Page 1

Operating Guide

CCR2+ Controller

Master Controller Slave Unit

ENGLISH

CCR2+ Disinfection Process Control & Temperature Registration www.danfoss.com

© Danfoss | 2022.01

AQ282339078428en-010203 | 1

Page 2

CCR2+ Controller

1219 20 21 ... 35 36

6

A

1278910 19 20

A

TVM

12789 19 20

TVM

TVM

TVM

TVM

TVM

TVM

TVM

...

LBus

24VDC

RS485

A1-4

C

V1-4

C

C

V5-8CV9-12

C

V13-16

C

V17-20

CCR2+ Controller

TCP/IP

RJ45

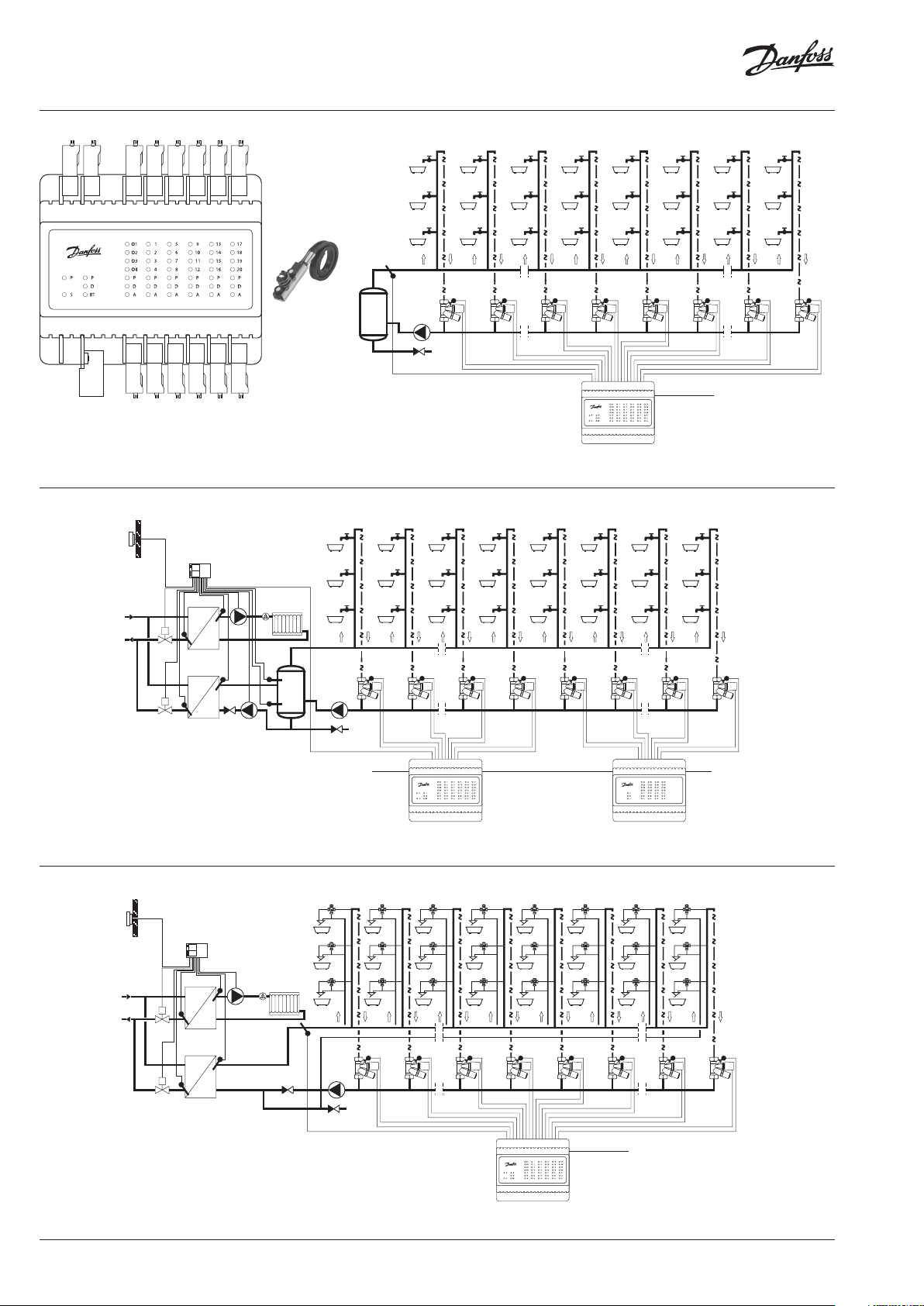

Fig. 1 CCR2+ & ESMC

S5-8 S9-12

B1-3 S0

S1-4

GGGGGG

S13-16

S17-20

ECL...

M

S

S

S

M

S

S0

S1

MTCV

S2 S7 S8 S9 S10 S19 S20

V1

TWA

V2

TWA

V7

TWA

V8

TWA

V9

TWA

V10

TWA

MTCV MTCV MTCV MTCV MTCV MTCV MTCV

V19

TWA

V20

TW

24 VDC

Fig. 2 Installa tion with CCR2+ Controller (up to 20 risers/lo ops)

S

S

S1 S2 S19 S20 S21 S... S35 S36

MTCV

V1

TWA

V2

TWA

V19

TWA

V20

TWA

V21

TWA

V...

TWA

V35

TWA

MTCV MTCV MTCV MTCV MTCV MTCV MTCV

V3

TW

Fig. 3a Install ation with CCR2+ Controller (Master) and CCR+ Slave Unit (more th at 20 risers)

543

HC

MIX

ECL...

S

M

TVM

543

HC

MIX

TVM

543

HC

MIX

S

S0

S

M

S

MTCV

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

S1

S2 S7 S8 S9 S... S19 S20

V1

TWA

MTCV MTCV MTCV MTCV MTCV MTCV MTCV

Fig. 3b

24 VDC24 VDC

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

V2

TWA

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

V7

TWA

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

V8

TWA

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

543

HC

MIX

TVM

543

HC

MIX

TVM

543

HC

MIX

V9

TWA

V...

