Operating Guide

CCR3 Controller

CCR3 - CONTROLLER

ENGLISH

CCR3 Controller www.danfoss.com Page 4

Multilingual CCR3 instructions are provided on SD card included in CCR3 package or on http://www.danfoss.com

© Danfoss | 2016.08

VI.D3.A3.02 | 1

CCR3 Controller

58 mm

158.5mm

Fig.1 CCR3 Controller

Abb. 1 CCR3 Regler

1 pav. CCR3 reguliato rius

1. att. Regulat ors CCR3

Rys. 1 Sterow nik CCR3

Рис.1 Контроллер CCR3

CCR3 - CONTROLLER

CCR3 - CONTROLLER

SD

FLASH

CARD

Fig. 2 Dimens ions and installatio ns on DIN relay 35 mm

Abb. 2 Abmessu ngen und Installat ionen auf 35 mm-DI N-Schiene

2 pav. Matmenys i r montavimas ant DIN re lės 35 mm

2. att. Izmē ri un uzstādīšana uz D IN 35 mm sliedes

Rys. 2 Wymi ary i montaż na sz ynie DIN 35 mm

Рис.2 Монтажные размеры контроллера на DIN-рейке

Do not in stall or

remove SD c ard

when connected

to the current.

90 mm

90 mm

Bei eingeschalteter

Stromversorgung

darf d ie SDSpeicherkarte

weder eingesetzt

noch entfernt

werden.

35 mm

Neįdėkite ir

neišimkite SD

kortel ės, jei

įjungta srovė.

31 mm

10

35 mm

62 mm

Neievietojiet

un neiz ņemiet

SD kart i,

kad ierī ce ir

pievienota

strāvas avotam.

Nie nal eży

wkładać ani

wyjmować

karty S D, gdy

urządzenie jest

podłączone do

prądu.

Не устанавливайте

и не удаля йте

карту SD , если

контр оллер CCR3

подкл ючен к сети

питания.

