Page 1

Programming Guide

VLT® Compressor Drive CDS 803

6–30 kW

vlt-drives.danfoss.com

Page 2

Page 3

VLT® Compressor Drive CDS 803

Programming Guide

Contents

1

Introduction 9

1.1

Purpose of the Programming Guide 9

Manual and Software Version 9

1.2

Additional Resources 9

1.3

1.3.1

Supplementary Documentation 9

1.3.2

VLT® Motion Control Tool MCT 10 Software Support 9

Safety 10

2

Safety Symbols 10

2.1

Qualified Personnel 10

2.2

Safety Precautions 10

2.3

Electrical Diagrams 12

3

3.1

Wiring Schematic 12

Contents

3.2

Control Terminals 13

4

Programming 14

4.1

Programming Interfaces 14

4.2

Local Control Panel (LCP) 14

4.3

Menus 15

4.3.1

Access to Parameters 15

4.3.1.1

4.3.1.2

4.3.2

Status Menu 16

4.3.3

Quick Menu 16

4.3.3.1

4.3.3.2

4.3.3.3

4.3.3.4

4.3.4

Main Menu 25

4.4

Uploading and Downloading Parameter Settings 25

Programming via the Quick Menu 15

Programming via the Main Menu 15

The Start-up Quick Guide for Compressor Open-loop Applications 16

Compressor Functions Quick Guide 19

The Start-up Quick Guide for Compressor Closed-loop Applications 21

Changes Made 25

4.4.1

Data Transfer from Drive to LCP 25

4.4.2

Data Transfer from LCP to Drive 26

4.5

Restoring Factory Default Settings 26

4.5.1

Recommended Initialization (via Parameter 14-22 Operation Mode) 26

4.5.2

Two-finger Initialization 27

AU356039245821 en-000201/130R0597 | 3Danfoss A/S © 2021.07

Page 4

VLT® Compressor Drive CDS 803

Programming Guide

5

Parameter Descriptions and Functions 28

Introduction to Parameters 28

5.1

5.1.1

Reading the parameter table 28

Common Parameters 29

5.2

5.2.1

Parameter Group 0-** Operation and Display 29

5.2.1.1

5.2.1.2

5.2.1.3

5.2.1.4

5.2.1.5

5.2.1.6

5.2.2

Parameter Group 1-** Load and Motor 35

5.2.2.1

5.2.2.2

Parameter Group 0-0* Basic Settings 29

Parameter Group 0-1* Set-up Operations 31

Parameter Group 0-3* LCP Custom Readout 32

Parameter Group 0-4* LCP Keypad 34

Parameter Group 0-5* Copy/Save 34

Parameter Group 0-6* Password 35

Parameter Group 1-0* General Settings 35

Parameter Group 1-7* Start Adjustments 36

Contents

Parameter Group 2-** Brakes 36

5.2.3

5.2.3.1

5.2.4

Parameter Group 3-** Reference/Ramps 36

5.2.4.1

5.2.4.2

5.2.4.3

5.2.4.4

5.2.4.5

5.2.5

Parameter Group 4-** Limits/Warnings 40

5.2.5.1

5.2.5.2

5.2.5.3

5.2.5.4

5.2.6

Parameter Group 5-** Digital In/Out 42

5.2.6.1

5.2.6.2

Parameter Goup 2-1* Brake Energy Function 36

Parameter Group 3-0* Reference Limits 36

Parameter Group 3-1* References 37

Parameter Group 3-4* Ramp 1 39

Parameter Group 3-5* Ramp 2 40

Parameter Group 3-8* Other Ramps 40

Parameter Group 4-1* Motor Limits 40

Parameter Group 4-4* Adjustable Warnings 2 41

Parameter Group 4-5* Adjustable Warnings 41

Parameter Group 4-6* Speed Bypass 42

Parameter Group 5-0* Digital I/O Mode 42

Parameter Group 5-1* Digital Inputs 43

5.2.6.3

5.2.6.4

5.2.7

Parameter Group 6-** Analog In/Out 52

5.2.7.1

5.2.7.2

5.2.7.3

5.2.7.4

5.2.7.5

Parameter Group 5-4* Relays 49

Parameter Group 5-5* Pulse Input 51

Parameter Group 6-0* Analog I/O Mode 52

Parameter Group 6-1* Analog Input 53 53

Parameter Group 6-2* Analog Input 54 55

Parameter Group 6-7* Analog/Digital Output 45 56

Parameter Group 6-9* Analog/Digital Output 42 59

AU356039245821 en-000201/130R05974 | Danfoss A/S © 2021.07

Page 5

VLT® Compressor Drive CDS 803

Programming Guide

5.2.8

Parameter Group 8-** Communications and Options 63

5.2.8.1

5.2.8.2

5.2.8.3

5.2.8.4

5.2.8.5

5.2.8.6

5.2.9

Parameter Group 13-** Smart Logic 70

5.2.9.1

5.2.9.2

5.2.9.3

5.2.9.4

5.2.9.5

5.2.10

Parameter Group 14-** Special Functions 83

Contents

Parameter Group 8-0* General Settings 63

Parameter Group 8-3* FC Port Settings 64

Parameter Group 8-4* FC MC Protocol Set 66

Parameter Group 8-5* Digital/Bus 66

Parameter Group 8-8* FC Port Diagnostics 68

Parameter Group 8-9* Bus Feedback 69

Smart Logic Controller 70

Parameter Group 13-0* SLC Settings 70

Parameter Group 13-2* Timers 74

Parameter Group 13-4* Logic Rules 74

Parameter Group 13-5* States 80

5.2.10.1

5.2.10.2

5.2.10.3

5.2.10.4

5.2.10.5

5.2.10.6

5.2.11

Parameter Group 15-** Drive Information 88

5.2.11.1

5.2.11.2

5.2.11.3

5.2.12

Parameter Group 16-** Data Readouts 93

5.2.12.1

5.2.12.2

5.2.12.3

5.2.12.4

5.2.12.5

Parameter Group 14-0* Inverter Switching 83

Parameter Group 14-1* Mains On/Off 84

Parameter Group 14-2* Trip Reset 85

Parameter Group 14-3* Current Limit Control 86

Parameter Group 14-5* Environment 87

Parameter Group 14-6* Auto Derate 87

Parameter Group 15-0* Operating Data 88

Parameter Group 15-3* Alarm Log 90

Parameter Group 15-4* Drive Identification 90

Parameter Group 16-0* General Status 93

Parameter Group 16-1* Motor Status 95

Parameter Group 16-3* Drive Status 97

Parameter Group 16-5* Ref. & Feedb. 98

Parameter Group 16-6* Inputs and Outputs 99

5.2.12.6

5.2.12.7

5.2.13

Parameter Group 20-** Drive Closed Loop 104

5.2.13.1

5.2.13.2

5.2.13.3

5.2.13.4

5.2.14

Parameter Group 28-** Compressor Functions 107

Parameter Group 16-8* Fieldbus & FC Port 102

Parameter Group 16-9* Diagnosis Read-Outs 103

Parameter Group 20-0* Feedback 104

Parameter Group 20-2* Feedback/Setpoint 105

Parameter Group 20-8* PI Basic Settings 105

Parameter Group 20-9* PI Controller 106

AU356039245821 en-000201/130R0597 | 5Danfoss A/S © 2021.07

Page 6

VLT® Compressor Drive CDS 803

Programming Guide

5.2.14.1

5.2.14.2

5.2.14.3

5.3

6–10 kW Specific Parameters 108

5.3.1

Parameter Group 0-** Operation and Display 108

5.3.1.1

5.3.1.2

5.3.2

Parameter Group 1-** Load and Motor 109

5.3.2.1

5.3.2.2

5.3.2.3

5.3.2.4

5.3.2.5

5.3.2.6

Contents

Parameter Group 28-0* Short Cycle Protection 107

Parameter Group 28-1* Oil Return Management 107

Parameter Group 28-6* Compressor Readouts 108

Parameter Group 0-0* Basic Settings 108

Parameter Group 0-4* LCP Keypad 109

Parameter Group 1-0* General Settings 109

Parameter Group 1-1* Motor Selection 110

Parameter Group 1-2* Motor Data 111

Parameter Group 1-3* Adv. Motor Data 114

Parameter Group 1-4* Adv. Motor Data II 115

Parameter Group 1-6* Load Depen. Setting 116

5.3.2.7

5.3.2.8

5.3.2.9

5.3.3

Parameter Group 2-** Brakes 120

5.3.3.1

5.3.4

Parameter Group 3-** Reference/Ramps 122

5.3.4.1

5.3.4.2

5.3.5

Parameter Group 4-** Limits/Warnings 123

5.3.5.1

5.3.5.2

5.3.6

Parameter Group 5-** Digital In/Out 125

5.3.6.1

5.3.6.2

5.3.6.3

5.3.7

Parameter Group 6-** Analog In/Out 128

Parameter Group 1-7* Start Adjustments 116

Parameter Group 1-8* Stop Adjustments 118

Parameter Group 1-9* Motor Temperature 119

Parameter Group 2-0* DC Brakes 120

Parameter Group 3-1* References 122

Parameter Group 3-8* Other Ramps 123

Parameter Group 4-1* Motor Limits 123

Parameter Group 4-5* Adjustable Warnings 124

Parameter Group 5-1* Digital Inputs 125

Parameter Group 5-4* Relays 126

Parameter Group 5-5* Pulse Input 127

5.3.7.1

5.3.7.2

5.3.8

Parameter Group 8-** Communications and Options 130

5.3.8.1

5.3.8.2

5.3.8.3

5.3.9

Parameter Group 13-** Smart Logic 132

5.3.9.1

Parameter Group 6-1* Analog Input 53 128

Parameter Group 6-2* Analog Input 54 129

Parameter Group 8-0* General Settings 130

Parameter Group 8-4* FC MC Protocol Set 130

Parameter Group 8-5* Digital/Bus 132

Parameter Group 13-1* Comparators 132

