Page 1

Operating Guide

CCR3+ Controller

ENGLISH

DEUTSCH

LIETUVIŲ K.

CCR3+ Controller www.danfoss.com Page 2

Regler CCR3+ www.heating.danfoss.de Seite14

CCR3+ valdiklis

www.heating.danfoss.lt 22 psl.

© Danfoss | 2022.01

AQ29035882028101-010206 | 1

Page 2

CCR3+ Controller

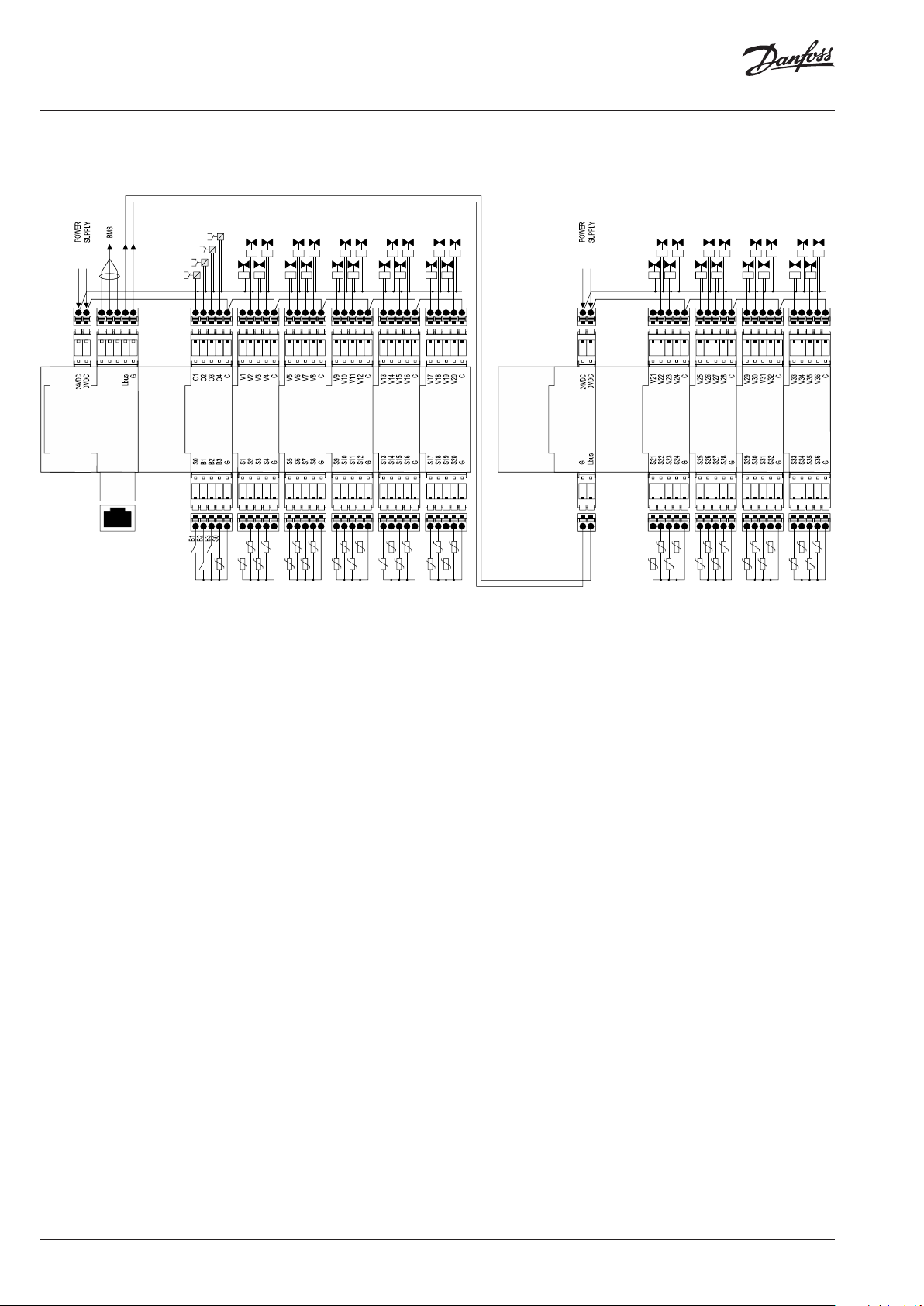

Fig. 1 Installa tion with CCR3+ Controller (up to 20 risers/l oops)

Abb. 1 Install ation mit CCR3+ Regler (bis zu 20 Stränge/ Kreise)

1 pa v. Montavimas su CCR3+valdikliu (ne daug iau kaip 20 stovų / ciklų)

Fig. 2 Installa tion with CCR23 Controller (Master) and CCR+ Slave Unit (mor e that 20 risers)

Abb. 2 Installation mit CCR3+ Regler (Führungsregler) und CCR+ Nebenregler (mehr als 20 Stränge)

2 pa v. Montavimas su CCR23valdikliu ir CCR+prapl ėtimo moduliu(daugiau kai p 20 vamzdyno stovų)

2 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 3

CCR3+ Controller

G

G

Lbus

24VDC

G

B

A

POWER

Master

LBus

0V

RS485

24VDC

CCR3+ Controller

TCP/IP

LAN

C

CCCCC

O4

V4

V8

V12

O3

V3

O2

O1

Module 0

V7

V2 V6 V10 V14 V18

V1

V5

Module 1

Module 2

V16

V11

V15

V9

V13

Module 3

Module 4

105 mm

C

O1-4

B1-3 S0

G

V1-4

S1-4

C

G

C

V5-8CV9-12

S5-8GS9-12

C

V13-16

S13-16

G

G

V20

V19

V17

Module 5

C

V17-20

S17-20

G

90 mm

122 mm

45 mm

Return Temperatur e

60 mm

MADE IN POLAND

CCR3+

Controller

50 mm

003Z0396

Supply 24VDC

20171213V3.12

Danfoss A/S

6430 Nordborg, Denmark

RoHS

36 mm

BOTOM

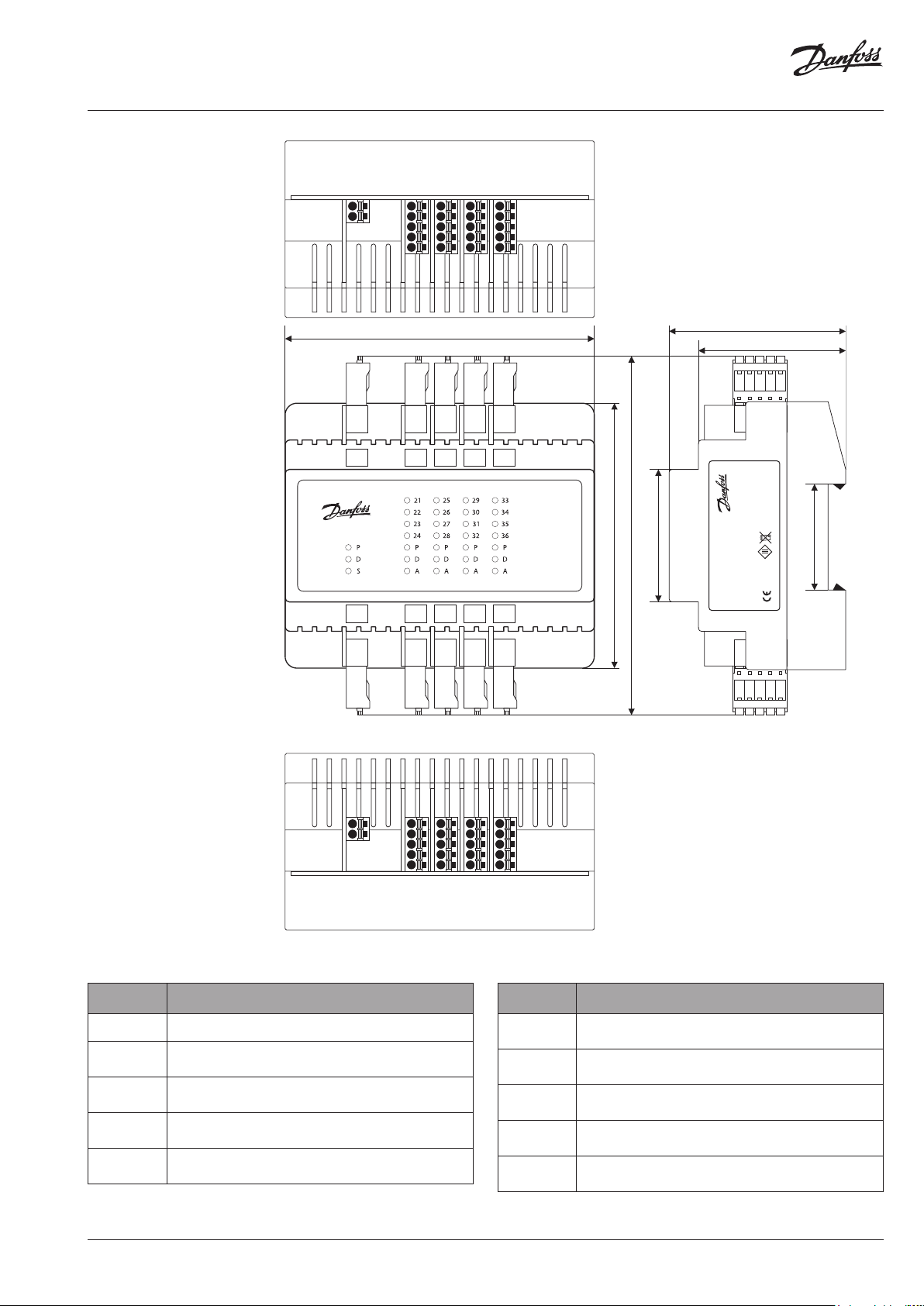

Fig. 3 Wiring sc heme - CCR3+ Master Controller

Abb. 3 Schaltbild – CCR3+ Führungsregler

3 pa v. Laidų schema – CCR3+valdiklis

Connector/port

Stecker/Klemme

Jungti s/ lizdas

0V

24VDC

Lbus

RS485

C

O1,.. ,O4

C

V1-4

C

V5-8

C

V9 -12

Description / Beschreibung / Aprašymas

0V – ground (-) powe r supply / 0V – Masse (-) Span nungsversorgu ng /

0 V – įžeminimas (-) maitinimas

24 VD C(+) power supp ly / 24 V DC(+) Spannungsversorgung /

24 V pastovioji srovė (+) maitinimas

G – ground Lbu s port (for syste m expansion) / G – Mass e Lbus-Anschluss (f ür

Systemerweiterung) / G –Lbus magistralė sįžeminimo jungt is (sistemai prapl ėsti)

Lbus – Lbus port (fo r system expans ion) / Lbus – Lbus-Anschluss (f ür Systemerwei terung) /

Lbus – Lbus magistr alėsjungtis(siste mai praplėsti)

G – ground (Mod bus RS 485) / G – Masse (Mo dbus RS 485) / G – įžemini mas (Modbus RS 485)

B – port B (Mod bus RS 485) / B – Anschlus s B (Modbus RS 485) / B – B jun gtis (Modbus RS 48 5)

A – port A (Mod bus RS 485) / A – Anschlus s A (Modbus RS 485) / A – A jung tis (Modbus RS 48 5)

C – common por t dedicated to ou tputs O1-O4 / C – geme insamer Anschlu ss für Ausgän ge

O1–O4 / C – bendra j ungtis skirt aišėjimams O1-O4

O1 – output: Ale rt Broken Sen sor / O1 – Ausgang: Warnu ng gebrochen er Sensor / O1 – išėjimas:

Pažeisto jutiklio įspėjimo signalas

O2 – output: Ale rt Low Temp / O2 – Ausgang: Warn ung niedrige Temp. / O2 - iš ėjimas: Per žemos

temperatūros įspėjimo signalas

O3 – output: Ale rt High Temp / O3 – Ausgang: Wa rnung hohe Temp. / O3 - išėji mas: Per aukšto s

temperatūros įspėjimo signalas

O4 – output: n ot in use / O4 – Ausgang: Ni cht verwende t / O4 - išėjimas: nenaudojamas

C – common por t dedicated to ac tuators V1-4 / C – gemeinsamer Anschluss für Stellantriebe