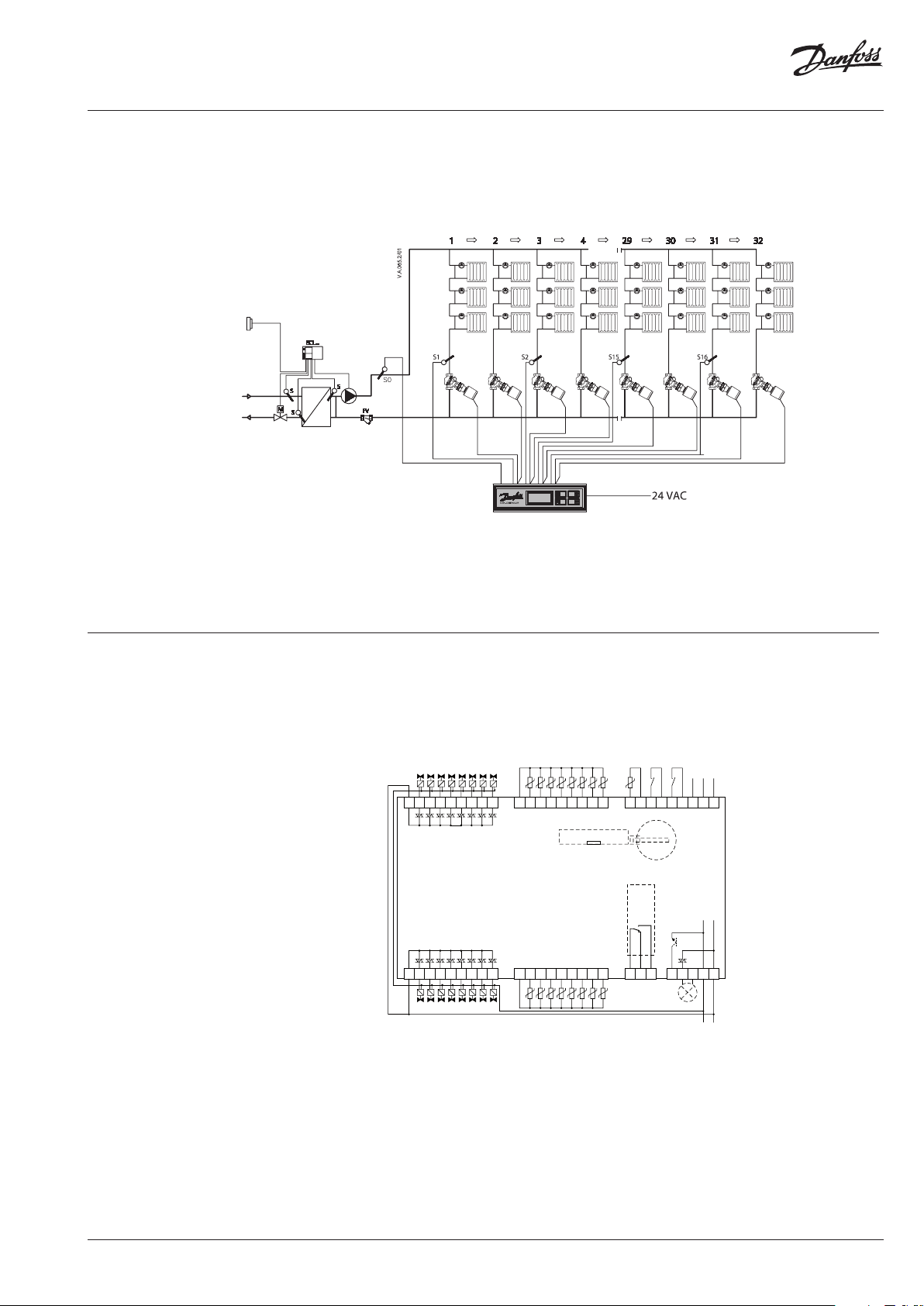

Fig. 3 CCR3 Contolle r: scheme with 16 risers

Abb. 3 CCR3 Regler : Anlage mit 16 Strängen

3 pav. CCR3 reguliato rius: schema su 16 stovų

3. att. Reg ulators CCR3: shēma ar 16 stāvva diem

Rys. 3 Sterow nik CCR3: schemat z 16 pionami

Рис.3 Контро ллер CCR3: Сзема с 16 стояками

2 | © Danfoss|2016.08

VI.D3.A3.02

CCR3 Controller

Fig. 4 CCR3 Controll er: scheme with 32 rise rs

Abb. 4 CCR3 Regler : Anlage mit 32 Strängen

4 pav. CCR3 reguliato rius: schema su 32 stovais

4. att. Reg ulators CCR3: shēma ar 32 stāv vadiem

Rys. 4 Sterow nik CCR3: schemat z 32 piona mi

Рис.4 Контролл ер CCR3: Схема с 32 стояками

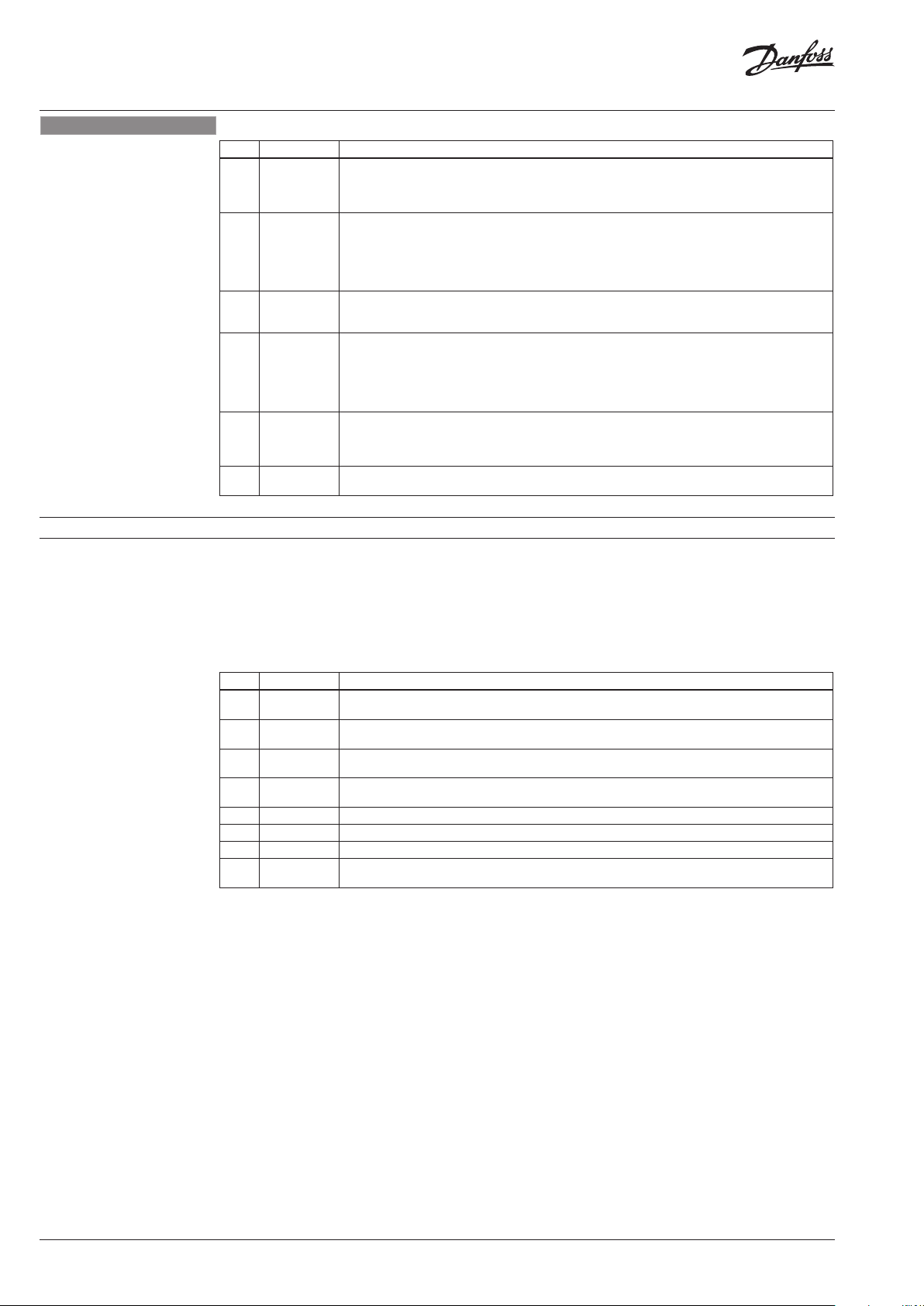

Fig. 5 Wiring

Abb. 5 Verdrahtun g

5 pav. Sujungim as

5. att. Vadojums

Rys. 5 Podł ączenia elek tryczne

Рис.5 Подключение силовых цепей

outlet: ac tuators 1-8

Triac output

Ausgang: Antriebe 1-8

Triac-Ausgang

Išėjimas: pavaros 1–8

TRIAC išė jimas

izeja: izpildmehānismi 1–8

TRIAC izvade

