi-drop network topology. This interface contains the following features:

•

Ability to select from the following communication protocols:

-

FC (default protocol)

-

Modbus RTU

•

Functions can be programmed remotely using the RS485 connection or in parameter group 8-** Communications and Options.

•

A switch (BUS TER) is provided on the control card for bus termination resistance.

N O T I C E

Altering between the supported communication protocols can be accessed and changed via the LCP as parameter 8-30 Protocol is

not available in VLT® Motion Control Tool MCT 10.

3.2.4.2 Configuring RS485 Serial Communication

Procedure

1.

Connect RS485 serial communication wiring to terminals (P RS485) 68 and (N RS485) 69.

-

Use shielded serial communication cable.

-

Properly ground the wiring. Refer to 3.2.5 EMC-compliant Electrical Installation.

AQ321748767627en-000301 / 130R0570 | 19Danfoss A/S © 2021.06

+

e30bi768.10

RS485

69

GND

68

VLT® Compressor Drive CDS 803

Operating Guide

2.

Configure all required settings such as address, baud rate, and so on in parameter group 8-** Communications and Options.

For more details on parameters, refer to VLT® Compressor Drive CDS 803 Programming Guide listed in 1.2 Additional Re-

sources.

Example

Illustration 7: RS485 Wiring Connection

Installation

3.2.5 EMC-compliant Electrical Installation

To obtain an EMC-compliant installation, be sure to follow all electrical installation instructions. Also, remember to practice the following:

•

When using relays, control cables, a signal interface, fieldbus, or brake, connect the shield to the enclosure at both ends. If the

ground path has high impedance, is noisy, or is carrying current, break the shield connection on 1 end to avoid ground current

loops.

•

Convey the currents back to the unit using a metal mounting plate. Ensure good electrical contact from the mounting plate by

securely fastening the mounting screws to the drive chassis.

•

Use shielded cables for motor output cables. An alternative is unshielded motor cables within metal conduit.

•

Ensure that motor and brake cables are as short as possible to reduce the interference level from the entire system.

•

Avoid placing cables with a sensitive signal level alongside motor and brake cables.

•

For communication and command/control lines, follow the particular communication protocol standards. For example, USB

must use shielded cables, but RS485/ethernet can use shielded UTP or unshielded UTP cables.

•

Ensure that all control terminal connections are rated protective extra low voltage (PELV).

N O T I C E

TWISTED SHIELD ENDS (PIGTAILS)

Twisted shield ends increase shield impedance at higher frequencies, which increases the leakage current.

Use integrated shield clamps instead of twisted shield ends.

-

N O T I C E

SHIELDED CABLES

If shielded cables or metal conduits are not used, the unit and the installation do not meet regulatory limits on radio frequency

(RF) emission levels.

N O T I C E

EMC INTERFERENCE

Failure to isolate power, motor, and control cables can result in unintended behavior or reduced performance.

Use shielded cables for motor and control wiring.

-

Provide a minimum 200 mm (7.9 in) separation between mains input, motor cables, and control cables.

-

AQ321748767627en-000301 / 130R057020 | Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

Installation

N O T I C E

EMI/EMC NON-COMPLIANCE

Panel components not installed by Danfoss will invalidate the EMI/EMC compliance and other certifications.

N O T I C E

INSTALLATION AT HIGH ALTITUDE

There is a risk for overvoltage. Isolation between components and critical parts could be insufficient and may not comply with

PELV requirements.

Use external protective devices or galvanic isolation. For installations above 2000 m (6500 ft) altitude, contact Danfoss re-

-

garding protective extra low voltage (PELV) compliance.

N O T I C E

PROTECTIVE EXTRA LOW VOLTAGE (PELV) COMPLIANCE

Prevent electric shock by using PELV electrical supply and complying with local and national PELV regulations.

AQ321748767627en-000301 / 130R0570 | 21Danfoss A/S © 2021.06

L1

L2L3PEL1L2L3PEPEu

v

w

2

1

3

5

IEC 60309

16

17

18

14

12

8

7

10

9

4

11

13

446

15

90

+DC

BR-

B

M

AINS

L1 L2 L3

91 92 93

RELA

Y 1 RELA

Y 2

99

- L

C -

UV

W

MO

T

OR

VLT® Compressor Drive CDS 803

Operating Guide

Installation

Illustration 8: Example of Proper EMC Installation

AQ321748767627en-000301 / 130R057022 | Danfoss A/S © 2021.06

1

Programmable logic controller (PLC)

2

Minimum 16 mm2 (6 AWG) equalizing cable

3

Control cables

4

Minimum 200 mm (7.9 in) between control cables,

motor cables, and mains cables

5

Mains supply

6

Bare (unpainted) surface

7

Star washers

8

Brake cable (shielded)

9

Motor cable (shielded)

10

Mains cable (unshielded)

11

Output contactor

12

Cable insulation stripped

13

Common ground busbar. Follow local and national

requirements for cabinet grounding.

14

Brake resistor

15

Metal box

16

Connection to motor

17

Motor

18

EMC cable gland

VLT® Compressor Drive CDS 803

Operating Guide

Installation

AQ321748767627en-000301 / 130R0570 | 23Danfoss A/S © 2021.06

e30bb765.11

B

a

c

k

Com.

1-20 Motor Power

[5] 0.37kW - 0.5HP

Setup 1

A

B

1

12

13

14

15

11

11

10

9

8

7

6

5

4

3

2

C

D

Status

Main

Menu

Quick

Menu

Hand

On

OK

M

enu

Off

Reset

Auto

On

Alarm

Warn.

On

11

1

Parameter number and name.

2

Parameter value.

VLT® Compressor Drive CDS 803

Operating Guide

Commissioning

4 Commissioning

4.1 Programming Interfaces

The drive can be programmed in 3 different ways:

•

Locally via the LCP.

•

Externally via the RS485 interface by either

-

using Modbus RTU

-

or by installing VLT® Motion Control Tool MCT 10.

For the full menu and parameter specifications, refer to the VLT® Compressor Drive CDS 803 Programming Guide listed in 1.2 Addi-

tional Resources.

4.2 Local Control Panel (LCP)

The LCP is divided into 4 functional sections.