V1–4 / C – bendra p avaroms skirt a jungtis V1-4

V1..V4 – out puts to actuator s / V1..V4 – Ausgänge z u Stellantrieben / V 1..V4 – išėjimai

į pavaras

C – common por t dedicated to ac tuators V5- 8 / C – gemeinsamer Anschluss für Stellantriebe

V5–8 / C – ben dra pavaroms skir tajungtis V5- 8

V5..V 8 – outputs to ac tuators / V5. .V8 – Ausgänge zu St ellantrieben / V 5..V8 – išėj imai į

pavaras

C – common por t dedicated to ac tuators V9-12 / C – gemeins amer Anschluss f ür

Stellantriebe V9–12 / C – bendra jungti s, skirta pavar oms V9-12

V9. .V12 – outputs t o actuators / V9 ..V12 – Ausg änge zu Stellantri eben / V9.. V12 – išėjimai

į pavaras

AQ29035882028101-010206

POWER

TCP/IP

Master

RJ45

B1

B2

B3

Module 0

S0

G

S5

S1

S6

S2

S7

S3

Module 1

Module 2

S8

S4

G

G

Connector/port

Stecker/Klemme

Jungti s/ lizdas

C

V13-1 6

C

V17-2 0

TC P/I P, L AN

B1-3, S0

G

S1-4

G

S5-8

G

S9 -12

G

S13-16

G

S17-20

G

S9

S10

S11

Module 3

S12

G

S18

S14

S19

S15

Module 4

Module 5

S20

S16

G

G

Description / Beschreibung / Aprašymas

C – common por t dedicated to ac tuators V13-16 / C – gemeinsame r Anschluss fü r

Stellantri ebe V13–16 / C – bendra j ungtis, skirt a pavaroms V13-16

V13..V16 – outputs to ac tuators / V13..V16 – Ausgänge zu Ste llantrieben / V13..V16 –

išėjimai į pav aras

C – common por t dedicated to ac tuators V17-20 / C – gemeinsame r Anschluss für

Stellantri ebe V17–20 / C – bendra ju ngtis, skirt a pavaroms V17-20

V17. .V2 0 – outp uts to actuators / V 17.. V20 – Ausgänge zu Ste llantrieben / V 17.. V20 –

išėjimai į pav aras

TCP/I P port or IP M odbus port / T CP/IP -Anschluss oder IP Modbus-Anschluss / TCP/IP jungtis

arba IP Mod bus jungtis

B1,B2, B3 defined inputs / B1,B2, B3 definierte Eingänge / B1,B2, B3 numatytieji įėjimai

S0 – temp. sensor / S0 – Temp.-S ensor / S0 – temp. jutik lis

G – common grou nd dedicated to in puts/sensor / G – gem einsame Masse fü r Eingänge/

Sensor / G – bendras įžeminimas, skirt as įėjimams / jutikliams

S1..S 4 – inputs fro m sensors / S1.. S4 – Eingänge v on Sensoren / S1.. S4 – įėjimai i š jutiklių

G – common grou nd dedicated to se nsor S1-4 / G – gemeinsam e Masse

für Sensor en S1–4 / G – bendras įžeminimas, skirtas jutikliams S1-4

S5..S8 – inpu ts from sensors / S5 ..S8 – Eingänge vo n Sensoren / S5..S 8 – įėjimai iš jutikli ų

G – common grou nd dedicated to se nsors S5-8 / G – gem einsame Masse f ür Sensoren S5– 8 /

G – bendras įžeminimas, skirtas jutikliams S5-8

S9. .S12 – input s from sensors / S 9..S 12 – Eingänge von S ensoren / S9. .S12 – įėji mai iš jutiklių

G – common groun d dedicated to se nsors S9-12 / G – gemeinsame M asse für Sensor en S9–12 /

G – bendras įžeminimas, skirtas jutikliams S9-12

S13.. S16 – inputs from se nsors / S13.. S16 – Eingänge von Se nsoren / S13.. S16 – įėjimai

iš jutiklių

G – common grou nd dedicated to se nsors S13-16 / G – gemeinsame Masse f ür Sensoren

S13–16 / G – bendras įžeminimas, skirtas jutikliams S13-16

S17. .S 20 – inp uts from sens ors / S17. .S 20 – Ein gänge von Senso ren / S17. .S 20 – įėjim ai iš jutiklių

G – common grou nd dedicated to se nsors S17-20 / G – gemeinsame Masse f ür Sensoren

S17–20 / G – bendras įžeminimas, skirtas jutikliams S17-20

S17

S13

© Danfoss | 2022.01 | 3

Page 4

CCR3+ Controller

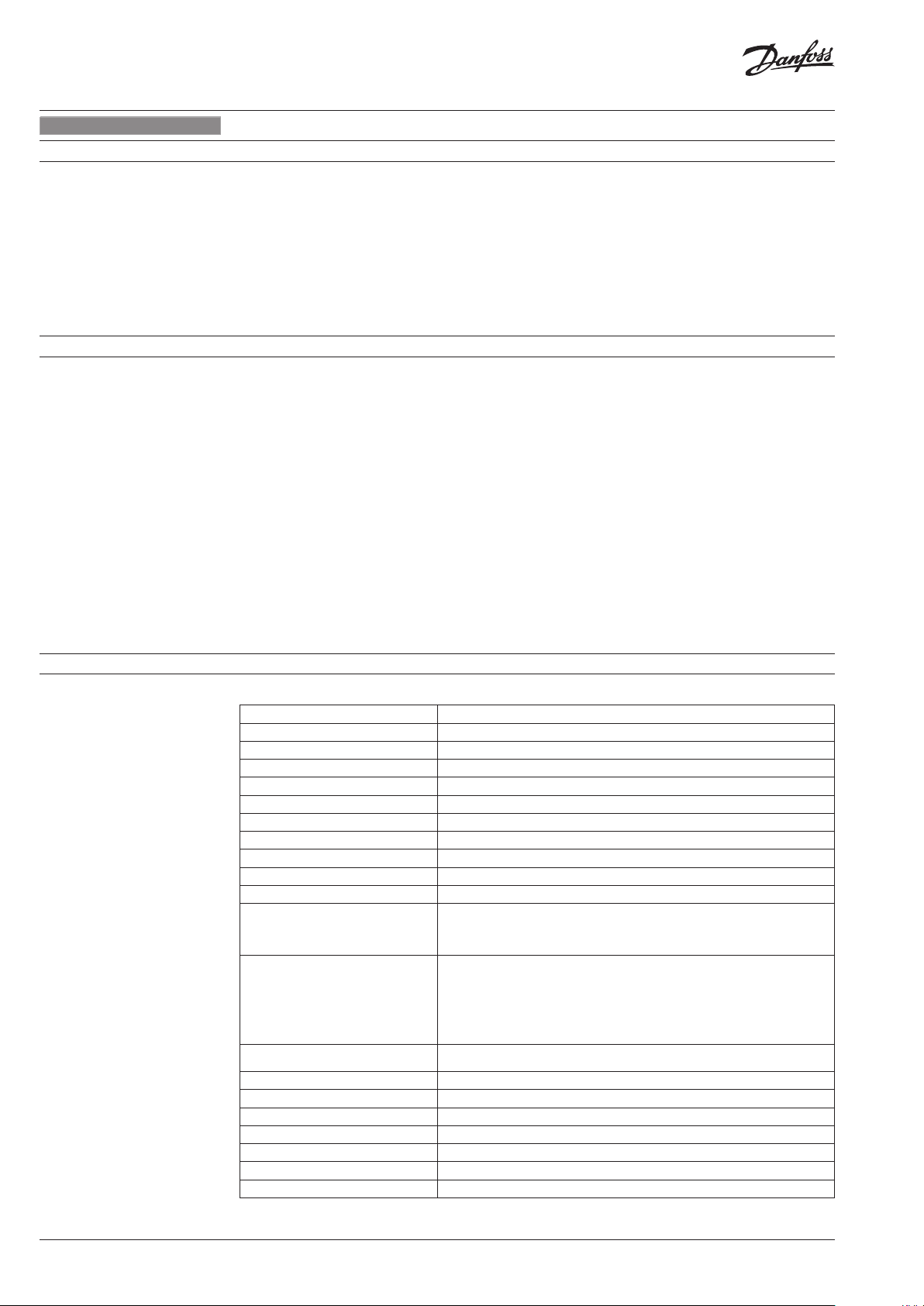

B3 - Def.input B3

PT1000

Power

Supply

Board

Master

Controller

Board

TCP/IP - LAN

WEB SERVER

BMS TCP/IP

ETHERNET

INTERNET

Dened output O4

Dened output O3

Dened output O2

Def. output O4

24VDC

0V

Empty

Socket

Place

B1 - Def.input B1

B2 - Def.input B2

CCR3+ Master

Wiring diagram

Actuators of risers’ valves V1...V20

KO4

KO3

KO2

KO1

Module 0

Input / Output

Board

S0 - main

sensor

Input / Output

Open collector outputs connect to 0V

V2V3V4V5V6V7V8V9V10

V1

Module 1

Board

Module 2

Input / Output

Board

Risers’ temperature sensors S1...S20

V12

V11

Module 3

Input / Output

Board

Type of sensor - PT1000

V14

V16

V13

V15

Module 4

Input / Output

Board

V18

V20

V17

V19

Module 5

Input / Output

Board

24VDC

Empty

Socket

Place

LBus 2x0.5mm2

(L=max. 100m)

