Page 1

Compressor Drives

Troubleshooting Check List

CDS 302/CDS 303

http://cc.danfoss.com

Page 2

Page 3

Check List

Content

Introduction ......................................................................................................................................... 4

For Your Safety ..................................................................................................................................... 5

Diagnostics...........................................................................................................................................6

Initial Trouble Shooting (visual inspection of the installation) ....................................................... 7

Input power wiring ................................................................................................................................................................................... 7

Output to motor ........................................................................................................................................................................................ 7

Grounding .................................................................................................................................................................................................... 7

Control wiring ............................................................................................................................................................................................. 7

Programming .............................................................................................................................................................................................. 7

Compressor Motor .................................................................................................................................................................................... 7

Cable routing .............................................................................................................................................................................................. 7

Peripheral equipment (sensors, contactors, etc) ............................................................................................................................7

Trip on over Temperature ....................................................................................................................................................................... 7

Drive interior ............................................................................................................................................................................................... 7

EMC Precautions ........................................................................................................................................................................................ 7

Vibration ....................................................................................................................................................................................................... 7

Environmental conditions ...................................................................................................................................................................... 7

Proper clearance ........................................................................................................................................................................................ 7

Trouble shooting ................................................................................................................................8

Fault Symptoms - Display of the drive .............................................................................................................................................. 8

No display (blank display) ...................................................................................................................................................................... 8

Intermittent display .................................................................................................................................................................................. 8

Fault Symptoms in the compressor (motor) ....................................................................................................................................9

Common drives and motor problems ..............................................................................................11

Control logic problems ..........................................................................................................................................................................11

Programming problems ........................................................................................................................................................................11

IGBT, Motor or load problems ............................................................................................................................................................12

Procedure to conduct the dynamic test to check the IGBT .....................................................................................................12

Faults in the drive ....................................................................................................................................................................................12

EMC - Electro Magnetic Compatibility .............................................................................................................................................13

Static test procedures .......................................................................................................................14

Rectier test (static) ................................................................................................................................................................................14

IGBT static test ..........................................................................................................................................................................................15

3FRCC.PC.036.A2.02

Page 4

Check List

Introduction

Many frequency converters that are sent back

to Danfoss every year for factory analysis

are diagnosed with No Fault Found (NFF).

Establishing whether a frequency converter is

faulty or not prior returning it to the factory can

increase the uptime of the compressor solution,

reduce the unnecessary use of resources and

limit the number of NFF.

The purpose of this check list is to facilitate

users, eld technicians, engineers and service

personnel working with Danfoss frequency

converters to identify faults and perform a

rst diagnosis on the drive before sending it to

inspection and analysis.

PERFORM THE FOLLOWING FAULT DIAGNOSIS

BEFORE RETURNING A FREQUENCY CONVERTER FOR

FACTORY INSPECTION.

CHECK ALL POSSIBILITIES.

IN CASE OF DOUBT, PLEASE SEEK DANFOSS SUPPORT.

