Page 1

MAKING MODERN LIVING POSSIBLE

OOperating Instructions

VLTp Inverter Scroll CDS 801

Page 2

Page 3

Page 4

Page 5

Contents

Contents

VLT® Inverter Scroll CDS 801 Operating Instructions

1 General

1.1 Coverage

1.1.1 Disclaimer 4

1.1.2 Coverage 4

1.2 Safety Instructions

1.3 Approvals

1.4 General Warning

1.5 Disposal Instruction

1.6 Before Commencing Repair Work

1.7 ESD Precautions

1.8 Product Identification

1.9 Unpacking the Drive

1.10 Table of Abbreviations

2 Mechanical Installation

2.1 Dimensions and Weight

2.2 Installation Orientation and Clearances

2.2.1 Surface Mounting 9

4

4

4

4

5

5

5

5

5

5

6

7

7

9

2.2.2 Structural Mounting 11

2.3 Air Circulation/Cooling

2.4 Condensation and Dripping Water

2.5 Vibration and Mechanical Resonances

3 Electrical Installation

3.1 Electrical Connection in General

3.2 Tightening Torque

3.3 Cable Quality and Dimensioning

3.4 Fuses/Circuit Breakers

3.5 EMC Correct Installation

3.6 Electrical Connections

3.6.1 Routing of Motor and Supply Cable 15

3.6.2 Power Supply Connection (Mains) 16

3.6.3 Motor (Compressor) Connection 16

3.6.4 Sensor Connections 18

3.6.5 4-way Reversing Valve Connection 18

3.6.6 Condenser Fan Motor Control Connection (EXT_FAN) 18

12

12

12

13

13

13

13

13

14

15

3.6.7 EEV Controller (HP Mode) Connection (EEV_2) 18

3.6.8 Serial Communication Cable Connection 19

3.6.9 Connector Specification 20

3.6.10 Allocation of Connector Pins 21

MG10V402 - VLT® is a registered Danfoss trademark 1

Page 6

Contents

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6.11 Overview Wiring Diagram 22

4 Serial Communication (Modbus RTU)

5 Commissioning

5.1 Initial Configuration of the Performer VSD sub-system

5.2 Drive Setup

5.2.1 Drive Parameters

(Modbus Registers, node 162) 27

5.2.2 Drive Parameters

(Modbus Registers, node 163) 28

5.3 Condenser Fan Speed Reference Output

5.4 Crankcase Heating

5.5 Ambient Temperature Source

5.6 Pressure sensor scaling

5.7 Normal Operation

6 Embedded Application Controller “Thermo Control”

6.1 Introduction

6.2 Applications

6.2.1 Generic AC 31

25

27

27

27

29

29

29

30

30

31

31

31

6.2.2 Generic AC/HP (Reversible) 32

6.2.3 Ground Source Heat Pump (Reversible) 33

6.3 Application Controller

6.3.1 Introduction 33

6.3.2 System Modes 33

6.3.2.1 Off 33

6.3.2.2 AC 33

6.3.2.3 HP 34

6.3.2.4 Defrost 34

6.3.3 Compressor Capacity Control 34

6.3.3.1 Single Loop Room Temperature Control 35

6.3.3.2 Open Loop/ External Speed Control 35

6.3.4 Condensing Pressure Control 36

6.3.4.1 AC Mode 36

6.3.4.2 HP Mode 38

6.3.4.3 Defrost Mode 39

6.3.5 Auxiliary Functions 39

33

6.3.5.1 Start-Up Sequence 39

6.3.5.2 Restart Timer 40

6.3.5.3 Compressor Safety Envelope 40

6.3.5.4 Oil Return 40

2 MG10V402 - VLT® is a registered Danfoss trademark

Page 7

Contents

VLT® Inverter Scroll CDS 801 Operating Instructions

6.3.5.5 Derating 40

6.3.5.6 Discharge temperature cut out 41

6.3.5.7 Max Suction Pressure (MOP) 41

6.3.5.8 Frequency Cancelation 41

6.3.5.9 System Status 41

6.4 Thermo Controller Register Overview (Node 162)

7 Fault Conditions, Messages and Causes

8 Troubleshooting

9 Specifications

10 Special Operating Conditions

11 Maintenance

11.1 Replacement of Internal Cooling Fan

11.2 Cleaning

12 Service and Spare Parts

Index

42

44

47

48

50

51

51

51

52

53

MG10V402 - VLT® is a registered Danfoss trademark 3

Page 8

General

VLT® Inverter Scroll CDS 801 Operating Instructions

11

1 General

1.1 Coverage

The earth leakage current exceeds 3.5 mA

•

A stop command does not disconnect power

•

from the drive

1.1.1 Disclaimer

Danfoss can accept no responsibility for possible errors in

catalogues, brochures and other printed material. Danfoss

reserves the right to alter its products without notice. This

also applies to products already on order provided that

such alterations can be made without subsequential

changes being necessary in specifications already agreed.

All trademarks in this material are property of the

respective companies. Danfoss and the Danfoss logotype

are trademarks of Danfoss A/S. All rights reserved.

Coverage

1.1.2

This instruction covers 3 different drive sizes with single

phase 208-240 V power supply matching compressor sizes

for

- 13 kW/3 t cooling capacity

- 16 kW/4 t cooling capacity

- 20 kW/5 t cooling capacity

from software version 1.09.

1.2

Safety Instructions

1.3 Approvals

The drive has been designed/approved in accordance with

the following standards:

Safety UL/EN 60335-1, 60335-2-34 (UL 984)

Household UL/EN 60730

Industrial EN 61800-3 (frequency converter standard)

Software UL 1998 cl. B

Polymerics UL 746 C

EMC With ferrite: EN 55011 cl. A, EN 55014

Harmonics EN 61000-3-12, IEEE 519-1992

Surge EN 61642-12

Immunity EN 61000-6

Transient EN 61000-4

Corrosion UL 50E, ISO 9223, EN 61000-5-1, ASTM B117

Environment IEC 60721-3-3 cl. 3K4

Enclosure NEMA 250-2003

Table 1.1 Standards Complied to

The equipment complies with the flicker requirement according to

IEC/EN61000-3-11 at 230 V nominal voltage under the condition that

the service current capacity is

permissible system impedance Z

≥

100 A per phase or a maximum

= 0.1892

MAX

Ω

1.2.1 High Voltage Warning

WARNING

The voltage of the variable speed drive is dangerous

whenever it is connected to mains. Incorrect installation of

the variable speed drive may cause damage to the

equipment, serious injury or death. Consequently, it is

essential to comply with the instructions in this manual as

well as local and national rules and safety regulations.

1.2.2 Safety Instructions

Make sure the drive is properly connected to

•

earth

Do not remove the mains connector or motor

•

(compressor) connector while the drive is

connected to power

Protect personnel against supply voltage

•

Protect the variable speed drive against over-

•

current according to national and local

regulations

4 MG10V402 - VLT® is a registered Danfoss trademark

Page 9

130ZB121.10

IP00/CHASSIS -25

C/ -13 F to 52 C/125 F

PERFORMER

MADE IN DENMARK

R

CDS801 Variable Speed Drive

P/N: 176L7002 S/N: 010199D082

20 kW/5 TR cooling capacity

IN: 1x208-230V 50-60Hz 33A 6,7 kW

OUT: 3x270V 45-210Hz 33A

VSD

o o o o

CAUTION:

See manual before use.

Lire le manual avant utilisation

WARNING:

Stored charge, wait 5 min. before service.

Energia aimacenada, asperar 5 min. para descaega antes de lisar.

E337256

* 1 7 6 L 7 0 0 2 0 1 0 1 9 9 D 0 6 2 *

Charge stockée, attendre 5 min. avant l’emploi.

Leer manual antec deusar.

General

VLT® Inverter Scroll CDS 801 Operating Instructions

1.4 General Warning

WARNING

Touching the electrical parts may be fatal - even after the

equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected.

Be aware that there may be high voltage on the DC link

even when the LED is turned off.

Before touching any potentially live parts of the drive, wait

at least 1 minute.

CAUTION

Leakage Current

The earth leakage current from the variable speed drive

exceeds 3.5 mA. Grounding and bounding shall comply

with UL 1995/NEC.

Residual Current Device

This product can cause a D.C. current in the protective

earth, only an RCD of Type B (time delayed) shall be used

in the supply side of this product. See also Application Note

on RCD, MN90G.

Protective earthing of the drive and the use of RCDs must

always follow national and local regulations.

WARNING

Installation in high altitudes:

At altitudes above 6000 ft (2000 m), contact Danfoss

regarding SELV.

1 1

1.6 Before Commencing Repair Work

1. Disconnect the variable speed drive from mains

(flip the circuit breaker or pull fuses).

2. Wait for at least 5 minutes for discharge of the

DC-link capacitors.

3. Remove motor (compressor) cable.

1.7 ESD Precautions

A variable speed drive is a sensible electronic device.

Electrostatic discharge (ESD) can cause a malfunction or

destroy the frequency converter. Do not touch

components on the printed circuit board (PCB). When

handling the drive make sure that necessary ESD

precautions are taken, i.e. wearing wrist straps, using antistatic mats etc.

1.8 Product Identification

A product identification label is placed on the drive

chassis. It carries the ordering code i.e. 76L7002. The last 3

digits of the numeric string indicate the production date,

i.e. 062 means week 6 in 2012. Do not remove the identification label from the drive (loss of warranty).

Avoid unintended start

While the variable speed drive is connected to mains, the

motor (compressor) can be started/stopped using serial

communication commands.

- Disconnect the frequency converter from mains

whenever personal safety considerations make it

necessary to avoid unintended start.

1.5

Disposal Instruction

Equipment containing electrical

components may not be disposed

together with domestic waste.

It must be separately collected with

electrical and electronic waste according

to local and valid legislation.

Illustration 1.1 Product Identification Label

1.9 Unpacking the Drive

NOTE

To avoid damage to the drive caused by electrostatic

discharge, people handling the drive should wear wrist

traps for proper grounding at all time!

