Data sheet

CCR3+ Controller

Return temperature controller & temperature registration

Description

The CCR3+ Controller is an electronic controller

for return temperature control in risers in

one-pipe heating system based on supply

temperature signal. With CCR3+ controller onepipe heating system becomes efficient variable

flow system with riser’s flow control based on

heat demand.

CCR3+ is dedicated to be used with AB-QM

automatic balancing & control valve equipped

with thermo actuators type TWA-Z (NO) and

remote temperature sensors type ESMC.

CCR3+ together with AB-QM and TWA-Z is

complete one-pipe electronic solution:

AB-QTE

Main data:

• Designed for AB-QM DN 10-32 mm

• Maximum number of controlled risers:

20 (extension +16 via Slave Unit)

• No distance limitation between risers (control

valves) and controller

• Pulse Wide Modulation (PWM) algorithm

• Return temperature (curve) adjustable in 9

points

• Individual riser setting possible

• Possible connection to BMS system

• Build in web server for access via mobile

devices or PC (readings, settings, datalogs,

etc)

• LED status indicators

• Flow control in risers based on heat demand

• Build in Web-Server App, Wi-Fi connection

and LAN port

Benefits

Ordering

• Improved room temperature control

• Eliminated overheating of the building

• Reduced heating cost with payback time less

than 4 years

• Remote control and access of all temperature

setting (no need to have direct access to

risers!)

Inclusive in the box: CCR3+ Controller, 1 pcs ESMC sensor

Typ e Designation Supply voltage Actuat or type/nos. Code No.

CCR3+ Controller

Accessory

Typ e Designation Voltage Comments Code No.

TWA-Z (NO) Thermal actuators 24 V 1.2 m. cable 08 2F1220

Set:

TWA-Z (NO) with

ESMC (PT 1000)