•

A. Display

•

B. Menu key

•

C. Navigation keys and indicator lights

•

D. Operation keys and indicator lights

Illustration 9: Local Control Panel (LCP)

A. Display

The LCD display is illuminated with 2 alphanumeric lines. Table 7 describes the information that can be read from the display.

Table 7: Legend to Section A

AQ321748767627en-000301 / 130R057024 | Danfoss A/S © 2021.06

3

Setup number shows the active setup and the edit setup. If the same setup acts as both active and edit setup, only that setup

number is shown (factory setting). When active and edit setup differ, both numbers are shown in the display (setup 12). The

number flashing indicates the edit setup.

4

Motor direction is shown to the bottom left of the display – indicated by a small arrow pointing either clockwise or counterclockwise.

5

The triangle indicates if the LCP is in Status, Quick Menu, or Main Menu.

6

Com. (yellow indicator): Flashes during bus communication.

7

On (green indicator): Control section is working correctly.

8

Warn. (yellow indicator): Indicates a warning.

9

Alarm (red indicator): Indicates an alarm.

10

[Back]: For moving to the previous step or layer in the navigation structure.

11

[▵] [▿] [▹]: For navigating among parameter groups and parameters, and within parameters. They can also be used for setting local reference.

12

[OK]: For selecting a parameter and for accepting changes to parameter settings.

13

[Hand On]: Starts the motor and enables control of the drive via the LCP.

N O T I C E

[2] Coast inverse is the default option for parameter 5-12 Terminal 27 Digital Input. If there is no 24 V supply to terminal 27,

[Hand On] does not start the compressor. Connect terminal 12 to terminal 27.

14

[Off/Reset]: Stops the compressor (Off). If in alarm mode, the alarm is reset.

15

[Auto On]: The drive is controlled either via control terminals or serial communication.

VLT® Compressor Drive CDS 803

Operating Guide

B. Menu key

Press [Menu] to select among Status, Quick Menu, or Main Menu.

C. Navigation keys and indicator lights

Table 8: Legend to Section C

Commissioning

D. Operation keys and indicator lights

Table 9: Legend to Section D

4.2.1 Programming via the Quick Menu

Procedure

1.

To enter the Quick Menu, press [Menu] until indicator in display is placed above Quick Menu.

2.

Press [▵] [▿] to select quick guide, closed-loop setup, compressor setup, or changes made, then press [OK].

3.

Press [▵] [▿] to browse through the parameters in the Quick Menu.

Press [OK] to select a parameter.

4.

Press [▵] [▿] to change the value of a parameter setting.

5.

Press [OK] to accept the change.

6.

7.

Press either [Back] twice to enter Status, or press [Menu] once to enter Main Menu.

4.2.2 Programming via the Main Menu

Procedure

1.

Press [Menu] until indicator in display is placed above Main Menu.

Press [▵] [▿] to browse through the parameter groups.

2.

AQ321748767627en-000301 / 130R0570 | 25Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

3.

Press [OK] to select a parameter group.

4.

Press [▵] [▿] to browse through the parameters in the specific group.

5.

Press [OK] to select the parameter.

6.

Press [▵] [▿] to set/change the parameter value.

7.

Press [OK] to accept the change or press [Back] to go back to the previous level.

Commissioning

4.2.3 Data Transfer from Drive to LCP

Once the setup of a drive is complete, Danfoss recommends storing the data in the LCP or on a PC via VLT® Motion Control Tool

MCT 10.

W A R N I N G

Stop the compressor before performing this operation.

Procedure

1.

Go to parameter 0-50 LCP Copy.

2.

Press [OK].

3.

Select [1] All to LCP.

Press [OK].

4.

4.2.4 Data Transfer from LCP to Drive

Connect the LCP to another drive to copy the parameter settings to this drive as well.

W A R N I N G

Stop the compressor before performing this operation.

Procedure

1.

Go to parameter 0-50 LCP Copy.

2.

Press [OK].

3.

Select [2] All from LCP.

4.

Press [OK].

4.2.5 Restoring Factory Default Settings

There are 2 different ways of initializing the drive to factory default settings:

•

Via parameter 14-22 Operation Mode (this is the recommended way).

Two-finger initialization

•

Some parameters will not be reset, see more details in

and 4.2.5.2 Two-finger Initialization.

4.2.5.1 Recommended Initialization (via Parameter 14-22 Operation Mode)

Initialization of the drive to default settings (via parameter 14-22 Operation Mode).

Procedure

1.

Select parameter 14-22 Operation Mode.

2.

Press [OK].

3.

Select [2] Initialisation and press [OK].

Cut off the mains supply and wait until the display turns off.

4.

Reconnect the mains supply.

5.

4.2.5.1 Recommended Initialization (via Parameter 14-22 Operation Mode)

The drive is now reset, except the following parameters:

Parameter 1-06 Clockwise Direction

Parameter 1-13 Compressor Selection

Parameter 4-18 Current Limit

Parameter 8-30 Protocol

AQ321748767627en-000301 / 130R057026 | Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

Parameter 8-31 Address

Parameter 8-32 Baud Rate

Parameter 8-33 Parity / Stop Bits

Parameter 8-35 Minimum Response Delay

Parameter 8-36 Maximum Response Delay

Parameter 8-37 Maximum Inter-char delay

Parameter 15-00 Operating hours to parameter 15-05 Over Volt's

Parameter 15-03 Power Up's

Parameter 15-04 Over Temp's

Parameter 15-05 Over Volt's

Parameter 15-30 Alarm Log: Error Code

Parameter group 15-4* Drive identification parameters

4.2.5.2 Two-finger Initialization

Procedure

1.

Power off the drive.

2.

Press [OK] and [Menu].

3.

Power up the drive while still pressing the keys above for 10 s.

Commissioning

The drive is now reset, except the following parameters:

Parameter 1-06 Clockwise Direction

Parameter 15-00 Operating hours

Parameter 15-03 Power Up's

Parameter 15-04 Over Temp's

Parameter 15-05 Over Volt's

Parameter 15-30 Alarm Log: Error Code

Parameter group 15-4* Drive identification parameters

Initialization of parameters is confirmed by AL80 in the display after the power cycle.

4.3 Starting Up the Drive for the First Time

The procedure in this section requires user-wiring and application programming to be completed. The following procedure is recommended after application setup is completed.

1.

Press [Auto On].

If warnings or alarms occur, see the Warnings and Alarms section.