AU356039245821 en-000201/130R05976 | Danfoss A/S © 2021.07

Page 7

VLT® Compressor Drive CDS 803

Programming Guide

5.3.10

Parameter Group 14-** Special Functions 134

5.3.10.1

5.3.10.2

5.3.10.3

5.3.10.4

5.3.11

Parameter Group 15-** Drive Information 136

5.3.11.1

5.3.12

Parameter Group 20-** Drive Closed Loop 137

5.3.12.1

5.3.12.2

5.3.13

Parameter Group 28-** Compressor Functions 137

5.3.13.1

5.3.13.2

5.3.13.3

Contents

Parameter Group 14-1* Mains On/Off 134

Parameter Group 14-2* Trip Reset 134

Parameter Group 14-5* Environment 135

Parameter Group 14-9* Fault Settings 136

Parameter Group 15-4* Drive Identification 136

Parameter Group 20-0* Feedback 137

Parameter Group 20-8* PI Basic Settings 137

Parameter Group 28-0* Short Cycle Protection 138

Parameter Group 28-1* Oil Return Management 138

Parameter Group 28-4* Anti-reverse Protection 139

5.4

18–30 kW Specific Parameters 139

5.4.1

Parameter Group 0-** Operation and Display 139

5.4.1.1

5.4.1.2

5.4.2

Parameter Group 1-** Load and Motor 141

5.4.2.1

5.4.2.2

5.4.2.3

5.4.2.4

5.4.3

Parameter Group 2-** Brakes 144

5.4.3.1

5.4.4

Parameter Group 3-** Reference/Ramps 144

5.4.4.1

5.4.4.2

5.4.5

Parameter Group 4-** Limits/Warnings 145

5.4.5.1

Parameter Group 0-0* Basic Settings 139

Parameter Group 0-4* LCP Keypad 140

Parameter Group 1-1* Motor Selection 141

Parameter Group 1-6* Load Depen. Setting 142

Parameter Group 1-7* Start Adjustments 142

Parameter Group 1-8* Stop Adjustments 143

Parameter Group 2-0* DC Brakes 144

Parameter Group 3-1* References 144

Parameter Group 3-8* Other Ramps 145

Parameter Group 4-1* Motor Limits 145

5.4.5.2

5.4.6

Parameter Group 5-** Digital In/Out 147

5.4.6.1

5.4.6.2

5.4.6.3

5.4.7

Parameter Group 6-** Analog In/Out 150

5.4.7.1

5.4.7.2

Parameter Group 4-5* Adjustable Warnings 146

Parameter Group 5-1* Digital Inputs 147

Parameter Group 5-4* Relays 148

Parameter Group 5-5* Pulse Input 149

Parameter Group 6-1* Analog Input 53 150

Parameter Group 6-2* Analog Input 54 150

AU356039245821 en-000201/130R0597 | 7Danfoss A/S © 2021.07

Page 8

VLT® Compressor Drive CDS 803

Programming Guide

5.4.8

Parameter Group 8-** Communications and Options 151

5.4.8.1

5.4.8.2

5.4.9

Parameter Group 13-** Smart Logic 153

5.4.9.1

5.4.10

Parameter Group 14-** Special Functions 155

5.4.10.1

5.4.10.2

5.4.10.3

5.4.10.4

5.4.11

Parameter Group 15-** Drive Information 156

5.4.11.1

5.4.11.2

5.4.12

Parameter Group 20-** Drive Closed Loop 157

Contents

Parameter Group 8-0* General Settings 151

Parameter Group 8-4* FC MC Protocol Set 151

Parameter Group 13-1* Comparators 153

Parameter Group 14-1* Mains On/Off 155

Parameter Group 14-2* Trip Reset 155

Parameter Group 14-5* Environment 155

Parameter Group 14-9* Fault Settings 156

Parameter Group 15-4* Drive Identification 156

Parameter Group 15-9* Parameter Info 156

5.4.12.1

5.4.12.2

5.4.13

Parameter Group 28-** Compressor Functions 158

5.4.13.1

5.4.13.2

5.4.13.3

6

Troubleshooting 161

6.1

Warnings and Alarms 161

6.2

Warning Words 164

6.3

Alarm Words 165

6.4

Extended Status Words 166

6.5

Descriptions of Warnings and Alarms 167

6.6

LCP Errors Messages 174

Parameter Group 20-0* Feedback 157

Parameter Group 20-8* PI Basic Settings 158

Parameter Group 28-0* Short Cycle Protection 158

Parameter Group 28-1* Oil Return Management 158

Parameter Group 28-3* Crankcase Heating 159

AU356039245821 en-000201/130R05978 | Danfoss A/S © 2021.07

Page 9

•

Edition

Remarks

Software version

AU356039245821, version 0201

Editorial update

6.0–10 kW (8–15 hp): Version 2.00

18–30 kW (25–40 hp): Version 61.20

VLT® Compressor Drive CDS 803

Programming Guide

Introduction

1 Introduction

1.1 Purpose of the Programming Guide

This Programming Guide provides information for advanced programming of the drive. It provides a complete overview and description of all parameters.

The Programming Guide is intended for use by qualified personnel.

To operate the drive safely and professionally, read and follow the Programming Guide and pay particular attention to the safety

instructions and general warnings.

VLT® is a registered trademark for Danfoss A/S.

1.2 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

Table 1: Manual and Software Version

1.3 Additional Resources

1.3.1 Supplementary Documentation

Other resources are available to understand advanced drive functions and programming.

•

The Operating Guide provides information on safety, installation, and commissioning. It also provides a list of warnings and

alarms, and general specifications.

•

The Design Guide provides detailed information about capabilities and functionality to design motor control systems.

•

The Modbus RTU Operating Instructions explains how to physically establish and configure communication between the Danfoss

FC Series and a controller using the Modbus RTU protocol. Download the Operating Instructions from www.danfoss.com in the

sections Service and Support/Documentation.

See

www.danfoss.com for supplementary documentation.

1.3.2 VLT® Motion Control Tool MCT 10 Software Support

Download the software from the Service and Support download page on www.danfoss.com.

During the installation process of the software, enter CD-key 34544400 to activate the CDS 803 functionality. An activation key is not

required for using the CDS 803 functionality.

The latest software does not always contain the latest updates for the drive. Contact the local sales office for the latest drive updates

(in the form of *.upd files), or download the drive updates from the Service and Support download page on www.danfoss.com.

AU356039245821 en-000201 / 130R0597 | 9Danfoss A/S © 2021.07

Page 10

VLT® Compressor Drive CDS 803

Programming Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AU356039245821 en-000201 / 130R059710 | Danfoss A/S © 2021.07

Page 11

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x200

6.0–10 (8.0–15)

15

3x400

6.0–7.5 (8.0–10)

4

3x400

10–30 (15–40)

15

VLT® Compressor Drive CDS 803

Programming Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

AU356039245821 en-000201 / 130R0597 | 11Danfoss A/S © 2021.07

Page 12

L1

L2

L3

3-phase

power

input

PE

PE

+10 V DC

0-10 V DC-

0-10 V DC-

50 (+10 V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20 mA A OUT / D OUT

45 0/4-20 mA A OUT / D OUT

18 (D IN)

19 (D IN)

27 (D IN)

29 (

D IN)

12 (+24 V OUT)

24 V (NPN)

20 (COM D IN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

Bus ter.

RS485

Interface

RS485

(N RS485) 69

(P RS485) 68

(Com RS485 ) 61

(PNP)-Source

(NPN)-Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240 V AC 3 A

Not present on all power sizes

Do not connect shield to 61

01

02

03

relay 1

relay 2

UDC+

UDC-

Motor

U

V

W

e30bj246.10

06

05

04

240 V AC 3 A

VLT® Compressor Drive CDS 803

Programming Guide

3 Electrical Diagrams

3.1 Wiring Schematic

Electrical Diagrams

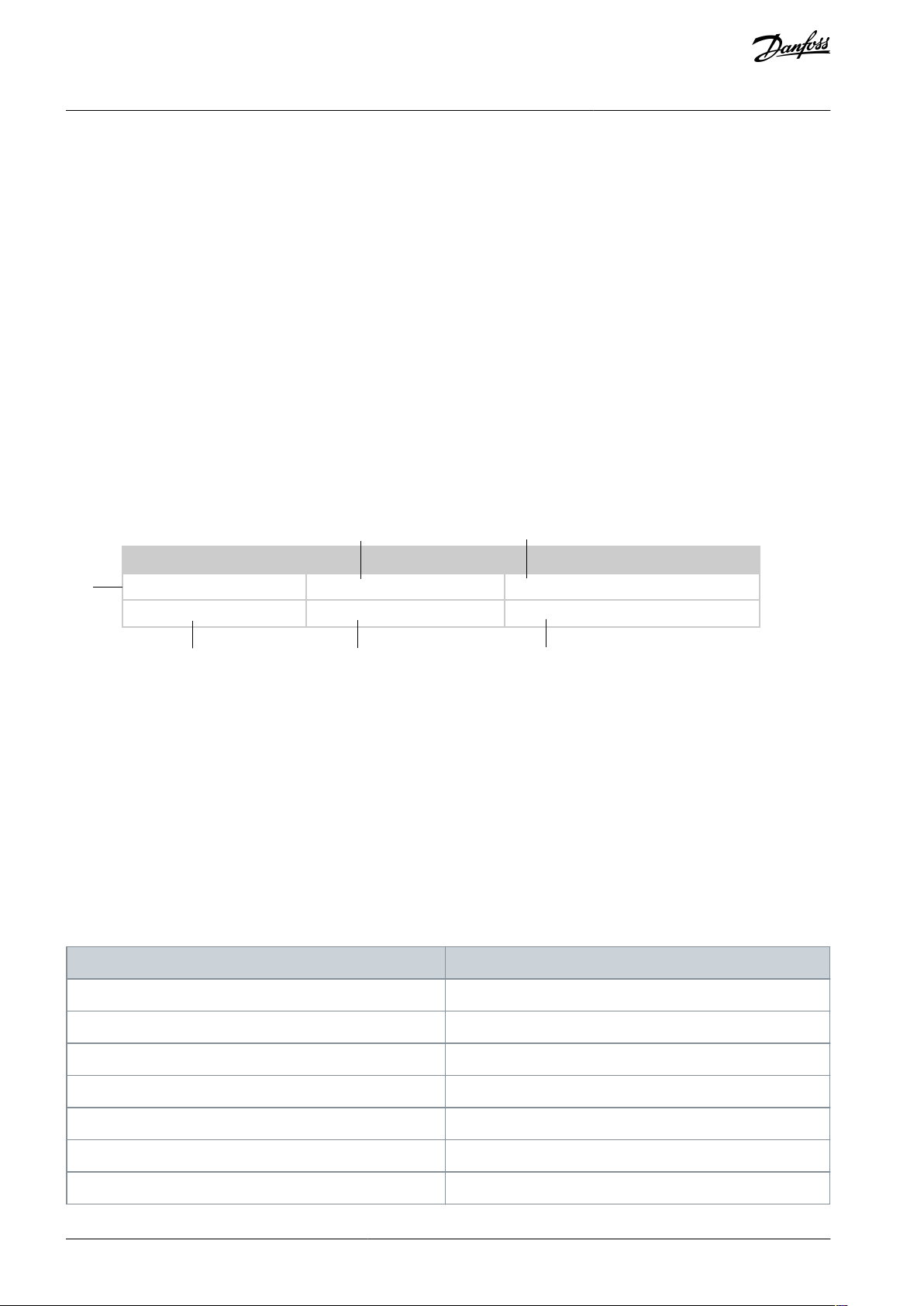

Illustration 1: Basic Wiring Schematic Drawing

There is no access to UDC- and UDC+ on the following units:

IP20, 380–480 V, 30 kW (40 hp).

-

N O T I C E

AU356039245821 en-000201 / 130R059712 | Danfoss A/S © 2021.07

Page 13

e30bf892.10

12 20 55

181927 29 42 54

45 50 53

DIGI IN

61 68 69

N

P

COMM. GND

+24 V

GND

GND

10 V OUT

10 V/20 mA IN

0/4-20 mA A OUT/DIG OUT

BUS TER.