ESMC (PT 1000) Surface sensor - 2 meters cable 08 7N 0011

CCR+ Slave Unit System expansion (add 16 risers) 24 Vdc - 003Z3852

Return Temperature Controller &

Temperature Registration

Thermal actuators with surface sensor 24 V - 003Z0388

24 Vdc NO/20 003Z0396

© Danfoss | 2018.12

VD.GM.E1.02 | 1

Data sheet CCR3+ Controller

Applications

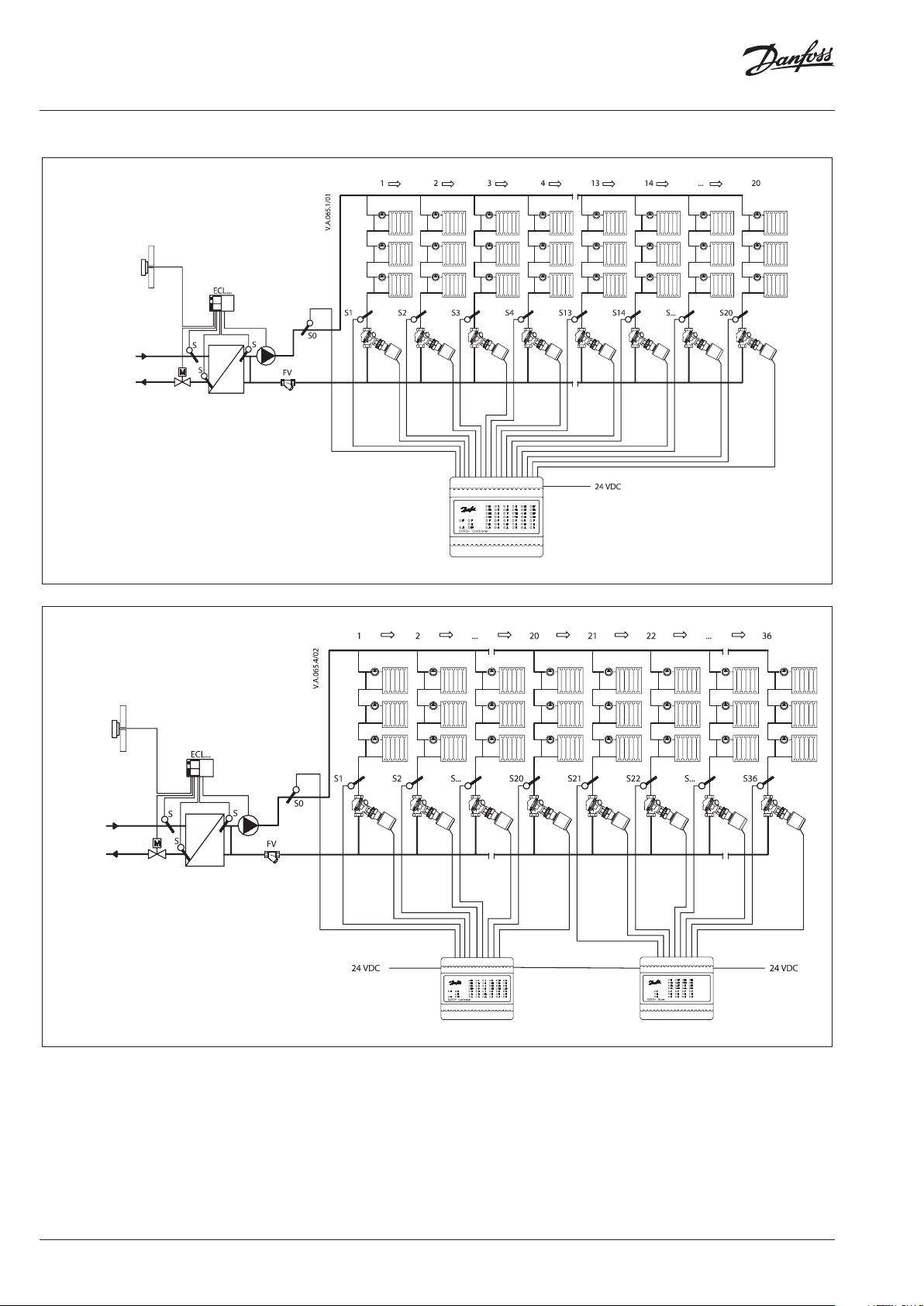

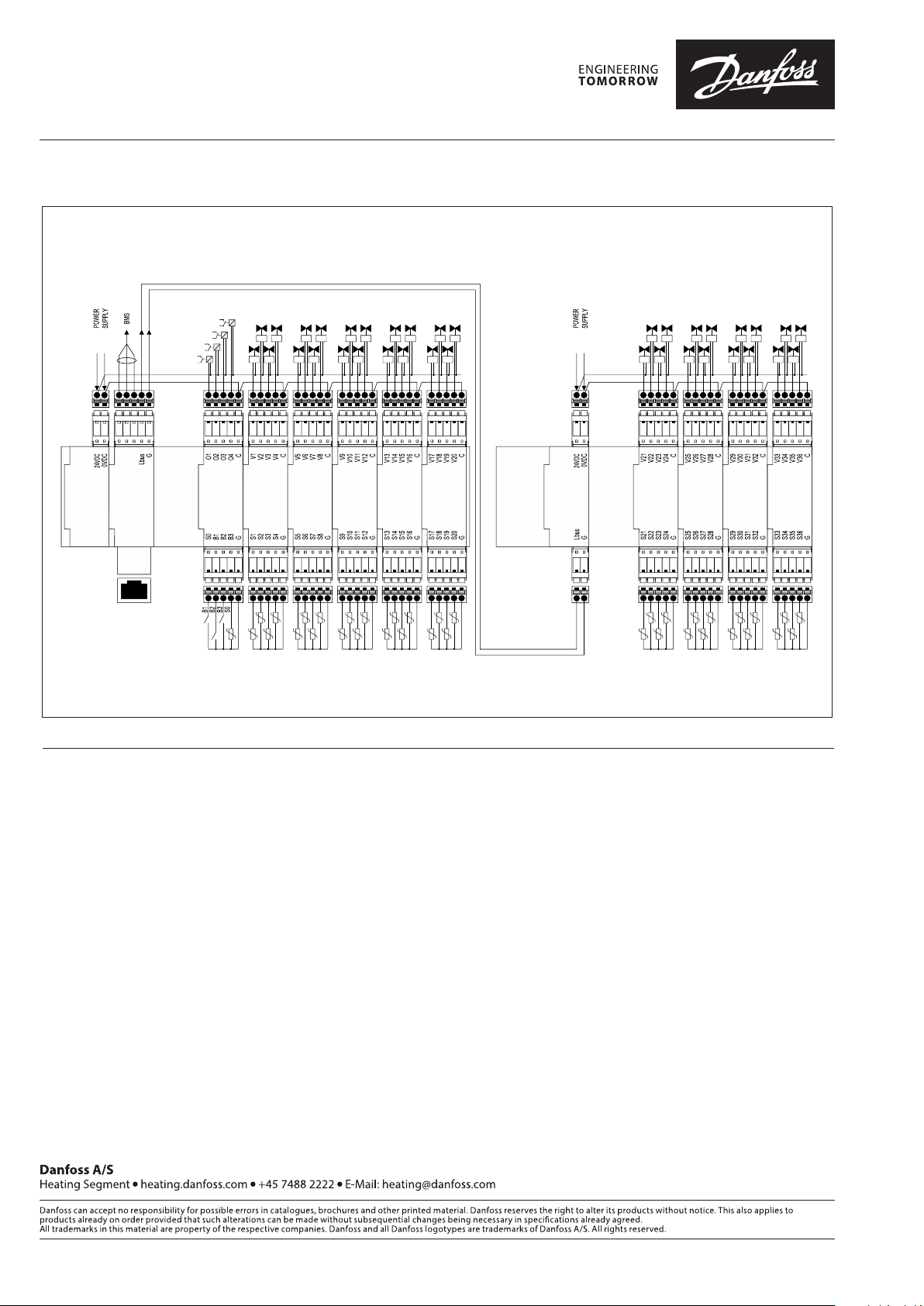

Fig. 1 CCR3+ Controller: scheme with 20 risers

Fig. 2 CCR3+ Controller: scheme with 36 risers

2 | © Danfoss | 2018.12

VD.GM.E1.02

Data sheet CCR3+ Controller

Applications (Continuous)

AB-QTE solution converts one-pipe heating

system - usually permanent flow system - into

efficient variable flow system.

This innovative solution dynamically controls the

flow in risers according to the load in risers by

return temperature control. Wide range of return

temperature setting (9 setting points) ensures

high efficiency of the system in whole range of

supply temperature from 35-90 °C.

In one-pipe systems flow in the risers is always

present even when all TRV’s are closed; water

flow through the by-pass which result in high

operating costs (heat losses, pumping costs,

overheating etc). TRV on the radiator controls

room temperature by controlling flow through

the radiator, while flow ratio between radiator

and by-pass is varying; however total flow in

risers remains permanent. At partial loads (some

TRV’s are closed) return water temperature in

risers increases, which results in overheating of

rooms due to very hot risers.

After the building is renovated heating system

becomes oversized since the heat losses of the

building decrease. As a result overheating issue