Apply an external run command. Examples of external run commands are a switch, button, or programmable logic control-

2.

ler (PLC).

Adjust the speed reference throughout the speed range.

3.

Ensure that the system is working as intended by checking the sound and vibration levels of the compressor.

4.

Remove the external run command.

5.

AQ321748767627en-000301 / 130R0570 | 27Danfoss A/S © 2021.06

Status

Color

Warning

Constant yellow light

Alarm

Flashing red light

VLT® Compressor Drive CDS 803

Operating Guide

Troubleshooting

5 Troubleshooting

5.1 Acoustic Noise or Vibration

If the compressor application makes noise or vibrations at certain frequencies, adjust the following parameters to avoid resonance

problems within the system.

•

Upper and lower frequency limits, Parameter group 4-6* Speed Bypass.

•

Switching pattern and switching frequency, parameter group 14-0* Inverter Switching.

5.2 Warnings and Alarms

A warning or an alarm is signaled by the relevant indicator on the front of the drive and indicated by a code on the display.

A warning remains active until its cause is no longer present. Under certain circumstances, operation of the compressor may still be

continued. Warning messages may be critical.

In the event of an alarm, the drive has tripped. To restart operation, reset alarms once their cause has been rectified.

This may be done in 4 ways:

By pressing [Reset].

•

Via a digital input with the Reset function.

•

Via serial communication.

•

•

By resetting automatically using the [Auto Reset] function, see parameter 14-20 Reset Mode.

A trip is the action following an alarm. The trip coasts the compressor and is reset by pressing [Reset] or by a digital input (parameter

group 5-1* Digital Inputs). The original event that caused an alarm cannot damage the drive or cause dangerous conditions. A trip

lock is an action when an alarm occurs, which could damage the drive or connected parts. A trip lock situation can only be reset by

cycling power.

Refer to the VLT® Compressor Drive CDS 803 Programming Guide listed in

gramming.

1.2 Additional Resources for parameter details and pro-

Table 10: Indicator Lights

The alarm words, warning words and extended status words can be read out via serial bus or optional fieldbus for diagnosis. See

also parameter 16-90 Alarm Word, parameter 16-92 Warning Word, and parameter 16-94 Ext. Status Word.

N O T I C E

MOTOR RESTART

After a manual reset pressing [Reset], press [Auto On] or [Hand On] to restart the motor.

If an alarm cannot be reset, the reason may be that its cause has not been rectified, or the alarm is trip-locked, see Table 11.

C A U T I O N

ALARM RESET

Alarms that are trip-locked offer extra protection, meaning that the mains supply must be switched off before the alarm can be

reset. After being switched back on, the drive is no longer blocked and may be reset as described above once the cause has been

rectified.

Alarms that are not trip-locked can also be reset using the automatic reset function in parameter 14-20 Reset Mode (Warning: auto-

matic wake-up is possible!)

alarm for a given fault.

Table 11 specifies whether a warning occurs before an alarm, or whether to show a warning or an

AQ321748767627en-000301 / 130R057028 | Danfoss A/S © 2021.06

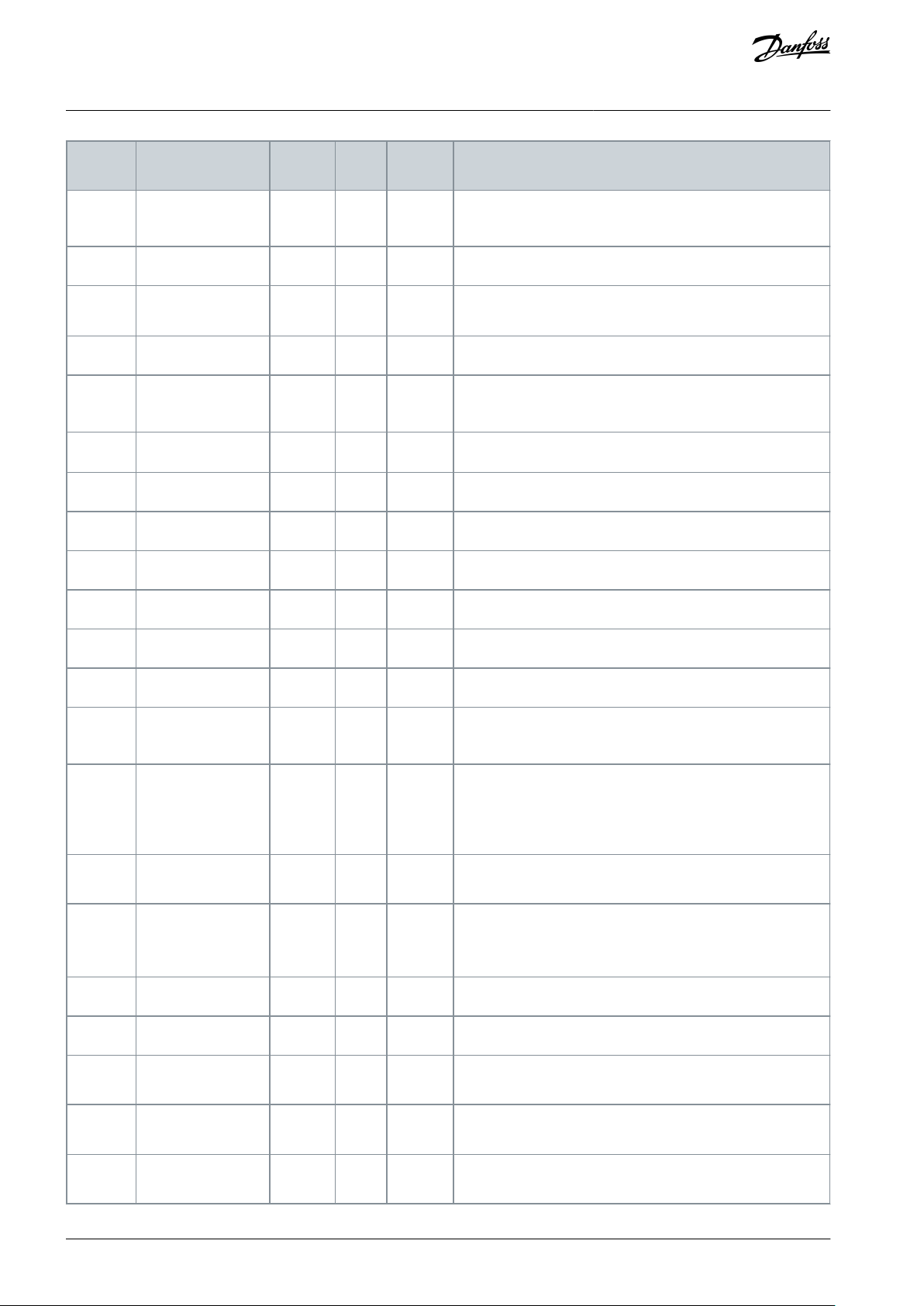

Fault

number

Fault text

Warning

Alarm

Trip

locked

Cause of problem

2

Live zero error

X

X

Signal on terminal 53 or 54 is less than 50% of the value set in

parameter 6-10 Terminal 53 Low Voltage, parameter 6-12 Terminal 53 Low Current, parameter 6-20 Terminal 54 Low Voltage, or