4 FRCC.PC.036.A2.02

Page 5

Check List

For Your Safety

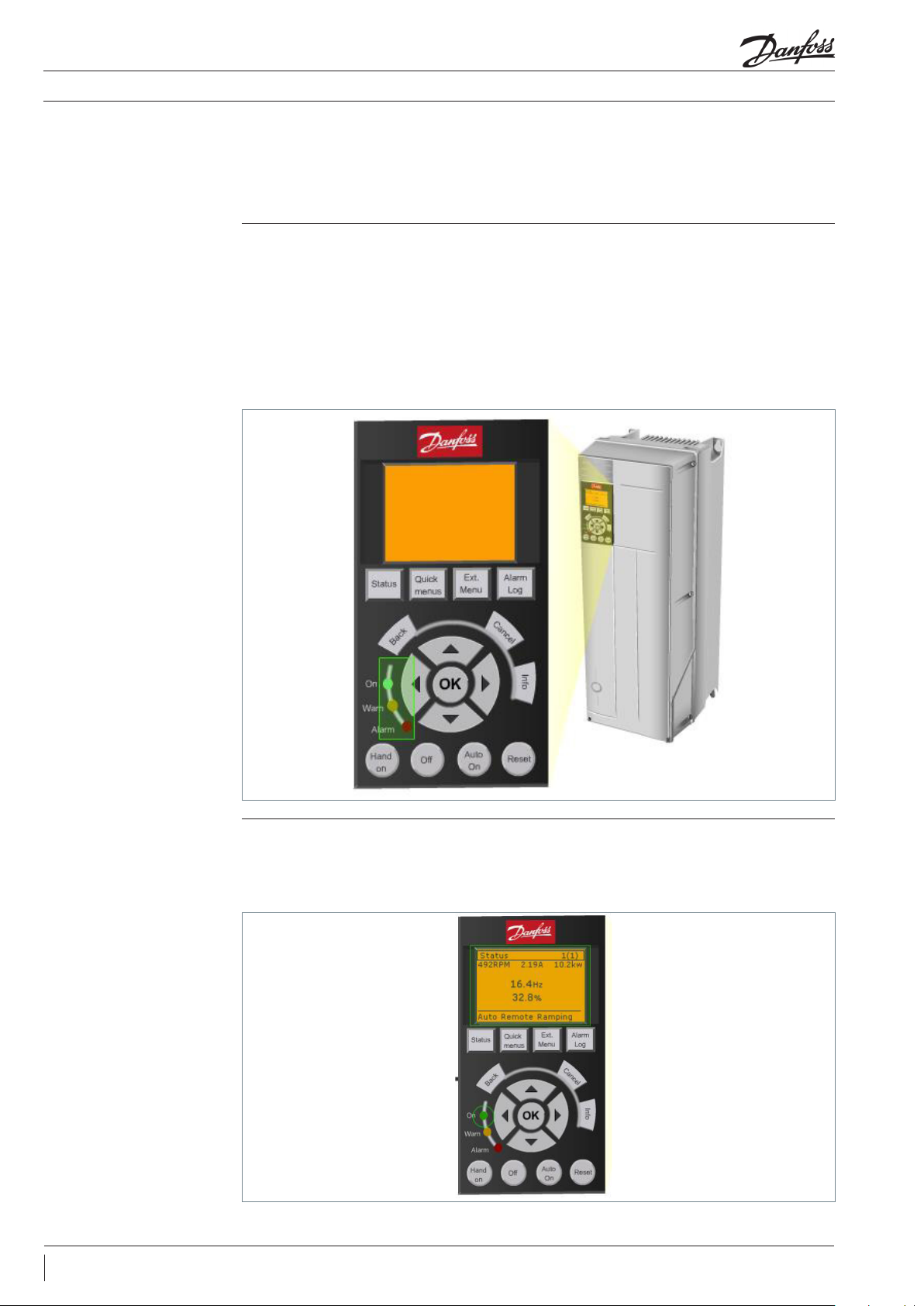

Figure 1: Drive must be

turned OFF for 20min before

repair can start

Frequency Converters (FC) contain dangerous

voltages when connected to the line voltage.

Only a competent technician should carry out

the service.

Some instructions should be compulsorily

followed to ensure safety while working with the

FC.

• Do not touch electrical parts of the FC when the

AC line is connected.

• Frequency converters contain DC-link capacitors

that can remain charged even when the

frequency converter is not powered. To avoid

electrical hazards, disconnect AC mains, any

permanent magnet type motors, and any

remote DC-link power supplies, including

battery backups, UPS and DC-link connections

to other frequency converters.

• Wait for at least 20 minutes before touching any

of the components.

• When repair or inspection is done, the AC line

must be disconnected.

• The STOP key on the control panel does not

disconnect the AC line.

• During operation and programming of the

parameters, the motor may start without

warning. So you have to activate the STOP key

when changing data.