increases even more.

CCR3+ controller is part of AB-QTE solution

for one-pipe heating systems. It converts

one-pipe heating system (usually constant flow

system) into efficient variable flow system. This

innovative solution dynamically controls the

flow in the riser according to the load in risers by

return temperature control. Wide range of return

temperature setting (9 setting points) ensures

high efficiency of the system in whole range of

supply temperature from 35-90 °C.

In traditional one-pipe systems flow in the risers

is present even when all TRV’s are closed. Water

flows through the by-pass at all times. TRV on

the radiator controls room temperature by

controlling flow through the radiator, while flow

ratio between radiator and by-pass is varying.

Total flow in risers remains permanent though.

At partial loads (some TRV’s are closed) return

water temperature in risers increases. Result is

high operating costs: heat losses, pumping costs,

overheating, etc. In case building is renovated

overheating issue increases even more as

heating system becomes oversized.

AB-QTE concept solution:

• AB-QM mounted in the risers provides right

water balance in the risers at all system

condition. Every riser get designed flow and

each riser is independent from the rest of

installation.

• CCR3+ with temperature sensors and

actuators mounted on AB-QM controls flow

in risers through the return temperature

control. When return temperature increases

CCR3+ automatically detects this change and

reduces flow in risers according to set points

(lower load in risers – lower flow needed).

This results in improved room temperature

control and greatly reduced overheating of

the building.