24VDC

Slave

Controller

and Power

Supply

Board

CCR+ Slave

Wiring diagram

Actuators of risers’ valves V21...V36

Open collector outputs connect to 0V

V22

V24

V26

V28

V30

V32

V34

+ -

Empty

Socket

Place

V21

V23

Module 1

Input / Output

Board

V25

V27

V29

V31

Module 2

Input / Output

Risers’ temperature sensors S21...S36

Module 3

Input / Output

Board

Board

Type of sensor - PT1000

V33

V35

Module 4

Input / Output

Board

V36

Fig. 4 Wiring sc heme CCR3+ Master Controller with CCR+ Slave

Abb. 4 Schaltbild CCR3+ Führungsregler mit CCR+ Nebenregler

4 pav. Laidų jung imo schema - CCR3+valdiklio su CCR+ praplėtim o moduliu

4 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 5

CCR3+ Controller

24VDC

Power

24VDC

CCR+ Slave

LBus

G

OV

C

V24

6

V23

V22

V21

Module

105 mm

C

V21-24

C

V28

7

V27

V26

V25

Module

C

V25-28

CC

V32

V36

V31

V35

V30 V34

V29

V33

Module 8

Module 9

C

C

V33-36

V29-32

90 mm

122 mm

45 mm

60 mm

50 mm

MADE IN POLAND

Danfoss A/S

6430 Nordborg, Denmark

36 mm

RoHS

CCR+ Slave Unit

20171212VS.12

003Z3852

Supply 24VDC

G

S21-24

G

G

G

G

S33-36

S29-32

S25-28

CCR+ Slave Unit

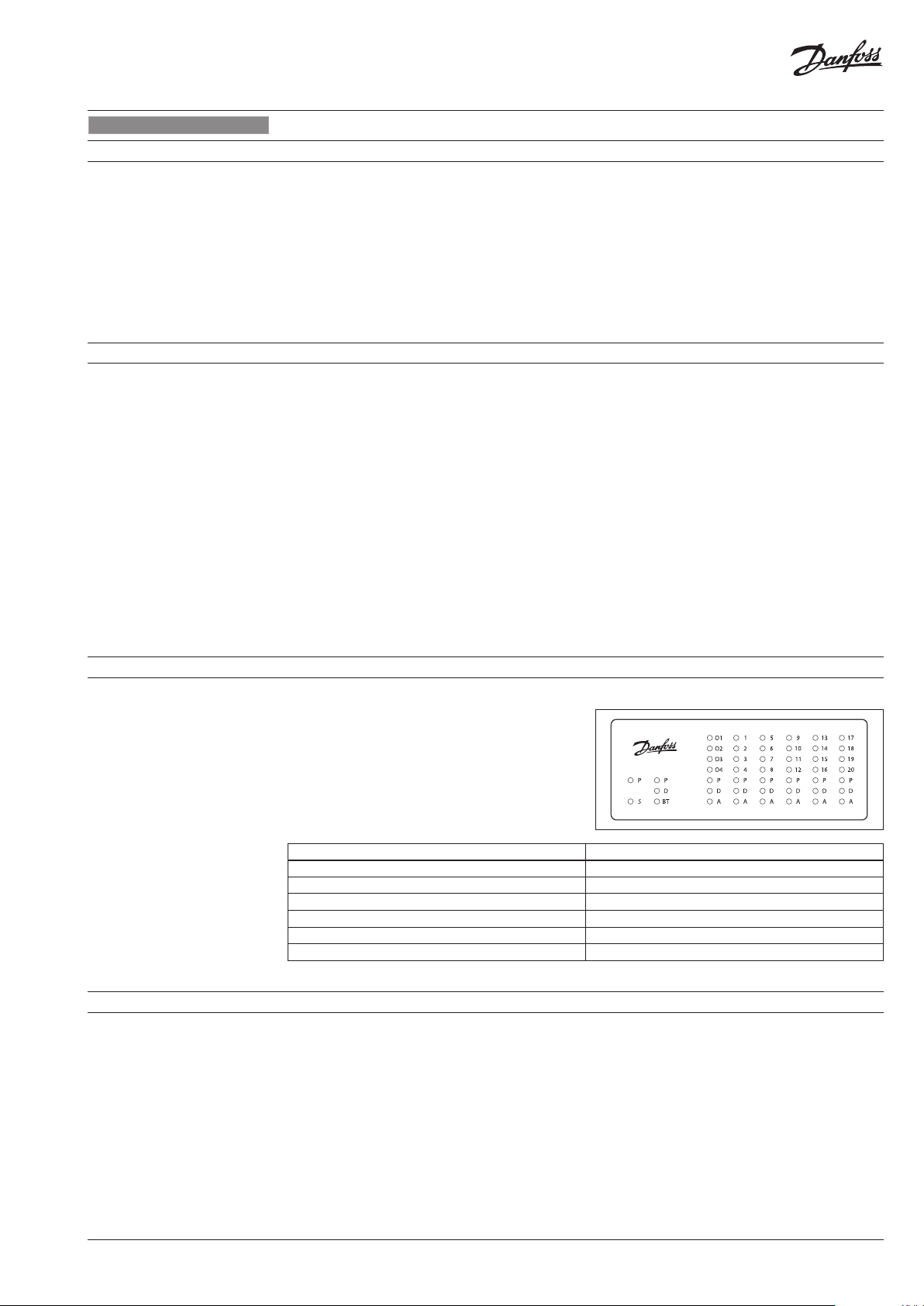

Fig. 5 Wiring scheme - CCR+ Slave Unit

Abb. 5 Schaltbild – CCR+ Nebenregler

5 pa v. Laidų schema – CCR+ praplėtimo modulis

Connector/port

Stecker/Klemme

Jungti s / lizdas

0V

24VDC

C

V21-24

C

V24 -28

C

V29-32

C

V33-36

Description / Beschreibung / Aprašymas

0V – ground (-) powe r supply / 0V – Masse (-) Span nungsversorgu ng / 0 V – įžeminimas

(-) maitinimas

24 VDC power s upply / 24 V DC Spannungsversorgung / 24 V pastovioji srovė maitinimas

C – common por t dedicated to ac tuators / C – gemei nsamer Anschlus s für Stellantrieb e /

C – bendra pavaroms skirta jungtis

V21..V2 4 – outputs to ac tuators / V21..V 24 – Ausgänge zu St ellantrieben / V 21..V24 –

išėjimai į pav aras

C – common por t dedicated to ac tuators / C – gemei nsamer Anschlus s für Stellantrieb e /

C – bendra pavaroms skirta jungtis

V24..V28 – outputs to act uators / V24..V28 – Ausgänge zu Stella ntrieben / V24..V28 –

išėjimai į pav aras

C – common por t dedicated to ac tuators / C – gemei nsamer Anschlus s für Stellantrieb e /

C – bendra pavaroms skirta jungtis

V29. .V32 – outpu ts to actuators / V 29..V3 2 – Ausgänge zu Stel lantrieben / V2 9..V32 –

išėjimai į pav aras

C – common port dedicated to actuators / C – gemeinsamer Anschluss für Stellantriebe /

C – bendra pavaroms skirta jungtis

V33..V36 – out puts to actu ators / V33..V36 – Au sgänge zu Ste llantrie ben / V33..V36 –

išėjimai į pavaras

AQ29035882028101-010206

Slave

G

Lbus

1

S29

S30

S31

Module

S32

2

S33

S34

S35

Module

S36

G

Connector/port

Stecker/Klemme

Jungti s / lizdas

Lbus

S21-24

G

S25-2 8

G

S29-32

G

S33-36

G

0

S25

S21

S26

S22

S27

S23

Module 0

Module

S28

S24

G

GG

Description / Beschreibung / Aprašymas

G – ground Lbu s port (for syste m expansion) / G – Mass e Lbus-Anschluss (f ür

Systemerweiterung) / G –Lbus magistralė sįžeminimo jungt is (sistemai prapl ėsti)

Lbus – Lbus port (fo r system expans ion) / Lbus – Lbus-Anschluss

(für Systemerweiterung) / Lbus – Lbus magis tralėsjungtis(sis temai praplės ti)

S21.. S24 – inputs fr om sensors / S21. .S24 – Eing änge von Sensore n / S21..S24 – įėjimai

iš jutiklių

G – common grou nd dedicated to se nsors / G – gemeins ame Masse für Sens oren /

G – bendras jutikliams skirtas įžeminimas

S25..S28 – input s from sensors / S25.. S28 – Eingänge von Se nsoren / S25..S28 – įėjima i

iš jutiklių

G – common grou nd dedicated to se nsors / G – gemeins ame Masse für Sens oren /

G – bendras jutikliams skirtas įžeminimas

S29..S32 – inputs from sen sors / S29..S32 – Ei ngänge von Senso ren / S29..S32 – įėji mai

iš jutiklių

G – common grou nd dedicated to se nsors / G – gemeins ame Masse für Sens oren /

G – bendras jutikliams skirtas įžeminimas

S33..S36 – input s from sensors / S33. .S36 – Eingänge von S ensoren / S33..S36 – įėji mai

iš jutiklių

G – common grou nd dedicated to se nsors / G – gemeins ame Masse für Sens oren /

G – bendras jutikliams skirtas įžeminimas

© Danfoss | 2022.01 | 5

Page 6

CCR3+ Controller

LANGUAGE

ENGLISH

1. Product description

2. Application

The CCR3+ Controller is a controller used to

control return temperature in one pipe heating

systems with functions such as temperature

registration and monitoring riser temperature.

The controller is connected to thermo actuators

type TWA-Z (NO) and remote temperature

sensors PT1000, type ESMC installed on each

riser.

3. Technical data

CCR3+ controller is part of AB-QTE solution

for one-pipe heating systems. It converts

one-pipe heating system (usually constant ow

system) into ecient variable ow system. This

innovative solution dynamically controls the

ow in the riser according to the load in risers by

return temperature control. There are few basic

rules to be followed, even more valid in case of

renovation:

• Optimize ow temperature that is driven by

substation control (too high ow temperature

can inuence eciency of rst radiators in the

riser/loop and result in oscillation of ow).

• Optimize return temperature that is driven

by CCR3+ (too high return temperature can

result in lower energy eciency).

• Install temperature sensor in front of AB-QM

as close to last radiator in the riser/loop as

possible.

• Set AB-QM according to the required heat

load of the riser/loop.

• Ensure correct radiator bypass ow setting

(typically around 25-35 %). If the resistance of

the radiator is much too high compared to the

bypass this may result in underow through

radiator if the ow in riser/loop is reduced.

Temperature sensor (S0, S1-S20 / S21-36) Pt1000, S0 – type ESMC/ESM11, S1-S20 / S21-36 – type ESMC

Temperature range (registration) –20 °C … +120 °C

Measuring accuracy +/- 0.5 K

Inputs: B1, B2 & B3 Free contact (5 V 1 mA)

Number of control valves (risers) 20 basic, additional 16 with system ex tension via CCR+ Slave Unit

Output signal to actuators 24 VDC max. 1 A

Alarm signal output 24 VDC max. 1 A

Relay output 0-24 VDC max. 1A

Type of memory Build-In

Capacity of memor y 8 GB

Timer: Real time clock Built-in bat tery – powered for 10 years

- Wi-Fi (communication p ort only)

Communication interfaces

Default IP settings:

Ambient temperature

Transport temperature –10 … +60 °C

IP rating IP 20

Power supply 24 VDC

Power consumption (Controller only) 1)10 VA

Power consumption (Slave Unit only) 1)3 VA

Weight 0.3 kg

Installation DIN rail 35 mm

1)

To select proper p ower transformer please f ollow formula: 24 V 10 VA (controller) + 7 VA*/pe r each actuator

- TPC/IP port (LAN cable connection)

- Modbus RS 485 RTU

- IP Modbus (L AN cable connection)

- Default L AN IP address (static): 192.168.1.100

- Default WiFi acess IP address (static): 192.168.1.10

- IP address mask: 255.255.255.0

- Gateway address: 192.168.1.1

- DNS address: 192.168.1.1

- CCR name: ccrplus

- Default password: admin1234

0 … +50 °C ( for CCR3+ only. The ambient temperature for actuators TWA-Z (NO)

should not be above 30 °C)

Following above rules will ensure optimal

control performance of CCR3+ as well as energy

eciency and reliability of heating systems.

For further application insights please contact

Danfoss representative.

6 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 7

CCR3+ Controller

ENGLISH

4. Installation

5. Switching the control on

For easy access the CCR3+ Controller is installed in

the

technical box on DIN rail 35mm. Box with

DIN rail should be mounted in the wall (substation or boiler

room) as close as possible to the

heat source. DIN rail and box are not included. It is

recommended to install

the standard 24 VDC

transformer in the same box as CCR3+ (not

supplied).

Before switching the controller on for the rst

time, disconnect all cables and connect a 24VDC

source to the disconnected power plug. Use a

voltmeter to measure the voltage on the power

cable plug before it is connected to the

controller.

If the voltage is correct:

1. Read the instructions before you operate the

controller

2. Disconnect all cables

3. Connect the power to the transformer (not

connected to CCR3+)

4. Turn the power to the transformer on

5. Veried currency – 24 VDC

6. Connect the cable from the transformer to the

CCR3+ Controller input

The transformer power depends on numbers of

actuators (number of risers in heating

installation). To select proper power transformer

please follow formula: 24 V 10VA (controller) + 7

VA*/per each actuator.

Example (building with 20 risers):

10VA (for controller) + 7 VA x 20 actuators = 150 V

The LED diodes on device should blink at

start-up.

Before any plugs are connected to the

controllers, input and output connectors:

1. Set all parameters on the controller

2.