TWA

V19

TWA

V20

TWA

24 VDC

2 | © Danfoss | 2022.01

AQ282339078428en-010203

Page 3

CCR2+ Controller

G

G

Lbus

24VDC

G

B

A

POWER

Master

LBus

0V

RS485

24VDC

CCR2+ Controller

TCP/IP

LAN

C

CCCCC

O4

V4

V8

V12

0

O3

V3

O2

O1

Module

V7

V2 V6 V10 V14 V18

V1

V5

Module 1

Module 2

V16

4

V11

V15

V9

V13

Module 3

Module

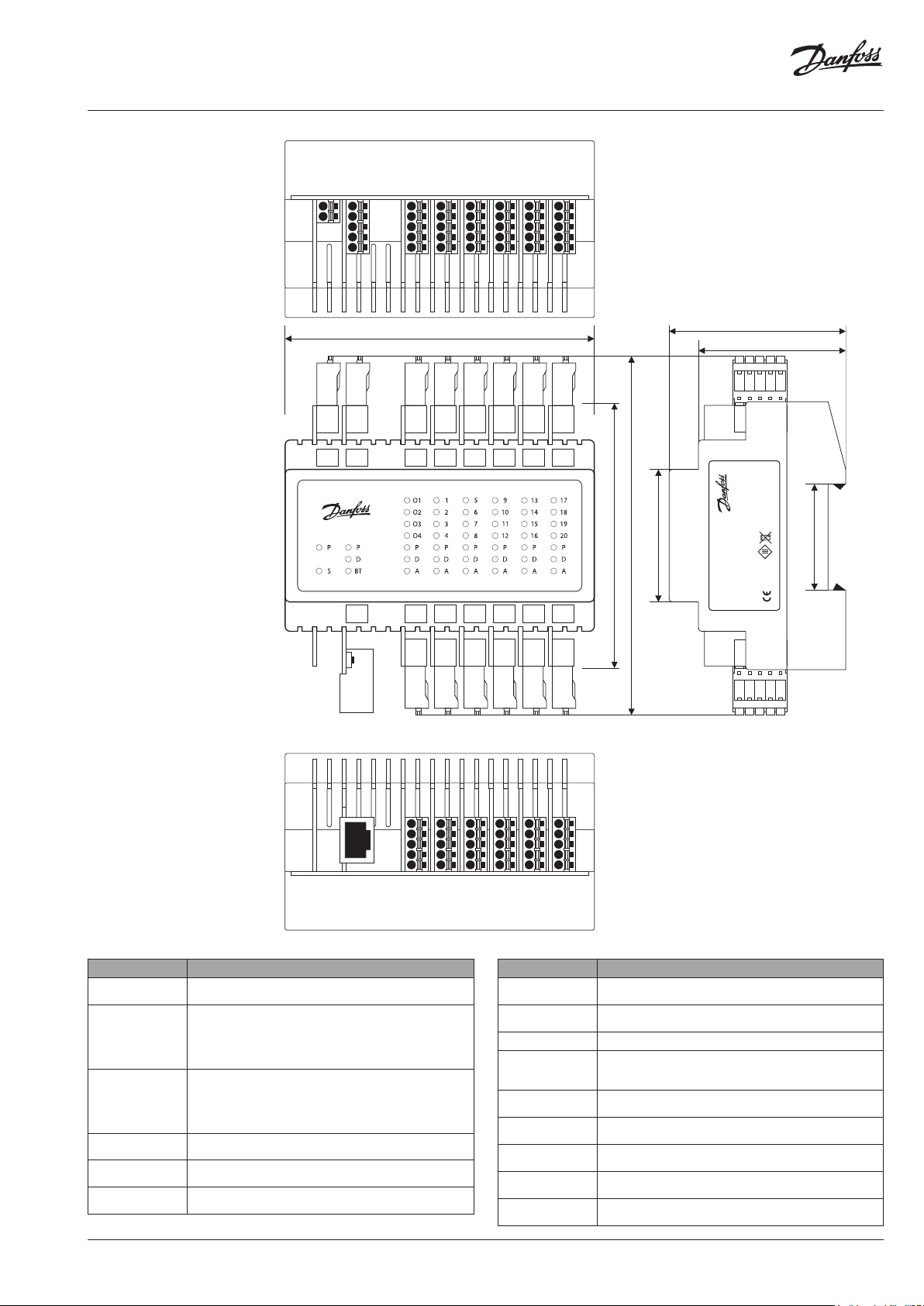

105 mm

C

O1-4

B1-B3 S0

G

V5-8CV9-12

V1- 4

S5-8 S9-12

S1-4

GGGGG

C

C

V13-16

S13-16

C

V20

5

V19

V17

Module

C

V17-20

S17-20

90 mm

122 mm

45 mm

Disinfection

60 mm

MADE IN POLAND

CCR2+

Process Controller

50 mm

20171213V2.40

003Z3851

Supply 24VDC

Danfoss A/S

6430 Nordborg, Denmark

36 mm

RoHS

Fig. 4a Wiring scheme - CCR+

Master Controller

Connector/port Description

0V

24VDC

Lbus

RS485

C

O1,.. ,O4

C

V1-4

C

V5-8

C

V9 -12

0V – ground (-) power supply

24 V DC(+) power supply

G – ground Lbus port (for system expansion)

Lbus – Lbus port (for system expansion)

G – ground (Modbus RS 485)

B – port B (Modbus RS 485)

A - port A (Modbus RS 485)

