Design Guide

VLT® Compressor Drive CDS 803

6–30 kW

vlt-drives.danfoss.com

VLT® Compressor Drive CDS 803

Design Guide

Contents

1

Introduction 7

1.1

Purpose of this Design Guide 7

Additional Resources 7

1.2

Supplementary Documentation 7

1.2.1

1.2.2

VLT® Motion Control Tool MCT 10 Software Support 7

1.3

Manual and Software Version 7

1.4

Approvals and Certifications 7

Safety 9

2

Safety Symbols 9

2.1

Qualified Personnel 9

2.2

Safety Precautions 9

2.3

3

Product Overview 11

Contents

3.1

VLT® Compressor Drive CDS 803 Family Overview 11

3.2

VLT® Compressor Drive CDS 803 Features 12

3.2.1

Compressor Features 12

3.2.1.1

3.2.1.2

3.2.1.3

3.2.1.4

3.2.1.5

3.2.1.6

3.2.1.7

3.2.2

Application Features 16

3.2.2.1

3.2.2.2

3.2.2.3

3.2.2.4

3.2.2.5

Secure Start-up 12

Compressor Minimum Speed Detection 13

Short-cycle Protection 14

Anti-reverse Protection 14

Oil Return Management 15

Data Readouts and Commissioning 15

Undersized Compressor 16

Automatic Motor Adaptation (AMA) 16

Motor Thermal Protection 16

Built-in PID Controller 17

Automatic Restart 17

Flying Start 17

3.2.2.6

3.2.2.7

3.2.2.8

3.2.2.9

3.2.2.9.1

3.2.2.9.2

3.3

VLT® Compressor Drive CDS 803 Protections 19

Frequency Bypass 17

Motor Preheat 17

Programmable Set-ups 18

Smart Logic Control (SLC) 18

Comparators 19

Logic Rules 19

AJ330233902305en-000201/130R0596 | 3Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

3.3.1

3.3.2

3.3.3

3.3.4

Contents

Mains Input Protection 19

3.3.1.1

3.3.1.2

Output Protection 20

3.3.2.1

3.3.2.2

3.3.2.3

3.3.2.4

3.3.2.5

Temperature Protection 21

3.3.3.1

3.3.3.2

3.3.3.3

Internal Protection 21

Mains Supply Failure, Momentary Dropouts, and Surges 19

Missing Mains Phase Detection 20

Short-circuit Protection (Phase-to-phase) 20

Ground Fault Protection (Output Phase-to-Ground) 20

Locked Rotor Detection 20

Output Phase Loss Detection 20

Overload Protection 20

Minimum and Maximum Temperature Protection 21

Automatic Temperature Derating 21

Temperature-controlled Fans 21

3.3.4.1

3.3.4.2

3.4

Ecodesign for Power Drive Systems 21

3.4.1

Losses in Mains Cabling 23

3.4.2

Input Filters: Line Reactors and Harmonic Filters 23

3.4.3

Drive, Input Side 24

3.4.4

DC Link 24

3.4.5

Drive, Output Side 25

3.4.6

Motor Cables and Motor 26

4

Specifications 27

4.1

Electrical Data 27

4.1.1

Electrical Data 3x200–240 V AC 27

4.1.2

Electrical Data 3x380–480 V AC 27

4.2

Mains Supply (L1, L2, L3) 28

4.3

Compressor Output (U, V, W) 28

4.4

Control Input/Output 29

DC Overvoltage Protection 21

Internal Faults 21

4.4.1

10 V DC Output 29

4.4.2

24 V DC Output 29

4.4.3

Analog Inputs 29

4.4.4

Analog Outputs 29

4.4.5

Digital Inputs 29

4.4.6

Digital Outputs 30

4.4.7

Relay Outputs, Enclosure Sizes H3–H5 30

AJ330233902305en-000201/130R05964 | Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

4.4.8

Relay Outputs, Enclosure Size H6 30

4.4.9

RS485 Serial Communication 31

4.5

Ambient Conditions 31

4.6

Conforming Standards 32

4.7

Cable Lengths and Cross-sections 32

4.8

Acoustic Noise 32

4.9

Mechanical Dimensions 33

4.9.1

Drive Dimensions 33

4.9.2

Shipping Dimensions 34

4.10

dU/dt 34

5

Mechanical Installation Considerations 36

5.1

Safe Transportation and Storage 36

5.1.1

Reforming the Capacitors 36

5.2

Side-by-side Installation 37

Contents

5.3

Operating Environment 37

5.3.1

Gases 38

5.3.2

Dust 38

5.3.3

Air Humidity 39

5.3.4

Vibration and Shock 39

5.3.5

Derating for Ambient Temperature and Switching Frequency 39

5.3.5.1

5.3.5.2

5.3.5.3

5.3.6

Derating for Low Air Pressure and High Altitudes 41

5.4

IP21/NEMA Type 1 Enclosure Kit 41

5.5

Acoustic Noise or Vibration 43

5.6

Recommended Disposal 43

6

Electrical Installation Considerations 45

6.1

Electrical Installation in General 45

6.1.1

Fastener Torque Ratings 45

Derating Curves, 6.0, 7.5, and 10 kW 39

Derating Curves, 18.5–22 kW 40

Derating Curves, 30 kW 40

6.2

Fuses and Circuit Breakers 45

6.2.1

Recommendation of Fuses and Circuit Breakers 45

6.3

Electrical Wiring 46

6.3.1

Wiring Schematic 46

6.3.2

Terminal Overview of Enclosure Sizes H3–H5 47

6.3.3

Terminal Overview of Enclosure Size H6 48

6.3.4

Connecting to Mains and Compressor Terminals 48

AJ330233902305en-000201/130R0596 | 5Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

6.3.5

6.3.6

6.4

Setting Up RS485 Serial Communication 51

6.5

Electromagnetic Compatibility 52

6.5.1

6.5.2

6.5.3

6.5.4

6.5.5

6.5.6

6.5.7

6.5.8

6.6

Harmonics Emission 61

Contents

6.3.4.1

Relay Terminals 49

Control Terminals 50

EMC Emission Test Results 53

Emission Requirements 53

Immunity Requirements 54

EMC Compatibility 56

EMC-compliant Electrical Installation 57

EMC-compliant Cables 59

Shielded Control Cables 60

RFI Filter Switch 61

IT Grid Installations 49

6.6.1

Harmonics Emission Requirements 62

6.6.2

Harmonics Test Results (Emission) 62

6.7

Galvanic Isolation (PELV) 63

6.8

Ground Leakage Current 63

6.8.1

Using a Residual Current Device (RCD) 65

7

How to Order 67

7.1

Drive Configurator 67

7.2

Type Code Description 67

7.3

Accessories and Spare Parts 68

8

Appendix 69

8.1

Abbreviations 69

8.2

Conventions 69

AJ330233902305en-000201/130R05966 | Danfoss A/S © 2021.05

Edition

Remarks

Software version

AJ330233902305, version 0201

Software update for 18–30 kW (25–40 hp) drives.

6.0–10 kW (8–15 hp): Version 2.0

18–30 kW (25–40 hp): Version 61.20

Description

Conformity mark

EU/EC Declaration of Conformity (EC/CE - European Conformity/Conformité Européenne)

Low Voltage Directive/Electromagnetic compatibility (EMC)/Restriction of Hazardous Substances

(RoHS)

Countries of use: Europe

ACMA Declaration of Conformity (RCM - Regulatory Compliance Mark)

Australian Communications Media Authority (ACMA)

Low Voltage Directive/Electromagnetic compatibility (EMC)

Countries of use: Australia and New Zealand

VLT® Compressor Drive CDS 803

Design Guide

Introduction

1 Introduction

1.1 Purpose of this Design Guide

This Design Guide is intended for qualified personnel, such as:

•

Project and systems engineers.

•

Design consultants.

•

Application and product specialists.

The Design Guide provides technical information to understand the capabilities of the VLT® Compressor Drive CDS 803 for integration into motor control and monitoring systems. Its purpose is to provide design considerations and planning data for integration of

the drive into a system. It caters for selection of drives and options for a diversity of applications and installations. Reviewing the

detailed product information in the design stage enables developing a well-conceived system with optimal functionality and efficiency.

This manual is targeted at a worldwide audience. Therefore, wherever occurring, both SI and imperial units are shown.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Supplementary Documentation

Various resources are available to understand advanced drive operation, programming, and directives compliance.

•

The Programming Guide provides information on how to program and includes complete parameter descriptions.

•

The Operating Guide provides detailed information about installation and commissioning of the drive.

See www.danfoss.com for supplementary documentation.

1.2.2 VLT® Motion Control Tool MCT 10 Software Support

Download the software from the Service and Support download page on www.danfoss.com.

During the installation process of the software, enter CD-key 34544400 to activate the CDS 803 functionality. An activation key is not

required for using the CDS 803 functionality.

The latest software does not always contain the latest updates for the drive. Contact the local sales office for the latest drive updates

(in the form of *.upd files), or download the drive updates from the Service and Support download page on www.danfoss.com.