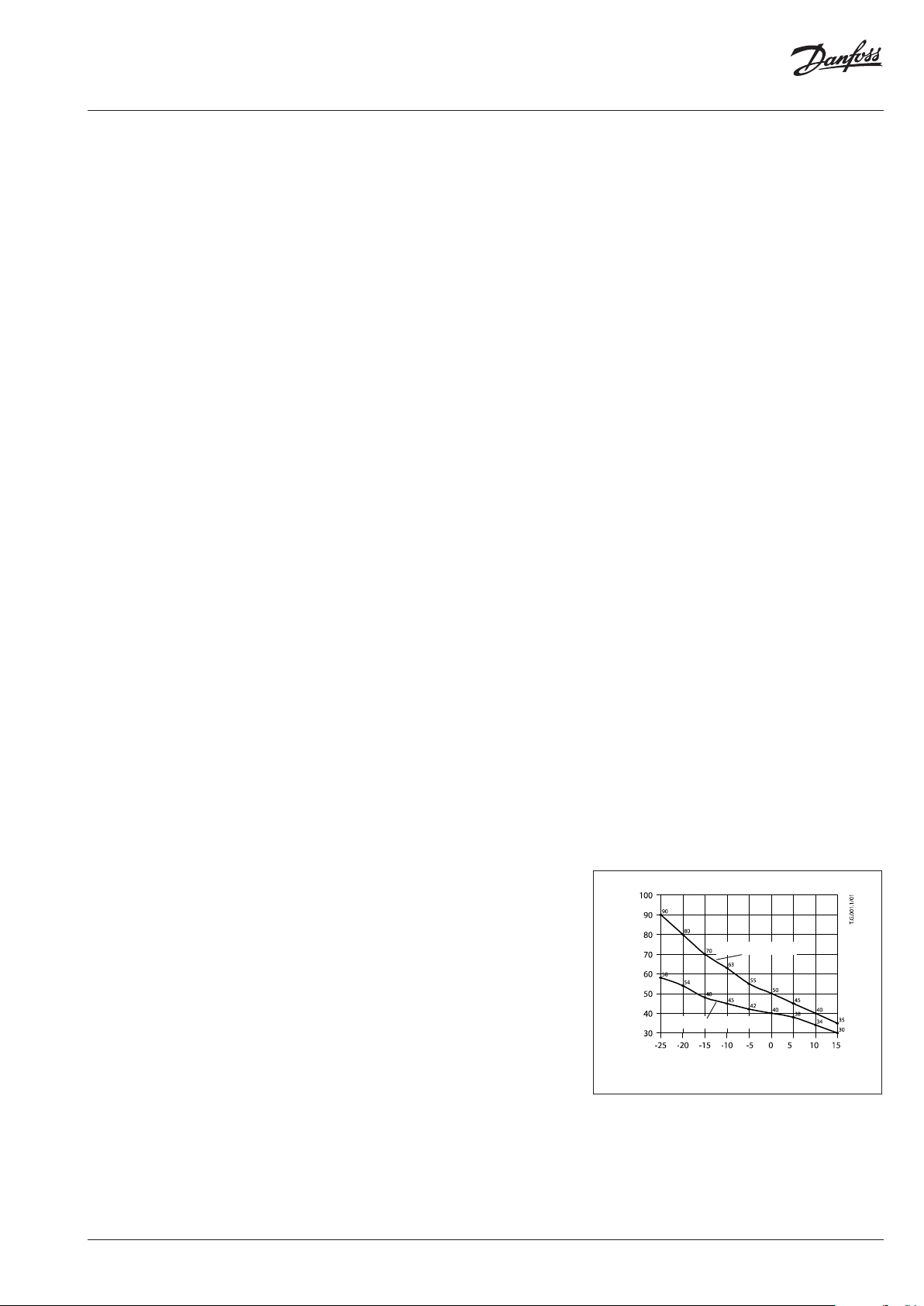

Compared to self- acting solution (QT

thermostatic elements), AB-QTE solution

covers very wide temperature setting

range, as presented in Fig. 3. All points of

return temperature setting correspond to

supply temperature what allows automatic

adaptation to weather condition according

the rules: lower outside temperature , higher

supply temperature – except higher return

temperature, but all time optimized at any

supply parameter.

• Thus one-pipe system becomes energy

efficient variable flow system.

• AB-QTE solution is perfect from service,

monitoring and maintenance point of view.

The CCR2+ incorporates LED status indicator,

build in Web-Server App, Wi-Fi connection

and LAN port, which allow the user to

manually set, log and monitor measured

parameters from the system on smart device

or PC.

Danfoss AB-QTE solution for one-pipe

renovation system is a top end solution

where the first double curve system control

is proposed. First: on primary side , usually

in sub-station where weather compensatory

control supply temperature according out-door

temperature (based on weather compensator

curve). Second one: on secondary side where

return temperature curve is adjusted based

on supply water temperature. Lower outside

temperature requires higher supply temperature

which yields to also higher return temperature.

Key point: at all times optimized. Thus one-pipe

system becomes energy efficient variable flow

system.

The return temperature can be adjusted in

eight points, each correspondent to one flow

temperature.