5FRCC.PC.036.A2.02

Page 6

Check List

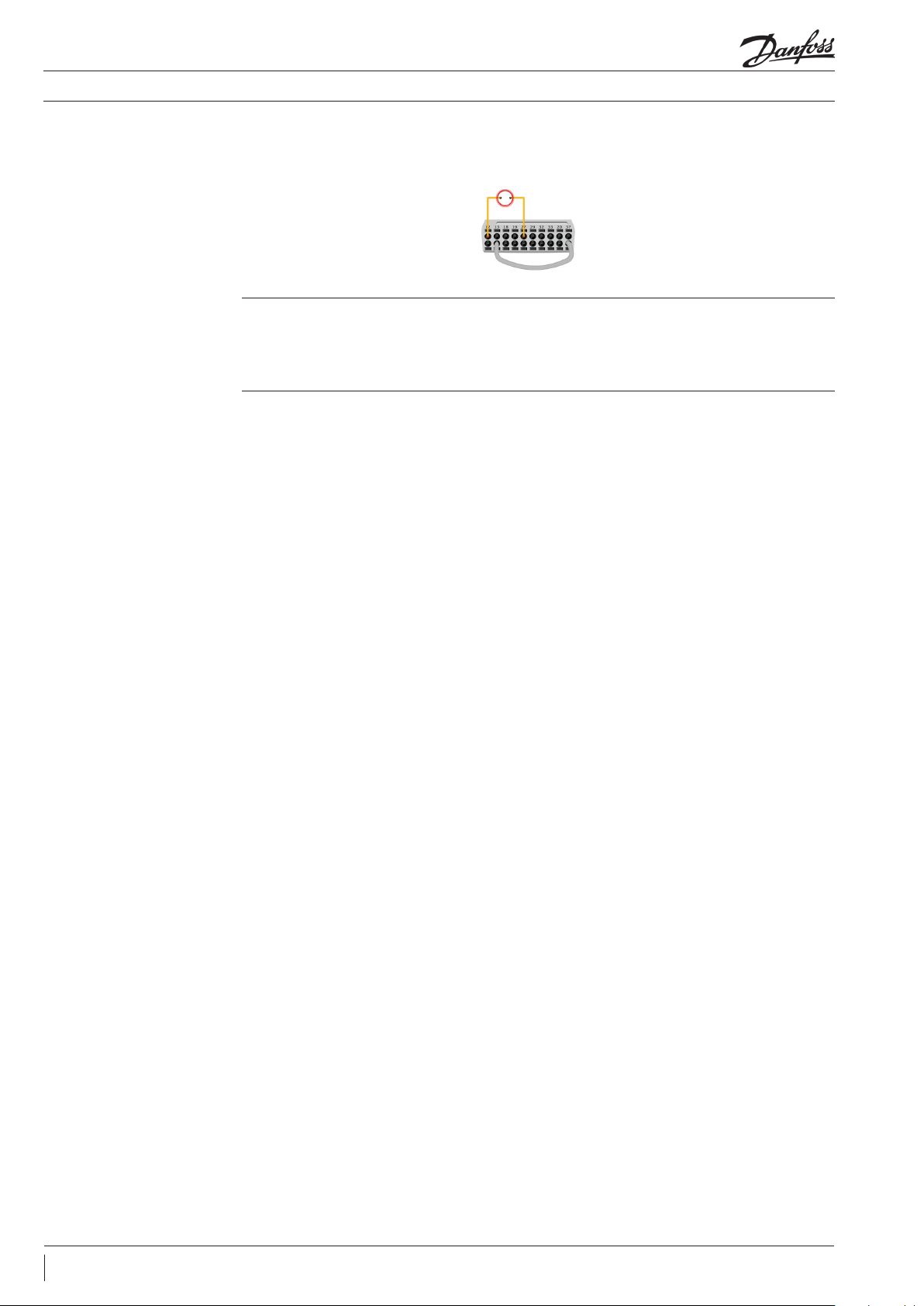

Diagnostics

WARNINGS and ALARM

Fault detection via LCP: messages are displayed

when the frequency converter fault circuit

detects a faulty condition or an unresolved fault.

A warning light ashing display indicates

potential problems.

There are two levels of alarms; Reset Alarms and

Trip-lock Alarms.

Alarm Log Check the content of the alarm log.

5 latest alarms are available through the “Alarm

Log” button key on the LCP.