OFF ON

DIGI IN

DIGI IN

DIGI IN

0/4-20 mA A OUT/DIG OUT

10 V/20 mA IN

VLT® Compressor Drive CDS 803

Programming Guide

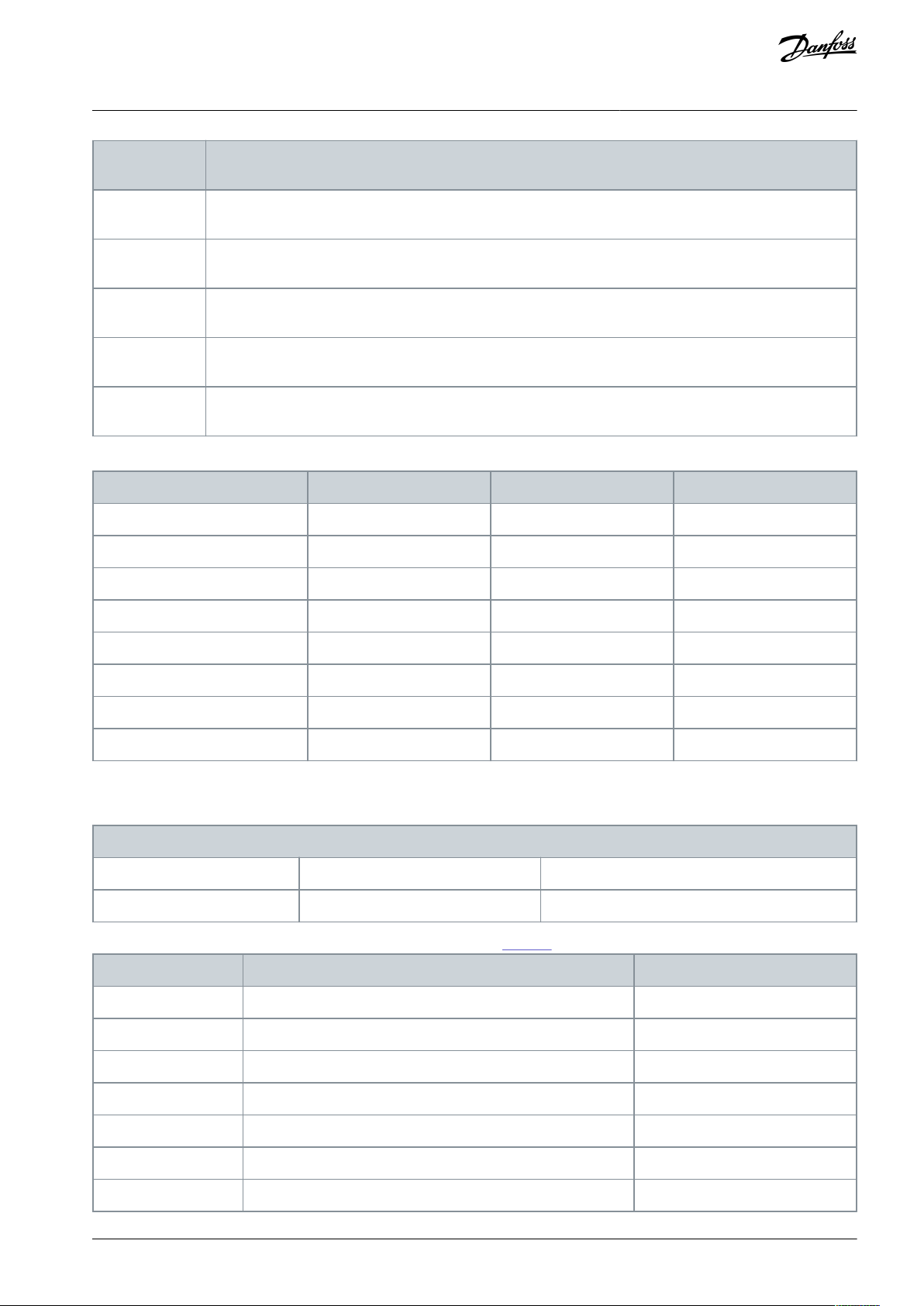

3.2 Control Terminals

Illustration 2: Control Terminals

Electrical Diagrams

AU356039245821 en-000201 / 130R0597 | 13Danfoss A/S © 2021.07

Page 14

e30bb765.11

B

a

c

k

Com.

1-20 Motor Power

[5] 0.37kW - 0.5HP

Setup 1

A

B

1

12

13

14

15

11

11

10

9

8

7

6

5

4

3

2

C

D

Status

Main

Menu

Quick

Menu

Hand

On

OK

M

enu

Off

Reset

Auto

On

Alarm

Warn.

On

11

1

Parameter number and name.

2

Parameter value.

3

Setup number shows the active setup and the edit setup. If the same setup acts as both active and edit setup, only that setup

number is shown (factory setting). When active and edit setup differ, both numbers are shown in the display (setup 12). The

number flashing indicates the edit setup.

4

Motor direction is shown to the bottom left of the display – indicated by a small arrow pointing either clockwise or counterclockwise.

5

The triangle indicates if the LCP is in Status, Quick Menu, or Main Menu.

VLT® Compressor Drive CDS 803

Programming Guide

4 Programming

4.1 Programming Interfaces

The drive can be programmed in 3 different ways:

•

Locally via the LCP.

•

Externally via the RS485 interface by either

-

using Modbus RTU

-

or by installing VLT® Motion Control Tool MCT 10.

Refer to the 1.3 Additional Resources for further information on Modbus RTU and VLT® Motion Control Tool MCT 10.