wylot: siłowniki 1–8

Wyjście triakowe

выход: прив оды 1-8

Триак-выход

C

V2 V3 V4 V5 V6 V7 V8

V1

CCR3

CONTROLLER

V13

V10 V9

C

outlet: ac tuators 9-16

Triac output

Ausgang: Antriebe 9-16

Triac-Ausgang

Išėjimas: pavaros 9-16

TRIAC išė jimas

izeja: izpildmehānismi 9-16

wylot: siłowniki 9–16

Wyjście triakowe

выход: прив оды 9-16

Триак-выход

V11 V12

TRIAC izvade

V15 V16

V14

temperature sensors

S1-S8

Temperaturfühler

S1-S8

Temperatūros jutikliai

S1–S8

temperatūras sensori

S1–S8

czujniki temperatury

S1–S8

температурные датчики

S1-S8

M S1 S2 S3 S4 S5 S6 S7 S8

M S9 S10 S11 S12 S13 S14 S15 S16

temperature sensors

temperature sensors

S9-S16

S9-S16

Temperaturfühler

Temperaturfühler

S9-S16

S9-S16

Temperatūros jutikliai

Temperatūros jutikliai

S9–S16

S9–S16

temperatūras sensori

temperatūras sensori

S9–S16

S9–S16

czujniki temperatury

czujniki temperatury

S9–S16

S9–S16

температурные датчики

температурные датчики

S9-S16

S9-S16

temp.