The setting can be automatically applied for

all risers or using from menu additional setting

function return temperature can be modified

individually to each riser by:

Shift factor – allow to move up and down the

curve in each point, setting range ±10 °C.

flow temperature

Temperature [°C]

return temperature

Outdoor temperature [°C]

Fig. 3 Return temperature curve graphs

VD.GM.E1.02

© Danfoss | 2018.12 | 3

Data sheet CCR3+ Controller

Technical data

Temperature sensor (S0, S1-S20 / S21-36) Pt1000, S0 – type ESMC/ESM11, S1-S20 / S21-36 – type ESMC

Temperature range (registration) –20 °C … +120 °C

Measuring accuracy +/- 0.5 K

Inputs: B1, B2 & B3 Free contact (5 V 1 mA)

Number of control valves (risers) 20 basic, additional 16 with system extension via CCR+ Slave Unit

Output signal to actuators 24 VDC max. 1 A

Alarm signal output 24 VDC ma x. 1 A

Relay output 0-24 VDC max. 1A

Type of memor y Build-In

Capacit y of memory 8 GB

Timer: Real time clock Built-in bat tery – powered for 10 years

- Wi-Fi (communication port only)

Communication interfaces

Default IP settings:

Ambient temperature

Transport temperature –10 … +60 °C

IP rating IP 20

Power supply 24 VDC

Power consumption (Controller only) 1)10 VA

Power consumption (Slave Unit only) 1)VA

Weight 0.3 kg

Installation DIN rail 35 mm

1)

To select pro per power transformer pl ease follow formula: 24 V 10VA (controller) + 7 VA*/per each ac tuator

- TPC/IP port (LAN cable connection)

- Modbus RS 485 RTU

- IP Modbus (L AN cable connection)

- Default L AN IP address (static): 192.168.1.100

- Default WiFi acess IP address (static): 192.168.1.10

- IP address mask: 255.255.255.0

- Gateway address: 192.168.1.1

- DNS address: 192.168.1.1

- CCR name: ccrplus

- Default password: admin1234

0 … +50 °C ( for CCR3+ only. The ambient temperature for actuators TWA-Z (NO)

should not be above 30 °C)

Settings Flow on AB-QM and temperature setting on

CCR3+ Controller need to be set to achieve best

performance and efficiency of one-pipe heating

system.

Recommended is a following 3 steps setting

procedure:

1. AB-QM setting

2. CCR3+ Controller setting

3. Follow up

There are two main reasons that influence onepipe system efficiency and therefore AB-QM and

CCR3+ setting:

1. renovation status of the building since

renovation is major reason for heating system

to become oversized, generally, after building

is renovated (wall & roof insulation, new

windows) existing heating system becomes

significantly oversized.

2. a dynamic nature of the heating load that is

changing unpredictably in he building due

to partial loads, internal gains and weather

conditions.

Notes:

• Install temperature sensor in front of AB-QM

and as close to last radiator in the riser/loop as

possible.

• After renovation, it is important to optimize

(reduce) flow temperature. Too high supply

water temperature can influence radiators

performance and result in oscillation of flow.

In addition, optimized flow temperature

improves efficiency of the one-pipe heating

system. This procedure should consider the worst

riser condition (big load, bad isolation etc).

• Ensure correct radiator a bypass flow setting

(typically around 25-35 %). If the resistance of

the radiator is much too high compared to the

bypass this may result in underflow through

radiator if the flow in riser/loop is reduced.

1. AB-QM setting

First it is necessary to set the AB-QM for required

flow before the actuators is mounted. Required

flow setting shall not be higher than calculated

design flow value Flow can be adjust according

standard AB-QM setting recommendation from

20 % to 100 %.

2. CCR3+ controller setting

Return temperature setting should be done

centrally on CCR3+ for all risers.

To simplify setting procedure it is required to

adjust only 9 return temperature points which

correspondent to supply temperature, e.g:

supply temp. 40 °C (required return temp. 38 °C),

supply temp. 45 °C (required return temp. 40 °C),

etc.

4 | © Danfoss | 2018.12

VD.GM.E1.02

Data sheet CCR3+ Controller

Settings (Continuous)

Mounting

These settings will apply for risers. Later, if

needed from menu we can choose option to

change setting individually for each riser. Setting

point can be moved up and down – according to

request. This option allows in easy way adapting

risers to individual demands.

For additional information about temperature

choosing for nominal condition including

Dynamic factor method please look in data sheet

for thermostatic actuators QT, page 6.

For simplification CCR3+ Controller offers default

setting (factory setting curve) that fits to typical

renovated system based on EN 15316 and ISO

13790.