parameter 6-22 Terminal 54 Low Current. See also parameter

group 6-0* Analog I/O Mode.

3

No motor

X

(1)

No motor is connected.

4

Mains ph. loss

XXX

Missing phase on the supply side or too high voltage imbalance. Check the supply voltage. See parameter 14-12 Response

to Mains Imbalance.

7

DC over volt

XXDC-link voltage exceeds limit.

8

DC under volt

X

X

DC-link voltage drops below voltage warning low limit.

9

Inverter overld.

XXMore than 100% load for too long.

10

Motor ETR over

X

(2)

X

The compressor is too hot due to more than 100% load for too

long.11Motor th over

XXThe thermistor or the thermistor connection is disconnected.

13

Overcurrent

XXX

Inverter peak current limit is exceeded.

14

Earth Fault

XXX

Discharge from output phases to ground.

16

Short Circuit

XXShort circuit in the motor or on the motor terminals.

17

Ctrl. word TO

X

X

No communication to the drive. See parameter group 8-0*

General Settings.

18

Start failed

X

The speed has not been able to exceed parameter 1-78 Motor

Start Min Speed [Hz] during start within the allowed time.

30

U phase loss

X

X

(2)

Motor phase U is missing. Check the phase.

For 6–10 kW drives: See parameter 4-58 Missing Motor Phase

Function.

31

V phase loss

X

X

(2)

Motor phase V is missing. Check the phase.

For 6–10 kW drives: See parameter 4-58 Missing Motor Phase

Function.

32

W phase loss

X

X

(2)

Motor phase W is missing. Check the phase.

For 6–10 kW drives: See parameter 4-58 Missing Motor Phase

Function.

36

Mains failure

XXSupply voltage to the drive is lost.

38

Internal fault

XXContact the local Danfoss supplier.

VLT® Compressor Drive CDS 803

Operating Guide

Table 11: Warnings and Alarms

Troubleshooting

AQ321748767627en-000301 / 130R0570 | 29Danfoss A/S © 2021.06

Fault

number

Fault text

Warning

Alarm

Trip

locked

Cause of problem

46

Gate drive voltage

fault

XXThe supply on the power card is out of range.

47

24V supply low

XXX

24 V DC may be overloaded.

49

Speed limit

X

The compressor runs at a speed lower than specified in pa-

rameter 1-87 Compressor Min Speed for Trip [Hz].

50

AMA calibration

X

AMA calibration failed

51

AMA check

U

nom,Inom

X

Motor voltage, current and power configured wrong in parameters.

52

AMA low,I

nom

X

Motor current too low.

53

AMA big motor

X

Motor is too large for the AMA to be performed.

54

AMA small mot

X

Motor is too small for the AMA to be performed.

55

AMA par. range

X

Parameter values found is outside of the acceptable range.

56

AMA interrupt

X

The AMA is interrupted by user.

57

AMA timeout

X

The AMA takes too long time to complete.

58

AMA internal

X

Contact the local Danfoss supplier.

59

Current limit

X

X

The current is higher than the value in parameter 4-18 Current

Limit.

60

External interlock

X

External interlock has been activated. To resume normal operation, apply 24 V DC to the terminal programmed for external

interlock and reset the drive (via serial communication, digital

I/O, or by pressing [Off/Reset]).

66

Heat Sink Temperature Low

X

(3)

This warning is based on the temperature sensor in the IGBT

module.

69

Pwr. Card Temp

XXX

The internal temperature has exceeded the allowed operating

boundary. Check that the ambient operating temperature is

within the limits. Check the fan operation.

80

Drive initialised

X

All parameter settings are initialized to default settings.

87

Auto DC Braking

X

The drive is auto DC braking.

95

Broken belt

X

(2)X(2)

The torque is below the torque level set for no load indicating

a broken belt.

96

Start delayed

X

Power to the drive has been on for a shorter time than specified in parameter 28-01 Interval Between Starts twice.

97

Stop delayed

X

Stopping the motor has been delayed due to short cycle protection being active.

VLT® Compressor Drive CDS 803

Operating Guide

Troubleshooting

AQ321748767627en-000301 / 130R057030 | Danfoss A/S © 2021.06

Fault

number

Fault text

Warning

Alarm

Trip

locked

Cause of problem

99

Locked rotor

X

The rotor is blocked or cannot run due to heavy load.

126

Motor Rotating

X

High back EMF voltage. Stop the rotor of the PM motor.

127

Back EMF too high

X

The drive cannot start the motor due to the rotor running at a

higher speed than normal condition.

208

ORM Fault

XXRunning in hand mode with low speed for too long time.

VLT® Compressor Drive CDS 803

Operating Guide

1

Only applicable for 18–30 kW.

2

Only applicable for 6–10 kW.

3

Only applicable for 30 kW.

Troubleshooting

For full specifications of warnings and alarms, refer to the VLT® Compressor Drives CDS 803 Programming Guide listed in

tional Resources.