Check the alarm code and refer to the

troubleshooting session of the Operating

Instructions VLT® CDS 302 and CDS 303 on page

135. It contains guidance for the complete list

of alarms and warnings.

Figure 2: WARNINGS

and ALARM messages

are displayed when the

frequency converter fault

detects a faulty condition

a) In case of reset alarm: you can stop and then

start the unit.

b) In case of trip-lock alarm, you have to

disconnect the mains, wait for dark display,

then stop and start.

If the troubleshooting suggested does not

resolve the problem, please contact Danfoss for

support.

Do not exchange the drive before contacting

Danfoss support.

6 FRCC.PC.036.A2.02

Page 7

Check List

Initial Trouble Shooting (visual inspection of the installation)

Input power wiring

Output to motor

Grounding

Control wiring

Programming

Compressor Motor

This list shows a variety of conditions that

should be inspected visually as a part of initial

troubleshooting.

Check for loose connections. Check for proper fusing. Check for blown fuses.

Check for loose connections. Check for switching

components in the output circuit. Check for

faulty contacts in the switch gear.

The drive requires a dedicated ground wire

from its chassis to the building ground. It is also

suggested that the motor be grounded to the

drive chassis. The use of conduit or mounting

Check for broken or damaged wires and

connections. Check the voltage source of the

signals. Though not always necessary depending

Check that the drive parameter settings are

correct according to the motor, application and

I/O conguration.

Check nameplate of the Compressor. Ensure the

compressor matches the drive. Check that drive’s

Display: Warnings, alarms, drive status; fault

history and many other items are available on the

local control panel of the drive.

of the drive to a metal surface is not considered

a suitable ground. Check for good grounding

connections that are tight and free of oxidation.

on the installation condition, the use of shield

cable or a twisted pair is recommended. Ensure

the shield is terminated correctly.

compressor par. 1-13 is set according to the

compressor e.g.:

Cable routing

Peripheral equipment

(sensors, contactors, etc)

Trip on over Temperature

Drive interior

EMC Precautions

ID Name Setup 1 Factory Setup Unit

113 Compressor Selection VZH117-R410A VZH117-R410A

Avoid routing motor wiring. AC line wiring and

signal wiring in parallel. If parallel routing is

unavailable, try to maintain a separation of 15-

Look for peripheral equipment such as switches

or input fuses circuit breakers that may be in the

input power side of the drive or output side of

the motor. Examine operation and condition of

Check the operational status of all cooling fans.

Check for blockage or constrained air passages.

Drive interior must be free of dirt, metal, chips,

moisture and corrosion. Check for burnt or

damaged power components or carbon deposits

that were the result of a disastrous component

Check for proper installation with regards to

electromagnetic capability. Refer to the CDS

manual, in the chapter “How to install” and then

20cm between the cables or separate them with

a grounded conductive partition. Avoid routing

cables through free air.

these items as possible causes for operational

faults. Check function and installation of pressure

sensors or temperature sensors etc. used for

feedback to the drive.

failure. Check for cracks or breaks in the housing

of the power semiconductors or pieces of broken

components housing loose inside the unit.

“ Electrical Installation – EMC Protection “ for

further details.

Vibration

Environmental conditions

Proper clearance

Look for unusual amounts of vibration to which

the drive may be subject. The drive should be

Under specic conditions these units can

be operated within a maximum ambient

temperature of 50°C (24h average maximum

These drives require a top and bottom clearance

of 10cm to ensure proper airow for cooling.

mounted solidly or the use of shock mounts

employed.

45 °C). Humidity level must be less than 95%

non-condensing. Check for harmful airborne

contaminates such as sulphur based compounds.

Drives with exposed heat sinks out the back of

the drive must be mounted on a at solid surface.

7FRCC.PC.036.A2.02

Page 8

Check List

Trouble shooting

Fault Symptoms - Display

of the drive

No display (blank display)

Figure 3: No Display in the

LCP (blank)

A fault must have been ocurred when there is:

a) No Display in the LCP (blank)

b) Intermittent display in the LCP

There are three LED indicators lights near the

bottom of the LCP.