Make sure that there is no external voltage on

the

temperature sensor plugs

3. Make sure that the voltage on the relay

contacts is not too high (max. 24 VDC)

6. Switching on

7. Types of Logins and Access

When controller is connected to power, LED

indicator start to blink. The meaning of LED

status is:

LED Description

P (orange) – Power inside controller (+5V) Lights when DDC PCB is power on

D (white) – Data transfer indicator for LAN Blink when DDC is communicating by TCP/IP

S (orange) - Input power indicator (24VDC) Lights when power supply PCB is working

BT (blue)– Basic transmission indicator for Wi-Fi Blink when DDC is communicating by WiFi

A (red) – Alert status on I/O module LED lights when/if: to low temp., broken sensor

O1..4 ; 1-20 (green)– Digital Output Status Lights when Output is closed to 0V

Controller has a built in WEB Server App to

communicate with all devices with html

browsers via following communication

interfaces:

• Wi-Fi communication port

• LAN cable connection (TCP/IP port)

AQ29035882028101-010206

© Danfoss | 2022.01 | 7

Page 8

CCR3+ Controller

ENGLISH

8. Wi-Fi settings (no cable needed - recommended for all types of devices)

1. Switch on Wi-Fi

2. Scan for Wireless Network Connection

3. Select CCR WI-Fi network

4. Enter password (default is »admin1234«)

5. Connect

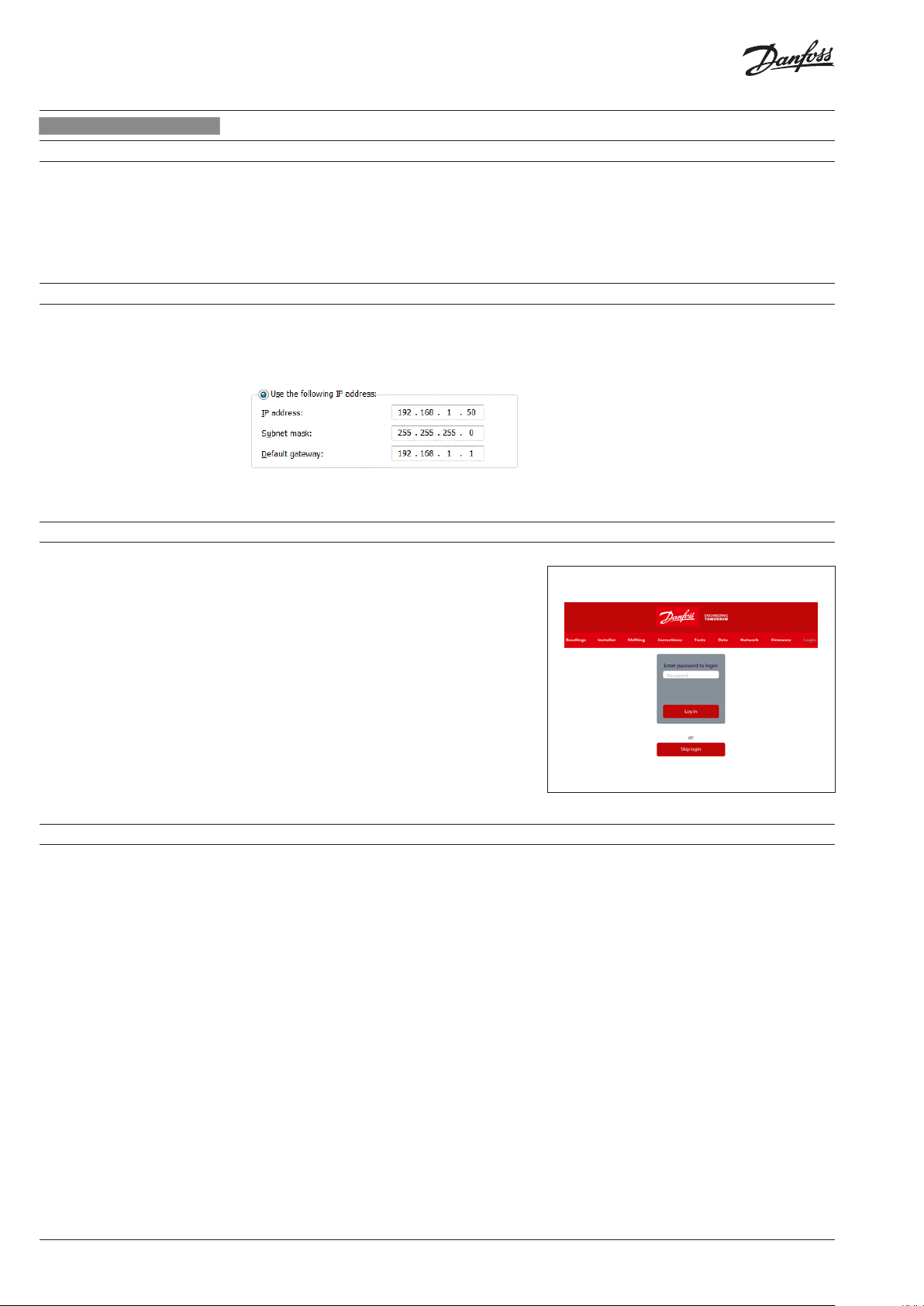

9. Local Network settings (only for LAN cable connection with PC)

1. Enter »Local Network settings«

2. Go to »Properties« -> »Internet Protocol

Version 4 (TCP/IPv4)

3. Congure IP address:

4. Conrm with »OK« and close menu in PC.

10. Run CCR3+ application

Launch your browser from a computer or

wireless device that is connected to the CCR3+.

Tap the IP address into web browser window:

1. Wi-FI access: Type 192.168.1.10 into Web

Browser

2. LAN connection: Type 192.168.1.100 into Web

Browser

CCR3+ application will open.

For 1st login enter password »admin1234«

Important: Change of password to secure any

unauthorized interaction from 3rd parties.

Note: You can Skip login for access to data only

in CCR3+ (reading, overview only).

11. CCR3+ Dashboard (Web App Screen)

When the setup and is complete, the reading

display will be shown on the screen.

The CCR3+ App screen has a dashboard that

oer plenty of status overview, basic and

advanced settings. The manufacturer reserves

the right to change Firmware in production to

improve handling and functionality. An up - to

- date list of settings for the given rmware is

available on the Danfoss website.

New settings can automatically upgrade

according to guidelines in instruction.

• Readings: Informations about basic settings,

device status, current time and date, storage

capacity

• Installer: Advanced and service settings

• Shifting: Shift return temperature

• Corrections: Temperature sensor calibration

settings

• Tes ts: Device outputs testing tool

• Data: Access to Data log le

• Network: BMS and IP/TPC settings

• Firmware: Firmware upgrade tool

• Login: Login option

8 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 9

CCR3+ Controller

ENGLISH

11. CCR3+ DASHBOARD

(Web App Screen)

(continuous)

READINGS MENU:

No. Name Description

Output status (Dened output O1..O4)

1 O1..O 4

2 B1..B3

3 RT Clock

4 S0-main temp.

5 Ret.Set.Temp

6 Alerts

7 Riser

8 Valve output

9 Valve [%] … ..% – valve open ratio – percentage of lling the PWM func tion (0 … 100 % in 10 % steps)

Temperature

10

[°C]

11 Set. Temp.[°C]

12 Alerts

Open - no alarm or break alarm circuit

Closed – shortcut to ground in alarm circuit

See Outputs settings in Installer Menu.

Input status

Open - input Bx open

Closed – input B1 close to G

Free contact relay (not used in CCR3+ process, only for monitoring in BMS). Binary inputs or P T10 00

sens or (5V, 1mA).

The Real Time clock , show current time, date, day of the week.

Data used in archive le.

S0 – value of (°C) supply temperature. The same readings apply to sensors S1 … S20.

Open - no sensor or break sensor circuit

Closed – shortcut to ground in sensor circuit

Fault – temp. values exeed Fault temp. max or is bellow Fault temp. max (correspondent to Fault temp.

settings in Installer Menu)

Information about setting return temperature correspondent to current ow temperature, in °C degree.

Required range set in points in the Installer Menu. Func tion used for temperature alarm output.

Set. Temperature is = Return Set. Temperature +/- Shift T. Set.

General information about CCR3+ status

OK – system is running without alarms

Aler t (red) – system has alarms

Riser St atus (sensors: S1-S36; valves: V1-V36)

Number of risers (look to: Advanced Menu)

Riser statuses are indicated with color.

OK – riser status is OK

High (red) - if temp. on Sx sensor is higher then Ret.Set.Temp

Low (bl ue) - if temp. on Sx sensor is lower then Ret.Set.Temp.

Open (yellow) - no sensor or break sensor circuit

Closed (grey) - shortcut to ground in sensor circuit

N/A (white) - non relevant (non selected) risers

Status of valve: V1 … V36

1 – open, valve output closed to C (powered up), (taking PWM into account).

0 – valve closed, valve output closed to C (powered down), (taking PWM into account).

Valve is 1-Open if: PWM min < Valve % <PWM max

Temperature readings in riser

Open - no sensor or break sensor circuit

Closed – shortcut to ground in sensor circuit

Information about return temperature correspondent to Ret.Set.Temp and Shift setting (correspondent

to Shift T.Set in Shifting Menu)

Set. Temperature is = Return Set.

Temperature +/- Shif t T. Set.

Temperatures status (same color as described in pos. “Riser status” ):

Riser RX – riser status information:

OK – riser status is OK

High (red) - if temp. on Sx sensor is higher then Ret.Set.Temp

Low (bl ue) - if temp. on Sx sensor is lower then Ret.Set.Temp.

Open (yellow) - no sensor or break sensor circuit

Closed (grey) - shortcut to ground in sensor circuit

N/A (white) - non relevant (non congurated) risers

AQ29035882028101-010206

INSTALLER MENU:

No. Name Description

13 TRet(35)

14 TRet(4 0)

15 TRet(45)

16 TRet(50)

17 TRet(55)

18 TRet(63)

19 TRet(70)

20 TRet(80)

Required return temperature for measure supply temperature: 35°C

Factory setting: 30°C

Required return temperature for measure supply temperature: 40°C

Factory setting: 35°C

Required return temperature for measure supply temperature: 45°C

Factory setting: 38°C

Required return temperature for measure supply temperature: 50°C

Factory setting: 40°C

Required return temperature for measure supply temperature: 55°C

Factory setting: 42°C

Required return temperature for measure supply temperature: 63°C

Factory setting: 45°C

Required return temperature for measure supply temperature: 70°C

Factory setting: 48°C

Required return temperature for measure supply temperature: 80°C

Factory setting: 54°C

© Danfoss | 2022.01 | 9

Page 10

CCR3+ Controller

LANGUAGE

ENGLISH

11. CCR3+ DASHBOARD

(Web App Screen)

(continuous)

No. Name Description

21 TR et(90)

22 Integration time

23 Proportional factor

24 Dif. T ime

25 PWM interval

26 PWM min.

27 PWM max.

28 Fault temp min.

29 Risers Nr

30 Current time

31 Current date

32 Alarm Delay

33 Alarm di.temp.+/-

34 Alarm Relay Type

35 Archive Frequency

36 Output O1

37 Output O2

38 Output O3

39 Output O4 N/A: Selected Output O4 not in use

40 Pump protection Factory setting: YES

41 Summer mode

42 Set Settings Click »Set Set tings« to conrm changes.

43 Load set tings 1 Load settings from memory 1.

44 Load settings 2 Load settings from memory 2.

45 Save settings 1 Save settings into memory 1.

46 Save settings 2 Save settings from memor y 2.

Required return temperature for measure supply temperature: 90°C

Factory setting: 58°C

Integration time of the control signal (depend of actuators type). The shorter time, quicker

temperature changes (no stable regulation). The longer time slower reaction for temperature

change (stable regulation).

Factory setting: 6 sec (for dedicated T WA-Z (NO) actuators); setting range 1-100

Control gain of control signal (depend on actuators type). The higher gain control the bigger

valves reac tion (no stable regulation). The lower gain control weak reaction for temperature

change (stable regulation).

Factory setting: 50 (for dedicated T WA-Z (NO) actuators); setting range 1-100

Dierential time of control signal. The longer the value, faster control in reaction to the control

value change - approaching to the set value but not reaching it yet. Too high value results in

unstable control.

Factory setting: 15

Time period of pulse width modulation (PWM}.

Factory setting: 10s

At »close« signal to actuator, PWM describes minimum % of open period to the actuator. Lower

the value, longer the reaction time of the actuator. Too high value can result in not closed valve.

Factory setting: 10%

At »open« signal to actuator, PWM describes maximum % of open period to the actuator. Higher

the value, longer the reaction time of the actuator. Too low value can result in not opened valve.

Factory setting: 90%

Set lower temperature. Temperature alarm output indicated signal when temperature drop

below this value.

Setting range between 0 °C and 50 °C

Factory setting: 0 °C

Number of active risers.

Factory setting: 20

Set the real time »Clock, hour & minutes”

e. g.: 12: 40

Sets the real date

e.g .: 2018 -02-26

Alarm delay time (relevant for Output which: Over temperature or Broken Sensor).

Higher the value, longer the reac tion time alarm signal.

Factory setting: 0 min

Set upper/lower deviation temperature counted from Required Return Temperature.

Temperature alarm output indicated signal when temperature exceed this range.

Factory setting: 5°C

Alarm output

StillOn – continuous alarm signal: O4 (24 VDC)

Pulse – pulse alarm signal 24 VDC every second

Factory setting: Pulse

Data archiving interval. The time can be set to any value between 10 seconds and 4 hours.