Actuators:

more details on data sheet TWA-Z

Temperature sensors:

more details on data sheet PT1000 (ESM, ESMB,

ESMC, ESMT, ESMU)

Note: to compensate lo ng distance from sensor to CCR3+

controller (addi tional cable resistance can infl uence accuracy of

temperature m easuring), please use correctio n factors according

CCR3+ (see CCR3+ instructions). Cables shor ter than 10 m (0,75

mm2) and 15 (1,00 mm2) do not require any cor rection.

3. Follow up

Achieved energy efficiency of AB-QTE solution

depends on CCR3+ Controller setting. For

maximum results it is strongly recommended to

perform follow up on the installation during first

weeks of system operating. Easy access to setting

from one central place (where CCR3+ Controller

is installed) allows making any changes without

extra cost and efforts!

Temperature registration The CCR3+ Controller can measure temperature

with accuracy: ±0,5 °C.

Temperatures are measured by PT 1000

temperature sensors installed on the risers. If the

CCR3+ is used solely for recording temperatures,

it is not necessary to install any actuators on the

AB-QM valves.

Sampling time (data collection) intervals can

be adjusted using the control’s keypad from 1

minute.

Data are stored on internal memory. The data

collecting period depends strongly on and the

sampling interval.

Data are saved in *.csv format and can be

downloaded any time in Data menu.

The data can be visualised in spreadsheet and

graphs.