Free

sensor

contacts /

S0

temp.

fühler

S0

Temp.

jutiklis

S0

temp.

sensors

S0

czujnik

bezpotencjałowych/

temp.

S0

темп..

датчик

S0

M B1 M B2 M M A

S0 B

NO T1

C

NC

Input

Potentialfreie

Kontakte /

Eingabe

Nemokama

kontaktai/

įėjimas

Bezmaksas

kontakti /

Ievade

Styków

Wejście

Контакты

без /

Ввод

„ModBus“ „do BMS“

0V 0V 24V

T2

ModBus do BMS

ModBus do BMS

ModBus un BMS

ModBus do BMS

шина ModBus

выполнить BMS

ALARM

Supplay

voltage 24

Netzspannung

24 VAC

Maitinimo

įtampa 24 V

kintamoji srovė

Padeves

spriegums 24 V

maiņstrāva

Napięcie

zasilające

24 V AC

Напряжение

питания 24 В

пер. тока

RS 485

Fbus

RS 485

Fbus

RS 485

„Fbus“

RS 485

FBus

RS 485

FBus

RS 485

FBus

VAC

VI.D3.A3.02

© Danfoss |2016.08 | 3

CCR3 Controller

ENGLISH

1. Product description

2. Application

The CCR3 Controller is a controller used to control

return temperature in one pipe heating systems

with functions such as temperature registration

and monitoring riser temperature. The controller

is connected to thermo actuators type TWA-Z (NO)

and remote temperature sensors PT1000, type

ESMC installed on each riser.

CCR 3 controller is part of AB-QTE solution for

one-pipe heating systems. It converts one-pipe

heating system (usually constant flow system)

into efficient variable flow system. This innovative

solution dynamically controls the flow in the

riser according to the load in risers by return

temperature control. There are few basic rules to

be followed, even more valid in case of renovation:

• Set AB-QM according to the required heat load

of the riser/loop.

• Ensure correct radiator a bypass flow setting

(typically around 25-35 %). If the resistance of

the radiator is much too high compared to the

bypass this may result in underflow through

radiator if the flow in riser/loop is reduced.

3. Technical data: CCR3 Controller

Temperature sensor (S0, S1-S16)

Temperature range (registration) –20 °C … +120 °C

Measuring accuracy +/- 0,5 K

Inputs: B1 and B2 Free contact (5 V 1 mA)

Number of control valves (risers)

Output signal to actuators (Triac t ype) 24 VAC max. 1 A

Alarm signal output (Triac type) 24 VAC max. 1 A

Relay output 0-24 VAC/DC max. 1A

OC output ( Transistor type) 0-20 VDC NPN Open collec tor max. 200 mA

Type of memor y card (included) SD

Maximum memory card 2 GB (included)

Timer: Real time clock

Ambient temperature 0 … +50 °C ( for CCR3 only. The ambient temperature for actuators

Transport temperature –10 … +60 °C

IP rating IP 20

Power supply 24 VAC

Power consumption 6 VA

Weight 0,9 kg

Installation DIN rail 35 mm

• Optimise flow temperature that is driven by

substation control (too high flow temperature

can influence efficiency of first radiators in the

riser/loop and result in oscillation of flow).

• Optimise return temperature that is driven by

CCR 3 (too high return temperature can result in

lower energy efficiency).

• Install temperature sensor in front of AB-QM

as close to last radiator in the riser/loop as

possible.

Following above rules will ensure optimal control

performance of CCR3 as well as energy efficiency

and reliability of heating systems. For further

application insights please contact Danfoss

representative.

Pt1000, S0

16 basic, additional 16 with parallel connection ( 32 all together ,

one temperature sensor is used as common for two risers )

Built-in bat tery

– type ESMC/ESM11, S1-S16 – type ESMC

– powered for 10 years

TWA-Z (NO) should not be above 30 °C)

4 | © Danfoss | 2016.08

VI.D3.A3.02

CCR3 Controller

ENGLISH

LANGUAGE

4. Installation

For easy access the CCR3 Controller is installed in the

technical box on DIN rail 35 mm. Box with DIN rail

should be mounted in the wall (sub-station or

boiler

DIN rail

to install

same box as CCR3 (not supplied).