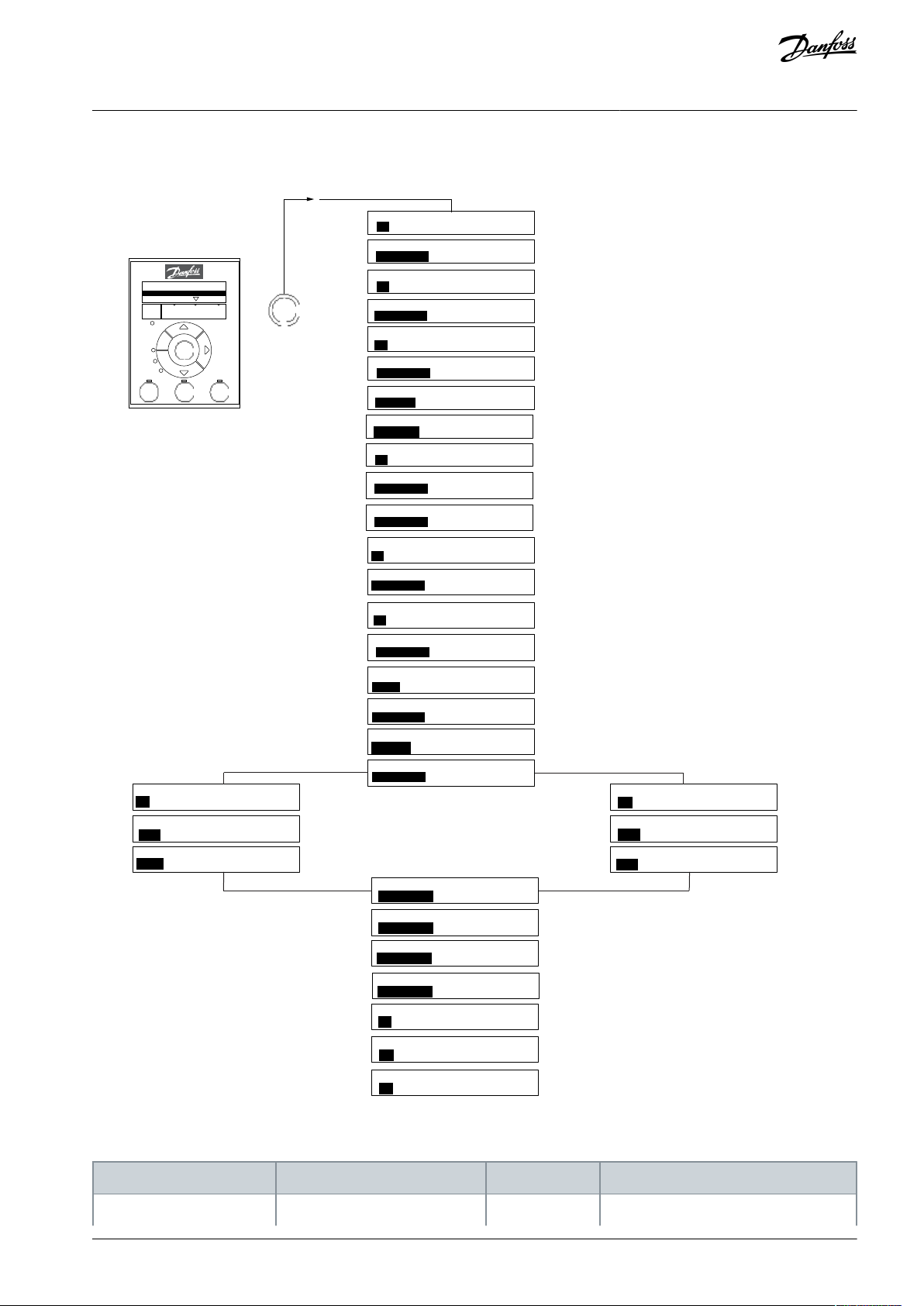

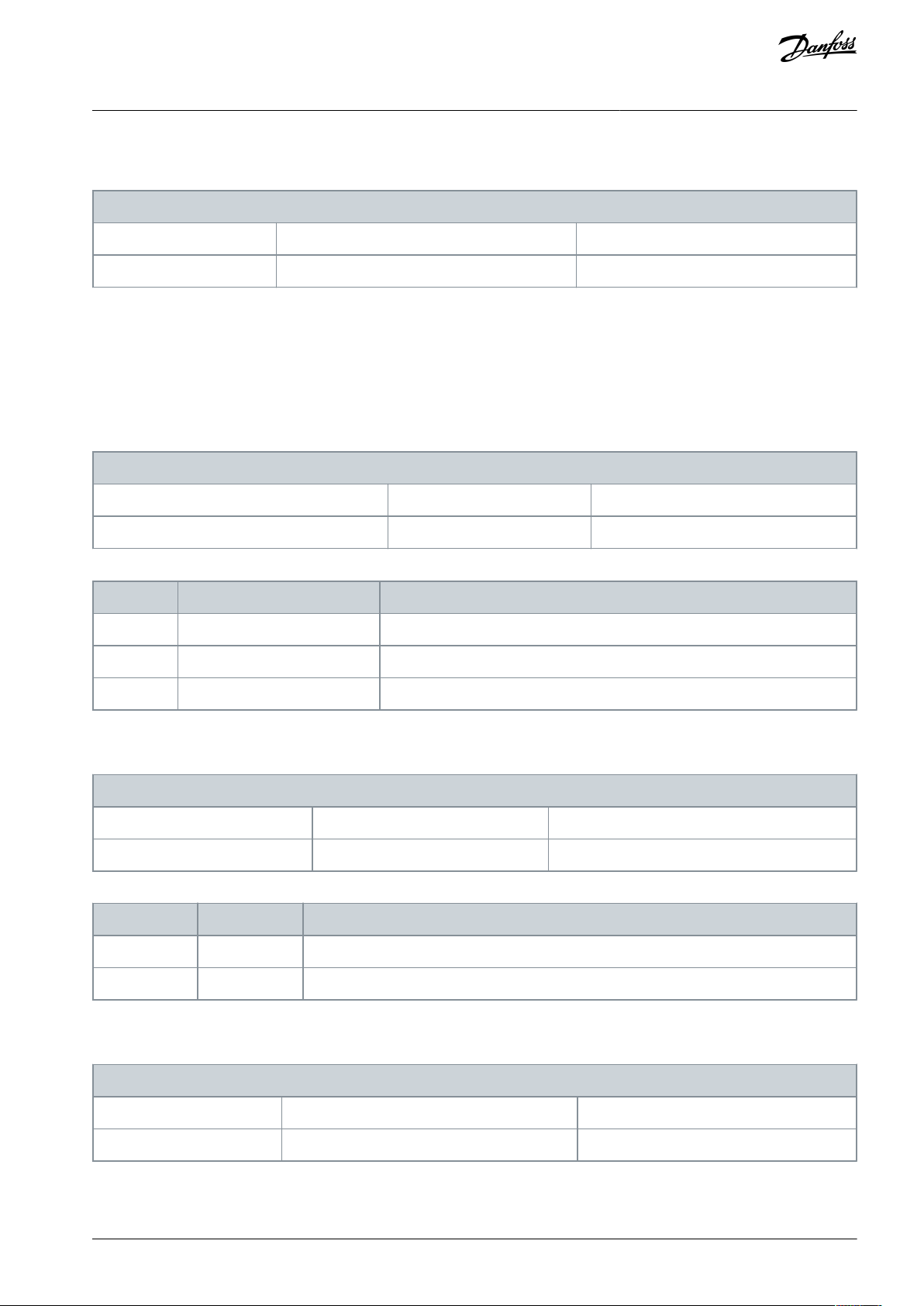

4.2 Local Control Panel (LCP)

The LCP is divided into 4 functional sections.

•

A. Display

•

B. Menu key

•

C. Navigation keys and indicator lights

•

D. Operation keys and indicator lights

Programming

Illustration 3: Local Control Panel (LCP)

A. Display

The LCD display is illuminated with 2 alphanumeric lines. Table 3 describes the information that can be read from the display.

Table 3: Legend to Section A, Illustration 3

AU356039245821 en-000201 / 130R059714 | Danfoss A/S © 2021.07

Page 15

6

Com. (yellow indicator): Flashes during bus communication.

7

On (green indicator): Control section is working correctly.

8

Warn. (yellow indicator): Indicates a warning.

9

Alarm (red indicator): Indicates an alarm.

10

[Back]: For moving to the previous step or layer in the navigation structure.

11

[▵] [▿] [▹]: For navigating among parameter groups and parameters, and within parameters. They can also be used for setting local reference.

12

[OK]: For selecting a parameter and for accepting changes to parameter settings.

13

[Hand On]: Starts the motor and enables control of the drive via the LCP.

N O T I C E

[2] Coast inverse is the default option for parameter 5-12 Terminal 27 Digital Input. If there is no 24 V supply to terminal 27,

[Hand On] does not start the compressor. Connect terminal 12 to terminal 27.

14

[Off/Reset]: Stops the compressor (Off). If in alarm mode, the alarm is reset.

15

[Auto On]: The drive is controlled either via control terminals or serial communication.

VLT® Compressor Drive CDS 803

Programming Guide

B. Menu key

Press [Menu] to select among Status, Quick Menu, or Main Menu.

C. Navigation keys and indicator lights

Table 4: Legend to Section C, Illustration 3

D. Operation keys and indicator lights

Table 5: Legend to Section D, Illustration 3

Programming

4.3 Menus

4.3.1 Access to Parameters

The are 2 different ways of accessing the parameters from the LCP:

•

Quick Menu

•

Main Menu

The Quick Menu contains a collection of parameters used for programming the most common functions.

The Main Menu contains all parameters in the drive.

4.3.1.1 Programming via the Quick Menu

Procedure

1.

To enter the Quick Menu, press [Menu] until indicator in display is placed above Quick Menu.

2.

Press [▵] [▿] to select quick guide, closed-loop setup, compressor setup, or changes made, then press [OK].

3.

Press [▵] [▿] to browse through the parameters in the Quick Menu.

Press [OK] to select a parameter.

4.

Press [▵] [▿] to change the value of a parameter setting.

5.

Press [OK] to accept the change.

6.

7.

Press either [Back] twice to enter Status, or press [Menu] once to enter Main Menu.

4.3.1.2 Programming via the Main Menu

Procedure

AU356039245821 en-000201 / 130R0597 | 15Danfoss A/S © 2021.07

Page 16

... the Quick Guide starts

OK

press

Select Open Loop

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

Reset

Off

Auto

On

Alarm

Warn.

On

Open Loop

Compressor Function

Setup 1

B

a

c

k

Com.

e30bi585.10

0-06 Grid Type

0-60 Main Menu Password

Size related

0

Size related

1-13 Compressor Selection

200.000

3-03 Maximum Reference

[1]

3-15 Reference 1 Source

Analog Input 53

Size related

3-41 Ramp 1 Ramp Up Time

Size related

3-42 Ramp 1 Ramp Down Time

[2]

5-12 Terminal 27 Digital Input

Coast inverse

Size related

5-40 Function Relay

Size related

6-10 Terminal 53 Low Voltage

10.00

6-11 Terminal 53 High Voltage

V

[0]

8-01 PI Control Site

Digital and ctrl. word

[0]

8-30 Protocol

FC

[2]

8-32 Baud

9600

0-01 Language

[0]

English

VLT® Compressor Drive CDS 803

Programming Guide

1.

Press [Menu] until indicator in display is placed above Main Menu.

2.

Press [▲] [▼] to browse through the parameter groups.

3.

Press [OK] to select a parameter group.

4.

Press [▲] [▼] to browse through the parameters in the specific group.

5.

Press [OK] to select the parameter.

6.

Press [▲] [▼] to set/change the parameter value.

7.

Press [OK] to accept the change or press [Back] to go back to the previous level.

4.3.2 Status Menu

In the Status menu, view the following:

•

Motor frequency [Hz], parameter 16-13 Frequency.

•

Motor current [A], parameter 16-14 Motor current.

•

Motor speed reference in percentage [%], parameter 16-02 Reference [%].

•

Feedback, parameter 16-52 Feedback [Unit].

•

Motor power parameter 16-10 Power [kW].

•

Custom readout parameter 16-09 Custom Readout.

4.3.3 Quick Menu

Use the Quick Menu to program the most common functions. The Quick Menu consists of:

Quick menu for open-loop applications.

•

Compressor functions.

•

Closed-loop setup quick menu.

•

Changes made.

•

Programming

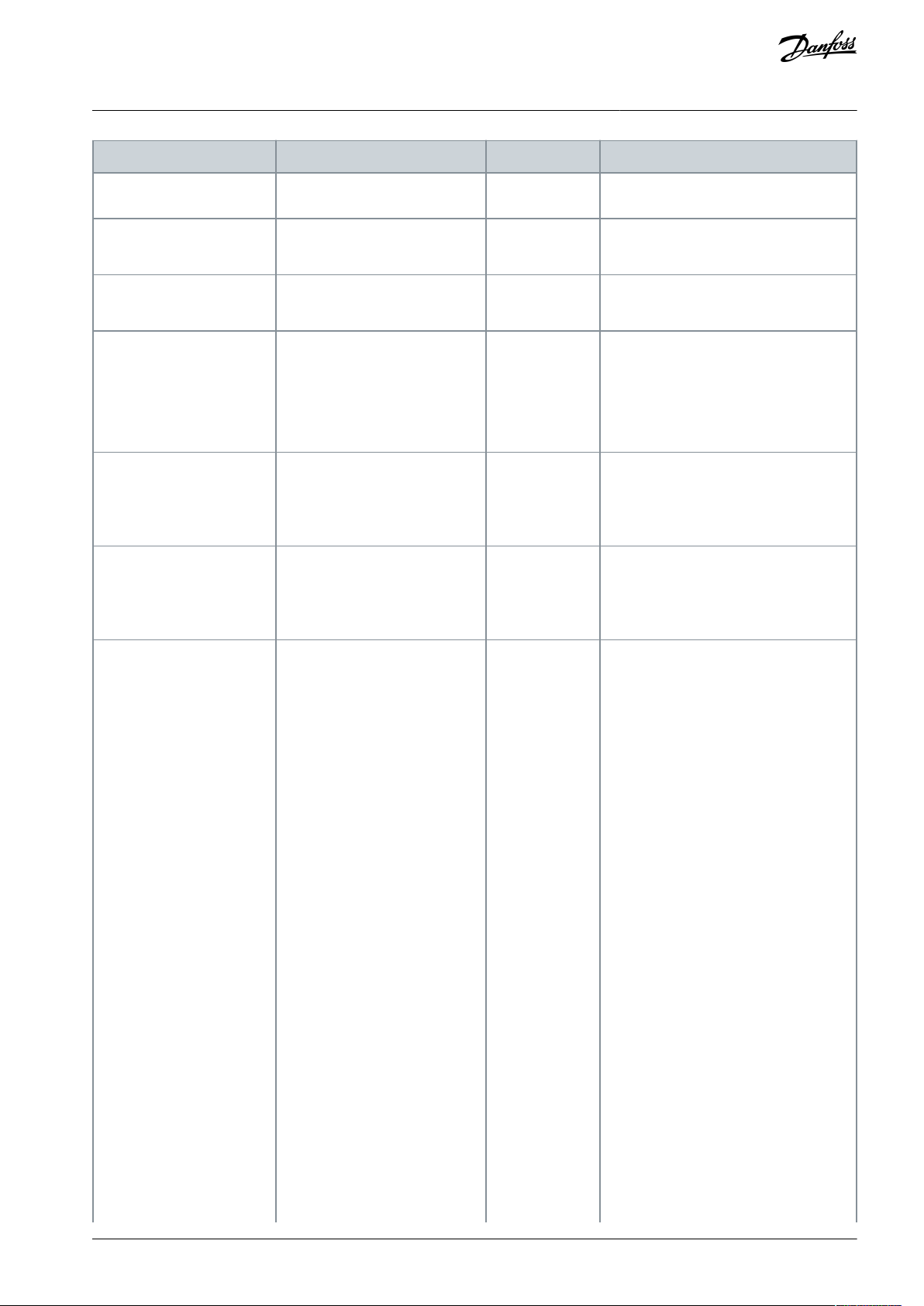

4.3.3.1 The Start-up Quick Guide for Compressor Open-loop Applications

Illustration 4: Smart Guide for Open-loop Applications

AU356039245821 en-000201 / 130R059716 | Danfoss A/S © 2021.07

Page 17

Parameter

Option

Default

Function

Parameter 0-01 Language

[0] English

[1] Deutsch

[2] Français

[3] Dansk

[4] Español

[5] Italiano

[28] Bras.port

[0] English

Select the language for the display.

Parameter 0-06 GridType

[0] 200–240 V/50 Hz/IT-grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[100] 200–240 V/60 Hz/IT-grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

Size related

Select operating mode for restart after

reconnection of the drive to mains voltage after power-down.

Parameter 0-60 Main Menu

Password

0–999

0

Define the password for access to the

LCP.