C – common port dedicated to outputs O1-O4

O1 - output: Heat Force

O2 - output: Start next CCR/Slave Unit

O3 - output: Disinfection finished

O4 - output: Alarm

C – common port dedicated to actuators V1-4

V1..V4 – outputs to actuators

C – common por t dedicated to actuators V5-8

V5. .V8 – outputs to ac tuators

C – common port dedicated to actuators V9 -12

V9. .V12 – outputs to actuators

TCP/IP

RJ45

4

B1

TCP/IP

Master

POWER

RJ45

S2

B2

S3

B3

Module 1

Module 0

S4

S0

G

G

S10

S6

S11

S7

Module 2

Module

S12

S8

G

G

3

S9

S5

S1

S13

S14

S15

Module

S16

G

S17

S18

S19

Module 5

S20

G

Connector/port Description

C

V13 -16

C

V17-2 0

C – common port dedicated to actuators V13-16

V13..V16 – outputs to actuators

C – common port dedicated to actuators V17-20

V17.. V2 0 – outputs to ac tuators

TC P/ IP, L AN TCP/ IP port or IP Modbus port

B1-3, S0

G

S1-4

G

S5-8

G

S9 -12

G

S13 -16

G

S17-2 0

G

B1,B2, B3 defined inputs

S0 – temp. sensor

G – common ground dedicated to inputs/sensor

S1.. S4 – inputs from sensors

G – common ground dedicated to sensor S1-4

S5..S8 – inputs from sensors

G – common ground dedicated to sensors S5-8

S9. .S12 – inputs from sensors

G – common ground dedicated to sensors S9-12

S13.. S16 – inputs from sensors

G – common ground dedicated to sensors S13-16

S17. .S 20 – inputs from sensors

G – common ground dedicated to sensors S17-20

AQ282339078428en-010203

© Danfoss | 2022.01 | 3

Page 4

CCR2+ Controller

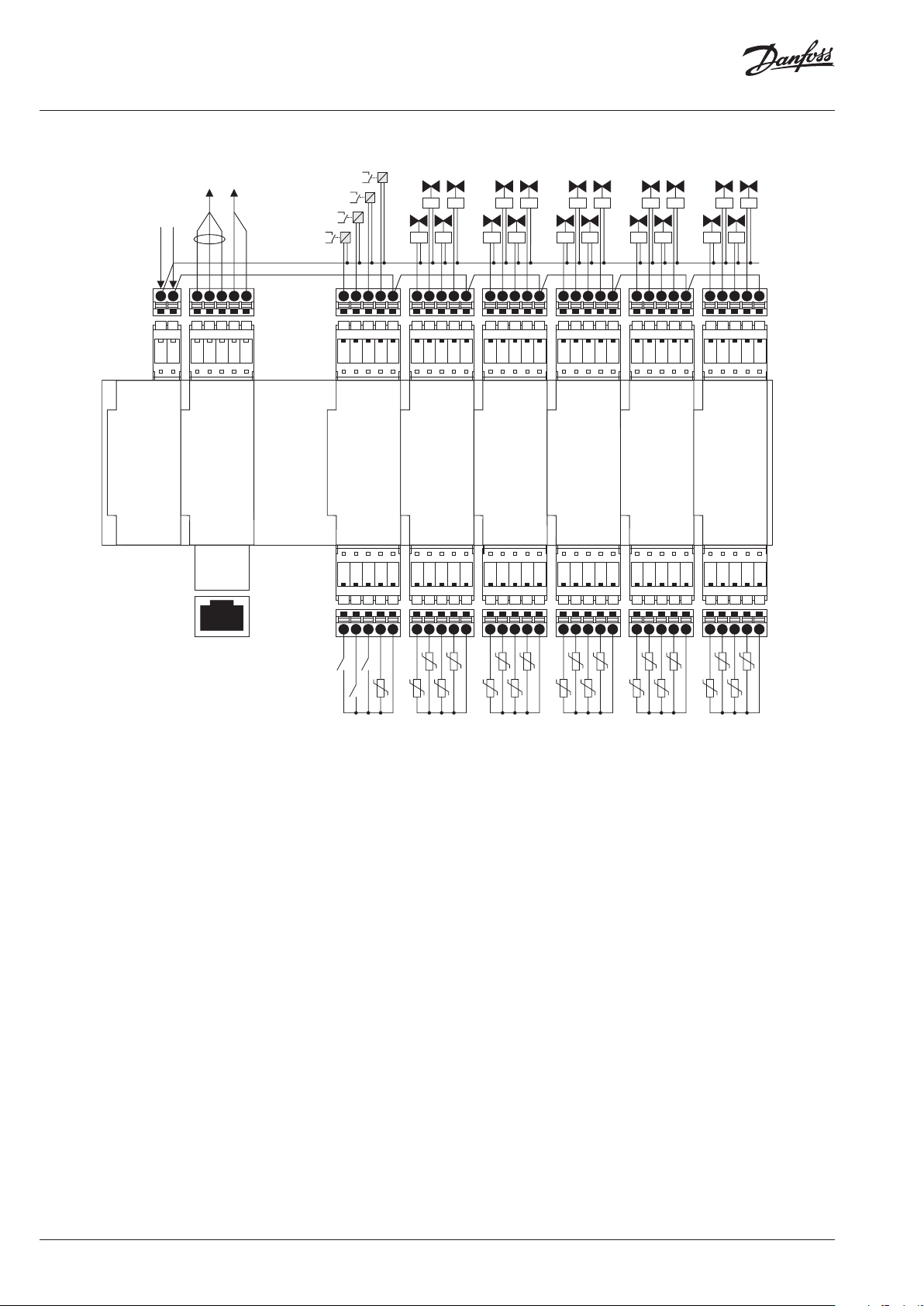

Actuators of risers’ valves V1...V20

B3 - ext. alarm

PT1000

Power

Supply

Board

POWER

SUPPLY

0VDC

24VDC

BMS

B

A

G

Master

Controller

Board

TCP/IP - LAN

CCR

Lbus

SLAVE

G

Alarm

Disinfection finished

Start next CCR

Heat force

24VDC

0V

Empty

Socket

Place

KO4

KO3

KO2

KO1

O1

O2

O4

O3

Module 0

Input / Output

Board

B1

B2

B3

S0

V2V3V4

V1

C

V1

Module 1

Input / Output

S1

G

V2

Board

S2

Open collector outputs connect to 0V

V8

V10

V12

V3

S3

V4

S4

C

G

V5V6V7

V6

V5

Module 2

Input / Output

Board

S5

S6

V7

S7

V8

S8

C

G

V9

V11

V9

V11

V10

Module 3

Input / Output

Board

S9

S10

S11

C

V12

S12

G

V14

V16

V13

V15

V14

V13

V16

V15

Module 4

Input / Output

Board

S13

S14

S15

S16

V18

V17

C

V17

Module 5

Input / Output

S17

G

V19

V18

Board

S18

V20

C

V20

V19

S20

S19

G

WEB SERVER

BMS TCP/IP

ETHERNET

INTERNET

B1 - start dis.

B2 - stop dis.

Fig. 4b Wiring scheme CCR2+ Master Controller

B1

B2

B3

S0

S0 - main

Risers’ temperature sensors S1...S20

sensor

Type of sensor - PT1000

4 | © Danfoss | 2022.01

AQ282339078428en-010203

Page 5

CCR2+ Controller

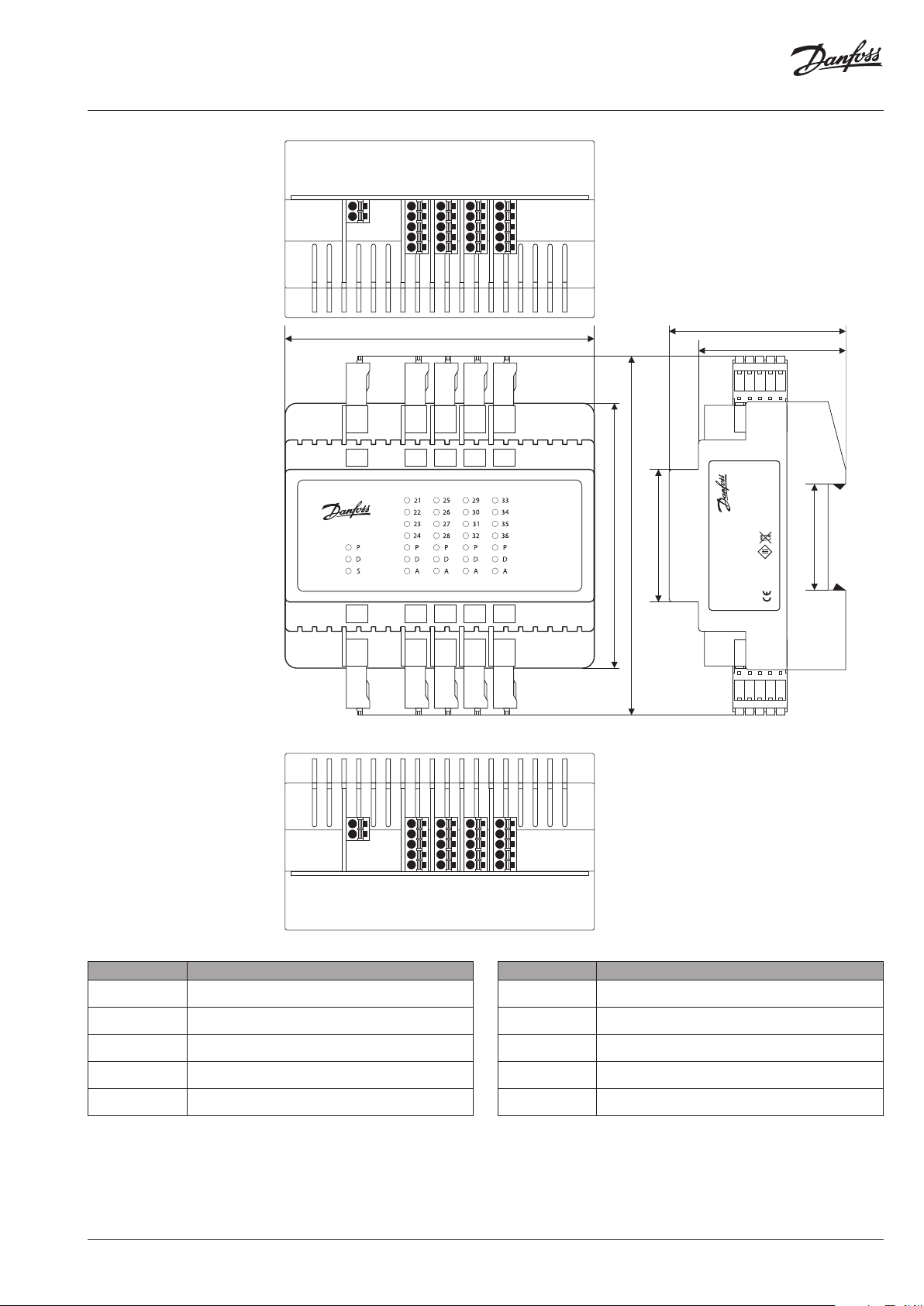

24VDC

Power

24VDC

CCR+ Slave

LBus

G

OV

G

C

V24

6

V23

V22

V21

Module

105 mm

C

V21-24

S21-24

G

C

V28

7

V27

V26

V25

Module

C

V25-28

S25-28

G

CC

V32

V36

V31

V35

V30 V34

V29

V33

Module 8

Module 9

C

C

V33-36

V29-32

S33-36

S29-32

G

G

90 mm

122 mm

45 mm

CCR+ Slave Unit

60 mm

50 mm

MADE IN POLAND

CCR+ Slave Unit

20171212VS.12

003Z3852

Supply 24VDC

Danfoss A/S

6430 Nordborg, Denmark

36 mm

RoHS

Fig. 5 Wiring Scheme - CCR+

Slave Unit

Connector/port Description

0V

24VDC

C

V21-24

C

V24 -28

C

V29-32

C

V30-36

0V – ground (-) power supply

24 VDC power supply

C – common port dedicated to actuators

V21..V 24 – outputs to ac tuators

C – common port dedicated to actuators

V24..V28 – outputs to actuators

C – common port dedicated to actuators

V29..V32 – outputs to actuators

C – common port dedicated to actuators

V33..V36 – outputs to actuators

AQ282339078428en-010203

Slave

G

Lbus

1

S29

S30

S31

Module

S32

2

S33

S34

S35

Module

S36

G

0

S25

S21

S26

S22

S27

S23

Module 0

Module

S28

S24

G

GG

Connector/port Description

Lbus

S21-24

G

S25 -28

G

S29-32

G

S33-36

G

G – ground Lbus port (for system expansion)

Lbus – Lbus port (for system expansion)

S21.. S24 – inputs from sensors

G – common ground dedicated to sensors

S25..S28 – inputs from sensors

G – common ground dedicated to sensors

S29.. S32 – inputs from sensors

G – common ground dedicated to sensors

S33..S36 – inputs from sensors

G – common ground dedicated to sensors

© Danfoss | 2022.01 | 5

Page 6

CCR2+ Controller

Heat forc

Start next CCR

Disinfection finished

Alarm- dis. faile

Connection of two CCR2+

with one S0 sensor in sequence mode

20180904

Connection of two CCR2+

with individual S0 sensor in sequence mode

Heat forc

Start next CCR

Disinfection finished

Alarm- dis. faile

20180904

Fig. 6 Connec tion of two CCR2+ with

one S0 sensor in sequence mode

24VDC

0V

d

KO2

KO1

e

O1

B1

B1

B2

B1 - start dis.

B2 - stop dis.