5. Switching the control on

Before switching the controller on for the first

time, disconnect all cables and connect a 24 VAC

source to the disconnected power plug. Use a

voltmeter to measure the voltage on the power

cable plug before it is connected to the controller.

If the voltage is correct:

1. Read the instructions before you operate the

2. Disconnect all cables

3. Connect the power to the transformer (not

4. Turn the power to the transformer on

5. Verified currency – 24 V

6. Connect the cable from the transformer to the

6. Control start menu

room) as close as possible to the heat source.

and box are not included. It is recommended

the standard 24 VAC transformer in the

controller

connected to CCR3 ”one”)

CCR3 Controller input

The transformer power depends on numbers of

actuators (number of risers in heating installation).

For standard application (16 actuators-16 risers)

30 W transformer is recommended, (for 32

actuators-32 risers) 60 W recommended.

Do not install (and remove) SD card when the CCR3

is connected to the current. It must be turned off (risk

of losing data).

The controller should display its name and the

software version – CONTROLLER START MENU –

display according to point 5.

Before any plugs are connected to the controllers,

input and output connectors:

1. Set all parameters on the controller

2.

Make sure that there is no external voltage on the

temperature sensor plugs

3. Make sure that the voltage on the relay contacts

is not too high (max. 24 VAC)

Start process

After switching the controller detected SD card on

and verified card memory.

If the card is placed correctly, the controller will verify

the present files:

• access

• one set

• all set

If the above-mentioned file is detected, the

controller

will ask whether it should be used or

aborted.

If no files (new card, used for the first time) there will

be no request.

The next controller will automatically generate a folder

with files:

• folder ACCESS:

allow change of access code to menu (details

on request or www.danfoss.com side)

•

folder DATA: file with record date folder SETTINGS

No. LCD Dis play FUNCTION DESCRIPTION

1 Danfoss

OPCCR -3.20

2 SD Free

.....

3 SD Free

199 6 MB

4 NO

SD CARD!

5 072254

123 456

Welcome Menu

Abbreviation: the type of the CCR3 Controller

Diagnosis: available SD card memory

Available memory In MB

e.g.: 2 GB

No SD card in CCR3

Only when no card in CCR3

Series number of CCR3 and number of software.

Code used for services.

with files

-

all set: file with settings. Each time the of control is

switched on, setting parameters are archived.

function provides verification history of all settings

- arch.set: file with archive of all settings.

Switching the controller on for the 2nd time with the

above-mentioned record file the request procedure

for setting change or abortion will start.

Display information during the start process

After switching the CCR3 Controller on, the LCD

display automatically presents the start menu.

The table below shows the various information

and change possibilities during the operation of

CCR3 Controller.

This

VI.D3.A3.02

© Danfoss | 2016.08 | 5

CCR3 Controller

ENGLISH

7. Control reading menu

When the setup is complete, the reading display

will be shown on the screen.

Pressing the “+” key turns the subsequent reading

display on. The “-” key turns the previous reading

display on.

No. LCD Dis play FUNCTION DESCRIPTION

6 Sensor0

…………

7 Valv e1

…….

8 SetT R1

…….

9 Time

………

10 Archiver

AC xx

11 DayToE nd

……..

12 Alert T2

…….

8. Menu Access Code - access to settings

Pressing an arrow “▲” result in exit from the reading

displays and enter to the ACCESS CODE menu,

described in chapter 8.

When exit from the menu the first reading display

is shown. A list of readings and possible displayed

options are shown in the table below.

Current return temperature measure by sensors.

Information: S0 – supply temperature, S1-S16 – return temperature measure in risers.

When info display Sensor .... Open ( no sensor ), when : Sensor ..... Closed ( short cut ).

Status of control valves, display from V1-V16

Information:

0 % ON no control signal for ac tuators (valve fully open when NO is used) or 100 % OFF (valves is closed).

During the controlling intermediate status is displayed: e.g. 17 %

Information about setting return temperature correspondent to current flow temperature, in C degree.

Display for R1-R16, e.g.: 45,0 °C

Current date and time

e.g .: 10- 04-27

17:45:10

Information about number of data storage in SD card(files)

e.g.: 38 storage file, InProces

xx = number of stored files; 1 file stored per day

Information how many days data can be stored on existing SD card.