1.2 Addi-

AQ321748767627en-000301 / 130R0570 | 31Danfoss A/S © 2021.06

P6K0

P7K5

P10K

Typical shaft output [kW]

6.0

7.510Typical shaft output [hp]

8.01015

Enclosure size

H4H4H5

Maximum cable size in terminals (mains, compressor) [mm2 (AWG)]

16 (6)

16 (6)

16 (6)

Output current @ 40 °C (104 °F) ambient temperature

Continuous (3x200–240 V) [A]

222842

Intermittent (3x200–240 V) [A]

24.2

30.8

46.2

Output current @ 50 °C (122 °F) ambient temperature

Continous (3x200–240 V) [A]

19.82333

Intermittent (3x200–240 V) [A]

21.8

25.3

36.3

Maximum input current

Continuous (3x200–240 V) [A]

21

28.341Intermittent (3x200–240 V) [A]

23.1

31.1

45.1

Maximum mains fuses, see 3.2.2.1 Recommendation of Fuses and Circuit Breakers

Estimated power loss [W], best case/typical

(1)

182/204

229/268

369/386

Weight enclosure protection IP20 [kg (lb)]

7.9 (17.4)

7.9 (17.4)

9.5 (22.9)

Efficiency [%], best case/typical

(2)

97.3/97.1

98.5/97.1

97.2/97.1

P6K0

P7K5

P10K

P18K

P22K

P30K

Typical shaft output [kW]

6.0

7.51018.52230

Typical shaft output [hp]

8.01015253040Enclosure size

H3H3H4H5H5

H6

Maximum cable size in terminals (mains, motor) [mm

2

(AWG)]

4 (10)

4 (10)

16 (6)

16 (6)

16 (6)

35 (2)

VLT® Compressor Drive CDS 803

Operating Guide

6 Specifications

6.1 Electrical Data

6.1.1 Electrical Data 3x200–240 V AC

Table 12: 3x200–240 V AC

Specifications

1

Applies to dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses may increase. LCP and

typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to Danfoss

2

Efficiency measured at nominal current. For energy efficiency class, see

mart website.

6.6 Conforming Standards. For part load losses, see Danfoss MyDrive® ecoS-

6.1.2 Electrical Data 3x380–480 V AC

Table 13: 3x380–480 V AC

MyDrive® ecoSmart website.

AQ321748767627en-000301 / 130R057032 | Danfoss A/S © 2021.06

P6K0

P7K5

P10K

P18K

P22K

P30K

Output current @ 40 °C (104 °F) ambient temperature (45 °C (113 °F) for 30 kW)

Continuous (3x380–440 V) [A]

12

15.523374461

Intermittent (3x380–440 V)[A]

13.2

17.1

25.3

40.7

46.8

67.1

Continuous (3x441–480 V) [A]

111421374461Intermittent (3x441–480 V) [A]

12.1

15.4

23.1

40.7

46.8

67.1

Output current @ 50 °C (122 °F) ambient temperature (52 °C (125 °F) for 18.5–22 kW)

Continuous (3x380–440 V) [A]

10.91420.93744

48.8

Intermittent (3x380–440 V) [A]

12

15.42340.7

46.8

53.7

Continuous (3x441–480 V) [A]

10

12.6

19.13744

41.6

Intermittent (3x441–480 V) [A]

11

13.92140.7

46.8

45.8

Maximum input current

Continuous (3x380–440 V) [A]

11.2

15.1

22.1

35.2

42.657Intermittent (3x380–440 V) [A]

12.3

16.6

24.3

38.7

45.7

62.7

Continuous (3x441–480 V) [A]

9.4

12.6

18.4

34.8

41.5

55.8

Intermittent (3x441–480 V) [A]

10.3

13.9

20.2

38.2

44.2

60.5

Maximum mains fuses, see 3.2.2.1 Recommendation of Fuses and Circuit Breakers.

Estimated power loss [W], best case/typical

(1)

104/131

159/198

248/274

412/456

475/523

733

Weight enclosure protection rating IP20 [kg (lb)]

4.3 (9.5)

4.5 (9.9)

7.9 (17.4)

9.5 (20.9)

9.5 (20.9)

24.5 (54)

Efficiency [%], best case/typical

(2)

98.4/98

98.2/97.8

98.1/97.9

98.1/97.9

98.1/97.9

97.8

Supply voltage

200–240 V ±10%

Supply voltage

380–480 V ±10%

Supply frequency

50/60 Hz

Maximum imbalance temporary between mains phases

3.0% of rated supply voltage

True power factor (λ)

≥0.9 nominal at rated load

Displacement power factor (cosφ) near unity

(>0.98)

Switching on the input supply L1, L2, L3 (power-ups)

Maximum 2 times/minute

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

The unit is suitable for use on a circuit capable of delivering not

more than 100000 A

rms

symmetrical Amperes, 240/480 V maxi-

mum.

Output voltage

0–100% of supply voltage

VLT® Compressor Drive CDS 803

Operating Guide

Specifications

1

Applies to dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses may increase. LCP and

typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to Danfoss

2

Efficiency measured at nominal current. For energy efficiency class, see

mart website.

6.6 Conforming Standards. For part load losses, see Danfoss MyDrive® ecoS-

6.2 Mains Supply (L1, L2, L3)

6.3 Compressor Output (U, V, W)

MyDrive® ecoSmart website.

AQ321748767627en-000301 / 130R0570 | 33Danfoss A/S © 2021.06

Output frequency

0–200 Hz (VVC+), 0–400 Hz (u/f)

Switching on output

Unlimited

Ramp times

0.05–3600 s

Terminal number

50

Output voltage

10.5 V ±0.5 V

Maximum load

25 mA

Terminal number

12

Maximum load

80 mA

Number of analog inputs

2

Terminal number

53, 54

Terminal 53 mode

Parameter 6-61 Terminal 53 Setting: 1=voltage, 0=current

Terminal 54 mode

Parameter 6-63 Terminal 54 Setting: 1=voltage, 0=current

Voltage level

0–10 V

Input resistance, R

i

Approximately 10 kΩ

Maximum voltage

20 V

Current level

0/4–20 mA (scalable)

Input resistance, R

i

<500 Ω

Maximum current

29 mA

Resolution on analog input

10 bit

Number of programmable analog outputs

2

Terminal number

42, 45

(1)

Current range at analog output

0/4–20 mA

The load resistor to common at analog out

500 Ω

Maximum voltage at analog output

17 V

Accuracy on analog output

Maximum error: 0.4% of full scale

Resolution on analog output

10 bit

Programmable digital inputs

4

Terminal number

18, 19, 27, 29

VLT® Compressor Drive CDS 803

Operating Guide

6.4 Control Input/Output

6.4.1 10 V DC Output

The 10 V DC output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.2 24 V DC Output

The 24 V DC output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

Specifications

6.4.3 Analog Inputs

The analog inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.4 Analog Outputs

1

Terminals 42 and 45 can also be programmed as digital outputs.