MG10V402 - VLT® is a registered Danfoss trademark 5

Page 10

General

VLT® Inverter Scroll CDS 801 Operating Instructions

11

1.10 Table of Abbreviations

VSD Variable speed drive

VFD Variable frequency drive, also used instead of VSD

EMC Electromagnetic compatibility

RCD Residual current device

SELV Safety extra low voltage

ESD Electrostatic discharge

PCB Printed circuit board

AWG American wire gauge

EEV Electronic expansion valve

RTU Remote terminal unit

OEM Original equipment manufacturer

AC Air-conditioning

HP Heat pump

RLA Rated load amperage

AOC Application oriented controller

MOC Motor oriented controller

Table 1.2 Abbreviations

6 MG10V402 - VLT® is a registered Danfoss trademark

Page 11

196 mm/7.7 in

374 mm/

14.7 in

175ZB032.13

394 mm/15.5 in

216 mm/8.5 in

255 mm/10 in

98 mm/

3.8 in

Mechanical Installation

2 Mechanical Installation

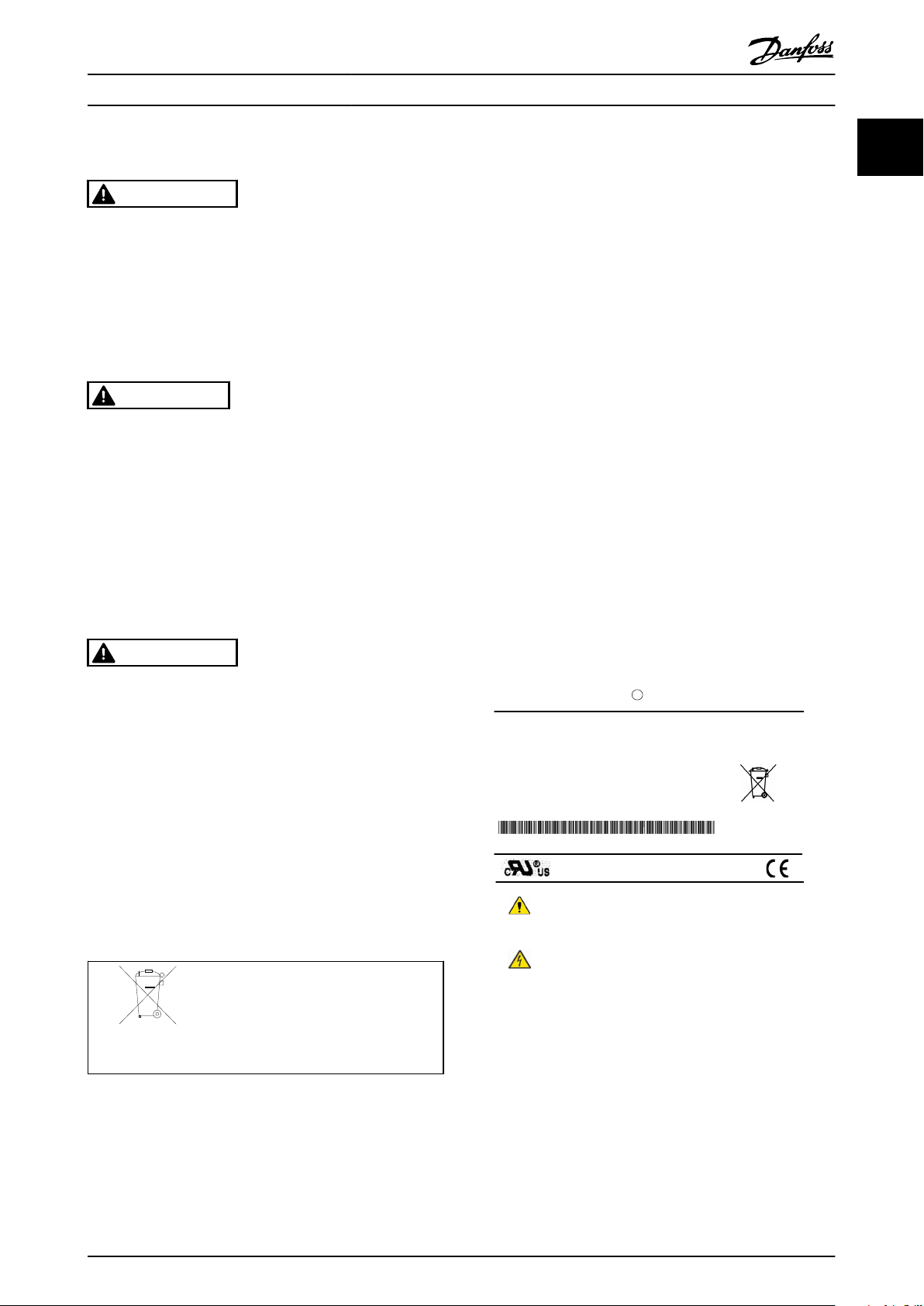

2.1 Dimensions and Weight

VLT® Inverter Scroll CDS 801 Operating Instructions

2 2

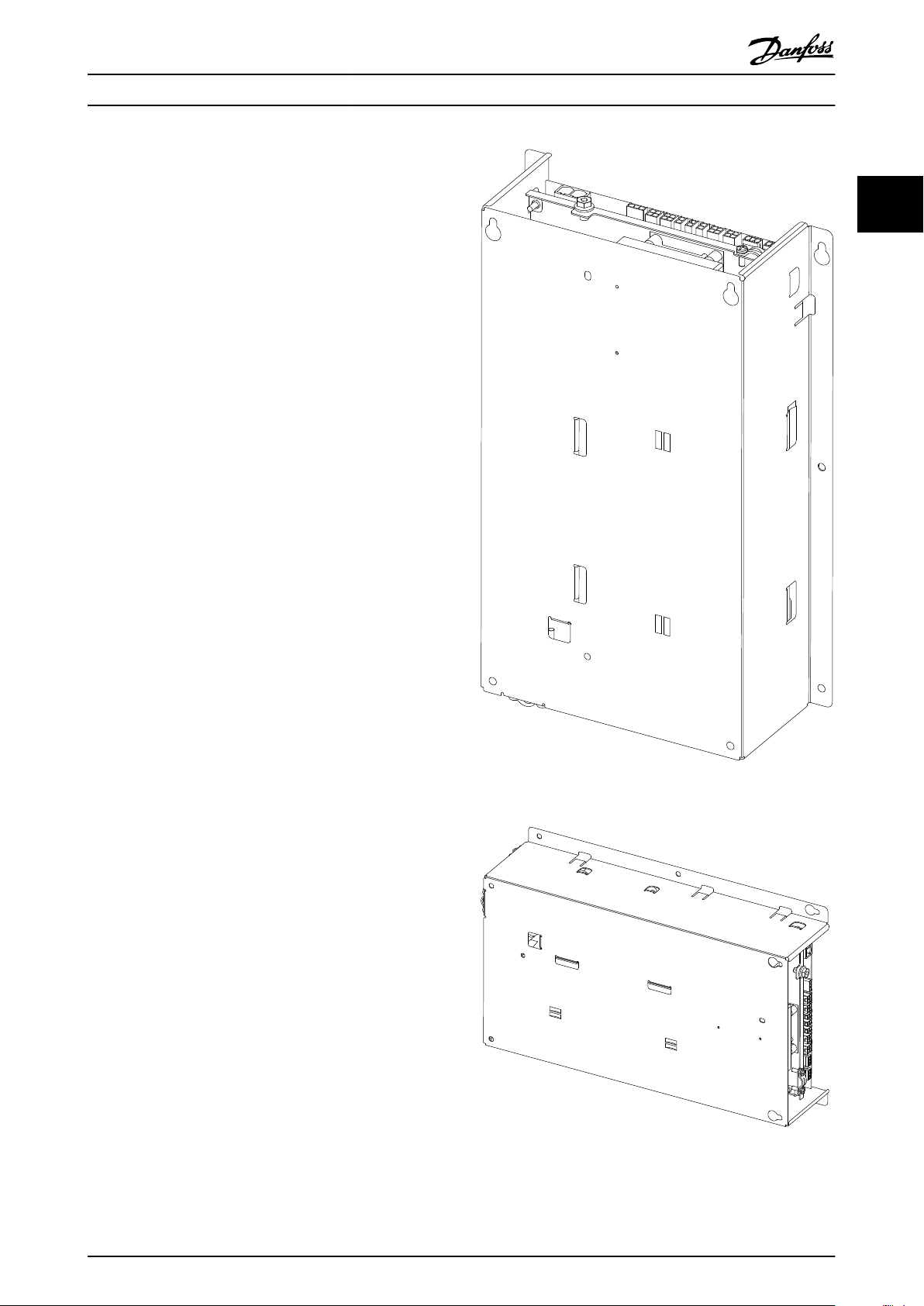

Illustration 2.1 Dimensions

MG10V402 - VLT® is a registered Danfoss trademark 7

Page 12

236 mm/9.3 in

216 mm/8.5 in 394 mm/15.5 in

180 mm/

7.1 in

98 mm/

3.8 in

175ZB031.13

255 mm/10 in

180 mm/

7.1 in

Mechanical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

22

Illustration 2.2 Dimensions

Mounting holes: ¼ inch, Ø 6 mm

Weight: 10.3 lbs/5.5 kg

8 MG10V402 - VLT® is a registered Danfoss trademark

Page 13

175ZB036.10

175ZB037.10

Mechanical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

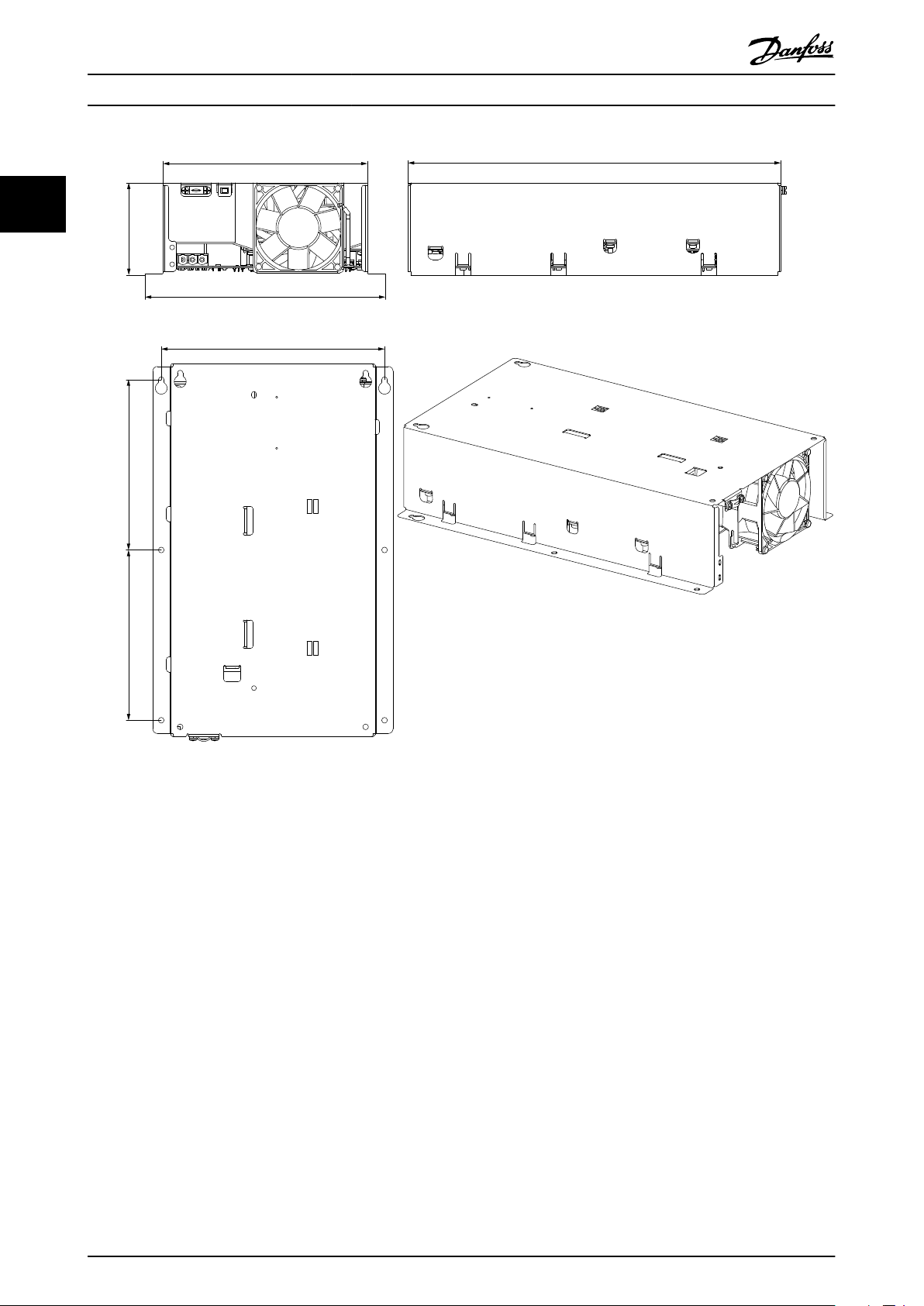

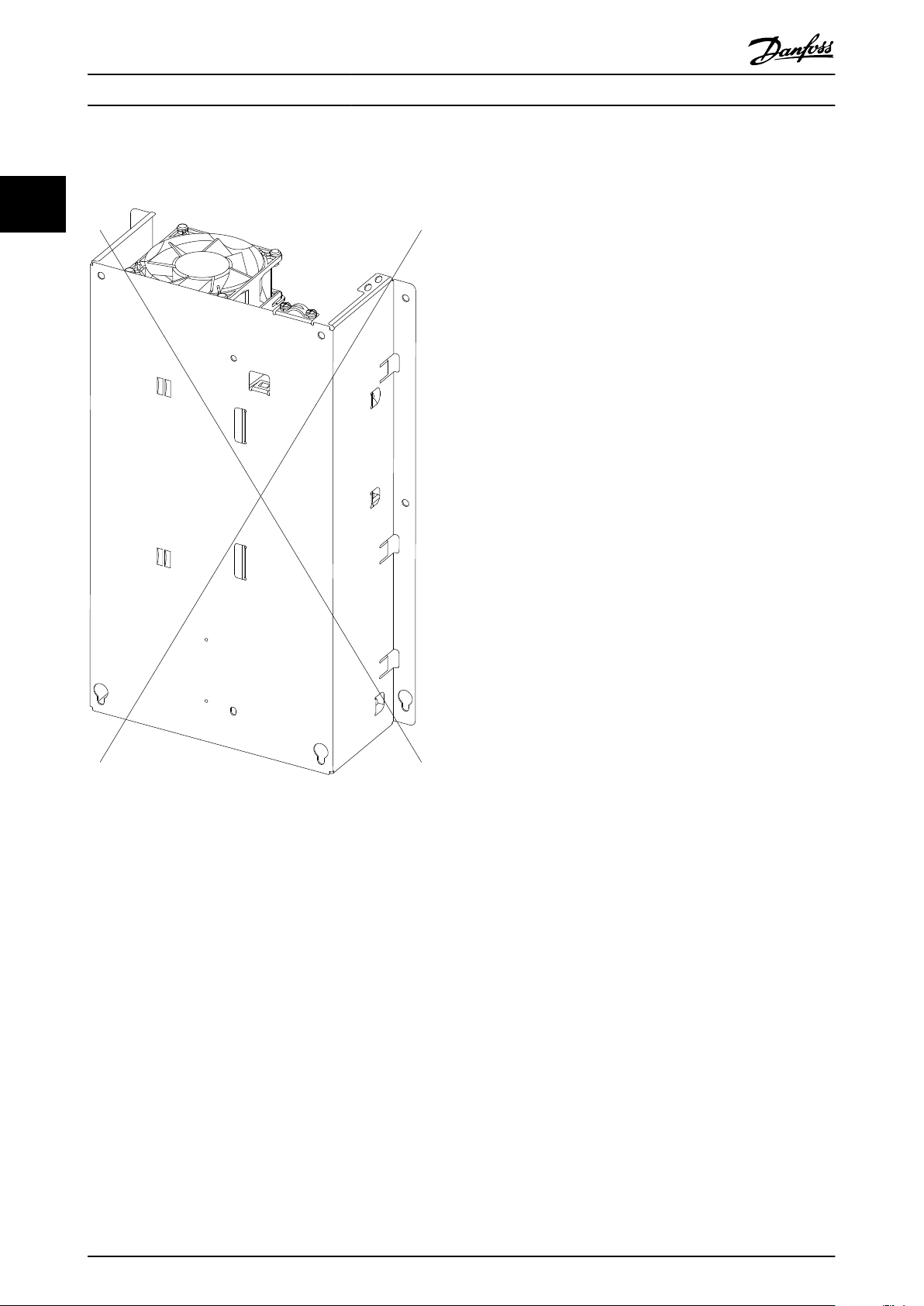