Parameter 1-13 Compressor Selection

6–10 kW

[24] VZH028-R410A

[25] VZH035-R410A

[26] VZH044-R410A

[27] VLZ028

[28] VLZ035

[29] VLZ044

Size related

Select which compressor to use.

Parameter 1-13 Compressor Selection

18–30 kW

[21] VZH088-R410A

[22] VZH117-R410A

[23] VZH170-R410A

[30] VZH088-R452B

[31] VZH088-R454B

[32] VZH117-R452B

[33] VZH117-R454B

[34] VZH170-R452B

[35] VZH170-R454B

Parameter 3-03 Maximum Reference

0–200 Hz

200 Hz

The maximum reference is the highest

obtainable by summing all references.

VLT® Compressor Drive CDS 803

Programming Guide

Table 6: Open-loop Applications Set-up

Programming

AU356039245821 en-000201 / 130R0597 | 17Danfoss A/S © 2021.07

Page 18

Parameter

Option

Default

Function

Parameter 3-15 Reference 1

Source

[0] No function

[1] Analog in 53

[2] Analog in 54

[7] Pulse input 29

[11] Local bus reference

[1] Analog in

53

Select the input to be used for the reference signal.

Parameter 3-41 Ramp 1 Ramp

Up Time

0.05–3600.0 s

Size related

Ramp-up time from 0 to parameter 1-25

Motor Nominal Speed.

Parameter 3-42 Ramp 1 Ramp

Down Time

0.05–3600.0 s

Size related

Ramp-down time from nominal motor

speed to 0.

Parameter 5-12 Terminal 27

Digital Input

[0] No operation

[1] Reset

[2] Coast inverse

[3] Coast and reset inverse

[4] Quick stop inverse

[5] DC-brake inverse

[6] Stop inverse

[7] External Interlock

[8] Start

[9] Latched start

[10] Reversing

[11] Start reversing

[14] Jog

[16] Preset ref bit 0

[17] Preset ref bit 1

[18] Preset ref bit 2

[19] Freeze reference

[20] Speed up

[22] Speed down

[23] Set-up select bit 0

[34] Ramp bit 0

[52] Run permissive

[53] Hand start

[54] Auto start

[60] Counter A (up)

[61] Counter A (down)

[62] Reset Counter A

[63] Counter B (up)

[64] Counter B (down)

[65] Reset Counter B

[2] Coast inverse

Select the input function for terminal 27.

Parameter 5-40 Function Relay

[0] Function relay

See parameter 5-40 Function Relay

Size related

Select the function to control output relay 1.

Parameter 5-40 Function Relay

[1] Function relay

See parameter 5-40 Function Relay

Drive running

Select the function to control output relay 2.

Parameter 6-10 Terminal 53 Low

Voltage

0–10 V

Size related

Enter the voltage that corresponds to

the low reference value.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

AU356039245821 en-000201 / 130R059718 | Danfoss A/S © 2021.07

Page 19

Parameter

Option

Default

Function

Parameter 6-11 Terminal 53

High Voltage

0–10 V

10 V

Enter the voltage that corresponds to

the high reference value.

Parameter 8-01 Control Site

[0] Digital and ctrl.word

[1] Digital only

[2] Controlword only

[0] Digital and

ctrl. word

Select if digital, bus, or a combination of

both should control the drive.

Parameter 8-30 Protocol

[0] FC

[2] Modbus RTU

[0] FC

Select the protocol for the integrated

RS485 port.

Parameter 8-32 Baud Rate

[0] 2400 Baud

[1] 4800 Baud

[2] 9600 Baud

[3] 19200 Baud

[4] 38400 Baud

[5] 57600 Baud

[6] 76800 Baud

[7] 115200 Baud

9600

Select the baud rate for the RS485 port.

28-01 Interval between Starts

e30bd874.14

28-02 Minimum Run Time

28-00 Short Cycle Protection

[1] Enabled

28-10 Oil Return Management

[1] On

300 s

Size related

28-12 Fixed Boost Interval

28-13 Boost Duration

60 s

28-17 ORM Boost Speed [Hz]

OK

press

Select Compressor Function

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

Reset

Off

Auto

On

Alarm

Warn.

On

Open Loop

Compressor Function

Setup 1

B

a

c

k

Com.

... the Quick Guide starts

Size related

Size related

Parameter

Option

Default

Function

Parameter 28-00 Short Cycle Protection

[0] Disabled

[1] Enabled

[1] Enabled

Select if short cycle protection is to be used.

Parameter 28-01 Interval between Starts

0–3600 s

300 s

Enter the minimum allowed time between starts.

Parameter 28-02 Minimum Run Time

10–3600 s

Size related

Enter the minimum allowed time to run before stop.

Parameter 28-10 Oil Return Management

[0] Off

[1] On

[1] On

Select if oil return management is to be used.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

4.3.3.2 Compressor Functions Quick Guide

Illustration 5: Quick Guide for Compressor Functions

Table 7: Compressor Functions

AU356039245821 en-000201 / 130R0597 | 19Danfoss A/S © 2021.07

Page 20

Parameter

Option

Default

Function

Parameter 28-12 Fixed Boost Interval

1–168 h

Size related

Oil Boosts is performed at fixed time intervals

Parameter 28-13 Boost Duration

60–300 s

60 s

Enter the boost duration for the oil return.

Parameter 28-17 ORM Boost Speed [Hz]

80–200 Hz

Size related

Enter speed of the compressor during oil return boost.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

AU356039245821 en-000201 / 130R059720 | Danfoss A/S © 2021.07

Page 21

e30bd875.13

0-01 Language

[0]

English

0-06 Grid Type

Size related

0-60 Main Menu Password

[0]

1-13 Compressor Selection

Size related

1-00 Configuration Mode

Open loop

[0]

3-02 Minimum Reference

Size related

3-03 Maximum Reference

200.000

3-10 Preset Reference

[0] 0.00 %

3-15 Reference 1 Source

Analog in 53

[1]

3-41 Ramp 1 Ramp Up Time3-41 Ramp 1 Ramp Up Time

5-12 Terminal 27 Digital Input

Coast inverse

[2]

5-12 Terminal 27 Digital Input

Coast inverse

[2]

5-40 Function Relay 1 5-40 Function Relay 1

6-19 Terminal 53 mode

Voltage mode

[1]

6-19 Terminal 53 mode

Voltage mode

[1]

6-10 Terminal 53 Low Voltage

6-10 Terminal 53 Low Voltage

6-11 Terminal 53 High Voltage

10.00

V

6-11 Terminal 53 High Voltage

10.00

V

6-14 Terminal 53 Low Ref./Feedb.

Size related

6-14 Terminal 53 Low Ref./Feedb.

Size related

6-15 Terminal 53 High Ref./Feedb.

200.000

Hz

6-15 Terminal 53 High Ref./Feedb.

200.000

6-29 Terminal 54 mode

Current mode

6-29 Terminal 54 mode

[0]

6-22 Terminal 54 Low Current

4.00

mA

6-22 Terminal 54 Low Current

4.00

mA

6-23 Terminal 54 High Current

20.00

mA

6-23 Terminal 54 High Current

20.00

mA

6-24 Terminal 54 Low Ref./Feedb.

0

0.000

6-24 Terminal 54 Low Ref./Feedb.

0

Size related

6-25 Terminal 54 High Ref./Feedb.

6-25 Terminal 54 High Ref./Feedb.

Size related

20-00 Feedback 1 Source 20-00 Feedback 1 Source

20-81 PI Normal/Inverse control

8-01 Control Site

Digital and ctrl.word

[0]

8-01 Control Site

Digital and ctrl.word

[0]

8-30 Protocol

[0]

FC

8-30 Protocol

[0]

FC

8-32 Baud

[2]

9600 Baud

8-32 Baud

[2]

9600 Baud

3-42 Ramp 1 Ramp Down Time

5

6-29 Terminal 54 mode

0.00

[1]

Voltage mode

6-20 Terminal 54 Low Voltage

1.00

V

6-21 Terminal 54 High Voltage

5.00

V

... the Quick Guide starts

OK

press

Select Closed Loop

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

Reset

Off

Auto

On

Alarm

Warn.

On

Compressor Function

Closed Loop

Setup 1

B

a

c

k

Com.

Size related

Size related

Size related

Size related

6-29 Terminal 54 mode6-29 Terminal 54 mode

Size related

Size related

Size related

Parameter

Option

Default

Function

Parameter 0-01 Language

[0] English

0

Select the language for the display.

VLT® Compressor Drive CDS 803

Programming Guide

4.3.3.3 The Start-up Quick Guide for Compressor Closed-loop Applications

Illustration 6: Closed-loop Quick Guide

Table 8: Closed-loop Applications Setup

AU356039245821 en-000201 / 130R0597 | 21Danfoss A/S © 2021.07

Programming

Page 22

Parameter

Option

Default

Function

[1] Deutsch

[2] Français

[3] Dansk

[4] Spanish

[5] Italiano

[28] Bras.port

Parameter 0-06 GridType

[0] 200–240 V/50 Hz/IT-grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[100] 200–240 V/60 Hz/IT-grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

Size related

Select the operating mode for restart after reconnection of the drive to mains

voltage after power-down.

Parameter 0-60 Main Menu

Password

0–999

0

Define the password for access to the

LCP.

Parameter 1-00 Configuration

Mode

[0] Open loop

[3] Closed loop

[0] Open loop

Select closed loop.

Parameter 1-13 Compressor

Selection

6–10 kW

[24] VZH028-R410A

[25] VZH035-R410A

[26] VZH044-R410A

[27] VLZ028

[28] VLZ035

[29] VLZ044

Size related

Select the compressor in use.

Parameter 1-13 Compressor

Selection

18–30 kW

[21] VZH088-R410A

[22] VZH117-R410A

[23] VZH170-R410A

[30] VZH088-R452B

[31] VZH088-R454B

[32] VZH117-R452B

[33] VZH117-R454B

[34] VZH170-R452B

[35] VZH170-R454B

Parameter 3-02 Minimum Reference

0–200 Hz

30 Hz (6–10 kW)

The minimum reference is the lowest value obtainable by summing all references.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

AU356039245821 en-000201 / 130R059722 | Danfoss A/S © 2021.07

Page 23

Parameter

Option

Default

Function

50 Hz (18–

30 kW)

Parameter 3-03 Maximum

Reference

0–200 Hz

200 Hz

The maximum reference is the highest

obtainable by summing all references.

Parameter 3-10 Reference 1

Source

-100 – 100%

0%

Set up a fixed setpoint in preset reference

[0].

Parameter 3-15 Reference 1

Source

[0] No function

[1] Analog in 53

[2] Analog in 54

[7] Pulse input 29

[11] Local bus reference

[1] Analog in 53

Select the input to be used for the reference signal.

Parameter 3-41 Ramp 1 Ramp

Up Time

0.05–3600.0 s

90.00 s (6–

10 kW)

180.00 s (18–

30 kW)

Ramp-up time from 0 to parameter 1-25

Motor Nominal Speed.

Parameter 3-42 Ramp 1 Ramp

Down Time

0.05–3600.0 s

30.00 s (6–

10 kW)

180.00 s (18–

30 kW)

Ramp-down time from nominal motor

speed to 0.