B3 - ext. alarm

C

C

C

G

C

G

C

G

C

G

V34

V33

V35

Module 4

Input / Output

Board

S33

S35

S34

V9

V11

V10

Module 3

Input / Output

Board

S9

S11

S10

V34

V33

V35

Module 4

Input / Output

Board

S33

S35

S34

V9

V11

V10

Module 3

Input / Output

Board

S9

S11

S10

V36

S36

V12

S12

V36

S36

V12

S12

C

G

C

Input / Output

G

C

G

C

Input / Output

G

V13

Module 4

S13

V13

Module 4

S13

V14

Board

S14

V14

Board

S14

C

C

V20

V16

V17

V19

V18

V15

Module 5

Input / Output

Board

S15

S16

S17

S19

S20

S18

G

G

C

C

V20

V16

V17

V19

V18

V15

Module 5

Input / Output

Board

S15

S16

S17

S19

S20

S18

G

G

V21

V22

V24

V23

V26

0VDC

Slave

24VDC

Board

B

A

Master 1

Controller

Board

Slave

Board

B

A

Master 1

Controller

Board

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

0VDC

24VDC

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

Power

Supply

Board

Power

Supply

Board

24VDC

24VDC

Controller

and Power

0VDC

TCP/IP - LAN

Controller

and Power

0VDC

TCP/IP - LAN

Supply

Supply

SECOND

SLAVE

UNIT

SECOND

MASTER

UNIT

KO4

KO3

MAIN

SLAVE

UNIT

C

O2

O4

O3

S0

G

B2

B3

B3

S0

S0 - main

sensor

PT1000

FORCE

HEATING

SOURCE

MAIN

MASTER

UNIT

KO1

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

V21

V22

V23

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

S24

O4

S0

V24

S24

O4

S0

Input / Output

G

C

Input / Output

G

C

Input / Output

G

C

Input / Output

G

V25

Module 2

Board

S25

V1

Module 1

Board

S1

V25

Module 2

Board

S25

V1

Module 1

Board

S1

S26

V2

S2

V26

S26

V2

S2

V31

V28

S28

V4

S4

V28

S28

V4

S4

Input / Output

G

C

Input / Output

G

C

Input / Output

G

C

Input / Output

G

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V31

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V27

S27

V3

S3

V27

S27

V3

S3

TEMP S.0

Fig. 7 Connec tion of two CCR2+ with

individua l S0 sensor in sequence mode

SECOND

KO4

d

KO3

KO2

KO1

e

24VDC

0V

C

O1

O2

O4

O3

S0

G

B1

B2

B3

B1

B2

B3

S0

S0 - main

sensor

PT1000

B1 - start dis.

B2 - stop dis.

B3 - ext. alarm

SLAVE

UNIT

SECOND

MASTER

UNIT

MAIN

SLAVE

UNIT

FORCE

HEATING

SOURCE

MAIN

MASTER

UNIT

C

C

C

G

C

G

V34

V33

V35

Module 4

Input / Output

Board

S33

S35

S34

V9

V11

V10

Module 3

Input / Output

Board

S9

S11

S10

V36

S36

V12

S12

C

G

C

Input / Output

G

V13

Module 4

S13

V14

Board

S14

C

C

V20

V16

V17

V19

V18

V15

Module 5

Input / Output

Board

S15

S16

S17

S19

S20

S18

G

G

Power

Supply

Board

24VDC

Controller

and Power

0VDC

TCP/IP - LAN

Slave

Supply

Board

B

A

Master 1

Controller

Board

V21

V22

V24

V23

V26

0VDC

24VDC

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

S24

O4

S0

Input / Output

G

C

Input / Output

G

V25

Module 2

Board

S25

V1

Module 1

Board

S1

S26

V2

S2

V31

V28

S28

V4

S4

Input / Output

G

C

Input / Output

G

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V27

S27

V3

S3

TEMP S.0

C

C

C

G

C

G

V34

V33

V35

Module 4

Input / Output

Board

S33

S35

S34

V9

V11

V10

Module 3

Input / Output

Board

S9

S11

S10

V36

S36

V12

S12

C

G

C

Input / Output

G

V13

Module 4

S13

V14

Board

S14

C

C

V20

V16

V17

V19

V18

V15

Module 5

Input / Output

Board

S15

S16

S17

S19

S20

S18

G

G

V21

V22

V24

V23

V26

0VDC

Slave

24VDC

Board

B

A

Master 1

Controller

Board

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

Controller

and Power

Supply

KO1

0VDC

24VDC

Power

Supply

Board

TCP/IP - LAN

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

S24

O4

S0

Input / Output

G

C

Input / Output

G

V25

Module 2

Board

S25

V1

Module 1

Board

S1

S26

V2

S2

V31

V28

S28

V4

S4

Input / Output

G

C

Input / Output

G

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V27

S27

V3

S3

TEMP S.0

6 | © Danfoss | 2022.01

AQ282339078428en-010203

Page 7

CCR2+ Controller

Heat forc

Connection of two CCR2+

with one S0 sensor in sequence mode

20180904

Connection of two CCR2+

with individual S0 sensor in sequence mode

Heat forc

Start next CCR

Disinfection finished

Alarm- dis. faile

20180904

Fig. 8 Connec tion of two CCR2+ with

individual S0 sensor in parallel mode

Alarm- dis. failed

Disinfection finished

Start next CCR

e

24VDC

0V

KO4

KO3

KO2

KO1

O1

O2

O4

O3

S0

B1

B2

B3

B1

B2

B3

S0

B1 - start dis.

B2 - stop dis.

B3 - ext. alarm

C

G

S0 - main

sensor

PT1000

SECOND

SLAVE

UNIT

SECOND

MASTER

UNIT

MAIN

SLAVE

UNIT

FORCE

HEATING

SOURCE

MAIN

MASTER

UNIT

C

C

C

Input / Output

G

C

Input / Output

G

V33

Module 4

Board

S33

V9

Module 3

Board

S9

C

V34

V36

V35

S35

S36

S34

G

C

C

Input / Output

G

V17

Module 5

Board

S17

C

V20

V19

V18

S19

S20

S18

G

V11

V12

V14

V13

S12

G

V15

Module 4

Input / Output

Board

S13

S15

S14

V16

S16

V10

S11

S10

Power

Supply

Board

24VDC

Controller

and Power

0VDC

TCP/IP - LAN

Slave

Supply

Board

B

A

Master 1

Controller

Board

V21

V22

V24

V23

V26

0VDC

24VDC

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

S24

G

C

O4

S0

G

V25

Module 2

Input / Output

Board

S25

S26

V1

V2

Module 1

Input / Output

Board

S1

S2

V31

V28

S28

V4

S4

Input / Output

G

C

Input / Output

G

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V27

S27

V3

S3

TEMP S.0

C

C

C

Input / Output

G

C

Input / Output

G

V33

Module 4

Board

S33

V9

Module 3

Board

S9

C

V34

V36

V35

S35

S36

S34

G

C

C

Input / Output

G

V17

Module 5

Board

S17

C

V20

V19

V18

S19

S20

S18

G

V11

V12

V14

V13

S12

G

V15

Module 4

Input / Output

Board

S13

S15

S14

V16

S16

V10

S11

S10

V21

V22

V24

V23

V26

0VDC

Slave

24VDC

Board

B

A

Master 1

Controller

Board

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

Controller

and Power

Supply

KO1

0VDC

24VDC

Power

Supply

Board

TCP/IP - LAN

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

S24

G

C

O4

S0

G

V25

Module 2

Input / Output

Board

S25

S26

V1

V2

Module 1

Input / Output

Board

S1

S2

V31

V28

S28

V4

S4

Input / Output

G

C

Input / Output

G

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V27

S27

V3

S3

TEMP S.0

Fig. 9 Connection of two CCR2+ with one

S0 sensor in parallel mode

SECOND

KO4

d

KO3

KO2

KO1

e

24VDC

0V

C

O1

O2

O4

O3

S0

G

B1

B2

B3

B1

B2

B3

S0

S0 - main

sensor

PT1000

B1 - start dis.

B2 - stop dis.