1.3 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

Table 1: Manual and Software Version

1.4 Approvals and Certifications

AJ330233902305en-000201 / 130R0596 | 7Danfoss A/S © 2021.05

Description

Conformity mark

VIT-SEPRO Declaration of Conformity (VIT - All-Union Institute of Transformer Engineering)

Low Voltage Directive/Electromagnetic compatibility (EMC)

Country of use: Ukraine

089

Moroccan Declaration of Conformity (CMIM - Moroccan Conformity Mark)

Low Voltage Directive/Electromagnetic compatibility (EMC)

Country of use: Morocco

Eurasian Economic Union Declaration of Conformity (EAC - Eurasian Conformity Mark)

Customs Union Technical Regulations (CU TR)

Low voltage Directive/Electromagnetic compatibility (EMC)/Restriction of Hazardous Substances Direc-

tive (RoHS)

Countries of use: Eurasian Economic Union (Russia, Belarus, Kazakhstan, Armenia, and Kirghizstan)

Certification of Compliance UL listed (UL - Underwriters Laboratories)

Safety organization

Countries of use: USA and Canada

Certification of Compliance UL recognized (UL - Underwriters Laboratories)

Safety organization

Countries of use: USA and Canada

VLT® Compressor Drive CDS 803

Design Guide

Introduction

N O T I C E

The VLT® Compressor Drive CDS 803 with SXXX in the type code is certified against UL 508C. Example:

CDS803P7K5T4E20H4XXCXXXSXXXXAXBXCXXXXDX

The VLT® Compressor Drive CDS 803 with S096 in the type code is certified against UL/EN/IEC 60730-1. Example:

CDS803P30KT4E20H2XXXXXXS096XAXBXCXXXXDX

AJ330233902305en-000201 / 130R05968 | Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AJ330233902305en-000201 / 130R0596 | 9Danfoss A/S © 2021.05

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x200

6.0–10 (8.0–15)

15

3x400

6.0–7.5 (8.0–10)

4

3x400

10–30 (15–40)

15

VLT® Compressor Drive CDS 803

Design Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

AJ330233902305en-000201 / 130R059610 | Danfoss A/S © 2021.05

e30bj117.10

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

3 Product Overview

3.1 VLT® Compressor Drive CDS 803 Family Overview

Danfoss offers CDS drives in different-sized enclosures with power ratings from 6.0–30 kW (8.0–40 hp). Common for all drives are

the following:

•

I/Os

-

4 digital inputs (PNP or NPN)

-

2 digital outputs

-

2 analog inputs (voltage or current)

-

2 analog outputs

-

2 relay outputs

•

RS485 serial communication

-

Danfoss FC protocol and VLT® Motion Control Tool MCT 10 support

-

Modbus RTU

The drive is a free-standing, wall-mountable, or cabinet-mountable drive available in different ratings to fit various applications. The

complete overview is listed in Table 3.

Illustration 1: VLT® Compressor Drive CDS 803 Family

AJ330233902305en-000201 / 130R0596 | 11Danfoss A/S © 2021.05

•••

•••

Power [kW]

P6K0

P7K5

P10K

P18K

P22K

P30K

Electrical

Mains voltage [V]

3x200–240

3x380–480

3x200–240

3x380–480

3x200–240

3x380–480

3x380–480

3x380–480

3x380–480

Typical shaft output [hp]

8.010152530

40

Mechanical

Enclosure size

H4H3H4H3H5H4H5H5H6

IP protection rating

(1)

IP20

IP20

IP20

IP20

IP20

IP20

Compliance

RFI filter

H4 RFI filter

EN 55011 A1

EN/IEC 61800-3 C2

H2 RFI filter

EN 55011 A2

EN/IEC 61800-3 C3

UL rating

UL Listed

UL 508C

UL Recognized

UL 60730-1

VLT® Compressor Drive CDS 803

Design Guide

Table 3: Overview of VLT® Compressor Drive CDS 803 Family

Product Overview

1

All CDS 803 drives can be upgraded to IP21/NEMA Type 1 with an IP21/NEMA Type 1 Conversion Kit.

3.2 VLT® Compressor Drive CDS 803 Features

Various application functions are programmed in the drive for enhanced system performance. The functions require minimum programming or setup. For activation of the functions, refer to the VLT® Compressor Drive CDS 803 Programming Guide listed in 1.2

Additional Resources.

3.2.1 Compressor Features

The VLT® Compressor Drive CDS 803 offers various specialized functions for use in combination with compressor systems.

3.2.1.1 Secure Start-up

To ensure that the compressor ramps fast to the defined start speed, the VLT® Compressor Drive CDS 803 always runs a start-up

sequence. The compressor runs at the start speed for a defined fixed time.

•

If a locked rotor or flooded compressor occurs, it is detected during start-up.

•

If the drive fails to start the compressor, it trips on Alarm 18, Start failed.

AJ330233902305en-000201 / 130R059612 | Danfoss A/S © 2021.05

Speed

Speed

Start

speed

Start-up sequence

Time

Time

Compressor

start minimum

speed

A18, Start

failed

Compressor start

maximum time to trip

e30bj077.10

e30bj078.10

Speed

Motor speed

low limit

Compressor

minimum

speed for trip

Minimum

speed

detection

timer start

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

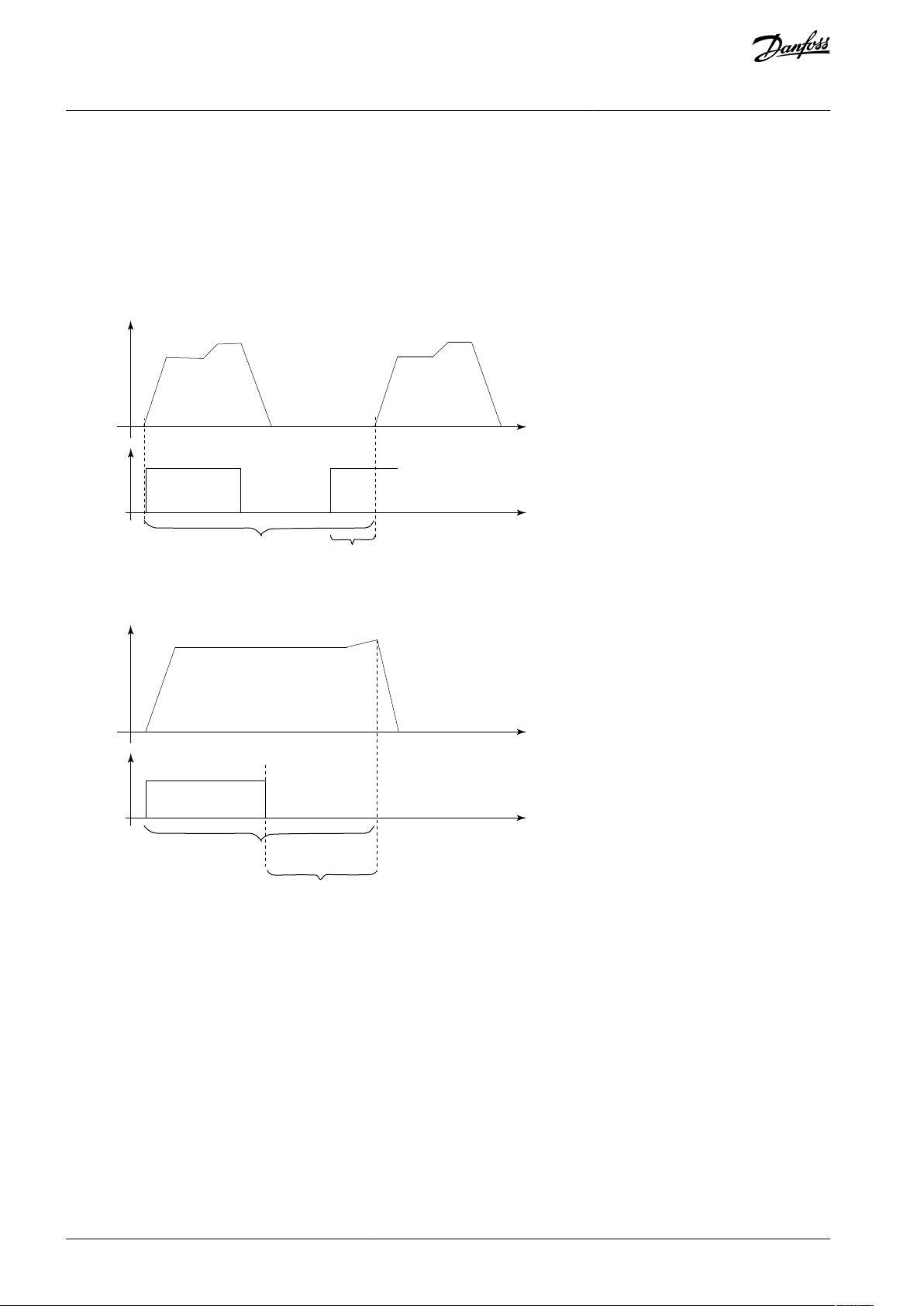

Illustration 2: Compressor Start-up Sequence

3.2.1.2 Compressor Minimum Speed Detection

To avoid a malfunction inside the compressor due to missing or low lubrication the VLT® Compressor Drive CDS 803 protects the

compressor if the speed drops below the minimum speed detection limit for too long.

•

In case of excessive low speed the drive issues Alarm 49, Speed limit.

Illustration 3: Minimum Speed Detection

AJ330233902305en-000201 / 130R0596 | 13Danfoss A/S © 2021.05

e30bj250.10

Speed

Start signal

On

Off

Time

Time

Interval between

Starts expires

Warning 96

“Start Delay”

e30bj251.10

Speed

Start signal

On

Off

Time

Time

Minimum run time expired

Warning 97

“Stop Delay”

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

3.2.1.3 Short-cycle Protection

The VLT® Compressor Drive CDS 803 includes a compressor short-cycling protection that prevents mechanical wear to the compressor and reduces the risk of oil shortage caused by starting and stopping too often. The short-cycle protection consists of 2 timers:

•

The interval between starts ensures that a new start first becomes active when the start time has expired.