Please note that this is information valid for current archiving interval.

e.g.: 884

Alarm output active or not . Function used for sensor and actuators circuit detection

(for example shortcut detection)

No Active or Active

To set the parameters, press the up arrow key “▲”

from R

eading Menu

and enter the access code (three

digits) to enter the required settings group.

The “+/-“ keys change the digit values in the code,

the arrow keys “▲/▼”navigate the cursor through

the code digits.

No LCD Display FUNCTION DESCRIPTION

13 AcceCode

***

Access codes to the controller’s setting menus. Available menus:

– Install Menu (code: 427). Advanced settings

– Real Time menu (code 576).Real time clock and date setting

- Control Menu (code 437): exp ert settings for PID control

Quadruple pressing up arrow key “▲” without ente ring any code will give access to “SD Card Exchange”.

–

SD card can be safely pulled out from CCR3 (process of date

recording is interrupted).

The access codes are standard for the individual

menus.

It is possible to change the access codes by

entering new codes through the SD memory

card and restarting the controller. Detailed

instructions are available on request.

The controller’s settings can be entered using the

keypad or globally through the SD memory card

(controller restart required). Details are available

on request.

To enter the required setting group press arrow key

“▲” after last code digit. If the code is not correct,

the display shows:

SD Card Exchange – this means that the SD card can

safely be pulled out from CCR3 "One pipe controller"

(process of date recording is interrupted). The settings

menu is closed automatically after four minutes of

inactivity and the display returns to

Reading Menu.

The manufacturer reserves the right to change the

controller’s settings and readings in production to

improve handling and functionality. An up-to-date

list of settings for the given software version is

available on Danfoss’ web site. New settings can

automatically upgrade CCR3 Controller through

the SD memory card (controller restart required).

6 | © Danfoss | 2016.08

VI.D3.A3.02

CCR3 Controller

ENGLISH

9. INSTALL MENU SETTINGS (Code: 427)

From ACCESS CODE menu enter code: 427

(procedure in chapter 7). The Install Menu is displayed

in details in the table below. The arrow keys “▲/▼”

move the menu windows, the “+/ - “keys change the

To exit the setting menu, press the up arrow key “▲”

after changing the last setting. The setting menu is

closed automatically after 4 minutes of inactivity.

values in the window selected by the arrows.

No LCD Display FUNCTION DESCRIPTION

14 INSTALL

Menu

15 TRet (35)

.....

16 TRe t (40)

.....

17 TRet (45)

.....

18 TRet (50)

.....

19 TR et (55)

.....

20 TRet (63)

.....

21 TRet (70)

.....

22 TRet (80)

.....

23 TRet (90)

.....

24 Shift1

..0 °C..

25 RiserNr 16Number of risers used in the system: settings from: 1-16

26 V Type

…….

27 VCharact

…….

28 Cor Cal

S0 ….

…. °C

29 Rel.Test

……….

Information about menu: Install

Recommended for service.

Required return temperature for measure supply temperature: 35 °C

Factory setting: 30 °C

Required return temperature for measure supply temperature: 40 °C

Factory setting: 34 °C

Required return temperature for measure supply temperature: 45 °C

Factory setting: 38 °C

Required return temperature for measure supply temperature: 50 °C

Factory setting: 40 °C

Required return temperature for measure supply temperature: 55 °C

Factory setting: 42 °C

Required return temperature for measure supply temperature: 63 °C

Factory setting: 45 °C

Required return temperature for measure supply temperature: 70 °C

Factory setting: 48 °C

Required return temperature for measure supply temperature: 80 °C

Factory setting: 54 °C

Required return temperature for measure supply temperature: 90 °C

Factory setting: 58 °C

Shift return temperature valid for all setting points. It can be adjusted up and down. The lowest shift setting

is to 10 degrees (anti frost setting value).