B3 - ext. alarm

SLAVE

UNIT

SECOND

MASTER

UNIT

MAIN

SLAVE

UNIT

FORCE

HEATING

SOURCE

MAIN

MASTER

UNIT

C

C

C

Input / Output

G

C

Input / Output

G

C

Input / Output

G

C

Input / Output

G

V33

Module 4

Board

S33

V9

Module 3

Board

S9

V33

Module 4

Board

S33

V9

Module 3

Board

S9

C

V34

V36

V35

S35

S36

S34

G

C

C

Input / Output

G

C

Input / Output

G

V17

Module 5

Board

S17

V17

Module 5

Board

S17

C

V20

V19

V18

S19

S20

S18

G

C

V20

V19

V18

S19

S20

S18

G

V11

V12

V14

V13

S12

V36

S36

V12

S12

G

C

G

C

G

V15

Module 4

Input / Output

Board

S13

S15

S14

V14

V13

V15

Module 4

Input / Output

Board

S13

S15

S14

V16

S16

V16

S16

V10

S11

S10

V34

V35

S35

S34

V11

V10

S11

S10

V21

V22

V24

V23

V26

0VDC

Slave

24VDC

Supply

Board

B

A

Master 1

Controller

Board

Slave

Supply

Board

B

A

Master 1

Controller

Board

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

0VDC

24VDC

Empty

Socket

Place

G

Lbus

G

G

Lbus

Empty

Socket

Place

Controller

and Power

0VDC

24VDC

Power

Supply

Board

TCP/IP - LAN

Controller

and Power

KO1

0VDC

24VDC

Power

Supply

Board

TCP/IP - LAN

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

V21

V22

V23

Module 1

Input / Output

Board

S21

S23

S22

O1

O2

O3

Module 0

Input / Output

Board

B1

B2

B3

S24

O4

S0

V24

S24

O4

S0

G

C

G

C

G

C

G

V25

Module 2

Input / Output

Board

S25

S26

V1

V2

Module 1

Input / Output

Board

S1

S2

V26

V25

Module 2

Input / Output

Board

S25

S26

V1

V2

Module 1

Input / Output

Board

S1

S2

V31

V28

S28

V4

S4

V28

S28

V4

S4

Input / Output

G

C

Input / Output

G

C

Input / Output

G

C

Input / Output

G

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V29

Module 3

Board

S29

V5

Module 2

Board

S5

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V31

V32

V30

S31

S32

S30

V7

V6

V8

S7

S8

S6

V27

S27

V3

S3

V27

S27

V3

S3

TEMP S.0

AQ282339078428en-010203

© Danfoss | 2022.01 | 7

Page 8

CCR2+ Controller

Temperature sensor (S0, S1-S20 / S21-36)

Pt1000, S0- type ESMC / ESM11, S1 … S36 – type ESMB

Temperature range (registration)

–20 °C … +120 °C

- IP Modbus (L AN cable connection)

- default password: admin1234

1. Product description

2. Technical data

The CCR2+ is a control used for optimizing

the thermal disinfection process in hot water

systems with functions such as temperature

registration and monitoring circulation hot water

actuators type TWA-A and remote temperature

sensors PT1000, type ESMB, installed on each

thermostatic circulation valve, type MTCV

(Multifunctional Thermostatic Circulation Valve).

systems. The control is connected to thermo

Measuring accuracy ± 0,1 K

Inputs: B1, B2 and B3 Free contact (5 V 1 mA)

Number of control valves (risers) 20, additional 16 with system extension via CCR+ Slave Unit

Output signal to actuators 24 VDC max. 1 A

Alarm signal output 24 VDC max. 1 A

Relay output 0 … 24 DC max. 1 A

Type of memory Build-In

Capacity of memor y 8 GB

Timer: Real time clock Built-in bat tery - service life 10 years

- Wi-Fi (communication p ort only)

Communication interfaces

Default IP settings

- TPC/IP port (LAN cable connection)

- Modbus RS 485 RTU

- Default L AN IP address (static): 192.168.1.100

- Default WiFi access IP address (static): 192.168.1.10

- IP address mask: 255.255.255.0

- Gat eway addr ess: 192 .168.1.1

- DNS ad dress: 192.16 8.1.1

- CCR name: ccrplus

1)

To select proper p ower transformer

please follo w formula: 24 V 10VA

(controller) + 7 VA*/per each actuator

3. Installation

Ambient temperature 0 … 50 °C

Transport temperature –10 … +60 °C

IP rating IP 20,

Power supply 24 VDC

Power consumption (Master controller only)

Power consumption (Slave Unit only)

Weight 0.3 kg

Installation DIN rail 35 mm

1)

1)

10 VA

3 VA

For easy access, the CCR2+ controllers should

be installed in electrical enclosure on DIN rail 35

mm. Enclosure with DIN rail should be mounted

onto the wall (sub - station or boiler room) as

close as possible to the heat source. DIN rail and

enclosure are not included.

It is recommended to install the standard 24

VDC transformer in the same box as CCR2+

(not supply). The transformer power depends

on numbers of actuators (number of risers in

heating installation). To select proper power

transformer please follow formula: 24 V 10VA

(controller) + 7 VA*/per each actuator

Example (building with 20 risers):

10VA (for controller) + 7VA x 20 actuators = 150VA

8 | © Danfoss | 2022.01

AQ282339078428en-010203

Page 9

CCR2+ Controller

4. Switching the control on

5. Switching on

Before switching the control on for the rst time,

disconnect all cables and connect a 24 VDC

The LED diodes on device should blink at

start-up.

source to the disconnected power plug. Use a

voltmeter to measure the voltage on the power

cable plug before it is connected to the control.

If the voltage is correct:

1. Read the instructions before you operate the

control

2. Disconnect all cables

3. Connect the power to the transformer (not

Before any plugs are connected to the control’s,

input and output connectors:

1. Set all parameters on the controller

2. Make sure that there is no external voltage on

the temperature sensor plugs

3. Make sure that the voltage on the relay

contacts is not too high (max. 24 VDC)

connected to CCR2+)

4. Turn on the power to the transformer

5. Veried currency - 24 VDC

6. Connect the cable from the transformer to the

CCR2+ input

When controller is connected to power, LED

indicator start to blink. The meaning of LED

status is:

LED Description

P (orange) – Power inside controller (+5V) Lights when DDC PCB is power on

D (white) – Data transfer indicator for LAN Blink when DDC is communicating by TCP/IP

S (orange) - Input power indicator (24VDC) Light s when power supply PCB is working

BT (blue)– Basic transmission indicator for Wi-Fi Blink when DDC is communicating by WiFi

A (red) – Alert status on I/O module LED lights when/if: to low temp., broken sensor

O1..4 ; 1-20 (green)– Digital Output Status Lights when Output is closed to 0V

6. Types of Logins and Access

Controller has a built in WEB Server App to

communicate with all devices with html browsers

via following communication interfaces:

• Wi-Fi communication port

• LAN cable connection (TCP/IP port)

7. Wi-Fi settings (no cable needed - recommended for all types of devices)

1. Enter Wi-Fi settings

2. Switch on Wi-Fi

3. Scan for Wireless Network Connection

4. Select CCRplus

5. Enter password (default is »admin1234«)

8. Local Network settings (only for LAN cable connection with PC)

1. Go to »Local Network settings«

2. Go to »Properties« -> »Internet Protocol

Version 4 (TCP/IPv4)

3. Congure IP address:

AQ282339078428en-010203

4. Conrm with »OK« and close menu in PC.

© Danfoss | 2022.01 | 9

Page 10

CCR2+ Controller

7

"Days lef t

How much data can be stored per day in the system memory (for actually settings)

Data used in archive le and scheduler.

9. RUN CCR2+ APPLICATION

Launch your browser from a computer or

wireless device that is connected to the CCR2+.

Tap the IP address into web browser window:

1. Wi-FI access: Type 192.168.1.10 into Web

Browser

2. LAN connection: Type 192.168.1.100 into Web

Browser

CCR2+ application will open.

For 1st login enter password »admin1234«

IMPORTANT: Change of password to secure any

unatorized interaction from 3rd parties

NOTE: You can Skip login for access to data only

in CCR+ (reading, overview only)

10. CCR2+ DASHBOARD (Web App Screen)

When the setup and is complete, the reading

display will be shown on the screen.

The Basic CCR2+ App screen has a dashboard

that oer plenty of status overview, basic and

advanced settings. The manufacturer reserves

the right to change Firmware in production to

improve handling and functionality. An up - to

- date list of settings for the given rmware is

available on the Danfoss website.

New settings can automatically upgrade

according to guidelines in instruction.

READINGS MENU:

No. Name Description

1 Scheduler

2 S0-main temp.

3 B1-start dis.

4 B2-stop dis.

5 B3-ext. alarm

6 Trigger timeout

Open – Schedule programme active

Close - Scheduler programme not active

S0 – value of (°C) supply temperature. The same readings apply to sensors S1 … S20.