•

The minimum run time ensures that the compressor always runs for a defined minimum time before stopping the compressor.

•

Warning 96, Start Delay is shown in the display if there is a start signal and the INTERVAL BETWEEN STARTS has not expired.

•

Warning 97, Stop Delay is shown in the display if there is a stop signal and the MINIMUM RUNTIME has not expired.

Illustration 4: Short Cycle Protection, Start Delay

Illustration 5: Short Cycle Protection, Stop Delay

3.2.1.4 Anti-reverse Protection

The anti-reverse protection function prevents the compressor scroll set from running in the wrong direction during stop.

AJ330233902305en-000201 / 130R059614 | Danfoss A/S © 2021.05

e30bj079.10

Speed

Time

Anti-reverse

protection

e30bj080.10

ORM boost speed

ORM boost time

ORM Min

speed limit

Decrease ORM

timer

Increase ORM

timer

Increase ORM

timer

ORM low speed running time expire

ORM timer reset

ORM low speed running time starts Time

VLT® Compressor Drive CDS 803

Design Guide

Illustration 6: Anti-reverse Protection

Product Overview

3.2.1.5 Oil Return Management

The oil return management (ORM) function helps retrieve oil trapped in the cooling system by ramping up periodically (oil boost

speed).

•

The ORM becomes active when the compressor has run below the ORM minimum speed limit for a given time defined by ORM

running time.

•

When ORM is active, the speed increases to a predefined ORM boost speed for a given time defined by ORM boost time

•

Additional a fixed boost interval timer shall trigger the ORM function in case no ORM has run within the defined ORM interval.

Illustration 7: Oil Return Management

3.2.1.6 Data Readouts and Commissioning

The VLT® Motion Control Tool MCT 10 supports the VLT® Compressor Drive CDS 803. The MCT is an efficient tool, for example for

readouts and commissioning.

VLT® Motion Control Tool MCT 10 supports the following readouts:

•

Readouts of alarms, warnings, and fault log in 1 view.

•

Compare a saved project with an online drive.

•

Scope & logging: Easy problem analysis.

•

Offline commissioning.

•

Save/send/mail projects anywhere.

•

Multiple drives in project file. Enables the service organization to be more efficient.

•

Compressor readout of frequency in RPS.

AJ330233902305en-000201 / 130R0596 | 15Danfoss A/S © 2021.05

e30bj082.10

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

3.2.1.7 Undersized Compressor

Programmable compressor choices allow downscaling of a drive to operate with an undersized compressor or running an oversized

drive under extreme conditions. This functionality is useful in applications which are outside the specified appliance area:

•

High ambient temperature installations.

•

High altitude installations.

N O T I C E

UL 60730-1 certification restricts for only allowing 1 dedicated compressor combination and does not offer the ability to run an

undersized compressor.

3.2.2 Application Features

The VLT® Compressor Drive CDS 803 offers custom application functions for enhanced performance.

3.2.2.1 Automatic Motor Adaptation (AMA)

Automatic motor adaptation (AMA) is an automated test procedure used to measure the electrical characteristics of the motor. AMA

provides an accurate electronic model of the motor, allowing the drive to calculate optimal performance and efficiency. Running

the AMA procedure also maximizes the automatic energy optimization feature of the drive.

AMA is performed without the motor rotating and without uncoupling the load from the motor.

N O T I C E

Automatic motor adaptation (AMA) is not required when used with a VZH Danfoss compressor.

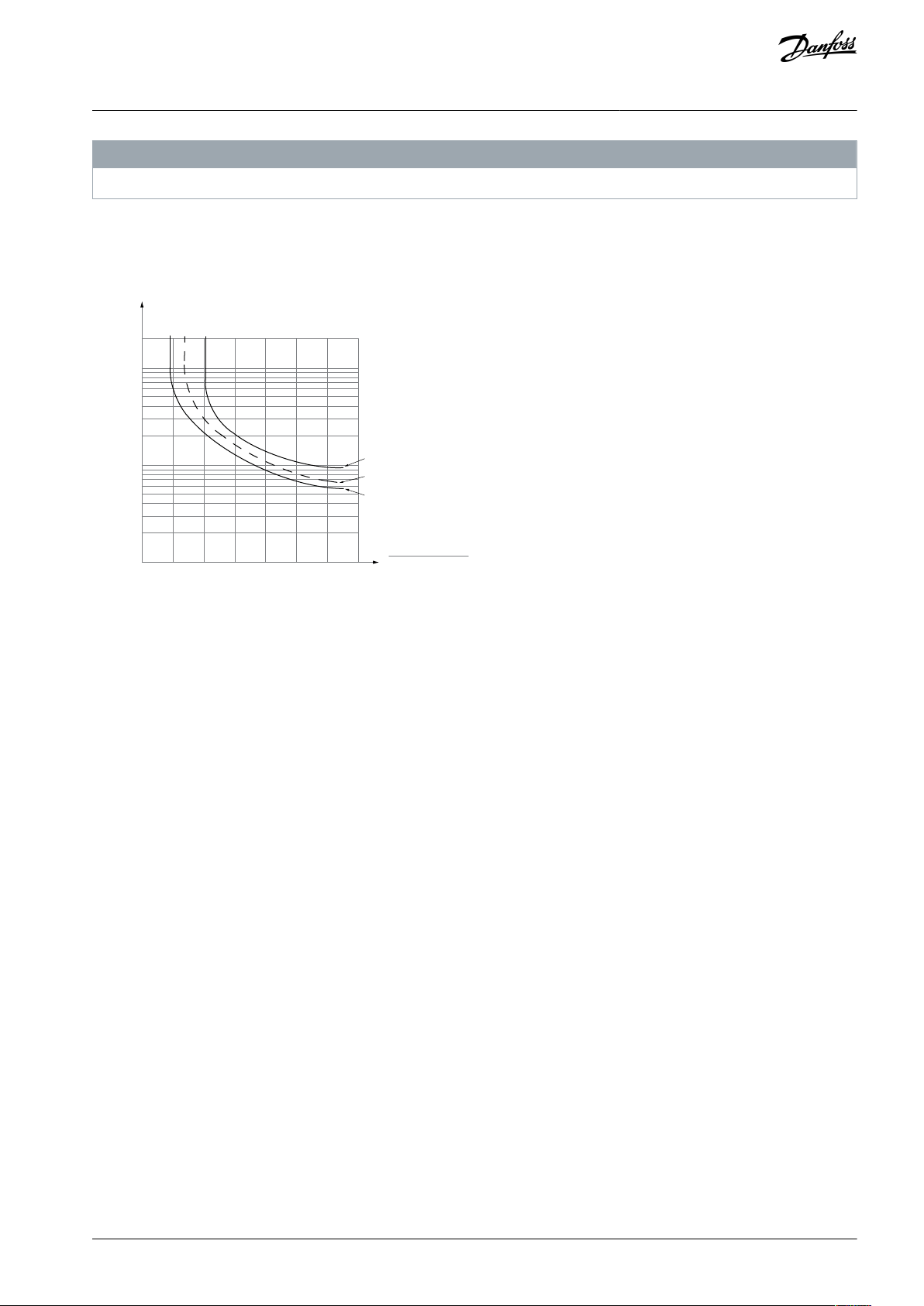

3.2.2.2 Motor Thermal Protection

Motor thermal protection can be provided via:

•

Mechanical thermal switch (Klixon type) on a DI.

•

Built-in electronic relay (ETR).

AJ330233902305en-000201 / 130R059616 | Danfoss A/S © 2021.05

1.21.0 1.4

30

10

20

100

60

40

50

1.81.6 2.0

2000

500

200

400

300

1000

600

t [s]

e75za052.13

I

M,N

(parameter 1-24)

I

M

f

OUT

= 2 x f

M,N

(parameter 1-23)

f

OUT

= 1 x f

M,N

f

OUT

= 0.2 x f

M,N

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

N O T I C E

Electronic thermal protection (ETR) is used in combination with a VZH Danfoss compressor.

ETR calculates motor temperature by measuring current, frequency, and operating time. The drive shows the thermal load on the

motor in percentage and can issue a warning at a programmable overload setpoint. Programmable options at the overload allow

the drive to stop the motor, reduce output, or ignore the condition. Even at low speeds, the drive meets I2t Class 20 electronic

motor overload standards.

Illustration 8: ETR Characteristics

The X-axis shows the ratio between I

motor

and I

nominal. The Y-axis shows the time in seconds before the ETR cuts off and trips

motor

the drive. The curves show the characteristic nominal speed at twice the nominal speed and at 0.2 x the nominal speed. At lower

speed, the ETR cuts off at lower heat due to less cooling of the motor. In that way, the motor is protected from being overheated

even at low speed. The ETR feature calculates the motor temperature based on actual current and speed. The calculated temperature is visible as a readout parameter in parameter 16-18 Motor Thermal.

3.2.2.3 Built-in PID Controller

The built-in proportional, integral, derivative (PID) controller eliminates the need for auxiliary control devices. The PID controller

maintains constant control of closed-loop systems where regulated pressure, flow, temperature, or other system requirements must

be maintained.

The drive can use 2 feedback signals from 2 different devices, allowing the system to be regulated with different feedback requirements. The drive makes control decisions by comparing the 2 signals to optimize system performance.