Factory setting: 1 min

Alert Broken Sensor (default): O1 output is closed to common (C) when sensor is broken (sensor

is short-cuted or not connected)

Alert Low Temp (default): O2 output is closed to common (C) when sensor temperature is

bellow Set. Temperature

Alert High Temp (default): O3 output is closed to common (C) when sensor temperature is

higher than Set. Temperature

Enabled – Summer mode is switch on (valves are closed, Vx output closed to common (C)

Disabled – Summer mode is switch o (valves are operating in normal PWM auto mode)

Factor setting: Enabled

10 | © Danfoss | 2022.01

SHIFTING MENU:

No. Name Description

Shift T.Set 1 -

47

Shift T.Set 36

Set Settings Click »Set Settings« to conrm changes.

Load settings 1 Load settings from memory 1.

Load settings 2 Load settings from memory 2.

Save settings 1 Save settings into memory 1.

Save settings 2 Save settings from memory 2.

Shift return temperature valid for all setting points. It can be adjusted up and down. The lowest

shift setting is to 10 degrees (anti frost setting value).

Each riser can be adjusted individually, riser by riser (from 1 to 36).

Factory setting: 0±°C; in range of ±10 °C

AQ29035882028101-010206

Page 11

CCR3+ Controller

ENGLISH

LANGUAGE

11. CCR3+ DASHBOARD

(Web App Screen)

(continuous)

CORRECTIONS MENU:

No. Name Description

48 S0, … , S36

Cable Length

49

Cable Calculator

Save settings Click »Save Settings« to conrm changes.

Sensor calibration: S0 … S36 in range: ±9.9 °C

Do not make calibration when sensor cables are shorter than 10 meters.

For longer cable then 10 meters, used correction factors from table below.

Useful tool for calculating cable corrections by selecting cable length (m) and cross (mm2).

TESTS MENU:

No. Name Description

Open: Selected output contact is open

50 O1…O4

51 V1, …, V36

Save settings Click »Save Settings« to conrm changes

Set all as Open All Open

Set all as Close All Close

Set all as AutoPWM All Auto PWM

DATA MENU

Delete all logs

No. Name Description

52 Delete all logs Erasing of log le

53 GO to By selec ting time period, log les will be shown and ready for download (*.CSV)

Close: Selected output is closed to common (C)

Auto

Factory setting: Auto

Open: selected valve is open, contac t open

Close: selec ted valve is closed, shortcuted to common (C)

Auto OnO : selected valve works in On/o mode

AutoPWM: selected valve work s in PWM mode

Factory setting: AutoPWM

Note: In case o f changing IP address in

CCR+ Controller, changes sho uld also be

applied in P C local network set tings.

NETWORK MENU:

No. Name Description

54 Modbus

55 Modbus baud rate

56 Modbus parity

57 Modbus address

58 LAN IP address

59 LAN IP address mask

60 LAN Gateway address

LAN name (min. 2

61

char., max. 15 char.)

62 LAN DHCP

63 LAN connected clients Number of LAN connected clients to CCR3+

WIFI name (min. 2

64

char., max. 15 char.)

WIFI pass (min. 8 char.,

65

max. 15 char.)

66 WIFI connected client Shows IP and name of Wi-Fi connected device

Change Login

67

password:

Slave Unit Comm.

68

Status

Save Settings Click »Save Set tings« to conrm changes

Enable – Modbus is switch on

Disable – Modbus is switched o

Type of date transmission:

ModBus 96 (9.600)

Mod Bus 19 (19.000)

ModBus 38 (38.400)

FBus

Factory setting: ModBus 96

None (transmission parity disabled)

Even (»Even« type of transmission parity enabled)

Odd (»Odd« type of transmission parity enabled)

Factory setting: Odd

Unit Address for Mobus RTU RS485

Factory setting: 1

The IP address that the router assigned to this device when it joined the network. This number

can change if a device is disconnected and rejoins the network

Factory setting: 192.168.1.100

Identif y network address of an IP address

Factory setting: 255.255.255.0

The gateway address (or default gateway) is a router inter face connected to the local network

that sends packets out of the local network

Factory setting: 192.168.1.1

Name of CCR3+ (relevant for net work search)

Please note that after changing this value, local network dns server need to be refreshed. This

process is depend on current network conguration and can take up to few hours.

Factory setting: ccrplus

Dynamic Host Conguration Protocol

Disable

Enable

Factory setting: Disable

Wi-Fi name (can be changed)

Factory setting: ccrwi

Password name (can be changed)

Factory setting: admin1234

Password name for access to CCR3+ App

Factory setting: admin1234

Shows Slave Unit communication status between CCR3+ Controller

0% – no communication

100% – communication OK

Possible (readable values): 0 – 100%

AQ29035882028101-010206

© Danfoss | 2022.01 | 11

Page 12

CCR3+ Controller

ENGLISH

11. CCR3+ DASHBOARD

(Web App Screen)

(continuous)

12. SERVICES

FIRMWARE MENU:

Name Description

Upgrade of firmware

Reset settings to default To return all setting to default (except Network settings) click on “Return Defaults”

Reset to defaults passwords To reset all passwords to defaults (admin1234) click on “Reset Passwords«.

Reset network settings Reset all network settings to defaults

NOTE: When uplo ading firmware, do not i nterrupt the web browser by cl osing the window, clicking a lin k, or loading a new page . No

not power-o ff CCR3+. It could corru pt the firmware.

To update CCR3+ with new f irmware first download firmware file from Danfoss website.

Then follow procedure: Browse file -> Start upgrade!

When the upload is complete, CCR+ restarts. The upgrade process typically takes several minutes.

LOGIN MENU – push user to change password

No. Name Description

69 Login Access with login password enable changes in all setting

Skip login Access without password allows only data readings. Changes of settings values can not be done.

Reset Wi-Fi password

Reset the setting only Go to firmware menu and click on “Return Defaults”

Reset password only (but not

change other parameters)

Recovery (device can be

recover back to factor y

firmware)

Available via long press on reset button (located on LAN port) for at least 5 seconds.

Wi-Fi password is reset to “admin0 0X” where x is the number of BT (blue) LED blinks.

Go to firmware menu and click on “Reset passwords”

Via long press on reset button, power down and with access code “369” (code for recovery to

default f irmware). To perform a recover y, you need to make these steps:

1. turn off power supply

2. press hardware button

3. turn on power supply, power led will be ON

4. hold but ton for more than 5 sec until ALL 3 leds turned ON

5. when all 3 leds is turned immediately release the button

From this moment you need to enter 3 digits code

In this mode there are two hardware button function:

- short press increase code number,

- long press switch to nex t code digit

Currently code number is signaled by lighting of led diode: blue led = 1 digit, white led = 2 digit,

orange led = 3 digit

Example to enter code 123:

- first led diode (blue) is turned ON, then make a short button press 1 time, blue led should

blink once

- make a long press until white led is turned on

- using shor t button press 2 times, white led should blinks 2 times

- make a long press until orange led is turned on

- using shor t button press 3 times, orange led should blinks 3 times

- if code is entered properly than recovery has started.

DO NOT TURN OFF POWER SUPPLY!

12 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 13

CCR3+ Controller

ENGLISH

13. Modbus settings

Supported functions:

1. Read holding registers (0x03)

2. Write single register (0x06)

3. Write multiple registers (0x16)

1. Read holding register start addresses:

from 0 to 195:

0 – Valve output riser

(1=output closed - valve is o pen, 0=output op en, valve

is closed)

1 – Valve output pwm riser

(valve open in percentage: 0% .. 100%, unsigned decimal)

2 – Temperature value

(valve open in percentage: 0% .. 100%, unsigned decimal)

3 – Set temperature

(temperature in ° C with one decimal place pre cision,

unsigned deci mal --> example: 529 = 52.9°C)

4 – Status(alert)*

- 0 - OK

- 1 - temp too low/high

- 4 - sensor closed (short circuit)

- 5 - sensor open (sensor not connected etc...)

Example: To get riser 6 temperature

Formula: (6(Riser) - 1) × 5 + 2 (Temp Value) = 27

180

Output 1 open/closed

181

Output 2 open/closed

182

Output 3 open/closed

183

Output 4 open/closed

184

B4 open/closed

185

RTC year

186

RTC month

187

RTC day

188

RTC hour

189

RTC minute

190

B1 open/closed

191

B2 open/closed

192

B3 open/closed

193

S0 temp

194

Ret. Set. Temp

195

Status (alert)

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

from 300 to 331:

Tret 1

Tret 2

Tret 3

Tret 4

Tret 5

Tret 6

Tret 7

Tret 8

Tret 9

Integration time

Prop factor

Dif. time

PWM interval

PWM min

Pwm max

Riser number

RTC year

RTC month

RTC day

RTC hour

RTC minute

Alarm delay

Alarm diftemp

Alarm type

Valve type

Valve characteristic

Out1

Out2

Out3

Out4

Pump protection

Summer mode

2. Write single register – data can be written into start addresses:

from 300 to 331

- from 400 to 435

400

401

402

403

404

405

406

407

408

409

410

411

412

413

414

415

416

417

418

419

420

421

422

423

424

425

426

427

428

429

430

431

432

433

434

435

from 400 to 435 :

Shift value 1

Shift value 2

Shift value 3

Shift value 4

Shift value 5

Shift value 6

Shift value 7

Shift value 8

Shift value 9

Shift value 10

Shift value 11

Shift value 12

Shift value 13

Shift value 14

Shift value 15

Shift value 16

Shift value 17

Shift value 18

Shift value 19

Shift value 20

Shift value 21

Shift value 22

Shift value 23

Shift value 24

Shift value 25

Shift value 26

Shift value 27

Shift value 28

Shift value 29

Shift value 30

Shift value 31

Shift value 32

Shift value 33

Shift value 34

Shift value 35

Shift value 36

AQ29035882028101-010206

3. Write multiple register – data can be written into start addresses:

- from 300 to 331

- from 400 to 435

© Danfoss | 2022.01 | 13

Page 14

CCR3+ Controller

LANGUAGE

DEUTSCH

1. Produktbeschreibung

2. Anwendung

Der Regler CCR3+ wird für die Regelung der

Rücklauftemperatur in Einrohr-Heizungssystemen

eingesetzt. Er verfügt über spezielle Funktionen

wie die Temperaturerfassung und Überwachung

Der Regler CCR3+ ist Teil der Lösung AB-QTE

für Einrohr-Heizungssysteme. Diese wandelt

ein Einrohr-Heizungssystem (in der Regel ein

System mit konstantem Durchuss) in ein ezientes System mit variablem Durchuss um. Die

innovative Lösung regelt den Durchuss in den

Strängen über die Rücklauftemperaturregelung

dynamisch entsprechend der Last in den

Strängen. Es sind einige Grundregeln zu

befolgen, vor allem bei Modernisierungen:

• Stellen Sie das AB-QM entsprechend der

erforderlichen Heizlast des Strangs/Kreises ein.

• Stellen Sie sicher, dass der Durchuss am

Heizkörper-Bypass richtig eingestellt ist

(üblicherweise 25–35%). Wenn der Widerstand

des Heizkörpers im Vergleich zu dem des

Bypasses viel zu hoch ist, kann dies ggf. zu

einem zu geringen Durchuss durch den

Heizkörper führen, wenn der Durchuss

im Strang/Kreis verringert wird.

von Strangtemperaturen. Der Regler wird mit

thermischen Stellantrieben TWA-Z (NO) und

Pt1000-Temperaturfühlern vom Typ ESMC

verbunden, die in jedem Strang montiert sind.

• Optimieren Sie die Vorlauftemperatur, die

über die Übergabestation geregelt wird

(eine zu hohe Vorlauftemperatur kann

die Ezienz des ersten Heizkörpers

im Strang/Kreis beeinussen und zu

Durchussschwankungen führen).

• Optimieren Sie die Rücklauftemperatur,

die über den CCR3+ geregelt wird (eine zu

hohe Rücklauftemperatur kann zu einer

geringeren Energieezienz führen).

• Installieren Sie denTemperaturfühler

in Fließrichtung vor dem AB-QM und so

nah wie möglich am letzten Heizkörper

im Strang/Kreis.

Durch das Befolgen der oben genannten Regeln

werden eine präzise Regelung des CCR3+

sowie eine optimale Energieezienz und

Betriebssicherheit des Heizungssystems sichergestellt. Weitere Anwendungsinformationen

erhalten Sie von einem Danfoss-Ansprechpartner.