Open - no sensor or break sensor circuit

Closed – shortcut to ground in sensor circuit

If the S0 is disinfection source, statutes are shown in color:

- Grey: S0 is start disinfection source

- Red: S0 temp. is OK(greater than disinfection temp.)

- Blue: S0 temp. is too low during disinfec tion process (lower than disinfec tion temp)

- Yellow: S0 temp. sensor is broken

Input status B1 - G

Open – input B1 open

Close – input B1 close to G

If the B1 is disinfection source, statutes are shown in grey color.

Function is used in parallel and sequences connection.

Input status B2 - G

Open – input B2 open

Close – input B2 close to G

Close (shor tcut B2-G) always nished disinfection process. The end of the disinfection process can

be realised automatically (look to: Advanced Menu – This is Master) or manually if it is necessary to

stop the process. When it is done manually, system reset all previous screen information (faults).

Information about external fault(used in sequence mode to indicate errors on primar y CCR2+

master)

To be used when input B1 source is not stable (f.ex. thermostat switch, or S0 temp. source is not

stab le)

Timer will start to count down the disinfection timeout when B1 is open or. S0 temp. is less that

Dis.Set.Temp.

Timer is reseted if S0 temp. is higher that Dis.Set.Temp. or B1 input is closed.

In case of timeout count down to 0, disinfection will be stopped with timeout fault.

• Readings: Informations about basic settings,

device status, current time and date, storage

capacity

• User: Basic disinfection settings

• Installer: Advanced and service settings

• Corrections: Temperature sensor calibration

settings

• Scheduler: Schedule settings

• Tests: Device outputs testing tool

• Data: Access to Data log le

• Network: BMS and IP/TPC settings

• Firmware: Firmware upgrade tool

• Login: Login option

8 RT Clock

10 | © Danfoss | 2022.01

The Real Time clock , show current time, date, day of the week

AQ282339078428en-010203

Page 11

CCR2+ Controller

The setted disinfection temperature (look to: User Menu)

(hottest) risers.

Factory setting: 20 min

Close – shortcut to common (C)

Close – shortcut to common (C)

10. CCR2+ DASHBOARD

(Web App Screen)

(continuous)

No. Name Description

Disinfection mode: Is disinfection permitted?

9 Disinfection

10 Dis. Set. Temp.

11 Dis. time [HH:MM]

12 Min. divide adv. (%)

13 Divide time

14 Circ. Set Temp.

15 O1- heat forc e

16 O2-star t next

17 Disinfection Disinfec tion process is enabled or disabled. (can be changed in User menu->Disinfec tion)

18 Total Dis.Adv Advance of Disinfection progress, calculated from all (active and non active) risers.

19 Dis. timeout Time to nish

20 Divide adv.

21 Divide timeout Time left to compare Divide adv. and Min.Divide adv. to make decision about divide risers.

22 Ris. in group

23 O3-dis. nished

Choice between:

Enable – disinfection is permitted

Disable – disinfection is switched o in settings

The relations between temperature and corresponding time is provided from the Brunette

Resources reference table.

Disinfec tion time in the risers.

Disinfec tion time countdown is independent for each riser (look to: User Menu).

Timer is counting when riser temp. is bigger then Dis. Set. Temp.

Minimum required and maximum recommended time depend on the disinfection temperature

and should be selected from the Brunet t Resources reference table.

Dividing risers into groups

If dividing is Enable, system is counting progress of disinfection of active risers, between divide

time period. If in divide time period progress of disinfection is less than Min. divide, adv. active

risers will be automatical divided to half. New active group will continue with most promising

Group division period

If dividing is Enable, Controller will calculate the average disinfection progress of active risers,

between Divide time period. If in divide time period progress of disinfection is less than Min.

divide adv. Active risers will be automatical divided to half. New active group will continue with

most promising (hottest) risers.

Electronically controlled circulation temperature after disinfec tion in riser. Controller can maintain

the requested circulation temperature in the riser after the disinfection process. This func tion is

recommended for control valves with only actuators (PI control signal). For self - ac ting valves like

MTCV (with basic thermostat element) recommended setting is 5 °C.

Factory setting: 5°C

Outputs status:

Open – when disinfection is not active

Close – when disinfection is in progress

Outputs status:

Open – when disinfection is not in progress or not nish

Close – when disinfection is nished in sequence mode

Advance of Disinfection progress, calculated from active risers. Af ter divide time period, Divide

adv. Is compared to Min.Divide adv. If Divide adv. is less than Min.Divide adv. risers will be divided

to half.

Number of risers in the currently disinfected group.

If no division was made, this is the total number of risers. Option of choice divides risers into

groups during disinfection or is used in Installer Menu. Function: To be used division enables

disinfection process to accelerate in extensive hot water circulation installations.

Outputs status:

Open – O3 is closed to common (C)

AQ282339078428en-010203

24 O4-alarm

25 Riser

26 Valve output

27 Valve [%] % of opening of valve (V1 … V36) in PWM mode

28 Temperature [°C]

29 InGroup

30 Disinfection % of riser disinfection progress

31 Time to end [HH:MM]

Outputs status:

Open – O4 is closed to common (C)

Riser Status

Order number of risers (look to: Installer Menu)

Number of riser in risers status section

Open - no sensor or break sensor circuit

Closed – shortcut to ground in sensor circuit

Riser statuses are indicated with color.

- White: non relevant (disabled in Installer->risers number) risers

- Red: Disinfec tion in process, all temperature is OK

- Blue: Disinfection in process but riser temperature is lower than Dis. Set.Temp

- Yellow: if Sn temp. sensor or cable is broken

Status of valve: V1 … V36

1 – valve is open in % shown in Valve [%] column.

0 – valve is closed Valve [% ] = 0%. Status 1 is shown when valve open ratio is more than 0%.

Temperature readings in riser

Sensor S1,.., S36 temperature

Open - no sensor or break sensor circuit

Closed – shortcut to ground in sensor circuit

Place in ranking of disinfection progress of risers (at dividing period system will continue

disinfection with best ranking risers)

Count down timer is counting when temp. on riser is higher that Dis. Set.Temp.

After timer count down to zero, riser is disinfected successfully.

© Danfoss | 2022.01 | 11

Page 12

CCR2+ Controller

10. CCR2+ DASHBOARD

(Web App Screen)

(continuous)

No. Name Description

Riser Rx – riser status information:

-OK: disinfection nished successfully

32 Dis. status

-DisFault: disinfection has failed in riser Rx

-SensFaultL: temperature too low or sensor or shortcut to ground in sensor circuit

-SensFaultH: temperature too high or no sensor or break sensor circuit

-LowTe mp: temperature too low to perform disinfection

-InProcess: disinfection in process

USER MENU:

No. Name Description

33 Disinfection

Disinfection

34

temperature

35 Disinfection time

Circulation

36

temperature

Save Settings Click »Save Set tings« to confirm changes

Is disinfection permitted?

Possible choices:

Enable – disinfection permitted

Disable – disinfection is switched off

Set disinfection temperature.

Disinfec tion is initiated when the temperature on sensor S0 exceeds the set temperature.

Exceeding the set temperature on a riser sensor (S1 … S20), triggers the disinfec tion time

countdown for the given riser.

Factory setting: 65°C

Set disinfection time in the risers.

Disinfection time countdown is independent for each riser. Minimum required and maximum

recommended time depend on the disinfec tion temperature and should be selected from the

table in chapter »Temperature set in the circulation risers and disinfection time«

Factory setting: 15min

Electronically controlled circulation temperature after disinfec tion in riser. The CCR2+ can

maintain the requested circulation temperature in the riser after the disinfection process. This

function is recommended for control valves with only actuators (PI control signal). For self - acting

valves like MTCV (with basic thermostat element ) recommended setting is 5 °C.

Factory setting: 5°C

INSTALLER MENU:

No. Name Description

Dividing risers into groups:

37 Divide group

38 Divide time

39 Min. divide adv. (%)

40 Risers number

41 CCR Sy stem

42 Integration time

43 Proportional factor

Required

44

temperature

Enable – when the disinfection progress is slower than the set progress in MinAdvan

Disable – switched o regardless of the disinfection progress

Factory setting: Enable

Group division period. If dividing is Enable, Controller will calculate the average disinfection

progress of active risers, between Divide time period. If in divide time period progress of

disinfection is less than Min. divide adv. Active risers will be automatical divided to half. New

active group will continue with most promising (hottest) risers.