3.2.2.4 Automatic Restart

The drive can be programmed to restart the motor automatically after a minor trip, such as momentary power loss or fluctuation.

This feature eliminates the need for manual resetting and enhances automated operation for remotely controlled systems. The

number of restart attempts and the duration between attempts can be limited.

3.2.2.5 Flying Start

Flying start allows the drive to synchronize with an operating motor rotating at up to full speed in either direction. This prevents

trips due to overcurrent draw. It minimizes mechanical stress to the system since the motor receives no abrupt change in speed

when the drive starts.

3.2.2.6 Frequency Bypass

In some applications, the system can have operational speeds that create a mechanical resonance. This mechanical resonance can

generate excessive noise and possibly damage mechanical components in the system. The drive has 4 programmable bypass-frequency bandwidths (parameters 4-60 to 4-63). The bandwidths allow the motor to step over speeds that induce system resonance.

3.2.2.7 Motor Preheat

Instead of using a space heater, Danfoss provides motor preheat functionality. To preheat a motor in a cold or damp environment, a

small amount of DC current can be trickled continuously into the motor to protect it from condensation and cold starts.

AJ330233902305en-000201 / 130R0596 | 17Danfoss A/S © 2021.05

. . .

. . .

Par. 13-11

Comparator Operator

Par. 13-43

Logic Rule Operator 2

Par. 13-51

SL Controller Event

Par. 13-52

SL Controller Action

e30bb671.13

Coast

Start timer

Set Do X low

Select set-up 2

. . .

Running

Warning

Torque limit

Digital input X 30/2

. . .

=

TRUE longer than..

. . .

. . .

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

3.2.2.8 Programmable Set-ups

The drive has 2 setups that can be independently programmed. Using multi-setup, it is possible to switch between independently

programmed functions activated by digital inputs or a serial command. Independent set-ups are used, for example, to change references, or for day/night or summer/winter operation, or to control multiple motors. The LCP shows the active setup.

Setup data can be copied from drive to drive by downloading the information from the removable LCP or by using VLT® Motion

Control Tool MCT 10.

3.2.2.9 Smart Logic Control (SLC)

Smart logic control (SLC) is a sequence of user-defined actions (see parameter 13-52 SL Controller Action [x]) executed by the SLC

when the associated user-defined event (see parameter 13-51 SL Controller Event [x]) is evaluated as TRUE by the SLC.

The condition for an event can be a particular status, or that the output from a logic rule or a comparator operand becomes TRUE.

The condition leads to an associated action as shown in

Illustration 9.

Illustration 9: SLC Event and Action

Events and actions are each numbered and linked in pairs (states), which means that when event [0] is fulfilled (attains the value

TRUE), action [0] is executed. After the 1st action is executed, the conditions of the next event are evaluated. If this event is evaluated

as true, then the corresponding action is executed. Only 1 event is evaluated at any time. If an event is evaluated as false, nothing

happens in the SLC during the current scan interval and no other events are evaluated. When the SLC starts, it only evaluates event

[0] during each scan interval. Only when event [0] is evaluated as true, the SLC executes action [0] and starts evaluating the next

event. It is possible to program 1–20 events and actions.

When the last event/action has been executed, the sequence starts over again from event [0]/action [0]. An example with 4 events/

actions is shown in Illustration 10:

AJ330233902305en-000201 / 130R059618 | Danfoss A/S © 2021.05

e30ba062.15

State 1

13-51.0

13-52.0

State 2

13-51.1

13-52.1

Start

event P13-01

State 3

13-51.2

13-52.2

State 4

13-51.3

13-52.3

Stop

event P13-02

Stop

event P13-02

Stop

event P13-02

Par. 13-11

Comparator Operator

=

TRUE longer than.

. . .

. . .

Par. 13-10

Comparator Operand

Par. 13-12

Comparator Value

e30bb672.10

. . .

. . .

. . .

. . .

Par. 13-43

Logic Rule Operator 2

Par. 13-41

Logic Rule Operator 1

Par. 13-40

Logic Rule Boolean 1

Par. 13-42

Logic Rule Boolean 2

Par. 13-44

Logic Rule Boolean 3

e30bb673.10

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

Illustration 10: Order of Execution when 4 Events/Actions are Programmed

3.2.2.9.1 Comparators

Comparators are used for comparing continuous variables (output frequency, output current, analog input, and so on) to fixed preset values.

Illustration 11: Comparators

3.2.2.9.2 Logic Rules

Combine up to 3 boolean inputs (TRUE/FALSE inputs) from timers, comparators, digital inputs, status bits, and events using the

logical operators AND, OR, and NOT.

Illustration 12: Logic Rules

3.3 VLT® Compressor Drive CDS 803 Protections

The drive has a range of built-in protection functions to protect itself and the compressor during operation. For details of any required setup, in particular compressor parameters, refer to the VLT® Compressor Drive CDS 803 Programming Guide listed in 1.2

Additional Resources for parameter details and programming.

3.3.1 Mains Input Protection

The VLT® Compressor Drive CDS 803 offers various built-in input protections for the 3-phase power terminals L1, L2, and L3.

3.3.1.1 Mains Supply Failure, Momentary Dropouts, and Surges

During a mains dropout, the drive keeps running until the internal DC-link voltage drops below the minimum stop level, which is

typically around 15% or more below the lowest rated supply voltage of the drive. The mains voltage before the dropout and the

motor load determine how long it takes for the drive to coast.

AJ330233902305en-000201 / 130R0596 | 19Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

The drive withstands mains fluctuations such as:

•

Transients

•

Momentary dropouts

•

Short voltage drops

•

Surges

The drive automatically compensates for input voltages ±10% from the mains nominal to provide full rated output current. With

auto restart selected, the drive automatically powers up after a voltage trip. With flying start parameterization, the drive can synchronize to a motor spinning freely after a mains dropout and bring it back to normal operation.

Product Overview

3.3.1.2 Missing Mains Phase Detection

The drive monitors the mains input and reacts according to the programmed configuration if improper conditions, such as missing

or detecting too high imbalance between the input phases.

Operation under severe mains imbalance conditions reduces the lifetime of the drive. Conditions are considered severe if the motor

is operated continously near nominal load. The default setting issues a warning, but automated derating of the load can also be

parameterized among multiple choices.

3.3.2 Output Protection

The VLT® Compressor Drive CDS 803 offers various built-in protection features for the compressor terminals U, V, and W.

3.3.2.1 Short-circuit Protection (Phase-to-phase)

The drive is protected against short circuits on the output side by current measurements. A short circuit between 2 output phases

causes an overcurrent internally and turns off all outputs once the short-circuit current exceeds the maximum limit. A drive that

works correctly limits the current it can draw from the supply. Still, it is recommended to use fuses and/or circuit breakers on the

supply side as protection if there is a component breakdown inside the drive (1st fault). Mains side fuses are mandatory for UL compliance.

N O T I C E

To ensure compliance with IEC 60364 for CE or NEC 2017 for UL, it is mandatory to use fuses and/or circuit breakers.

3.3.2.2 Ground Fault Protection (Output Phase-to-Ground)

The drive is protected against ground faults on all output terminals, U, V, and W.

3.3.2.3 Locked Rotor Detection

Sometimes the rotor is locked because of excessive load or other factors preventing the compressor from rotating.

The drive detects the locked rotor situation and trips accordingly to prevent overheating the compressor and the drive.

N O T I C E

In regulation with UL 60730-1 certified products, the locked rotor detection cannot be disabled.

3.3.2.4 Output Phase Loss Detection

The drive monitors all outputs to detect any missing or interrupted connections. If no currents are drawn on any output, it is assumed that no motor is connected and will cause this event to be triggered. If a single phase is lost, an output phase missing event

is triggered. In both scenarios all outputs are turned off. The missing output phase function is enabled by default to avoid motor

damage. Disabling this protection is possible via parameterization.

N O T I C E

In regulation with UL 60730-1 certified products, the output phase loss detection cannot be disabled.

3.3.2.5 Overload Protection

If excessive current outputs or high temperatures are observed for an unwanted period, the protections trip the drive and turn all

the outputs off. The time before the drive trips is controlled by parameterization of the monitored protections.

Voltage limit

The inverter turns off to self-protect the internal components when the maximum voltage limits are reached.

AJ330233902305en-000201 / 130R059620 | Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

Output current limit

The inverter turns off to self-protect the internal components when the maximum current limits are reached.

Overtemperature

The inverter turns off to self-protect the internal components when the maximum temperature limits are reached.

Electronic thermal relay (ETR)

ETR is an electronic feature that simulates a bimetal relay based on internal measurements. See also 3.2.2.2 Motor Thermal Protec-

tion.

Product Overview

N O T I C E

In regulation wih UL 60730-1 certified products, the output overload conditions, such as motor overload (ETR), cannot be disa-

bled.

3.3.3 Temperature Protection

The VLT® Compressor Drive CDS 803 offers various built-in temperature protection features for monitoring the operation environment.

3.3.3.1 Minimum and Maximum Temperature Protection

The drive has built-in temperature sensors and reacts immediately to critical temperature limits. At low temperature, a warning will

be triggered. If high temperature limits are exceeded, the drive trips on an alarm and turns off all outputs.

3.3.3.2 Automatic Temperature Derating

Automatic temperature derating can be enabled via parameterization to allow continued operation during high temperatures.

3.3.3.3 Temperature-controlled Fans

Sensors in the drive regulate the operation of the internal cooling fans. Often, the cooling fans do not run during low-load operation, when in sleep mode, or in standby. The sensors reduce noise, increase efficiency, and extend the operating life of the fan.