If the green power on LED is illuminated but the

backlit display is dark, this indicates that the LCP

itself is defective and must be replaced.

It should be certain that the display is completely

dark. An error code exists in the drive which

indicates that communications may have failed

with the control card.

This is typically seen when an option card has

been installed in the drive and is either not

connected properly or is malfunctioning.

• If neither indication is available, then the

source of the problem may be elsewhere.

Intermittent display

Figure 4: intermittent

display

8 FRCC.PC.036.A2.02

Cutting out or ashing of the entire display and

power LED indicates that the power supply

(SMPS) is shutting down as a result of being

overloaded.

This may be due to improper control wiring or a

fault within the drive itself.

Page 9

Check List

Figure 5: Check control

cables

Trouble shooting

• The rst step is to rule out the problem in the control wiring.

Figure 6: Disconnect all

control wiring

Fault Symptoms in the

compressor (motor):

Motor will not run

• Disconnect all control wiring by unplugging the

control terminal blocks from the control card.

All control wiring should be checked for shorts

or incorrect connections.

• First verify that the unit is properly powered up

and there is no warning or alarm .

• The most common cause of this is either

incorrect control logic or an incorrectly

programmed drive.

• If the display stays lit then the problem is in the

control wiring.

• If the display continues to cut out, the fault

can be located in either the LCP itself or on

the Power card.

Such occurrences will result in one or more of the

following status messages being displayed:

LCP Stop

Figure 7: LCP stop = OFF key

pressed

Stand by (gure 8)

The LCP stop message is displayed when the OFF

key has been pressed.

The stand by message is displayed when there is

no start signal at terminal 18.

The bottom section of the display will also be

ashing when this occurs.

Ensure that a start command is present at

terminal 18.

9FRCC.PC.036.A2.02

Page 10

Check List

Trouble shooting

Stop (gure 9)

Figure 9: Check pressure

switch

Run OK: 25Hz

Quick tip:

Message displayed when the Terminal 27 is low

(no signal).

The RUN OK status display indicates that a run

command has been given to the drive but the

reference (speed command) is zero or missing.

Improperly connected wiring or interrupted

wiring is a common service issue for a motor

Ensure that terminal 27 is logic 1 (pressure

switch).

Check the control wiring to ensure that a

proper reference signal is present at the drive

input terminals and that the unit is properly

programmed to accept the signal provided.

not operating or the drive not responding to a

remote input.

10 FRCC.PC.036.A2.02

Page 11

Check List

Common drives and motor problems

Control logic problems

Figure 10: checking control

signal in the control card

The common drives and motor problems occur

due to an error in the

• Control logic

• Programming

Control logic problem occurs when the drive

does not respond to a given command.

Control logic problem is located by using the

status information displayed by the drive.

Correct reading indicates that the desired signal

is detected by the microprocessor of the drive.

• Motor/load

• Internal drive

If there is not a correct indication, the next step is

to determine whether the signal is present at the

control terminals of the drive.

This can be performed with a voltmeter or

oscilloscope.

Programming problems

• If the signal is present at the terminal,

the control card is defective and must be

replaced.

• If the signal is not present, the problem is

external to the drive.

Three areas where programming errors may

aect the drive and motor operation are

motor settings, references and limits, and I/O

conguration.

The drives must be set up correctly for the

compressors connected to it. If not, the

compressor may fail to start or use higher than

normal amount of current.

Check if the correct compressor is selected in

pa r. 1-13.

The circuitry providing the signal along with its

associated wiring must then be checked.

Any references or limits set incorrectly will result

in less than acceptable drive performance.

In case of doubt, reset the drive to factory

settings using par. 14-22.

Download again the OEM settings using the

copy and paste function in par. 0-50.