2.2 Installation Orientation and Clearances

2.2.1 Surface Mounting

The drive can be installed horizontally (see Illustration 2.4)

or vertically (see Illustration 2.3) on any plain surface with

the PCB pointing towards the surface. Typically, the 6

mounting holes in the side flaps of the chassis are used for

installation.

For vertical installation, the upper two mounting holes can

be used as suspension holes.

NOTE

If the drive is installed on a sheet metal surface, the

clearance between the drive PCB and the mounting

surface must be observed. As a minimum, sheet metal

gauge 22, 33/1000 inch or 1 mm should be used. If

electrical contact with the mounting surface can not be

avoided an additional isolation foil should be used.

2 2

NOTE

For outdoor units, do not install the drive horizontally with

the PCB in the top or bottom. Water condensing on the

PCB cannot be properly drained.

Illustration 2.3 Horizontal Orientation

Illustration 2.4 Vertical Orientation

MG10V402 - VLT® is a registered Danfoss trademark 9

Page 14

175ZB038.12

Mechanical Installation

To avoid insufficient cooling, do not install the drive with

the cooling fan in the top, see Illustration 2.5.

VLT® Inverter Scroll CDS 801 Operating Instructions

22

Illustration 2.5 Wrong Drive Orientation

10 MG10V402 - VLT® is a registered Danfoss trademark

Page 15

175ZB041.10

175ZB042.10

Mechanical Installation

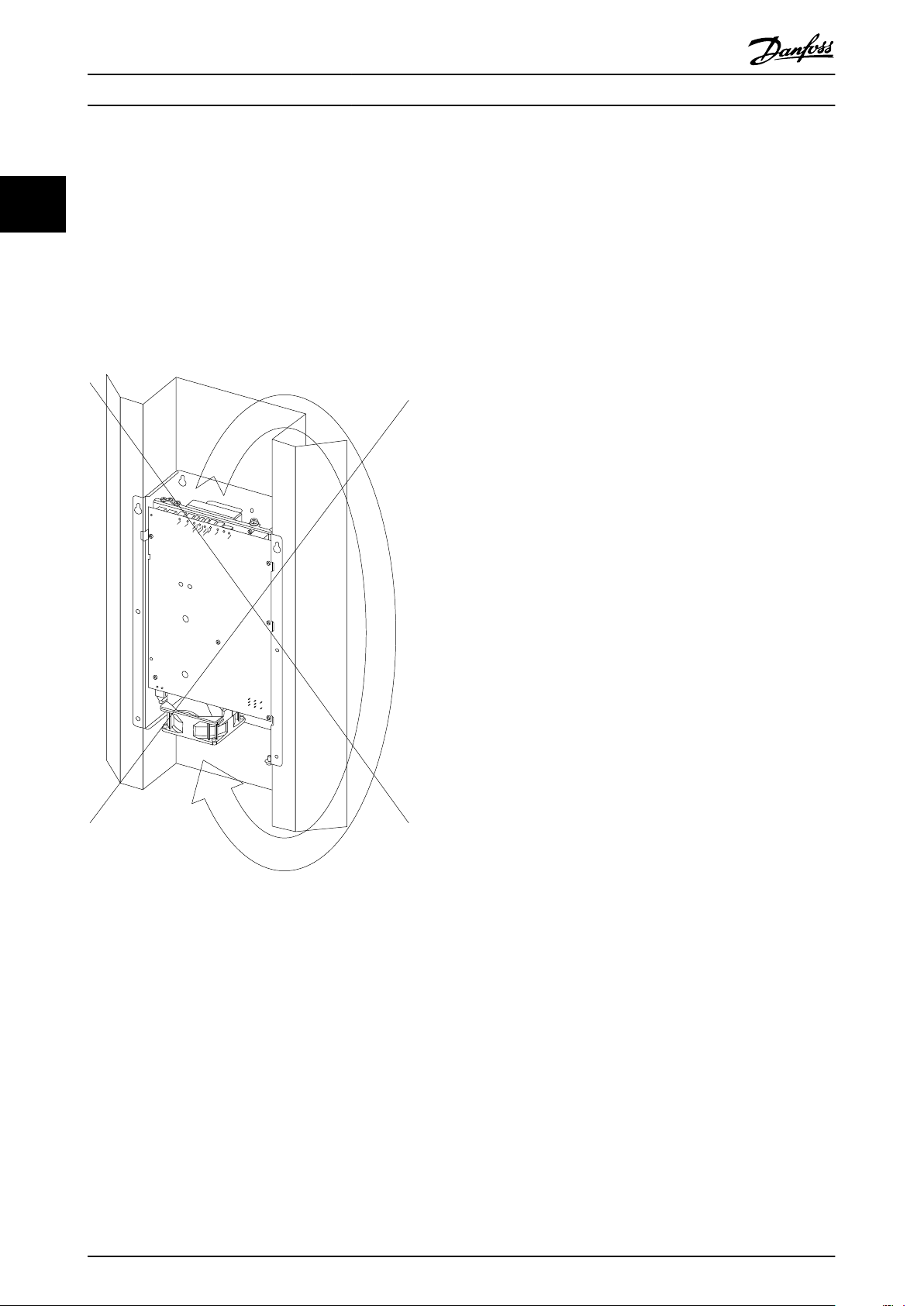

2.2.2 Structural Mounting

VLT® Inverter Scroll CDS 801 Operating Instructions

The drive can be integrated in any kind of mechanical

structure of air conditioning equipment Illustration 2.6 and

Illustration 2.7.