3. Technische Daten

Temperaturfühler (S0, S1–S20/S21–36) PT1000, S0 – Typ ESMC/ESM11, S1-S20/S21-336 – Typ ESMC

Temperaturbereich (Erfassung) –20°C … +120°C

Messgenauigkeit +/- 0,5 K

Eingang: B1, B2 und B3 Potentialfreie Kontakte (5V, 1mA)

Anzahl der Regelventile (Stränge) 20 (Standard), weitere 16 durch Systemerweiterung mit CCR+ Nebenregler.

Ausgangssignal an Stellantriebe 24VDC max. 1A

Alarmsignalausgang 24VDC max. 1A

Relaisausgang 0-24VDC max. 1A

Speicherart Eingebaut

Speicherkapazität 8GB

Zeitgeber: Echtzeituhr Eingebaute Batterie – Betriebsdauer 10Jahre

– WLAN (nur Kommunikationsport)

Kommunikationsschnittstellen

Standard-IP-Einstellungen:

Umgebungstemperatur

Transporttemperatur –10 … +60°C

Schutzart IP20

Spannungsversorgung 24VDC

Leistungsaufnahme (nur Regler)

Leistungsaufnahme (nur Nebenregler) 1)3VA

Gewicht 0,3kg

Installation 35-mm-DIN-Schiene

1)

Den richtige n Leistungstransformator wäh len Sie mit folgender Form el: 24V10VA (Regl er) + 7VA*/pro Stellantrieb

1)

– TPC/IP-Port (LAN-Kabelverbindung)

– ModbusRS 485RTU

– IP-Modbus (LAN-Kabelverbindung)

– Standard-LAN-IP-Adresse (statisch): 192.168.1.100

– Standard-WLAN-Zugangs-IP-Adresse (statisch): 192.168.1.10

– IP-Adressmaske: 255.255.255.0

– Gat eway -Adress e: 192 .168.1.1

– DNS -Adre sse: 192.168.1.1

– CCR-Name: ccrplus

– Standard-Passwort: admin1234

0 bis +50°C ( gilt nur für den CCR3+; die Umgebungstemperatur für die Stellantriebe

TWA-Z (NO) darf nicht höher sein als 30°C)

10VA

14 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 15

CCR3+ Controller

DEUTSCH

LANGUAGE

4. Installation

5. Einschalten des Reglers

Für einen einfachen Zugang sollten die CCR3+

Regler im

Technikschrank auf DIN-Schienen

(35mm) installiert werden. Der Schaltkasten

mit der DIN-Schiene sollte an der Wand (Übergabestation oder

Kesselraum) und so nah wie

möglich an der Wärmequelle montiert werden.

DIN-Schiene und Kasten sind nicht im Lieferumfang

enthalten. Es wird empfohlen, den

standardmäßigen Transformator (24VDC) und den CCR3+

im selben Schaltkasten (nicht im Lieferumfang

enthalten) zu installieren.

Vor dem ersten Einschalten des Reglers sind alle

Kabel zu trennen. Zudem ist eine 24-VDC-Spannungsversorgung an den getrennten Netzstecker

anzuschließen. Prüfen Sie die Spannung am

Netzkabelstecker mit einem Voltmeter, bevor

er an den Regler angeschlossen wird.

Bei ordnungsgemäßer Spannung:

1. Lesen Sie die Anleitung sorgfältig durch,

bevor Sie mit Arbeiten am Regler beginnen.

2. Trennen Sie alle Kabel.

3. Schließen Sie den Transformator (der nicht

an den CCR3+ angeschlossen ist) an die

Spannungsversorgung an.

4. Schalten Sie die Spannungsversorgung

zum Transformator ein.

5. Geprüfte Stromstärke – 24VDC

6. Schließen Sie das Kabel vom Transformator

an den Eingang des Reglers CCR3+ an.

Die Transformatorleistung hängt von der

Anzahl der Stellantriebe (Anzahl der Stränge im

Heizungssystem) ab. Den richtigen Leistungstransformator wählen Sie mit folgender Formel:

24V10VA (Regler) + 7VA*/pro Stellantrieb.

Beispiel (Gebäude mit 20 Strängen):

10VA (für Regler) + 7VA x 20Stellantriebe = 150V

Die LED-Dioden am Gerät sollten beim Start

blinken.

Vor dem Anschließen von Steckern an den

Ein- und Ausgang des Reglers:

1. Stellen Sie alle Parameter am Regler ein.

2.

Achten Sie darauf, dass keine externe Spannung

an den

Steckern des Temperatursensors anliegt.

3. Vergewissern Sie sich, dass die Spannung

an den Relaiskontakten nicht zu hoch ist

(max. 24VDC).

6. Einschalten

Wenn der Regler an die Stromversorgung

angeschlossen ist, beginnt die LED-Anzeige zu

blinken. Die Bedeutung des LED-Status ist:

LED Beschreibung

P (orange) – Spannung im Regler (+5V) Leuchtet, wenn die DDC-Platine eingeschaltet ist.

D (weiß) – Datenübertragungsanzeige für LAN Blinkt, wenn DDC über TCP/IP kommuniziert.

S (orange) – Anzeige der Eingangsleistung (24VDC) Leuchtet, wenn die Stromversorgungsplatine funktioniert.

BT (blau)– Grundlegende Übertragungsanzeige für WLAN Blinkt, wenn DDC über WLAN kommunizier t.

A (rot) – Alarmstatus am I/O-Modul LED leuchtet wenn: zu niedrige Temperatur, Sensor defekt

O1..4 ; 1–20 (grün)– Status des Digitalausgangs Leuchtet, wenn der Ausgang auf 0V geschlossen ist.

7. Arten von Anmeldungen und Zugrien

Der Regler verfügt über eine eingebaute

WEB-Server-App, um mit allen Geräten mit

html-Browsern über folgende Kommunikationsschnittstellen zu kommunizieren:

• WLAN-Kommunikationsport

• LAN-Kabelverbindung (TCP/IP-Port)

AQ29035882028101-010206

© Danfoss | 2022.01 | 15

Page 16

CCR3+ Controller

LANGUAGE

DEUTSCH

8. WLAN-Einstellungen (kein Kabel erforderlich – empfohlen für alle Gerätetypen)

1. WLAN einschalten

2. Nach drahtloser Netzwerkverbindung suchen

3. Wählen Sie CCR-WLAN-Netzwerk

4. Passwort eingeben (Standard ist „admin1234“)

5. Verbinden

9. Lokale Netzwerkeinstellungen (nur bei LAN-Kabelverbindung mit PC)

1. Gehen Sie zu „Lokale Netzwerkeinstellungen“.

2. Gehen Sie zu „Eigenschaften“ ->

„Internetprotokollversion 4 (TCP/IPv4)“.

3. Kongurieren Sie die IP-Adresse:

4. Mit „OK“ bestätigen und Menü im PC schließen.

10. CCR3+ Anwendung ausführen.

Starten Sie Ihren Browser von einem Computer

oder drahtlosen Gerät, das mit dem CCR3+

verbunden ist. Geben Sie die IP-Adresse im

Webbrowser-Fenster ein:

1. WLAN-Zugang: Geben Sie 192.168.1.10 in den

Webbrowser ein.

2. LAN-Verbindung: Geben Sie 192.168.1.100 in

den Webbrowser ein.

Die CCR3+ Anwendung wird geönet.

Für die erste Anmeldung geben Sie das Passwort

„admin1234“ ein.

Wichtig: Eine Änderung des Passwortes ist

notwendig, um unbefugten Zugri von Dritten

zu verhindern.

Hinweis: Sie können die Anmeldung in CCR3+

überspringen, um nur Zugri auf die Daten zu

haben (Lesen, nur Übersicht).

11. CCR3+ Dashboard (Web-App-Bildschirm)

Nach abgeschlossener Konguration wird

die Werte-Anzeige eingeblendet.

Der Anwendungsbildschirm CCR3+ verfügt

über ein Dashboard, das viele Statusübersichten

sowie Grund- und erweiterte Einstellungen

bietet. Der Hersteller behält sich das Recht vor,

die Firmware bei der Herstellung zu verändern,

um die Handhabung und Funktionalität zu

verbessern. Eine aktuelle Liste der Einstellungen

für die jeweilige Firmware ist auf der DanfossWebsite erhältlich.

Neue Einstellungen können automatisch

gemäß den Anweisungen in der Anleitung

aktualisiert werden.

• Readings/Werte: Informationen über

Grundeinstellungen, Gerätestatus, aktuelle

Uhrzeit- und Datumangaben, Speicherkapazität

• Installateur: Erweiterte und Service-

Einstellungen

• Shifting/Verschieben: Verschiebung

der Rücklauftemperatur

• Korrekturen: Kalibriereinstellungen

des Temperaturfühlers

• Tes ts: Testwerkzeug für die Geräteausgänge

• Daten: Zugri auf die Datenprotokolldatei

• Netzwerk: BMS– und IP/TPC-Einstellungen

• Firmware: Firmware-Upgrade-Tool

• Login: Login-Option

16 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 17

CCR3+ Controller

LANGUAGEDEUTSCH

11. CCR3+ DASHBOARD

(Web-App-Bildschirm)

(Fortsetzung)

WERTE-MENÜ:

Nr. Bezeichnung Beschreibung

Ausgangsstatus (denierter Ausgangswer t O1...O4)

1 O1..O 4

2 B1..B3

3 Echtzeit-Uhr

S0-

4

Haupttemp.

Rücklauf-

5

temperatureinstellungen

6 Alarme

7 Strang

Venti l-

8

Ausgang

9 Ventil [%]

Temperatur

10

[°C]

11 Temp. [°C]

12 Alarme

Open – kein Alarm oder Bruch in Alarmschaltung

Closed – Kurzschluss nach Masse in der Alarmschaltung

Siehe Ausgangseinstellungen im Installateur-Menü.

Eingangsstatus

Open – EingangBx oen

Closed – EingangB1 nach G geschlossen

Freies Kontak trelais (im CCR3+ Prozess nicht verwendet, nur zur Überwachung in BMS).

Binäreingänge oder PT1000-Sensor (5V, 1mA).

Die Echtzeituhr zeigt die aktuelle Uhrzeit, das Datum und den Wochentag an.

Daten, die in der Archivdatei verwendet werden.

S0 – Wert der (°C) Vorlauf temperatur. Die gleichen Werte gelten für die Sensoren S1 .... S20.

Open – kein Sensor oder Defekt in Sensorschaltung

Closed – Kurzschluss nach Masse in der Sensorschaltung

Fehler – Temp.werte übersteigen die Vorgabeder Fehler Temp. Max. oder liegen unter Fehler

Temp. Max. (entspricht Fehler Temp.einstellungen im Installateur-Menü)

Angaben zur Einstellung der Rücklauftemperatur entsprechend der aktuellen Vorlauftemperatur in °C.

Der erforderliche Bereich ist im Installateur-Menü in Punkten festgelegt. Funk tion wird für die

Temperaturalarmausgabe verwendet.

Temperatureinstellung ist = Rücklauftemperatureinstellung +/- Verschiebung T.einstellung

Allgemeine Angaben zum CCR3+ Status

OK – System läuft ohne Alarme

Alert (rot) – System hat aktive Alarme

Strangstatus (Sensoren: S1-S36; Ventile: V1-V36)

Anzahl der Stränge (siehe Erweitertes Menü)

Der Strangstatus ist farblich gekennzeichnet.

OK – Strangstatus ist OK

High (rot) – wenn Temp. auf Sx-Sensor höher ist als Ret. Set.Temp

Low (blau) – wenn Temp. auf Sx-Sensor niedriger ist als Ret. Set.Temp

Open (gelb) – kein Sensor oder Bruch in Sensorschaltung

Closed (grau) – Kurzschluss nach Masse in der Sensorschaltung

N/A (we iß) – nicht relevante (nicht ausgewählte) Stränge

Status des Ventils: V1 … V36

1 – oen, Ventil-Ausgang geschlossen nach C (eingeschaltet), (unter Berücksichtigung von PWM).

0 – Ventil geschlossen, Ventil-Ausgang geschlossen nach C (ausgeschaltet), (unter Berücksichtigung

von PWM).

Ventil ist 1 – Oen, wenn: PWM Min. < Ventil % <PWM Max.