Each riser can be adjusted individually, riser by riser (from 1 to 16)

Factory setting: 0 ºC; in range of ±10 °C

If more than 16 risers: choose 16 and connect selected risers parallel using one ac tuator’s output for t wo risers

(for two actuators) (max additional 16 risers)

Factory setting: 16

Type of control valves: normal open or normal closed

Option to choose: NO or NC

Factor y setting: NO

Type of valves characteristic

Option to choose: Linear or Hyperbolic

Factory setting: Linear (setting for 24 VAC actuator)

Sensor calibration: S0-S16 in range: ±9,9 °C

Do not make calibration when sensor cables are shorter then:

- for cable 0,75 mm

- for cable 1,00 mm

Correction factor

total length

(two - core cable)

in meter 0,5 0,75 1,00 1,5

10 - 0,2 - 0,1 - 0,1 - 0,1

15 - 0,5 - 0,3 - 0,2 - 0 ,1

20 - 0,4 - 0,3 - 0,2 - 0,1

25 - 0,5 - 0,3 - 0,3 - 0,1

30 - 0,6 - 0,4 - 0,3 - 0,2

35 - 0,7 - 0,5 - 0,4 - 0,2

40 - 0,8 - 0,5 - 0,4 - 0,2

45 - 0,9 - 0,6 - 0,5 - 0,2

50 - 1, 0 - 0,7 - 0,5 - 0,3

75 - 1,5 - 1,0 - 0,8 - 0,4

100 - 2,0 - 1,4 - 1, 0 - 0,5

125 - 2,5 - 1,7 - 1, 3 - 0,6

150 - 3,0 - 2,0 - 1, 5 - 0,8

Factory setting: 0 °C

Relay test (Triac output)

AUTO – normal working operation

V1-V16 – forced signal for valves output V1-V16

Rel C-NO - not used

T1 Out – not used

T2 Out – forced signal (24 VAC) for alarm T2.

Factory setting: Auto

2

– 10 meters,

2

– 15 meters.

cable cross section

2

(mm

)

VI.D3.A3.02

© Danfoss | 2016.08 | 7

CCR3 Controller

ENGLISH

No LCD Display FUNCTION DESCRIPTION

30 AlertRel

... …

31 Archiver

...

32 ArchFreq

...

33 DateForm Form of date display:

34 Reset

…….

35 Ecs?

+ YES

10. REAL TIME CLOCK SETTINGS (code 576)

Alarm output (Triac)

StillOn – continuos alarm signal: T2 – 24 VAC

Pulse – pulse alarm signal 24 VAC every second

Factory setting: Pulse

Information about data archiving:

Never – the feature is switched off,

1 File – data is stored in one file on the SD card,

2 Files – data is stored alternatively in two files to improve write reliability. This function decreases term of

date storage (twice).

Factory setting: 1 File

Data archiving interval. The time can be set to any value between 10 seconds and 4 hours. The data from

each day saved in different files (with data name).

Factory setting: 1 min

YY-MM- DD – year, month, day

YY-DD-MM – year, day, month

DD-MM-YY – day, month, year

MM-DD - YY – month, day, year

Factory setting: YY-MM-DD

Reset to factory settings

Yes - return to factory settings

No – keep adjust settings

Note: To complete reset proced ure turn CCR3 off and back on.

Exit win dows from Install Men u. Enter “+” to closed set ting or basic menu will close automatically af ter 4 minutes

From ACCESS CODE menu enter code: 576

(procedure in chapter 7). The Real Time menu is

displayed as detailed in the table below.

The arrow keys “▲/▼”move the menu windows,

the “+/-“keys change the values in the window

selected by the arrows.

No LCD Display IN STALL MENU - FUNCTION DESCRI PTION

36 Real Time

Menu

37 RealTime

12:00:00

38 RealTime

12:00:00

39 RealTime

12:00:00

40 Year Sets the year for the current date

41 Month Sets the month for the current date

42 Day Sets the da y for the current date

43 Ecs?

+ YES

Information about menu: real Time

Sets the real time clock “hour”

Sets the real time clock “minute”

Sets the real time clock “second”

Exit win dows from Install Men u. Enter “+” to closed set ting or basic menu will close automatically af ter 4 minutes

To exit the setting menu, press the up arrow key after

changing the last setting. The setting menu is closed

automatically after 4 minutes of inactivity.

8 | © Danfoss | 2016.08

VI.D3.A3.02

CCR3 Controller

ENGLISH

11. CONTROL MENU (code 437)

From ACCESS CODE menu enter code: 437

(procedure in chapter 7). The Control menu is

displayed as detailed in the table below. The arrow

keys “▲/▼”move the menu windows, the “+/-“keys

change the values in the window selected by

the arrows. To exit the setting menu, press the

up arrow key after changing the last setting.