3.3.4 Internal Protection

The VLT® Compressor Drive CDS 803 offers various built-in internal protection features ensuring that the drive is fully operational.

3.3.4.1 DC Overvoltage Protection

The internal DC-link voltage is increased when the motor acts as a generator. This occurs in the following situations:

•

The load drives the motor (at constant output frequency from the drive), that is, the load generates energy.

•

During deceleration (ramp-down) if the moment inertia is high, the friction is low, and the ramp-down time is too short for the

energy to be dissipated as a loss in the drive, the motor, and the installation.

•

Incorrect slip compensation setting may cause higher DC-link voltage.

•

Back EMF from PM motor operation. If coasted at high RPM, the PM motor back EMF may potentially exceed the maximum

voltage tolerance of the drive and cause damage. To prevent this, the maximum output frequency is automatically limited

based on an internal calculation. This calculation is based on motor parameterizations.

Monitoring of the internal voltage ensures that the drive trips when the DC-link voltage is too high. The drive turns off the output to

protect itself when a certain voltage level is reached. Enabling overvoltage control (OVC) reduces the risk of the drive tripping due

to an overvoltage on the DC link. This is controlled by automatically extending the ramp-down time.

3.3.4.2 Internal Faults

The drive has various internal self-monitoring functions which ensure that the drive is fully operational. For warning and alarm details, refer to VLT® Compressor Drive CDS 803 Programming Guide listed in 1.2 Additional Resources.

3.4 Ecodesign for Power Drive Systems

The Ecodesign Directive is the legislative framework that sets requirements on all energy-related products in the domestic, commercial, and industrial sectors throughout Europe.

The Ecodesign requirements are only mandatory within the European Union. These requirements are like the legislative requirements for energy-related products which apply in North America and Australia.

Terms like Complete Drive Module (CDM) and Power Drive Systems (PDS) are used to define the elements in the design. The objective is to make more efficient and fewer energy consuming designs.

AJ330233902305en-000201 / 130R0596 | 21Danfoss A/S © 2021.05

Mains &

cabling

Transmis-

sion

Load-

Machine

Driven Equipment

Extended Product

Motor System

Vollständiges Antriebsgerät (CDM)

Motor Starter

(Contactor, Softstarter,…)

Motor control equipment = CDM or starter

Feeding

section

Auxiliaries

Basic

Drive

Module

(BDM)

Complete Drive Module (CDM)

Power Drive System (PDS)

e30bu372.10

Relative torque

producing current

Relative

motor stator

frequency

100 %

50 %

25 %

0 %

0 % 50 % 90 %

e30bu373.10

VLT® Compressor Drive CDS 803

Design Guide

Product Overview

The CDM contains the drive controller as well as auxiliary devices and input components.

Illustration 13: Drive System Design

The efficiency classes IE0 to IE2 of the drive controller as specified in IEC 61800-9-2 (EN 50598-2) refer to the 90/100 operating point,

i.e. 90 % motor stator frequency and 100% torque current (see Illustration 14).

Illustration 14: Operating Point according to IEC 61800-9-2 (EN 50598)

Since in the future all component manufacturers will disclose their loss data according to this new standard, optimized applications

can be designed with a wide range of different components. The new Standard allows an accurate preliminary calculation of the

power losses, so that the ROI (Return of Investment) can be reliably determined. Up to now the overall efficiency of speed-regulated

electric motors was estimated with the aid of approximate energy consumption calculations.

It is now possible to determine the total losses of a system for the 8 operating points defined in the standard, including the part

load operation, via a simple addition of power losses. Danfoss helps its customers to avoid having to rely on system solution providers, to ensure that their systems will retain a competitive advantage also in the future.

EC 61800-9-2 (EN 50598-2) shifts the focus from the individual component to the efficiency of the whole drive system. The new

efficiency classes (International Efficiency for Systems, IES)

allow a simple determination of the total losses for a whole drive system (PDS).

Danfoss offers the MyDrive® ecoSmart™ tool, which is available online or as a Smartphone app to assist with the efficiency calcula-

tion. Use MyDrive® ecoSmart™ to:

Look up part load data as defined in IEC 61800-9-2, for VLT® and VACON® drives

•

Calculate efficiency class and part load efficiency for drives and power drive systems

•

Create a report documenting part load loss data and IE or IES efficiency class.

•

For more information, refer to

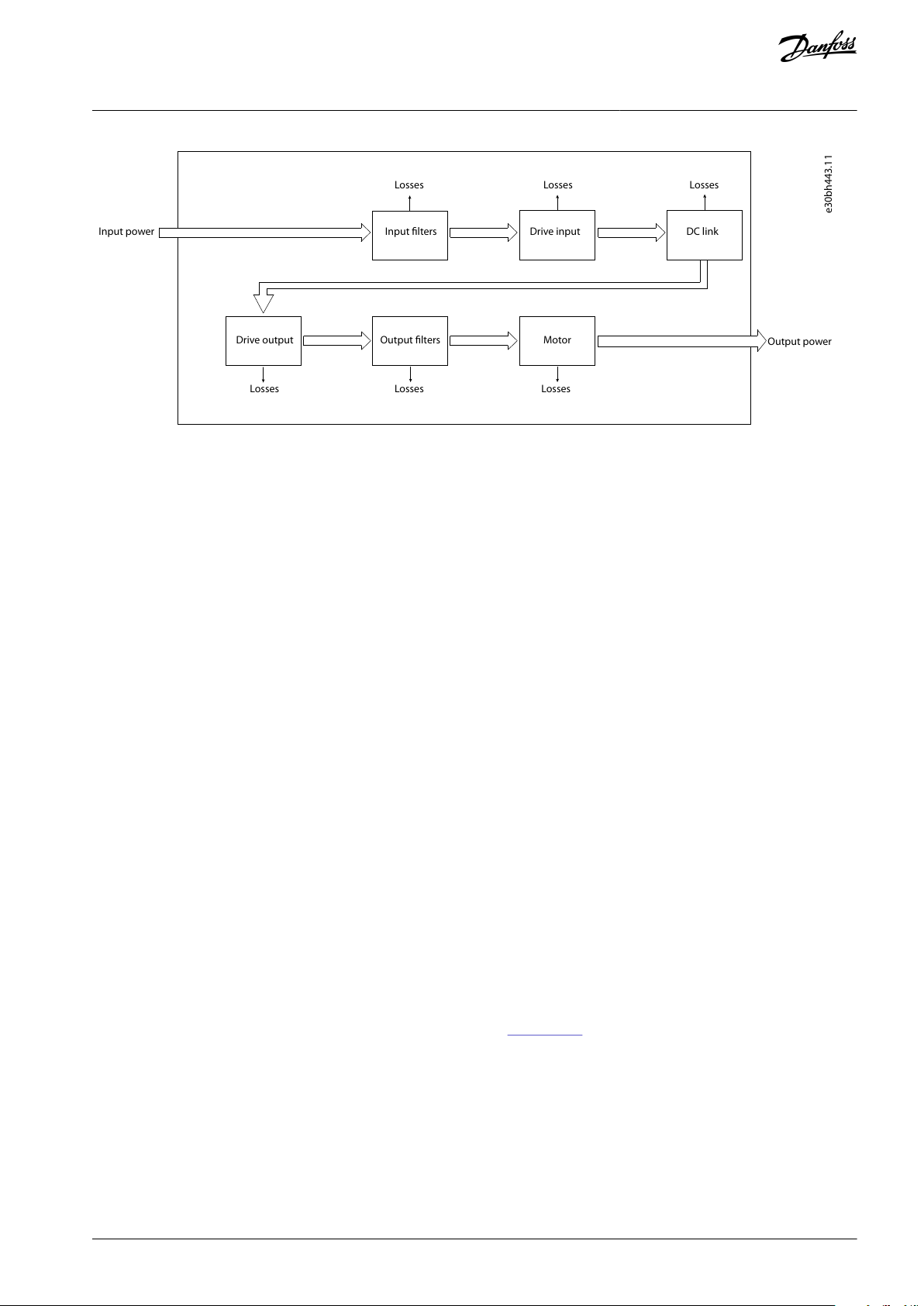

Refer to Illustration 15 to see the components in the PDS which contribute to losses in the design. Mains cables and the load ma-

chine are not a part of the PDS, even though their losses can be significant and could be a part of the evaluation of the overall

energy efficiency of the installation.

http://ecosmart.danfoss.com.

AJ330233902305en-000201 / 130R059622 | Danfoss A/S © 2021.05

Input power

e30bh443.11

Output power

Input filters

Drive input

DC link

Drive output

Output filters

Motor

Losses

Losses

Losses

Losses

Losses

Losses

VLT® Compressor Drive CDS 803

Design Guide

Illustration 15: Losses in a Power Drive System

Product Overview

3.4.1 Losses in Mains Cabling

The cabling from the supply must be considered, as the selection of suitable cables is often a problem, especially when dedicated

feeding transformers are installed. From the impedance of the cables, the energy losses are created in the ohmic part. Calculate the

active power losses for a 3-phase system with a star point groundingas follows:

P

= 3 x R x I

L,mains

Because the load, when using drives and motors, also include reactive power and harmonic currents, these parameters also contribute to losses. The ratio between active and apparent power is normally called the power factor. Having a PDS with a power factor

close to 1 result in the lowest losses in the mains. Using filters on the input side of the drive can lower the power factor.