… ..% – Verhältnis Ventil oen – Prozentsatz der Er füllung der PWM-Funktion (0 … 100% in

10%-Schritten)

Temperaturmessungen im Strang

Open – kein Sensor oder Defekt in Sensorschaltung

Closed – Kurzschluss nach Masse in der Sensorschaltung

Angaben zur Rücklauftemperatur entsprechend der Einstellungen Rücklauftemperatureinstellungen

und Verschiebung (entsprechend Verschiebung T.einstellungen im Menü Verschiebung)

Temperatureinstellung ist = Rücklauftemperatureinstellung

+/- Verschiebung T.einstellung

Temperaturstatus (gleiche Farbe wie in Pos. „Strangstatus“ beschrieben):

StrangRX – Strang-Statusinformationen:

OK – Strangstatus ist OK

High (rot) – wenn Temp. auf Sx-Sensor höher ist als Ret. Set.Temp

Low (bl au) – wenn Temp. auf Sx-Sensor niedriger ist als Ret.Set.Temp

Open (gelb) – kein Sensor oder Bruch in Sensorschaltung

Closed (grau) – Kurzschluss nach Masse in der Sensorschaltung

N/A (weiß) – nicht relevante (nicht kongurierte) Stränge

INSTALLATEUR-MENÜ:

Nr. Bezeichnung Beschreibung

13 TRet(35)

14 TRet(40)

15 TRet(45)

16 TRet(50)

17 T Ret(55)

18 TR et(63)

19 TRet(70)

20 TRet(80)

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 35°C

Werkseinstellung: 30 °C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 40 °C

Werkseinstellung: 35°C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 45°C

Werkseinstellung: 38°C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 50 °C

Werkseinstellung: 40 °C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 55 °C

Werkseinstellung: 42°C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 63°C

Werkseinstellung: 45°C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 70 °C

Werkseinstellung: 48°C

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 80°C

Werkseinstellung: 54°C

AQ29035882028101-010206

© Danfoss | 2022.01 | 17

Page 18

CCR3+ Controller

LANGUAGE

DEUTSCH

11. CCR3+ DASHBOARD

(Web-App-Bildschirm)

(Fortsetzung)

Nr. Bezeichnung Beschreibung

21 TR et(90)

22 Nachstellzeit

23 Proportionalfaktor

24 Dif. Zeit

25 PWM-Intervall

26 PWM Min.

27 PWM Max.

28 Fehler Temp. Min.

29 Anzahl Stränge

30 Aktuelle Uhrzeit

31 Aktuelles Datum

32 Alarm-Verzögerung

33 Alarm Di.temp.+/-

34 Alarmrelais-Typ

Archivierungs-

35

häugkeit

36 Ausgang O1

37 Ausgang O2

38 Ausgang O3

39 Ausgang O4 N/A: Ausgewählter AusgangO4 wird nicht verwendet

40 Pumpenschutz Werkseinstellung: JA

41 Sommermodus

Einstellungen

42

vornehmen

43 Einstellungen1 laden Einstellungen aus Speicher1 laden.

44 Einstellungen2 laden Einstellungen aus Speicher2 laden.

Einstellungen1

45

speichern

Einstellungen2

46

speichern

Erforderliche Rücklauftemperatur bei gemessener Vorlauftemperatur: 90 °C

Werkseinstellung: 58°C

Integrationszeit des Regelsignals (je nach Typ des Stellantriebs). Je kür zer die Zeit, desto

schneller veränder t sich die Temperatur (keine stabile Regelung). Je länger die Zeit, desto

langsamer verändert sich die Temperatur (stabile Regelung).

Werkseinstellung: 6s (für spezielle Stellantriebe TWA-Z (NO)); Einstellbereich 1 bis 100

Verstärkung des Regelsignals ( je nach Typ des Stellantriebs). Je höher die Verstärkung,

desto größer die Ventilreaktion (keine stabile Regelung). Je niedriger die Verstärkung,

desto geringer die Veränderung der Temperatur (stabile Regelung).

Werkseinstellung: 50 (für spezielle Stellantriebe TWA-Z (NO)); Einstellbereich 1 bis 100

Dierentialzeit des Regelsignals. Je größer der Wer t, desto schneller wird die Regelung an den

veränder ten Regelwert angepasst – Annäherung an den eingestellten Wert, jedoch noch kein

Erreichen. Ein zu hoher Wert führ t zu einer instabilen Regelung.

Werkseinstellung: 15

Zeitdauer der Pulsweitenmodulation (PWM).

Werkseinstellung: 10s

Bei einem „Schließen“-Signal zum Stellantrieb entspricht die PWM dem minimalen Prozentwert

der Önungsperiode des Stellantriebs. Je niedriger der Wert, desto länger die Reaktionszeit

des Stellantriebs. Ein zu hoher Wert kann dazu führen, dass das Ventil nicht geschlossen wird.

Werkseinstellung: 10%

Bei einem „Önen“-Signal zum Stellantrieb entspricht die PWM dem maximalen Prozentwert

der Önungsperiode des Stellantriebs. Je höher der Wert, desto länger die Reaktionszeit

des Stellantriebs. Ein zu niedriger Wert kann dazu führen, dass das Ventil nicht geönet wird.

Werkseinstellung: 90%

Einstellung niedrigere Temperatur. Der Temperaturalarm-Ausgang zeigt ein Signal an, wenn die

Temperatur unter diesen Wert fällt.

Einstellbereich zwischen 0°C und 50°C

Werkseinstellung: 0°C

Anzahl aktiver Stränge.

Werkseinstellung: 20

Stunden- und Minuteneinstellung der Echtzeituhr

z.B.: 12:40

Einstellung des tatsächlichen Datums.

z.B.: 2018-02-26

Alarm-Verzögerungszeit (relevant für Ausgänge, wenn: Übertemperatur oder gebrochener Sensor).

Je höher der Wert, desto länger die Reaktionszeit des Alarmsignals.

Werkseinstellung: 0min

Stellen Sie die Temperatur der oberen/unteren Abweichung von der erforderlichen Rücklauftemperatur ein. Der Temperaturalarm-Ausgang zeigt ein Signal an, wenn die Temperatur diesen

Bereich überschreitet.

Werkseinstellung: 5 °C

Alarmausgang

StillOn – kontinuierliches Alarmsignal: O4 (24VDC )

Pulse – Impuls-Alarmsignal (24VDC, jede Sekunde)

Werkseinstellung: Pulse

Datenarchivierungsintervall. Die Zeit kann auf jeden Wert zwischen 10Sekunden und 4Stunden

eingestellt werden.

Werkseinstellung: 1min

Warnung gebrochener Sensor (Standardwert): Ausgang O1 ist geschlossen nach Bezugspotenzial

(C), wenn der Sensor gebrochen ist (Sensor kurzgeschlossen oder nicht angeschlossen)

Warnung niedrige Temp. (Standardwert): Ausgang O2 ist geschlossen nach Bezugspotential (C),

wenn die Sensortemperatur unter Temperatureinstellung liegt.

Warnung hohe Temp. (Standardwert): Ausgang O3 ist geschlossen nach Bezugspotential (C),

wenn die Sensortemperatur über Temperatureinstellung liegt.

Enabled – Sommermodus ist aktiviert (Ventile sind geschlossen, AusgangVx geschlossen

nach Bezugspotential (C))

Disabled – Sommermodus ist deaktiviert (Ventile arbeiten im normalen PWM-Automodus)

Werkseinstellung: Enabled

Klicken Sie auf „Einstellungen vornehmen“, um Änderungen zu bestätigen.

Einstellungen in Speicher1 sichern.

Einstellungen in Speicher2 sichern.

MENÜ VERSCHIEBUNG:

Nr. Bezeichnung Beschreibung

Verschiebung

T.einstellung1 –

47

Verschiebung

T.einstellung36

Einstellungen

vornehmen

Einstellungen1 laden Einstellungen aus Speicher1 laden.

Einstellungen2 laden Einstellungen aus Speicher2 laden.

Für alle Einstellpunkte gültige Rücklauftemperaturverschiebung. Sie kann erhöht und gesenkt

werden. Die niedrigste Verschiebungseinstellung entspricht 10Grad (Frostschutz-Einstellung).

Jeder Strang kann separat eingestellt werden (Strang für Strang, von 1 bis 36).

Werkseinstellung: 0±°C; im Bereich von ±10°C

Klicken Sie auf „Einstellungen vornehmen“, um Änderungen zu bestätigen.

18 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 19

CCR3+ Controller

DEUTSCH

LANGUAGE

11. CCR3+ DASHBOARD

(Web-App-Bildschirm)

(Fortsetzung)

Hinweis: Bei ein er Änderung der

IP-Adresse i m CCR+ Regler sollte n

Änderungen auch in den lokalen

Netzwe rkeinstellungen des PC s

übernommen werden.

Einstellungen1

speichern

Einstellungen2

speichern

Einstellungen in Speicher1 sichern.

Einstellungen in Speicher2 sichern.

KORREKTUR-MENÜ:

Nr. Bezeichnung Beschreibung

48 S0, … , S36

Kabellänge

49

Kabelrechner

Einstellungen

speichern

Sensorkalibrierung: S0 … S36 im Bereich: ±9,9°C

Keine Kalibrierung vornehmen, wenn die Sensorkabel kürzer sind als 10Meter.

Für längere Kabel als 10Meter, ver wenden Sie die Korrekturfaktoren aus der folgenden Tabelle.

Nützliches Werkzeug zur Berechnung von Kabelkorrekturen durch Auswahl von Kabellänge

(m) und -durchmesser (mm2).

Klicken Sie auf „Einstellungen speichern“, um Änderungen zu bestätigen.

TEST-MENÜ:

Nr. Bezeichnung Beschreibung

Open: Ausgewählter Ausgangskontakt ist oen

50 O1…O4

51 V1, …, V36

Einstellungen

speichern

Alle auf Oen stellen Alle oen

Alle auf geschlossen

stellen

Alle auf AutoPWM

stellen

DATEN-MENÜ

Alle Protokolle löschen

Nr. Bezeichnung Beschreibung

52 Alle Protokolle löschen Löschen der Protokolldatei

53 WEITER zu

NETZWERK-MENÜ:

Nr. Bezeichnung Beschreibung

54 Modbus

55 Modbus-Baudrate

56 Modbus-Parität

57 Modbus-Adresse

58 LAN-IP-Adresse

59 LAN-IP-Adressmaske

60 LAN-Gateway-Adresse

LAN-Name

61

(min. 2Zeichen,

max. 15Zeichen)

62 LAN DHCP

Verbundene

63

LAN-Clients

WLAN-Name

64

(min. 2Zeichen,

max. 15Zeichen)

Close: Ausgewählter Ausgang ist geschlossen zum Bezugspotential (C)

AUTO

Werkseinstellung: AUTO

Open: ausgewähltes Ventil ist oen, Kontakt oen

Open: ausgewähltes Ventil ist geschlossen, kurzgeschlossen zum Bezugspotential (C)

Auto OnO : ausgewähltes Ventil arbeitet im On/O-Modus

AutoPWM: ausgewähltes Ventil arbeitet im PWM-Modus

Werkseinstellung: AutoPWM

Klicken Sie auf „Einstellungen speichern“, um die Änderungen zu bestätigen.

Alle geschlossen

Alle Auto PWM

Durch die Auswahl des Zeitraums werden die Protokolldateien angezeigt und stehen zum

Download bereit (*.CSV).

Enable – Modbus ist eingeschaltet

Disable – Modbus ist ausgeschaltet

Art der Datenübertragung:

ModBus 96 (9.600)

Mod Bus 19 (19.000)

ModBus 38 (38.400)

FBus

Werkseinstellung: ModBus 96

None (Übertragungsparität deaktiviert)

Even („Gerade“ Übertragungsparität aktiviert)

Odd(„Ungerade“ Übertragungsparität aktiviert)

Werkseinstellung: Odd

Geräteadresse für Mobus RTU RS485

Werkseinstellung: 1

Die IP-Adresse, die der Router diesem Gerät zugewiesen hat, als er mit dem Netzwerk

verbunden wurde. Diese Nummer kann sich ändern, wenn ein Gerät getrennt und wieder

mit dem Netzwerk verbunden wird.