2 2

Illustration 2.7 Horizontal Installation in Mechanical Structure

CAUTION

During mechanical installation of the drive make sure that

no screws can touch electrical parts on the PCB. Screws

touching the electrical parts on the PCB can cause

personal injury and product damage.

Illustration 2.6 Vertical Installation in Mechanical Structure

MG10V402 - VLT® is a registered Danfoss trademark 11

Page 16

175ZB043.10

Mechanical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

2.3 Air Circulation/Cooling

2.5

The drive must be installed in a way that allows for free

22

airflow. However short circuiting the airflow (warm air reentering the drive’s cooling fan) must be avoided (see

Illustration 2.8). A clearance of 5 inches (12.7 cm) must be

observed in both ends of the drive chassis. Install the drive

in a location where coldest possible air can be drawn into

the drive, i.e. from the bottom part of an outdoor unit.

Counter flow (static pressure) must not restrict the

operation of the internal cooling fan of the drive.

Vibration and Mechanical Resonances

The mechanical structure (sheet metal) carrying the drive

must be designed to withstand vibration and consequently

resonances induced by the compressor or condenser fan.

See vibration specification for the drive further down this

document.

Also refer to 6.3.5.8 Frequency Cancelation explaining the

possibility to program bypass frequencies in the drive to

avoid mechanical resonances of the structure.

Illustration 2.8 Wrong Drive Airflow

2.4

Condensation and Dripping Water

The printed circuit board assembly of the drive is

conformally coated and thus sufficiently protected against

condensation during off time. Nevertheless, the drive

should not be exposed to dripping water (rain) or

condensing water slung around by the condenser fan. In

outdoor units, it is recommendable to install the drive in a

rain proof compartment.

12 MG10V402 - VLT® is a registered Danfoss trademark

Page 17

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3 Electrical Installation

3.1 Electrical Connection in General

NOTE

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. Copper conductors required.

3.2 Tightening Torque

Power supply plug terminals 1.5 Nm/1.1 lbf ft

Ground screw 3.0 Nm/2.2 lbf ft

Motor plug (compressor) 1.5 Nm/1.1 lbf ft

EMC clamp for motor cable 1.5 Nm/1.1 lbf ft

Proper temperature rating of the cable must be observed.

In installations with ambient temperatures above 30 °C

maximum current derating applies, therefore hightemperature cable with 90 °C conductor temperature, e.g.

Nexans Rheyflex is recommended. Copper type cable only.

Maximum cable length 2 m.

Cable specification for installations in North America:

3-wire cable, minimum cross section AWG 10, voltage

rating 600 V, temperature rating 221 °F/105 °C, 2/64

moisture resistant UL style 1230 standard bare copper

type. In North America, standards for radiated emission are

currently not enforced. Furthermore, FCC parts 15

regulations explicitly exempt air-condition devices.

Maximum cable length 7 ft. Local compressor grounding.

3

3

Table 3.1 Tightening Torque

3.3 Cable Quality and Dimensioning

Power supply cable

There is no need for using shielded cable for the supply of

the variable speed drive.

Motor cable

The cable from the drive to the compressor (motor) must

be shielded to comply with EMC regulations for conducted

and radiated emissions in accordance with EN 55011 class

A and EN 55014 (with ferrite). A proper ground connection

of the shield in both ends is essential to obtain the best

suppression of emissions. See also 3.6 Electrical

Connections.

Power Supply Cable Specification

Power connections must be made in accordance with local

and national codes. 2-wire cable plus ground conductor,

minimum AWG 10, voltage rating minimum 300 V,

minimum temp. rating 105 °C/221°F

Min. circuit ampacity

4 t unit 35 A

5 t unit 40 A

Table 3.2 Power-supply Cable Specificatoin

Motor Cable Specification

Depending on the desired level of EMC compliance

according to European or North American standards for

radiated emissions such as EN 55014/55011 or FCC part 15,

a suitable cable connection drive and compressor must be

selected. It is recommended to use shielded cable under

all circumstances.

Cable specification for installations in the EU:

4-wire cable with protective earth (PE) and shield (min 80%

coverage), minimum cross section 4 mm2 for 13 kW units

and 6 mm2 for 16 and 20 kW units, voltage rating 600 V.

3 t unit 30 A

Min. circuit ampacity 13 kW/3 t unit 30 A

16 kW/4 t unit 35 A

20 kW/5 t unit 40 A

Table 3.3 Motor Cable Specification

Sensor and Transmitter Cables

Refer to the documentation provided with the Danfoss

sensors and transmitters.

For serial communication connections, see 4 Serial

Communication (Modbus RTU).

3.4

Fuses/Circuit Breakers

Branch circuit protection

To protect the installation against electrical and fire hazard,

all branch circuits in an installation must be short-circuited

and over-current protected according to national and local

regulations.

Short circuit protection

Danfoss requires using the fuses mentioned in Table 3.4 to

protect service personnel or other equipment in case of an

internal failure in the unit or short-circuit on DC-link of the

drive. The variable speed drive provides full short circuit

protection in case of a short-circuit on the motor output in

accordance with UL regulations.

Over-current protection

Overload protection must be provided to avoid

overheating of the cables in the installation. Over-current

protection must always be carried out according to

national regulations (NEC Article 430 “Motors, Motor

Circuits and Controllers” and NEC Article 440 “Airconditioning and refrigeration equipment”).

MG10V402 - VLT® is a registered Danfoss trademark 13

Page 18

Electrical Installation

Fuses

13 kW/3 t unit 176L0767 RLA 22A max. fuse amperage 30 A

16 kW/4 t unit 176L0766 RLA 28A max. fuse amperage 35 A

20 kW/5 t unit 176L0765 RLA 33A max. fuse amperage 40 A

VLT® Inverter Scroll CDS 801 Operating Instructions

3

Table 3.4 Fuses

NOTE

Fuses of type class RK5 must be used in US installations.

Recommended circuit breakers

HVCR type fusible circuit breaker may be used, see rating

above.

3.5 EMC Correct Installation

Follow these guidelines when compliance with EN 55011

cl. A or EN 55014 is required.

Good engineering practice to ensure EMC-correct electrical

installation:

Use only shielded/braided screened/armored

•

motor cables and control cables. The shield

should provide a minimum coverage of 80%. The

shield material must be metal, not limited to but

typically copper, aluminum, steel or lead. There

are no special requirements for the mains cable.

Connect the shield to ground at both ends for

•

motor cables and control cables.

Avoid terminating the shield with twisted ends

•

(pigtails). Such a termination increases the high

frequency impedance of the screen, which

reduces its effectiveness at high frequencies. Use

low impedance cable clamps (delivered with the

drive) and EMC glands instead.

Ensure good electrical contact between the de-

•

coupling plate and the metal chassis of the

variable speed drive.

Where possible, avoid using unshielded/

•

unarmored motor or control cables inside

cabinets housing the drive.

14 MG10V402 - VLT® is a registered Danfoss trademark

Page 19

175ZB044.10

175ZB045.10

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6 Electrical Connections

3.6.1 Routing of Motor and Supply Cable

Do not route supply, sensor and communication cables in

parallel with the motor cable. Separate cables from each

other as much as possible (see Illustration 3.2).

Furthermore, the motor cable should be kept as short as

possible.

Do not route cables across the PCB (see Illustration 3.1).

3

3

Illustration 3.1 Wrong Routing of Motor and Supply Cables

Illustration 3.2 Cable Separation

MG10V402 - VLT® is a registered Danfoss trademark 15

Page 20

175ZB052.11

L1

L2/N

T1

C

T3

A

T2

B

T1

C

T3

A

T2

B

130ZB122.10

T

3

T

1

T

2

R

C

S

175ZB047.10

3

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6.2 Power Supply Connection (Mains)

1. Connect the ground cable.

2.

Connect L2 or L1 and N, see Illustration 3.3.

Mains cables must be dimensioned according to national

and local standards.

Illustration 3.3 Power Supply Connections

Motor (Compressor) Connection

3.6.3

Danfoss offers different compressor models according to

the desired level of EMC compliance for radiated

emissions. Compressors for installations in the EU have a

rectangular terminal box with provision for using EMC

gland sets for shielded cable, while the models for installations in North America have a round shaped terminal

box (see Illustration 3.4 and Illustration 3.5).

The order of phases is inevitable in both cases. Always

connect T1 on the drive with T1 on the compressor and T2

and T3 accordingly, see Illustration 3.7.

Observe maximum current ratings for spade type angular

cable connectors according to manufacturer’s product

data.

Illustration 3.4 Motor (Compressor) Connection, EU Models

EU models:

The terminal box provides punch outs on the right side for

25 mm glands and in the bottom for 28 mm glands.

Connect wires for T1, T2, T3 and ground (PE) inside the

terminal box and install EMC cable gland set accordingly.

NAM models:

Connect wires for T1, T2, T3 and local grounding.

Illustration 3.5 Motor (Compressor) Connection, NAM Models

16 MG10V402 - VLT® is a registered Danfoss trademark

Page 21

C

UP

T1

R

T3

T2

S

175ZB132.10

175ZB046.11

T3 T2 T1

130ZB123.10

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3

3

Illustration 3.6 Connection Box, Europe/Asia

Illustration 3.7 Motor (Drive) Connection

Use of Ferrite on drive output terminals:

To comply with the most stringent standard for radiated

emissions (EN 55011 cl. B) a ferrite must be installed at the

output terminals of the drive as shown in Illustration 3.8.

The motor phase wires (T1, T2, T3) must be wound twice

around the ferrite, while the PE wire is directly connected

to the chassis, see Illustration 3.8.

Illustration 3.8 Wire Routing on Ferrite

MG10V402 - VLT® is a registered Danfoss trademark 17

Page 22

175ZB048.11

P_C

P_O

S_D

S_AUX

S_AMBIENT

175ZB049.11

RLY_1

175ZB051.11

EXT_FAN

175ZB099.11

EEV_2

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3

3.6.4 Sensor Connections

Connect the sensors as marked on the PCB, see

Illustration 3.9:

Aux. temperature sensor (S aux.) (if applicable)

Compressor discharge temperature (Sd)

Ambient temperature (S amb.)

Compressor suction pressure (P0)

Compressor discharge pressure (Pc)

Condenser Fan Motor Control

3.6.6

Connection (EXT_FAN)

Two different control signals are available, 0-10 V (max.

current 20 mA) analogue output and 24 V PWM duty cycle

with scalable frequency, see Modbus register description in

5 Commissioning. Connect the control signal of the

condenser fan (or any other external device like a

circulator pump) as shown and marked on the PCB, see

Illustration 3.11.