2

L1

3.4.2 Input Filters: Line Reactors and Harmonic Filters

Line reactor

A line reactor is an inductor which is wired in series between a power source and a load. Line reactors, also called input AC reactors,

are typically used in motor drive applications.

The main function of the line reactor lies into its current limiting characteristics. Line reactors also reduce the main harmonics, limit

the inrush currents, and protect drives and motors. An overall improvement of the true power factor and the quality of the input

current waveform can be achieved.

Line reactors are classified by their percent impedance (denoted as percent IZ or %IZ), which is the voltage drop due to impedance,

at the rated current, expressed as a percent of rated voltage. The most common line reactors have either 3% or 5% impedance.

When to use line reactors

It is important to consider the installation environment for the drives. In some situations, distortion from the grid can damage the

drive and precautions must be taken.

A simple menas of prevention is to ensure a minimum of impedance in front of the drive.

When calculating the impedance, the contribution from the supply transformer and the supply cables is also a part of the circuit. In

specific cases, an additional transformer or reactor is recommended. If the conditions listed exist, consider adding impedance (line

reactor or transformer) in front of the drive:

•

The installation site has switched power factor correction capacitors.

•

The installation site has lightening strikes or voltage spikes.

•

The installation site has power interruptions or voltage dips.

Danfoss offers the line reactor program VLT® Line Reactor MCC 103, see

Harmonic filters

The purpose of using harmonic filters is to reduce the distortion on the mains. The distortion is generated by the drives when

switching the voltage to generate a frequency on the output. The harmonics should be limited both seen from energy consumption

perspective and disturbance of other users in the grid.

There are 2 categories of harmonic solutions:

•

Passive.

•

Active.

Passive solutions consist of capacitors, inductors, or a combination of both in different arrangements. The simplest solution is to add

inductors/reactors of typically 3–5% in front of the drive. This added inductance reduces the number of harmonic currents pro-

Danfoss.com.

AJ330233902305en-000201 / 130R0596 | 23Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

duced by the drive. More advanced passive solutions combine capacitors and inductors in trap arrangement specially tuned to

eliminate harmonics starting from, for example, the 5th harmonic.

For more details on the Danfoss passive solutions, refer to VLT® Advanced Harmonic Filters AHF 005/AHF 010 Design Guide.

The active solutions determine the exact current that cancels the harmonics present in the circuit and synthesizes and injects that

current into the system. Thus, the active solution mitigates the real-time harmonic disturbances, which makes these solutions effective at any load profile.

For more details on the Danfoss active solutions, refer to VLT® Low Harmonic Drive Operating Instructions, and VLT® Advanced Active Filter AAF 006 Operating Instructions.

Product Overview

3.4.3 Drive, Input Side

RFI (radio frequency interference)

Drives generate radio frequency interference (RFI) due to their variable-width current pulses. Drives and motor cables radiate these

components and conduct them into the mains system.

RFI filters are used to reduce this interference on the mains according to IEC 61800-3 in order not to disturb radio services. Maximum allowed emission depends on the environment where the PDS is used.

The need for reducing the interferences and the losses created by the coils is a trade-off that is hard to influence in the use of drives.

Even though the losses exist, it is important to fulfill the legislation demands for the installation environment.

RFI filter on IT grid

If the drive is supplied from an isolated mains source (IT mains, floating delta) or TT/TN-S mains with grounded leg (grounded delta),

the RFI filter must be turned off.

In the OFF position, the internal capacitors between the chassis (ground), the input RFI filter, and the DC link are cut off. As the RFI

switch is turned off, the drive is not able to meet optimum EMC performance.

By opening the RFI filter switch, the ground leakage currents are also reduced, but not the high-frequency leakage currents caused

by the switching frequency of the drive. It is important to use isolation monitors that are designed for use with power electronics

(IEC 61557-8). For example, Deif type SIMQ, Bender type IRDH 275/375, or similar.

The Danfoss VLT® drives can be ordered with different types of RFI filters. See more details on RFI, the use of RFI filters, and EMC

compliance in 6.5 Electromagnetic Compatibility.

Passive diode rectifier input

The use of diode rectifiers on the input side of the drives are the most cost-effective design. The energy flow goes from the mains to

the load and have low losses. On the other hand, diodes create harmonics in the mains when rectifying and thereby create losses.

These harmonics can be reduced by having DC-link coils, which are used in the Danfoss VLT® drives.

An energy flow from the drive back to the grid is not possible with this design as the energy is generated back from the application

to the DC link. Use a DC chopper and a connected resistor to absorb the energy. This reduces the energy efficiency significantly.

3.4.4 DC Link

The DC link is a power storage facility for the output section of the drive. There are 2 major components to the DC-link section:

•

Capacitors

•

Coils

In Illustration 16 only 1 capacitor is shown, but it is always a series of capacitors.

AJ330233902305en-000201 / 130R059624 | Danfoss A/S © 2021.05

1

3

+

+

2 4

e30bh114.10

1

Direct current (AC ripple)

2

Rectifier

3

Direct current

4

Inverter

VLT® Compressor Drive CDS 803

Design Guide

Illustration 16: Wiring Diagram of the DC Link

Product Overview

With Danfoss VLT® drives, this intermediate section always uses DC coils, also known as DC line reactors or DC chokes. For cost considerations, most other drive manufacturers do not offer these DC line reactors as standard equipment. Danfoss regards these coils

as essential for 2 main reasons:

•

The ability to reduce harmonic noise (interference) by 40%.

•

The ability to ride through a temporary loss of power. This allows the drive to avoid numerous unplanned shutdowns.

3.4.5 Drive, Output Side

The output side of the drive contains IGBTs used for generating a variable AC voltage with variable frequency. If no filters are used,

overvoltage spikes, due to reflection of the voltage waveform, can be measured on the motor connection. This situation is often

linked with long motor cables used in the installation and can reach values up to twice the level of the DC-link voltage.

From a user perspective, losses on the output side of the drive can be influenced by using a lower switching frequency, but this also

contributes to higher losses in the motor and filters installed. To optimize energy efficiency, a compromise must be found when

selecting the components used, for example, filters, motor type, and others. Often, output filters are used with the purpose of reducing stress on the insulation.

In the following sections, the aspect of different filter types is discussed in perspective of energy efficiency versus function.

Common-mode filters

Common-mode HF filters are placed between the drive and the motor. They are nanocrystaline cores that mitigate high-frequency

noise in the motor cable (shielded or unshielded) and eliminate bearing currents, and hence Electro Discharge Machining (EDM) or

bearing etching in the motor. Bearing currents caused by drives are also referred to as common-mode currents.

Since the common-mode filters mitigate high frequency, these filters absorb energy and contribute also to losses. Here, the tradeoff is the advantage described compared with the losses.

More information on VLT® Common Mode Filters MCC 105 can be found on www.Danfoss.com.

dU/dt filters

At the IGBTs on the output switch, the voltage is not a clean sinus curve. It contains fast changes in voltage levels over a very short

time. The use of dU/dt filters increases the raise time of the motor voltage to reduce the stress on the motor insulation. If not avoided, the problem will typically not show at once, but after some time, the insulation breaks and creates problems.

The switching frequency influences the losses in the dU/dt filters. These losses can be up to 1% of the rated power. Here, the tradeoff is the possible damage of the motor over time compared with the cost of energy losses.

Danfoss offers the VLT® dU/dt Filter MCC 102 as a possible solution. Find more information on www.Danfoss.com.

Sine-wave filters

A more advanced, but also more costly solution, is using sine-wave filters.

The VLT® Sine-Wave Filter MCC 101 is a differential-mode low-pass filter that suppresses the switching frequency component com-

ing from the drive and smoothes out the phase-to-phase voltage of the drive to become sinusoidal. This reduces the motor insula-

AJ330233902305en-000201 / 130R0596 | 25Danfoss A/S © 2021.05

VLT® Compressor Drive CDS 803

Design Guide

tion stress and bearing currents. By supplying the motor with a sinusoidal voltage waveform, the switching acoustic noise from the

motor is also eliminated.

For more detailed information, see the VLT® Sine-Wave Filter MCC 101 factsheet.

However, this type of filter also produces a voltage drop and there may be a reduction in the available control bandwidth. This can

sometimes make it impossible to use this filter type. Again, as for the dU/dt filter, losses are linked to the switching frequency.

For more detailed information, see the VLT® Output Filters Design Guide.

Product Overview

3.4.6 Motor Cables and Motor

Motor cables

Motor cables introduce mainly ohmic losses: the longer the cables, the more resistance. In general, when correctly selected, the

losses in cables shorter than 25 m (82 ft) can be neglected. In single-wire cables with individual shielding, current causes losses in

the cable shielding. These losses can be neglected when using 3-wire cables.

Motor

There are many different types of motors that can be operated with a drive. The solution for dealing with losses in motors is therefore depending on the individual motor type and installation. In standard IEC 61800-9-2:2017 annex D, a discussion on motor load

and losses is found.

A method to evaluate the losses generated in the motor operated with a drive can be found in the standards IEC 60034-2-1 and IEC

TS 60034-2-4.