The analog outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.5 Digital Inputs

AQ321748767627en-000301 / 130R057034 | Danfoss A/S © 2021.06

Logic

PNP or NPN

Voltage level

0–24 V DC

Voltage level, logic 0 PNP

<5 V DC

Voltage level, logic 1 PNP

>10 V DC

Voltage level, logic 0 NPN

>19 V DC

Voltage level, logic 1 NPN

<14 V DC

Maximum voltage on input

28 V DC

Input resistance, R

i

Approximately 4 kΩ

Digital input 29 as thermistor input

Fault: >2.9 kΩ and no fault: <800 Ω

Digital input 29 as pulse input

Maximum frequency 32 kHz push-pull-driven & 5 kHz (O.C.)

Number of digital outputs

2

Terminals 42 and 45

Terminal number

42, 45

(1)

Voltage level at digital output

17 V

Maximum output current at digital output

20 mA

The load resistor at digital output

1 kΩ

Programmable relay output

2

Relay 01 and 02

01–03 (NC), 01–02 (NO), 04–06 (NC), 04–05 (NO)

Maximum terminal load (AC-1)

(1)

on 01–02/04–05 (NO) (Resistive

load)

250 V AC, 3 A

Maximum terminal load (AC-15)

(1)

on 01–02/04–05 (NO) (Induc-

tive load @ cosφ 0.4)

250 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 01–02/04–05 (NO) (Resistive

load)

30 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 01–02/04–05 (NO) (Induc-

tive load)

24 V DC, 0.1 A

Maximum terminal load (AC-1)

(1)

on 01–03/04–06 (NC) (Resistive

load)

250 V AC, 3 A

Maximum terminal load (AC-15)

(1)

on 01–03/04–06 (NC) (Inductive

load @ cosφ 0.4)

250 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 01–03/04–06 (NC) (Resistive

load)

30 V DC, 2 A

Minimum terminal load on 01–03 (NC), 01–02 (NO)

24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

Programmable relay output

2

VLT® Compressor Drive CDS 803

Operating Guide

The digital inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.6 Digital Outputs

Specifications

1

Terminals 42 and 45 can also be programmed as analog output.

The digital outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.7 Relay Outputs, Enclosure Sizes H3–H5

1

IEC 60947 parts 4 and 5. Endurance of the relay varies with different load type, switching current, ambient temperature, drive configuration, work-

ing profile, and so forth. Mount a snubber circuit when connecting inductive loads to the relays.

The relay outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.8 Relay Outputs, Enclosure Size H6

AQ321748767627en-000301 / 130R0570 | 35Danfoss A/S © 2021.06

Relay 01 and 02

01–03 (NC), 01–02 (NO), 04–06 (NC), 04–05 (NO)

Maximum terminal load (AC-1)

(1)

on 04–05 (NO) (Resistive load)

(2)

(3)

400 V AC, 2 A

Maximum terminal load (AC-15)

(1)

on 04–05 (NO) (Inductive load

@ cosφ 0.4)

240 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 04–05 (NO) (Resistive load)

80 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 04–05 (NO) (Inductive load)

24 V DC, 0.1 A

Maximum terminal load (AC-1)

(1)

on 04–06 (NC) (Resistive load)

240 V AC, 4 A

Maximum terminal load (AC-15)

(1)

on 04–06 (NC) (Inductive load

@ cosφ 0.4)

240 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 04–06 (NC) (Resistive load)

50 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 04–06 (NC) (Inductive load)

24 V DC, 0.1 A

Minimum terminal load on 01–03 (NC), 01–02 (NO), 04–06 (NC),

04–05 (NO)

24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

Terminal number

68 (P, TX+, RX+), 69 (N, TX-, RX-)

Terminal number

61 common for terminals 68 and 69

Enclosure protection rating

IP20

Enclosure kit available

IP21, TYPE 1

Maximum vibration exposure

1.0 g

Maximum relative humidity

5–95% (IEC 60721-3-3; Class 3K3 (non-condensing) during opera-

tion)

Aggressive environment (IEC 60721-3-3), coated (standard), enclosure sizes H3–H5

Class 3C3

Aggressive environment (IEC 60721-3-3), non-coated enclosure

size H6

Class 3C2

Environmental testing (IEC 60068-2-43 H2S)

10 days

Ambient temperature, enclosure sizes H3–H5, 6–10 kW/8–15 hp

(1)

50 °C (122 °F)

Ambient temperature, enclosure size H5, 18–22 kW/25–30 hp

(1)

52 °C (125.6 °F)

Ambient temperature, enclosure size H6, 30 kW/40 hp

(1)

45 °C (113 °F)

Minimum ambient temperature during full-scale operation

0 °C (32 °F)

Minimum ambient temperature at reduced performance, enclosure sizes H3–H5

-20 °C (-4 °F)

Minimum ambient temperature at reduced performance, enclosure size H6

-10 °C (14 °F)

Temperature during storage/transport

-30 to +65/70 °C (-22 to +149/158°F)

Maximum altitude above sea level without derating

1000 m (3281 ft)

Maximum altitude above sea level with derating

3000 m (9843 ft)

VLT® Compressor Drive CDS 803

Operating Guide

1

IEC 60947 parts 4 and 5. Endurance of the relay varies with different load type, switching current, ambient temperature, drive configuration, work-

ing profile, and so forth. Mount a snubber circuit when connecting inductive loads to the relays.

2

Overvoltage Category II.

3

UL applications 250 V AC, 3 A.

Specifications

The relay outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.4.9 RS485 Serial Communication

The RS485 serial communication outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

6.5 Ambient Conditions

AQ321748767627en-000301 / 130R057036 | Danfoss A/S © 2021.06

Derating for high altitude, see 3.1.2.2 Derating for Low Air Pres-

sure and High Altitudes.

Safety standards

EN/IEC 61800-5-1, UL 508C, EN/IEC/UL 60730-1

EMC standards, Emission

EN 61800-3, EN 61000-6-3/4, EN 55011, IEC 61800-3

EMC standards, Immunity

EN 61800-3, EN 61000-3-12, EN 61000-6-1/2, EN 61000-4-2, EN

61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6

Energy efficiency class

(1)

IE2

Maximum compressor cable length, shielded/armored (EMC-correct installation)

See EMC Emission Test Results in the VLT® Compressor Drive De-

sign Guide listed in 1.2 Additional Resources.