Factory setting: 20 min

Dividing risers into groups

If dividing is Enable, system is counting progress of disinfection of active risers, between divide

time period. If in divide time period progress of disinfection is less than Min. divide adv. Active

risers will be automatical divided to half. New active group will continue with most promising

(hottest) risers.

Number of risers connected to the CCR2.

Factory setting: 20

Function used for big systems. System expansion is done with several CCR2+ Controllers (with

connected CCR+ Slave Unit on each), which are connected:

Sequence – disinfection step by step (rst primary CCR2+ Master with CCR+ Slave Unit, than

secondar y CCR2+ Master with CCR+ Slave Unit, etc), If disinfection signal appears, the disinfection

process starts only in primary CCR2+ Master (with Slave Unit) and after implementation (successful

performed or not), output O2 becomes shor tcut with C, which allows the start of the process in

secondar y CCR2+ Master (with Slave Unit). When the last riser is disinfected, the primary CCR2+

Master will send a signal to ECL (or another control) and the supply disinfection temperature

returns to comfort temperature.

Parallel – disinfection is per formed at the same time. If disinfection signal appears, output O2

becomes shortcut with C. This is the signal for CCR2+ to start the disinfection. Parallel function

allows the start of the disinfec tion in all system (all CCR2+ with CCR+ Slave Units in the same time).

Main CCR2+ Master revokes the disinfection order for other CCR2+s (with CCR+ Slave Units).

Factory setting: Parallel

Integration time of the disinfection temperature (and circulation temperature) sustenance process

in risers controlled by MTCV valves. The shor ter the time, the quicker temperature changes (no

stabile regulation). The longer the time, the slower reaction for temperature changes (stable

regulation).

Factory setting: 60 sec

Proportional factor of the disinfection temperature regulation (and circulation temperature)

in risers is controlled by MTCV valves. The higher Propor tional factor will eect in the bigger

valves reac tion (no stabile regulation). The lower Proportional factor, the weaker reaction for

temperature change (stable regulation).

Factory setting: 100

Information about Temperature in installation (for BMS alarming only).

Setting range between +10 °C and +100 °C.

This setting is used for temperature alarm output when real temperature in system exceed upper

and lower deviation count from Required Temperature.

Factor y setting : 55 °C

12 | © Danfoss | 2022.01

AQ282339078428en-010203

Page 13

CCR2+ Controller

10. CCR2+ DASHBOARD

(Web App Screen)

(continuous)

No. Name Description

Set upper deviation temperature counted from Required Temperature. Temperature alarm output

45 Dif. Temp +

46 Dif. Temp

47 Alarm Delay

48 Aler t relay type

49 Archive frequency

50 DisSources

51 DisSources type

52 Date format

53 CCR is

54 Current time Sets the real time »Clock, hour & minutes”

55 Current date Sets the real date “Day, Month, Year”

56 Start risers number

57 Trigger timeout

Set Settings Click »Set Set tings« to conrm changes

Load settings 1 Load settings from memory 1

Load settings 2 Load settings from memory 2

Save settings 1 Save settings into memory 1

Save settings 2 Save settings into memory 2

indicated signal when temperature exceed this range.

Setting range between +1 °C and +20 °C

Factory setting: +10°C

Set lower deviation temperature counted from Required Temperature. Temperature alarm output

indicated signal when temperature drop below this range.

Setting range between −1 °C and −20 °C

Factory setting: -10°C

Set Alarm Delay. The temperature alarm delay when real temperature exceed exceed upper and

lower deviation counted from Required Temperature.

Setting range between 0 minute and 100 minute

Factory setting : 10 min

Alarm output:

StillOn – continuous alarm signal

Pulse – pulse alarm signal 24 VDC every second

Factory setting: Pulse

Data archiving interval. The time can be set to any value between 10 seconds and 4 hours.

Factory setting: 1 min

Disinfec tion sources for running disinfec tion and continuing the process, There are a few

combinations which allow initiation of the process based on one signal or in relation to many

needed signals.

Disinfection is initiated when:

-S0: sensor S0 reports a temperature higher than the disinfection temperature

-B1: input shorted to ground,

-S0+SCH: sensor S0 reports a temperature higher than the disinfection temperature in the

scheduled time period,

-B1+SCH: B1 input shorted to G (ground) in the scheduled time period, SCH - week ly schedule

runs and continues until it is complete, even if schedule was to terminate it,

-SCH: weekly schedule runs and continues until it is complete, even if schedule was to terminate it,

-S0/B1+SCH: B1 input shorted to G (fault to frame, ground) or sensor S0 repor ts a temperature

higher than the disinfection temperature in the scheduled time period,

-S0& B1: B1 input shorted to G and sensor S0 reports a temperature higher than the disinfection

temperature,

-S0&B1+SCH: B1 input shor ted to G and sensor S0 reports a temperature higher than the

disinfection temperature in the scheduled time period.

Factory setting: S0

Relevant for input:

StillOn – Disinfection is started when input contact is shorted to M

Pulse – Disinfection is started by short pulse of input contact to M

Factory setting: Pulse

Form of date display:

YY - MM - DD – year, month, day

YY - DD - MM – year, day, month

DD - MM - YY – day, month , year

MM - DD - YY – month, day, year

Factor y setting: YY - M M - DD

Status of CCR2:

Register - functions as temperature registration

Reg+Dis - functions as disinfection control with registration

Factory setting: Reg+Dis

Setting is active, when dividing is Enable

Controller start disinfection with less number of risers set in »Start riser number«. Rest of risers are

not active. When disinfection in started risers is nished, rest of risers are sequently ac tivated and

disinfected. If disinfection progress is less that Min.Div.Adv., risers will be divided.

Factory setting 20. Cannot be more than Risers number

Factory setting: 20

To be used when input source is not stable (B1: f.ex. thermostat switch, or S0: temp. source is not

stab le)

Timer will start to count down the disinfection timeout when B1 is open or. S0 temp. is less that

Dis.Set.Temp.

Timer is reseted if S0 temp. is higher that Dis.Set.Temp. or B1 input is closed.

In case of timeout count down to 0, disinfection will be stopped with timeout fault.

Enabled

Disabled

Factory setting: Disabled

CORRECTIONS MENU:

No. Name Description

58 S0, … , S36

Cable Length Cable

Calculator

Save settings Click »Save Settings« to conrm changes

Sensor correction: S0 … S36 in range: ±9,9 °C

Do not make calibration when sensor cables are shorter than 10 meters.

For longer cable then 10 meters, used correction factors from table below.

Usefull tool for calculating cable correc tions by selecting cable length (m) and cross (mm2)

AQ282339078428en-010203

© Danfoss | 2022.01 | 13

Page 14

CCR2+ Controller

10. CCR2+ DASHBOARD

(Web App Screen)

(continuous)

SCHEDULER MENU:

No. Name Description

1. Sunday

2. Monday

3. Tuesday

59

4. Wednesday

5. Thursday

6. Friday

7. Saturday

Set Settings Click »Set Set tings« to conrm changes

Load settings 1 Load settings from memory 1

Load settings 2 Load settings from memory 2

Save settings 1 Save settings into memory 1

Save settings 2 Save settings into memory 2

Disinfec tion schedule for selected (Active/non Active) day of the week. To be used in B1+SCH,

S0+SCH mode.

Active: Disinfection is permitted in selected time periods

non Active: Schedule is not ac tive

Start time (hh:mm): set star t time period of disinfection

Stop time (hh:mm): set nishing time period of disinfection

TESTS MENU:

No. Name Description

Open: Selected output contact is open

60 O1…O4

61 V1, …, V36

Save settings Click »Save Settings« to conrm changes

Set all as Open All Open

Set all as Close All Close

Set all as Auto OnO All Auto On/O

Set all as AutoPWM All Auto PWM

Close: Selec ted output is closed to common (C)

Auto

Factory setting: Auto

Open: selected valve is closed

Close: selec ted valve is open, shor tcuted to common (C)

Auto OnO : selected valve works in On/o mode

AutoPWM: selected valve work s in PWM mode

Factory setting: AutoPWM

DATA MEN U:

No. Name Description

62 Delete all logs Erasing of log le

63 GO to By selec ting time period, log les will be shown and ready for download (*.CSV)

NETWORK MENU:

No. Name Description

64 Modbus

65 Modbus baudrate

66 Modbus parity

67 Modbus address

68 LAN IP address

69 LAN IP address mask

LAN Gateway

70

address

LAN name (min. 2

71

char., max. 15 char.)

72 LAN DHCP

LAN connected

73

clients

WIFI name (min. 2

74

char., max. 15 char.)