Illustration 3.9 Sensor Connections

4-way Reversing Valve Connection

3.6.5

The relay for the 4-way reversing valve is connected as

shown and marked on the PCB, see Illustration 3.10.

Max. load:

250 V AC, 4 A

24 V DC, 4 A

See 3.6.10 Allocation of Connector Pins.

Illustration 3.10 4-way Reversing Valve Connection

Illustration 3.11 Condenser Fan Motor Control Connection (EXTFan)

EEV Controller (HP Mode) Connection

3.6.7

(EEV_2)

Connect the EEV Controller as shown and marked on the

PBC, see Illustration 3.12.

Illustration 3.12 EEV_2 Controller Connection

18 MG10V402 - VLT® is a registered Danfoss trademark

Page 23

175ZB024.12

Shield

MASTER

EEV_1

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6.8 Serial Communication Cable Connection

Connect the RS-485 cable(s) to the PCB of the Variable Speed Drive as follows, see Illustration 3.13:

1. Attach the positive (+) polarity wire to the screw terminal.

2. Attach the negative (-) polarity wire to the screw terminal.

3. Attach the drain cable to the drain terminal (D).

4. Attach the cable with the shield to the compression clamp on the chassis.

5. Connect the other end of the RS-485 cable to the OEM Controller ensuring that the polarity of the wires matches

the polarity at the drive.

The two 3-pole connectors are marked on the circuit board as “Master” which connects to the OEM Controller, and “EEV_1”

which connects to the indoor EEV Controller (separate internal Danfoss bus).

The compression clamp is suitable to two sets of cable. Make sure to establish a good connection between the shield and

the compression clamp and the chassis.

3

3

Illustration 3.13 Serial Communication Connection Cable

When selecting a transmission line for RS-485, it is necessary to examine the required distance of the cable and the data

rate of the system. Losses in a transmission line are a combination of AC losses (skin effect), DC conductor loss, leakage, and

AC losses in the dielectric. In high-quality cable, the conductor losses and the dielectric losses are on the same order of

magnitude.

The recommended maximum Modbus cable length between the drive and the OEM Controller should not exceed 100 ft (30

m).

While the RS-485 specification does not specify cabling, the recommendation is 24 AWG shielded twisted-pair cable with a

shunt capacitance of 16 pF/ft and 100 Ω impedance.It is also possible to use the same cable commonly in the twisted-pair

Ethernet cabling. This cable is commonly referred to as Category 5 cable. The cable has a maximum capacitance of 17 pF/ft

(14.5 pF/ft typical) and characteristic impedance of 100 Ω.

MG10V402 - VLT® is a registered Danfoss trademark 19

Page 24

175ZB055.10

175ZB033.10

175ZB054.10

175ZB034.10

175ZB056.10

3

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6.9 Connector Specification

All counterpart plugs listed in Table 3.5 are of female type, all connectors installed on the PCB are of male type.

Connector Poles Manufacturer Type Color Remarks

Supply (L1,L2) 2 Phoenix Contact PC 16/2-ST-10,16 Green Marked L1, L2

Motor (T1, T2,T3) 3 Phoenix Contact PC 16/3-ST-10,16 Green Marked T1, T2, T3

Indoor EEV Controller (EEV_1) 3 Dinkel EC381R-4620-03P Green Marked RS-485, +, -, D

Modbus Master bus (MASTER) 3 Dinkel EC381R-4620-03P Green Marked RS-485, +, -, D

Outdoor EEV Controller (EEV_2) 4 Molex 39-01-2040 White

Condenser fan speed ref. (EXT_FAN) 4 Molex 39-01-2040 White

Ambient temperature (S_AMBIENT) 2 Molex 39-01-2020 White

Auxiliary temperature (S_AUX) 2 Molex 39-01-2020 White

Compressor discharge temp. (S_D) 2 Molex 39-01-2020 White

Compressor suction pressure (P_0) 4 Molex 39-01-2040 White

Compressor discharge pressure (P_C) 4 Molex 39-01-2040 White

Reversing valve relay (RLY_1) 3 Molex 39-01-4030 White

Cooling fan (INT_FAN) 3 Molex 39-01-4030 White

Crimping contact Manufacturer Type

All connectors Molex 39-00-0213

Alternative manufacturer see manuf. reference lists

Table 3.5 Connector Specification

Illustration 3.14 2-pole Connector

Illustration 3.15 3-pole Connector

Illustration 3.16 4-pole Connector

Illustration 3.17 Bus Connector

20 MG10V402 - VLT® is a registered Danfoss trademark

Illustration 3.18 Crimping Contact

Page 25

12

34

1 12

2

1

2

1

234

12

34

1 12 2

3

3

4

EEV_2

1 Ground

2 + (RS485)

3 - (RS485)

4 +24V

EXT_FAN

1 Ground

2 0-10V

3 PWM

4 not used

S_AMBIENT, S_AUX, S_D

1 PT1000

2 PT1000

P_O

1 Ground

2 Signal

3 +5V

4 not used

P_C

1 Ground

2 Signal

3 +5V

4 not used

RLY_1

1 NC

2 COM

3 NO

175ZB057.10

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6.10 Allocation of Connector Pins

The position of the connector pins for sensors, transmitters, serial communication, etc. is shown in Illustration 3.19.

NOTE

All connections are seen from the cable side

Illustration 3.19 Allocation of Connector Pins

3

3

MG10V402 - VLT® is a registered Danfoss trademark 21

Page 26

Main power supply

208-230V 60 Hz

distribution

Condenser

fan motor

i.e. ECM 142

High-pressure

switch

Safety

circuit

breaker

Fuse

Fuse

Optional

Not scope of Danfoss delivery

Compressor,

order of phases

must be observed!

T1

T1

T2

T2

T3

T3

Chassis

L1 L2

Modbus serial

communication

with OEM controller

Modbus serial

communication

with indoor EEV

controller

EEV_1

EEV_2

MASTER

EXT_FAN

S_AMBIENT

S_AUX

S_D

P_O

P_C

RLY_1

Inverter PCA

Outdoor unit

Indoor unit

Indoor unit

temp. sensor

PT 1000(S2)

Schematic Wiring Diagram

Air-Conditioning System

Agenda:

Low voltage

High voltage

Prefabricated cable

Screended cable

Power supply

indoor EEV

controller

18-30 v AC/DC

EEV

Outdoor

unit

EEV

Controller

OEM

Controller

(Thermostat)

Ambient temperature

sensor PT 1000(S. amb.)

Compr. dischange temp.

sensor PT 1000(Sd)

Compressor suction

pressure sensor (Po)

Compressor discharge

pressure sensor (Pc)

Aux. temperature

sensor PT 1000

175ZB100.10

3

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3.6.11 Overview Wiring Diagram

The following 3 wiring diagrams show typical system configurations for an AC system (see Illustration 3.20), a combined

AC/HP system (see Illustration 3.21) and a ground source heat pump system (see Illustration 3.22), with all Danfoss

components.

Illustration 3.20 AC only System

22 MG10V402 - VLT® is a registered Danfoss trademark

Page 27

Main power supply

208-230V 60 Hz

distribution

Condenser

fan motor

i.e. ECM 142

High-pressure

switch

Not scope of Danfoss delivery

Compressor,

order of phases

must be observed!

Modbus serial

communication

with OEM controller

Modbus serial

communication

with indoor EEV

controller

Inverter PCA

Outdoor unit

Ambient temperature

sensor PT 1000(S. amb.)

Compr. dischange temp.

sensor PT 1000(Sd)

Compressor suction

pressure sensor (Po)

Compressor discharge

pressure sensor (Pc)

Aux. temperature

sensor PT 1000

T1

T2

T3

T1

T2

T3

L1 L2

EEV_1

EEV_2

MASTER

EXT_FAN

S_AMBIENT

S_AUX

S_D

P_O

P_C

RLY_1

Safety

circuit

breaker

Chassis

Fuse

Fuse

Optional

Indoor unit

Indoor unit

temp. sensor

PT 1000(S2)

Schematic Wiring Diagram

Combined Air-Conditioning

and Heat Pump System

Agenda:

Low voltage

High voltage

Prefabricated cable

Screended cable

Power supply

indoor EEV

controller

18-30 v AC/DC

175ZB101.10

EEV

Outdoor

unit

EEV

Controller

EEV

Outdoor

unit

EEV

Controller

OEM

Controller

(Thermostat)

4-way

reversing

valve

Coil

supply according

to coil

i.e. 230 or 24VAC

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

3

3

Illustration 3.21 Combined AC/HP System

MG10V402 - VLT® is a registered Danfoss trademark 23

Page 28

Main power supply

208-230V 60 Hz

distribution

High-pressure

switch

Not scope of Danfoss delivery

Compressor,

order of phases

must be observed!

Safety

circuit

breaker

4-way

reversing

valve

Coil

L1 L2

Chassis

T1

T2

T3

T1 T2 T3

Inverter PCA

EEV_1

EEV_2

MASTER

EXT_FAN

S_AMBIENT

S_AUX

S_D

P_O

P_C

RLY_1

Modbus serial

communication with

EEV controller

Modbus serial

communication with

OEM controller

Compact unit

Schematic Wiring Diagram

Combined Air-Conditioning

and ground source Heat

Pump System

Agenda:

Low voltage

High voltage

Prefabricated cable

Screended cable

175ZB102.12

Indoor unit

temp. sensor

PT 1000(S2)

EEV

unit

EEV

Controller

OEM

Controller

(Thermostat)

Ambient temperature

sensor PT 1000(S. amb.)

Compr. discharge temp.

sensor PT 1000(Sd)

Compressor suction

pressure sensor (Po)

Compressor discharge

pressure sensor (Pc)

Aux. temperature

sensor PT 1000

supply according

to coil type

i.e. 230 or 24VAC

3

Electrical Installation

VLT® Inverter Scroll CDS 801 Operating Instructions

Illustration 3.22 Ground Source Heat Pump System with one EEV

24 MG10V402 - VLT® is a registered Danfoss trademark

Page 29

OEM

Controller,

Modbus

Master

Indoor EEV

Controller for

AC operation

Modbus node #165

RS 485

Interfaces

Application control

Microprocessor

Modbus node #162

Motor control

Microprocessor

Modbus node #163

Outdoor EEV

Controller for

Heatpump operation

Modbus node #164

Drive PCB

Internal bus

Outdoor sectionIndoor section

175ZB023.12

Serial Communication (Modbu...

VLT® Inverter Scroll CDS 801 Operating Instructions

4 Serial Communication (Modbus RTU)

General

The serial communication bus is used to receive Modbus Slave Messages from an external source. In normal operation, this

will be a Modbus Master usually called the “OEM Controller”. When not in service, the OEM or manufacturing can access the

device for configuration or service, see Illustration 4.1 and Illustration 4.2.