Maximum compressor cable length, unshielded/unarmoured

50 m (164 ft)

Maximum cross-section to compressor, mains

See 6.1 Electrical Data for more information

Cross-section DC terminals for filter feedback on enclosure size

H3

4 mm2/11 AWG

Cross-section DC terminals for filter feedback on enclosure sizes

H4–H6

16 mm2/6 AWG

Maximum cross-section to control terminals, rigid wire

2.5 mm2/14 AWG

Maximum cross-section to control terminals, flexible wire

2.5 mm2/14 AWG

Minimum cross-section to control terminals

0.05 mm2/30 AWG

VLT® Compressor Drive CDS 803

Operating Guide

1

Refer to 3.1 Mechanical Installation.

6.6 Conforming Standards

1

Determined according to EN 50598-2 at:

Rated load.

•

•

90% rated frequency.

•

Switching frequency factory setting.

•

Switching pattern factory setting.

•

For power loss data according to EN 50598-2, refer to Danfoss MyDrive® ecoSmart website.

Specifications

N O T I C E

The VLT® Compressor Drive CDS 803 with SXXX in the type code is certified against UL 508C. Example:

CDS803P7K5T4E20H4XXCXXXSXXXXAXBXCXXXXDX

The VLT® Compressor Drive CDS 803 with S096 in the type code is certified against UL/EN/IEC 60730-1. Example:

CDS803P30KT4E20H2XXXXXXS096XAXBXCXXXXDX

6.7 Cable Lengths and Cross-sections

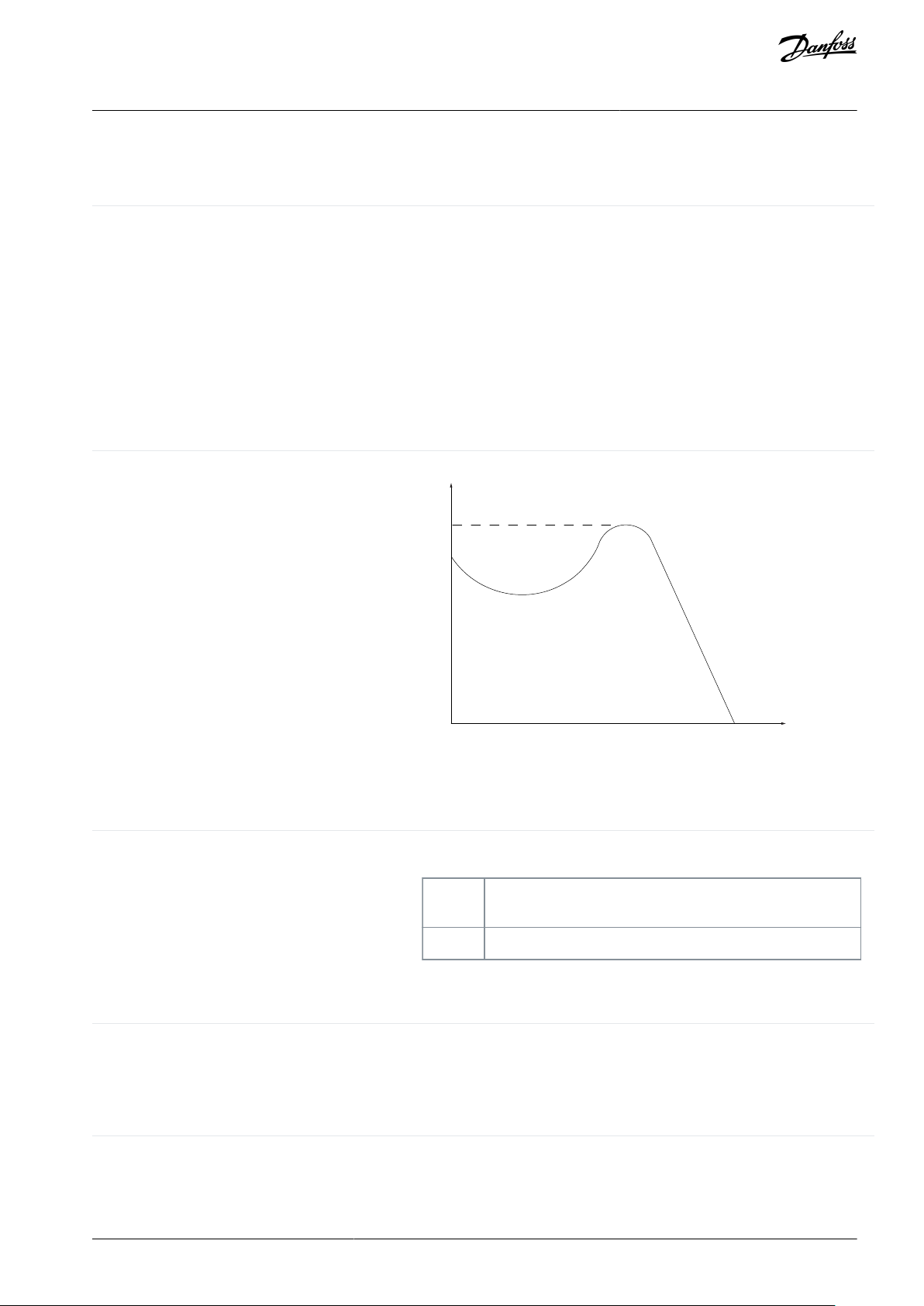

6.8 Acoustic Noise

Acoustic noise from the drives comes from 3 sources:

•

DC-link coils

•

Integral fan

•

RFI filter inductor

AQ321748767627en-000301 / 130R0570 | 37Danfoss A/S © 2021.06

Enclosure

Level [dBA]

(1)

H3

53.8H464H563.7H671.5

Enclosure size

200–240 V AC

[kW (hp)]

380–480 V AC [kW

(hp)]

IP rating

Maximum

weight [kg (lb)]

Height [mm

(in)]

Width [mm

(in)]

Depth [mm

(in)]H3–

6.0–7.5 (8.0–10)

IP20

4.5 (9.9)

280 (11)

155 (6.1)

320 (12.6)

H4

6.0–7.5 (8.0–10)

10 (15)

IP20

7.9 (17.4)

380 (15)

200 (7.9)

315 (12.4)

H5

10 (15)

18.5–22 (25–30)

IP20

9.5 (20.9)

395 (15.6)

233 (9.2)

380 (15)

H6

–

30 (40)

IP20

24.5 (54.0)

850 (33.5)

370 (15.6)

460 (18.1)

VLT® Compressor Drive CDS 803

Operating Guide

Table 14: Typical Values Measured at a Distance of 1 m (3.28 ft) from the Unit

1

The values are measured under the background of 35 dBA noise and the fan running at full speed.