AJ330233902305en-000201 / 130R059626 | Danfoss A/S © 2021.05

P6K0

P7K5

P10K

Typical shaft output [kW]

6.0

7.510Typical shaft output [hp]

8.01015

Enclosure size

H4H4H5

Maximum cable size in terminals (mains, compressor) [mm2 (AWG)]

16 (6)

16 (6)

16 (6)

Output current @ 40 °C (104 °F) ambient temperature

Continuous (3x200–240 V) [A]

222842

Intermittent (3x200–240 V) [A]

24.2

30.8

46.2

Output current @ 50 °C (122 °F) ambient temperature

Continous (3x200–240 V) [A]

19.82333

Intermittent (3x200–240 V) [A]

21.8

25.3

36.3

Maximum input current

Continuous (3x200–240 V) [A]

21

28.341Intermittent (3x200–240 V) [A]

23.1

31.1

45.1

Maximum mains fuses, see 6.2.1 Recommendation of Fuses and Circuit Breakers

Estimated power loss [W], best case/typical

(1)

182/204

229/268

369/386

Weight enclosure protection IP20 [kg (lb)]

7.9 (17.4)

7.9 (17.4)

9.5 (22.9)

Efficiency [%], best case/typical

(2)

97.3/97.1

98.5/97.1

97.2/97.1

P6K0

P7K5

P10K

P18K

P22K

P30K

Typical shaft output [kW]

6.0

7.51018.52230

Typical shaft output [hp]

8.01015253040Enclosure size

H3H3H4H5H5

H6

Maximum cable size in terminals (mains, motor) [mm

2

(AWG)]

4 (10)

4 (10)

16 (6)

16 (6)

16 (6)

35 (2)

VLT® Compressor Drive CDS 803

Design Guide

4 Specifications

4.1 Electrical Data

4.1.1 Electrical Data 3x200–240 V AC

Table 4: 3x200–240 V AC

Specifications

1

Applies to dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses may increase. LCP and

typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to Danfoss

2

Efficiency measured at nominal current. For energy efficiency class, see

mart website.

4.1.2 Electrical Data 3x380–480 V AC

Table 5: 3x380–480 V AC

MyDrive® ecoSmart website.

4.6 Conforming Standards. For part load losses, see Danfoss MyDrive® ecoS-

AJ330233902305en-000201 / 130R0596 | 27Danfoss A/S © 2021.05

P6K0

P7K5

P10K

P18K

P22K

P30K

Output current @ 40 °C (104 °F) ambient temperature (45 °C (113 °F) for 30 kW)

Continuous (3x380–440 V) [A]

12

15.523374461

Intermittent (3x380–440 V)[A]

13.2

17.1

25.3

40.7

46.8

67.1

Continuous (3x441–480 V) [A]

111421374461Intermittent (3x441–480 V) [A]

12.1

15.4

23.1

40.7

46.8

67.1

Output current @ 50 °C (122 °F) ambient temperature (52 °C (125 °F) for 18.5–22 kW)

Continuous (3x380–440 V) [A]

10.91420.93744

48.8

Intermittent (3x380–440 V) [A]

12

15.42340.7

46.8

53.7

Continuous (3x441–480 V) [A]

10

12.6

19.13744

41.6

Intermittent (3x441–480 V) [A]

11

13.92140.7

46.8

45.8

Maximum input current

Continuous (3x380–440 V) [A]

11.2

15.1

22.1

35.2

42.657Intermittent (3x380–440 V) [A]

12.3

16.6

24.3

38.7

45.7

62.7

Continuous (3x441–480 V) [A]

9.4

12.6

18.4

34.8

41.5

55.8

Intermittent (3x441–480 V) [A]

10.3

13.9

20.2

38.2

44.2

60.5

Maximum mains fuses, see 6.2.1 Recommendation of Fuses and Circuit Breakers.

Estimated power loss [W], best case/typical

(1)

104/131

159/198

248/274

412/456

475/523

733

Weight enclosure protection rating IP20 [kg (lb)]

4.3 (9.5)

4.5 (9.9)

7.9 (17.4)

9.5 (20.9)

9.5 (20.9)

24.5 (54)

Efficiency [%], best case/typical

(2)

98.4/98

98.2/97.8

98.1/97.9

98.1/97.9

98.1/97.9

97.8

Supply voltage

200–240 V ±10%

Supply voltage

380–480 V ±10%

Supply frequency

50/60 Hz

Maximum imbalance temporary between mains phases

3.0% of rated supply voltage

True power factor (λ)

≥0.9 nominal at rated load

Displacement power factor (cosφ) near unity

(>0.98)

Switching on the input supply L1, L2, L3 (power-ups)

Maximum 2 times/minute

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

The unit is suitable for use on a circuit capable of delivering not

more than 100000 A

rms

symmetrical Amperes, 240/480 V maxi-

mum.

Output voltage

0–100% of supply voltage

VLT® Compressor Drive CDS 803

Design Guide

Specifications

1

Applies to dimensioning of drive cooling. If the switching frequency is higher than the default setting, the power losses may increase. LCP and

typical control card power consumptions are included. For power loss data according to EN 50598-2, refer to Danfoss

2

Efficiency measured at nominal current. For energy efficiency class, see

mart website.

4.6 Conforming Standards. For part load losses, see Danfoss MyDrive® ecoS-

4.2 Mains Supply (L1, L2, L3)

4.3 Compressor Output (U, V, W)

MyDrive® ecoSmart website.

AJ330233902305en-000201 / 130R059628 | Danfoss A/S © 2021.05

Output frequency

0–200 Hz (VVC+), 0–400 Hz (u/f)

Switching on output

Unlimited

Ramp times

0.05–3600 s

Terminal number

50

Output voltage

10.5 V ±0.5 V

Maximum load

25 mA

Terminal number

12

Maximum load

80 mA

Number of analog inputs

2

Terminal number

53, 54

Terminal 53 mode

Parameter 6-61 Terminal 53 Setting: 1=voltage, 0=current

Terminal 54 mode

Parameter 6-63 Terminal 54 Setting: 1=voltage, 0=current

Voltage level

0–10 V

Input resistance, R

i

Approximately 10 kΩ

Maximum voltage

20 V

Current level

0/4–20 mA (scalable)

Input resistance, R

i

<500 Ω

Maximum current

29 mA

Resolution on analog input

10 bit

Number of programmable analog outputs

2

Terminal number

42, 45

(1)

Current range at analog output

0/4–20 mA

The load resistor to common at analog out

500 Ω

Maximum voltage at analog output

17 V

Accuracy on analog output

Maximum error: 0.4% of full scale

Resolution on analog output

10 bit

Programmable digital inputs

4

Terminal number

18, 19, 27, 29

VLT® Compressor Drive CDS 803

Design Guide

4.4 Control Input/Output

4.4.1 10 V DC Output

The 10 V DC output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.2 24 V DC Output

The 24 V DC output is galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

Specifications

4.4.3 Analog Inputs

The analog inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.4 Analog Outputs

1

Terminals 42 and 45 can also be programmed as digital outputs.

The analog outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.5 Digital Inputs

AJ330233902305en-000201 / 130R0596 | 29Danfoss A/S © 2021.05

Logic

PNP or NPN

Voltage level

0–24 V DC

Voltage level, logic 0 PNP

<5 V DC

Voltage level, logic 1 PNP

>10 V DC

Voltage level, logic 0 NPN

>19 V DC

Voltage level, logic 1 NPN

<14 V DC

Maximum voltage on input

28 V DC

Input resistance, R

i

Approximately 4 kΩ

Digital input 29 as thermistor input

Fault: >2.9 kΩ and no fault: <800 Ω

Digital input 29 as pulse input

Maximum frequency 32 kHz push-pull-driven & 5 kHz (O.C.)

Number of digital outputs

2

Terminals 42 and 45

Terminal number

42, 45

(1)

Voltage level at digital output

17 V

Maximum output current at digital output

20 mA

The load resistor at digital output

1 kΩ

Programmable relay output

2

Relay 01 and 02

01–03 (NC), 01–02 (NO), 04–06 (NC), 04–05 (NO)

Maximum terminal load (AC-1)

(1)

on 01–02/04–05 (NO) (Resistive

load)

250 V AC, 3 A

Maximum terminal load (AC-15)

(1)

on 01–02/04–05 (NO) (Induc-

tive load @ cosφ 0.4)

250 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 01–02/04–05 (NO) (Resistive

load)

30 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 01–02/04–05 (NO) (Induc-

tive load)

24 V DC, 0.1 A

Maximum terminal load (AC-1)

(1)

on 01–03/04–06 (NC) (Resistive

load)

250 V AC, 3 A

Maximum terminal load (AC-15)

(1)

on 01–03/04–06 (NC) (Inductive

load @ cosφ 0.4)

250 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 01–03/04–06 (NC) (Resistive

load)

30 V DC, 2 A

Minimum terminal load on 01–03 (NC), 01–02 (NO)

24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

Programmable relay output

2

VLT® Compressor Drive CDS 803

Design Guide

The digital inputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.6 Digital Outputs

Specifications

1

Terminals 42 and 45 can also be programmed as analog output.

The digital outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.7 Relay Outputs, Enclosure Sizes H3–H5

1

IEC 60947 parts 4 and 5. Endurance of the relay varies with different load type, switching current, ambient temperature, drive configuration, work-

ing profile, and so forth. Mount a snubber circuit when connecting inductive loads to the relays.