11FRCC.PC.036.A2.02

Page 12

Check List

Common drives and motor problems

IGBT, Motor or load

problems

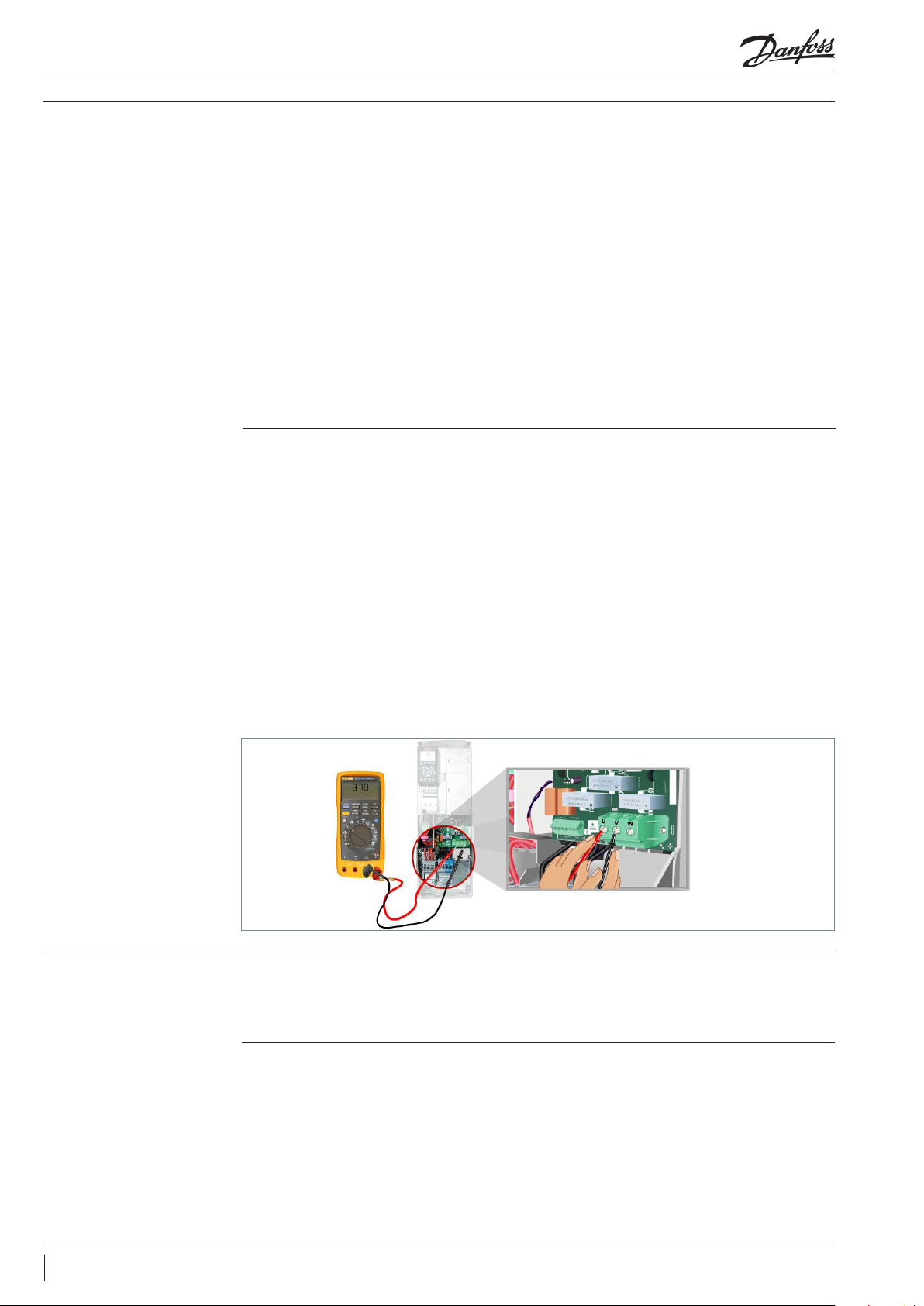

Procedure to conduct the

dynamic test to check the

IGBT

The motor or motor wiring can develop a phase

to phase or phase to ground short resulting in

alarm indication and a trip of the unit.

A motor with the unbalanced or nonsymmetrical impedances on all the three phases

can result in uneven or rough operation or

unbalanced output current.