NOTE

The Modbus communication is available after the drive has performed an internal test routine, approximately 15 seconds

after power up.

The Modbus implementation has been designed to conform to the Modbus Standard Protocol.

For details, refer to

Modbus Application Protocol Specification, V1.1b

•

Modbus Over Serial Line Specification and Implementation Guide, V1.02

•

Modicon Modbus Protocol Reference Guide

•

PI–MBUS–300 Rev. J

4 4

Also visit www.modbus.org

For details about setting up the Modbus serial communication, refer to the Modbus RTU Communication Setup Manual.

Illustration 4.1 Modbus Communication Set-up, for AC only, and Combined AC/HP Systems

MG10V402 - VLT® is a registered Danfoss trademark 25

Page 30

OEM

Controller,

Modbus

Master

EEV

Controller

Modbus node #165

RS 485

Interfaces

Application control

Microprocessor

Modbus node #162

Motor control

Microprocessor

Modbus node #163

Drive PCB

Internal bus

175ZB129.10

Serial Communication (Modbu...

VLT® Inverter Scroll CDS 801 Operating Instructions

44

Illustration 4.2 Modbus Communication Set-up for Ground Source Heat Pump Systems

26 MG10V402 - VLT® is a registered Danfoss trademark

Page 31

Commissioning

VLT® Inverter Scroll CDS 801 Operating Instructions

5 Commissioning

5.1 Initial Configuration of the Performer

VSD sub-system

System components offered by the OEM, such as outdoor

units, indoor units/air handlers, evaporator modules or

furnaces are often manufactured in different locations and

first merged into a complete system at the end user’s site.

Furthermore, numerous combinations of such components

are feasible. Therefore it is extremely important to prepare

the components during manufacturing for a late merge in

the field.

Alternatively, the configuration of each individual

component can be made in the field. This can be done

with Danfoss Update tool or Modbus tool allowing

programming the drive, application controller and EEV

Controller via the serial communication interface (Modbus

RTU).

This functionality can also be incorporated in the OEM

Controller by establishing a protected service menu,

allowing accessing all Modbus registers.

Individual solutions can be worked out in cooperation with

the product support team.

5.2

Drive Setup

The variable speed drive including the embedded

application controller and the EEV Controller(s) can be

individually configured by setting various parameters

(Modbus registers). This manual is limited to the drive

parameters. For the application controller and the EEV

Controller(s), refer to the separately provided documentation.

NOTE

Changing the setting of some registers requires re-booting

before the setting becomes effective. For details, refer to

the Modbus RTU Communication Setup Manual.

The timeouts and response times of Modbus messages to

and from the drive is in accordance with the Modbus

standard.

5.2.1

Drive Parameters

(Modbus Registers, node 162)

Register 40001-40010, PCA Bar Code (read only)

These registers (10) allow reading the bar code information

on the PCA, which is also found on the product identification label on the drive chassis.

Register 40011-40020, Ordering code (read only)

These registers (10) allow reading the Danfoss ordering

code, which is also found on the product identification

label on the drive chassis, typically starting with 176L…..

Register 40021 and 40022, Operation Time Counter (read

only)

These registers allow reading the accumulated time the

drive has been powered. The value is given in seconds.

Register 40101-40110, AOC Software Version (read only)

These registers (10) allow reading the software version

number for the application oriented microprocessor.

Register 40111-40120, AOC Registers Version (read only)

These registers (10) allow reading the registers version

number for the application oriented microprocessor.

Register 40121 and 40122, Drive Status

These registers describe the exact operation condition of

the system in a 32 bit structure. See separate description

in 7 Fault Conditions, Messages and Causes.

Register 40131, OEM Reset

Setting this register to logic “1” resets the drive to the

OEM defaults (configuration defaults set by the OEM in

production) stored in the EEPROM.

Register 40132, Danfoss Reset

Setting this register to logic “1” resets the drive to the

Danfoss defaults (factory defaults as listed in this manual

and Modbus register map files)

Register 40133, Overwrite Defaults

Setting this register to logic “1” allows overwriting the

factory defaults. This should only be done with assistance

from Danfoss.

NOTE

Do not set registers 40132 and 40133 to logic “1” at the

same time.

5 5

In the following chapters, the drive parameters are

described by the register number.

MG10V402 - VLT® is a registered Danfoss trademark 27

Page 32

Commissioning

VLT® Inverter Scroll CDS 801 Operating Instructions

Register 40134, Test Register

This register has been created as a test tool to verify

proper Modbus communication. To test the communication, write any value between 0 and 65535 to the

register and verify that the same value is successfully

reported back from the slave node (drive).

Register 40135, Drive Reboot

Setting this register to logic “1” initiates a reboot

sequence; this equals cycling power to the drive.

Register 40141, OEM baud rate (default 19200)

This register allows setting the baud rate for the Modbus

55

serial communication.

Value

0 9600 kbps

1 19200 kbps

Register 40146, EEV Indoor Unit Address (def. 165, min 1,

max 247)

This register allows setting the bus address (node address)

of the EEV Controller in the indoor unit. The default

address is 165 and can be set to a value between 1 and

247.

NOTE

Must be set to the same value on EEV Controllers.

Register 40147, EEV Outdoor Unit Address (def. 164, min 1,

max 247)

This register allows setting the bus address (node address)

of the EEV Controller in the outdoor unit (if applicable, in

systems with 2 EEV’s only). The default address is 164 and

can be set to a value between 1 and 247.

NOTE

Table 5.1 OEM Baud Rate

Register 40142, OEM Parity

This register allows setting the Parity of the Modbus

protocol.

Value

0 None

1 Odd

2 Even (default)

Table 5.2 OEM Parity

Register 40143, OEM Stop Bits

This register allows setting the number of stop bits of the

Modbus protocol.

Value

1 1 stop bit (default)

2 2 stop bits

Must be set to the same value on EEV controllers.

Register 40148, OEM Communication Timeout (def. 20 sec,

min 0 sec, max. 3600 sec)

The time set in this register determines the duration from

loosing communication with the OEM controller to

stopping the system. When communication is reestablished, the drive will resume operation automatically.

Setting this register to 0 sec. means that the drive will not

stop in case of loosing communication.

Registers 40499 and 40500, Sensor S_AUX

These registers allow reading the temperature reading of

the auxiliary sensor input S_AUX in degrees centigrade

(°C); in case a PT 1000 sensor is connected.

Register 40501-40550, OEM Data registers

Danfoss has established 50 OEM registers that the OEM

customer can use freely to store product information. All

registers are of type unsigned 16.

Drive Parameters

Table 5.3 OEM Stop Bits

5.2.2

(Modbus Registers, node 163)

Register 40144, Drive AOC Address (def. 162, min 1, max

247)

This register allows setting the bus address (node address)

of the application oriented microprocessor of the drive.

The default address is 162 and can be set to a value

between 1 and 247.

Register 40145, Drive MOC Address (def. 163, min 1, max

247)

This register allows setting the bus address (node address)

of the motor oriented microprocessor of the drive. The

default address is 163 and can be set to a value between 1

and 247.

NOTE

The same address must be set in MOC register 40145.

28 MG10V402 - VLT® is a registered Danfoss trademark

Register 40101-40110, MOC Software Version (read only)

These registers (10) allow reading the software version

number for the motor control oriented microprocessor.

Register 40111 and 40120, MOC Registers Version (read

only)

These registers (10) allow reading the register version

number for the motor control oriented microprocessor.

Register 40131, OEM Reset

Setting this register to logic “1” resets the drive to the

OEM defaults (configuration defaults set by the OEM in

production) stored in the EEPROM.

Register 40132, Danfoss Reset

Setting this register to logic “1” resets the drive to the

Danfoss defaults (factory defaults as listed in this manual

and Modbus register map files)

Page 33

Commissioning

VLT® Inverter Scroll CDS 801 Operating Instructions

Register 40133, Overwrite Defaults

Setting this register to logic “1” allows overwriting the

factory defaults. This should only be done with assistance

from Danfoss.

Register 40134, Test Register

This register has been created as a test tool to verify

proper Modbus communication. To test the communication, write any value between 0 and 65535 to the

register and verify that the same value is successfully

reported back from the slave node (drive).

Register 40145, Drive MOC Address (def. 163, min 1, max

247)

This register allows setting the bus address (node address)

of the motor control oriented microprocessor of the drive.

The default address is 163 and can be set to a value

between 1 and 247.

Register 40201 and 40202, Compressor Power

Consumption in kWh (read only)

These registers allow reading the power consumption of

the compressor.

Register 40203 and 40204, Compressor Power in kW (read

only)

These registers allow reading the input power to the

compressor.

Register 40205 and 40206, Supply Voltage (read only)

These registers allow reading the supply voltage (line

voltage) applied to the drive.

Register 40207 and 40208, Inverter Temperature (read

only)

These registers allow reading the internal inverter

temperature measured in the power module of the drive

in °C.

Register 40209 and 40210, UDC Voltage (read only)

These registers allow reading the DC voltage in the

intermediate circuit of the drive.

Register 40211 and 40212, Internal Fan Speed (read only)

These registers allow reading the speed of the integrated

cooling fan in the drive in a percentage.

5.3

Condenser Fan Speed Reference Output

When the condenser fan speed control mode is selected in

the application controller the drive calculates the optimum

fan speed for efficiency optimization and provides a speed

reference output signal for the variable speed condenser

fan motor. When the speed control is deselected the

output can be used to control any other external device

such as a circulator pump in a ground source heat pump,

simply by using the Modbus external speed register and

the control signal describe hereinafter.

The following signals are simultaneously available:

Analog output 0-10 V

•

Frequency duty cycle output 24 V PWM, 0-10 kHz

•

Reg. 41609 and 41610, Outdoor fan capacity PCT min

Reg. 41611 and 41612, Outdoor fan capacity PCT max

Reg. 41613 and 41614, Outdoor fan control signal freq

5.4 Crankcase Heating

The variable speed drive comprises an electronic crankcase

heating, by injecting a DC voltage to the compressor

motor. The resulting current heats the motor windings and

therewith effectively prevents refrigerant from accumulating in the compressor sump. An additional heating belt

is not required.

Register 40479 and 40480 Crankcase heating on

temperature (min 50 °F/10 °C, max +77 °F/+25 °C)

This register allows setting the temperature at which the

crankcase heating is activated. Setting register 40481 to

value "0" deactivates the crankcase heating function

permanently (default is "1"/ON).

The temperature equals the ambient temperature

measured by the drive in the outdoor unit.

NOTE

The crankcase heating is not active when power is disconnected to the drive as well as when the compressor is in

operation. Crank case heating will also not be active when

drive is stopped because of an alarm.

The power consumption of the crankcase heating is

approximately 40 W.