6.9 Shipping Dimensions

Table 15: Shipping Dimensions

Specifications

6.10 Accessories and Spare Parts

Refer to the VLT® Compressor Drive CDS 803 Design Guide listed in

1.2 Additional Resources.

AQ321748767627en-000301 / 130R057038 | Danfoss A/S © 2021.06

°C

Degrees Celsius

°F

Degrees Fahrenheit

A

Ampere/AMP

AC

Alternating current

AMA

Automatic motor adaptation

AWG

American wire gauge

DC

Direct current

EMC

Electro-magnetic compatibility

ETR

Electronic thermal relay

f

M,N

Nominal motor frequency

hp

Horsepower

Hz

Hertz

I

INV

Rated inverter output current

I

LIM

Current limit

I

M,N

Nominal motor current

I

VLT,MAX

Maximum output current

I

VLT,N

Rated output current supplied by the drive

kg

Kilogram

kHz

Kilohertz

kW

Kilowatt

LCP

Local control panel

m

Meter

mA

Milliampere

MCT

Motion Control Tool

Nm

Newton meter

nsSynchronous motor speed

P

M,N

Nominal motor power

PELV

Protective extra low voltage

RPM

Revolutions per minute

s

Second

VLT® Compressor Drive CDS 803

Operating Guide

7 Appendix

7.1 Abbreviations

Appendix

AQ321748767627en-000301 / 130R0570 | 39Danfoss A/S © 2021.06

T

LIM

Torque limit

U

M,N

Nominal motor voltage

V

Volts

VLT® Compressor Drive CDS 803

Operating Guide

7.2 Conventions

•

Numbered lists indicate procedures.

•

Bulleted and dashed lists indicate listings of other information where the order of the information is not relevant.

•

Bolded text indicates highlighting and section headings.

•

Italicized text indicates the following:

-

Cross-reference.

-

Link.

-

Footnote.

-

Parameter name.

-

Parameter option.

-

Parameter group name.

-

Alarms/warnings.

•

All dimensions in drawings are in metric values (imperial values in brackets).

•

An asterisk (*) indicates the default setting of a parameter.

Appendix

AQ321748767627en-000301 / 130R057040 | Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

Index

A

Abbreviations................................................................................................ 39

Acoustic noise.........................................................................................28, 37

Alarms...............................................................................................................28

Alarms, overview.......................................................................................... 29

Ambient conditions.....................................................................................36

Ambient temperature..........................................................................12, 36

Analog input.................................................................................................. 34

Analog output............................................................................................... 34

Approvals and certifications.......................................................................6

C

Cable cross-section......................................................................................37

Cable length...................................................................................................37

Cable requirements.....................................................................................12

Circuit breakers............................................................................................. 13

Compressor output (U, V, W)....................................................................33

Control input/output........................................................................... 34, 34

Control terminals..........................................................................................18

Conventions...................................................................................................40

Cooling clearance.........................................................................................12

D

Data storage...................................................................................................26

DC voltage output, 10 V.............................................................................34

DC voltage output, 24 V.............................................................................34

Default settings.............................................................................................26

Derating....................................................................................................12, 12

Digital input....................................................................................................34

Digital output................................................................................................ 35

Discharge time.............................................................................................. 11

E

Electrical data..........................................................................................32, 32

Electrical installation................................................................................... 12

EMC-compliant installation...................................................................... 20

Energy efficiency

Power loss data.............................................................................. 32,33

class..........................................................................................................37

F

Factory settings.............................................................................................26

Fastener torque ratings..............................................................................12

Fuses................................................................................................................. 13

H

High altitudes................................................................................................ 12

I

Indicator light......................................................................................... 25, 25

Input current

Maximum input current..............................................................32,33

Installation

Qualified personnel............................................................................10

Start up....................................................................................................27

L

Leakage current............................................................................................ 11

Index

Local control panel...................................................................................... 24

Low air pressure............................................................................................12

M

Main menu......................................................................................................25

Mains supply (L1, L2, L3)............................................................................33

Maximum altitude........................................................................................36

O

Output current....................................................................................... 32, 33

Output frequency.........................................................................................34

Output voltage..............................................................................................33

P

PC tool, download.......................................................................................... 6

Programming.................................................................................................24

Programming interfaces............................................................................24

Q

Qualified personnel.................................................................................6, 10

Quick menu.................................................................................................... 25

R

Ramp times.....................................................................................................34

Relay outputs..........................................................................................35, 35

Relay terminals..............................................................................................17

Reset/restart operation.............................................................................. 28

RS485................................................................................................................ 36

RS485 serial communication.............................................................19, 19

S

Shipping dimensions.................................................................................. 38

Side-by-side installation............................................................................ 12

Software version............................................................................................. 6

Standards

EN 50598-2.......................................................................................32,33

EN 60664-1.............................................................................................33

IEC 60721-3-3........................................................................................36

IEC 60068-2-43 H2S............................................................................ 36

UL Safety standards............................................................................37

EMC standards, emission..................................................................37

EMC standards, immunity................................................................37

Storage.............................................................................................................36

Store data........................................................................................................26

Supplementary documentation................................................................6

Supply frequency......................................................................................... 33

Supply voltage.............................................................................................. 33

Switching frequency................................................................................... 12

Symbols........................................................................................................... 10

T

Terminal overview....................................................................................... 18

Transport......................................................................................................... 36

True power factor.........................................................................................33

V

Vibration................................................................................................... 28, 37

VLT® Motion Control Tool MCT 10.....................................................6, 24

AQ321748767627en-000301/130R0570 | 41Danfoss A/S © 2021.06

VLT® Compressor Drive CDS 803

Operating Guide

Voltage

Safety warning..................................................................................... 10

W