• To determine whether the problem is internal

or external to the drive, disconnect the motor

from the drive output terminals.

Dynamic tests have to be done without the

compressor connected to UVW connector, and

the Drive has to be programmed to a proxy 50Hz

at start.

The Dynamic test can indicate if one of the IGBT

doesn’t switch, and the output voltage will drop

on the fault terminal, UVW.

Program the multimeter to AC 1000V RM.

• Connect the positive terminal of the multimeter

lead to the U connector, and connect the

negative terminal to the V terminal.

• Perform the dynamic output test procedure on

all three phases with a digital voltmeter.

• If the three voltage measurements are

balanced, the drive is functioning correctly.

The problem is therefore external to the drive.

• If the voltage measurements are not

balanced, the drive is malfunctioning.

This typically means that one or more output

IGBT is not switching on and o correctly.

If one of the IGBT fails, the drive is damaged

and must be replaced.

• Connect the positive terminal of the multimeter

lead to the U connector, and connect the

negative terminal to the W terminal.

• Connect the positive terminal of the multimeter

lead to the V connector, and connect the

negative terminal to the W terminal.

The meter reading will be between 360V - 380V

when performing the dynamic test at 400V

mains and 50Hz/3000RPM output depending on

instrument used.

The reading should be within ±1.5 percent. When

the reading exceeds this, the IGBT is damaged.

Figure 11: Dynamic test

Faults in the drive

Drive temperature sensor /

Over temperature fault

Current sensor fault

• If the drive is stopped and cooled, the LCP

reading shall show the ambient temperature.

When a current sensor fails, it is indicated

sometimes by an earth fault alarm that cannot be

reset, even with the motor leads disconnected.

• Disconnect the motor from the drive, and then

observe the current in the display of the drive.

Note: Both faults above are non-reparable. Drive needs to be replaced

• If not, the temperature sensor or temperature

measurement circuit is defective.

• If the motor is disconnected from the unit, the

LCP shall read out 0.00A.

• If anything else is shown, this indicates a

defective current sensor.

12 FRCC.PC.036.A2.02

Page 13

Check List

EMC - Electro Magnetic

Compatibility

Common drives and motor problems

Eects of EMI

Sources of EMI

Electro Magnetic compliance or EMC are the

voltage and current which are not sinusoidal but

pulsating.

Electromagnetic Compatibility (EMC) concerns

for typical commercial and industrial equipment.

EMI related disturbances to drive operation are

uncommon, but the following detrimental EMI

eects may be seen:

• Motor speed uctuations

• Serial communication transmission errors

• Drive CPU exception faults

• Unexplained drive trips

Drives utilize Insulated-Gate Bipolar Transistors

(IGBTs) to provide an ecient and cost eective

means to create the Pulse Width Modulated

(PWM) output waveform necessary for accurate

motor control.

Detrimental Eects To These Systems May

Include The Following:

• Pressure/ow/temperature signal transmitter

signal distortion or aberrant behaviour

• Radio and TV interference

• Telephone interference

• Computer network data loss

• Digital control system faults

These devices rapidly switch the xed DC bus

vo ltage creating a variable frequency, variable

voltage PWM waveform.

This high rate of voltage change [dV/dt] is the

primary source of the drive generated EMI.

13FRCC.PC.036.A2.02

Page 14

Check List

Static test procedures

Rectier test (static)

Symptom:

Step 1

Figure 12: Multimeter

should read a voltage drop

of 0,4V

Step 2

POWER MUST BE OFF / MAINS AND MOTOR

CABLES DISCONECTED!

Verication of: Rectier (input, mains) / IGBT

(Output, motor)

Failure of the rectier module will usually result

in blown input line fuses.

• Connect the negative terminal of the

multimeter meter lead to the positive DC bus.

• Connect the positive terminal of the multimeter

lead to the input terminal L1,L2,L3 in turn.

Now reverse the meter leads, i.e. connect

the positive terminal of the meter lead to the

positive DC bus.

• If rectier or IGBT fail, the complete power

card has to be exchanged, since in the CDS

drives, the rectier and IGBT are integrated in

one power card.