Parameter 5-12 Terminal 27

Digital Input

[0] No operation

[1] Reset

[2] Coast inverse

[3] Coast and reset inverse

[4] Quick stop inverse

[5] DC-brake inverse

[6] Stop inverse

[7] External Interlock

[8] Start

[9] Latched start

[10] Reversing

[11] Start reversing

[14] Jog

[16] Preset ref bit 0

[17] Preset ref bit 1

[18] Preset ref bit 2

[19] Freeze reference

[20] Speed up

[22] Speed down

[23] Set-up select bit 0

[34] Ramp bit 0

[52] Run permissive

[53] Hand start

[54] Auto start

[60] Counter A (up)

[61] Counter A (down)

[62] Reset Counter A

[63] Counter B (up)

[2] Coast inverse

Select the input function for terminal 27.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

AU356039245821 en-000201 / 130R0597 | 23Danfoss A/S © 2021.07

Page 24

Parameter

Option

Default

Function

[64] Counter B (down)

[65] Reset Counter B

Parameter 5-40 Function Relay [0] Function relay

See parameter 5-40 Function Relay

[9] Alarm (6–

10 kW)

[65] Comparator

5 (18–30 kW)

Select the function to control output relay 1.

Parameter 5-40 Function Relay [1] Function Relay

See parameter 5-40 Function Relay

Drive running

Select the function to control output relay 2.

Paraneter 6-19 Terminal 53

Mode

(1)

[0] Current mode

[1] Voltage mode

[1] Voltage

mode

Program terminal 53 to either current or

voltage.

Parameter 6-10 Terminal 53

Low Voltage

0–10 V

0.07 V (6–10 kW)

0 V (18–30 kW)

Enter the voltage that corresponds to the

low reference value.

Parameter 6-11 Terminal 53

High Voltage

0–10 V

10 V

Enter the voltage that corresponds to the

high reference value.

Parameter 6-14 Terminal 53

Low Ref./ Feedb. Value

-4999 – 4999

Size related

Enter the reference value that corresponds to the voltage set in parameter

6-10 Terminal 53 Low Voltage.

Parameter 6-15 Terminal 53

High Ref./ Feedb. Value

-4999 – 4999

200

Enter the reference value that corresponds to the voltage set in parameter

6-11 Terminal 53 High Voltage.

Parameter 6-29 Terminal 54

Mode

[0] Current mode

[1] Voltage mode

[0] Current

mode (6–10 kW)

[1] Voltage

mode (18–

30 kW)

Program terminal 54 to either current or

voltage.

Parameter 6-20 Terminal 54

Low Voltage

0–10 V

0.07 V (6–10 kW)

1 V (18–30 kW)

Enter the voltage corresponding to the

low reference value set in parameter 6-24

Terminal 54 Low Ref./Feedb. Value.

Parameter 6-21 Terminal 54

High Voltage

0–10 V

10 V (6–10 kW)

5 V (18–30 kW)

Enter the voltage corresponding to the

high reference value set in parameter Ter-

minal 54 High Ref./Feedb. Value.

Parameter 6-22 Terminal 54

Low Current

0.00–20.00 mA

4.00 mA

Enter the current that corresponds to the

low reference value.

Parameter 6-23 Terminal 54

High Current

0–10 V

10 V

Enter the current that corresponds to the

high reference value.

Parameter 6-24 Terminal 54

Low Ref./ Feedb. Value

-0.00–20.00 mA

Size related

Enter the reference value that corresponds to the current set in parameter

6-20 Terminal 54 Low Voltage.

Parameter 6-25 Terminal 54

High Ref./ Feedb. Value

-4999 – 4999

Size related

Enter the reference value that corresponds to the current set in parameter

6-21 Terminal 54 High Voltage.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

AU356039245821 en-000201 / 130R059724 | Danfoss A/S © 2021.07

Page 25

Parameter

Option

Default

Function

Parameter 8-01 Control Site

[0] Digital and ctrl.word

[1] Digital only

[2] Controlword only

[0] Digital and

ctrl. word

Select if digital, bus, or a combination of

both should control the drive.

Parameter 8-30 Protocol

[0] FC

[2] Modbus RTU

[0] FC

Select the protocol for the integrated

RS485 port.

Parameter 8-32 Baud Rate

[0] 2400 Baud

[1] 4800 Baud

[2] 9600 Baud

[3] 19200 Baud

[4] 38400 Baud

[5] 57600 Baud

[6] 76800 Baud

[7] 115200 Baud

9600

Select the baud rate for the RS485 port.

Parameter 20-00 Feedback 1

Source

[0] No function

[1] Analog Input 53

[2] Analog Input 54

[3] Pulse input 29

[100] Bus Feedback 1

[101] Bus Feedback 2

[0] No function

Select which input to use as the source of

the feedback signal.

Parameter 20-01 Feedback 1

Conversion

[0] Linear

[1] Square root

[0] Linear

Select how to calculate the feedback.

VLT® Compressor Drive CDS 803

Programming Guide

Programming

1

When parameter 6-19 Terminal 53 Mode is [0] Current mode, the next parameters will be parameter 6-12 Terminal 53 Low Current and parameter 6-13

Terminal 53 High Current. When parameter 6-19 Terminal 53 Mode is [1] Voltage mode, the next parameters will be parameter 6-10 Terminal 53 Low

Voltage and parameter 6-11 Terminal 53 High Voltage. When parameter 6-29 Terminal 54 Mode is [0] Current mode, the next parameters will be parameter 6-22 Terminal 54 Low Current and parameter 6-23 Terminal 54 High Current. When parameter 6-29 Terminal 54 Mode is [1] Voltage, the next parame-

ters are parameter 6-20 Terminal 54 Low Voltage and parameter 6-21 Terminal 54 High Voltage.

4.3.3.4 Changes Made

Changes Made lists all parameters changed from default settings.

The list shows only parameters which have been changed in the current edit set-up.

•

Parameters which have been reset to default values are not listed.

•

•

The message Empty indicates that no parameters have been changed.

4.3.4 Main Menu

The Main Menu is used for programming all parameters. The Main Menu parameters can be accessed immediately unless a password

has been created via parameter 0-60 Main Menu Password. For most applications, it is not necessary to access the Main Menu parameters. The Quick Menu provides the simplest and quickest access to the typical required parameters.

4.4 Uploading and Downloading Parameter Settings

4.4.1 Data Transfer from Drive to LCP

Once the setup of a drive is complete, Danfoss recommends storing the data in the LCP or on a PC via VLT® Motion Control Tool

MCT 10.

Stop the compressor before performing this operation.

W A R N I N G

AU356039245821 en-000201 / 130R0597 | 25Danfoss A/S © 2021.07

Page 26

VLT® Compressor Drive CDS 803

Programming Guide

Procedure

1.

Go to parameter 0-50 LCP Copy.

2.

Press [OK].

3.

Select [1] All to LCP.

Press [OK].

4.

4.4.2 Data Transfer from LCP to Drive

Connect the LCP to another drive to copy the parameter settings to this drive as well.

W A R N I N G

Stop the compressor before performing this operation.

Procedure

1.

Go to parameter 0-50 LCP Copy.

2.

Press [OK].

3.

Select [2] All from LCP.

4.

Press [OK].

4.5 Restoring Factory Default Settings

There are 2 different ways of initializing the drive to factory default settings:

•

Via parameter 14-22 Operation Mode (this is the recommended way).

Two-finger initialization

•

Some parameters will not be reset, see more details in

4.5.2 Two-finger Initialization.

4.5.1 Recommended Initialization (via Parameter 14-22 Operation Mode) and

Programming

4.5.1 Recommended Initialization (via Parameter 14-22 Operation Mode)

Initialization of the drive to default settings (via parameter 14-22 Operation Mode)

Procedure

1.

Select parameter 14-22 Operation Mode.

Press [OK].

2.

3.

Select [2] Initialisation and press [OK].

Cut off the mains supply and wait until the display turns off.

4.

Reconnect the mains supply.

5.

The drive is now reset, except the following parameters:

Parameter 0-03 Regional Settings

Parameter 1-06 Clockwise Direction

Parameter 1-13 Compressor Selection

Parameter 4-18 Current Limit

Parameter 8-30 Protocol

Parameter 8-31 Address

Parameter 8-32 Baud Rate

Parameter 8-33 Parity / Stop Bits

Parameter 8-35 Minimum Response Delay

Parameter 8-36 Maximum Response Delay

Parameter 8-37 Maximum Inter-char delay

Parameter 15-00 Operating hours to parameter 15-05 Over Volt's

Parameter 15-03 Power Up's

Parameter 15-04 Over Temp's

Parameter 15-05 Over Volt's

AU356039245821 en-000201 / 130R059726 | Danfoss A/S © 2021.07

Page 27

VLT® Compressor Drive CDS 803

Programming Guide

Parameter 15-30 Alarm Log: Error Code

Parameter group 15-4* Drive identification parameters

4.5.2 Two-finger Initialization

Procedure

1.

Power off the drive.

2.

Press [OK] and [Menu].

3.

Power up the drive while still pressing the keys above for 10 s.

The drive is now reset, except the following parameters:

Parameter 1-06 Clockwise Direction

Parameter 15-00 Operating hours

Parameter 15-03 Power Up's

Parameter 15-04 Over Temp's

Parameter 15-05 Over Volt's

Parameter 15-30 Alarm Log: Error Code

Parameter group 15-4* Drive identification parameters

Initialization of parameters is confirmed by AL80 in the display after the power cycle.

Programming

AU356039245821 en-000201 / 130R0597 | 27Danfoss A/S © 2021.07

Page 28

2

5

6

1

3

4

e30bi709.10

Default value:

Parameter type:

Setup:

Conversion index:

Data type: Change during operation:

Parameter Number: Paramter Name

Conversion index

Conversion factor

100175

3600000

74

36007060671/6061000000

5

100000

VLT® Compressor Drive CDS 803

Parameter Descriptions and

Programming Guide

Functions

5 Parameter Descriptions and Functions

5.1 Introduction to Parameters

The * in parameter numbers indicates a group or subgroup of parameters for which the first 1 or 2 numbers are the same. For example, 0-** indicates the group of parameters that all start with 0. 0-0* indicates the subgroup of parameters that share the first 2

numbers, which are 0-0.

An asterisk (*) after an option number indicates the default option. For example, [0]* English is the default option for parameter 0-01

Language.

Organization of the parameter chapter

The VLT® Compressor DriveCDS 803 uses 2 different software version depending on the power range. The 6–10 kW drives use one

software version, while 18–30 kW drives use another software version. The chapter is split into the following 3 sections:

•

Common Parameters: This section contains all available parameters shared across all power ranges.

•

6–10 kW Specific Parameters: This section contains the parameters available only for 6–10 kW drives.

•

18–30 kW Specific Parameters: This section contains the parameters available only for 18–30 kW drives.