VD.GM.E1.02

© Danfoss | 2018.12 | 5

Data sheet CCR3+ Controller

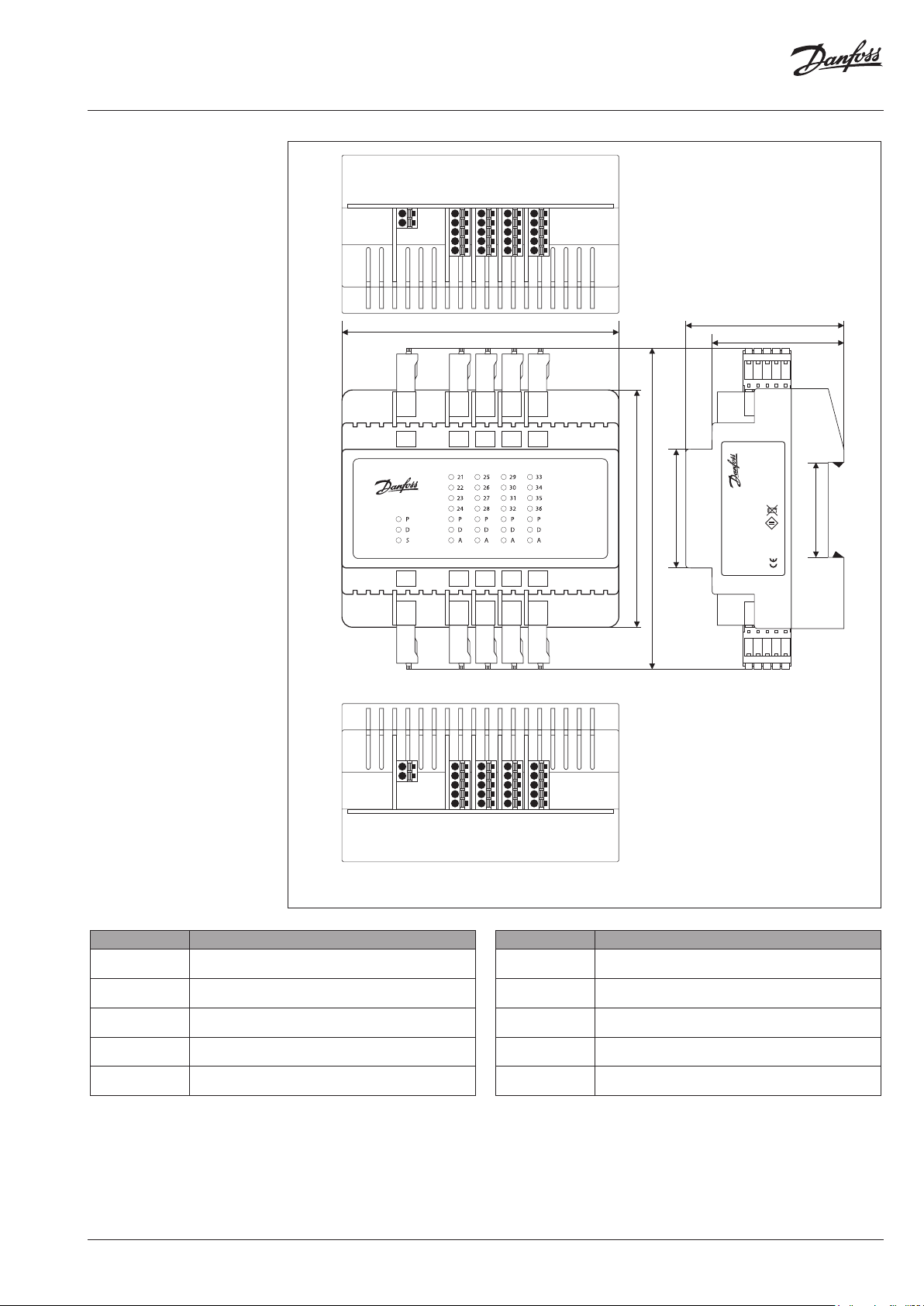

Wiring, Dimensions and

Installation

G

G

Lbus

24VDC

G

B

A

POWER

Master

LBus

0V

RS485

24VDC

CCR3+ Controller

TCP/IP

LAN

C

CCCCC

O4

V4

V8

V12

O3

V3

O2

O1

Module 0

V7

V2 V6 V10 V14 V18

V1

V5

Module 1

Module 2

V16

V11

V15

V9

V13

Module 3

Module 4

105 mm

C

O1-4

B1-3 S0

G

V1-4

S1-4

C

G

C

V5-8CV9-12

S5-8GS9-12

C

V13-16

S13-16

G

G

V20

V19

V17

Module 5

V17-20

S17-20

G

60 mm

50 mm

C

Danfoss A/S

MADE IN POLAND

6430 Nordborg, Denmark

90 mm

45 mm

122 mm

CCR3+

003Z0396

20171213V3.12

Return Temperatur e

Controller

RoHS

Supply 24VDC

36 mm

BOTOM

Connector/port Description

0V

24VDC

Lbus

RS485

C

O1,.. ,O4

C

V1-4

C

V5-8

C

V9 -12

0V – ground (-) power supply

24 V DC(+) power supply

G – ground Lbus port (for system expansion)

Lbus – Lbus por t (for system expansion)

G – ground (Modbus RS 485)

B – port B (Modbus RS 485)

A - port A (Modbus RS 485)

C – common port dedicated to outputs O1-O4

O1,.. O4 – defined outputs

C – common port dedicated to actuators V1-4

O1 - output: Alert Broken Sensor

O2 - output: Alert Low Temp

O3 - output: Alert High Temp

O4 - output: not in use

C – common port dedicated to actuators V5-8

V5. .V8 – outputs to ac tuators

C – common port dedicated to actuators V9-12

V9. .V12 – outputs to actuators

6 | © Danfoss | 2018.12

S5

S1

POWER

TCP/IP

Master

RJ45

B1

B2

B3

Module 0

S0

G

S6

S2

S7

S3

Module 1

Module 2

S8

S4

G

G

Fig. 4 Wiring scheme - CCR3+ Master Controller

Connector/port Description

C

V13 -16

C

V17-2 0

TC P/IP, LA N TCP/ IP port or IP Modbus port

B1-3, S0

G

S1-4

G

S5-8

G

S9 -12

G

S13 -16

G

S17-2 0

G

S9

S10

S11

Module 3

S12

G

S18

S14

S19

S15

Module 4

Module 5

S20

S16

G

G

C – common port dedicated to actuators V13-16

V13..V16 – outputs to actuators

C – common port dedicated to actuators V17-20

V17.. V20 – outputs to actuators

B1,B2, B3 defined inputs

S0 – temp. sensor

G – common ground dedicated to inputs/sensor

S1.. S4 – inputs from sensors

G – common ground dedicated to sensor S1-4

S5..S8 – inputs from sensors

G – common ground dedicated to sensors S5-8

S9. .S12 – inputs from sensors

G – common ground dedicated to sensors S9-12

S13.. S16 – inputs from sensors

G – common ground dedicated to sensors S13-16

S17. .S 20 – inputs from sensors

G – common ground dedicated to sensors S17-20

S17

S13

VD.GM.E1.02

Data sheet CCR3+ Controller

Wiring, Dimensions and

Installation (Continuous)