Werkseinstellung: 192.168.1.100

Identizieren der Netzwerkadresse einer IP-Adresse

Werkseinste llung: 255.255.255.0

Die Gateway-Adresse (oder das Standard-Gateway) ist eine Router-Schnittstelle, die mit

dem lokalen Netzwerk verbunden ist und Pakete aus dem lokalen Netzwerk sendet.

Werkseinstellung: 192.168.1.1

Name des CCR3+ (relevant für die Netzwerksuche)

Bitte beachten Sie, dass nach der Änderung dieses Wertes der lokale Netzwerk-DNS Server aktualisiert werden muss. Dieser Vorgang ist abhängig von der aktuellen

Netzwerkkonguration und kann einige Stunden dauern.

Werkseinstellung: ccrplus

Dynamisches Host-Kongurationsprotokoll

Disable

Enable

Werkseinstellung: Disable

Anzahl der mit CCR3+ verbundenen LAN-Clients

WLAN-Name (kann geändert werden)

Werkseinstellung: ccrwi

AQ29035882028101-010206

© Danfoss | 2022.01 | 19

Page 20

CCR3+ Controller

LANGUAGEDEUTSCH

11. CCR3+ DASHBOARD

(Web-App-Bildschirm)

(Fortsetzung)

WLAN-Pass

65

(min. 8Zeichen,

max. 15Zeichen)

Verbundener

66

WLAN-Client

Login-Passwort

67

ändern:

Nebenregler Komm.68

Status

Einstellungen

speichern

Passwortname (kann geändert werden)

Werkseinstellung: admin1234

Zeigt IP und Namen des mit dem WLAN verbundenen Geräts an.

Passwortname für den Zugri auf die CCR3+ App

Werkseinstellung: admin1234

Zeigt den Kommunikationsstatus zwischen dem Nebenregler und dem CCR3+ Regler an.

0% – keine Kommunikation

100% – Kommunikation OK

Möglich (lesbare Werte): 0 – 100%

Klicken Sie auf „Einstellungen speichern“, um die Änderungen zu bestätigen.

FIRMWARE-MENÜ:

Bezeichnung Beschreibung

Firmware-Upgrade

Einstellungen auf

Standardwerte zurücksetzen

Passwörter auf

Standardwerte zurücksetzen

Netzwerkeinstellungen

zurücksetzen

HINWEIS: Unterbrechen Sie be im Hochladen der Firmware d en Webbrowser nicht, inde m Sie das Fenster schließen, auf e inen Link

klicken oder eine neue Seite laden. CCR3+ nicht ausschalten. Dies könnte die Firmware beschädigen.

Um den CCR3+ mit neuer Firmware zu aktualisieren, laden Sie zunächst die Firmware-Datei

von der Danfoss-Website herunter.

Befolgen Sie dann die folgenden Schritte: Datei durchsuchen -> Upgrade starten!

Um alle Einstellungen auf die Standardeinstellungen zurückzusetzen (außer

Netzwerkeinstellungen), klicken Sie auf „Standardeinstellungen zurücksetzen“.

Um alle Passwörter auf die Standardeinstellungen (admin1234) zurückzusetzen,

klicken Sie auf „Passwörter zurück setzen“.

Alle Netzwerkeinstellungen auf Standardeinstellungen zurücksetzen

Wenn der Upload abgeschlossen ist, startet der CCR+ neu. Der Upgrade-Prozess dauert in der Regel

mehrere Minuten.

12. DIENSTLEISTUNGEN

LOGIN-MENÜ – Benutzer auordern, das Passwort zu ändern

Nr. Bezeichnung Beschreibung

69 Einloggen Zugri mit Login-Passwort ermöglicht Änderungen in allen Einstellungen

Login überspringen

WLAN-Passwor t

zurücksetzen

Nur die Einstellung

zurücksetzen

Nur Passwor t zurücksetzen

(aber andere Parameter

nicht ändern)

Wiederherstellung

(Gerät kann auf die

werkseitige Firmware

zurückgesetzt werden)

Der Zugri ohne Passwor t erlaubt nur das Lesen von Daten. Änderungen der Einstellwerte

können nicht vorgenommen werden.

Verfügbar durch langes Drücken der Reset-Taste (am LAN-Anschluss) für mindestens

5Sekunden.

Das WLAN-Passwort wird auf „admin00X“ zurückgesetz t, wobei x die Anzahl der blinkenden

BT (blauen) LEDs ist.

Gehen Sie zum Firmware -Menü und klicken Sie auf „Standardeinstellungen zurücksetzen“.

Gehen Sie zum Firmware -Menü und klicken Sie auf „Passwörter zurücksetzen“.

Durch langes Drücken der Reset-Taste, Ausschalten und mit Zugangscode „369“ (Code für

die Wiederherstellung auf die Standardfirmware). Um eine Wiederherstellung durchzuführen,

müssen Sie folgende Schritte ausführen:

1. Spannungsversorgung ausschalten

2. Hardware-Taste drücken

3. Spannungsversorgung einschalten, Power-LED leuchtet

4. Taste länger als 5Sekunden gedrückt halten, bis ALLE 3 LEDs leuchten

5. Wenn alle 3 LEDs leuchten, sofort die Taste loslassen

Von diesem Moment an müssen Sie den 3-stelligen Code eingeben.

In diesem Modus gibt es zwei Hardwaretastenfunktionen:

– kurz drücken, um die Codezahl zu erhöhen,

– lange drücken, um zur nächsten Codezahl überzugehen

Die aktuelle Codezahl wird durch das Leuchten der LED-Diode angezeigt: blaue LED = 1.Ziffer,

weiße LED = 2.Ziffer, orangefarbene LED = 3.Zif fer.

Beispiel für die Eingabe des Codes 123:

– die erste LED-Diode (blau) wird eingeschaltet, dann einen kur zen Tastendruck,

die blaue LED sollte einmal blinken.

– lange drücken, bis die weiße LED eingeschaltet ist.

– durch kurzen Tastendruck 2-mal sollte die weiße LED 2-mal blinken.

– lange drücken, bis die orangefarbene LED eingeschaltet ist.

– durch kurzen Tastendruck 3-mal sollte die orangefarbene LED 3-mal blinken.

– wenn der Code korrekt eingegeben wurde, startet die Wiederherstellung.

SCHALTEN SIE DIE SPANNUNGSVERSORGUNG NICHT AUS!

20 | © Danfoss | 2022.01

AQ29035882028101-010206

Page 21

CCR3+ Controller

LANGUAGEDEUTSCH

13. Modbus-Einstellungen

Unterstützte Funktionen:

1. Halteregister lesen (0x03)

2. Einzelregister schreiben (0x06)

3. Mehrerer Register schreiben (0x16)

1. Lesen der Startadressen des Halteregisters:

von 0 bis 195:

0 – Ventil Ausgang Strang

(1=Ausgang geschlossen – Ventil is t offen, 0=Ausgan g offen, Ventil

ist geschlossen)

1 – Ventil Ausgang pwm Strang

(Ventil öffnet in Prozent: 0% .. 100%, Dezimalzahl ohne Vorzeichen)

2 – Temperaturwert

(Ventil öffnet in Prozent: 0% .. 100%, Dezimalzahl ohne Vorzeichen)

3 – Temperatureinstellung

(Temperatur in °C mit einer Dezimalstellengenauigkeit, Dezimalzahl

ohne Vorzeiche n --> Beispiel: 529 = 52,9°C)

4 – Status(alarm)*

– 0 – OK

– 1 – Temp. zu niedrig/hoch

– 4 – Sensor geschlossen (Kurzschluss)

– 5 – Sensor of fen (Sensor nicht angeschlossen etc....)

Beispiel: Temperaturberechnung des Strangs6

Formel: (6(Strang) – 1) × 5 + 2 (Temp.-Wert) = 27

180

Ausgang1 of fen/geschlossen

181

Ausgang2 of fen/geschlossen

182

Ausgang3 of fen/geschlossen

183

Ausgang4 of fen/geschlossen

184

B4 offen/geschlossen

185

RTC Jahr

186

RTC Monat

187

RTC Ta g

188

RTC Stunde

189

RTC Minute

190

B1 offen/geschlossen

191

B2 offen/geschlossen

192

B3 offen/geschlossen

193

S0 -Temp .

194

Rücklauftemperatureinstellung

195

Status(alarm)

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

von 300 bis 331:

Tret1

Tret2

Tret3

Tret4

Tret5

Tret6

Tret7

Tret8

Tret9

Nachstellzeit

Prop.faktor

Dif.zeit

PWM-Intervall

PWM Min.

PWM Max.

Stranganzahl

RTC Jahr

RTC Monat

RTC Ta g

RTC Stunde

RTC Minute

Alarm-Verzögerung

Alarm-Diff.temp.

Alarmtyp

Venti ltyp

Ventil-Charakteristik

Out1

Out2

Out3

Out4

Pumpenschutz

Sommermodus

400

Verschiebungswert1

401

Verschiebungswert2

402

Verschiebungswert3

403

Verschiebungswert4

404

Verschiebungswert5

405

Verschiebungswert6

406

Verschiebungswert7

407

Verschiebungswert8

408

Verschiebungswert9

409

Verschiebungswert10

410

Verschiebungswert11

411

Verschiebungswert12

412

Verschiebungswert13

413

Verschiebungswert14

414

Verschiebungswert15

415

Verschiebungswert16

416

Verschiebungswert17

417

Verschiebungswert18

418

Verschiebungswert19

419

Verschiebungswert20

420

Verschiebungswert21

421

Verschiebungswert22

422

Verschiebungswert23

423

Verschiebungswert24

424

Verschiebungswert25

425

Verschiebungswert26

426

Verschiebungswert27

427

Verschiebungswert28

428

Verschiebungswert29

429

Verschiebungswert30

430

Verschiebungswert31

431

Verschiebungswert32

432

Verschiebungswert33

433

Verschiebungswert34

434

Verschiebungswert35

435

Verschiebungswert36

2. Einzelregister schreiben – Daten können in Startadressen geschrieben werden:

– von 300 bis 331

– von 400 bis 435

von 400 bis 435:

AQ29035882028101-010206

3. Mehrerer Register schreiben – Daten können in Startadressen geschrieben werden:

– von 300 bis 331

– von 400 bis 435

© Danfoss | 2022.01 | 21

Page 22

CCR3+ Controller

LANGUAGE

LIETUVIŲ K.

1. Produkto aprašymas

2. Taikymas

3. Techniniai duomenys

CCR3+ valdiklis naudojamas valdyti grąžinamą

temperatūrą vieno vamzdžio šildymo

sistemose ir turi temperatūros registravimo

bei stovo temperatūros stebėjimo funkcijas.

CCR3+ reguliatorius yra AB-QTE sprendimo,

skirto vienvamzdžio šildymo sistemoms, dalis.

Jis konvertuoja vienvamzdę šildymo sistemą

(paprastai nuolatinio srauto sistemą) į efektyvią

kintamojo srauto sistemą. Šis pažangus

sprendimas dinamiškai valdo srautą stovuose,

pagal stovų apkrovą reguliuodamas grąžinamą

temperatūrą. Yra kelios pagrindinės taisyklės, į

kurias būtina atsižvelgti, ypač atliekant renovaciją:

• AB-QM būtina nustatyti atsižvelgiant į

reikiamą stovo / kontūro šilumos apkrovas.

• Būtina užtikrinti tinkamą radiatoriaus apėjimo

srauto parametrą (paprastai 25–35 %). Jeigu

radiatoriaus įtaka labai didelė palyginus su

apėjimu, gali būti tiekiamas per mažas srautas,

jeigu sumažinamas stovas / kontūras.

Valdiklis prijungtas prie terminės pavaros, kurios

tipas TWA-Z )NO), ir nuotolinių temperatūros

jutiklių PT1000, kurių tipas ESMC, sumontuotų

ant kiekvieno stovo.

• Optimizuokite srauto temperatūrą, kuri

reguliuojamaiššilumos punkto valdiklio (per

aukšta srauto temperatūra gali daryti įtaką

pirmųjų radiatorių efektyvumui stove / kontūre,

todėl gali pasireikšti srauto svyravimai).

• Optimizuokite CCR3+ grąžinimo temperatūrą

(dėl per aukštos grąžinamos temperatūros

gali sumažėti energetinis efektyvumas).

• Sumontuokite temperatūros jutiklį priešais