5.5

Ambient Temperature Source

The ambient temperature value can be provided from a

sensor connected directly to the drive, or it can be sent to

the unit via Modbus from the OEM controller.

Register 40216, Thermo in Ambient Temperature

An internal analog value from the ambient temperature

sensor connected to the drive at the S_Amb input. (-999

°C if not connected).

Register 40225, Thermo In External Ambient Temperature

The OEM controller writes the ambient temperature via

Modbus. When using the Modbus ambient temperature

signal, the OEM controller it must update the signal at

least every 60 s. Otherwise the drive goes into safe mode.

Register 40484, Thermo Setup Ambient Temperature

Source

Selects the source of ambient temperature used by

software control algorithms (Crankcase Heating and

Outdoor Fan Control).

5 5

MG10V402 - VLT® is a registered Danfoss trademark 29

Page 34

Commissioning

VLT® Inverter Scroll CDS 801 Operating Instructions

0 = 40216 Thermo In Ambient Temperature

1 = 40225 Thermo In External Ambient

Temperature

Default value of the register is 0, and therefore a

temperature sensor must be connected to the drive as

default unless this register is set to 1. It is important that

the ambient temperature value is a true measurement of

the ambient temperature outside the enclosure containing

the compressor and the drive. This value is used for

(crankcase heating and fan control).

55

5.6 Pressure sensor scaling

When using other pressure sensors than Danfoss AKS

sensors (specified in the sensor selection guide), the

pressure configuration registers must be changed to match

the range of the used sensors.

Register 41601 and 41602, Suction pressure min

Register 41603 and 41604, Suction pressure max

Register 41605 and 41606, Condenser pressure

min

Register 41607 and 41608, Condenser pressure

max

All pressure calculations in the drive is done in an absolute

pressure scale (atmospheric pressure = 1bar).

Example: Absolute pressure range 0-20 bar ⇒ pressure min

= 0 and pressure max = 20.

Optional Commands:

Optional available information:

The drive and the EEV Controller(s) allow reading a large

number of data to be polled by the Modbus Master (OEM

Controller), such as:

Setpoint and room temperature (in closed loop

•

operation)

Capacity request (in open loop operation)

•

Dehumidification Mode

•

Product identification

•

Operation status (alarms and warnings)

•

Operation data

•

Power consumption

•

Compressor speed

•

Pressure and temperature values

•

Etc.

•

If a pressure sensor with a gage pressure range is used

(atmospheric pressure = 0 bar), the min and max pressure

must be added with 1 to compensate for the offset in the

range when configuring the sensor.

Example: gage pressure scale 0-20 bar ⇒ pressure min = 1

and pressure max = 21.

5.7

Normal Operation

NOTE

After connecting power to the drive, wait at least 15

seconds until the initialization is completed before

accessing the Modbus communication.

Mandatory commands:

To operate the system a minimum number of commands

must be provided by the OEM

Controller:

Start

•

Stop

•

Reboot

•

30 MG10V402 - VLT® is a registered Danfoss trademark

Page 35

Indoor

Outdoor

Modbus

OEM

control

Modbus

Air flow

Air flow

EIM 316

S4

S2 AC

24V

Galvanic

Isolation

S4

S2 AC

+24V

Drive

P

o

P

c

Sd

Sd

Samb

P

o

Pc

Samb

175ZB116.10

Embedded Application Contro...

VLT® Inverter Scroll CDS 801 Operating Instructions

6 Embedded Application Controller “Thermo Control”

6.1 Introduction

The Residential Variable Speed Drive system is consisting of compressor, variable speed drive, application controller,

Electronic Expansion Valves (EEV), EEV controller and sensors.

Variable Speed Drive and EEV controller are set to be able to communicate using Modbus RTU protocol. Communication

details are available in the Modbus Communication Set-up Manual. Establishing the communication and configuring the

system requires individual parameters settings. These settings must be done through the OEM controller or any other PC

tool, using the Modbus communication.

This chapter describes the operation modes of the application controller. Included is also the parameter lists and parameter

descriptions.

6.2 Applications

6.2.1 Generic AC

6

6

Illustration 6.1 Generic AC

MG10V402 - VLT® is a registered Danfoss trademark 31

Page 36

OutdoorModbus

Indoor

S2 AC

S4

Air flow

Air flow

OEM

control

S2 HP

+24VModbus

Modbus

Drive

Galvanic

isolation

24V

S2

AC

S4

EIM 316

EIM 316

S2

HP

P

c

P

o

Sd

Samb

Pc

P0

Sd

Samb

175ZB117.10

6

Embedded Application Contro...

6.2.2 Generic AC/HP (Reversible)

VLT® Inverter Scroll CDS 801 Operating Instructions

Illustration 6.2 Generic AC/HP (Reversible)

32 MG10V402 - VLT® is a registered Danfoss trademark

Page 37

175ZB118.10

Drive

OEM

control

P

o

P

c

Sd

Samb

Pc

S2

S2

Sd

ModBus +24V

Po

Embedded Application Contro...

VLT® Inverter Scroll CDS 801 Operating Instructions

6.2.3 Ground Source Heat Pump (Reversible)

6

6

Illustration 6.3 Ground Source Heat Pump (Reversible)

6.3

Application Controller

6.3.1 Introduction

The Thermo Controller is an integrated part of the VLT

Inverter Scroll CDS 801 system. The purpose of the

application controller is to control the speed of the

compressor to a given load of the system. It also controls

the speed of the condenser fan (outdoor unit), both in A/C

mode, Defrost and HP mode. It is possible to select various

control modes for the compressor and the condenser fan.

It communicates with the EEV controllers, the OEM

controller and sets the relay for the 4-way valve. The

Thermo Controller has several built-in safety functions to

protect the compressor.

The following paragraphs describe the application

controller functionality and safety functions.

System Modes

6.3.2

System modes are:

Off

•

AC (cooling)

•

HP (heating)

•

Defrost

•

MG10V402 - VLT® is a registered Danfoss trademark 33

The system mode is selected by setting a value in the

THERMO_IN_MODE register.

6.3.2.1 Off

To set the system off:

set THERMO_IN_MODE = 0

The compressor and condenser fan shut down and the

indoor and outdoor EEVs close the valves.

The application controller continuously polls the EEVs for

their status register. If the status register polling fails, the

EEVs go into autonomous mode and attempt to control

superheat.

In autonomous mode, the EEV attempts to control the

superheat without Modbus communication. If an additional

suction pressure sensor is not connected to the EIM316,

the EIM316 will not have a suction pressure signal, and will

go in to error mode (Valve opening = 80 % of average

value).

6.3.2.2

In cooling mode, the Indoor EEV is active and receives the

suction pressure signal over the Modbus from the Thermo

Control controller. The outdoor EEV is inactive.

AC

Page 38

Embedded Application Contro...

VLT® Inverter Scroll CDS 801 Operating Instructions

6

In AC mode, the system sets the 4-way valve to operate

the indoor unit as evaporator and the outdoor unit as

condenser.

The indoor EEV controller actively controls the superheat

on the indoor evaporator.

The outdoor EEV valve will be closed.

The Thermo Control controller continuously polls the EEVs

for their status register. If the status register polling fails,

the EEVs go into autonomous mode and attempt to

control superheat.

To set the system in AC mode:

set THERMO_IN_MODE = 1

When conditions for start up are met:

The restart timer has elapsed

•

The requested compressor speed is higher than

•

the minimum allowed speed

The system go into a start-up sequence. The start-up

sequence is described in 6.3.5.1 Start-Up Sequence.

6.3.2.3

HP

To set the system in Defrost mode:

set THERMO_IN_MODE = 3

There is no specific control algorithms for defrosting,

compressor speed and fan speed must be handled by the

OEM controller. However, the limitations from the

compressor protection is different from AC mode. This

allows the OEM controller to execute a defrosting

sequence with good performance.

6.3.3 Compressor Capacity Control

The compressor speed control can be done through

different strategies. The compressor control strategy is

selected by setting the THERMO_IN_COMPRESSOR_MODE.

In Heat Pump mode, the outdoor EEV is active, and

receives the suction pressure signal over the Modbus from

the Thermo Control controller. The indoor EEV is inactive.

In HP mode, the system sets the 4-way valve to operate

the indoor unit as condenser and the outdoor unit as

evaporator.

The outdoor EEV controller actively controls the superheat

on the outdoor evaporator.

The indoor EEV valve will be closed.

The Thermo Control controller continuously polls the EEVs

for their status register. If the status register polling fails,

the EEVs go into autonomous mode and attempt to

control superheat.

To set the system in HP mode:

set THERMO_IN_MODE = 2

When conditions for start up are met:

The restart timer has elapsed

•

The requested compressor speed is higher than

•

the minimum allowed speed,

The system go into a start-up sequence. The start-up

sequence is described in 6.3.5.1 Start-Up Sequence.

6.3.2.4

The purpose of Defrost mode is to allow the OEM

controller to perform an efficient defrost routine. In Defrost

mode, the EEVs and 4-way valve work identically to AC

mode.

34 MG10V402 - VLT® is a registered Danfoss trademark

Defrost

Page 39

PI

Drive

AC/HP

system

Compressor Room

Σ

Troom

Setpoint

175ZB107.10

Drive

AC/HP

system

Compressor Room

External

speed command

Troom

175ZB108.10

Embedded Application Contro...

VLT® Inverter Scroll CDS 801 Operating Instructions

6.3.3.1 Single Loop Room Temperature Control

In single temperature control, the Inverter Scroll CDS 801 system attempts to maintain a temperature, typically a room

temperature, see Illustration 6.4.

The reference and the room temperature are sent from the OEM controller.

The Thermo Control controller calculates the necessary compressor speed and condenser fan speed.

To set the compressor control to single temperature closed loop control:

Set THERMO_IN_COMPRESSOR_MODE = 0

The Thermo Control controller reads the reference from

THERMO_IN_ROOM_TEMPERATURE_SET_POINT

and the actual room temperature from

THERMO_IN_ROOM_TEMPERATURE.

Illustration 6.4 Single Loop Room Temperature Control

6

6

6.3.3.2 Open Loop/ External Speed Control

In external speed control (see Illustration 6.5), the compressor speed is set externally from the OEM controller through the

Modbus.

When in external speed mode, the compressor derating and safety envelope functions are still active and takes precedence

over the external speed signal.

To set the compressor speed control into external speed control:

Set THERMO_IN_COMPRESSOR_MODE = 2

The external speed % is set in the THERMO_IN_COMPRESSOR_EXTERNAL_SPEED_PCT register.

Illustration 6.5 Open Loop/External Speed Control

0% Speed request = 0 Hz, and start will not be allowed until 60 s later. (control restart timer).

1% Speed request = 15 Hz

100% Speed request = 70 Hz, see Illustration 6.6

Can be overruled by derating functions (explained in 6.3.5.5 Derating).