WIFI pass (min. 8

75

char., max. 15 char.)

WIFI connec ted

76

client

Change Login

77

password:

Enable – Modbus is switch on

Disable – Modbus is switched o

Type of date transmission:

ModBus 96 (9.600)

Mod Bus 19 (19.000)

ModBus 38 (38.400)

FBus

Factory setting: ModBus 96

None (transmition parity disabled)

Even(»Even« type of transmition parity enabled)

Odd(»Odd« type of transmition parity enabled)

Factory setting: Odd

Unit Address for Mobus RTU RS485

Factory setting: 1

The IP address that the router assigned to this device when it joined the network. This number can

change if a device is disconnected and rejoins the network

Factory setting: 192.168.1.100

Identif y network address of an IP address

Factory setting: 255.255.255.0

The gateway address (or default gateway) is a router inter face connected to the local network that

sends packets out of the local network

Factory setting: 192.168.1.1

Name of CCR2+ (relevant for network search)

Please note that after changing this value, local network dns server need to be refreshed. This

process is depend on current network conguration and can take up to few hours.

Factory setting: ccrplus

Dynamic Host Conguration Protocol

Disable

Enable

Factory setting: disabled

Number of LAN connec ted clients to CCR2+

Wi-Fi name (can be changed)

Factory setting: ccrwi

Password name (can be changed)

Factory setting: admin1234

Shows IP and name of Wi-Fi connected device

Password name for access to CCR2+ App

Factory setting: admin1234

14 | © Danfoss | 2022.01

AQ282339078428en-010203

Page 15

CCR2+ Controller

10. CCR2+ DASHBOARD

(Web App Screen)

(continuous)

11. Service/trouble shooting

Slave Unit Comm.

78

Status

Save Settings Click »Save Set tings« to conrm changes

Note: In case o f changing IP address in CCR+ Controll er, changes sho uld also be applied in PC l ocal network setti ngs.

Shows Slave Unit communication status between CCR2+ Controller

0% – no communication

100% – communication OK

Possible (readable values): 0 – 100%

FIRMWARE MENU:

Name Description

Upgrade of firmware

Reset settings to default To return all setting to default (except Network settings) click on “Return Defaults”

Reset to defaults passwords To reset all passwords to defaults (admin1234) click on “Reset Passwords«.

Reset network settings Reset all network settings to defaults

NOTE: When uplo ading firmware, do not i nterrupt the web browser by cl osing the window, clicking a lin k, or loading a new page . No

not power-o ff CCR2+. It could corrup t the firmware.

To update CCR2+ with new firmware first download firmware file from Danfoss website.

Then follow procedure: Browse file -> Start upgrade!

When the upload is complete, CCR+ restarts. The upgrade process typically takes several minutes.

LOGIN MENU – push user to change password

Name Description

Login Access with login password enable changes in all setting

Skip login Access without password allows only data readings. Changes of settings values can not be done.

Reset Wi-Fi password

Reset the setting only Go to firmware menu and click on “Return Defaults”

Reset password only

(but not change other

parameters)

Recovery (device can be

recover back to factor y

firmware)

Available via long press on reset button (located on LAN port) for at least 5 seconds.

Wi-Fi password is reset to “admin0 0x” where x is the number of BT (blue) LED blinks.

Go to firmware menu and click on “Reset passwords”

Via long press on reset button, power down and with access code “369” (code for recovery to

default f irmware). To perform a recover y, you need to make these steps:

1. turn off power supply

2. press hardware button

3. turn on power supply, power led will be ON

4. hold but ton for more than 5 sec until ALL 3 leds turned ON

5. when all 3 leds is turned immediately release the button

From this moment you need to enter 3 digits code

In this mode there are two hardware button function:

- short press increase code number,

- long press switch to nex t code digit

Currently code number is signalled by lighting of led diode: blue led = 1 digit, white led = 2 digit,

orange led = 3 digit

Example to enter code 123:

- first led diode (blue) is turned ON, then make a short button press 1 time, blue led should

blink once

- make a long press until white led is turned on

- using shor t button press 2 times, white led should blinks 2 times

- make a long press until orange led is turned on

- using shor t button press 3 times, orange led should blinks 3 times

- if code is entered properly than recovery has started.

DO NOT TURN OFF POWER SUPPLY!

12. Modbus settings

*Note: Possible values of disinfection

status are:

- 0 - OK

- 2 - disinfection te mp too low

- 4 - disinfection in p rogress

- 8 - disinfection fa iled

- 16 (0x10 hex) - sensor fa ult L

(shorted to gnd)

- 64 (0x40 hex) - sens or fault H

(sensor not connec ted etc...)

AQ282339078428en-010203

Supported functions:

1. Read holding registers (0x03)

2. Write single register (0x06)

3. Write multiple registers (0x16)

1. Read holding register start addresses:

from 0 to 279:

0 – Valve output riser

(1=output closed - valve is o pen, active in disinfec tion;

0=out put open, valve is closed)

1 – Valve output pwm riser

(valve open in percentage: 0% .. 100%, unsigned decimal)

2 – Temperature value

(temperature in ° C with one decimal place pre cision,

unsigned deci mal --> example: 529 = 52.9°C)

3 – Is in disinfection group

(1=valve is in disinfection gr oup of valves, which is

in active disin fection state, 0=valve is no t in active

disinfectio n group of valves)

4 – Disinfection progress

(total disinfectio n progress in %)

5 – Disinfection time to end

(remaining tim e to end in sec.)

6 – Disinfection status*

Example: To get riser 6 temperature

Formula: (6(Riser) - 1) × 7 + 2 (Temp Value) = 37

© Danfoss | 2022.01 | 15

Page 16

CCR2+ Controller

from 252 to 279:

252

Scheduler open/closed

253

S0 temperature

254

B1 open/closed

255

B2 open/closed

256

B3 open/closed

257

Trigger timeout

258

Memory days left

259

RTC year

260

RTC month

261

RTC day

262

RTC hour

263

RTC minute

264

Disinfecton enabled/disabled

265

Disinfection set temperature

266

Disinfection time

267

Min. div. Adv

268

Divide time

269

Circulation set temperature

270

Output 1 value

271

Output 2 value

272

Disinfection status

273

Total disinfection advance

274

Disinfection timeout

275

Divide advance

276

Divide timeout

277

Risers in group

278

Output 3 value

279

Output 4 value

from 300 to 303:

300

Disinfection flag (enbled/disabled)

301

Disinfection temperature

302

Disinfection time

303

Circulation temperature

from 400 to 421 :

400

Divide group (enabled/disabled)

401

Divide time

402

Min. advance

403

Riser number

404

CCR system

405

Integration time

406

Proportional factor

407

Req. Temperature

408

Dif temp 1

409

Dif temp 2

410

Alarm dealy

2. Write single register – data can be written into start

addresses:

- from 300 to 303

- from 400 to 421

- from 600 to 620

411

Alert realy type

412

Archive frequency

413

Dis source

414

Date format

415

CCR is

416

RTC hour

417

RTC minute

418

RTC year

419

RTC month

420

RTC day

421

Start riser number

from 600 to 634 :

600

Start hour Sunday

601

Start minute Sunday

602

Stop hour Sunday

603

Stop minute Sunday

604

Active Sunday

605

Start hour Monday

606

Start minute Monday

607

Stop hour Monday

608

Stop minute Monday

609

Active Monday

610

Start hour Tuesday

611

Start minute Tuesday

612

Stop hour Tuesday

613

Stop minute Tuesday

614

Active Tuesday

615

Start hour Wednesday

616

Start minute Wednesday

617

Stop hour Wednesday

618

Stop minute Wednesday

619

Active Wednesday

620

Start hour Thursday

621

Start minute Thursday

622

Stop hour Thursday

623

Stop minute Thursday

624

Active Thursday

625

Start hour Friday

626

Start minute Friday

627

Stop hour Friday

628

Stop minute Friday

629

Active Friday

630

Start hour Saturday

631

Start minute Saturday

632

Stop hour Saturday

633

Stop minute Saturday

634

Active Saturday

3. Write multiple register – data can be written into

start addresses:

- from 300 to 303

- from 400 to 421

- from 600 to 620

ІМПОРТЕР:

UA: ТОВ з ІІ «Данфосс ТОВ», вул. Вікентія Хвойки, 15/15/6, м. Київ, 04080, Україна

16 | © Danfoss | DCS-SGDPT/SI | 2022.01

AQ282339078428en-010203

Loading...

Loading...