Procedure to conduct the static test on rectier:

• The multimeter should show the diode drop

of around 0.44 volt on the three terminals.

• Connect the negative terminal of the meter

lead to the input terminals L1, L2, L3 in turn.

• The multimeter should show diode open.

Figure 13: Multimeter

should show diode open

Step 3

Figure 14: Multimeter

should show a diode drop

of 0,44V

Now repeat the procedure by connecting to the

negative DC bus in order to the test the lower

part of the rectier bridge which consist of

diodes

• Connect the negative terminal of the meter

lead to the input terminals L1, L2, L3 in turn.

• The multimeter should show the diode drop

of around 0.44 volt on the three terminals.

14 FRCC.PC.036.A2.02

Page 15

Check List

Static test procedures

Step 4 Now reverse the meter leads, i.e. connect the

negative terminal of the meter lead to the

negative DC bus.

Figure 15: The multimeter

should show diode open

Note: A diode drop reading will vary depending on the model of the ohm meter

IGBT static test IGBT's are placed on the output of the CDS drives

Step 1

Figure 16: The multimeter

should show diode open

• Connect the positive terminal of the multimeter

lead to the positive DC bus.

• Connect the positive terminal of the meter lead

to the input terminals L1, L2, L3 in turn.

• The multimeter should show diode open.

• Connect the negative terminal of the

multimeter lead to the motor terminal U, V, W

in turn.

• The multimeter should show the diode open.

Step 2

Figure 17: The multimeter

should show the diode drop

of around 0.4 volt on the

three terminals

Step 3

Figure 18: The multimeter

should show open diode

Now reverse the meter leads, i.e. connect the

negative terminal of the meter lead to the

positive DC bus.

Now repeat the procedure by connecting to the

negative DC bus in order to test the second set

of IGBTs.

• Connect the positive terminal of the meter lead

to the motor terminals U, V, W in turn.

• The multimeter should show the diode drop

of around 0.4 volt on the three terminals.

• Connect the negative terminal of the

multimeter lead to the negative DC bus.

• Connect the positive terminal of the multimeter

lead to the motor terminal U, V, W in turn.

• The multimeter should show open diode.

15FRCC.PC.036.A2.02

Page 16

Check List

Static test procedures

Step 4 Now reverse the meter leads, i.e. connect

the positive terminal of the meter lead to the

negative DC bus.

Figure 19: The multimeter

should show diode drop

around 0.4 volts

• Connect the negative terminal of the meter

lead to the motor terminals U, V, W in turn.

• The multimeter should show diode drop

around 0.4 volts.

16 FRCC.PC.036.A2.02

Page 17

Page 18

Danfoss Commercial Compressors

Danfoss Inverter Scrolls

is a worldwide manufacturer of compressors and condensing units for refrigeration and HVAC applications. With a wide range

of high quality and innovative products we help your company to find the best possible energy efficient solution that respects

the environment and reduces total life cycle costs.

We have 40 years of experience within the development of hermetic compressors which has brought us amongst the global

leaders in our business, and positioned us as distinct variable speed technology specialists. Today we operate from engineering

and manufacturing facilities spanning across three continents.

Danfoss Turbocor Compressors

Danfoss Scrolls

Danfoss Optyma Condensing Units

Danfoss Maneurop Reciprocating Compressors

Danfoss Light Commercial Refrigeration

Compressors

Our products can be found in a variety of applications such as rooftops, chillers, residential air conditioners,

heatpumps, coldrooms, supermarkets, milk tank cooling and industrial cooling processes.

http://cc.danfoss.com

Danfoss Commercial Compressors, BP 331, 01603 Trévoux Cedex, France | +334 74 00 28 29

askcc@danfoss.com

Danfoss ca n accept no responsi bility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserves t he right to alter its p roducts with out notice. This als o applies to produ cts

already o n order provided t hat such alteratio ns can be made with out subsequenti al changes being n ecessary in spe cications alre ady agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Danf oss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

FRCC.PC.036.A2.02 © Danfoss | DCS (CC) | 2015.07

Loading...

Loading...