24VDC

Power

24VDC

CCR+ Slave

G

OV

G

LBus

C

V24

6

V23

V22

V21

Module

105 mm

C

V21-24

S21-24

G

C

V28

7

V27

V26

V25

Module

C

V25-28

S25-28

G

CC

V32

V36

V31

V35

V30 V34

V29

V33

Module 8

Module 9

C

C

V33-36

V29-32

S33-36

S29-32

G

G

90 mm

122 mm

45 mm

CCR+ Slave Unit

60 mm

50 mm

MADE IN POLAND

CCR+ Slave Unit

20171212VS.12

003Z3852

Danfoss A/S

6430 Nordborg, Denmark

36 mm

RoHS

Supply 24VDC

Connector/port Description

0V

24VDC

C

V21-24

C

V24 -28

C

V29-32

C

V30-36

0V – ground (-) power supply

24 VDC power supply

C – common port dedicated to actuators

V21..V 24 – outputs to ac tuators

C – common port dedicated to actuators

V24..V28 – outputs to actuators

C – common port dedicated to actuators

V29..V32 – outputs to actuators

C – common port dedicated to actuators

V33..V36 – outputs to actuators

VD.GM.E1.02

G

Lbus

Slave

0

S25

S21

S26

S22

S27

S23

Module 0

Module

S28

S24

G

GG

Fig. 5 Wiring scheme - CCR+ Slave Unit

1

2

S33

S29

S30

S34

S31

S35

Module

Module

S32

S36

G

Connector/port Description

Lbus G – ground Lbus port (for system expansion)

S21-24

G

S25 -28

G

S29-32

G

S33-36

G

Lbus – Lbus por t (for system expansion)

S21.. S24 – inputs from sensors

G – common ground dedicated to sensors

S25..S28 – inputs from sensors

G – common ground dedicated to sensors

S29.. S32 – inputs from sensors

G – common ground dedicated to sensors

S33..S36 – inputs from sensors

G – common ground dedicated to sensors

© Danfoss | 2018.12 | 7

Data sheet CCR3+ Controller

Wiring, Dimensions and

Installation (Continuous)

Power

Supply

Board

Master

Controller

Board

TCP/IP - LAN

WEB SERVER

BMS TCP/IP

ETHERNET

INTERNET

CCR3+ Master

Wiring diagram

Dened output O4

Dened output O3

Dened output O2

KO1

Def. output O4

24VDC

0V

Module 0

Empty

Input / Output

Socket

Board

Place

B1 - Def.input B1

B2 - Def.input B2

B3 - Def.input B3

KO3

KO2

S0 - main

KO4

sensor

PT1000

Input / Output

Actuators of risers’ valves V1...V20

Open collector outputs connect to 0V

V2V3V4V5V6V7V8V9V10

V1

Module 1

Module 2

Input / Output

Board

Board

Risers’ temperature sensors S1...S20

Type of sensor - PT1000

V11

Module 3

Input / Output

Board

V12

V14

V13

V15

Module 4

Input / Output

Board

V16

V18

V17

V19

Module 5

Input / Output

Board

CCR+ Slave

Wiring diagram

Actuators of risers’ valves V21...V36

Open collector outputs connect to 0V

V20

Empty

Socket

Place

24VDC

Controller

and Power

Slave

Supply

Board

24VDC

+ -

Empty

Socket

Place

V22

V24

V26

V21

V23

V25

Module 1

Input / Output

Module 2

Input / Output

Board

Board

Risers’ temperature sensors S21...S36

V28

V30

V32

V27

V29

V31

Module 3

Input / Output

Board

Type of sensor - PT1000

V34

V33

V35

Module 4

Input / Output

Board

V36

Fig. 6 Wiring sc heme CCR3+ Master Controller with CCR+ Slave

Tender text • One-pipe heating systems should have

electronic control of return temperature,

based on supply temperature signal.

• Temperature curve should be adjusted in

nine points from 35°C flow temperature up to

90°C.

• Control should base on: Return temperature

controller, automatic balancing & control

valve equipped with thermo actuators type

TWA-Z 24V (NO) and remote temperature

sensors type ESMC

• Controller allows return temperature control,

monitoring and registering temperatures

• Maximum number of controlled branches is

20, system can be expanded with slave unit

(+16)

• Controller allows connectivity with mobile

devices and personal computers

• Controller should have “Summer mode”

function (switchable in controller settings or

via BMS) to shut-off flow on control valves

when heating season is over.

• Controller allows connection to web

browser (HTLM) supported devices via Wi-Fi

communication port or LAN port

• Controller support BMS systems via RS 485

Modbus RTU and IP Modbus

• Unauthorized change of controller setting is

secured by password

• Controller should have Pulse Wide

Modulation (PWM) algorithm

• Build in pump protection function

• Controller can measure temperature with

accuracy: ±0,5 °C.

• Supply Voltage: 24V DC 50/60H

8 | © Danfoss | DHS-SRMT/SI | 2018.12

VD.GM.E1.02

Loading...

Loading...