The setting menu is closed automatically after 4

minutes of inactivity.

No LCD Display FUNCTION DESCRIPTION

44 Prop. Fac ……Control gain of control signal (depend on actuators typ e). The higher gain control the bigger valves reac tion

45 Int.Time

46 Diff.Ti me

47 PWM Per

48 PWM Min

49 PWM Max

50 BMSAdres

51 BMS TYPE

52 Ecs?

…….

…….

…….

…….

…….

…..

…….

+ YES

(no stable regulation). The lower gain control weak reaction for temperature change (stable regulation).

Factory setting: 50 (for dedicated T WA-Z (NO) actuators); setting range 1-100

Integration time of the control signal (depend of actuators type). The shorter time, quicker temperature

changes (no stable regulation). The longer time slower reaction for temperature change (stable regulation).

Factory setting: 6 sec (for dedicated TWA-Z (NO) actuators); set ting range 1-100

Differential time of control signal. The longer the value, faster control in reaction to the control value

change - approaching to the set value but not reaching it yet. Too high value resu lts in unstable control.

Factory setting: 15

Time period of pulse width madulation (PWM}.

Factory setting: 10s

At »close« signal to actuator, PWM describes minimum % of open period to the actuator. Lower the

value, longer the reac tion time of the actuator. Too high value can result in not closed valve.

Factory setting: 10 %

At »open« signal to actuator, PWM describes maximum % of open period to the actuator. Higher the

value, longer the reac tion time of the actuator. Too low value can resu lt in not opened valve.

Factory setting: 90 %

CCR3 address in BMS system

Factory setting: 1

Type of date transmission:

ModBus 96 (9.600)

Mod Bus 19 (19.000)

ModBus 38 (38.400)

FBus

Factory setting: Mod Bus 96

Exit win dows from Install Men u. Enter “+” to closed set ting or basic menu will close automatically af ter 4 minutes

12. USING THE DATA STORAGE CARD

The SD card may never be installed or removed from

the CCR3 Controller when data is being written to it,

this may lead to:

– data loss

– SD card damage

– CCR3 Controller damage.

INSTALLING THE SD CARD

Disconnect the controller from the power supply for

at least five seconds before inserting the SD card.

The SD card may only be installed after this pause.

REMOVING THE SD CARD

From ACCESS CODE menu quadruple press up arrow

key “▲” without entering any code it will give access

to “SD Card Exchange”. SD card can be pulled out

safely from CCR3 Controller (process of date recording

is interrupted).

Power failures occur as data written to the SD card may

also corrupt the archive or even damage files stored

on the card. To reduce this risk, it is recommended

to use a buffered power supply for a CCR3 Controller

used with the data archiving function and to set the

“Archive” setting to “2 Files.” The archive files will be

doubled, but the storage space will drop by half.

VI.D3.A3.02

© Danfoss | 2016.08 | 9

CCR3 Controller

Danf

already on order pro

All trademarks in this material are property of the respec

ENGLISH

13. CCR3 ModBus PROTOCOL

Data type: Coil [bool] Coil No. Description

MB_CoilOut [2 … 9] - open valves (0 … 7)

MB_CoilOut [10 … 17] - risers with open valves (riser: 8 … 15)

Data type: Register

[integer]

Baud rate:

Register No. Description

MB_RegisterOut [0 … 8] - temperature sensors S0 … S8 (8000 <=> 80 °C)

MB_RegisterOut [9 … 16] - temperature sensors S9 … S16 (8000 <=> 80 °C)

MB_RegisterOut [17 … 24] - temperature setting for risers 1 … 8

MB_RegisterOut [25 … 32] - temperature setting for risers 9 … 16

MB_RegisterOut [36+0 … 7] - control signal (opening) in % for valve in risers: 1 … 8

MB_RegisterOut [44+0 … 7] - control signal (opening) % for valve in riser: 9 … 16

data bits stop bits parity

9.600 8+1 N

19.200 8+1 N

38.400 8+1 N

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

10 | © Danfoss | DHS-SRMT/SI | 2016.08

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

73693840/VI.D3.A3.02

Loading...

Loading...