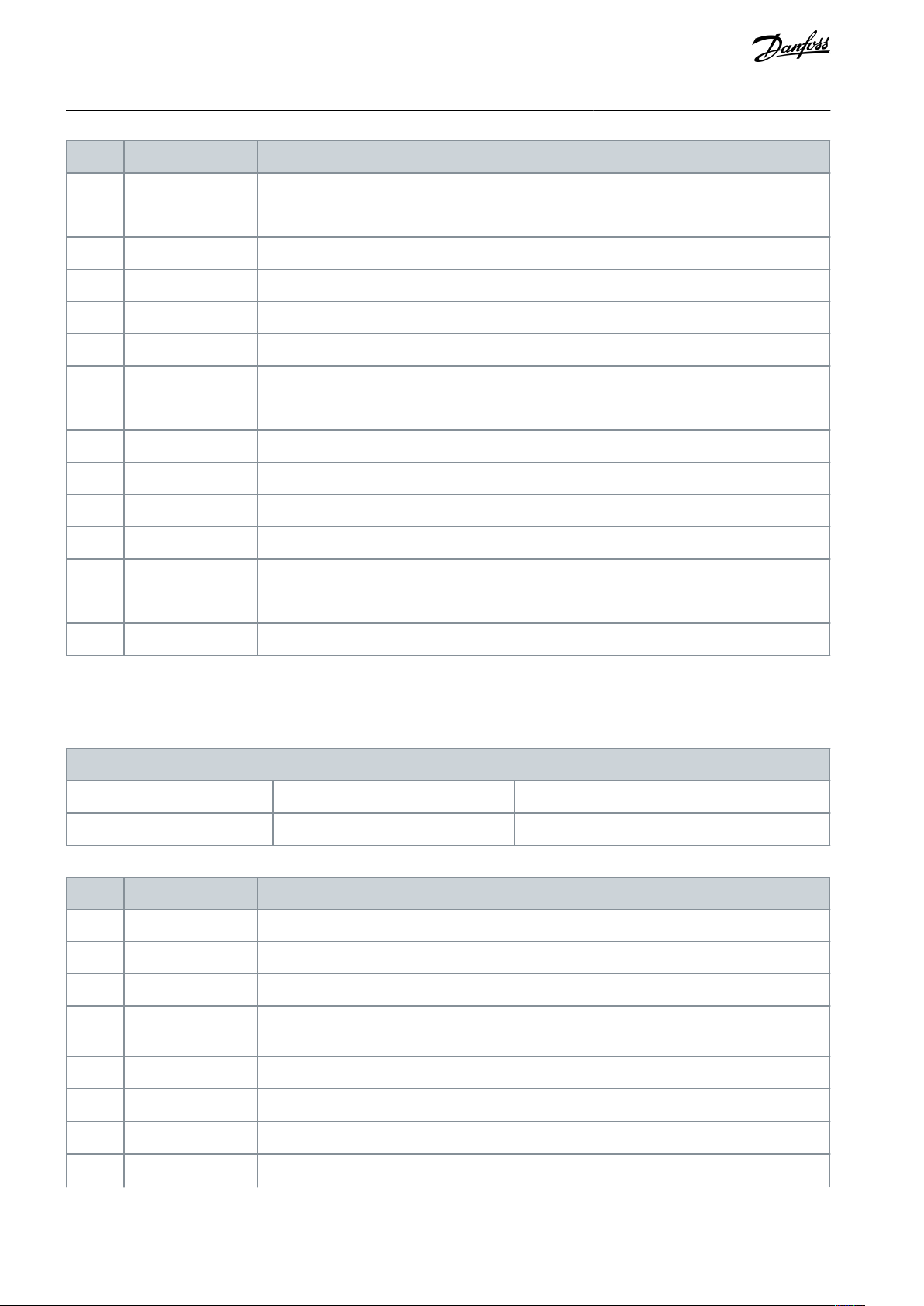

5.1.1 Reading the parameter table

This Programming Guide includes parameter and options tables. These descriptions explain how to read the parameter and options

tables.

Illustration 7: Parameter Table

1 indicates the value set in factory. Expressionlimit means the default value is not a fixed value and may link to power size and pa-

rameter dependency.

2 indicates whether the parameter type is option or range. Option means that the user is presented with a predefined selection to

choose between. Range means that the user can select any value within the specified range.

3 indicates the manner of parameter set-ups. 2 setups means that the parameter can be set individually in each of the 2 setups. For

example, 1 single parameter can have 2 different data values. 1 setup indicates that the data value is the same in all setups.

4 refers to the conversion index. Parameter values are transferred as whole numbers only. Conversion factors are therefore used to

transfer decimals. If a value is transferred as 100 and a conversion index of -1, the real value is 10.0.

5 indicates the different data types for the parameters.

6 indicates whether the parameter value can be changed while the drive is in operation. False indicates that the frequency convert-

er must be stopped before a change can be made.

Table 9: Conversion Table

AU356039245821 en-000201 / 130R059728 | Danfoss A/S © 2021.07

Page 29

Conversion index

Conversion factor

4

10000

3

1000210011001-10.1-20.01-30.001

-4

0.0001

-5

0.00001

-6

0.000001

Data type

Description

Type2Integer 8

Int83Integer 16

Int164Integer 32

Int325Unsigned 8

Uint8

6

Unsigned 16

Uint16

7

Unsigned 32

Uint32

9

Visible string

VisStr

33

Normalized value 2 bytes

N235Bit sequence of 16 boolean variables

V2

0-01 Language

Default value: English

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: True

VLT® Compressor Drive CDS 803

Programming Guide

Parameter Descriptions and

Functions

Table 10: Data type

5.2 Common Parameters

5.2.1 Parameter Group 0-** Operation and Display

5.2.1.1 Parameter Group 0-0* Basic Settings

Parameter 0-01 Language

Table 11: Parameter 0-01 Language

Defines the language to be used in the display.

AU356039245821 en-000201 / 130R0597 | 29Danfoss A/S © 2021.07

Page 30

Option

Name

Description

[0]*

English

[1]

Deutsch

[2]

Français

[3]

Dansk

[4]

Español

[5]

Italiano

[28]

Bras. Port

[255]

No text

0-04 Operating State at Power-up

Default value: Resume

Parameter type: Option

Setup: 2 setup

Conversion index: –

Data type: Uint8

Change during operation: True

Option

Name

Description

[0]*

Resume

Resumes operation of the drive, maintaining the same start/stop condition (applied by [Hand ON]/[Off]

on the LCP or local start via the digital input) as before the drive was powered down.

[1]

Forced

stop,

ref=old

Uses saved reference [1] to stop the drive, but at the same time retains the local speed reference in memory before powering down. After mains voltage is reconnected, and after receiving a start command

(pressing [Hand On] or using the local start command via a digital input), the drive restarts and operates

at the retained speed reference.

0-07 Auto DC Braking

Default value: On

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[0]

Off

This function is not active.

[1]*OnThis function is active.

VLT® Compressor Drive CDS 803

Programming Guide

Parameter 0-04 Operating State at Power-up

Table 12: Parameter 0-04 Operating State at Power-up

Parameter Descriptions and

Functions

Select the operating mode after recognition of the drive to mains voltage after power-down when operating in Hand (local) mode.

Parameter 0-07 Auto DC Braking

Table 13: Parameter 0-07 Auto DC Braking

Protective function against overvoltage at coast.

N O T I C E

Can cause PWM when coasted.

AU356039245821 en-000201 / 130R059730 | Danfoss A/S © 2021.07

Page 31

0-10 Active Set-up

Default value: Set-up 1

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: True

Option

Name

Description

[1]*

Set-up 1

Set-up 1 is active.

[2]

Set-up 2

Set-up 2 is active.

[9]

Multi Set-up

Used for remote setup selections via digital inputs and the serial communication port. This setup uses

the settings from parameter 0-12 Link Setups.

0-11 Programming Set-up

Default value: Active Set-up

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[1]

Set-up 1

Edit set-up 1.

[2]

Set-up 2

Edit set-up 2.

[9]*

Active Set-up

Edit parameters in the setup selected via digital I/Os.

0-12 Link Setups

Default value: Linked

Parameter type: Option

Setup: 2 setup

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[0]

Not linked

When selecting a different setup for operation, the setup change does not occur until the compressor is

coasted.

[20]*

Linked

Copies Not changeable during operation parameters from one setup to the other. It is possible to switch

setup while the compressor is running.

VLT® Compressor Drive CDS 803

Programming Guide

5.2.1.2 Parameter Group 0-1* Set-up Operations

Parameter 0-10 Active Set-up

Table 14: Parameter 0-10 Active Set-up

Select the setup in which the drive operates.

Parameter Descriptions and

Functions

Parameter 0-11 Programming Set-up

Table 15: Parameter 0-11 Programming Set-up

The number of the setup being edited is shown flashing in the LCP.

Parameter 0-12 Link Setups

Table 16: Parameter 0-12 Link Setups

If the setups are not linked, a change between them is not possible while the compressor is running.

AU356039245821 en-000201 / 130R0597 | 31Danfoss A/S © 2021.07

Page 32

0-30 Custom Readout Unit

Default value: %

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: True

Option

Name

Description

[0]

None

[1]*%[5]

PPM

[10]

l/Min

[11]

RPM

[12]

Pulse/s

[20]

l/s

[21]

l/min

[22]

l/h

[23]

m3/s

[24]

m3/min

[25]

m3/h

[30]

kg/s

[31]

kg/min

[32]

kg/h

[33]

t/min

[34]

t/h

[40]

m/s

[41]

m/min

[45]m[60]

Degree Celsius

[70]

mbar

[71]

bar

[72]Pa[73]

kPa

VLT® Compressor Drive CDS 803

Parameter Descriptions and

Programming Guide

Functions

5.2.1.3 Parameter Group 0-3* LCP Custom Readout

Parameter 0-30 Custom Readout Unit

Table 17: Parameter 0-30 Custom Readout Unit

Program a value to be shown in the display of the LCP. The value has a linear, squared, or cubed relation to speed. This relation

depends on the unit selected. The actual calculated value can be read in parameter 16-09 Custom Readout.

AU356039245821 en-000201 / 130R059732 | Danfoss A/S © 2021.07

Page 33

Option

Name

Description

[74]

m Wg

[80]kW[120]

GPM

[121]

gal/s

[122]

gal/min

[123]

gal/h

[124]

CFM

[127]

ft3/h

[140]

ft/s

[141]

ft/min

[160]

Degree Fahr

[170]

psi

[171]

lb/in

2

[172]

in WG

[173]

ft WG

[180]

hp

0-31 Custom Readout Min Value

Default value: 0 CustomReadoutUnit

Parameter type: Range [0 - Expressionlimit (999999.99)]

Setup: 1 setup

Conversion index: –

Data type: Int32

Change during operation: True

0-32 Custom Readout Max Value

Default value: 100 CustomReadoutUnit

Parameter type: Range [0.0 - Expressionlimit

(999999.99)]

Setup: 1 setup

Conversion index: -2

Data type: Int32

Change during operation: True

VLT® Compressor Drive CDS 803

Programming Guide

Parameter Descriptions and

Functions

Parameter 0-31 Custom Readout Min Value

Table 18: Parameter 0-31 Custom Readout Min Value

This parameter sets the minimum value of the custom-defined readout (occurs at 0 speed). It is only possible to select a value different from 0 when selecting a linear unit in parameter 0-30 Custom Readout Unit. For quadric and cubic units, the minimum value is 0.