The relay outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.8 Relay Outputs, Enclosure Size H6

AJ330233902305en-000201 / 130R059630 | Danfoss A/S © 2021.05

Relay 01 and 02

01–03 (NC), 01–02 (NO), 04–06 (NC), 04–05 (NO)

Maximum terminal load (AC-1)

(1)

on 04–05 (NO) (Resistive load)

(2)

(3)

400 V AC, 2 A

Maximum terminal load (AC-15)

(1)

on 04–05 (NO) (Inductive load

@ cosφ 0.4)

240 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 04–05 (NO) (Resistive load)

80 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 04–05 (NO) (Inductive load)

24 V DC, 0.1 A

Maximum terminal load (AC-1)

(1)

on 04–06 (NC) (Resistive load)

240 V AC, 4 A

Maximum terminal load (AC-15)

(1)

on 04–06 (NC) (Inductive load

@ cosφ 0.4)

240 V AC, 0.2 A

Maximum terminal load (DC-1)

(1)

on 04–06 (NC) (Resistive load)

50 V DC, 2 A

Maximum terminal load (DC-13)

(1)

on 04–06 (NC) (Inductive load)

24 V DC, 0.1 A

Minimum terminal load on 01–03 (NC), 01–02 (NO), 04–06 (NC),

04–05 (NO)

24 V DC 10 mA, 24 V AC 20 mA

Environment according to EN 60664-1

Overvoltage category III/pollution degree 2

Terminal number

68 (P, TX+, RX+), 69 (N, TX-, RX-)

Terminal number

61 common for terminals 68 and 69

Enclosure protection rating

IP20

Enclosure kit available

IP21, TYPE 1

Maximum vibration exposure

(1)

1.0 g

Maximum relative humidity

5–95% (IEC 60721-3-3; Class 3K3 (non-condensing) during opera-

tion)

Aggressive environment (IEC 60721-3-3), coated (standard), enclosure sizes H3–H5

Class 3C3

Aggressive environment (IEC 60721-3-3), non-coated enclosure

size H6

Class 3C2

Environmental testing (IEC 60068-2-43 H2S)

10 days

Ambient temperature, enclosure sizes H3–H5 (6–10 kW (8–15 hp))

(2)

50 °C (122 °F)

Ambient temperature, enclosure size H5 (18–22 kW (25–30 hp))

(2)

52 °C (125.6 °F)

Ambient temperature, enclosure size H6 (30 kW (40 hp))

(2)

45 °C (113 °F)

Minimum ambient temperature during full-scale operation

0 °C (32 °F)

Minimum ambient temperature at reduced performance, enclosure sizes H3–H5

-20 °C (-4 °F)

Minimum ambient temperature at reduced performance, enclosure size H6

-10 °C (14 °F)

Temperature during storage/transport

-30 to +65/70 °C (-22 to +149/158°F)

Maximum altitude above sea level without derating

1000 m (3281 ft)

Maximum altitude above sea level with derating

3000 m (9843 ft)

VLT® Compressor Drive CDS 803

Design Guide

1

IEC 60947 parts 4 and 5. Endurance of the relay varies with different load type, switching current, ambient temperature, drive configuration, work-

ing profile, and so forth. Mount a snubber circuit when connecting inductive loads to the relays.

2

Overvoltage Category II.

3

UL applications 250 V AC, 3 A.

Specifications

The relay outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.4.9 RS485 Serial Communication

The RS485 serial communication outputs are galvanically isolated from the supply voltage (PELV) and other high-voltage terminals.

4.5 Ambient Conditions

AJ330233902305en-000201 / 130R0596 | 31Danfoss A/S © 2021.05

Derating for high altitude, see 5.3.6 Derating for Low Air Pressure

and High Altitudes.

Safety standards

EN/IEC 61800-5-1, UL 508C, EN/IEC/UL 60730-1

EMC standards, Emission

EN 61800-3, EN 61000-6-3/4, EN 55011, IEC 61800-3

EMC standards, Immunity

EN 61800-3, EN 61000-3-12, EN 61000-6-1/2, EN 61000-4-2, EN

61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6

Energy efficiency class

(1)

IE2

Maximum compressor cable length, shielded/armored (EMC-correct installation)

See 6.5.1 EMC Emission Test Results.

Maximum compressor cable length, unshielded/unarmored

50 m (164 ft)

Maximum cross-section to compressor, mains

See 4.1 Electrical Data for more information

Cross-section DC terminals for filter feedback on enclosure size

H3

4 mm2/11 AWG

Cross-section DC terminals for filter feedback on enclosure sizes

H4–H6

16 mm2/6 AWG

Maximum cross-section to control terminals, rigid wire

2.5 mm2/14 AWG

Maximum cross-section to control terminals, flexible wire

2.5 mm2/14 AWG

Minimum cross-section to control terminals

0.05 mm2/30 AWG

VLT® Compressor Drive CDS 803

Design Guide

1

Refer to 5.3.4 Vibration and Shock for more details.

2

Refer to 5.3 Operating Environment.

4.6 Conforming Standards

1

Determined according to EN 50598-2 at:

Rated load.

•

•

90% rated frequency.

•

Switching frequency factory setting.

•

Switching pattern factory setting.

•

For power loss data according to EN 50598-2, refer to Danfoss

Specifications

MyDrive® ecoSmart website.

N O T I C E

The VLT® Compressor Drive CDS 803 with SXXX in the type code is certified against UL 508C. Example:

CDS803P7K5T4E20H4XXCXXXSXXXXAXBXCXXXXDX

The VLT® Compressor Drive CDS 803 with S096 in the type code is certified against UL/EN/IEC 60730-1. Example:

CDS803P30KT4E20H2XXXXXXS096XAXBXCXXXXDX

4.7 Cable Lengths and Cross-sections

4.8 Acoustic Noise

Acoustic noise from the drives comes from 3 sources:

•

DC-link coils

•

Integral fan

•

RFI filter inductor

AJ330233902305en-000201 / 130R059632 | Danfoss A/S © 2021.05

Enclosure

Level [dBA]

(1)

H3

53.8H464H563.7H671.5

e

f

a

e

e

f

a

d

e

A

a

b

B

C

D

e30bf984.10

Enclosure Size

H3H4H5

H6

IP class

IP20

IP20

IP20

IP20

Power [kW (hp)]

3x200–240 V

–

6.0–7.5

(8.0–10)

10 (15)

–

3x380–480 V

6.0–7.5

(8.0–10)

10

(15)

18.5–22

(25–30)

30 (40)

Height [mm (in)]

A

255 (10.0)

296 (11.7)

334 (13.1)

518 (20.4)

A

(1)

329 (13.0)

359 (14.1)

402 (15.8)

595 (23.4)/635 (25), 45 kW

a

240 (9.4)

275 (10.8)

314 (12.4)

495 (19.5)

Width [mm (in)]

B

100 (3.9)

135 (5.3)

150 (5.9)

239 (9.4)

b

74 (2.9)

105 (4.1)

120 (4.7)

200 (7.9)

Depth [mm (in)]

C

206 (8.1)

241 (9.5)

255 (10)

242 (9.5)

Mounting hole [mm (in)]

d

11 (0.43)

12.6 (0.50)

12.6 (0.50)

–

VLT® Compressor Drive CDS 803

Design Guide

Table 6: Typical Values Measured at a Distance of 1 m (3.28 ft) from the Unit

1

The values are measured under the background of 35 dBA noise and the fan running at full speed.

4.9 Mechanical Dimensions

4.9.1 Drive Dimensions

Specifications

Illustration 17: Dimensions

Table 7: Dimensions, Enclosure Sizes H3–H6

AJ330233902305en-000201 / 130R0596 | 33Danfoss A/S © 2021.05

Enclosure Size

H3H4H5

H6

e

5.5 (0.22)

7 (0.28)

7 (0.28)

8.5 (0.33)

f

8.1 (0.32)

8.4 (0.33)

8.5 (0.33)

15 (0.6)

Maximum weight kg (lb)

4.5 (9.9)

7.9 (17.4)

9.5 (20.9)

5.3 (11.7)

Enclosure size

200–240 V AC

[kW (hp)]

380–480 V AC [kW

(hp)]

IP rating

Maximum

weight [kg (lb)]

Height [mm

(in)]

Width [mm

(in)]

Depth [mm

(in)]H3–

6.0–7.5 (8.0–10)

IP20

4.5 (9.9)

280 (11)

155 (6.1)

320 (12.6)

H4

6.0–7.5 (8.0–10)

10 (15)

IP20

7.9 (17.4)

380 (15)

200 (7.9)

315 (12.4)

H5

10 (15)

18.5–22 (25–30)

IP20

9.5 (20.9)

395 (15.6)

233 (9.2)

380 (15)

H6

–

30 (40)

IP20

24.5 (54.0)

850 (33.5)

370 (15.6)

460 (18.1)

Cable length [m (ft)]

AC line voltage [V]

Rise time [μsec]

V

peak

[kV]

dU/dt [kV/μsec]

200 V 6.0 kW (8.0 hp)

5 (16)

240

0.128

0.445

2.781

25 (82)

240

0.224

0.594

2.121

50 (164)

240

0.328

0.596

1.454

200 V 7.5 kW (10 hp)

5 (16)

240

0.18

0.502

2.244

25 (82)

240

0.22

0.598

2.175

50 (164)

240

0.292

0.615

1.678

200 V 10 kW (15 hp)

36 (118)

240

0.176

0.56

2.545

50 (164)

240

0.216

0.599

2.204

400 V 6.0 kW (8.0 hp)

5 (16)

400

0.168

0.81

3.857

25 (82)

400

0.239

1.026

3.434

50 (164)

400

0.328

1.05

2.560

400 V 7.5 kW (10 hp)

5 (16)

400

0.168

0.81

3.857

25 (82)

400

0.239

1.026

3.434

50 (164)

400

0.328

1.05

2.560

400 V 18.5 kW (25 hp)

5 (16)

400

0.132

0.88