MG10V402 - VLT® is a registered Danfoss trademark 35

Page 40

10 100

15

70

Compressor speed

[Hz

]

Speed request

[%]

130ZB124.10

6

Embedded Application Contro...

Illustration 6.6 Compressor Speed vs. Speed Request

Condensing Pressure Control

6.3.4

VLT® Inverter Scroll CDS 801 Operating Instructions

The outdoor fan speed control can be done through different strategies. The fan control strategy is chosen by setting the

THERMO_IN_FAN_MODE register. The fan speed control strategy depends also on the system mode: AC vs. HP. If the system

is in AC mode, the outdoor fan controls the condensing pressure/temperature. This temperature has to be higher than the

ambient temperature, so that the condenser can reject heat. If the system is in HP mode, the outdoor fan controls the

evaporator pressure/temperature. This temperature has to be lower than the ambient temperature, so that the evaporator

can absorb heat. Fan speed control is illustrated in Table 6.1.

Mode THERMO_IN_FAN_MODE System mode = AC (and defrost) System mode = HP

Optimal COP 0 Pc,ref = f(P0) P0 = f(Pc)

Delta T 1 Tc,ref = Tamb + delta T

External Speed 2 Fan speed = THERMO_IN_FAN_EXTERNAL_SPEED_PCT

Bypass 3 Fan speed = THERMO_IN_FAN_EXTERNAL_SPEED_PCT

Table 6.1 Condensing Pressure Control

6.3.4.1

AC Mode

(delta T = 7K)

T0,ref = Tamb – delta T

(delta T = f(T0min, Tamb))

In AC mode, the fan controls condensing pressure, since the outdoor unit works as condenser.

Optimal Pressure Ratio Control

In Optimal COP mode, the fan speed control attempts to maintain a constant pressure ratio

Pc/P0 = constant

across the compressor, see Illustration 6.7. This ratio is the theoretically optimal pressure ratio for the Inverter Scroll CDS 801

compressor.

To run Optimal COP mode:

Set THERMO_IN_FAN_MODE = 0

36 MG10V402 - VLT® is a registered Danfoss trademark

Page 41

PI

Σ

2.09 P 2 TP 0 Tc set FanMotor

Condensing

Unit

P 2 T PcTc

175ZB109.10

PI

Σ

Tamb + Delta T FanMotor

Condensing

Unit

P 2 T PcTc

175ZB110.10

175ZB130.10

FanMotor

Condensing

Unit

External

speed setpoint

P

Fan

Protection

c

FanMotor

Condensing

Unit

External

speed command

Pc

175ZB111.10

Embedded Application Contro...

Illustration 6.7 AC Mode

VLT® Inverter Scroll CDS 801 Operating Instructions

Delta T Control

In Delta T mode, the fan speed control attempts to maintain a temperature difference of Delta T to ambient temperature,

see Illustration 6.8.

In AC mode, the fan speed control attempts to maintain condensing temperature Delta T above ambient temperature.

To run Delta T mode:

Set THERMO_IN_FAN_MODE = 1

The temperature difference Delta T is set through the register THERMO_SETUP_DELTA_TEMP.

6

6

Illustration 6.8 Delta T Control

Open Loop/External Speed Control

In external speed control, the fan speed is set externally

from the OEM controller through the Modbus. The speed

can be overruled by the fan protection functions like min

and max condensing pressure derating, see Illustration 6.9.

To set the fan speed control in to external speed control:

Set THERMO_IN_FAN_MODE = 2

protection functions, and will never be overruled by

functions like min and max condensing pressure derating,

see Illustration 6.10. To set the fan speed control in to

bypass:

Set THERMO_IN_FAN_MODE = 3

The external speed % is set in the

THERMO_IN_FAN_EXTERNAL_SPEED_PCT register.

The external speed % is set in the

THERMO_IN_FAN_EXTERNAL_SPEED_PCT register.

Illustration 6.10 Bypass Fan Speed Control

Illustration 6.9 Open Loop/External Speed Control

Bypass fan speed control

In Bypass speed control, the fan speed is set externally

from the OEM controller through the Modbus. In the

bypass mode the external speed is bypassing the fan

MG10V402 - VLT® is a registered Danfoss trademark 37

Page 42

PI

Σ

1

---- ----- 2

.

09

P 2 TPc T 0 set FanMotor Evaporator

P 2 T P0T 0

175ZB112.10

PI

Σ

Tamb - Delta T FanMotor Evaporator

P 2 T P 0T 0

175ZB113.10

6

Embedded Application Contro...

VLT® Inverter Scroll CDS 801 Operating Instructions

6.3.4.2 HP Mode

In HP mode the fan controls evaporator pressure since the outdoor unit works as an evaporator.

Optimal Pressure Ratio Control

In Optimal COP mode, the fan speed control attempts to maintain a constant pressure ratio

Pc/P0 = constant

across the compressor, see Illustration 6.11. This ratio is the theoretically optimal pressure ratio for the compressor.

To run optimal COP mode:

Set THERMO_IN_FAN_MODE = 0

Illustration 6.11 HP Mode

Delta T Control

In Delta T mode, the fan speed control attempts to maintain a temperature difference of Delta T to ambient temperature,

see Illustration 6.12.

In HP mode, the fan speed control attempts to maintain evaporator temperature Delta T below ambient temperature.

To run Delta T mode:

Set THERMO_IN_FAN_MODE = 1

The temperature difference Delta T is set through the register THERMO_SETUP_DELTA_TEMP.

Illustration 6.12 Delta T Control

38 MG10V402 - VLT® is a registered Danfoss trademark

Page 43

130ZB126.10

T0,ref

T ambientT0 min + 10 K T0 Min + 20K

T ambient

T ambient DeltaTemp

Delta T

Performe r VSD Opera ting Envelope

35

45

55

65

75

85

95

105

115

125

135

145

155

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Satura ted e vapora ting tem p

. (°F)

Saturated condensing temp. (

°F

)

2

6

10

14

18

22

26

30

34

38

42

46

50

54

58

62

66

70

-40 -36 -32 -28 -24 -20 -16 -12 -8 -4 0 4 8 12 16 20 24

°

C

900-4200

Line 1

Line 5

Line 6

Line 7

Line 14

A10

T 0MinLine

175ZB127.10

°

C

175ZB125.10

FanMotor

Evaporating

Unit

External

speed setpoint

P

Fan

Protection

0

FanMotor Evaporator

External

speed command

P

0

175ZB114.10

Embedded Application Contro...

VLT® Inverter Scroll CDS 801 Operating Instructions

To transfer heat to the evaporator, a temperature

difference is needed (evaporator temperature must be

lower than the ambient temperature). Under cold ambient

conditions this brings the suction pressure close(r) to the

edge of the operating envelope. It is therefore important

to make the temperature difference between evaporator

and ambient as small as possible under cold conditions.

The Delta T, (or the T0

) is therefore made dependent on

ref

the ambient temperature, see Illustration 6.13.

Illustration 6.13 shows how the set point for the Delta T

control mode in HP system mode is a function of ambient

temperature and T0

approaches the T0

. As the ambient temperature

min

line (see Illustration 6.14), the Delta T

min

is lowered. This is done to prevent too low evaporator

temperatures when the ambient temperature is low.

To set the fan speed control to external speed control:

Set THERMO_IN_FAN_MODE = 2

The external speed % is set in the

THERMO_IN_FAN_EXTERNAL_SPEED_PCT register.

Illustration 6.15 Open Loop/External Speed Control

Bypass fan speed control

In Bypass speed control, the fan speed is set externally

from the OEM controller through the Modbus. In bypass

mode, the external speed is bypassing the fan protection

functions, and will never be overruled by functions like

min and max condensing pressure derating, see

Illustration 6.16. To set the fan speed control in to Bypass:

Set THERMO_IN_FAN_MODE = 3

The external speed % is set in the

THERMO_IN_FAN_EXTERNAL_SPEED_PCT register.

6

6

Illustration 6.13 T0

Illustration 6.14 Definition of T0

leftmost line(s) of the envelope

Open Loop/ External Speed Control

In external speed control, the fan speed is set externally

from the OEM controller through the Modbus. The speed

can be overruled by the fan protection functions like min

and max condensing pressure derating, see Illustration 6.15.

= f(Tambient) in HP mode (Delta T)

ref

min

Illustration 6.16 Bypass Fan Speed Control

6.3.4.3 Defrost Mode

In Defrost mode the fan controls condensing pressure,

since the outdoor unit works as a condenser. The same fan

control options like in AC are available, when defrosting

the outdoor coil.

Auxiliary Functions

6.3.5

6.3.5.1 Start-Up Sequence

When the system starts up from idle in AC or HP mode,

the compressor follows a start up sequence, see

Illustration 6.17. This sequence is defined by a ramp (2.7

Hz/s), start speed (THERMO_SETUP_START_UP_SPEED_HZ)

line. The T0

line is the

min

and hold time for start speed

(THERMO_SETUP_START_UP_HOLD_TIME_SEC).

MG10V402 - VLT® is a registered Danfoss trademark 39

Page 44

Time

speed

Start speed

hold time

Start Speed

175ZB115.11

Ramp

175ZB131.10

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

-30 -20 -10 0 10 20 30 40 50 60 70 80

Saturated condensing

temp. ( °F)

Saturated evaporating temp. (° F)

Performer VSD Operating Envelope

900-4200 RPM

900-4200 RPM

1100-4200 RPM

1300-4200 RPM

1500-4200 RPM

1800-4200 RPM

900-4200 RPM

1100-4200 RPM

1300-4200 RPM

2200-3300 RPM

2300-2850 RPM

2400 RPM Derated

2100-3750 RPM

1500-4200 RPM

900-4200 RPM

(defrost)

6

Embedded Application Contro...

Illustration 6.17 Start-up Sequence

VLT® Inverter Scroll CDS 801 Operating Instructions

Illustration 6.18 Compressor Safety Envelope

When switching to and from Defrost mode, the start speed

hold time is disabled. The compressor then ramps up

continuously to the compressor speed setpoint and skips

the start speed hold time. This allows for a more efficient

defrosting.

6.3.5.2

Restart Timer

To increase compressor lifetime, there is a minimum time

between compressor starts. This restart time (at least 1

minute) is defined by

Restart time register: THERMO_SETUP_RESTART_TIME_SEC

When switching to and from Defrost mode, the restart

timer is disabled. This results in a quick switch in system

mode and allows for a more efficient defrosting of the

outdoor coil.

If the system mode is changed, or compressor is stopped

and started too frequently, the drive will stop and raise an

alarm. Only 6 compressor restarts within 600 s are allowed,

there after the system will stop and raise an alarm.

6.3.5.3

Given the allowed ranges of suction pressure and

condensing pressure, the compressor safety envelope

defines the speed range (min and max RPM) that the