Parameter 0-32 Custom Readout Max Value

Table 19: Parameter 0-32 Custom Readout Max Value

This parameter sets the maximum value to be shown when the speed of the compressor has reached the value set for parameter

4-14 Motor Speed High Limit [Hz].

AU356039245821 en-000201 / 130R0597 | 33Danfoss A/S © 2021.07

Page 34

0-42 [Auto On] key on the LCP

Default value: Enabled

Parameter type: Option

Setup: 2 setups

Conversion index: –

Data type: Uint8

Change during operation: True

Option

Name

Description

[0]

Disabled

To avoid unintended start of the drive from the LCP, select [0] Disabled.

[1]*

Enabled

[Auto On] is enabled.

0-44 [Off/Reset] key on the LCP

Default value: Enabled

Parameter type: Option

Setup: 2 setups

Conversion index: –

Data type: Uint8

Change during operation: True

Option

Name

Description

[0]

Disabled

Disable the [Off/Reset] key.

[1]*

Enabled

Enable both off and reset functions.

[7]

Enable Reset Only

Enable the reset function and disable the off function to avoid unintended stop of the drive.

0-50 LCP Copy

Default value: No copy

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[0]*

No copy

[1]

All to LCP

Copies all parameters in all setups from the drive memory to the LCP memory. For service purposes,

to copy all parameters to the LCP after commissioning.

[2]

All from LCP

Copies all parameters in all setups from the LCP memory to the drive memory.

[3]

Size indep. from

LCP

Copies only the parameters that are independent of the compressor size. The latter selection can be

used to program several drives with the same function without disturbing compressor data which is

already set.

VLT® Compressor Drive CDS 803

Programming Guide

5.2.1.4 Parameter Group 0-4* LCP Keypad

Parameter 0-42 [Auto On] Key on LCP

Table 20: Parameter 0-42 [Auto On] key on the LCP

Parameter 0-44 [Off/Reset] Key on LCP

Table 21: Parameter 0-44 [Off/Reset] key on the LCP

Parameter Descriptions and

Functions

5.2.1.5 Parameter Group 0-5* Copy/Save

Copy parameter settings between setups and to/from the LCP.

Parameter 0-50 LCP Copy

Table 22: Parameter 0-50 LCP Copy

AU356039245821 en-000201 / 130R059734 | Danfoss A/S © 2021.07

Page 35

0-51 Set-up Copy

Default value: No copy

Parameter type: Option

Setup: 1 setup

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[0]*

No copy

[1]

Copy from setup 1

Copy from setup 1 to setup 2.

[2]

Copy from setup 2

Copy from setup 2 to setup 1.

[9]

Copy from factory setup

Copy factory setting to programming setup (selected in parameter 0-11 Programming Set-

up).

0-60 Main Menu Password

Default value: 0

Parameter type: Range [0 - 999]

Setup: 1 setup

Conversion index: 0

Data type: Uint16

Change during operation: True

1-00 Configuration Mode

Default value: Open loop

Parameter type: Option

Setup: 2 setups

Conversion index: –

Data type: Uint8

Change during operation: True

Option

Name

Description

[0]*

Open loop

Compressor speed is determined by applying a speed reference or by setting speed when in hand-on

mode. Open loop is also used if the drive is part of a closed-loop control system based on an external PI

controller providing a speed reference signal as output.

[3]

Process

Control

Loop

Compressor speed is determined by a reference from the built-in PI controller varying the compressor

speed as of a closed-loop control process (for example, constant pressure or flow). Configure the PI controller in parameter group 20-** Drive Closed Loop.

VLT® Compressor Drive CDS 803

Programming Guide

Parameter 0-51 Set-up Copy

Table 23: Parameter 0-51 Set-up Copy

5.2.1.6 Parameter Group 0-6* Password

Parameter Descriptions and

Functions

Table 24: Parameter 0-60 Main Menu Password

Define the password for access to the Main Menu via the [Main Menu] key. Setting the value to 0 disables the password function.

5.2.2 Parameter Group 1-** Load and Motor

5.2.2.1 Parameter Group 1-0* General Settings

Parameter 1-00 Configuration Mode

Table 25: Parameter 1-00 Configuration Mode

Select which application control principle should be used.

N O T I C E

This parameter cannot be adjusted while the compressor is running.

AU356039245821 en-000201 / 130R0597 | 35Danfoss A/S © 2021.07

Page 36

1-71 Start Delay

Default value: 60 s

Parameter type: Range [0 - 120 s]

Setup: 2 setups

Conversion index: -1

Data type: Uint16

Change during operation: False

2-17 Over-voltage Control

Default value: Enabled

Parameter type: Option

Setup: 2 setups

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[0]

Disabled

No OVC required.

[2]*

Enabled

Activates OVC.

N O T I C E

The ramp time is automatically adjusted to avoid tripping of the drive.

3-02 Minimum Reference

Default value: ExpressionLimit

Parameter type: Range [0 – 200 ReferenceFeedbackUnit]

Setup: 2 setups

Conversion index: -3

Data type: Int32

Change during operation: False

VLT® Compressor Drive CDS 803

Parameter Descriptions and

Programming Guide

Functions

5.2.2.2 Parameter Group 1-7* Start Adjustments

Parameters for configuring special motor start features.

Parameter 1-71 Start Delay

Table 26: Parameter 1-71 Start Delay

This parameter enables a delay of the starting time. The drive begins with the start function selected in parameter 1-72 Start Function. Set the start delay time until acceleration is to begin.

5.2.3 Parameter Group 2-** Brakes

5.2.3.1 Parameter Goup 2-1* Brake Energy Function

Parameter group for selecting dynamic brake parameters.

Parameter 2-17 Over-voltage Control

Table 27: Parameter 2-17 Over-voltage Control

Select whether to enable OVC during ramp down. Enabling OVC reduces the risk of a drive trip due to overvoltage on the DC link

caused by generative power from the load.

5.2.4 Parameter Group 3-** Reference/Ramps

5.2.4.1 Parameter Group 3-0* Reference Limits

Parameters for setting the reference unit, limits, and ranges.

Also see parameter group 20-0* Feedback for information on settings in closed loop.

Parameter 3-02 Minimum Reference

Table 28: Parameter 3-02 Minimum Reference

The minimum reference is the lowest value obtainable by summing all references.

AU356039245821 en-000201 / 130R059736 | Danfoss A/S © 2021.07

Page 37

3-03 Maximum Reference

Default value: 200 ReferenceFeedbackUnit

Parameter type: Range [0 – 200 ReferenceFeedbackUnit]

Setup: 2 setups

Conversion index: -3

Data type: Int32

Change during operation: False

P3-03

P3-02

0

50

100%

P3-10

e30bb036.11

3-10 Preset Reference

Default value: 0%

Parameter type: Range [-100 – 100%]

Setup: 2 setups

Conversion index: -2

Data type: Int16[8]

Change during operation: True

3-14 Preset Relative Reference

Default value: 0%

Parameter type: Range [-100 – 100%]

Setup: 2 setups

Conversion index: -2

Data type: Int16

Change during operation: True

VLT® Compressor Drive CDS 803

Parameter Descriptions and

Programming Guide

Parameter 3-03 Maximum Reference

Table 29: Parameter 3-03 Maximum Reference

The maximum reference is the highest value obtainable by summing all references. The maximum reference unit matches the configuration selected in parameter 1-00 Configuration Mode.

Functions

5.2.4.2 Parameter Group 3-1* References

Illustration 8: References

Parameter 3-10 References

Table 30: Parameter 3-10 Preset Reference

Enter up to 8 different preset references (0–7) in this parameter, using array programming. For selecting dedicated references, select

[16] Preset reference bit 0, [17] Preset reference bit 1, or [18] Preset reference bit 2 for corresponding digital inputs in parameter group

5-1* Digital Inputs.

Parameter 3-14 Preset Relative Reference

Table 31: Parameter 3-14 Preset Relative Reference

AU356039245821 en-000201 / 130R0597 | 37Danfoss A/S © 2021.07

Page 38

Relative

Z=X+X*Y/100

Resulting

actual

reference

Y

X

e30ba059.13

Z

X

100

%

0-100

Z

Y

X+X*Y/100

P 3-14

e30ba278.11

3-15 Reference 1 Source

Default value: Analog input 53

Parameter type: Option

Setup: 2 setups

Conversion index: –

Data type: Uint8

Change during operation: False

Option

Name

Description

[0]

No function

[1]*

Analog input 53

[2]

Analog input 54

[7]

Pulse input 29

[11]

Local bus reference

3-17 Reference 3 Source

Default value: Local bus reference

Parameter type: Option

Setup: 2 setups

Conversion index: –

Data type: Uint8

Change during operation: False

VLT® Compressor Drive CDS 803

Parameter Descriptions and

Programming Guide

The actual reference, X, is increased or decreased with the percentage, Y, set in this parameter. This results in the actual reference, Z.

Actual reference (X) is the sum of the inputs selected in parameter 3-15 Reference 1 Source, parameter 3-16 Reference 2 Source, param-

eter 3-17 Reference 3 Source, and parameter 8-02 Control Source.

Illustration 9: Preset Relative Reference

Functions

Illustration 10: Actual Reference

Parameter 3-15 Reference 1 Source

Table 32: Parameter 3-15 Reference 1 Source

Select the input to be used for the 1st reference signal. Parameters 3-15 to 3-17 define up to 3 difference reference signals. The sum

of these signals defines the actual reference.

Parameter 3-17 Reference 3 Source

Table 33: Parameter 3-17 Reference 3 Source

Select the input to be used for the 3rd reference signal. Parameters 3-15 to 3-17 define up to 3 difference reference signals. The sum

of these signals defines the actual reference.

AU356039245821 en-000201 / 130R059738 | Danfoss A/S © 2021.07

Page 39

Option

Name

Description

[0]

No function

[1]

Analog input 53

[2]

Analog input 54

[7]

Pulse input 29

[11]*

Local bus reference

t

a cc

t

dec

e30bb801.11

P 3-*2

R amp ( X)

D ow n

T ime (D ec)

P 4-14

H igh-limit

R PM

Reference

P 1-23

M ot or

fr equenc y

P 4-12

L o w limit

Time

P 3-*1

Ramp (X) Up

Time (Acc)

3-41 Ramp 1 Ramp Up Time

Default value: ExpressionLimit

Parameter type: Range [0.05 – 3600 s]

Setup: 2 setups

Conversion index: -2

Data type: Uint32

Change during operation: False

3-42 Ramp 1 Ramp Down Time

Default value: ExpressionLimit

Parameter type: Range [0.05 – 3600 s]

Setup: 2 setups

Conversion index: -2

Data type: Uint32

Change during operation: False

VLT® Compressor Drive CDS 803

Parameter Descriptions and

Programming Guide

Functions

5.2.4.3 Parameter Group 3-4* Ramp 1

Configure the ramp time parameters for each of the 2 ramps (parameter group 3-4* Ramp 1 and parameter group 3-5* Ramp 2). The

ramp time is preset to the minimum value of 10 ms for all power sizes.

Illustration 11: Ramps

Parameter 3-41 Ramp 1 Ramp Up Time

Table 34: Parameter 3-41 Ramp 1 Ramp Up Time

Enter acceleration time from 0 RPM to parameter 1-25 Motor Nominal Speed. Select a ramp-up time such that the output current